Page 1

k.®

5483

Service

5483

Manual

H

Pfaff,D6750

Kaiserslautem,

Postfach

Telefax

3020/3040,

(0631)

17202

Telefon

(0831)

200-0,

Telex

45753

Page 2

Service

Notesonsafety:

The

When

Service

Work on live

VDE

Please

The

chainstitch,

Pfaff

Manual

machine

0105.

must

converting

and

repair

partsisnot

note:

illustrationsinthis

high-speed

5483-814/01

Differing or additional

660-91)

are

givenonpage

mechanisminthe

The

machine

for

the

onlybeused

it to

another

work

must

sewing

single-

adjusting

Pfaff

for

version, ali valid

onlybeperformedbyqualified

permitted,

Manual

and

38,

show

machine,

two-needle

instructions

and

5483

the

purposeithas

safety

rules

apart

from

exceptions

the

Pfaff

5483-814/01

whereas

for

machinesinversionHand

machines.

for

machines

the

Appendicesonpages40and44respectively.

versionisindicatedonthe

model

plateonthe

been

designed

mustbefollowed.

personnel.

according

single-needle,

adjusting

instructions

with floating

with -911/..

arm

for.

to DIN

foot

standard.

57105

two-thread

applytothe

(No. 91-055

backtacking

and

Tools,

gauges

Setofscrewdrivers

Setofalien

Setofopen-ended

Spanner/wrench,

Metal

rule

C-clamp

Adjustment

Gauge

Gauge

Packetofneedles

Needle

Spacers;

Shims:

Thread

and

keysofsizes

No.

08-880137-00

pin(5mm

No.

61-111642-19or08-880179-00

No.

61-111643-06

system:

0.3, 0.5,

0.3or0.6

and

material

other

equipment

with

blades

1.5to6.0

spanners/wrenches

22

mm

wide

dia.) No.

4463-35

in

version

in

versionHwithout

in

version

in

version

0.8

mm

or 1.2

thick

for

-911/..,

-814/01

-814/02

mm

(for

testing

needed

from2to10mm

mm

13-030341-05

5463-35

HO,

HO,

thick

subcl.

for

from7to14mm

-911/..,UY128

4463

4463-8FLand

-911/..)

purposes

KK

adjusting

wide

GAS

the

wide

4463-8

Pfaff

FR

5483:

Page 3

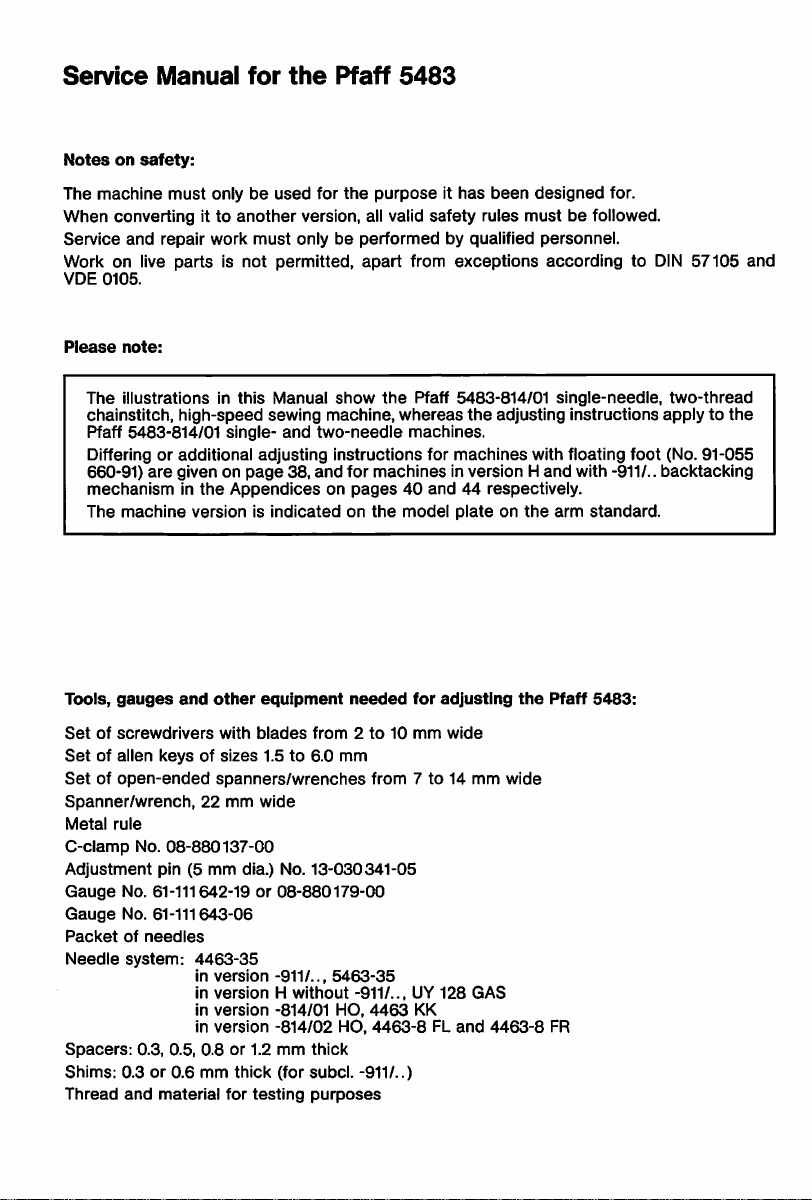

1

Preparations

for

adjustment

1.1

Remove

1.2 Take

Note:

This machineIs

Inserting a pin In

bearing

position.

out

the

the

plate

belt

two

equipped

the

guard.

face

plate

oneofthese

machine

screws

and

remove

the

face

plate.

with a bearingplatewithfour holes InIt (Fig.

holes

and

canbeblocked

pushing It Into a

with

the

needle

recess

barata

behind

1.0.1).

certain

By

the

1.0.1

P

Page 4

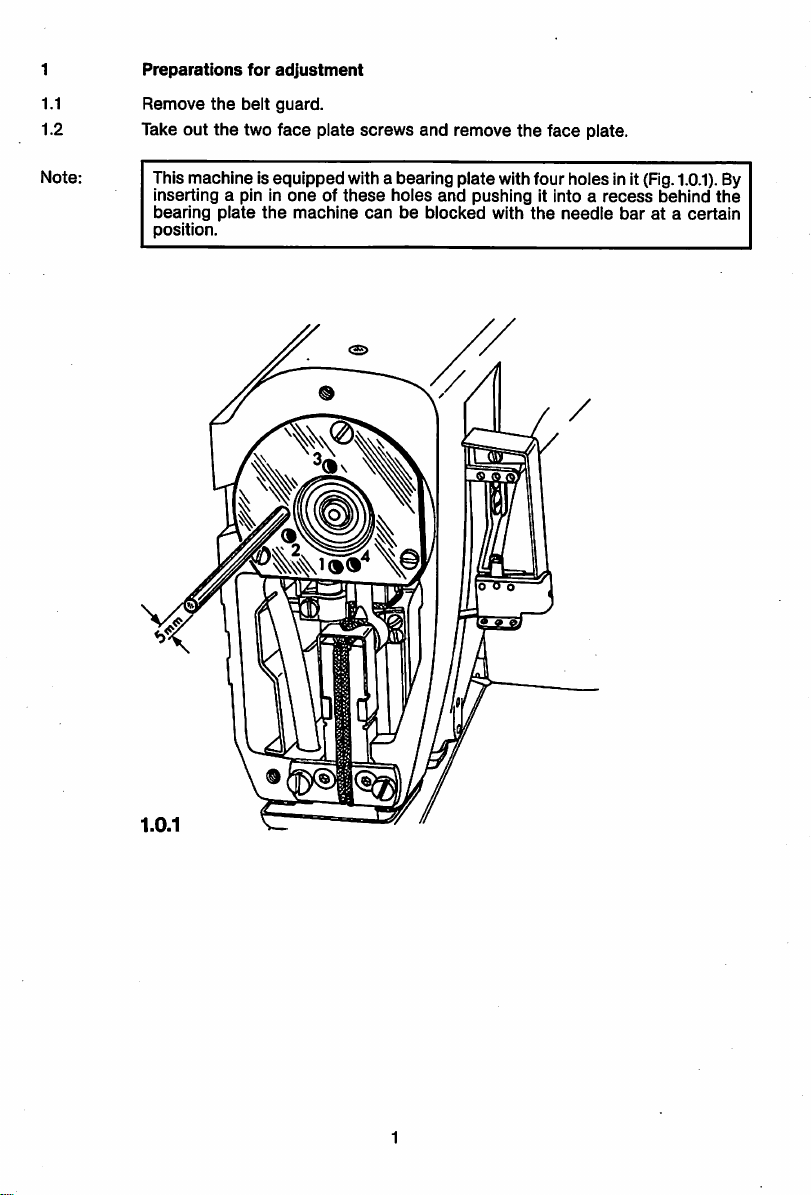

Position

of

needieinneedie

hoie

Correct

setting:

The

center

needle

mustbecenteredInthe

line

mustbe32mmfrom

the

needle

front

edgeofthe

holeIncrosswise

needle

direction

plate

(Fig. 2.0.2).

and

Its

2.1 Bring

2.2

insertanew

Into

2.3

2.4

2.5

Loosen

Turn

Turn

hole.

the

out

the

the

needle

needle

screws

screws

balance

bartotop

needle

(for

dead

needle

barasfarasIt will go;

1, 3

and

4.

5 by 2to3

wheel

until

turns.

the

center

system

needle

and

the

see

remove

Inside

long

the

front

groove

pointIsImmediately

presser

cover)

must

face

above

foot.

and

toward

push

the

It up

you.

needle

Page 5

2.6

Adjust

the

the

positionofthe

needle

holeIncrosswise

distanceof32

lineofthe

needle.

mm

between

2.7 In this position, tighten

screw

1,pull

2.8 Using

Then

2.9

Loosen

has

occurredinthe

2.10 Tighten

bar.

tighten

screw3again,

both

screw

screws

the

1.

needle

needle

screw

guide

stud

turn

the

bar

5, making

bar

direction

the

front

3 Just lightly

behind it

balance

frame,

sure

that

framesothat

and

thatInsewing

edgeofthe

and

screw

against

the

wheel

a few

then

tighten

slotted

guide

the

needleIscentered

direction

needle

plate

4 securely.

eyeofneedle

turnstomake

screw

3 again.

6 is parallel to

there

and

the

center

bar

frame

surenotwist

the

needle

In

Is a

2.

2.11

Check

this

adjustment

(see

"Correct

setting").

