Ultrasonic sensor UB500-F42-U-V15

Technical data

General specifications

Sensing range 30 ... 500 mm

Adjustment range 50 ... 500 mm

Dead band 0 ... 30 mm

Standard target plate 100 mm x 100 mm

Transducer frequency approx. 390 kHz

Response delay approx. 50 ms

Indicators/operating means

LED green solid green: Power on

Model Number

UB500-F42-U-V15

Single head system

Features

• Analog output 0 ... 10 V

• Extremely small unusable area

• TEACH-IN

• Interference suppression (adjustable divergence of sound cone in

close range)

• Temperature compensation

• Synchronization options

• Mode of operation adjustable

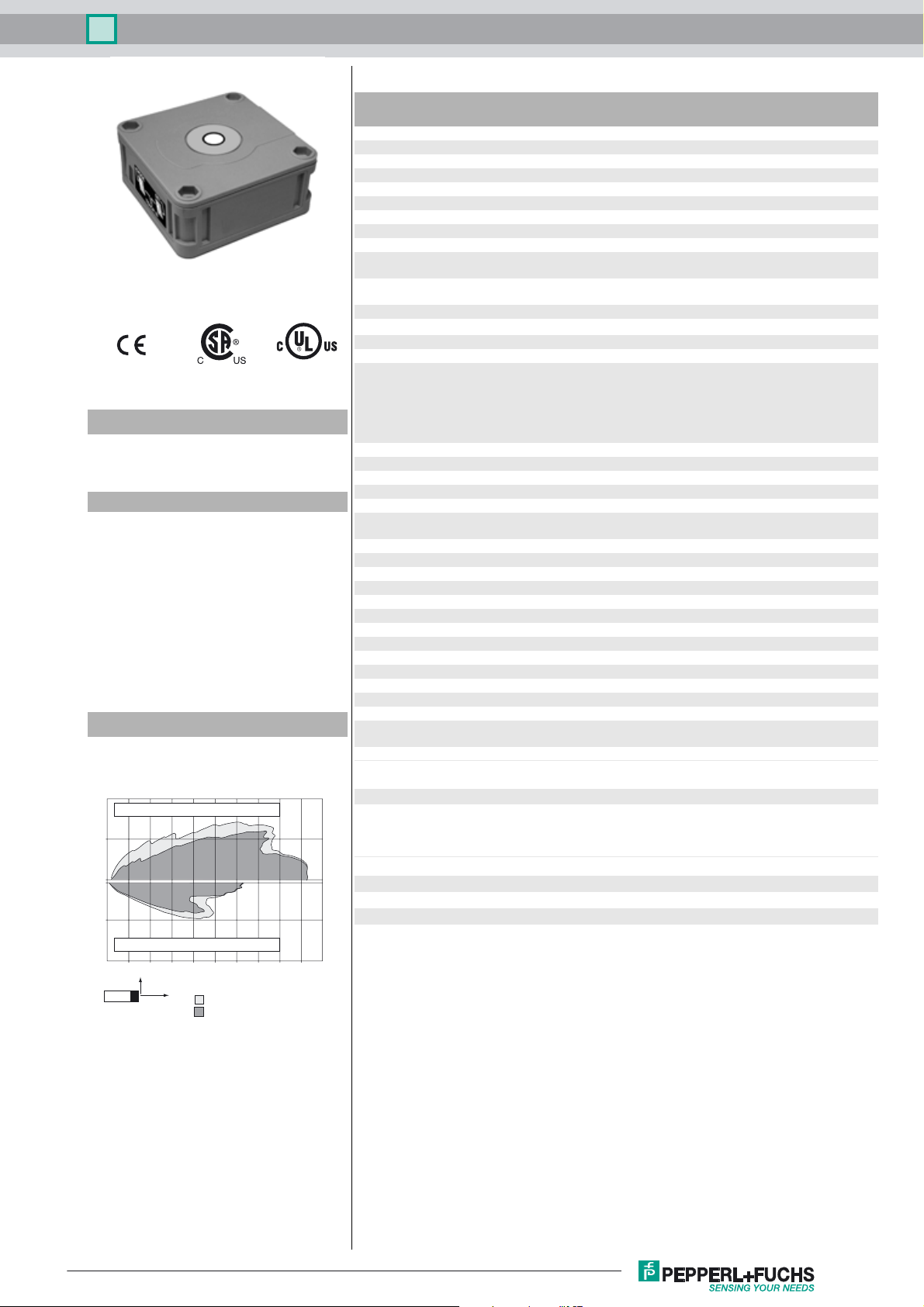

Diagrams

Characteristic response curve

Distance Y [m]

