Page 1

PROCESS AUTOMATION

INSTALLATION AND OPERATION MANUAL

6000 SERIES

PURGE/PRESSURIZATION SYSTEM

Page 2

6000 Series Purge/Pressurization System

I/O Manual

With regard to the supply of products, the current issue of the

following document is applicable:

The General Terms of Delivery for Products and Services of

the Electrical Industry, published by the Central Association

of the Electrical Industry (Zentralverband Elektrotechnik und

Elektroindustrie (ZVEI) e.V.) in its most recent version as

well as the supplementary clause: "Expanded reservation of

proprietorship".

b

Page 3

6000 Series Purge/Pressurization System

I/O Manual

Contents

Safety note and symbols used ................................................................................................. 1

Symbols used ....................................................................................................................................1

General instructions regarding ATEX ...................................................................................... 2

Certication information ........................................................................................................... 3

Certication markings .......................................................................................................................3

Warning labels ...................................................................................................................................4

Conditions of Safe use ......................................................................................................................4

Purpose ......................................................................................................................................5

Description ................................................................................................................................. 5

6000 control unit .......................................................................................................................6

Electrical & pneumatic diagrams ............................................................................................. 8

6000 control unit power connections ..............................................................................................8

Electrical installation - power and I.S. wiring ................................................................................ 10

Pneumatic requirements ................................................................................................................. 12

Mounting instructions ............................................................................................................. 13

Manifold assembly, LH & RH mount ..............................................................................................13

EPV-6000 vent .................................................................................................................................. 14

6000 Control unit with housing "WH" ...........................................................................................15

Tightening the cover plate ..............................................................................................................16

6000 series component kit ..................................................................................................... 17

Identication of components .........................................................................................................17

Electrical diagrams ......................................................................................................................... 18

Electrical installation - power and I.S. wiring ................................................................................ 20

Component kit installation .............................................................................................................21

Mounting templates - user interface, EPCU, solenoid .................................................................22

Sequence of events ................................................................................................................. 23

Turning on power to the enclosure ................................................................................................23

Turning off power to the enclosure ...............................................................................................24

Operation of the 6000 series and component kit ................................................................. 25

Operation ..........................................................................................................................................25

Set-up procedures of 6000 series system ....................................................................................29

Operation of the 6000 series system .............................................................................................29

Start-up label located on 6000 series control unit .......................................................................30

The user interface ....................................................................................................................31

Programming menu ................................................................................................................. 32

Purge settings ..................................................................................................................................33

Units ..................................................................................................................................................33

Inputs ................................................................................................................................................34

Outputs .............................................................................................................................................38

Password ..........................................................................................................................................39

Language ..........................................................................................................................................39

Bypass control .................................................................................................................................39

Restore defaults ..............................................................................................................................39

Stats ..................................................................................................................................................40

Statistics ...........................................................................................................................................41

Alarm.................................................................................................................................................43

c

Page 4

6000 Series Purge/Pressurization System

Fault ..................................................................................................................................................43

Clear statistics ................................................................................................................................44

Clear fault ........................................................................................................................................44

Operation screen .............................................................................................................................44

I/O Manual

System dimensions ................................................................................................................. 45

6000 series control unit ..................................................................................................................45

EPV-6000 vent .................................................................................................................................. 46

6000 series component kit .............................................................................................................47

Temperature hub .............................................................................................................................48

Temperature sensor ........................................................................................................................49

6000 Manifold ...................................................................................................................................50

General specications ............................................................................................................51

Model number designators .....................................................................................................54

Accessories .............................................................................................................................55

Maintenance and repair ..........................................................................................................56

Alarm and fault conditions .....................................................................................................56

Dismantling and decommissioning .......................................................................................57

Establishing connection sizes, lengths & bends ................................................................. 58

Programming worksheet .........................................................................................................59

Notes .........................................................................................................................................66

d

Page 5

6000 Series Purge/Pressurization System

Warning

Note

Safety note and symbols used

It is strongly urged that you follow all instructions and

recommendations in this manual, in addition to all

applicable codes, standards, and local requirements.

Failure to do so voids all warranties, both implicit and

explicit, and relieves the manufacturer of all liability.

Symbols used

This symbol calls your attention to

instructions or requirements that must be

followed. Failure to observe the instructions

and information that this symbol calls

Attention

attention to may result in the failure of the

device and any devices or systems

connected to it.

This symbol draws your attention to

important information.

Note

I/O Manual

This symbol warns the user of potential

danger. Failure to observe this warning may

lead to personal injury or death and/or

property damage.

This symbol accompanies a list of tools you

will need to install the unit.

Grounding points internal and external

will be identied with a ground symbol:

This symbol is used for AC power:

This symbol is used for DC power:

Pepperl+Fuchs GmbH

Lilienthalstraße 200

68307 Mannheim

Germany

1

Page 6

6000 Series Purge/Pressurization System

Note

Warning

Warning

I/O Manual

General instructions regarding ATEX

1. The guidelines

The guideline 2014/34/EU determines the essential

health and safety requirements relating to the design

and construction of equipment and protective systems

intended for use in potentially explosive atmospheres,

given in Annex II of the directive.

