Page 1

INSTALLATION AND OPERATION INSTRUCTIONS

ICE CREAM CABINET

MODEL NOS.

8000

IMPORTANT INFORMATION

A Warranty card is enclosed that must be completed

and mailed to the Perlick Corporation to register the

warranty. If the card is not returned to Perlick, the

warranty period will begin from the date the

equipment is shipped from the factory.

This manual has been prepared to assist you in the

installation of your Ice Cream Cabinet and to

acquaint you with its operation and maintenance.

We dedicate considerable time to ensure that our

products provide the highest level of customer

satisfaction. If, however service is required, your

dealer can provide you with a list of qualified service

agents. For your own protection, never return merchandise for credit without our approval.

We thank you for selecting a Perlick product and

assure you of our continuing interest in your

satisfaction.

WARNING: When lifting, the full weight of the

cabinet must be supported. Lift from the cabinet

base and not from the top. Improper lifting can

result in severe damage to the cabinet.

Table of Contents

Specifications.........................................................2

Preparing the Cabinet for Use ...............................3

Uncrating and Inspecting .......................................3

Electrical................................................................3

Installation..............................................................3

General information...............................................3

Cooling System .....................................................3

Temperature Control..............................................3

Oiling......................................................................3

Cleaning.................................................................3

Installation Into a Countertop ................................4

Installation Into a Topshelf Underbar .....................5

Replacement Parts................................................6

Wiring Diagram......................................................7

8300 West Good Hope Road • Milwaukee, WI 53223 • Phone 414-353-7060 • Fax 414-353-7069

Toll Free 800-558-5592 • E-Mail: Perlick@Perlick.com • www.Perlick.com

Form No. Z2029A

Rev. 08.03.04

Page 2

Installation and Operating Instructions

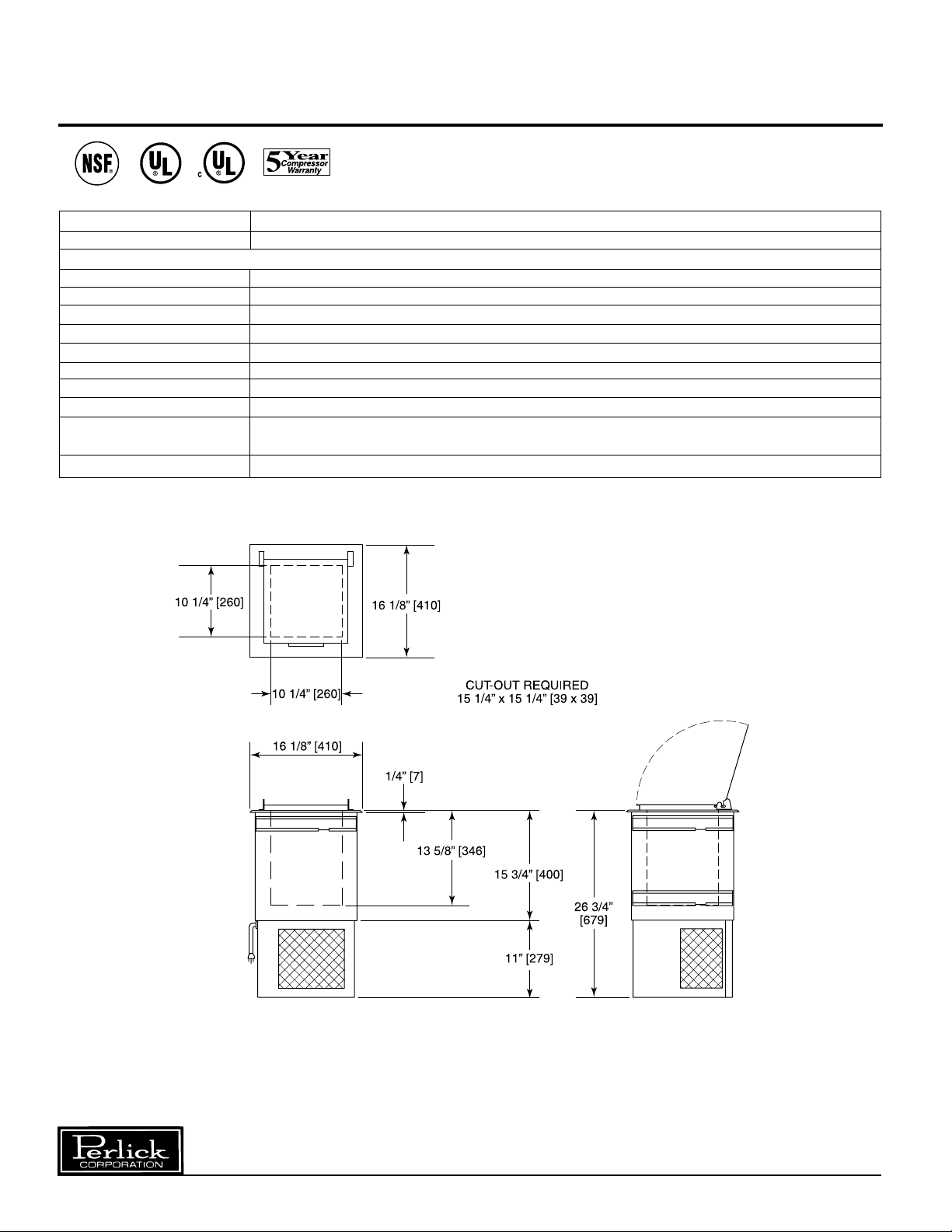