Page 6

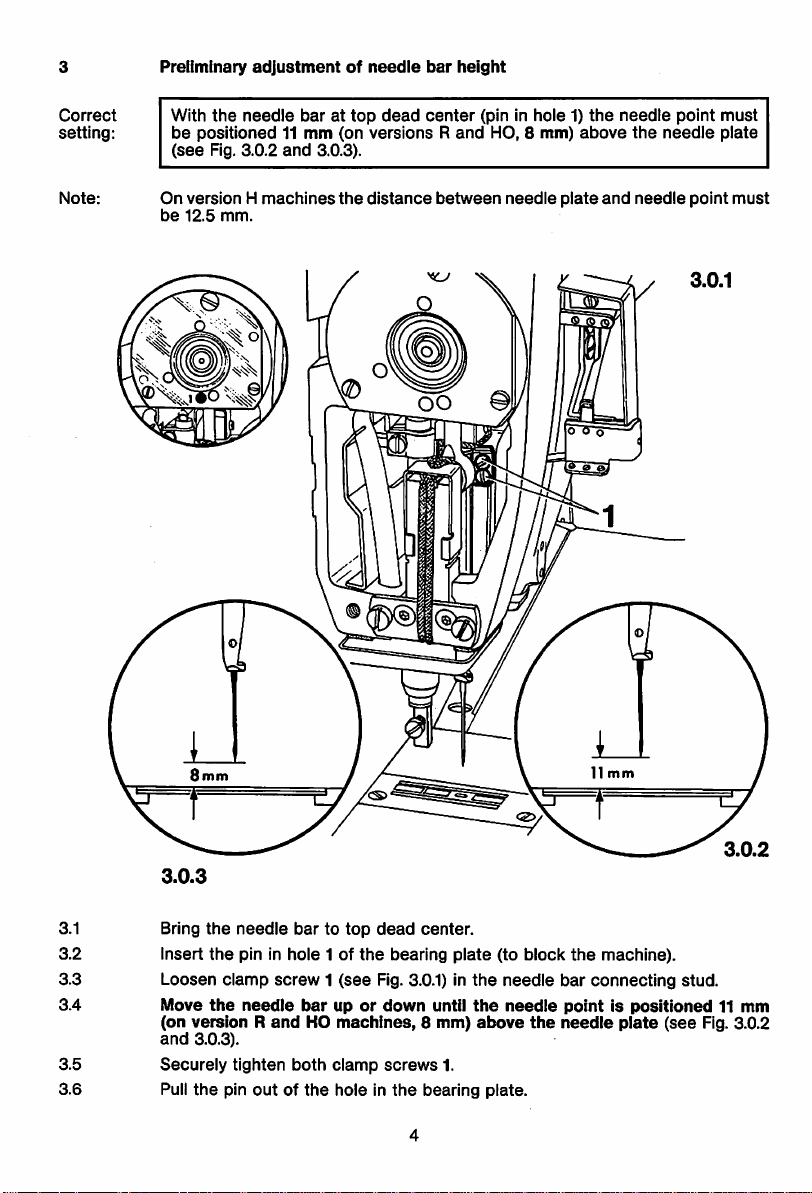

Preliminary

adjustmentofneedle

bar

height

Correct

setting;

Note:

With

the

be

(see

On

be

needle

positioned11mm

Fig.

3.0.2

versionHmachines

12.5

mm.

barattop

and

3.0.3).

dead

(on

versionsRand

the

distance

center

between

(pin In

HO, 8

needle

hole1)the

mm)

above

plate

and

needle

the

needle

point

needle

point

must

plate

must

3.0.3

3.1 Bring

3.2 Insert

the

the

needle

pin In

3.3 Loosen clamp

3.4

Move

the

needle

(on version R

and

3.0.3).

3.5

3.6

Securely

Pull

the

tighten

pin

bartotop

hole

1 of

the

screw1(see

barupor

andHOmachines,

both

clamp

outofthe

holeInthe

dead

center.

bearing

Fig. 3.0.1) in

down

until

8 mm)

screws

1.

bearing

plate

the

the

above

(to

needle

needle

plate.

block

the

machine).

bar

connecting

pointispositioned11mm

the

needle

plate

(see

stud.

Fig. 3.0.2

Page 7

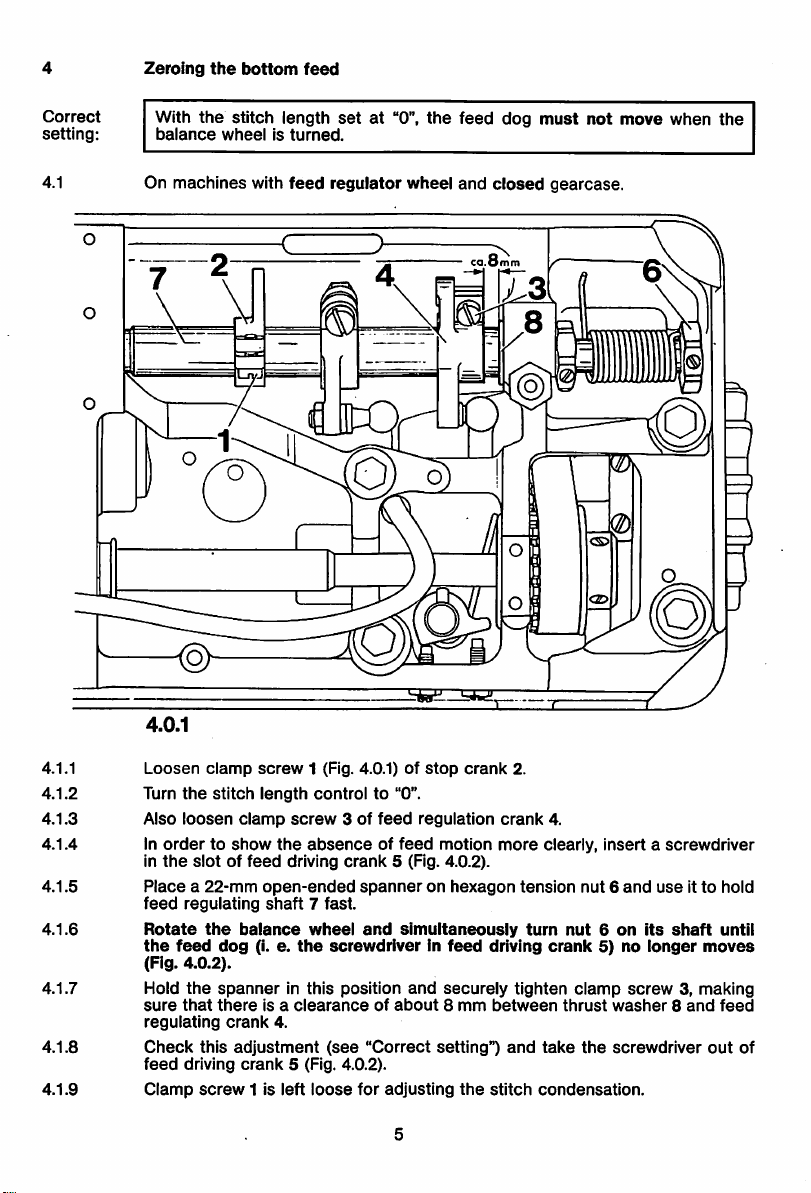

Zeroing

the

bottom

feed

Correct

setting;

4.1

With

the

balance

stitch

wheelIsturned.

On machines with

length

feed

setat"0",

regulator

the

wheel

feed

and

dog

closed

©

must

gearcase.

not

move

0

when

the

4.0.1

4.1.1

4.1.2

Loosen

Turn

4.1.3 Also

4.1.4 In

In

4.1.5

4.1.6

Placea22-mm

feed

Rotate

the

(Fig.

4.1.7 Hold

sure

regulating

4.1.8

4.1.9

Check

feed

Clamp

clamp

the

stitch

loosen

clamp

ordertoshow

the

slotoffeed

regulating

the

4.0.2).

the

that

this

driving

screw

balance

dog

spanner

there

crank

adjustment

crank

11s

feed

screw

1 (Fig. 4.0.1)ofstop

length

controlto"0".

screw

the

absenceoffeed

driving

open-ended

shaft

7 fast.

wheel

(1.e.the

screwdriverinfeed

In this

Is a

clearance

4.

(see

5 (Fig. 4.0.2).

left

loose

3 of

feed

regulation

crank

spanneronhexagon

and

position

of

"Correct

for

motion

5 (Fig. 4.0.2).

simultaneously

and

securely

about8mm

setting")

adjusting

crank

the

2.

crank

more

tension

driving

tighten

between

and

stitch

4.

clearly,

nut6and

turn

nut6on

crank

5) no

clamp

thrust

take

the

condensation.

Insertascrewdriver

useItto

its

ionger

shaft

hold

untii

moves

screw3,making

washer8and

screwdriver

feed

out

of

Page 8

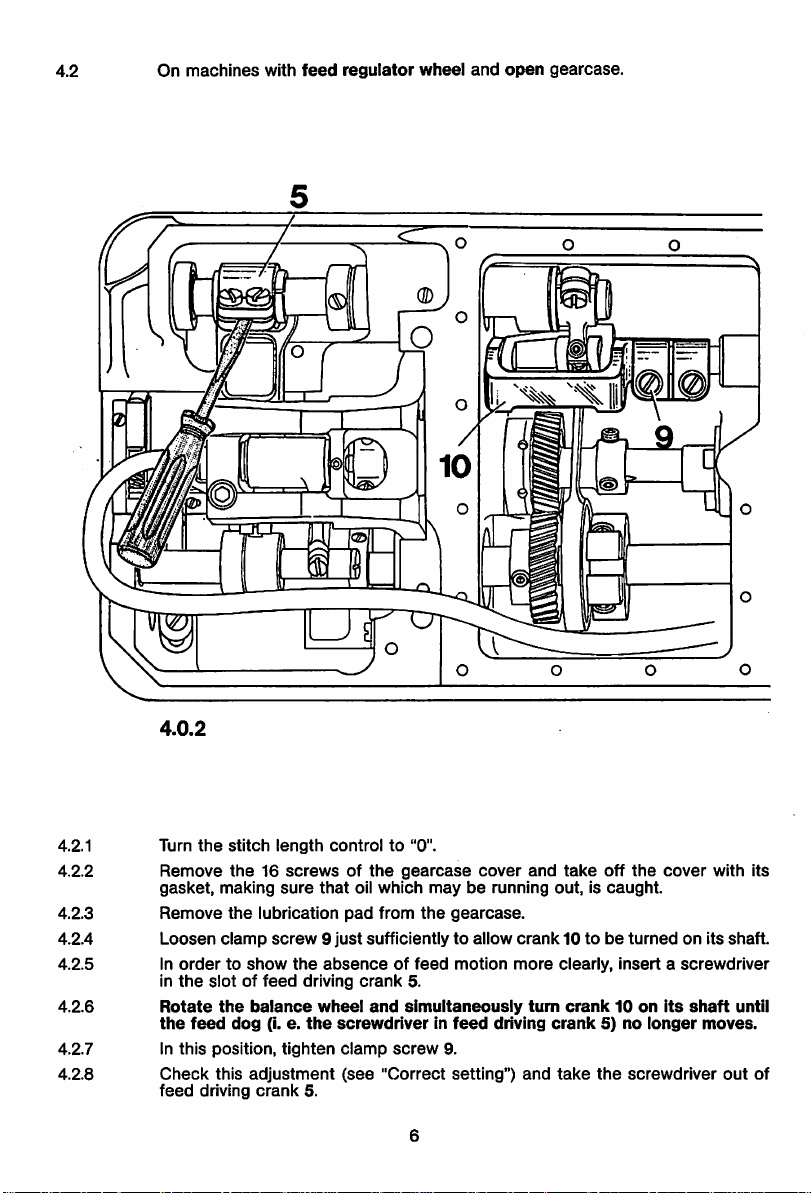

4.2

On

machines

with

feed

regulator

wheel

and

open

gearcase.

4.0.2

4.2.1 Turn

4.2.2

Remove

gasket,

4.2.3

4.2.4

4.2.5

4.2.6

Remove

Loosen

In

in

the

Rotate

the

4.2.7 In

4.2.8

Check

feed

the

stitch

the16screwsofthe

making

the

lubrication

clamp

screw9just

ordertoshow

slotoffeed

the

balance

feed

dog

(i.e.the

this

position,

this

adjustment

driving

crank

length

controlto"0".

sure

that

pad

the

absenceoffeed

driving

wheel

screwdriverinfeed

tighten

clamp

(see

5.

gearcase

oil

which

mayberunning

from

the

gearcase.

sufficientlytoallow

motion

crank

5.

and

simultaneously

screw

9.