0.2

Flat surface 100 mm x 100 mm

0.1

LED yellow solid: object in evaluation range

LED red normal operation: "fault"

Electrical specifications

Operating voltage U

No-load supply current I

Input/Output

Synchronization bi-directional

Synchronization frequency

Common mode operation ≤ 95 Hz

Multiplex operation ≤ 95/n Hz, n = number of sensors

Output

Output type 1 analog output 0 ... 10 V

Default setting evaluation limit A1: 50 mm , evaluation limit A2: 500 mm ,

Resolution 0.2 mm at max. sensing range

Deviation of the characteristic curve ± 1 % of full-scale value

Repeat accuracy ± 0.1 % of full-scale value

Load impedance > 1 kOhm

Temperature influence ± 1 % of full-scale value

Ambient conditions

Ambient temperature -25 ... 70 °C (-13 ... 158 °F)

Storage temperature -40 ... 85 °C (-40 ... 185 °F)

Mechanical specifications

Connection type Connector M12 x 1 , 5-pin

Degree of protection IP54

Material

Housing ABS

Transducer epoxy resin/hollow glass sphere mixture; foam

Mass 140 g

Compliance with standards and

directives

Standard conformity

Standards EN 60947-5-2:2007 + A1:2012

B

0

flashing: program function

program function: no object detected

17 ... 30 V DC , ripple 10 %

≤ 50 mA

0 level -U

1 level: +4 V...+U

input impedance: > 12 KOhm

synchronization pulse: ≥ 100 µs, synchronization interpulse

period: ≥ 2 ms

wide sound lobe

polyurethane, cover PBT

IEC 60947-5-2:2007 + A1:2012

EN 60947-5-7:2003

IEC 60947-5-7:2003

...+1 V

B

B

SS

0.0

-0.1

Round bar, Ø 25 mm

-0.2

0.0 0.2 0.4 0.6 0.8 1.0

Y

X

wide sonic beam

narrow sonic beam

Release date: 2016-02-26 14:09 Date of issue: 2016-02-26 133979_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

Distance X [m]

