Pepperl+Fuchs OPC, OPD, OPE User Manual

MANUAL

OPC / OPD / OPE

Optical Print Inspector

FACTORY AUTOM ATION

OPC / OPD / OPE

With regar d to the supply of products, the current issue of the following document is applicable: The

General Terms of Delivery for Products and Se rvices of the Elec trical Industry, published by the

Central Asso ciation of th e Electrical In dustry (Zentralverba nd Elektrote chnik u nd Elektroindustrie

(ZVEI) e.V.) in its most recent version as well as the supplem entary clause: "Expanded reservation

of proprietorship"

OPC / OPD / OPE

Contents

1 Introduction......................................................................... 5

2 Declaration of Conformity ................................................. 6

3 Safety................................................................................... 7

3.1 Symbols Used............................................................ ...................................7

3.2 Intended Use ........ ..................................................... .......... .........................7

4 Product Description ........................................................... 8

4.1 Use and Application....... .......... ............................................................... ......8

4.2 Indicators and Operating C ontrols .......... ......... .............................................9

4.3 Interfaces and Connections .................................................................... .... 12

4.4 Scope of Delivery ...... ...................................................... .......... ..................16

4.5 Accesso ries ................... .......... ...................................................... ......... .... 16

4.5.1 Power Supply ........................... .............................................................. 16

4.5.2 Network Cable.......................... .......... .................................................... 17

4.5.3 RS-232 Interface .. .......... ...................................................... .......... ........17

4.5.4 VGA Output ................................... .......... ...............................................1 7

5 Installation......................................................................... 18

5.1 Preparation ...... ......... ...................................................... .......... ..................18

5.2 Mounting the Device ............................... ......... ...........................................18

5.3 Setting up the Power Supply ...................................... .......... ....................... 20

5.4 Setting Up a Network Connection .................... ...........................................21

5.5 Storage and Transport................................................ .......... ....................... 23

6 Commissioning................................................................. 24

6.1 Connecting the Stationary Read Device...................................................... 24

7 Vision Configurator Software.......................................... 25

7.1 Application Window Structure ......................................... .......... ..................26

7.2 Menu Bar .................. .......... ...................................................... .......... ........27

7.2.1 File Menu ................................. .............................................................. 27

7.2.2 View Menu ............................... .......... ....................................................28

7.2.3 Sensor Menu .................................................... .......... ............................28

7.2.4 Image Menu ............................. .............................................................. 29

7.2.5 Administration Menu ................................................... .......... ..................30

7.2.6 Help Menu ...................... .......... .............................................................. 30

2015-0 7

3

OPC / OPD / OPE

Contents

7.3 Configuration Window ............................... ................................................. 31

7.3.1 System Tab ............. .......... ................................................................ ..... 31

7.3.2 Camera Tab ............................................... ......... ................................... 34

7.3.3 Image Filter Tab ............................... ...................................................... 34

7.3.4 Trigger Mode s Tab ........................................................ .......... ............... 36

7.3.5 Window Tab .......................................... ................................................. 39

7.4 Toolbar ........................ .......... ................................................................ ..... 46

7.5 Sensor Data ................................................... ......... ................................... 47

7.6 Sensor Output ............. .......... ...................................................... .......... ..... 47

7.7 Image Display ................................. .......... ................................................. 48

8 Operation .......................................................................... 50

8.1 Reading a 1- D/2-D Code...................... ...................................................... 50

8.2 Reading Overlong 1-D Codes ................................................ .......... .......... 5 1

8.3 Comparing a 1-D/2-D Code .................................... ................................... 52

8.4 Comparing a Logo ....... ................................................................ ............... 53

8.5 Checking the Presence of Materials with a Changeable Texture ................ 54

9 Maintenance and Repair.................................................. 56

9.1 Maintenance ...................................................... ........................................ 56

9.2 Repair ............................................. ........................................................... 56

10 Troubleshooting ............................................................... 57

10.1 What to Do in the Event of an Error ........................................ .......... .......... 57

11 Appendix........................................................................... 58

11.1 Network Interface ............................ .......... ................................................. 58

11.2 Software Interface ....... ...................................................... .......... ............... 58

11.2.1 Configuratio n Ove rview .............. ...................................................... ..... 66

11.2.2 Result Overview....................................................... .......... .................... 72

4

2015-0 7

OPC / OPD / OPE

Introduction

1 Introduction

Informative Symbols

Note!

This symbo l brings important information to your attention.

Action

This symbo l indicates a pa ragraph with instructions.

Contact

If you have any q uestions about the device, its functions, or acces sories, please

contact us at:

Pepperl+Fuchs GmbH

Lilienthalstraße 200

68307 Mannheim

Telephone: +49 62 1 776 -4411

Fax: + 49 621 776-2 74411

E-Mail: fa-info@pepperl-fuchs.com

2015-0 7

5

OPC / OPD / OPE

ISO9001

Declaration of Conformity

2 Declaration of Conformity

This product was developed and manufactured unde r obser vance of the

applica ble European standards and guidelines.

Note!

A Declaration o f Conformity can be reques ted from the manufacturer.

The product m anufacturer, Pepperl+Fuchs GmbH, D-68 307 Mannhe im, has a

certified quality assurance system that conforms to ISO 90 01.

6

2015-0 7

OPC / OPD / OPE

Safety

3 Safety

3.1 Symbols Used

This document contains information that you must observe for you r own p ersonal

safety and to prevent property damage. Warning mes sages are shown in

descending order according to the risk level, as follows:

Safety- Relevant Symbols

Danger!

This symbo l indicates an immine nt dang er.

Non-observance will result in pe rsonal injury or death.

Warning!

This symbo l indicates a po ssible fa ult or danger.

Non-observance may caus e personal injury or serious pro perty dama ge.

Caution!

This symbo l indicates a po ssible fa ult.

Non-observance could interrupt the device and any co nnected system s and

plants, or resu lt in th eir complete failure.

3.2 Intended Use

The stationary read devices OPC-*, OPD-*, and OPE-* are used to decode 1-D

and 2 -D codes.

The device is only approved for app ropriate and intended use. Ignoring these

instructions will void any warranty and ab solve the man ufacturer from a ny liab ility.

Protection of the pe rsonnel and the plant is not ensured if the device is not being

used accord ing to its intended use.

2015-0 7

7

OPC / OPD / OPE

Product Description

4 Product Description

4.1 Use and Application

The optical print inspector is available in three versions and reads both 1- D and 2D codes. For high speed, great depth of focu s, long barcodes, or detection tasks;

with the optical print inspector you always have the right vision sen sor at ha nd.

Use the innovative image proces sing technology from Pepperl+Fuchs for your

application.

You can configure the stationar y readers quickly and easily over a standa rd

Ethernet interface, using the software provided. The reader has an integrat ed fault

pattern memor y.

