Page 1

draught beer basics

Quality & Innovation

that inspires

Page 2

Page 3

draught beer

Beer is one of the oldest, and most popular,

beverages known to man. There are over 5,000

breweries in North America and Europe alone,

giving you, the consumer, more choices than

ever. Read on to learn about the basics of

draught beer, as well as important information

about Perlick beer dispensers. We’re proud to

provide brewery fresh flavor right in your home

to satisfy the palate of the most discriminating

beer connoissuer.

Page 4

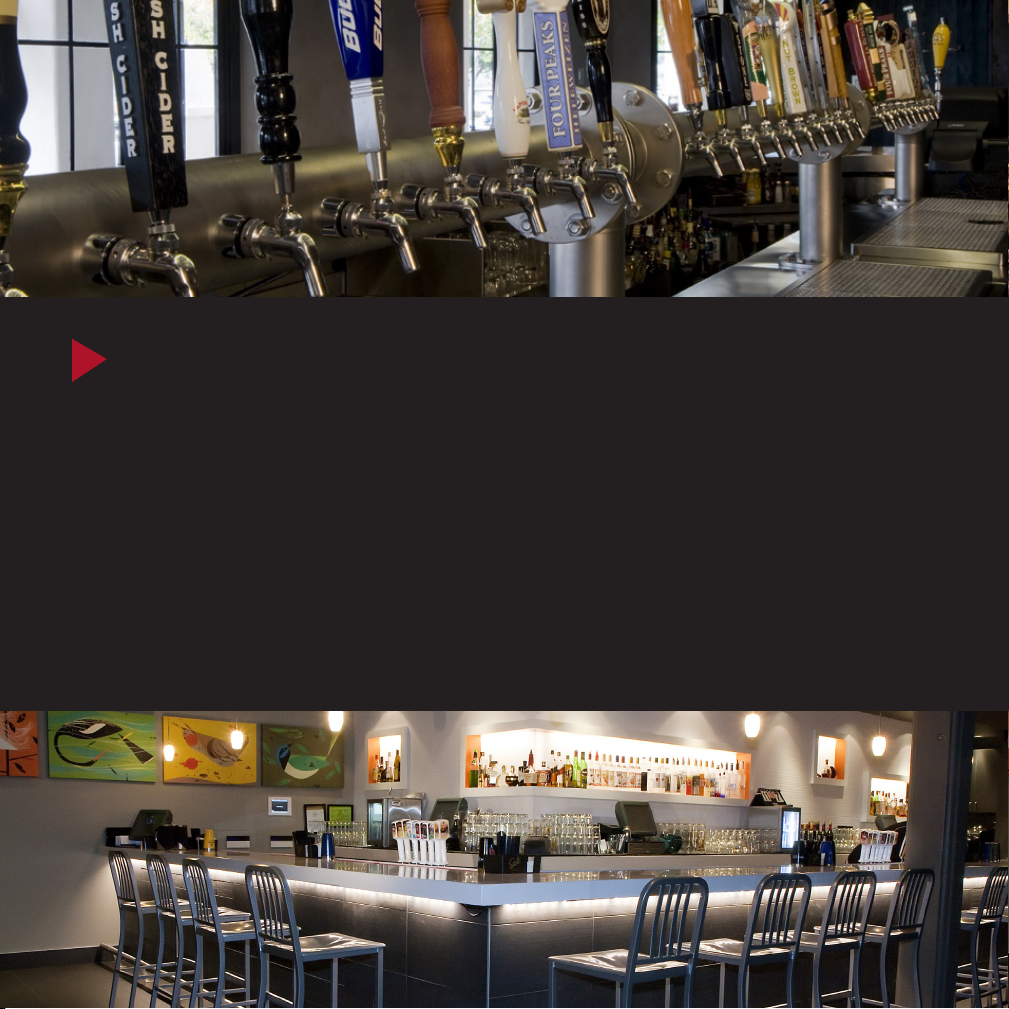

trust the brand the pros trust

Perlick is the pioneer of the beer dispensing industry, leading the

competition in innovating how venues move beer in the freshest,

coldest way possible. Since introducing our premier Century

Beer System in 1962, Perlick has gone on to design, engineer and

manufacture systems for bars/restaurants, stadiums and arenas around

the world.