Sizes and Specifications, Ice Cream Cabinet

MODEL NOS. 8000

CAPACITY 3 Gallons

DIMENSIONS IN. [mm]

HEIGHT 26

WIDTH 16

DEPTH 16

SHIP WEIGHT lbs. (kg) 114 (52)

COMPRESSOR H.P.

AMPS 1.6

INTERIOR Well dimensions: 13

EXTERIOR 20 gauge stainless steel top and removable hinged door lid.

ELECTRICAL 115 Volt, 60 Hz., 1 Phase AC. Can also be used on 100 volt, 50 hz. 1 phase A.C. Furnished with

three-prong, six foot rubber cord.Contact Perlick for other electrical requirements.

REFRIGERANT and CHARGE R134a 5.5 oz. (142).

5

⁄8” [346] H x 101⁄4” [260] W x 101⁄4” [260] D.

3

⁄4” [680]

1

⁄8” [410]

1

⁄8” [410]

1

⁄5 h.p.

Form No. Z2029A

Rev. 08.03.04

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

2

Page 3

Preparing the Cabinet for Use – ICE CREAM CABINET

Uncrating and Inspection

Remove all crating material before operating this

cooler. Carefully inspect cabinet for hidden damage.

If damage is discovered, file your claim immediately

with the transportation company. Perlick is

not responsible for damage in transit.

Electrical

For specifications, see data plate located on the

cabinet. Also, see wiring diagram located in this

publication CAUTION: Do not use any other voltage

than is specified as serious damage will result.

Installation

IMPORTANT: The unit must NOT be totally

enclosed. There can be no restriction of air

circulation. The condenser at cabinet front must be

provided with a minimum opening the same size as

the condenser (100% open). The cabinet back must

have a minimum opening one and one-half times

the condenser size (150% open). Cabinet sides

have a minimum of two inches air space. Be sure to

provide access so front cover of drop-in ice cream

cabinet can be removed to clean the condenser.

After placing the cabinet into its initial operation,

allow about 24 hours for the cabinet to reach and

maintain proper temperature.

General information – Ice Cream Cabinet

Cooling System

This cabinet maintains temperatures from the cold

walls of the storage compartment. If excessive frost

accumulates on the walls, remove the plug from the

electrical outlet. Never use a sharp instrument to

break ice from the cabinet walls

Temperature Control

An adjustable temperature control is located on the

front of the unit near the condenser. It is factory set

at a normal operating temperature. Make adjustments to attain the desired temperature..