Highlights:

■ Reads 1-D and 2-D codes at extremely high speeds of up to 10 m/s at

30 readings/s

■ Detects long barcodes of up to 200 mm long using multiple imag e capture

■ Reads up to four differen t codes at the same time

■ Logo comparison

■ Position of the reading field can be adjusted flexibly via rotary encoder input

(OPC and OPD)

■ Captures code s and logos at different distanc es and of different sizes with

one setting

■ Side lighting for reliable reading with highly reflective surfaces

2015-0 7

8

OPC / OPD / OPE

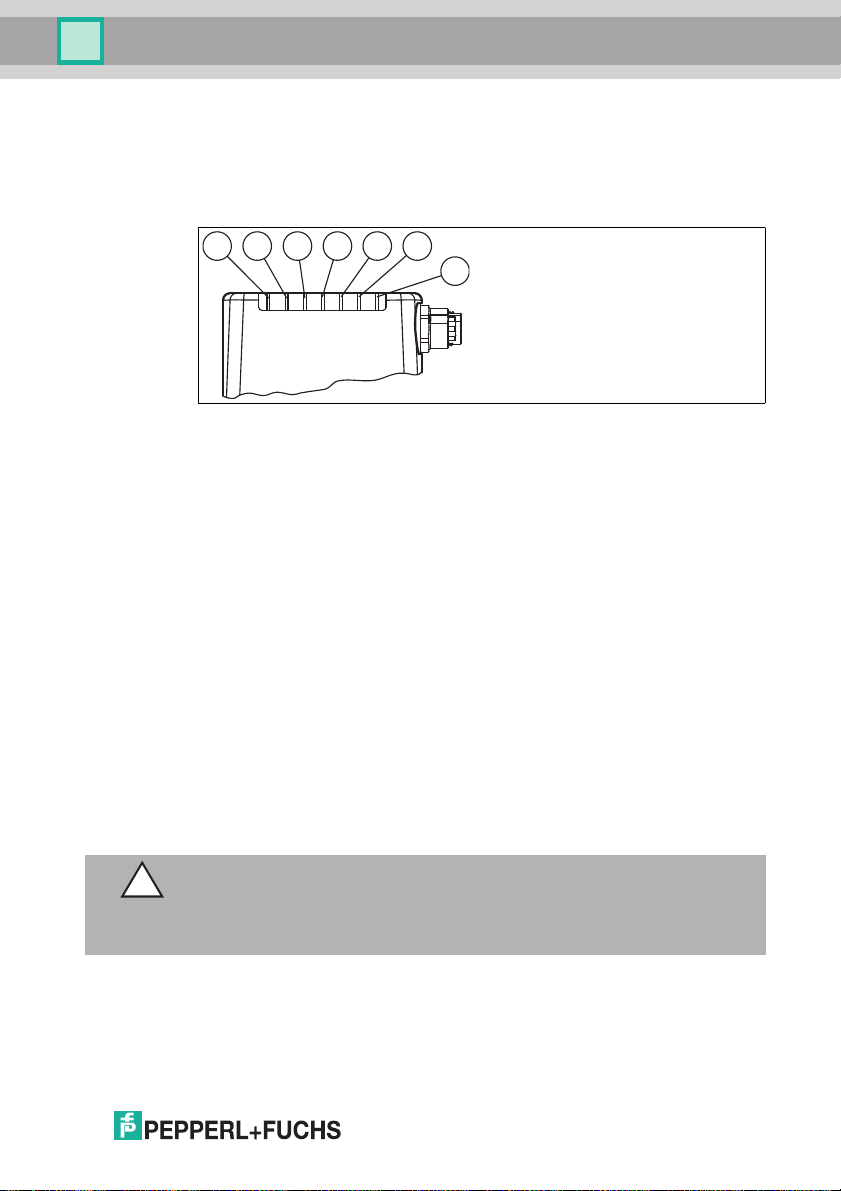

1 2 3 4 5 6

7

Product Description

4.2 Indicators and Operating Controls

OPC reader and OPD reader

The illumination unit has 7 LED indicators that provide information on t he various

device statuses.

Figure 4.1 Indicators and Operating Control s

1. DIAG 2

Yellow L ED. Generates different flashing sequences to signal diag nostic

messa ges.

2. DIAG 1

Yellow L ED. Generates different flashing sequences to signal diag nostic

messa ges.

3. Power (PW R)

Lights up green whe n the sensor is ready for operation.

4. Ready (READY)

Lights up yellow when the sensor is rea dy.

5. Reading process triggered (BAD)

Lights up yellow if the read ing was unsuccessful.

6. Reading process triggered (GOOD)

Lights up yellow if the read ing was successful.

7. Trigger senso r (TRG)

Lights up yellow when a c onnected trigg er sensor is activated.

Caution!

Software update

The READY LED flashes while the senso r is being programmed. During this time,

the sensor must not be switched off.