Approvals and certificates

UL approval cULus Listed, General Purpose

CSA approval cCSAus Listed, General Purpose

CCC approval CCC approval / marking not required for products rated

≤36 V

1

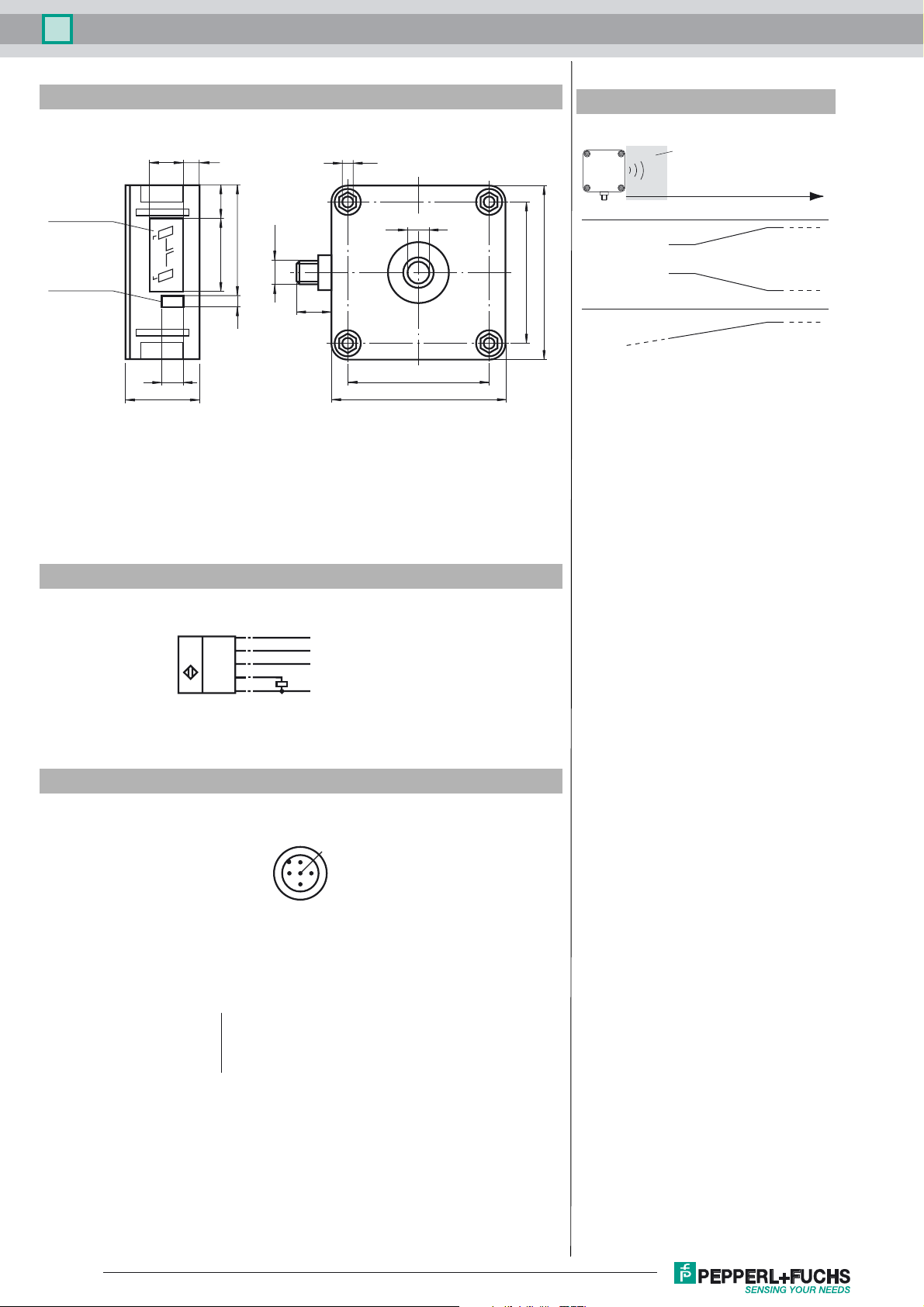

Ultrasonic sensor UB500-F42-U-V15

Dimensions

Membrane keys

LED window

Additional Information

Analogue output programmation

7.5

15

15.5

2

A

TEACH IN

1

MODE SET

A

10

34

52.5

34

M12x1

5

16

5.2

10

65

65

80

Rising ramp

80

Falling ramp

Zero line

A1 = 0

Unusable area

A1A1

A1 A2

Object distance

A2

A2

Electrical Connection

Standard symbol/Connections:

(version U)

U

Core colours in accordance with EN 60947-5-2.

Pinout

Wire colors in accordance with EN 60947-5-2

1 BN

2 WH

3 BU

4 BK

5 GY

(BN)

1

(WH)

2

(GY)

5

(BK)

4

(BU)

3

2

+ U

B

Teaching input

Sync.

Analog output

- U

B

1

5

4

3

(brown)

(white)

(blue)

(black)

(gray)

Release date: 2016-02-26 14:09 Date of issue: 2016-02-26 133979_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

2

Ultrasonic sensor UB500-F42-U-V15

Accessories

MH 04-3505

Mounting aid for FP and F42 sensors

MHW 11

Mounting brackets for sensors

DA5-IU-2K-V

Process control and indication equipment

V15-G-2M-PVC

Female cordset, M12, 5-pin, PVC cable

Functional Description

The sensor may be completely parameterised via two keys on the side panel of the housing. As a special feature provided by

this sensor, the ultrasound beam width may be adapted to the environmental conditions at the place of operation of the sensor.

Specifying the evaluation limits:

The evaluation limits determine the characteristic line and the working range of the analog output.