"Correct

setting")

cover

and

take

off

out,iscaught.

crank10tobeturnedonits

more

clearly,

insertascrewdriver

tum

crank5)no

and

take

crank10on

the

screwdriver

driving

the

cover

Its

longer

shaft

moves.

with

out

its

shaft.

until

of

Page 9

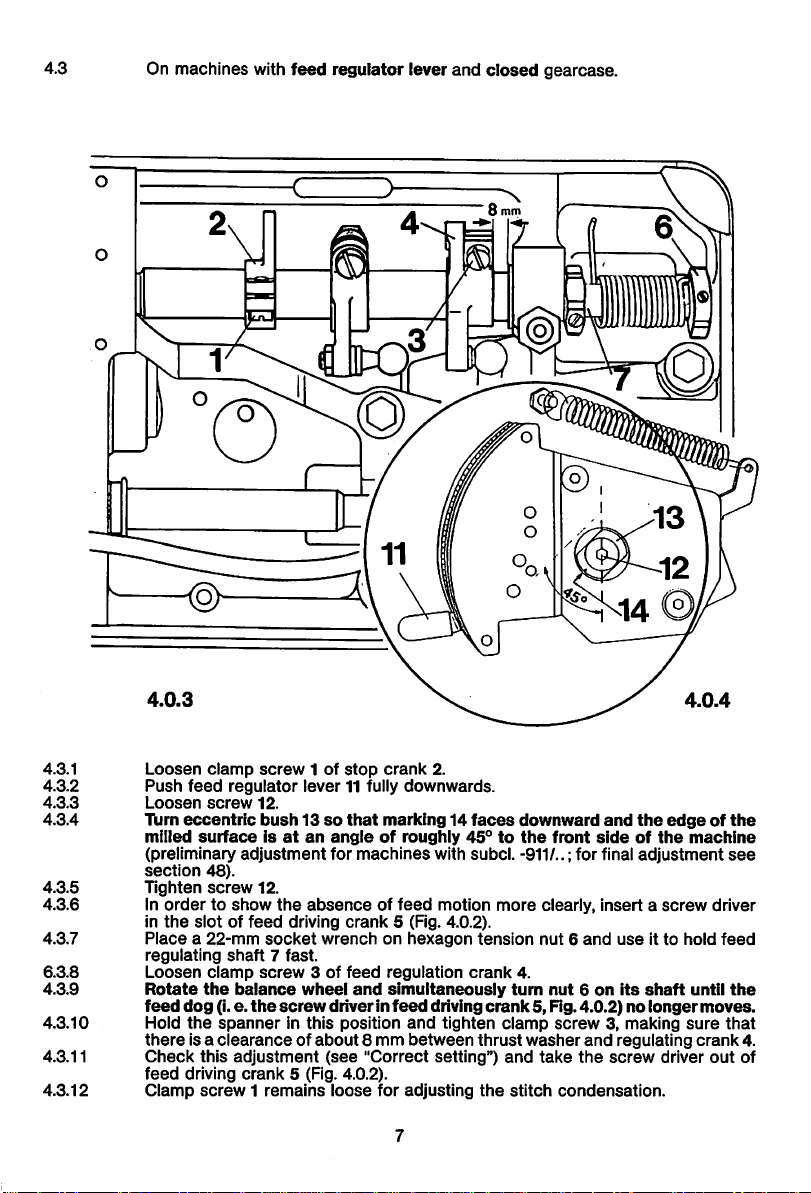

4.3

On

machines

with

feed

regulator

lever

and

closed

gearcase.

©

4.3.1

4.3.2

4.3.3

4.3.4

4.3.5

4.3.6

4.3.7

6.3.8

4.3.9

4.3.10

4.3.11

4.3.12

Loosen

Push

Loosen

Turn

milled

(preliminary

section

Tighten

In

In

Placea22-mm

regulating

Loosen

Rotate

feed

Hold

there

Check

feed

Clamp

clamp

screw

feed

regulator

screw

eccentric

surfaceisatanangleofroughly

adjustment

48).

screw

ordertoshow

the

slotoffeed

shaft7fast.

clamp

the

balance

dog

(i.e.

the

spannerInthis

Isa

clearanceofabout

this

adjustment

driving

crank

screw1remains

12.

bush13so

12.

the

driving

socket

screw

the

screw

5 (Fig. 4.0.2).

1 of

lever

for

absenceoffeed

wrenchonhexagon

3 of

wheel

driver in

(see

loose

stop

crank

11 fully

downwards.

that

marking14faces

machines

crank

5 (Fig. 4.0.2).

feed

regulation

and

simultaneously

feed

position

8 mm

"Correct

for

adjusting

2.

with

motion

driving

and

tighten

between

setting")

downward

45°tothe

subcl.

-911/..; for final

more

tension

crank

4.

turn

crank

clamp

thrust

washer

and

the

stitch

and

front

sideofthe

clearly,

Insertascrew

nut6and

nut6on

use

its

5, Fig.4.0.2)no

screw3,making

and

take

regulating

the

screw

condensation.

the

edgeofthe

machine

adjustment

It to

hold

shaft

until

longer

moves.

sure

crank

driver

see

driver

feed

the

that

out

4.

of

Page 10

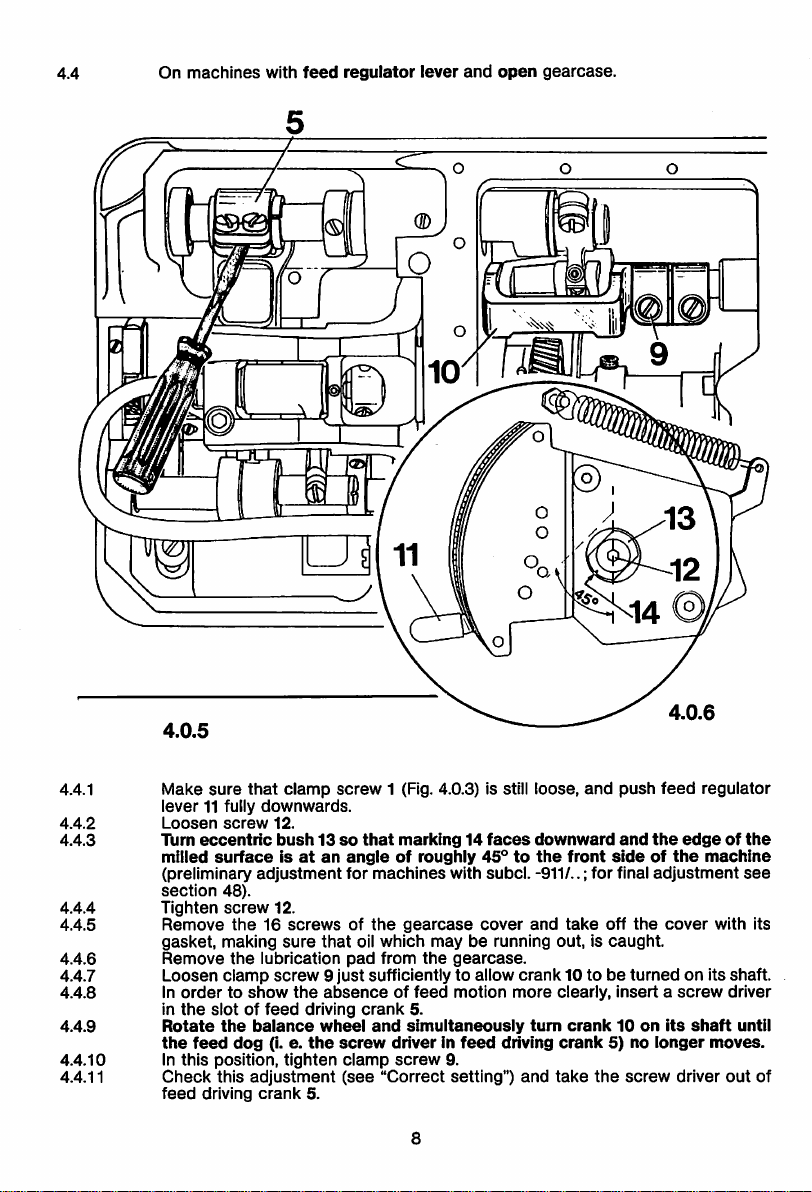

4.4

On

machines

with

feed

regulator

lever

and

open

gearcase.

4.4.1

4.4.2

4.4.3

4.4.4

4.4.5

4.4.6

4.4.7

4.4.8

4.4.9

4.4.10

4.4.11

4.0.5

Make

sure

that

clamp

lever

11 fully

Loosen

Turn

eccentric

milled

(preliminary

section

Tighten

Remove

gasket,

Remove

Loosen

In

ordertoshow

in

the

Rotate

the

feed

In

this

Check

feed

downwards.

screw

12.

surfaceisatanangleofroughly

adjustment

48).

screw

12.

the16screwsofthe

making

the

lubrication

clamp

screw9just

slotoffeed

the

balance

dog

(i. e.

position,

this

adjustment

driving

crank

screw

bush13so

sure

that

the

absenceoffeed

driving

wheel

the

screw

tighten

5.

for

pad

clamp

(see

1 (Fig. 4.0.3) is still loose,

that

marking14faces

machines

gearcase

oil

which

from

45°tothe

with

subcl.

cover

mayberunning out, is

the

gearcase.

sufficiently to allow

motion

crank

5.

and

simultaneously

driverinfeed

screw

"Correct

8

driving

9.

setting")

and

downward

front

-911/..; for final

and

take

off

crank

10 tobeturnedonits

more

clearly,

turn

crank10on

crank

and

take

the

push

feed

and

the

adjustment

the

cover

edgeofthe

sideofthe

caught.

insertascrew

its

5) no

longer

screw

driver

regulator

machine

with its

shaft.

driver

shaft

moves.

out

see

until

of

Page 11

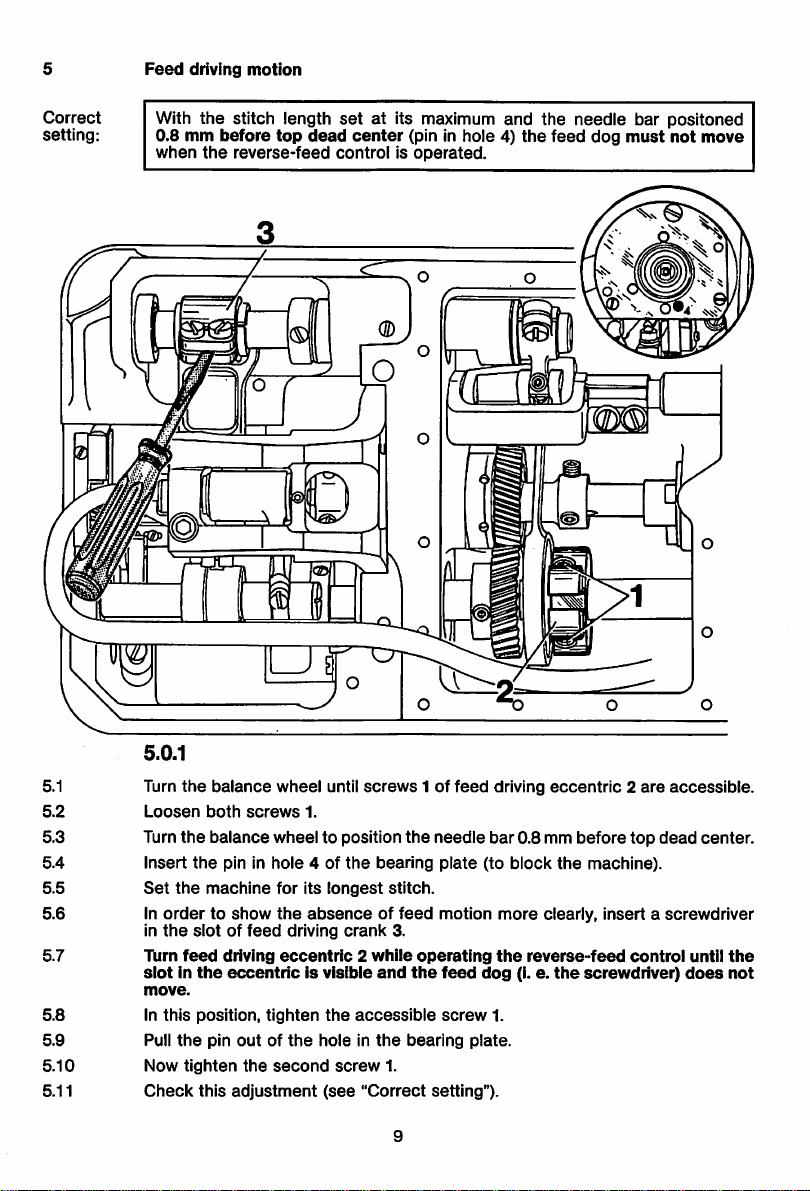

Feed

driving

motion

Correct

setting:

With

0.8

when

the

mm

the

stitch length

before

top

reverse-feed

setatits maximum

dead

center

(pin in

controlisoperated.

and

hole4)the

the

feed

needle

dog

bar positoned

must

not

move

5.0.1

5.1 Turn

5.2

Loosen

5.3 Turn

5.4

5.5

5.6

Insert

Set

In

in

5.7

Turn

slotInthe

move.