2015-0 7

9

OPC / OPD / OPE

Product Description

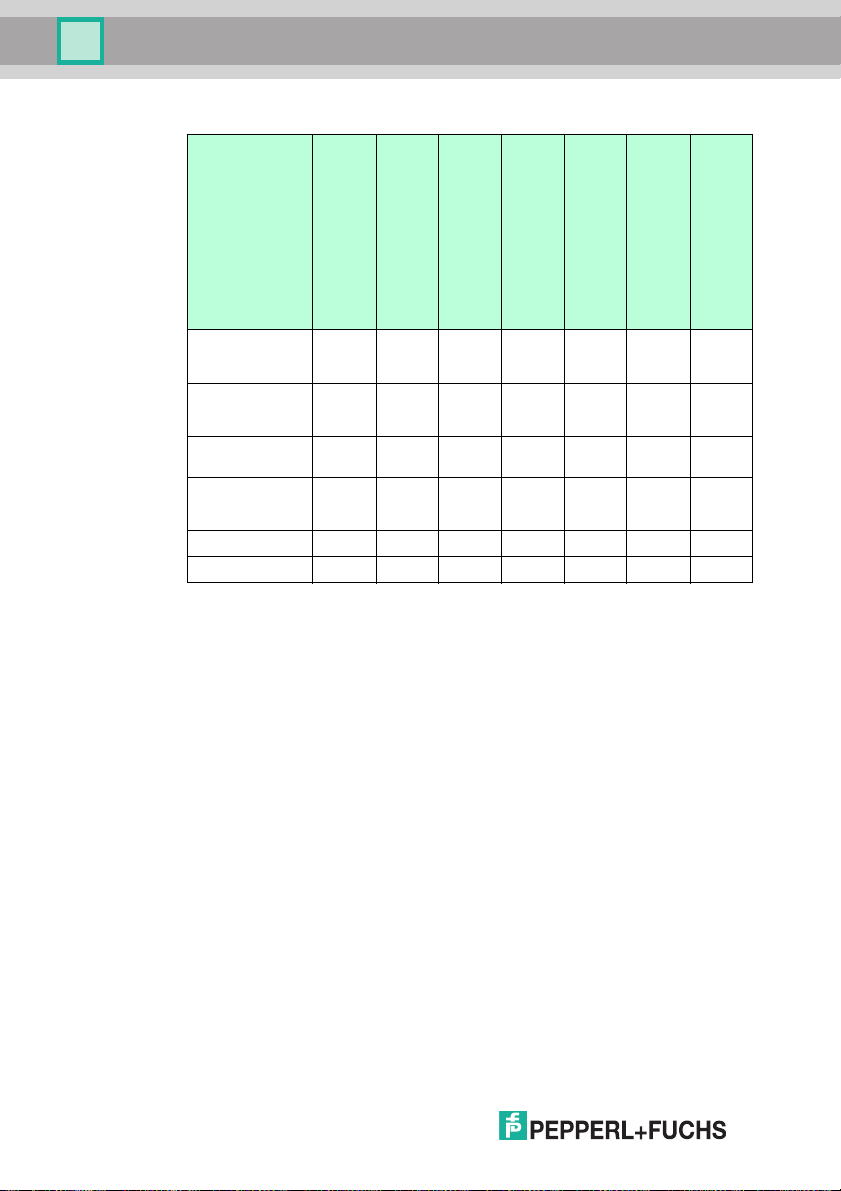

Definit ion of the LEDs an d Outputs for Individual Statuses

GOOD LED

Good read ON OFF OFF 80 ON OFF OFF

Bad read OFF ON OFF 81 OFF ON OFF

Good read and

match code OK

Good read and

match code not

OK

Bad read OFF ON ON 81 OFF ON OF F

Decoder timeout OFF ON 84 OFF ON OFF

ON OFF ON 82 ON OFF ON

OFF ON ON 83 OFF ON OF F

BAD LED

Match code operating mode

Status

Good output

Bad output

(Not

used)

(Not

used)

Match code output

10

2015-0 7

OPC / OPD / OPE

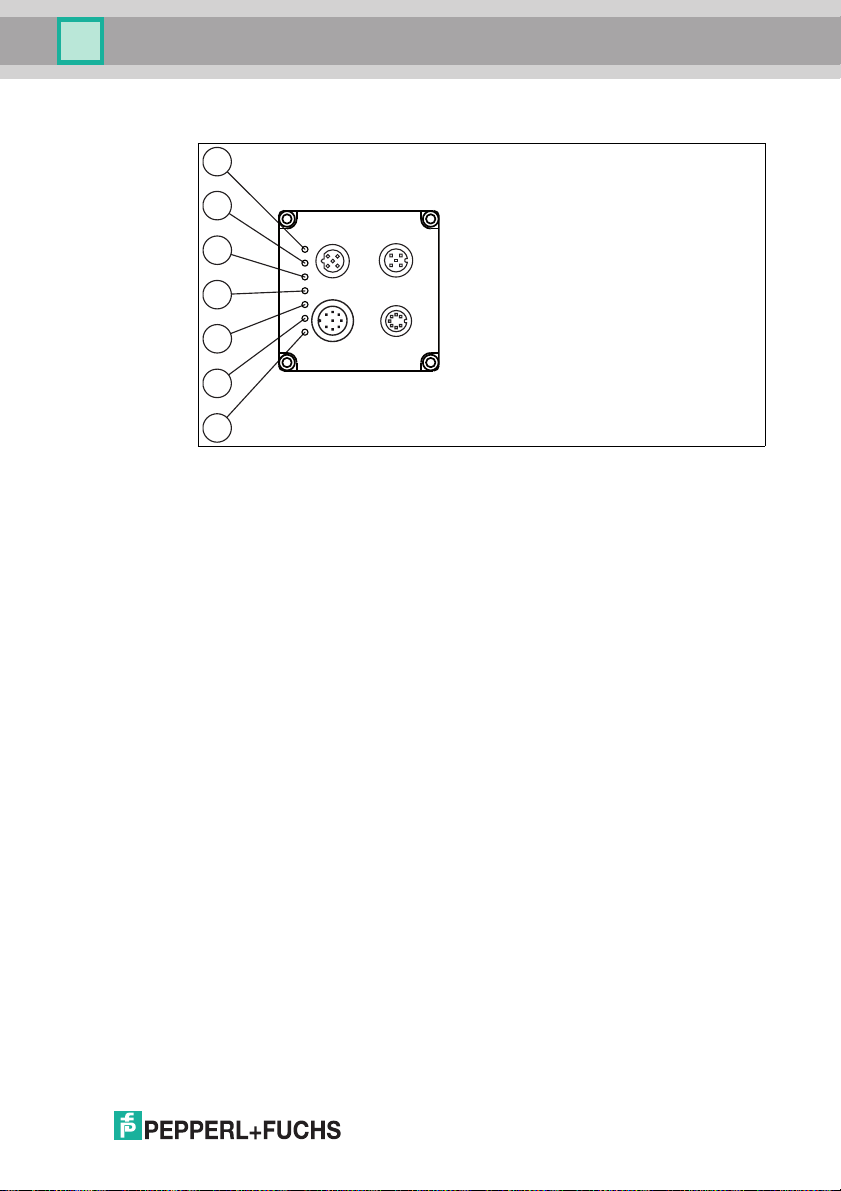

3

4

5

6

2

1

7

LAN

TRG

Fail

Status

PWR

LAN

RS 232

24VDC + IO

VGA

Match

Good

Product Description

OPE reader

1. Network (LAN ):

Lights up yellow as soon as a physical connec tion is established.

2. Trigger (TRG) :

Lights up yellow when a co nnected trigg er sensor is a ctivated.

3. Good (Good):

Lights up green if the reading is s uccess ful.

4. Error (Fail):

Lights up red if the r eadin g is uns uccess ful.

5. Result (Match):

Flashes green if the match code matches the read c ode.

Flashes red if the match code does not match the read code.

6. Status (Status):

Briefly flashes yellow when the device is switched on.

Flashes yellow during a firmware update.

Lights up green whe n the device is read y.

Lights up red in the event of a dev ice error.

7. Power (PW R):

Lights up green whe n the sensor is connected to a power supply.