Oiling

The Hermetic (sealed) compressor and the condenser fan motor require no oiling.

Cleaning

Condenser

The condenser (located behind the front grille)

should be inspected every 60 days, and cleaned, if

necessary. Failure to keep the condenser clean will

cause a loss in condensing unit efficiency and

warmer cabinet temperatures.

Cabinet

Use a damp cloth with mild detergent and water to

clean the inside and outside of the cabinet. Dry

thoroughly.

0

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

3

Form No. Z2029A

Rev. 08.03.04

Page 4

Installation – Ice Cream Cabinet

Installing Into a Countertop

■

Cut a 151⁄4” [387mm] x 151⁄4” [387mm] square

hole in the countertop for the drop-in ice

cream cabinet.

Note: If C27522 Dipper Well and Faucet Kit are

also being installed, cut the two (2) round holes

required. (Access from bottom and sides is

needed to secure unit to countertop).

■

Apply 1⁄4” [6mm] diameter bead of sealant

supplied

(

shown in cross sections.

■

Insert ice cream cabinet into opening as shown,

making sure there are no voids in sealant where

top flange meets the countertop.

) to bottom outer edge of top flange as

■

From underneath, install the (3) hold down

clips in each upper track through slots as shown

in cross sections in approximate positions

shown below.

■

With uniform pressure, tighten screws in hold

down clips evenly to ensure a positive seal to

the countertop.

■

Remove exposed excess sealant from top

flange and countertop.

■

The faucet and drain are to be connected to

comply with local codes.

Form No. Z2029A

Rev. 08.03.04

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

4

Page 5

Installation – Ice Cream Cabinet

Installing Into a Topshelf Underbar

Stainless Steel Module

■

A151⁄4” [387mm] x 151⁄4” [387mm] square

hole has been provided in the top of the

TS24DC cabinet for the drop-in ice cream

cabinet.

■

Apply 1⁄4” [6mm] diameter bead of sealant

supplied

(

shown in cross sections.

■

Insert ice cream cabinet into opening as shown,

making sure there are no voids in sealant where

top flange meets the countertop.

) to bottom outer edge of top flange as

■

From underneath, install the (3) hold down

clips in tracks in approximate positions

shown below.

■

With uniform pressure, tighten screws in hold

down clips evenly to ensure a positive seal.

■

Remove exposed excess sealant from top

flange and workboard.

■

The faucet and drain are to be connected to

comply with local codes.

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

5

Form No. Z2029A

Rev. 08.03.04

Page 6

Replacement Parts – Ice Cream Cabinet

MODEL NOS. 8000 Serial Numbers Above 500,000

Description Part #’s

1

⁄5 h.p. condensing unit C22649

Complete condensing unit (#UM65HNR) 515301065

Compressor (Model EM65HNR) 513307090

5W Fan motor assembly 215315009

Condenser coil 15352019

Terminal board 219101538

Cover, overload relay 513504007

Lid assembly C29314A

Left hinge bracket C27506-1

Right hinge bracket C27505-1

Mounting stud C27073-1

Wiring harness C25195-1

Temperature control C27523

Breaker strip C25181-1

Back unit cover C29341

Front unit cover C29342

Hold-down clip C27476

Form No. Z2029A

Rev. 08.03.04

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

6

Page 7

Wiring Diagram – Ice Cream Cabinet

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

7

Form No. Z2029A

Rev. 08.03.04

Page 8

8300 West Good Hope Road • Milwaukee, WI 53223 • Phone 414-353-7060 • Fax 414-353-7069

Toll Free 800-558-5592 • E-Mail: Perlick@Perlick.com • www.Perlick.com

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

8

Form No. Z2029A

Rev. 08.03.04

Loading...

Loading...