The same commercial-quality parts and craftsmanship go into each and

every beer dispenser we produce. It’s the same technology trusted by

professionals across North America, refined beautifully for the home.

Page 5

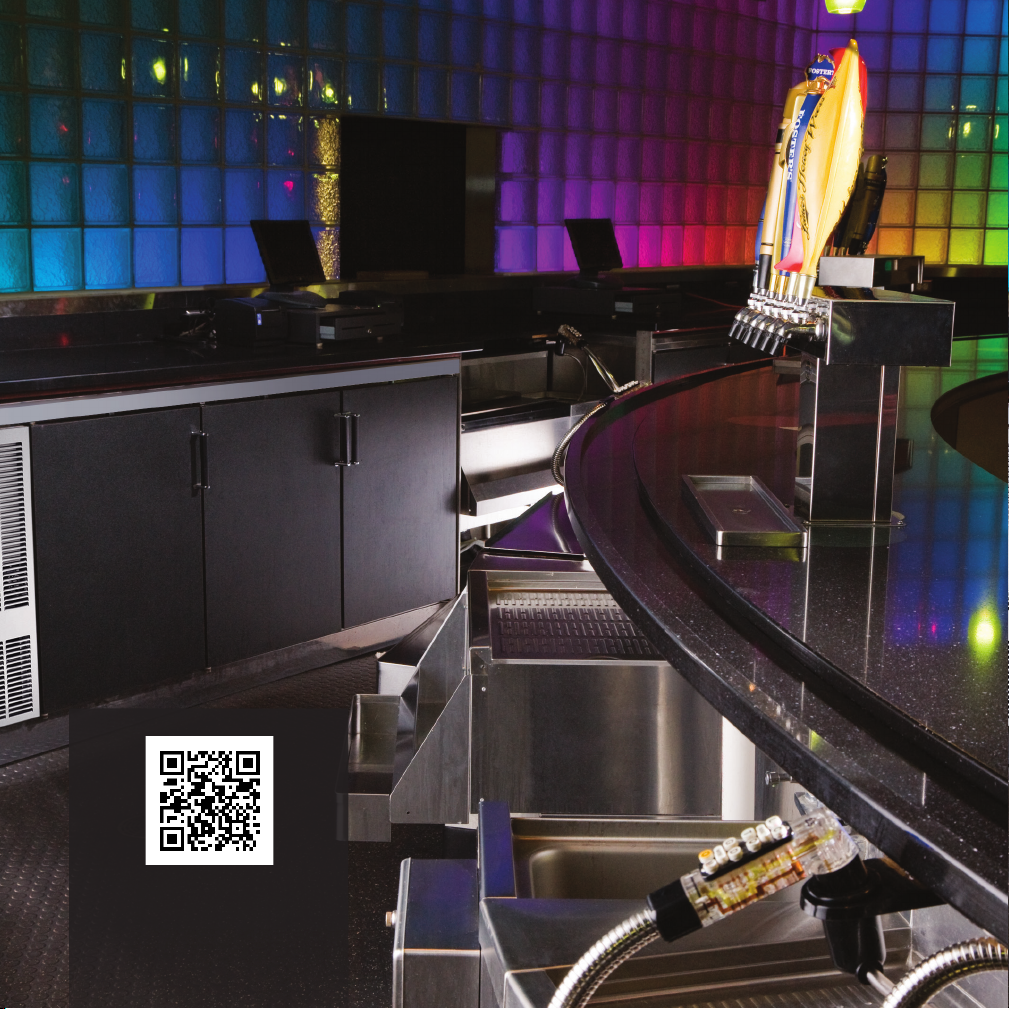

Scan the QR code to see a full list

of our large venue products

Page 6

the anatomy of beer

There is a reason beer is regarded as the world’s most

popular beverage. Its complex blend of flavors, aromas

and brewing styles create limitless unique beers ranging

from light, fragrant pilsners to bold, robust stouts.

COLOR is determined by the kilning of the malts,

as well as various methods of mashing, boiling

and fermentation.

FLAVOR is determined by the malt, hops and

water used in the brewing process.

Page 7

AROMA is determined by the malt, grain and

fermentation by-products.

HEAD is produced by bubbles of carbon

dioxide rising to the surface. Industry

experts recommend 1” to 1-1/2” head on

most varieties.

ALCOHOL CONTENT generally ranges

from 3% to just under 30% alcohol by

volume in beer.