2015-0 7

11

OPC / OPD / OPE

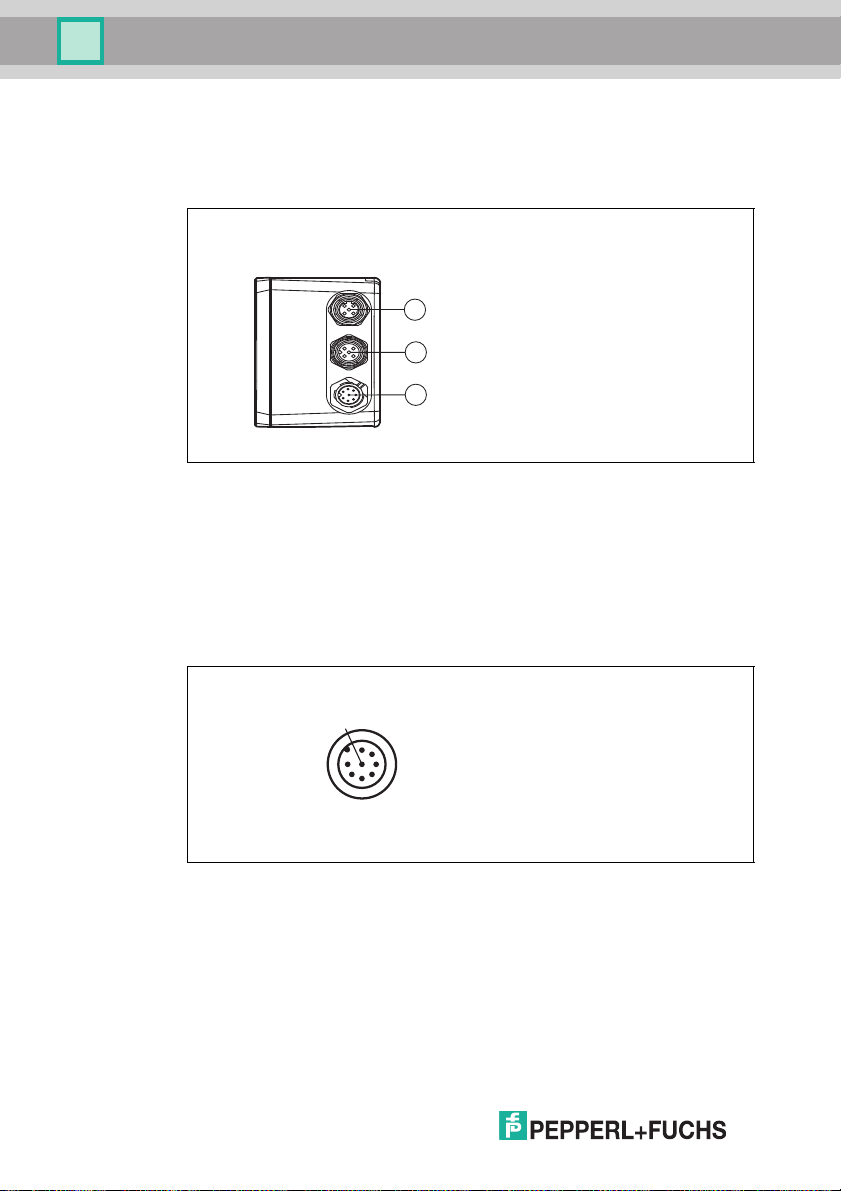

1

2

3

1

4

6

7

8

53

2

Product Description

4.3 Interfaces and Connections

OPC reader and OPD reader

The device includes the following connections:

Figure 4.2 Device Conne ctions

1. Network ( 4-pin M12 socket)

2. Input IO (5 -pin M12 socket)

3. Power sup ply, inputs, and outputs (8-pin M12 plug)

Power Supply

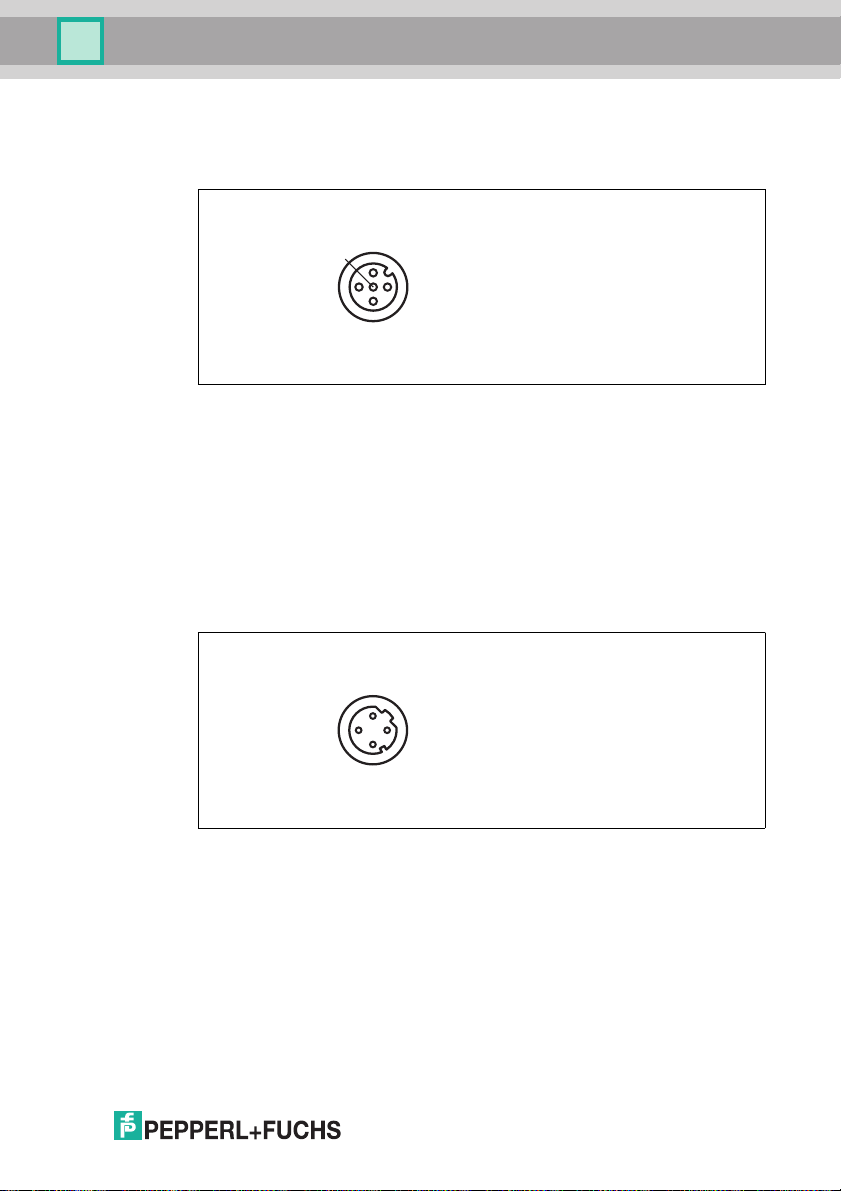

There is an 8-pin M12 plug on the side of the ho using for con necting the power

supply, and the inputs and outputs. The following d iagram shows the pinning:

12

Figure 4.3 Connection layout for oper ating voltage, and inputs and outputs

1. Trigg er IN

2. + UB

3. OUT Good

4. OUT Bad

5. IN 1

6. OUT 1

7. GND

8. OUT match code

2015-0 7

OPC / OPD / OPE

1

5

3

2

4

1

3

4

2

Product Description

RS-232 Interface

There is a 5-pin M12 soc ket on the side of the sensor housing. The following

diagram shows the pinnin g:

Figure 4.4 RS-232 input connection layout

1. + UB

2. TX RS-232

3. GND

4. RX RS-232

5. NC

Network

There is a 4-pin M12 soc ket on the side of the housing for connecting to the

networ k. The following diagr am shows the pinning:

Figure 4.5 Network connec tion layout

1. TX+ Ethernet

2. RX+ Ethernet

3. TX- Ethernet

4. RX- Ethernet

2015-0 7

13

OPC / OPD / OPE

3

4

2

1

LAN

TRG

Fail

Status

PWR

LAN

RS 232

24VDC + IO

VGA

Match

Good

1

4

6

7

8

53

2

Product Description

OPE reader

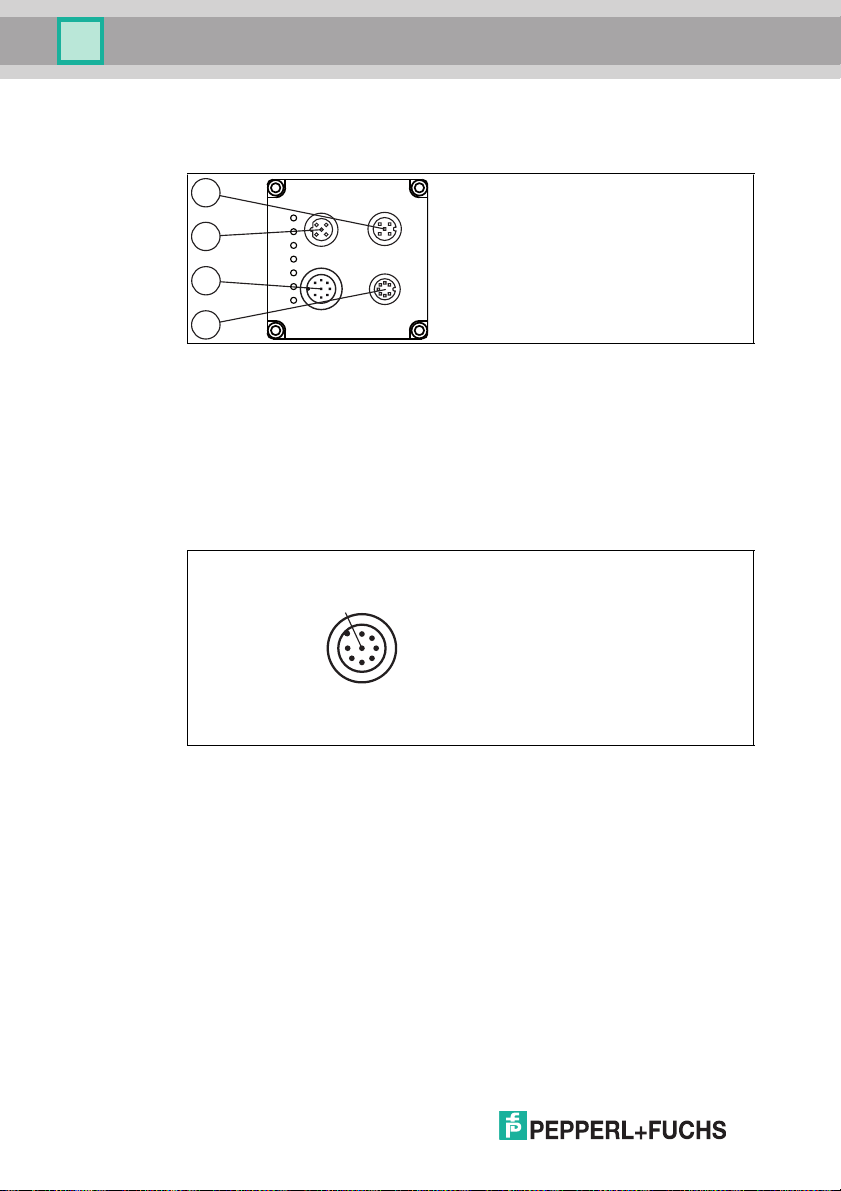

The device includes the following connections:

1. RS-232 interface (5-pin M12 s ocket)

2. Network ( 4-pin M12 socket)

3. Power sup ply, inputs, and outputs (8-pin M12 plug)

4. VG A output (7-pin M12 socket)

Power Supply

There is an 8-pin M12 plug on the back of the sensor housing to co nnect the

power supply, and to the inputs and outputs. The following d iagram shows the

pinning:

Figure 4.6 Connection layout for oper ating voltage, and inputs and outputs

1. IN T RG / OUT 1

2. +U B

3. OUT Good / IN 1

4. OUT Fail / IN 2

5. IN 3

6. IN 4 / OUT 2

7. GND

8. OUT Match

Pin 1, pin 3, pin 4, and pin 6 have dual assignments, but these dua l assignments

are not currently supported by the software: OUT 1, IN 1, IN 2, IN 3, IN 4 are

intended for future app lications.

14

2015-0 7

OPC / OPD / OPE

1

3

4

2

1

5

3

2

4

Product Description

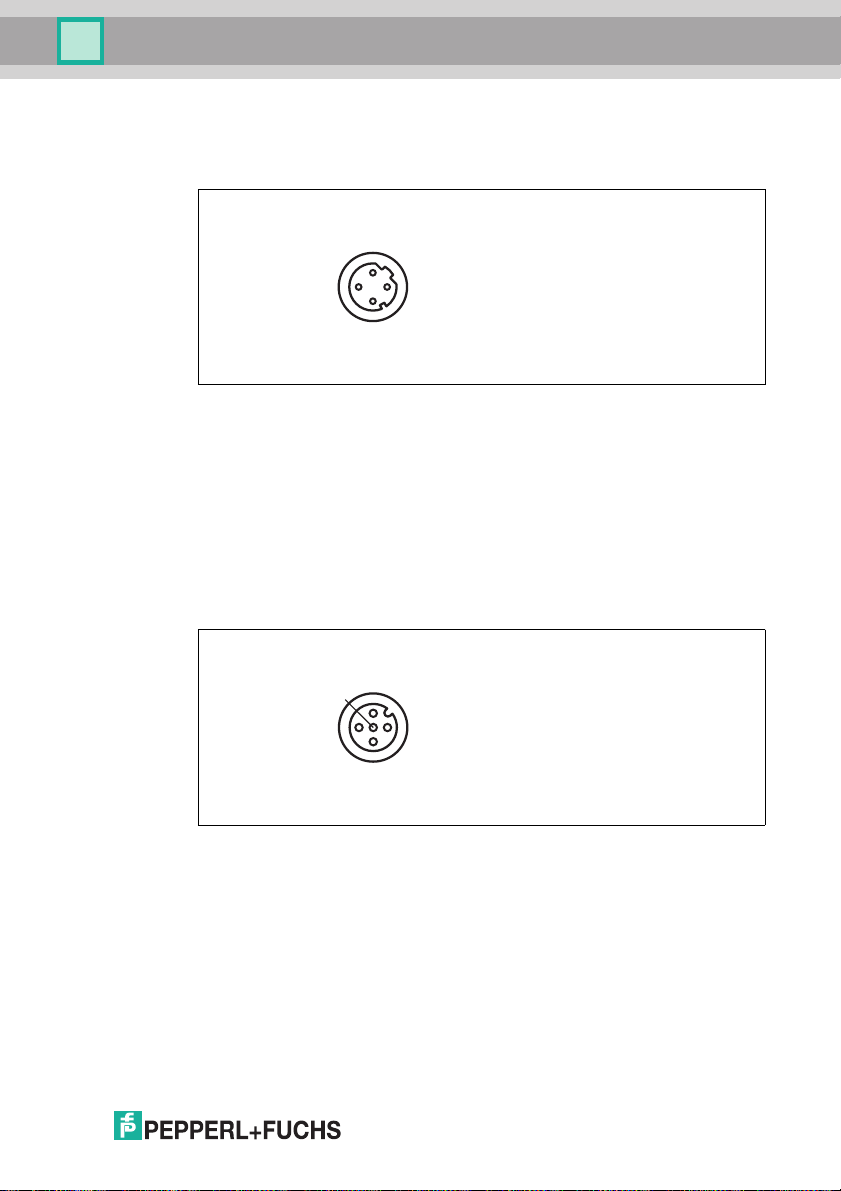

Network

There is a 4-pin M12 soc ket on the back of th e sensor hous ing to connec t to the

networ k. The following diagr am shows the pinning:

Figure 4.7 Network connec tion layout

1. TX+ Ethernet

2. RX+ Ethernet

3. TX- Ethernet

4. RX- Ethernet

RS-232 Interface

There is a 5-pin M12 soc ket on th e back o f the se nsor housing for connecting the

RS-232 interface or external lighting. When using as the RS-232 interface, do not

conn ect any cables to pin 1 or p in 5. The following diagram s hows the pinning:

Figure 4.8 RS-232 connec tion layout

1. +UB

2. TX RS-232

3. GND

4. RX RS-232

5. IN 5 / OUT 3

2015-0 7

15

OPC / OPD / OPE

1

3

4

5

6

7

2

L

Product Description

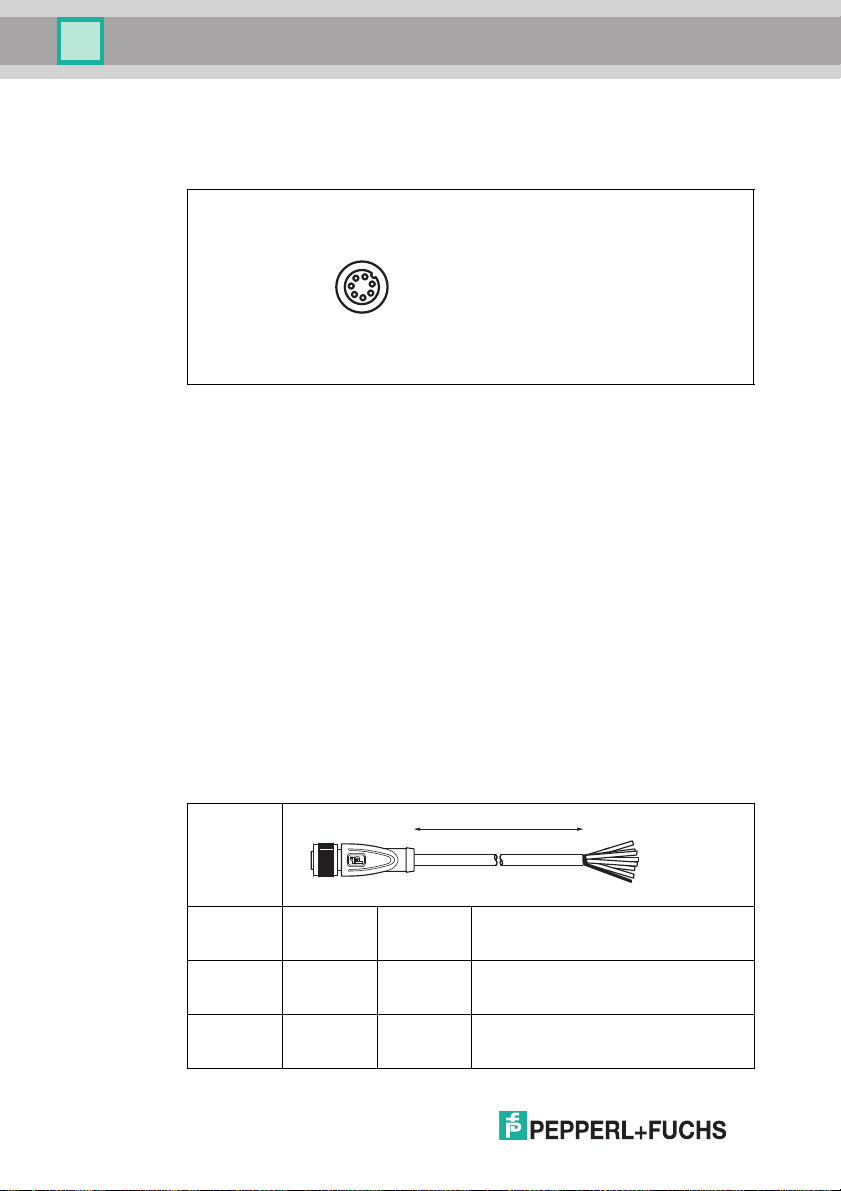

VGA Output

There is a 7-pin M9 socket on the back o f the se nsor housing to connect the VGA

plug. The following diagram shows the pinning:

1. OUT VSY NC

2. GND

3. OUT R

4. OUT G

5. GND

6. OUT B

7. OUT HSYNC

4.4 Scope of Delivery

■ Optical Print Inspector

■ Quick start guide

4.5 Accessories

Various accessories are available.

4.5.1 Power Supply

Use the following doub le-ended cordset to connect the p ower supply, inputs, and

outputs to the sensor.

Female field connec tor

Model

numb er

16

V19-G-2M PUR-ABG

V19-G-5M PUR-ABG

V19-G10M-PU RABG

8-pin M12

socket,

straig ht

8-pin M12

socket,

straig ht

8-pin M12

socket,

straig ht

L = 2 m Open cable end with multistranded

L = 5 m Open cable end with multistranded

L = 10 m Open cable end with multistranded

conductors

conductors

conductors

2015-0 7

OPC / OPD / OPE

Product Description

Other lengths on reques t.

Field-attachable M12 socket

Model num ber

V19-G-ABG-PG9 ■ 8-pin M12 socket, straight

4.5.2 Network Cable

The sensor is connected to the network using an M1 2 plug.

Desi gnation Description

V45-G RJ45 network p lug, field attachable

V1S -G M12 plug, 4-pin, field attachable

V1S D-G-2M -PURABG-V45X-G

V1S D-G-2M -PURABG-V45-G

4.5.3 RS-2 32 Interface

The sensor 's RS-232 interface is connected via an M12 plu g.

Desi gnation Description

V15S -G-5M-PUR-A BG Male single-ended cordset, M12, 5-pin, PUR c able, shielded

V15S -G-5M-PUR-A BGSU BD9

4.5.4 VGA Output

The sensor is connected to a monitor using a n M9 p lug.

■ Sc rew terminals for max. 0.75 mm

cable gland

■ Cable diam eter: 5 mm ... 8 mm

Double-ended cordset, RJ45 network plug with M12 plug,

crossed, 4-pin

Double-ended cordset, RJ45 network plug with M12 plug, 4pin

cap nut

Connection cab le, M12 plug, 5 -pin, 9 -pin to D-Sub housi ng

2

PG9

Desi gnation Description

ODZ-MAC-CAB -VIDEO Video connec tion cable, round plug, 7-pin on D-Sub socket,

2015-0 7

15-pin VGA, length: 2 m

17

OPC / OPD / OPE

Installation

5 Installation

5.1 Preparation

Unpacking the unit

1. Check that all package contents are prese nt and undam aged.

If anything is d amaged, in form the shipp er and contact the sup plier.

2. Check that all items are present and co rrect based o n your order and the

shipping documents.

If you have any question s, please contact Pepper l+Fuchs .

3. Keep the original packing material in case you nee d to store or ship the unit at

a later time.

5.2 Mounting the Device

Note!

Mounting an optic al device

■ Do not a im the senso r at the sun.

■ Protect the sensor from direct long-term expo sure to sun.

■ Prevent co ndensation from forming by no t exposing the sensor to any

major fluctuations in temperature.

■ Do not ex pose the sens or to the effects of any ag gressive chemicals.

