Absolute encoders ENA42HD-S***-CANopen

Technical data

General specifications

Detection type magnetic sampling

Device type Absolute encoders

Linearity error ≤ ± 0.1 °

Functional safety related parameters

MTTFd 480 a at 40 °C

Model Number

ENA42HD-S***-CANopen

Features

•Solid shaft

• Up to 31 bit overall resolution

• CANopen interface

• Free of wear magnetic sampling

• High resolution and accuracy

•Highly shock / vibration and

soiling resistant

• Sturdy construction

• Increased shaft load capacity

• Stainless steel housing

•IP69K

Description

The ENA42HD series are high precision encoders

with internal magnetic sampling.

This multiturn absolute encoder transmits a position

value corresponding to the shaft setting via its

interface.

The control module sends a start sequence to the

absolute encoder to obtain the position data. The

rotary encoder then sends the position data

synchronous to the cycles of the control module. It

is possible to select the counting direction with the

function input.

Mission Time (T

L10 10 E+8 revolutions

Diagnostic Coverage (DC) 0 %

Electrical specifications

Operating voltage U

Power consumption P

Time delay before availability t

Output code binary code

Code course (counting

Interface

Interface type CANopen

Resolution

Single

Multiturn up to 15 Bit

Overall resolution up to 31 Bit

Transfer rate min. 20 kBit/s , max. 1 MBit/s

Cycle time ≥ 1 ms

Standard conformity DSP 406

Connection

Connector M12 connector, 5 pin

Cable Ø6 mm, 4 x 2 x 0.14 mm

Standard conformity

Degree of protection DIN EN 60529 , IP66 / IP68 / IP69K

Climatic testing DIN EN 60068-2-3, no moisture condensation

Emitted interference EN 61000-6-4:2007

Noise immunity EN 61000-6-2:2005

Shock resistance DIN EN 60068-2-27, 300 g, 6 ms

Vibration resistance DIN EN 60068-2-6, 30 g, 10 ... 1000 Hz

Ambient conditions

Operating temperature -40 ... 85 °C (-40 ... 185 °F)

Storage temperature -40 ... 85 °C (-40 ... 185 °F)

Relative humidity 98 % , no moisture condensation

Mechanical specifications

Material

Housing

Flange stainless steel 1.4404 / AISI 316L

Shaft Stainless steel 1.4412 / AISI 440B

Mass approx. 350 g

Rotational speed max. 6000 min

Moment of inertia 30 gcm

Starting torque < 5 Ncm

Shaft load

Axial 270

Radial 270 N

) 20 a

M

B

0

v

direction) ad

turn up to 16 Bit

9 ... 30 V DC (with galvanic isolation)

≤ 1 W

< 250 ms

justable

stainless steel 1.4404 / AISI 316L

2

N

2

-1

Release date: 2018-07-27 09:21 Date of issue: 2018-07-27 t182481_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