CARBONATION is a by-product of fermentation.

Page 8

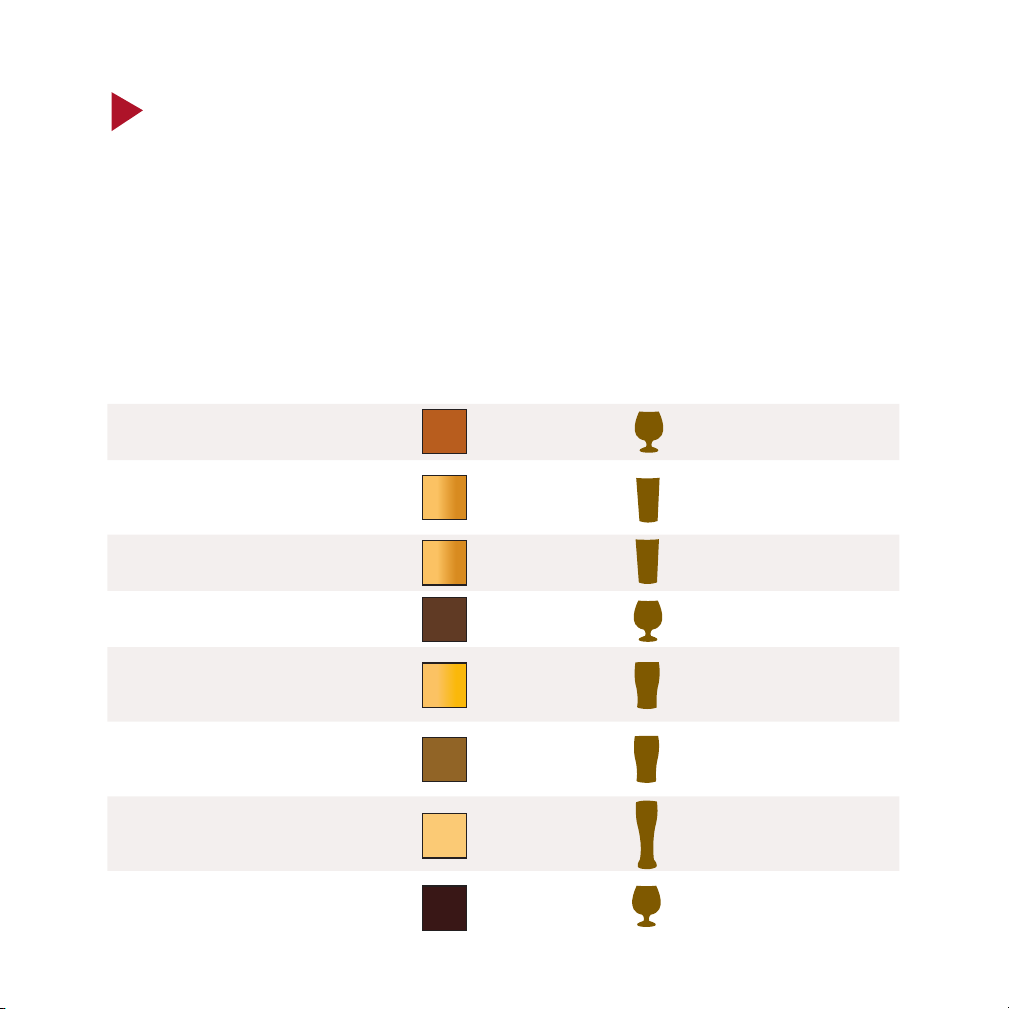

styles of beer

Because of its complexity, beer is defined by a style. These styles

dierentiate beers by a number of factors, including (but not limited

to) aroma, appearance, flavor and mouthfeel. There are three main

styles – Ale, Lager, and Hybrid - each having a variety of sub styles

that further categorize the beers characteristics. Below are a variety

of sub-styles with information on how to properly serve them and

recommended food pairings to experience beer as the brewmaster

intended.

Color Serving Temp Glass Type Pairings to Try

Abbey Tripel Strongest of the Belgian

Tripels; high alcohol content

50° - 55°F

10° - 13°C

Pesto, roasted asparagus,

cured meats, peach cobbler

Ale Beer that is fermented more quickly

and at warmer temperature with topfermenting yeast.

