Page 1

Replacing the Conveyor

Motor Assembly

For Simply Clean® Self-Cleaning Litter Box

Thank you for choosing PetSafe®. Our mission is to be the most trusted brand in the pet ownership experience. We want to ensure

your pet’s happiness and safety by providing you with the tools and techniques to successfully care for your pet. If you have any

questions, please contact the Customer Care Center at 1-800-732-2677 or visit our web site at www.petsafe.net.

Replacing the Conveyor Motor and Crank Disk

In this procedure, you replace both the conveyor motor and the crank disk that propels the motion of the conveyor rake fi ngers.

It is recommended that you perform the procedures in this document on a stable fl at surface that is large enough to securely

and safely hold the Simply Clean

components. We also recommend you remove the litter in the bowl as part of this procedure.

Requirements

To complete the procedures in this document, you need:

• A #1 Philips screwdriver

• A fl at head screwdriver (optional)

• A replacement conveyor motor kit

____________________________________________________________________________________________________________

®

Litter Box unit, and that provides suffi cient work area for you to work with the individual

Removing the Conveyor Motor

Cover the work surface with a large sheet, drop cloth, or

newspaper, and then:

1. Remove the conveyor cover and set it aside

(see Figure 1 below).

Figure 1: Removing the conveyor cover

2. Loosen the two thumbscrews that secure the

conveyor to the base (see Figure 2 below)

.

3. Carefully lift up on the

conveyor, until it rests in

an upright position

(see Figure 3 below).

4. Remove the bowl

(see Figure 4 below).

Set the bowl aside.

Figure 3: Conveyor in

an upright position

5. Disconnect the conveyor motor wire from the base.

Press in on the middle of the clip to release the locking

mechanism. If the clip does not easily release, use a fl at

head screwdriver to gently press in at the center of the clip.

Figure 4: Removing

the bowl

Figure 2: Loosening the thumbscrews

Figure 5: Disconnecting the conveyor motor wire

Press in to release

Pull up to unlatch

Page 2

6. Remove the conveyor from the base unit by lowering the

D

conveyor to its natural position fi rst. Next, lift up on the

non-motor corner of the conveyor until the retaining arm

extending down from the conveyor is free from the base

assembly, and then lift the conveyor off the base unit. Set

the conveyor on the work surface.

Lift conveyor

up and out

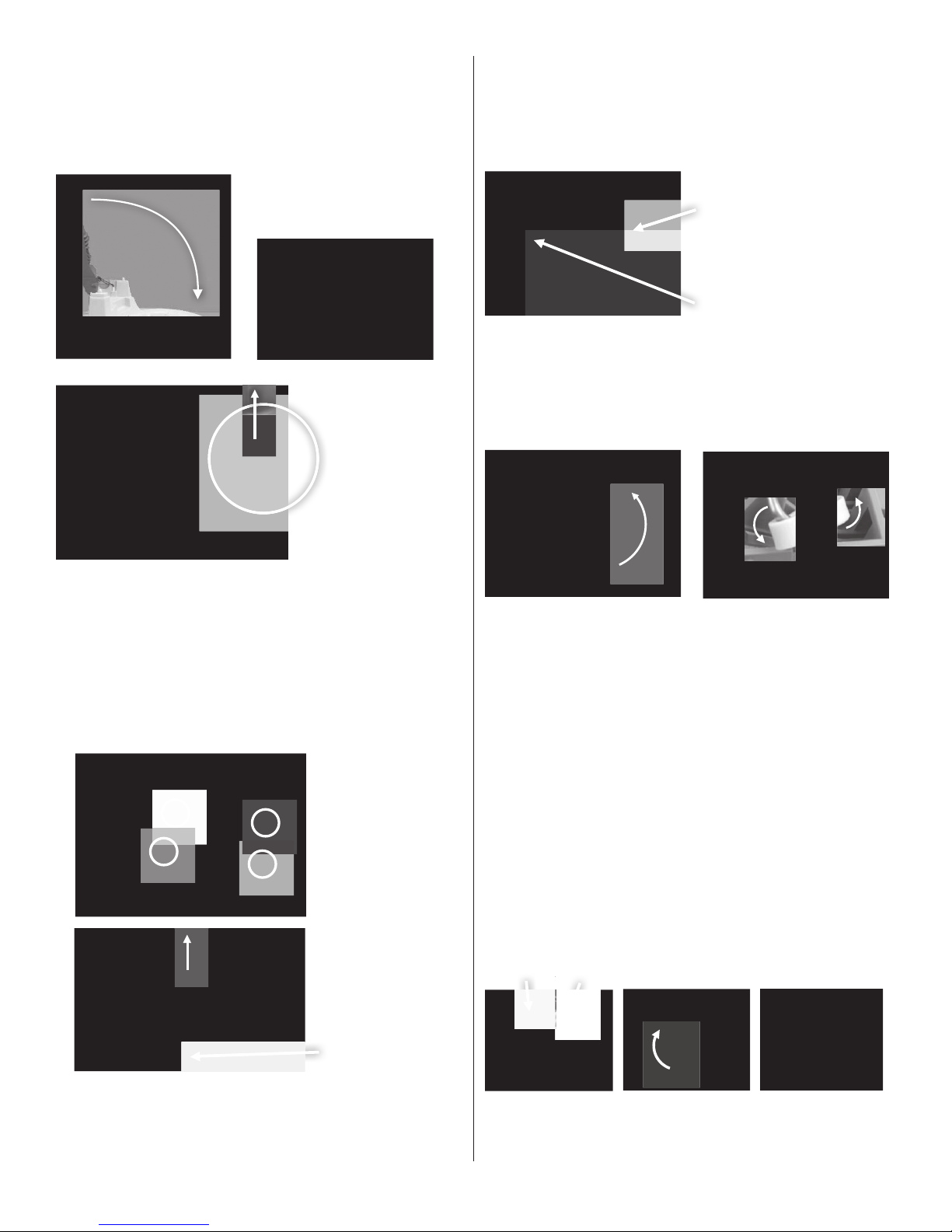

Replacing the Crank Disk

Turn the conveyor over to expose the crank disk, and then:

1. Rotate the drive shaft until it is fully extended above the

underside of the conveyor (see Figure 8 below).