5.8

5.9

5.10

5.11

In

Pull

Now

Check

the

balance

both

screws

the

balance

the

pin in

the

machine

ordertoshow

the

slotoffeed

feed

driving

eccentricIsvisible

this

position,

the

pin

outofthe

tighten

the

this

adjustment

wheel

until

screws1of

1.

wheel

to position

hole

4 of

the

for

its

longest

the

absenceoffeed

driving

crank

eccentric2while

tighten

the

accessible

holeinthe

second

screw

(see

"Correct

the

bearing

stitch.

3.

and

the

bearing

1.

9

feed

needle

plate

motion

operating

feed

screw

setting").

bar

(to

dog

1.

plate.

driving

0.8 mm

block

more

the

reverse-feed

(I. e.

eccentric2are

before

top

the

machine).

clearly,

insertascrewdriver

the

control

screwdriver)

accessible.

dead

center.

until

does

the

not

Page 12

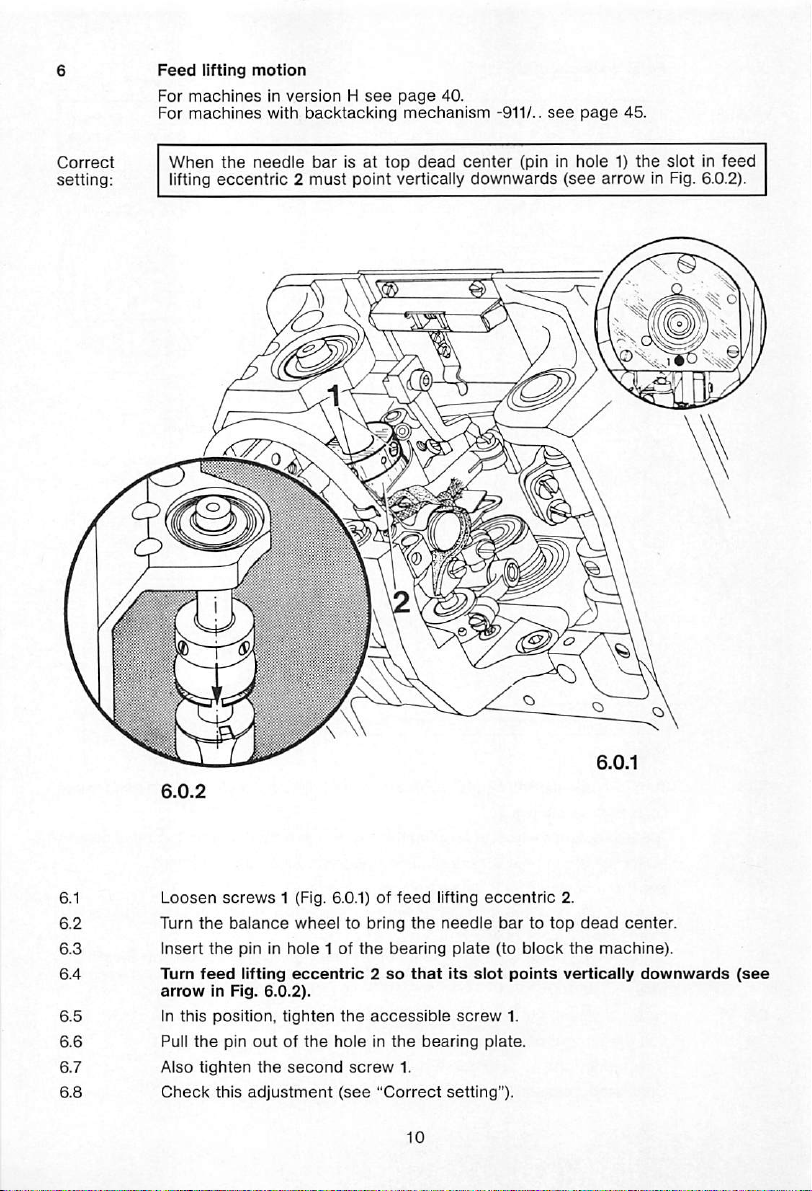

Feed

lifting

motion

For

machinesInversionHsee

For

machines

When

lifting

w/ith

backtacking

the

needle

eccentric2must

bar is at

point

page

mechanism

top

dead

vertically

40.

center

downwards

-911/..

see

(pin in hole 1)

(see

page

45.

arrow

the

slot in

in Fig. 6.0.2).

feed

Loosen

Turn

insert

Turn

arrow

In

this

Pull

Also

Check

screws

the

balance

the

pininhole1of

feed

lifting

in Fig.

position,

the

pin

tighten

this

1 (Fig. 6.0.1) of

wheeltobring

eccentric2so

6.0.2).

tighten

outofthe

the

second

adjustment

the

bearing

the

accessible

holeinthe

screw

(see

"Correct

feed

the

that

1.

lifting

needle

plate

its

bearing

setting").

slot

screw

eccentric

bartotop

(to

block

points

1.

plate.

2.

dead

the

machine).

vertically

center.

downwards

(see

Page 13

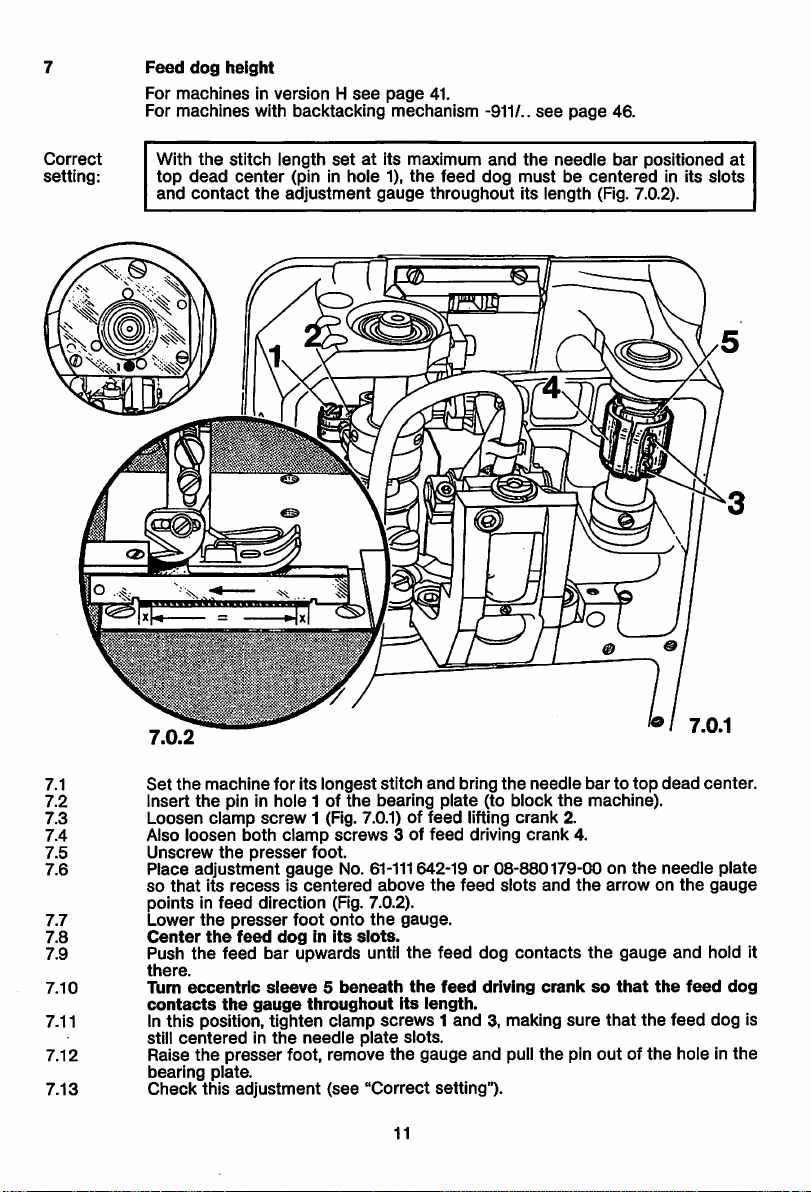

7

Feed

dog

height

For

machinesinversionHsee

For

machines

with

backtacking

page

41.

mechanism

-911/..

see

page

46.

Correct

setting:

With

top

and

7.0.2

the

dead

contact

stitch

center

the

length

setatits maximum

(pin in

adjustment

hole

1),

gauge

the

feed

throughout

and

the

dog

needle

mustbecentered

its

length

bar

positioned

(Fig. 7.0.2).

f

in its

at

slots

7.0.1

7.1

7.2 Insert

7.3

7.4 Also

7.5

7.6

7.7

7.8

7.9 Push

7.10

Set

the

machine

the

Loosen

pin in hole 1 of

clamp

loosen

Unscrew

Place

so

adjustment

that

its

the

recessiscentered

pointsinfeed

Lower

the

Center

there.

Turn

contacts

presser

the

the

feed

eccentric

the

for its

screw

both

clamp

presser

gauge

direction (Fig. 7.0.2).

foot

feed

doginits

bar upwards until

sleeve5beneath

gauge

7.11 In this position, tighten

still

7.12 Raise

7.13

bearing

Check

centeredinthe

the

presser

plate.

this

adjustment

needle

foot, remove

longest

1 (Fig. 7.0.1) of

foot.

the

screws

stitch

bearing

3 of

and

plate

feed

feed

bring

(to block

lifting

driving

the

needle

crank

crank

No. 61-111642-19 or 08-880179-00 on

above

the

feed

slots

and

onto

the

gauge.

siots.

the

feed

dog

contacts

the

feed

driving

throughout

clamp

plate

(see

"Correct

its

length.

screws1and

slots.

the

gauge

setting").

11

and

cranksothat

3, making

pull

the

bartotop

the

2.