Amber A beer named for its reddish-brown

color, ranging from pale to dark.

Bock A strong, dark German beer brewed

during the springtime.

British-Style Bitter A low-alcohol

content beer with a fruity aroma and avor.

Low carbonation.

Brown Ale Nutty, malty ale that is dark

brown in color with avors ranging from dry

to sweet.

Hefeweizen “Yeast wheat” in german;

an unltered wheat beer that is bottle

conditioned and cloudy when served.

Imperial Stout A strong, hoppy black ale

that originated in Britain for export to Czarist

Russia (also referred to as “Russian Stout”)

40 - 50°F

4.5° - 10°C

50° - 55°F

10° - 13°C

45° - 50°F

7 - 10°C

50° - 55°F

10° - 13°C

50° - 55°F

10° - 13°C

40° - 55°F

4.5° - 7°C

50° - 55°F

10° - 13°C

Bualo wings, pizza, spicy

food, nutty cheese like

parmesan and romano

Chicken, seafood, spicy

foods, Port-Salut

Rich foods like duck or

roasted pork, cured meats

Fish and chips, roasted

chicken or pork, mild

cheeses

Smoked sausage, roasted

pork, grilled salmon, gouda

Lighter fare, such as sushi,

seafood, weisswurst, citrus,

gruyere, feta or goat cheese

Foie gras, long-aged

cheeses, dark chocolate

Page 9

WEIZEN GLASS

India Pale Ale A strong, hoppy pale

ale that originated in Britain for export to

soldiers in India.

AMERICAN PINT

IMPERIAL PINT

PILSNER

DIMPLED MUG

Color Serving Temp Glass Type Pairings to Try

50° - 55°F

10° - 13°C

SNIFTER

Curry, spicy fare, blue

cheese

Lager Beer fermented slower, cooler

temperatures than ale, with bottomfermenting yeast, which is then aged for a

smooth, clean avor and aroma.

Pale Ale A mild version of India Pale Ale,

only fruittier

Pilsner A general name for pale, goldenhued, highly hopped bottom-fermenting

beers. The original was rst brewed in the

Bohemian town of Pilsen in 1842.

Porter Ale brewed from well roasted

barely. Dark brown in color, full-bodied in

texture, and bittersweet/chocolatey in avor

Stout An English or Irish style ale that is

opaque black, smooth and creamy

Vienna A German-style lager that is sweet,

malty and reddish in color originally brewed

in Vienna

Witbier “White Beer” in German; pale

golden color with a tart, refreshing avor.

Similar to Hefeweizen only spicier

45 - 50°F

7° - 10°C

50° - 55°F

10° - 13°C

40° - 50°F

4.5 - 10°C

50° - 55°F

10° - 13°C

50° - 55°F

10° - 13°C

45° - 50°F

7° - 10°C

50° - 55°F

10° - 13°C

BBQ, hamburgers, spicy

foods like chili, jack or brick

cheese, light pasta dishes,

bread pudding

Seafood, beef dishes, cajun

fare, lamb, liver pate

Light seafood, spicy

mexican or asian dishes,

mild cheeses, berry desserts

Blackened sh, smoked

foods, chili roasted meat,

Gruyere

Raw oysters, hearty stews,

braised dishes, chocolate

Roasted pork and chicken,

bratwurst, nutty cheeses,

pumpkin pie

Seafood, spring vegetables,

sushi, brunch dishes, any

food prepared with citrus

and herbs

Page 10

ALL ABOUT KEGS

Kegs are filled at the brewery and delivered directly to your local

retailer, ensuring you’ll be getting the freshest beer possible. Kegs

are designed to protect beer from both air and light, while still

enabling easy and rapid dispense. Most brewers use kegs made of

stainless steel, but there are also rubber-coated, aluminum, steel and recently - plastic kegs in the marketplace.

Below is a breakdown of how much beer is in a keg. To the right,

you’ll see our available beer dispenser models, along with their

capacities and keg layouts.

1/6 BARREL

Gallons 5.16 7.75 7.75

Ounces 661 992 992

No. of 12 oz. 55 82 82

No. of 16 oz. Beers 41 41 41

No. of Cases in Keg 2.3 3.4 3.4

Torpedo Keg

Nicknames

Weight 58 lbs 87 lbs 87 lbs

ALWAYS TAKE CARE WHEN MOVING FRESH KEGS! A quarter barrel 85 lbs. when full! Before moving

the keg, rmly grasp the slots on the top of the keg. Pull the keg towards you, lighting the far end of the keg o

the ground. Slowly roll the keg on its edge towards the dispenser (also called keg walking), and rock into place.