Crank

disk

Driveshaft

Figure 8: Positioning the drive shaft

2. Lift up on the drive shaft and rotate the crank disk

toward the center of the conveyor assembly. Twist the

bottom of the crank disk towards the drive shaft and then

slip it off the end of the shaft (see Figure 9 below).

Figure 6: Removing the conveyor

7. Remove the motor from the conveyor.

a. Use a #1 Philips screwdriver to remove the retaining

screws and brackets securing the motor to the conveyor

(see Figure 7 “A” below). Set the screws and brackets

aside to be used to attach the new motor.

b. Lift up on the motor to free the motor turn shaft from

the crank disk (see Figure 7 “B” below).

A.

B.

Lift off

motor

Figure 9: Removing the crank disk

NOTE: If a rake fi nger detaches from the drive shaft, hold the

drive shaft steady while gently pressing the rake fi nger against the

shaft to snap it back into place.

3. Attach the replacement crank disk to the drive shaft.

Align the crank disk with the inside surface towards the

drive shaft.

a. Lift the rake-fi nger assembly up to elevate the drive

shaft above the conveyor assembly, and attach the

crank disk to the drive shaft by inserting the exposed

end of the drive shaft into the open channel on the

crank disk (see Figure 10 “A” above).

b. Push the crank disk up and around until it

is perpendicular to the drive shaft (see Figure 10

“B” and “C” above).

Drive shaft Crank disk inside surface

Figure 7: Detaching the motor from the conveyor

www.petsafe.net 2

Crank

disk

A.

Figure 10: Attaching the crank disk to the drive shaft

B. C.

Page 3

Installing the Replacement

Conveyor Motor

To attach the motor to the conveyor:

1. Position the crank disk half-circle hole with the opening

on the side of the conveyor assembly (see Figure 11

below).

Crank disk

half-circle hole

2. Insert the conveyor motor’s drive shaft into the half-circle

hole on the crank disk (see Figure 12 below). Both the

crank disk and motor drive shaft align correctly for a

matched fi t.

Motor

drive shaft

4. Secure the conveyor motor in place with the two plastic

retaining brackets. Attach the semi-circle side towards

the conveyor motor for both brackets. (see Figure 14

below). Replace the screws and tighten with a #1 Philips

screwdriver.

Figure 14: Attaching the retaining brackets

5. Reattach the conveyor assembly to the base unit. First,

insert the plastic post on the motor side of the conveyor

into the cutout on the base unit. Next, then apply gentle

pressure to the retaining arm on the opposite side of the

conveyor while you insert it in the cutout on the other

side of the base unit (see Figure 15 below).

Conveyor

assembly

Crank

disk

Figure 12:

shaft to the crank disk

3. While holding the crank disk up so it does not detach

from the motor drive shaft, turn the motor assembly until

the two fl anges are properly aligned with, and fi tted to the

posts on the conveyor assembly (see Figure 13 below).

Figure 13: Aligning the motor assembly with the motor

posts on the conveyor

Aligning the motor drive

Motor

posts

Base unit

Figure 15: Attaching the conveyor to the base unit

6. Move the conveyor to its upright position, and then

reconnect the conveyor motor wire to the base (see Figure

16 below). Press down until the catch clicks into place.

Push down on clip

Figure 16: Attaching the conveyor motor

wire to the base unit

Completely connected

www.petsafe.net 3

Page 4

7. Flip the base over, move the conveyor to its upright

.

D

position, and then place the bowl back onto the base unit

(see “A” in Figure 17 below). Be sure to adjust your litter

guard so that the conveyor fi ts within the notch on the

guard (see “B” in Figure 17).

A.

B.B

9. Tuck the motor wires into the space between the conveyor

assembly and the base unit so they do not get pinched

between the two. Tighten the two thumbscrews to secure

the conveyor to the base (see Figure 19 below).

Do not pinch wires Wires unpinched

o not pinch wires

Figure 12: Securing the conveyor to the base unit

Figure 17: Replacing the Bowl

8. Lower the conveyor into place (see Figure 18 below).

If your bowl is full of litter, you may gently wiggle the

conveyor back and forth to bury the rake fi ngers in

the litter.

Testing Your Simply Clean® Litter Box

To verify that your repair was completed correctly:

1. Replace the conveyor cover and waste receptacle. Both

have to be in place for the unit to work properly.

2. Plug the unit into the power source. The Operating

Indicator LED should illuminate.

3. Without lifting up on, or removing the conveyor cover,

observe the area at the base of the conveyor for conveyor

movement.

If your conveyor is not moving:

• Make sure the conveyor cover is securely in place and the

waste receptacle is completely installed in its bay.

• Loosen the thumbscrews and lift up the conveyor to verify

that the motor connector is completely and properly

attached to the base unit. (see page 3, Figure 16 for

reference).

If your unit is still not working, contact PetSafe®

Customer Care Center at 1-800-732-2677

Monday – Friday: 8 am - 8 pm EST, or

Saturday: 9 am - 5 pm EST.

Radio Systems Corporation • 10427 Electric Avenue • Knoxville, TN 37932 • 1-800-732-2677 • www.petsafe.net • ©2008 Radio Systems Corporation • 400-1035

Loading...

Loading...