4.

the

the

sure

pin

machine).

the

arrowonthe

gauge

that

the

outofthe

dead

needle

and

the

feed

hole in

feed

center.

plate

gauge

hold it

dog

dog

the

is

Page 14

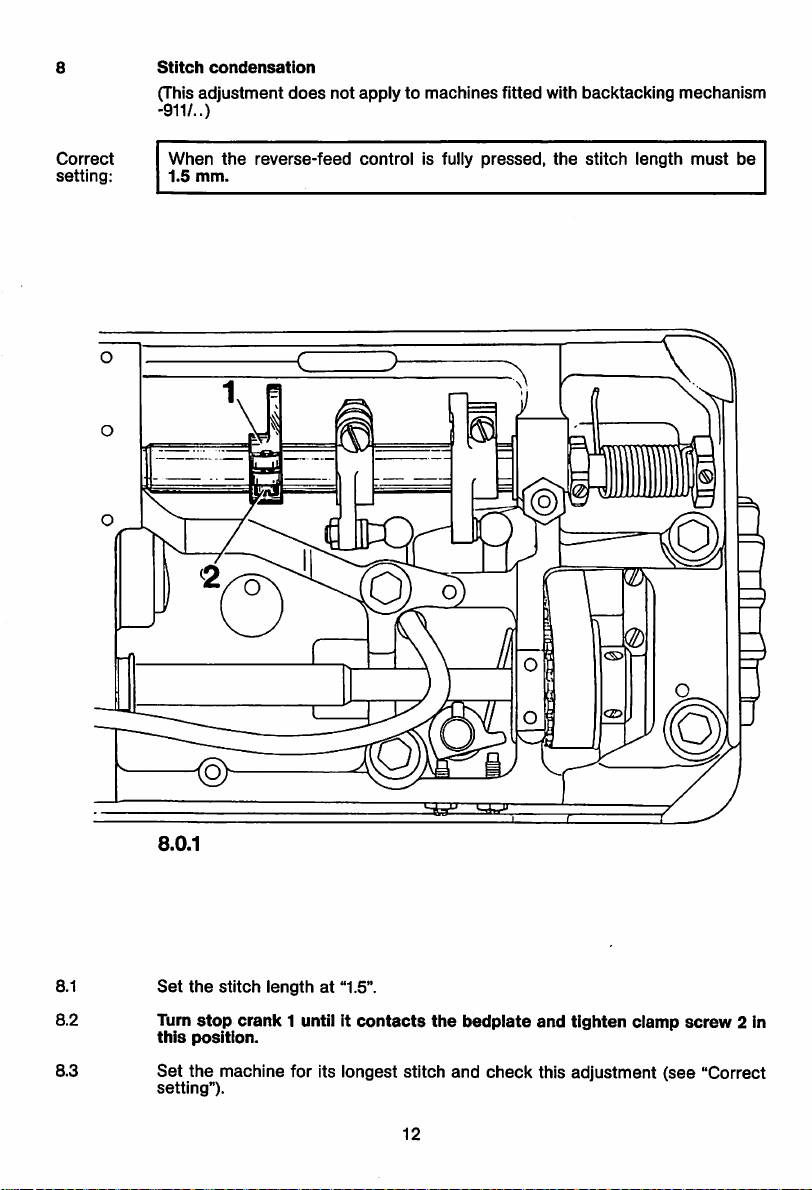

stitch

(This

-911/..)

condensation

adjustment

does

not

applytomachines

fitted

with

backtacking

mechanism

Correct

setting:

When

1.5

mm.

the

reverse-feed

control

is fully

pressed,

©

the

stitch

'VW

length

mum

Q)

must

be

8.0.1

8.1

Set

8.2 Turn

this

8.3

Set

setting").

the

stitch

lengthat"1.5".

stop

crank

position.

1 until it

the

machine for Its longest stitch

contacts

the

bedplate

and

12

check

and

tighten

clamp

this adjustment

(see

screw

"Correct

2 in

Page 15

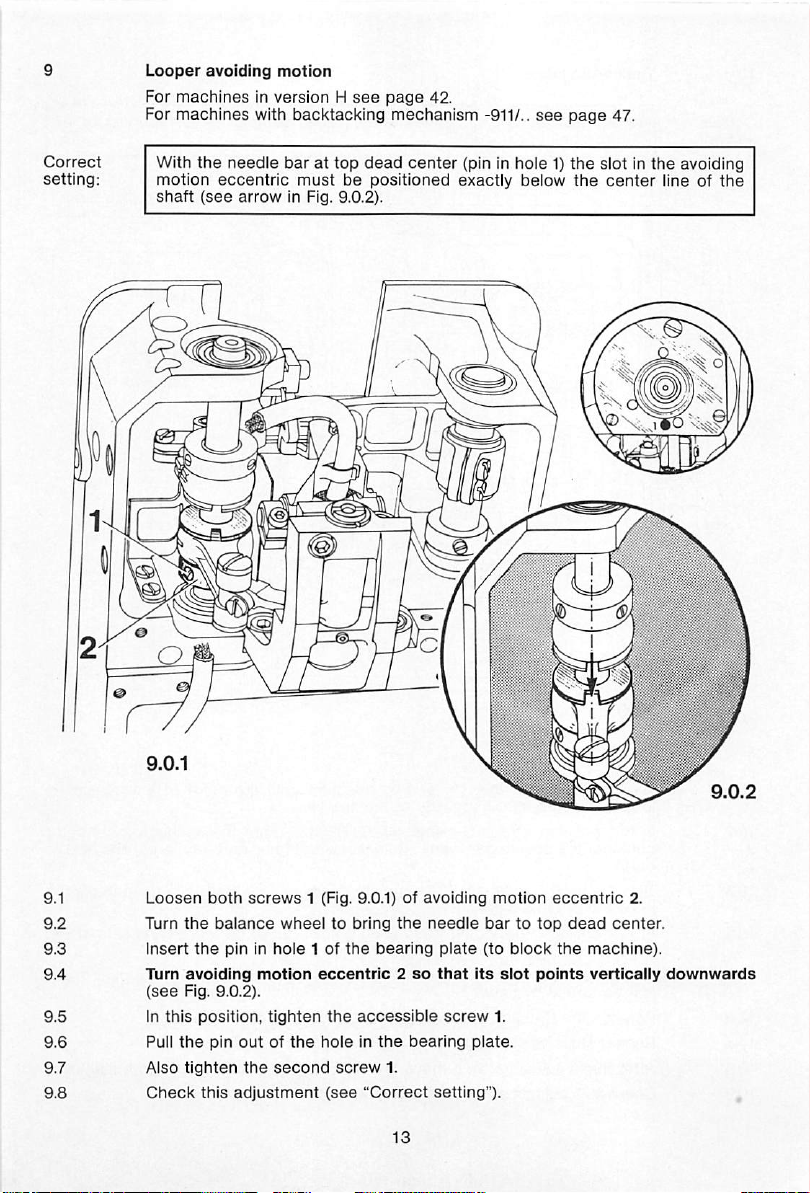

Looper

For

For

I

avoiding

machinesinversionHsee

machines

With

the

motion

shaft

eccentric

(see

motion

with backtacking

needle

barattop

arrow

in Fig. 9.0.2).

page

mechanism

dead

mustbepositioned

center

42.

-911/..

(pininhole1)the

exactly

see

below

page

the

47.

slotinthe

center

avoiding

line of

the

Loosen

Turn

Insert

Turn

(see

In

this

Pull

Also

Check

both

the

balance

the

avoiding

Fig.

9.0.2).

position,

the

pin

tighten

this

screws

wheeltobring

pin in

hole

motion

tighten

outofthe

the

second

adjustment

1 (Fig. 9.0.1)ofavoiding

the

needle

1 of

the

bearing

eccentric2so

the

accessible

holeinthe

screw

(see

bearing

1.

"Correct setting"). ,

plate

that

screw

motion

bartotop

(to

block

Its

slot

1.

plate.

eccentric

the

points

dead

machine).

vertically

2.

center.

downwards

Page 16

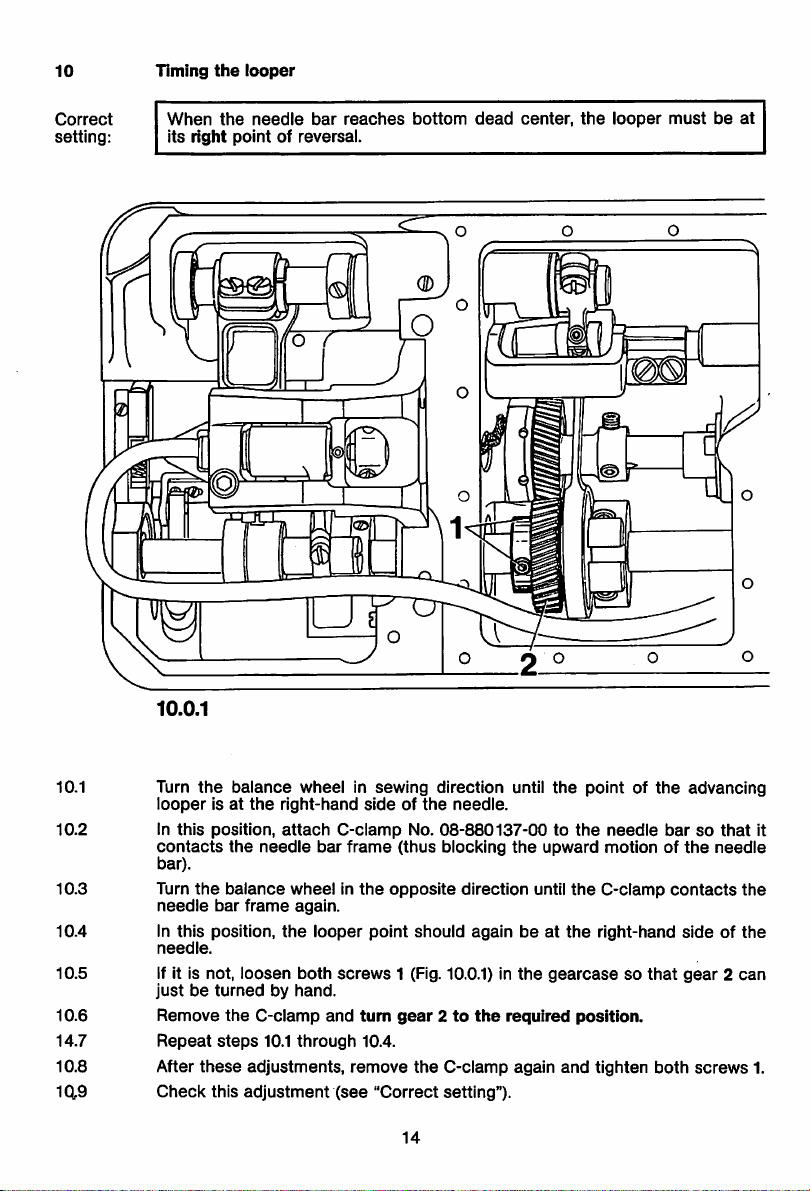

Timing

the

10

looper

Correct

setting:

When

its

right

the

needle

point

bar

reaches

of reversal.

J

bottom

dead

center,

the

looper

mustbeat

10.0.1

10.1 Turn

10.2 In

10.3

10.4 in

the

looperisat

this

position,

contacts

bar).

Turn

the

needle

this

position,

needle.

10.5 if it is not,

justbeturnedbyhand.

10.6

14.7

10.8 After

1(19

Remove

Repeat

Check

these

this

balance

the

the

needle

balance

bar

frame

loosen

the

C-clamp

steps

adjustments,

adjustment

wheel in

right-hand

attach

wheelinthe

again.

the

both

10.1

through

C-clamp

bar

frame

looper

screws

and

(see

sewing

sideofthe

(thus

opposite

point

1 (Fig. 10.0.1) in

tum

gear2to

10.4.

remove

"Correct

14

direction until

needle.

No.

08-880137-00tothe

blocking

the

direction

should

againbeat

the

the

required

the

C-clamp

setting").

again

the

pointofthe

needle

upward

until

motionofthe

the

C-clamp

the

right-hand

gearcasesothat

position.

and

tighten

advancing

barsothat

contacts

sideofthe

gear2can

both

screws

it

needle

the

1.

Page 17

11

Looper

For

heightonmachines

machines

in version H

without

see

page

subcl.

43.

-900/..

For machines with backtacking mechanism -911/..

see

page

48.

Correct

setting:

When

the

looper

holder

of 0.7 mm

needle

On

front

between

plate on single-needle machines (Fig.

two-needle

looper

machines,

and

is in its vertical position,

the

highest

the

there

needle

pointofthe

mustbea

plate.

there

and

mustbea

the

looper

11.0.2).

clearanceof1.0

clearance

undersideofthe

mm

between

the

11.1

11.2

11.3

11.4

11.5

11.6

Remove

Place

the

Turn

Loosen

Turn

highest

of

In

Continuedonnext

the

presser

balance

eccentric

1.0

this

bed

slide,

needle

foot

wheel

clamp

pointofthe

mm

between

position,

screw1and

bearing

tighten

cover

plate

onto

Inposition

the

until

stud3until

looper

front

clamp

page.

plate,

needle

the

screw

and

looper

looper

needle

plate

again

and

plate.

holderisvertical.