Mishandled kegs can result in foamy beer or, worse yet, injury!

Log

Sixth Barrel

Sixtel

1/4 BARREL

Quarter Barrel

Pony Keg

Stubby Quarter

SLIM 1/4 BARREL

Slim Quarter Barrel

Tall Quarter

Page 11

OR

OR

OR

OR

Meet your perlick

Beer dispenser

Temperature range:

beer dispenser

33° – 42°F

24” Signature Series

Beer Dispenser,

Single Faucet

15” Signature Series

Beer Dispenser,

Two Faucet

Beer Dispenser, Single

1/6

1/6

1/4

SLIM

1/4

1/6

1/6

Capacity:

1/6

One 1/6 barrel

Capacity:

Two 1/6 barrels

One 1/4 barrel

One slim 1/4 barrel

Capacity:

Two 1/6 barrels

24” C-Series

One 1/4 barrel

1/4

SLIM

One slim 1/4 barrel

1/4

Beer Dispenser,

Single Faucet

Beer Dispenser,

Two Faucet

Page 12

ALL ABOUT COUPLERS

A keg coupler connects the Carbon Dioxide gas line (CO2) to the

keg. The compressed gas powers the coupler to draw out the beer

from the keg. Dierent countries use dierence keg couplers, so it

is important to have the right coupler for the specific brand you are

going to be dispensing. Perlick residential beer dispensers come

standard with a Low Profile “D” Keg Coupler that can be used on

any barrel size of American “D” system sankey kegs*.

Please note that if you are using a coupler other than the one

provided by Perlick, it must be used with a short 1/4 barrel. A

traditional sized coupler will not fit in the cabinet with a standard

23 3/8” tall keg.

Coupler Size D* U G A

Perlick Part No. 40030 63908 63907 63909

In some instances, an “S” or “M”

size coupler will be required. An “S”

System keg coupler is much like the

“D”, but with a stem that extends

roughly a 1/4” further into the keg. The

“S” System

Keg Coupler

“M” System

Keg Coupler

“M” System coupler is relatively new to

the US market, and is only used by a

select number of breweries.

Page 13

Most of the beers brewed in the US and Canada will use the “D” sized coupler.

Imported beers can vary from country to country, even brewery to brewery.

Below you’ll find a list of some of the most popular imported keg beers and the

type of coupler they’ll require. If the beer you’ll be dispensing is not on this list,

consult the keg seller, distributor or brewery itself to find out which keg coupler

to use.

Below is a brief list of popular beers from around the world and the type of

coupler they require. Remember - you can only use System U, G, A, S or M

couplers with a short 1/4 barrel.

Beer Brand Country

Amstel Holland S

Beamish Ireland U

Beck’s Germany U

Bass Ale England G

Carlsberg Denmark S

Dos Equis Mexico D

Franziskaner Germany A

Foster’s Australia D

Grolsch Holland G

Guinness Stout Ireland U

Hacker-Pschorr Germany A

Harp Ireland U

Heineken Holland G

Hoegaarden Belgium S

Kirin Japan D

Coupler

Type

Beer Brand Country

Kornenbourg France A

Labatt’s Canada D

Lee Belgium S

Magner’s Irish Cider Ireland S

Modelo Mexico D

Newcastle England S

Paulaner Germany A

Peroni Italy S

Pilsner Urquell Czech S

Smithwick’s Ireland U

Spaten Germany A

Stella Artois Belgium S

Strongbow Cider England S

Tennant’s Scotland G

Warsteiner Germany A

Coupler

Type

Page 14

The difference between

Signature and c-series

Perlick has ten home beer dispensing models in its product portfolio – the

most of any manufacturer in our category. Each Perlick Beer Dispenser

is handcrafted right here in the Brew City using the same proprietary

equipment and designs used in bars, restaurants, stadiums and arenas

around the globe. Below are the dierences between our top of the line

Signature Series models and our C-Series Beer Dispensers.

