Page 1

INSTALLATION AND OPERATION INSTRUCTIONS

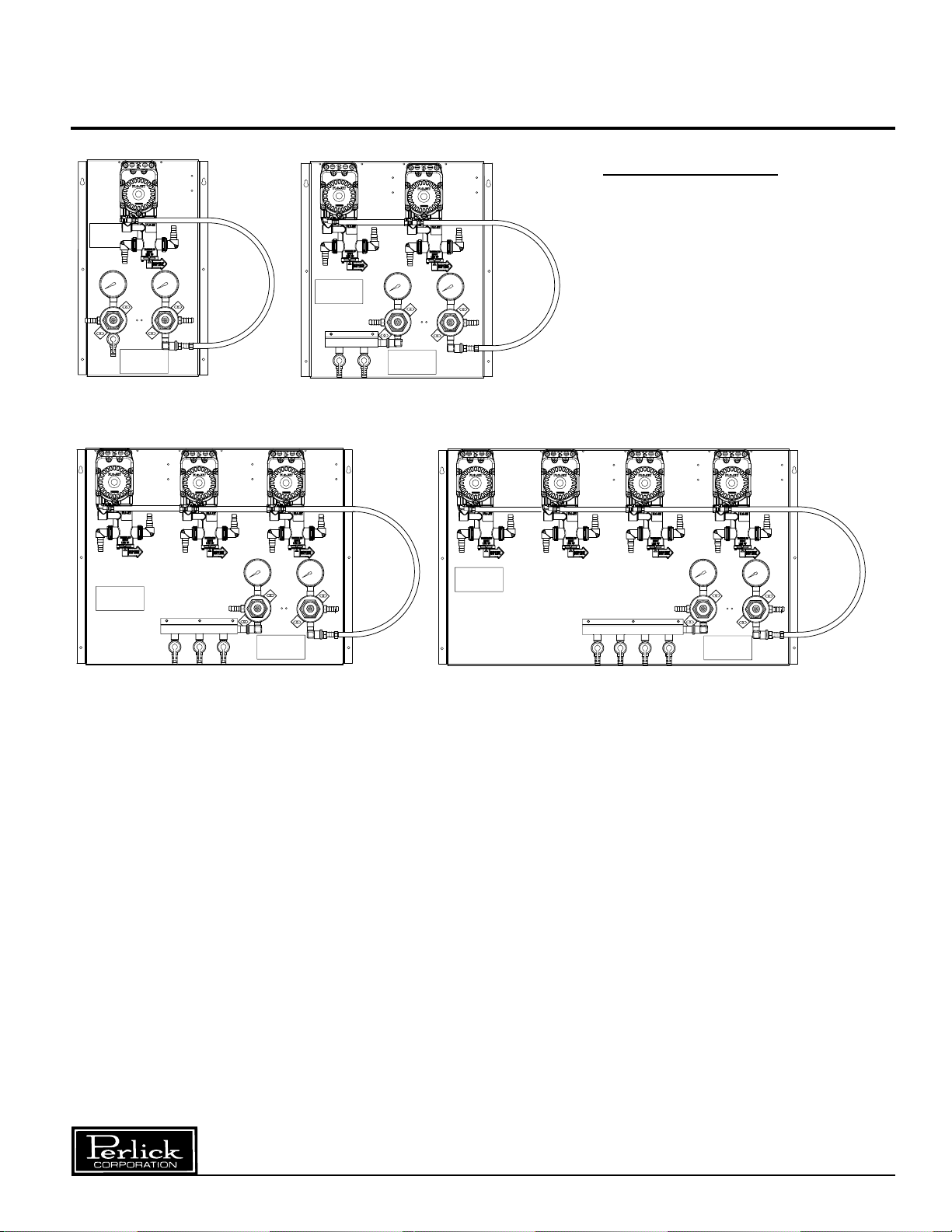

BEER PUMP PANELS

MODEL NO.

63134-1

63134-2

63134-3

63134-4

IMPORTANT INFORMATION

This manual has been prepared to assist you in the

operation of Perlick Beer Pump Panel System.