2 of

eccentric

there

the

undersideofthe

and

needle

screw1and

15

and

feed

dog.

operate

is a

the

bearing

clearanceof0.7

needle

plateontwo-needle

screw

2.

presser

stud

plate

bar

lifter to lower

3.

mm

between

(or a

clearance

machines).

the

Page 18

11.7 Ifa

proceedasfollows;

clearance

of 0.7 mm (or 1.0mm on

two-needle

machines)

cannotbeobtained,

10.7.1 Raise

11.7.2

11.7.3 Fitanappropriate

11.7.4

11.7.5

11.7.6

11.8

11.9

Loosen

spacer).

the

looper

Set

the

liminary

Replace

foot

onto

Check

between

when

If

necessary,

Check

the

presser

clamp

into

looper

adjustment)

the

needle

the

that

there

the

the

looper

this

adjustment

screw

needle

highest

repeat

foot

and

remove

4 in

looper

spacer

looper

blade

(see

holder5againasfarasit will go.

roughly parallel to

and

tighten

plate

and

the

holder5and

inside

clamp

operate

needle

front

the

plate.

is a

clearance

pointofthe

holder

is in its vertical position.

steps

(see

11.3

"Correct

of 0.7

looper

through

mm

11.6.

setting").

plate.

take

off

the

cover)onthe

the

front

screw

4.

presser

(or 1.0 mmontwo-needle

and

the

looper

edgeofthe

bar

liftertolower

undersideofthe

looper

(do

neck

and

bedplate

the

machines)

needie

not

push

(pre

presser

plate

lose

16

Page 19

12

Looper

angle

Correct

setting:

The

surfaceofthe

to

the

Imaginary

looper with

centerofthe

the

thread

bedplate

groove must beatan angle of 2°

(Fig. 12.0.2).

12.1

12.2

12.3

12.4

12.5

12.6

12.0.1

Raise

Remove

looper

Turn

the

Place

plate

grooved

In

this

Remove

the

presser

needle

holder

balance

adjustment

support

looper

position,

the

foot

plate

2.

wheeltomove

gauge

(see

arrow

surface

tighten

gauge.

with

and

in Fig.

into

clamp

the

presser

feed

dog,

No.

61-111843-06

12.0.2),

contact

screw

17

then

looper

with

1.

bar

lifter.

loosen

clamp

holder2to

against

pushItagainst

the

gauge.

Its

the

screw

vertical

left

the

looper

1 (Fig. 11.0.1)of

position.

edgeofthe

and

bring

cover

the

Page 20

13

Looper-to-needle

clearanceinsewing

direction

(preliminary

adjustment)

Correct

setting:

in sewing direction

point

and

needle

13.0.1

there

(see

mustbea

Fig. 13.0.2).

clearance

of 0.1 mm

between

looper

13.0.2

13.1

13.2

13.3

13.4

13.5

Checktomake

turn

the

left

Slightly

Adjust

0.1

In

If a

stud

balance

sideofthe

loosen

the

mm

between

this

position,

clearance

3 (Fig. 11.0.1)

positionofthe

sure

that

wheel

needle.

both

screws

looper

tighten

of 0.1 mm

hastobe

the

needle

until

the

guard

pointofthe

1 (Fig. 13.0.1) of

looper

and

screws

assembly

needle.

1.

point

both

cannotbeobtained,

corrected.Inthis

18

does

not

deflect

advancing

looper

assembly

so

that

the

settingofeccentric

case

repeat

the

looper

Is in line with

2.

thereisa

checkofstep

needle,

clearance

bearing

then

the

of

11.

Page 21

14

Looper-to-needle

clearance

crosswisetosewing

direction

Correct

setting:

When

of

3.2

center

the

looperIsat

mm (or

line of

3.6

needle

its right

mm on version HO

(see

point

Fig. 14.0.2).

of reversal,

machines)

there

between

mustbea

looper

clearance

point

and

14.0.2

14.0.1

14.1 Turn

the

balance

14.2 Loosen clamp

14.3

Place

the

3.2-mm

No. 91-111643-06

feed

(the

number

14.4

Make

sure

that

ended spanner, turn eccentric baii stud 3 untii

right

sideofthe

14.5 Tighten clamp

14.6

Check

this

adjustment

wheel

to bring

screw

1 in looper holder 2.

blade

(or 3.6-mm blade on version HO machines) of

against

mustbevisible).

driving link 4 Is

blade.

screw

1 securely.

(see

the

needle

"Correct

the

vertical

19

looper

with

setting").

to its right

its

notch

and,

with

the

point

of reversal.

facing in

the

aidofa

iooper point

the

direction of

6-mm

contacts

gauge

open-

the

Page 22

Needle

When

needle,

above

In

needle

15.0.1

15.0.3

this

bar

height

the

pointofthe

the

the

topofthe

position,

(see

bottom

there

Fig.

15.0.3).

and

looper-to-needie

advancing

edgeofthe

needle

must

eye

alsobea

clearance

looper

looper

is in line with

mustbepositioned

(Fig. 15.0.2).

clearance

(final

of 0.1 mm

adjustment)

the

left

1.0to1.2

between

sideofthe

mm

looper

and

^

/1.0-

f 1,2

mm

Turn the balance wheel in sewing direction until the point of the advancing

looper

is in line with

Inthis position, loosen both clamp screws 1

stud

2.

Move

needle

the top of the needle eye and the bottom edge of the looper (see Fig.

Make

sure

the

In this position, tighten both clamp screws 1 and check whether

0.1

mm clearance between looper and needle (see

see

steps

13.2

bar

3 upordown

needle

to 13.4.

the

left

bar Is not

sideofthe

until

there

turned

needle.

(Fig.

15.0.1)

inneedle bar connecting

Is a

clearanceof1.0to1.2mmbetween

during

the

adjustment.

Fig.

15.0.3).

For correction

15.0.2).

there

is a

Check this adjustment (see "Correct setting").

Page 23

16

Heightofrear

needle

guard

(for machines with backtacking mechanism -911/..

see

page

55)

Correct

setting;

the

the

needle

needle

With

of

in Fig. 16.0.2).

baratbottom

guard

must

dead

cover

the

center

needle

(pin in hole 3),

eye

by roughly 2/3

the

vertical

(see

surface

arrow

16.0.2

16.0.1

16.1 Turn

16.2 Insert

16.3

16.4

16.5

16.6

16.7

Loosen

Adjust

needle

In

this

Pull

Check

the

the

needle

eye.

position,

the

this

balance

pin in

screw

pin

outofthe

adjustment

wheeltobring

hole

3 of

1 of

rear

guard2so

tighten

screw

hole in

(see

the

needle

that

the

bearing

guard

Its

1.

the

bearing

"Correct

21

needle

plate

2.

vertical

setting").

bartobottom

(to

block

surface

plate.

the

covers

dead

center.

machine).

roughly

2/3ofthe

Page 24

17

Clearance

(for machines with backtacking mechanism -911/..

between

rear

needle

guard

and

needle

see

page

54)

Correct

setting:

The

the

17.0.1

needle

advancing

must

looper

still

contact

is in line with

the

rear

the

needle

right

guard

sideofthe

(a

lightly

needle

when

(see

0

the

point

Fig.17.0.2).

of

17.1

17.2

17.3

17.4

17.5

Turn

the

right

sideofthe

Loosen

Position

deflecting

In

this

Check

balance

screw

1 of

bracket2so

it:

position,

this

adjustment

wheel

needle.

the

tighten

until

rear

that

screw

(see

the

pointofthe

needle

the

1.

"Correct

22

guard

needle

setting").

advancing

bracket

guard

2.

contacts

looper

the

17.0.2

is in line with

needle

without

the

Page 25

18

Take-up

lever

Correct

setting:

The

freely In

of

this

mustbea

lever

18.0.2

take-up

the

slot.

Furthermore,

clearanceof0.3

and

the

lever

mustbepositionedonthe

middle of its

top

edgeofthe

slot

with

and

the

mm

needle

does

needle

between

bar

needle

not

strike

baratbottom

the

bottom

frame

(see

barsothatItmoves

the

top

and

bottom

dead

center,

edgeofthe

Fig. 18.0.2).

ends

there

take-up

18.1

18.2

18.3

18.4

18.5

Turn

the

balance

Loosen

Turn

In

edgeofthe

metal

Make

screw

clamp

the

balance

this

position

take-up

rule (0.3 mm thick) for

sure

that

1.

wheel

screw

wheel

there

take-up

until

1 a little.

to bring

mustbea

lever

and

lever

clamp

screw

the

needle

clearanceof0.3

the

top

this

adjustment.

2 is

23

1 in

bartobottom

edgeofthe

centered

take-up

In Its

lever

mm

needle

slot

2 Is

dead

between

bar

and

18.0.1

accessible.

center.

the

bottom

frame. Use

tighten

clamp

the

Page 26

Needle

thread

regulator

With

the

basic

material

needle

setting

regulator1mustbein line

19.0.2).

This

and

baratbottom

may

used.

with

havetobe

dead

the

middle

modified,

center,

the

holeoftake-up

dependingonthe

eyeofneedle

lever2(see

typeofthread

thread

Fig.

Turn

the

Loosen the

Adjust

needle

of

take-up

In

this

position,

balance

screw

lever

wheel

(see

thread

2.

tighten

to bring

the

needle

arrow in Fig. 19.0.1)of

regulator1so

the

screw

(see

that

arrow

bartobottom

needle

Its

eyeIslevel

In Fig. 19.0.1).

thread

dead

center.

regulator 1.

with

the

middle

19.0.1

hole

Page 27

20

Adjustable

thread

guide

Correct

setting:

Note:

The

hole.

This

and

adjustable

basic

the

stitch

setting

length

thread

may

used.

guide

mustbefixed in

havetobe

modified,

the

middle of its

dependingonthe

elongated

typeofthread

20.1

20.2

20.3

20.0.1

Loosen

Adjust

elongated

Make

sure

screw

thread

hole.

that

1 of

thread

guide2so

thread

guide

guide

that

2 is

2.

screw

vertical

25

1 is

positionedinthe

and

tighten

screw

middleofthe

1.

Page 28

21

Primary

looper

thread

regulator

Correct

setting:

The

and

21.0.2

distance

the

rear

between

edgeofthe

the

needle

front

edge

plate

of primary

cutout

looper

mustbe29 mm

thread

(see

regulator

Fig. 21.0.2).

2

21.1

21.2

21.3

21.4

Loosen

Adjust

between

Make

puller

Check

both

screws

thread

sure

fingers3and

this

regulator2lengthwise

its

front

that

thread

adjustment

1 of

edge

tighten

thread

and

the

regulator

both

(see

"Correct

regulator

rear

2 is

positioned

screws

26

2.

so

that

edgeofthe

1.

setting").

thereisa

needle

distanceof29

plate

roughlyinthe

21.0.1

mm

cutout.

middleofthread

Page 29

22

Secondary

looper

thread

regulator

Correct

setting:

The front edge of the secondary looper thread regulator 2 must be about

8.0 mm from

the

front

<s> ®

edge

of primary looperthread regulator 3 (Fig.22.0.2).

22.0.2

8 nini y

^ £

5-:

^

22.0.1

22.1

22.2 Adjustthread regulator2lengthwiseso that Itsfrontedge is8.0mm

22.3 In this position, tighten

22.4

Loosen

front

edgeofthread

Check

screw

this

adjustment

1 of

secondary

regulator

screw

(see

looper

thread

3.

1.

"Correct setting").

27

regulator 2.

from

the

Page 30

23

Looper

thread

puller

Correct

setting:

With

the needle bar at top dead center

thread

thread

puller

2 must be exactly at the front edge of secondary looper

regulator 3 (Rg. 23.0.2).