650SS Flow

Control Faucet

• Comes standard with Perlick’s industry exclusive stainless

steel forward-sealing 650SS Flow Control Faucet

• Stainless steel exteriors on both indoor and

outdoor models

• Powered by Perlick’s exclusive 995 Btu variable-speed

compressor with front-vented, RAPIDcool™ refrigeration

technology

• Comes standard with classic Draft Arm Tower with

optional upgrade to Adara Signature Tower (indoor

models only), shown left

630SS Faucet

• Comes standard with Perlick’s industry exclusive stainless

steel forward-sealing 630SS Faucet

• Black vinyl clad exterior on indoor models, stainless steel

exterior on outdoor models

• Powered by standard 525 compressor with front-vented,

RAPIDcool™ refrigeration technology

Perlick proudly oers 15- and

24-inch beer dispensers that are

UL-rated for outdoor use.

Page 15

nearly a century’s worth of

beer dispensing expertise -

right at your finger tips

The revolutionary new 650SS Flow Control Faucet is Perlick’s

latest innovation in beverage dispensing – and it is now standard

on all Signature Series Beer Dispensers. This newly-designed

industry exclusive faucet allows you to adjust the

speed of the pour, which is important for pouring

multiple styles of craft beer or when foaming is

an issue.

• Bright, wheat beers – like Hefeweizen – are highly carbonated and tend

to pour with an excessive head, requiring a slower pour. The ow control

lever adjusts the rate of the pour right at the faucet, allowing you to

control how fast beer enters the glass.

• In addition to accommodating a variety of beer styles, the

650SS eliminates waste that is normally caused by foaming

in hotter temperatures. Perlick’s exclusive air-cooled tower

keeps beer cold from the keg to the faucet, and the ow

control lever allows you to dictate the rate of ow to prevent

excessive foaming caused by cold beer coming in contact

with the hot air.

Winner of a 2014 GOOD DESIGN Award and

2015 Platinum Award for Design Excellence (ADEX)

Page 16

Page 17

Why trust Perlick for your

beer dispensing

With over 3,000 breweries in the U.S. alone, there are countless

beer styles with unique characteristics and flavor profiles to

choose from. You can trust Perlick beer dispensers to properly

pour beer each and every time you reach for a glass. Read on to

learn what makes Perlick the industry leader in all things beer.

• As pioneers in commercial refrigeration and beer dispenseing, Perlick has nearly 100 years of designing,

engineering and manufacturing expertise that is unmatched by the competition. Our residential beer

dispensers feature the same innovative, commercial-grade parts and craftsmanship as the Perlick beer

systems found at bars, restaurants and large venues around the world, but with styling that is rened for the

nest homes.

• All Perlick beer dispensers come standard with patented Perlick 600 Series forward-sealing faucets that

feature a revolutionary ball and oating front seal design to prevent beer from being exposed to air. This

eliminates the build-up of mold and bacteria that cause o-tasting beer.

• Towers are forced-air cooled to keep beer cold from the keg up through the tower and into the faucet.

• Stainless steel interiors and exteriors provide the most sanitary surface available to make cleaning simple, and

can stand up to heavy kegs

24” Signature Series Beer Dispenser with

two-faucet dispensing head shown

Page 18

24” Signature Series Beer Dispenser with

optional two-faucet Adara Signature

Dispensing Tower,shown

Page 19

accessories info

Perlick oers an array of accessories for all models, including the 15and 24-inch Beer Dispensers. Each accessory is designed specifically

for Perlick products, and the collection of beer dispenser products

are the same quality you’d find with our commercial beer dispensing

portfolio.

HARDWARE

A. Left or Right Hinge Kit (67439L/R)

B. Factory Installed Door Lock (L)

C. Casters (66736-15 or -24)

A. B. C.

beer dispenser-specific

D. Cleaning Kit (63797)

E. Faucet Lock (308-40C) - for 630SS

(C-Series) faucets only!

F. Sanitizer, 4oz. or 32oz. (BLC4/32)

G. Perlick Faucet Handle (67141-1)

D. E. F.

H. European Keg Coupler Kit (63992)

I. Drip Pan (67782)

G. H. I.

Page 20

troubleshooting info

When you’re expecting a full-bodied brew, a foamy or flat beer just

won’t do. If you experience excessive foam or no foam at all, chances

are there is a quick and easy fix that will get you back to pouring the

perfect beer in no time. Below are some of the most common beer

dispenser problems, as well as their solutions.