We dedicate considerable time to ensure that our

products provide the highest level of customer

satisfaction. If service is required, your dealer can

provide you with a list of qualified service agents. For

your own protection, never return merchandise for

credit without our approval.

We thank you for selecting a Perlick product and

assure you of our continuing interest in your

satisfaction.

8300 West Good Hope Road • Milwaukee, WI 53223 • Phone 414-353-7060 • Fax 414-353-7069

Toll Free 800-558-5592 • E-Mail: Perlick@Perlick.com • www.Perlick.com

Table of Contents

Installing the Panel ..............................................2

Panel Diagram.....................................................3

How to Operate the Beer Panel...........................4

Beer Pump Diagram............................................5

Cleaning Diagram................................................6

Cleaning Instructions ...........................................7

Winterizing a System with Beer Pumps...............7

Replacement Parts ..............................................7

Page 2

Installation – Beer Pump Panels

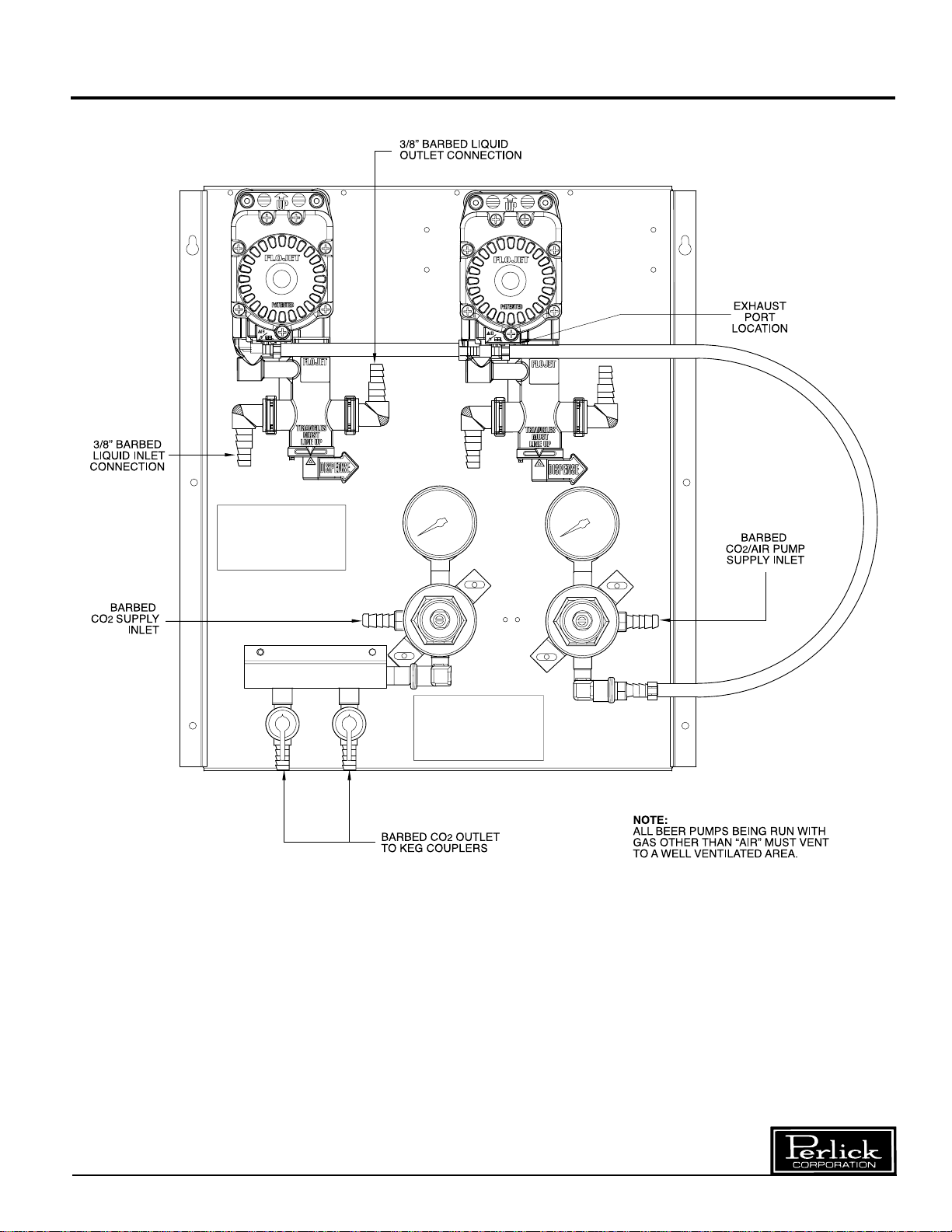

■ Use panel as a template to mark where holes

should be drilled on cooler wall.