Specifying the A1 evaluation limit by pressing the A1 key

Holding down the A1key > 2

seconds

Position the target object at

the desired distance

Briefly pressing the A1 key The sensor terminates the specification of the A1 eval-

The sensor switches to learn mode and the user may

specify the A1 evaluation limit

The yellow LED of the sensor flashes fast to indicate

that the target object is recognised. The red LED flashes if the object is not recognised.

uation limit and saves it as a non-volatile value. The

specified value is invalid if the object is uncertain (i.e.

the red LED lights up at irregular intervals). The learn

mode is exited.

The A2 evaluation limit is specified via the A2 key, analogous to the description above.

Alternatively, the evaluation limits may also be specified electrically via the learn input. To specify the A1 evaluation limit, the

learn input must be connected to

-U

; to specify the A2 evaluation limit, it must be connected to +UB. Specified values are saved upon the disconnection from

B

the learn input.

Evaluation limits may only be specified within the first 5 minutes after Power on. To modify the evaluation limits later, the user

may specify the desired values only after a new Power On.

Proceed as follows to parameterise the output function and the ultrasound beam width:

Press the A1 key during Power on and hold down the key for another second to ensure that the sensor starts the two-step parameterisation of the operating modes.

Step 1, parameterisation of the output function

The output function parameterised last is displayed. All output functions available may be selected via consecutive, brief strokes

of the A2 key. These strokes are visualised via short flashes of the green LED.

Operating mode Flash sequence of the green LED A2 key

Rising edge

Falling edge

Zero point straight

line

pause

pause

pause

The "Zero point straight line“ setting fixedly specifies the A1 evaluation limit to 0 (see specification of the evaluation limits). The

A2 evaluation limit determines the steepness of the output characteristic line.

Hold down the A1 key for 2 seconds to save the selected output mode, complete the parameterisation and ensure that the sensor returns to normal mode. If you briefly press the A1 key, Step 2 is entered (parameterisation of the ultrasound beam width).

Step 2, parameterisation of the ultrasound beam width

Via Step 2, the ultrasound beam width may be adapted to the requirements of the corresponding application.

The beam width parameterised last is displayed first. Available beam width settings may be selected via consecutive, brief

strokes of the A2 key. These strokes are visualised via the flash sequence of the red LED.

Release date: 2016-02-26 14:09 Date of issue: 2016-02-26 133979_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

3

Ultrasonic sensor UB500-F42-U-V15

Beam width Flash sequence of the red LED A2 key

Small beam

Medium beam

Large beam

pause

pause

pause

Hold down the A1 key for 2 seconds to save the selected beam shape, terminate the parameterisation and ensure that the sensor returns to normal mode. Briefly press the A1 key to return to Step 1 (parameterisation of the output function).

If the parameterisation mode is not terminated within 5 minutes (hold down the A1 key for 2 seconds), the sensor aborts this

mode without modifying the settings.

Synchronisation

The sensor provides a synchronisation port to suppress mutual influencing. If this port has not been connected, the sensor

works at an internally generated cycle rate. Several sensors may be synchronised via the following options.

External synchronisation:

The sensor may be synchronised via the external application of a square wave voltage. A synchronisation pulse on the synchronisation input initiates a measuring cycle. The pulse width must be greater than 100 µs. The measuring cycle is started with

the falling edge. A low level > 1 s or an open synchronisation input initiate the transition to normal sensor mode. A high level on

the synchronisation input deactivates the sensor.

Two modes are possible:

- Several sensors are controlled via the same synchronisation signal. The sensors work in common mode.

- The synchronisation pulses are forwarded at cyclic intervals to respectively one single sensor. The sensors work in multiplex mode.

Self-synchronisation:

The synchronisation ports of up to 5 sensors suitable for self-synchronisation are connected to each other. These sensors work

in multiplex mode after Power on. The On delay increases depending on the number of sensors to be synchronised. While the

learn mode is active, no synchronisation is possible (and vice-versa). To specify the switching points, the sensors must be operated in non-synchronised mode.

Note:

If the synchronisation option is not used, the synchronisation input must be connected to ground (0V) or the sensor must be

operated with a (4-pole) V1 connecting cable.

Release date: 2016-02-26 14:09 Date of issue: 2016-02-26 133979_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

4

Loading...

Loading...