PROBLEM: No beer is coming out of the tap!

• Check the gauge to see if there is any

pressure showing. It should read between

10-12 lbs. If it is not, your CO2 tank may be

empty

• Is the shut-o valve in the vertical (on)

position? (Note: diagram shows valve in

the o (horizontal) position).

PROBLEM: Flat beer

• Check the gauge. Is the pressure between

10-12 lbs? If not, turn the pressure up to its

appropriate level. Low pressure can cause

beer to flatten and pour slowly.

• Dirty glassware will cause the head

on a beer to quickly disappear.

Make sure your glassware is free

of impurities prior to pouring.

FLAT BEER

Page 21

PROBLEM: Foamy Beer

• Check the gauge (see page 18 for

location). Is the pressure between

10-12 lbs? If not, turn the pressure

down to its appropriate level. Too

high of pressure can cause beer to

overcarbonate in the keg and pour

foamy.

• Is the unit plugged in and cold?

Is the keg cold or, if purchased

at room temperature, has it been

in the dispenser for at least 24

hours? Attempting to tap a warm

keg in a refrigerated unit will

cause excessive foaming. Keep the

temperature in the unit 36° - 38°F,

and make sure the keg is properly

chilled prior to tapping.

• Have you cleaned the equipment

lately? Regular cleaning of the

system – from faucet to keg

coupler – is important to keep

beer stone, bacteria and mold

from building up. The factors listed

above can quickly ruin a perfect

brew! See page 24 and 25 for

cleaning instructions.

Foamy BEER

Page 22

maintenance info

To ensure brewery-fresh flavor, it is recommended that the beer

system be cleaned after every barrel or every two weeks to

eliminate bacteria, yeast and beer stone build-up in the system.

Below, you’ll find instructions on how to properly and thoroughly

clean your beer dispenser.

Supplies needed:

• Cleaning Kit - Includes cleaning pump

jar (A), coupling washer (B), 4 oz. BLC

line cleaning chemical (C), check ball

lifter (D), cleaning brush (E) and spanner

wrench (F) (Kit Part No. 63797, shown

right)

• Buckets

• Water (warm and cold)

CAUTION: The chemicals used to clean beer lines

are hazardous. Please follow all recommended

safety instructions on the chemical’s container.

1. Turn o the CO2, either at the CO2 cylinder or at the air distributor.

2. Remove tapping device (keg coupler) from the barrel.

3. If tapping device contains a check ball, insert check ball lifter into the bottom of the coupler

(Perlick Low Prole Coupler does not contain a check ball).

4. Place tapping device into a small bucket.

5. Using a spanner wrench, remove the beer faucet from the dispensing head.

6. Fill cleaning pump with warm water.

7. Attach cleaning pump jar connector with washer to where faucet was removed from

dispensing head.

E.

F.

D.

B.

C.

A.

Page 23

8. Pump the warm water through the system to remove all remaining

beer from the system. Empty tapping device bucket and rinse out.

Place tapping device back into the bucket.

9. Fill cleaning pump jar with water and cleaning chemical per the

recommendations on the cleaning chemical container.

10. Pump cleaning solution into system, keaving about a 1/2 the

solution in the cleaning pump jar.

11. Let stand 15 minutes, then pump remaining solution through the

system

12. Using a cleaning brush, clean the exterior surfaces of the tapping

device and rinse with clean fresh water

13. Rinse out cleaning pump jar with fresh water

14. Fill cleaning pump jar with clean warm water and pump entire jar

through the system

15. Repeat step 13 using clean cold water

16. During the 15 minutes that the solution is in the system, mix a small

container with water and cleaning chemical per the instructions

on the clenaing chemical container and disassemble the faucet per

faucet manufacturers recommendations and let soak in solution

17. Using cleaning brush, clean the components of the faucet

18. Rinse all components of the faucet in clean fresh water. Check all

seals on the faucet for wear and replace if necessary

19. Reassemble faucet

20. Remove cleaning pump jar from dispensing

tower connection and reinstall faucet using

spanner wrench to tighten properly

21. Turn on CO2 and tap new keg

Page 24

8300 West Good Hope Road

Milwaukee, WI 53223

phone 800.558.5592

web perlick.com/residential-products

FORM NO. 67962

REV. 02.04.2015

Loading...

Loading...