(Note: Make sure panel is level and pumps are

in the vertical position).

9

■ Drill

/64”pilot holes in cooler wall. Use fasteners

provided in installation kit to mount the beer

pump panel to the cooler wall.

■ Push CO

Supply barbed inlet.

Position clamp over joint and tighten.

2 supply line over Keg Pressure

(See diagram on page 3).

(Note: A

safety Relief Valve should be installed between

supply tank and shut-off point on carbon dioxide

supply line. Relief setting depends on maximum

system pressures).

■ Push air or CO2 supply line over Beer Pump

Pressure barbed inlet.

3).

Position clamp over joint and tighten. If

(See diagram on page

using compressed air, make sure air supply

is clean and dry. Air must have a pressure

dew point of 30°F. or lower to ensure pumps

operate properly.

■ Push beer line (from trunk housing) over barbed

Liquid outlet on flow reversal valve.

(see diagram on page 3)

. Position clamp over

joint and tighten.

■ Push connector hose over Liquid inlet on beer

pump inlet fitting.

(See diagram on page 3)

.

Position clamp over joint and tighten. (Note:

Connector hose should not exceed 10 feet in

length)

.

■ Install washer into hex nut on opposite end of

connector hose. Connect to top threaded fitting

of Perlick Smart Coupler.

■ Cut a piece of CO2 tubing and push one end

onto barbed CO

page3)

. Position clamp over joint and tighten.

2 outlet.

(See diagram on

Push the other end over the barbed gas inlet on

the Perlick Smart Coupler. Position clamp over

joint and tighten.

CAUTION: IF USING CO

2 AS A

PRESSURE SUPPLY FOR PUMPS,

PUMP EXHAUST MUST BE VENTED

TO A WELL VENTILATED AREA TO

AVOID POSSIBLE ASPHYXIATION.

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

2

Page 3

Diagram – Beer Pump Panel Diagram

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

3

Page 4

How to Operate – Beer Pump Panels

■ Adjust primary CO2 regulator by turning

adjusting screw counterclockwise until it turns

freely, then turn hand valve counterclockwise on

CO2 cylinder to the fully open position. Next, turn

regulator adjusting screw clockwise until desired

pressure is reached.

Note: If CO

2 is only being used for keg-

applied pressure, adjust to approximately

40 psig. If CO

2 is being used to supply

beer pumps, adjust to the required system

pressure plus an additional 15 psig.

■ Adjust the air compressor output regulator

pressure to a minimum of 15 psig. greater than

the maximum required system pressure required

to operate the beer pumps. Maximum setting

100 psig.

■ Adjust secondary CO2 regulator which

supplies the keg pressure located on the

beer pump panel to the proper pressure

setting. Setting depends on beer brand and

temperature. Desired goal is to maintain the

natural carbonation in the beer. Open the shutoff valves.

■ Ensure the Probe Valve on the Perlick Smart

Coupler is in closed position.

See figure 1

.

Ensure the Beer Pump Flow Reversal/Dispense

handle is in the dispense position. Adjust the

Secondary Air/ CO

2 regulator located on the

beer pump panel to a minimum operating

pressure of 10 psig.

■ Connect the coupler to a regulated water supply

with pressure less than 30 psig. Note: Pump

damage may occur with pressure higher

than 30 psig.

■ Open the water supply. Then open probe valve

on Perlick Smart coupler to the 45° position.

See figure 2.

The beer pump will slowly pump

up the beer line in the trunk housing to set psig.

Note: If pump continues to run for longer than

expected, check lines for possible leaks at one

or more of the connections.