■ Keep the lenses a nd reflector of the d evice clean. Clean with a so ft cloth,

using standard commercial glass cleaner if nece ssary.

We recommend to clea n the optical surface and to check screw fittings and

electric al conn ections at regular intervals.

18

Note!

Preventing reflection and glare

Reflection and glare from reflective surfaces can impair the captured image and

therefore lead to incorrect read ings. To prevent reflection and glare, install the

stationar y reading device at a s light angle.

The surface must be level to prevent the housing from becoming d istorted when

the fittings are tightened. After mounting the senso r, ensure that the re is still

enough space to co nnect the con nection cable to the sensor.

2015-0 7

OPC / OPD / OPE

12.5

54

2020

M12

M12

M6 x 9 (4x)

25

21.75

25

12

70 13.8

70

80

Installation

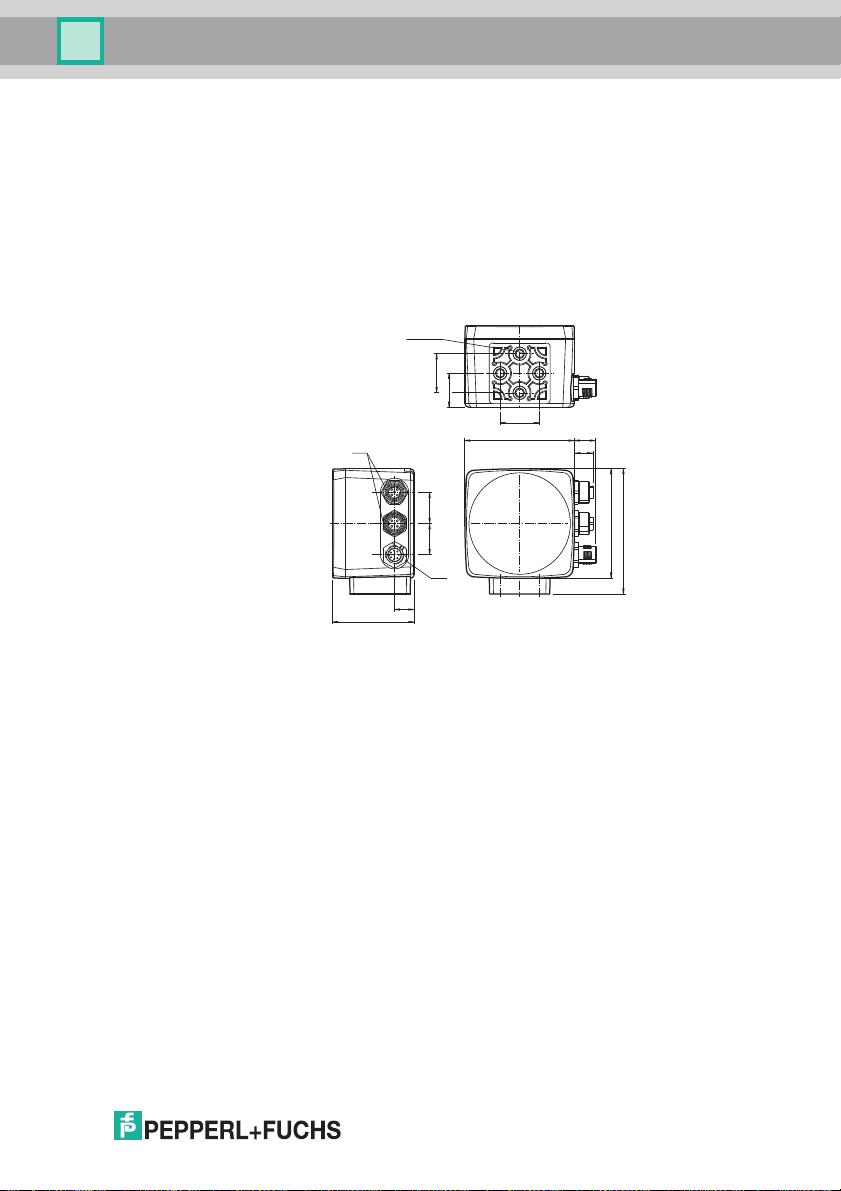

OPC and OPD mounting

The reader has four symmetrically positioned M6 threads on the base of the

housing to allow e asy mounting o f the r eader in your plant.

The read distance differs ac cording to the reader. You can find the correct read

distanc e in the tech nical data for the reader to be installed.

The following illustration shows all the relevant hous ing dim ensions in m m:

2015-0 7

19

OPC / OPD / OPE

Reading distance

11

60

60 65

M5

20 6

11

Code

52.7

20 ±0.1

72.5

Installation

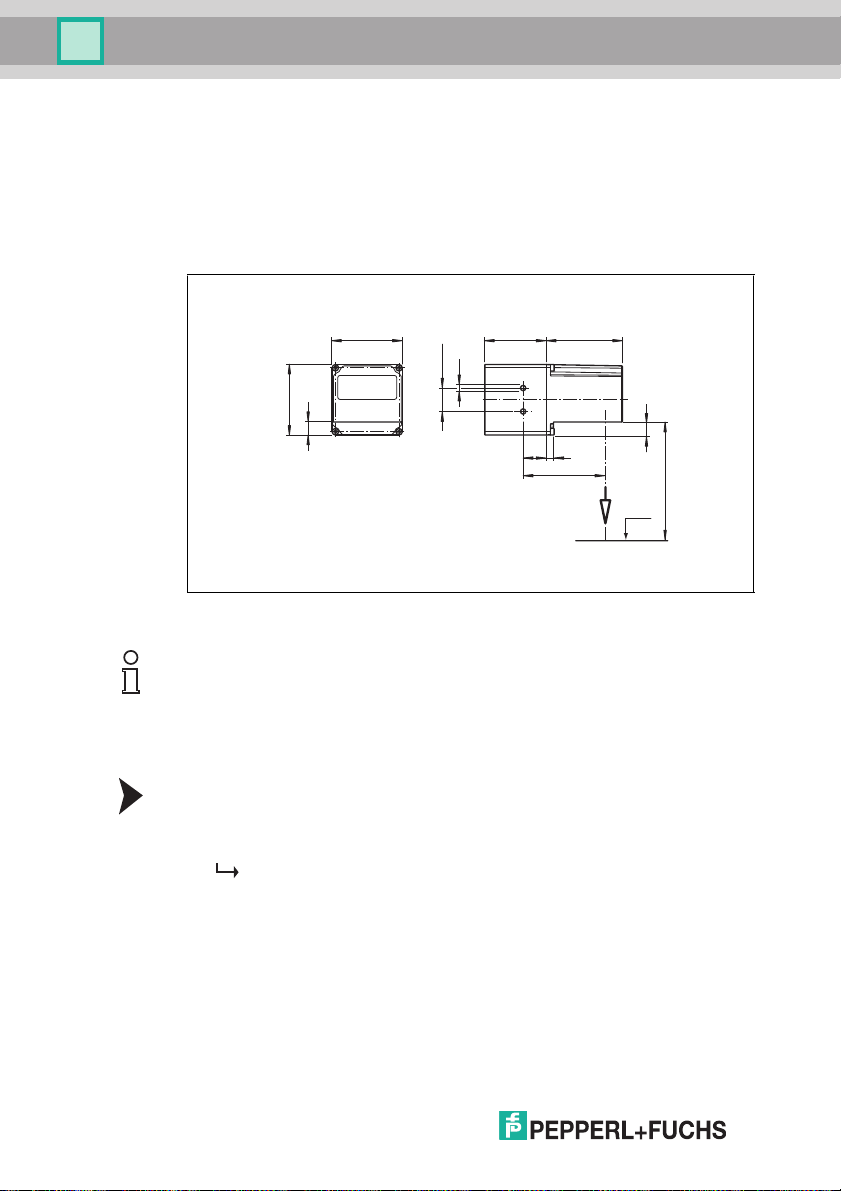

OPE mounting

The device has two M5 threads positioned on the base of the housin g to allow

easy mo unting of the reader in your plant.