1

Absolute encoders ENA42HD-S***-CANopen

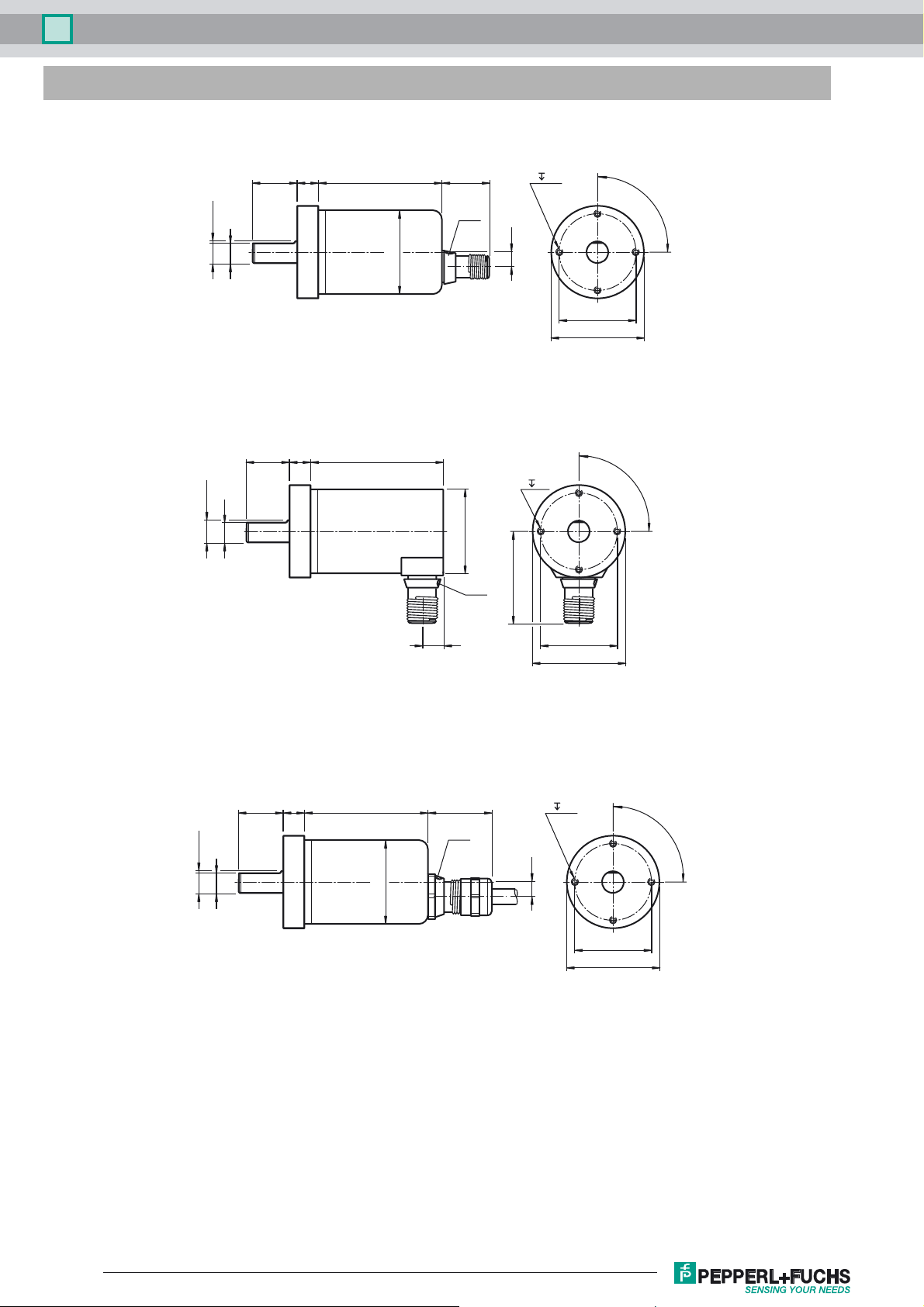

Dimensions

ø10h7

ø10h7

20 9.5 55.4 23

9

20 9.5 59.5

ø9

ø38.2

LED

ø38.2

LED

6.5

43

4 x M4

8

4 x M4

8

4 x 90°

ø35

ø42f7

4 x 90°

ø10h7

9

10

20 9.5 55.4 ~ 30

LED

ø38.2

6.5

4 x M4

8

ø35

ø42f7

4 x 90°

ø35

ø42f7

Release date: 2018-07-27 09:21 Date of issue: 2018-07-27 t182481_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

2

Absolute encoders ENA42HD-S***-CANopen

20 9.5 59.5

9

ø10h7

ø38.2

10

Electrical connection

Signal Wire end 5-pin, M12 x 1 connector

CAN GND green 1

+V

S

GND yellow 3

CAN-High white 4

CAN-Low brown 5

Shielding Shielding Housing

Pinout

red 2

1

2

3

5

4

LED

4 x M4

8

49.75

4 x 90°

ø35

ø42f7

Release date: 2018-07-27 09:21 Date of issue: 2018-07-27 t182481_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