(pin

in hole

1),

both eyes of looper

23.1

23.2

23.3

23.4

23.5

23.6

23.7

Loosen clamp screw 1just enough to allowthread puller2 to be turned on its

studbyhand.

Turn

the balancewheel to bringthe needle bar to top dead center.

Insertthe

pin

in hole1 of the bearing plate (to

block

the

machine).

llirn thread puller2 on its stud so that Its two eyes are exactly at the front

edgeofthread

Make

sure the

thread regulator 4, then tighten clamp screw 1.

Pull

the pin out ofthe hole Inthe bearing plate.

regulator

fingers

3.

of thread

puller

2 are

equidistant

from

primary

looper

Check this adjustment (see "Correct setting").

28

Page 31

24

Clearance

between

presser

foot

and

needle

plate

Correct

setting:

With

the

between

presser

presser

0^

bar

lifter 1 raised,

foot

and

(2)

needie

there

plate

must

be a

(Fig. 24.0.3).

clearance

of 7.0 mm

24.0.2

24.1

24.2

24.3

Screwonthe

freely

Screwonthe

bar

lifter

Turn

barsothat

24.4

24.5

Push

until It Is

Loosen

24.6 Turn

24.7

24.8

24.9

24.10

24.11 During

Adjust

of

the

Push

lifter5,and

Remove

needie

Check

screw

in Its

out

the

clamp

the

the

presser

presser

plate.

this

the

2.

1.

regulating

balance

the

feed

slots.

presser

It Is

just

7-mm-thlck

positioned

screw

wheel

presser

foot.

bar

lifting

tighten

gauge

adjustment

sewing

dog

and

the

foot

and

lower It

screw

2 (Fig. 24.0.2) to

sufficienttohold

bladeofthe

under

the

presser

presser

the

laterally

bracket4down

screw

under

(see

"Correct

the

foot

test

3 of

until

clamp

from

regulate

needle

gauge

bar

needle

until

3.

the

presser

29

plate,

making

onto

the

needle

reduce

the

presser

under

foot

lifting

bracket4and

enters

the

needleiscenteredinthe

untilitcontacts

presser

the

fulcrum

the

foot

the

foot

presser

(see

needle

and

setting").

foot

pressurebymeansofregulating

24.0.3

sure

the

feed

dog

moves

platebymeansofpresser

pressureonthe

downonthe

foot

Fig. 24.0.3).

raise

presser

holeinthe

the

raised

lower

the

needle

from

presser

needle

presser

foot

the

bar

onto

presser

plate.

rear

lifter 1.

foot.

hole

bar

the

Page 32

Knee

lever

rest

25

position

Correct

setting:

25.0.2

When In its rest position, knee lever connecting rod 1 must be roughly at

right angles to

the

front

edgeofthe

bedplate

(Fig.25.0.2).

m

CD

I

25.1

25.2

25.3

25.4

25.5

25.6

25.0.1

Raise

the

Push

knee

shaft3and

Loosen

Turn

to

In

Pull

the

this

locknut

stop

front

position,

knee

presser

lever

footbymeansofthe

lever

connecting

turn

it until it

4 of

screw5until

edgeofthe

lock

connecting

rod1together

snaps

into

stop

screw

5.

knee

lever

bedplate.

stop

screw

5 in

rod1outofcoupling

30

presser

with

position.

connecting

placebynut

bar

lifter.

coupling

sleeve2onto

rod

1 Is

roughlyatright

4.

sleeve2again.

knee

lever

aniges

Page 33

26

Knee

lever

play

Correct

setting:

When

beneath

between

26.0.2

the

presser

the

lifting

footisrestingonthe

needle

plate,

lever1and

lifting

there

must

collar

needle

plate

and

the

beaclearanceofabout

2 (Fig. 26.0.2).

feed

1.3

dog

Is

mm

26.0.1

26.1 Turn

26.2

26.3 Loosen both clamp

26.4 Adjust crank 4sothat

26.5 Inthis position, tighten both clamp screws 3, makingsure that the vertical knee

26.6 Remove

26.7

26.8

the

the

presser

Take

out

lever1and

lever

shaft

Check

this

Remove

balance

foot

the

two

lifting

has

the

gauge

adjustment

the

knee

wheel

to bring

onto

the

needle

screwsofthe

screws

3 of crank 4 on

there

collar

2. (Use

no vertical play.

and

Insert

(see

"Correct

lever

again.

the

feed

dog

below

plate.

rear

standard

the

is a clearance of

adjustment

the

knee

31

gauge.)

lever.

setting").

needle

plate

cover

and

remove

knee lever shaft.

about

1.3 mm between lifting

level,

the

and

latter.

lower

Page 34

27

Knee

lever

stroke

Ifmitation

Correct When

setting:

the

presser

27.0.2

the

needle

bar

knee

plate

lifter

lever Is fully

by a little

should

drop

operated,

more

by Its own weight.

than

the

7 mm, or 9

presser

©

foot

mm

on version H

must

be lifted from

0

and

the

27.0.1

27.1

27.2

27.3

27.4 Raise

Insert

Loosen

Turn

the

knee

lever.

locknut

stop

the

1 of

screw2outafew

presser

stop

foot by

screw

2.

turns.

meansofthe

presser

bar lifter.

27.5 Place the 7-mm- or 9-mm-thlck blade of the gauge under the presserfoot and

release

27.6 Move

sure

27.7 Hold

go,

the

the

the

the

then

presser

knee lever to

presser

back

foot Is not lifted off

knee

leveratthis

out

bar

lifter.

the

right until a noticeable resistance Is felt, but make

position

by half a turn,

and

the

and

lock

gauge.

turn

it in

stop

place

screw

2 inasfarasit will

with locknut 1.

27.8 Remove the gauge from under the presser foot and check this adjustment

(see

"Correct

setting").

32

Page 35

28

Guardoflooper-avoiding-motion

eccentric

Correct

setting:

Looper-avolding-motlon

of

its

motion.

28.0.1

eccentric3must

not

touch

guard

2 during

any

phase

28.1

28.2

28.3

Loosen

Adjust

not

In

both

the

touchitduring

this

position,

screws1which

are

positionofguard2so

any

phaseofits

tighten

screws

accessible

that

through

looper-avoiding-motion

motion.

1.

33

the

access

window.

eccentric3does

Page 36

29

Tension

release

(for

machines

without

subcl.

-900/..)

Correct

setting:

When

thread

29.0.2

the

presser

tension4must

footisraiseybymeansofthe

be

released.

knee

leverbyabout5mm,

29.1

29.2

29.3

Loosen

Raise

bracket3so

In

this

clamp

the

presser

position,

screw

footbyabout

that

thread

tighten

1 of

tension

tension4is

clamp

5 mm

screw

34

release

and

released.

1.

lever

adjust

2.

the

positionoftension

29.0.1

release

Page 37

30

Front

needle

(not

standardonall

guard

machines)

30.1

Correct

setting:

Vertical

When

needle,

edgeofthe

30.0.2

adjustment

the

point of

the

top

looper

the

advancing

edgeoffront

point.

looperIsopposite

needle

guard3mustbeIn line with

the

0);

center

O

line of

the

the

bottom

30.1.1 Turn

center

30.1.2

30.1.3

30.1.4

Loosen

Adjust

bottom

In

paralleltothe

30.1.5

Check

the

this

balance

lineofthe

both

screws1of

front

needle

edgeofthe

position,

looper

this

adjustment

wheel

until

the

needle.

needle

pointofthe

guard

guard3verticallysothat

looper

point.

tighten

both

screws1,making

blade.

(see

"Correct

35

bracket

setting").

advancing

2.

its

top

sure

that

30.0.1

looperIsopposite

edge

is in line

front

needle

guard

with

the

the

3 Is

Page 38

30.2

Lateral

adjustment

Correct

setting:

When

the

looper

pointIsopposite

beaclearanceof0.3to0.5

needle.

30.0.4

mm

the

center

between

line of

front

the

needle

30.0.3

needle,

there

guard2and

must

the

30.2.1 Turn

30.2.2

30.2.3

Loosen

Adjust

not

30.2.4 In

30.2.5 Turn

of

30.2.6

Ibrn

between

30.2.7 In

30.2.8

Check

touch

this

the

this

the

balance

clamp

the

positionofneedle

the

neckofthe

position,

the

balance

needle.

needle

guard

needle

position,

this

adjustment

wheel

screw

tighten

wheel

bracket3so

guard

tighten

1.

clamp

and

clamp

(see

to bring

looper

further

needle.

"Correct

the

loopertoIts left

guard

bracket3so

when

screw1just

until

the

that

screw

1.

setting").

36

the

latterIsat

lightly.

looper

thereisa

that

point is

clearance

point

front

Its

opposite

of reversal.

needle

left

guard2does

pointofreversal.

the

of

0.3to0.5

center

line

mm

Page 39

31

Stitch

length

limitation

31.1

31.1.1

31.1.2

31.1.3

31.1.4

31.2

31.0.1

On

machines

Loosen

Set

required

Turn

the

Tighten

On

machines

with

screws1and

stitch

stop

ringsothat

screws1and

with

feed

regulator

2.

length

maximumonregulator

lug4contacts

2.

feed

regulator

wheel

lever

wheel

stop5from

3.

below.

31.2.1

31.2.2

31.2.3

31.0.2

Loosen

so

Se

Position

then

whichever

screw6(through

requires.

required

stitch

stop8so

screwitfastinthis

the

length

that

limitation

the

access

hole), I.e.

maximumonregulator

it is in

contact

position

setting

37

may

with

with

require.

screw

the

remove

lever

7.

upper

edgeofregulator

6 in

the

It If

the

limitation

upperorlower

setting

lever

hole,

7,

Page 40

32

Floating

foot

(No.

91-055660-91)

Correct

setting:

When

before

32.0.2

presser

the

r

bar

floating

lifter 1 Is raised,

foot

starts

lifting

presser

bar8must

clearofthe

needle

Q)

have

plate.

risen 0.3 mm

32.0.1

32.1 Bring

32.2

If

not

pushItdown

32.3

Turn

32.4 Swing

on

the

32.5

32.6

While holding

rests

Check

pressurebyturningInthumb

the

take-up

fitted, lightly

In Its

knurled

nut3until

presser

needle

against

this

presser

adjustment

lever to Its

secure

elongated

highest

locking

holesasfarasIt will go.

Its

face

sideIsflush

bar lifter 1 down until

plate

the

without

foot

any

pressure.

In this position,

bar

collar6,and

(see

"Correct

nut

38

piece

3.

point

2 to

the

entire

push

tighten

setting")

[oh/

and

raise

the

backofthe

with

the

sole

up locking

the

and

presser

endofthe

bar

lifter 1.

machine

threaded

head

of floating foot 4 Is resting

two

set

piece2so

screws

the

7.

correct

that

amount

stud.

stud

and

5

of

Page 41

33

Final

worksteps

Replace

Clean

Screwonthe

screws

Replace

guard.

Thread

Replace

Place

the

the

gasket

crosswise.

and

the

the

fabric

oil-soaked

screwonthe

machine.

bed

under

Makeasewing

regulating

screw

lubrication

surfaceofthe

gearcase

cover

together

face

slide

and

the

the

presser

test

and,

while

2 (Fig. 24.0.2)sothat

padinthe

gearcase

plate,

cover

foot

doing

the

plate.

and

and

with

rear

lower

so,

the

gearcase

the

the

machine-bed

housing

the

adjust

fabric is

(large

gasketofthe

cover

with

foot

onto

it.

the

presser

fed

properly

cutouttoleft,

gearcase

supports,

foot

tightening

thread

tension,

pressurebymeans

evenattop

downwards).

cover.

and

speed.

the

the

cover

belt

of

39

Page 42

Appendix

for

machines

The

machines.