■ Gradually increase secondary regulator

pressure to the designed system pressure to

achieve a flow rate of one gallon per minute

from the dispensing head. Note: Maximum

beer pump operating pressure is 90 psig.

■ Open dispensing head faucet to purge air

trapped within the tubing.

■ Check all gas and liquid line fittings and

connections for leaks.

■ Close probe valve on Perlick Smart Coupler.

(See figure 1)

and disconnect coupler from

regulated water source.

■ Clean beer system. After cleaning and rinsing

the system, make sure the beer line is full of

cold water (beer dispensing from warm beer

lines will be poor quality).

■ Tap fresh keg with Perlick Smart Coupler. Open

dispensing head faucet until clear beer flows.

Smart Coupler Probe Valve Lever Positions

Figure 1

Closed Position

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

45° or Cleaning Position

Figure 2

Figure 3

Open Position

4

Page 5

Diagram #2 – Beer Pump

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

5

Page 6

Diagram #3 – Cleaning Diagram

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

6

Page 7

Cleaning Instructions

General Information

■ The cleaning of beer lines with the new integral

flow reversal feature incorporated into the

Perlick Beer Pump gives the line cleaner

numerous configurations for line cleaning.

Although the Perlick Beer Pump can be used as

an in-line pump for moving the solution from the

coupler to the faucet due to its capability of

working with negative lift, the following is the

recommended method for cleaning beer lines

with the Perlick Beer Pump with integral flow

reversal installed.

Cleaning from the Tap/Faucet End

■ Disconnect Perlick Smart Couplers from the

kegs following Smart Coupler instructions.

■ Couple the two Smart Couplers together using

Dual Cleaning Adapters (43681) which have a

pin of sufficient length to lift the internal slide

within the Smart Coupler to allow proper flow.

■ Determine which sets of lines will be cleaned

together and rotate the Dispense/Reverse Flow

handle to the Reverse Flow position on the line

which fluid will be pushed back from the

Tap/Faucet.

■ Rotate the Smart Coupler Valve Handle to the

Clean position on both couplers (See Smart

Coupler Instructions).

■ Relieve the line pressure by opening the

faucets.

■ Remove the faucet from the line, which will

have the Beer Line Cleaner pump connected

to it.

■ Connect Beer Line Cleaner pump to the shank.

■ Follow standard line cleaning procedures.

Perlick recommendes that the lines first be

flushed with clean warm water (Water temperature not to exceed 100°F). Mix line-cleaning

solution per the manufacturer’s directions.

Circulate the solution thoroughly (Time for

circulation dependent on the length of the

system and pump capabilities). Rinse the lines

using clean cold water (Ensure all line cleaning

solution has been removed from the lines to

prevent hazardous results).

■ Disconnect line-cleaning pump.

■ Remove and clean taps and couplers.

■ Reconnect taps and couplers and return Beer

Pump Dispense/Reverse Flow valve to the

Dispense position.

■ Reconnect couplers to keg and open dispensing

head faucets until clear beer flows.

Winterizing Systems with Beer Pumps

■ When a beer system with beer pumps will be

shut down for an extended period, clean the

system thoroughly. After completing the rinsing

step, prepare a mixture of 50% food grade

Glycerine and 50% water. Load the lines with

this mixture and make sure both ends of the

system are closed. Glycerine/water mixture

should remain in the lines for the duration of

the shutdown period.

Replacement Parts

44...................Air valve

40115 .............Regulator body

40129.............Regulator body

43553A...........Regulator repair kit

63705.............Beer pump, Flo-Jet, w/CO

63706.............Flow reversal valve

63707.............Elbow, flow reversal, 2/bag

63708.............Fitting, tee, gas, barbed

check valve

63709..............Fitting, elbow, gas, barbed

check valve

63710.............Beer pump, Flo-Jet, w/CO

2

elbow

1

/4” with

1

4” with

/

2

tee

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

7

Page 8

8300 West Good Hope Road • Milwaukee, WI 53223 • Phone 414-353-7060 • Fax 414-353-7069

Toll Free 800-558-5592 • E-Mail: Perlick@Perlick.com • www.Perlick.com

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

Form No. Z2149A

Rev. 08.24.04

Loading...

Loading...