3

Absolute encoders ENA42HD-S***-CANopen

Indicating elements

LED-indicator with dual color LED

CAN Run (green) Stat e Description

Blinking Pre-Operational Boot up message is sent, device configuration is possible, device is in CAN state

„Pre-Operational“

Single flash Stopped The Encoder is in CAN state „Stopped“

On Operational The encoder is in CAN state „Operational“

Off No power supply

Err (red) Sta te Description

Off No error The Encoder is in operating mode

Flickering AutoBitrate Auto baud mode is active and the encoder tries to find within the time out period a

Single flash Warning limit reached At least one of the error counters of the CAN controller has reached or exceeded the

Double flash Error control event A guard event (NTM slave or NTM master) or a heartbeat event has occured

On Bus off The CAN controller is in stae bus off. No communication possible anymore. Too

valid CAN message for baud rate measurement

warning level (too many error frames)

many error frames in the network.

Release date: 2018-07-27 09:21 Date of issue: 2018-07-27 t182481_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

4

Absolute encoders ENA42HD-S***-CANopen

Programmable CAN operating modes

Mode Explanation

The connected host requests the current actual position value via a remote transmission request telegram. The absolute

Polled mode

Cyclic mode

Sync mode

Programmable rotary encoder parameters

Parameter Explanation

Operating parameter

Resolution per revolution

Preset value

Min. and max. limit switch

Cam

encoder reads in the current position, calculates all parameters that have been set and sends back the process actual

value through the same CAN identifier.

The absolute encoder sends the current actual process value cyclically, without being prompted by the host. The cycle

time can be programmed in milliseconds for values between 1 ms and 65536 ms.

After the sync telegram has been received by the host, the absolute encoder sends the current actual process value. If

multiple nodes should respond to the sync telegram, the individual nodes report one after the other according to their

CAN identifier. There is no programming of an offset time. The sync counter can be programmed so that the rotary

encoder does not transmit until after a defined number of sync telegrams.

The direction of rotation (complement) can be specified by parameter as the operating parameter. This

parameter determines the direction of rotation in which the output code will ascend or descend.

The "Resolution" parameter is used to program the rotary encoder so that a desired number of steps can be

implemented in reference to one revolution.

The preset value is the desired position value that must be achieved for a specific physical setting of the axis.

The preset value parameter is used to set the actual position value to the desired actual process value.

A total of two positions can be programmed. The absolute encoder sets one bit to high state in the 32 Bit actual

process value if a value falls outside the range between these two positions.

8 freely programmable cams can be set within the overall resolution. This produces the functionality of a

mechanical cam shifting mechanism.

Release date: 2018-07-27 09:21 Date of issue: 2018-07-27 t182481_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

5

Absolute encoders ENA42HD-S***-CANopen

Model number

ENA4 2HD- S10S4 9 - B16 -

Connection type

C1 Cable, 1 m

C2 Cable, 2 m

C5 Cable, 5 m

CA Cable, 10 m

BD M12 device plug, 5-pin

Connection alignment

A axial

R radial

Electical interface

= 9 ... 30 V

B

Ver si on

HD Heavy Duty Line

Size

42 Housing diameter: 42 mm

Device type

ENA Absolute rotary encoder

Shaft diameter

10 10 x 20 mm

Shaft type

S Solid shaft

Multiturn resolution

00 Singleturn rotary encoder

12 Multiturn rotary encoder, 12 bit

14 Multiturn rotary encoder, 14 bit

15 Multiturn rotary encoder, 15 bit

Degree of protection

9 IP66/IP68/IP69K

Flange

S4 Servo flange V4A

CANopen, U

B16

Singleturn resolution

13 13 bit

16 16 bit

Release date: 2018-07-27 09:21 Date of issue: 2018-07-27 t182481_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

6

Loading...

Loading...