Service

in

versionH(without

following

Aii

Manual.

contains

other

the

adjustments

911/..)

differing

adjustment

canbefoundInthe

procedures

preceding

for

version

sectionsofthis

H

34

Correct

setting:

Feed

lifting

With

the

the

slotinfeed

in Fig. 34.0.2).

motion

needle

barata

lifting

position

eccentric2must

0.8mmbefore

point

top

dead

vertically

centre

downwards

(pin in

(see

hole

arrow

4),

Loosen

Turn

the

dead

Insert

Turn

Fig.

34.0.2).

in

this

Remove

Also

tighten

Check

screws

balance

centre.

the

feed

position,

pin

this

1 (Fig. 34.0.1) of

wheel to bring

pin in

hole

lifting

eccentric2so

tighten

from

the

the

second

adjustment

4 of

the

the

accessible

holeinthe

screw

(see

"Correct

feed

the

bearing

that

bearing

1.

34.0.1

lifting

eccentric

needle

bar to a position 0.8 mm before top

plate

(to

its

slot

screw

1.

plate.

block

faces

2.

the

machine).

downwards

setting").

(see

arrow

in

Page 43

35

Feed

dog

height

Correct

setting:

With

0.8 mm

in its

(see

the

stitch

before

slots

and

Rg. 35.0.2).

iength

top

contact

dead

setatits

centre

the

adjustment

maximum

(pin in hole 4),

gauge

and

the

the

needie

feed

dog

throughout

barata

position

mustbecentered

its

entire

length

35.0.2

35.1

35.2 Bring

35.3 insert

35.4

35.5

35.6

35.7 Place adjustment gauge (No.

35.8

35.9

33.10 Push

35.11 Turn

Set

the

machine

the

needle

the

loosen

that

clamp

its

pin in hole 4 of

recessiscentered

Loosen

Also

Screwonthe

so

pointsinfeed

Lower

the

Centre

there.

contacts

presser

the

the

feed bar upwards until

eccentric

the

for

its

longest

bar at a position 0.8 mm

the

screw

both

feed

1 (Rg. 35.0.1) of

clamp

presser

direction

sleeve5beneath

gauge

foot.

(see

foot

onto

dogInits

throughout

screws

slots.

stitch.

before

bearing plate (to block

feed

3 of

61-111642-19

above

eccentric

feed

driving

or 08-880179-00) on

the

feed

slots

Rg. 35.0.2).

the

gauge.

the

Its

the

feed dog

feed

length

contacts

driving

(see

Fig. 35.0.2).

top

dead

the

machine).

2.

crank

4.

and

the

the

cranksothat

centre.

arrowofthe

35.12 in this position, tighten clamp screws 1and 3, making sure that

35.13 Raise

centeredinthe

the

presser foot, remove

needie

plate

slots.

the

gauge from under

the

presser foot and pull

still

_ the pin out of the hole of the bearing plate.

35.14

Check

this

adjustment

(see

"Correct

41

setting").

the

gauge

the

35.0.1

needle plate

gauge

and hold it

the

feed

feed dog is

dog

Page 44

Looper

36

avoiding

motion

Correct

setting:

With

the

the

the

needle

slotinthe

centre

line of

bar

positioned

avoiding

the

motion

shaft

0.8 mm

(see

before

eccentric

Rg. 36.0.2).

top

dead

mustbepositioned

centre

(pin in hole 4),

exactly

below

36.0.1

36.1 Loosen both screws 1 (Rg. 36.0.1)in

36.2

36.3 Insert

36.4 Turn avoiding motion

36.5

36.6 Pull

36.7

36.8

Turn

the balance wheel to bringthe needle bar to a position 0.8 mm before top

dead

centre.

the

pin in hole 4 of

the

bearing plate (to block

eccentric2so

In

this

the

Also

Check

position,

tighten

this

tighten

pin out of

the

adjustment

the

second

the

accessible

hole of

the

screw

1.

(see

"Correct setting").

42

the

collar of avoiding motion eccentric 2.

the

machine).

that

its

siot

points

verticaiiy downwards.

screw

1.

bearing plate.

Page 45

37

Looper

height

Correct

setting;

When

the

of

3.2mmbetween

needle

plate

37.0.1

looper

(see

holder

is in its vertical position,

the

highest

pointofthe

Fig. 37.0.2).

looper

there

and

mustbea

the

undersideofthe

m

1

clearance

37.1

37.2

37.3

37.4

37.5

37.6

37.7

37.7.1

37.7.2

Remove

Place

lower

Turn

Loosen

Turn

highest

In

If

Raise

Loosen

spacer).

bed

slide,

the

needle

the

presser

the

balance

clamp

eccentric

this

position,

the

clearanceof3.2mmcannotbeobtained,

the

screw1and

pointofthe

presser

clamp

37.7.3 Fitanappropriate

the

looper

37.7.4

37.7.5

37.7.6

37.8

37.9

Set

liminary

Replace

foot

Check

looper

vertical

If

necessary,

Check

the

looper

adjustment)

the

onto

that

and

position.

this

into

needle

the

needle

there

the

repeat

adjustment

cover

plate,

plateInposition

foot

onto

wheel

bearing

screw

looper

tighten

foot

stud3until

clamp

and

4 in

spacer

looper

holder5againasfarasit will go.

blade

roughly parallel to

and

plate

plate.

is a

clearance

undersideofthe

steps

(see

the

until

the

screw

and

the

screw1and

remove

looper

(see

inside

tighten

and

operate

37.3to37.6

"Correct

needle

again

needle

looper

2 of

thereisa

undersideofthe

the

holder5and

front

clamp

of 3.2 mm

needle

setting").

43

plate,

and

feed

and

operate

dog.

the

plate.

holder

eccentric

is vertical.

bearing

clearanceof3.2mmbetween

screw

stud

needle

2.

proceedasfollows:

needle

plate.

take

off

the

cover)onthe

the

screw

the

presser

plate

front

4.

between

when

looper

edgeofthe

bar

lifter to

the

the

looper

presser

2.

plate

looper

lower

highest

bar

(see

Fig.37.0.2).

(do

neck

bedplate

the

point of

holder

lifter

not

and

presser

is in its

to

the

lose

push

(pre

the

Page 46

Appendix

for

machines

with

backtacking

mechanism

911/.

The following contains differing adjustment

with backtacking mechanism -911/.. Aii

the

preceding

sectionsofthis

Service

44

other

Manual.

procedures

adjustments

for machines fitted

can

be found in

Page 47

38

Correct

setting;

Feed

tifting

With

the

the

slotinfeed

in Fig. 38.0.2).

motion

needle

(subcl.

barata position 0.8 mm

lifting

eccentric2must

-911/..)

before

point

top

dead

vertically

center

downwards

(pin in

(see

hole

arrow

4),

38.0.2

38.1

38.2

38.3 insert

38.4 Turn

Loosen

Turn

dead

Fig.

38.0.2).

screws

the

balance

center.

the

pin in hole 4 of

feed

lifting

1 of

feed

wheeltobring

eccentric2so

38.5 In this position, tighten

38.6

38.7

38.8

Pull

the

Also

Check

pin

tighten

this

outofthe

the

second

adjustment

lifting

the

bearing

the

accessible

holeinthe

screw

(see

"Correct

eccentric

the

needle

that

bearing

1.

45

2.

bartoa

plate

(to block

its

slot

screw

plate.

setting").

faces

1.

position

the

machine).

0.8mmbefore

downwards

(see

38.0.1

arrow

top

in

Page 48

39

Feed

dog

height

(subcl.

-911/..)

Correct

With

setting: 0.8 mm

in its

the

before

slots

stitch

and

length

top

dead

contact

setatits maximum

center

the

(pin in hole 4),

adjustment

gauge

©

and

the

the

feed

throughout

needle

bar

dog

mustbecentered

its length.

positioned

39.1

39.2 Bring

39.3 Insert the pin in hole 4 of

39.4

39.5 Also loosen

39.6

39.7 Place adjustment gauge (No.

39.8

39.9

39.10 Push

39.11 Turn eccentric

Set

the

machine

the

Loosen

Screwonthe

clamp

for its

needle

screw

both

presser

longest

bar to a position 0.8 mm before

1 of

clamp

foot.

stitch.

the

bearing plate (to block

feed

lifting

screws

3 of

61-111642-19

so that its recess is centered above

pointsinfeed

Lower

the

Centre

the

there.

contacts

direction.

presser

the

feed

foot

onto

dogInIts

the

slots.

gauge.

feed bar upwards until the feed dog contacts

sleeve5beneath

the

gauge

throughout

the

Its

top

dead

center.

the

eccentric

feed

driving

2.

crank

machine).

4.

or 08-880179-00) on the needle plate

the

feed slots and the arrow of

the

gauge and hold it

feed driving cranksothat

length.

the

the

feed

gauge

dog

39.12 In this position, tighten clamp screws 1 and 3, making sure that the feed dog is

still

39.13 Raise the

centeredinthe

39.14

bearing

Check

presser

plate.

this

adjustment

needle

plate

foot, remove

(see

"Correct setting").

the

46

slots.

gauge

and pull

the

pin out of

the

hole in

the

Page 49

40

Correct

setting:

Looper

With

the

the

©

avoiding

the

slot in

center

motion

needle

bar

the

avoiding motion

line of

(subcl.

positioned

the

shaft

-911/..)

0.8 mm

(see

before

eccentric

Fig. 40.0.2).

top

dead

center

(pin in

hole

4),

mustbepositioned exactly below

40.0.2

40.0.1

40.1

40.2

Loosen

Turn

dead

the

center.

both

balance

screws

1 in

wheeltobring

the

collar

the

of avoiding

needle

bartoa position 0.8 mm

motion

eccentric

2.

40.3 Insert the pin in hole 4 of the bearing plate (to block the machine).

40.4 Tum avoiding motion eccentric 2

40.5 In this position, tighten

the

pin

tighten

this

outofthe

the

adjustment

40.6 Pull

40.7 Also

40.8

Check

second

the

hole of

screw

(see

so

that

accessible

the

screw

bearing plate.

1.

"Correct setting").

47

its

slot

points vertically downwards.

1.

before

top

Page 50

41

Looper

height

(subcl.

-911/..)

Correct When

the

looper holder Is In Its vertical position,

there

must

be a

clearance

setting: of 3,2 mm between the highest point of the looper and the underside of the

needle

plate.

m

41.1

41.2

41.3

41.4

41.5

41.6

41.7

41.7.1

41.7.2

41.7.3

41.7.4

41.7.5

41.7.6

41.8

41.9

Remove bed slide, cover plate, needle plate and feed dog.

Place the needle plate In position again and operate the presser bar lifterto

lower the presser foot onto the needle plate.

Turn the balance wheel until

the

looper holder Is vertical.

Loosen clamp screw 1 and screw 2 of eccentric bearing stud 3.

Turn

eccentric

highest point of

In this position, tighten clamp

Ifa clearance of 3.2 mm cannot be obtained, proceed as

Raise

the

bearing

the

stud

looper

3 until

there

and

the

screw1and

is a

clearance

underside of

screw

the

2.

presser foot and remove the needle plate.

of 3.2 mm

needle plate.

follows:

between

the

Loosen clamp screw 4Inlooper holder5 and take offthe looper(do not lose

spacer).

Fit

an appropriate spacer (see

the looper Into looper holder 5 again as far as It

Set the looper blade

liminary adjustment)

roughly

and

Replacethe needle plateand operate the presser bar

foot

onto

the

needle

plate.

inside

parallel

tighten clamp

front

to the

screw

cover)

on the looperneckand push

will

go.

front

edge of the bedplate (pre

4.

liftertolower

the presser

Check that there Is a clearance of 3.2 mm between the highest point of the

looper and the underside of the needle plate when the looper holder Is In Its

vertical

If necessary,

position.

repeat

steps

41.3 to 41.6

Check this adjustment (see "Correct setting").

48

Page 51

42

Correct

setting:

Backtacking

The

face

front

edgeofthe

mechanism

sideofthe

(subcl.

backtacking

bedplate.