The read distanc e diffe rs according to the re ader. You can find the correct read

distance in the technical data for the reader to be installed.

The following illustration shows all the relevant housing dimensions in mm:

Figure 5.1 Dimensions o f the angle housing

Note!

Connection to grou nd

When installing the device, ens ure that it is has a gr ound connection.

5.3 Setting up the Power Supply

Connecting the Supply Voltage

1. Insert the 8 -pin M12 socket into the plug p rovided on the side of the housing.

2. Screw the c ap nut onto the connector as far as it will go.

This en sures that the power c able cannot be inad vertently pulled out.

20

2015-0 7

OPC / OPD / OPE

Installation

5.4 Setting Up a Network Connection

Note!

Network Cab ling

Use a crossover network cable to conn ect the sensor directly to a computer. If you

are op erating the se nsor within a network, use a twisted-pair network cable.

Connecting the Network Cable

1. Use a network cable that has an RJ45 network connec tor on one side and a 4pin M12 plug on the other. Inse rt the M12 plug into the LAN socket on the sensor.

2. The sensor is supplied with the IP address 192.168.002.003. To connect it

to a PC, set up an IP address o n the PC where the first three segments are

identical to the sensor's IP addres s, e.g., 192.168.002.090. The last

segment mu st be different from the one in the sensor's IP address.

Note!

Documenting the Network Co nfigur ation

If you change the senso r's IP ad dress, make a note of this change so that you can

conn ect the senso r to a PC.

Reset ting the IP Address

If you do not know the IP address of the sensor, you can reset the IP add ress to

the factory default setting.

1. Connect the sensor to the power sup ply.

The sensor po wers up.

2. Wait until the LEDs flash.

3. Hold down buttons 1 and 2 on the back of the sens or simultaneously for

approx. two seconds.

The LED flash seque nce changes.

The sensor p owers up again and now use s the fa ctory default IP address.

2015-0 7

21

OPC / OPD / OPE

Installation

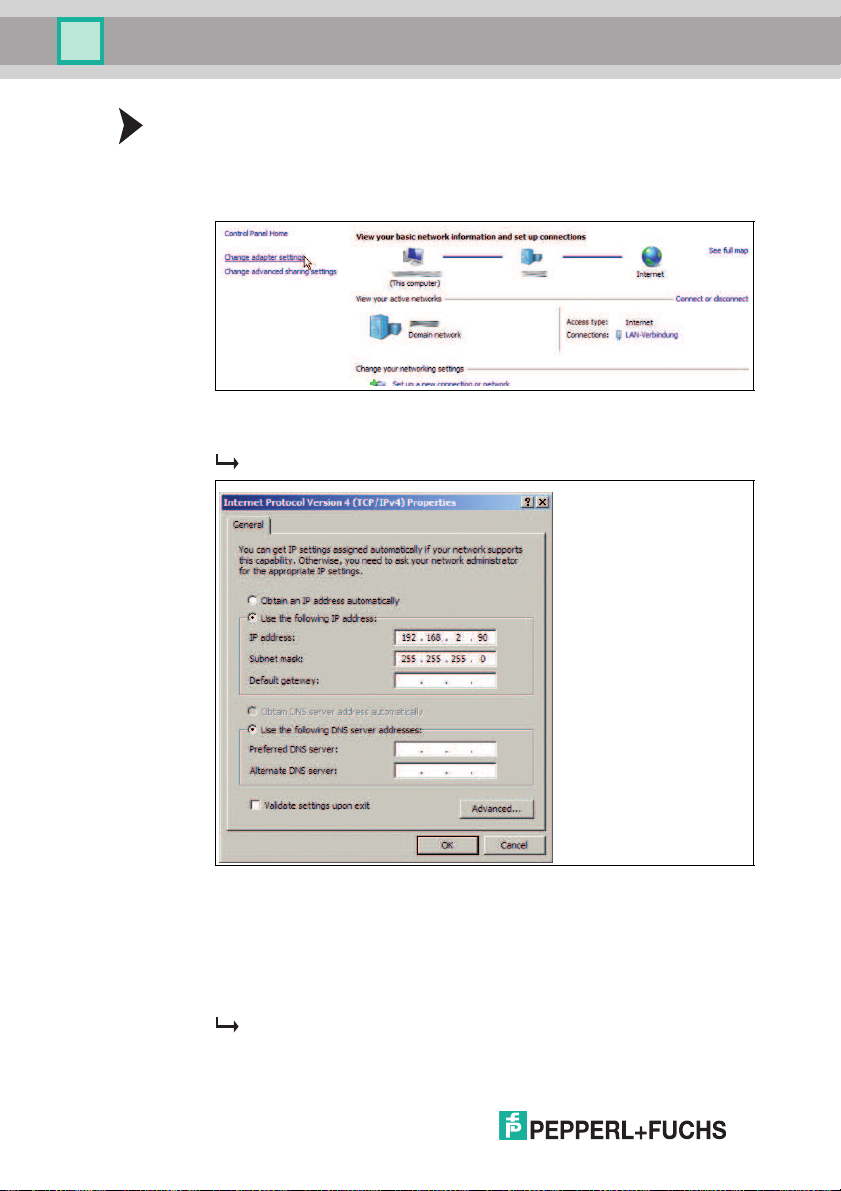

Setting the IP Address of the PC (Windows 7)

1. Select Start > Control Panel.

2. Select Network and Sharing Center.

3. Select Chang e Adapter Settings .

4. Right-click the required conne ction and select Properties.

5. Select Interne t Protocol Version 4 (TCP/IPv4) a nd click Properties.

The Properties window for the TCP/IP protocol o pens.

22

6. Select Use the Following IP Address.

7. Enter an IP addres s wher e the f irst three segm ents are identical to those of

the IP address for the sensor, e.g., 192.168.002.090 . The la st segment

must be different to the IP address of the sensor.

8. Enter 255.255.255.0 as the subnet mask.

9. Click OK and Close.

This c ompletes the network configuration and the sensor can b e used.

2015-0 7

OPC / OPD / OPE

Installation

5.5 Storage and transport

For st orage and transport purposes, package the unit using shock proof

pac kaging material and protect it against moisture. Th e best method of protection

is to package the unit us ing the origin al packaging. Further more, ensure that the

ambient condition s are within allowable range.

2015-0 7

23

Loading...

Loading...