The guideline 1999/92/EG is addressed to the operator/

user of facilities in explosive areas and governs the

safety regulations of persons during installation, handling,

and maintenance.

Furthermore, local laws and rules for electrical

installations and accident prevention have to be

observed.

2. General information for this manual

Preconditions for handling and operating the series

6000 controller safely are basic knowledge of safety

regulations and additional training and experience in

explosion protection.

4. General information about pressurized enclosures

The pressurized enclosure is one of the most

multifunctional applicable types of protection. It is based

on a rst ush operation which removes potential,

ignitable gas mixtures of the local environment from

the enclosure. After the ush, the overpressure will

be maintained by adding as much pressurized air as

necessary to compensate for the leaks of the enclosure

or components. This constant overpressure status

protects against the diffusion of potentially explosive

atmospheres.

During the ush, the internal pressure will be up to

10-12mbar. In the operation phase, it is reduced to

2-3 mbar. Hot spots at single components inside the

enclosure are monitored by temperature sensors

(optional) and if required turned off. This assures that no

unacceptable surface temperature will occur.

For applications with hazardous dust, the purge process

is omitted because purging would raise explosive dust.

Instead of pre-purging, the interior of the housing is

inspected for dust and cleaned manually if dust is

present.

This user manual contains important information and

instructions to handle the series 6000 controller in

explosive areas safely and to operate it according to

guideline 2014/34/EU.

This user manual, in particular the safety instructions,

has to be observed by everybody who works with the

components.

3. Responsibilities of users and installers

This equipment shall only be used within its

intended purpose. Refer to the manual for proper

usage.

The user and/or the installer is obligated to let only

competent, trained persons work at the 6000 Control Unit

who

• are familiar with the regulations about safety and

accident prevention and briefed in handling of the

component.

• are trained to work on explosion protection

equipment.

• know the appropriate instructions and rules for

the installation, handling, and maintenance of

explosion protected equipment.

For this reason, the pressurized enclosure is especially

suited for the use of non-Ex certied equipment in Exareas.

The enclosure has to be prepared specially for the use of

Ex p:

• all walls have to be additionally armed

• the doors have to be specially constructed

• tested for mechanical stability

• tested for overpressure resistance

When using an inert gas like nitrogen, an

asphyxiation hazard can exist.

EN 60079-2 and IEC 60079-2 do not cover both gas

and dust hazard atmospheres. The 6000 system

provides a solution for both at the same time but

would have to be evaluated by the certication

bodies for approval.

2

Page 7

6000 Series Purge/Pressurization System

Certication information

Marking for the 6000 control unit,

6000-__-S2-__-CK-__

Marking for the 6000 Control

unit, 6000-__-S2-UN-WH-__ and

6000-__-S2-__-XD-__

I/O Manual

Marking for the 6000 user interface controller, 6000-UIC-01

Marking for the 6000-ISB-___ termination board,

DIN mounted

Marking for the 6000 vent, EPV-6000-__-__

Marking for the 6000-TSEN-01

Marking for the 6000-TEMP-01

3

Page 8

6000 Series Purge/Pressurization System

Warning

Warning

Warning

Warning

I/O Manual

Warning Labels

WARNING - Conduit seal must be installed within 18

inches of the explosion-proof enclosure. To prevent

ignition of ammable or combustible atmospheres,

disconnect power before servicing.

WARNING - FOR ENCLOSURES IN HAZARDOUS

DUST ENVIRONMENTS

This enclosure shall not be opened unless the area

is known to be free of ammable materials or unless

all devices have been de-energized. Power must not

be restored after the enclosure has been opened until

combustible dusts have been removed and the enclosure

repressurized.

WARNING - FOR ENCLOSURES IN HAZARDOUS

GAS ENVIRONMENTS

This enclosure shall not be opened unless the area is

known to be free of ammable materials or unless all

devices have been de-energized. Power must not be

restored after the enclosure has been opened until the

enclosure is completely purged of all hazardous gas and

the enclosure repressurized.

WARNING - FOR ENCLOSURES IN HAZARDOUS

DUST AND GAS ENVIRONMENTS

This enclosure shall not be opened unless the area

is known to be free of ammable materials or unless

all devices have been de-energized. Power must not

be restored after the enclosure has been opened until

combustible dusts have been removed and completely

purged of all hazardous gas and the enclosure

repressurized.

Conditions of Safe Use

1. Conduit seals shall be certied in type of explosion

protection ameproof “db”, or explosion-proof Class

I/II Div 1 as required for the installation location

and suitable for the conditions of use. They shall be

correctly installed to the explosion-proof/ameproof

enclosure or conduit extensions as required. All NPT

threads are to be minimum 5 thread engagement,

wrench tight.

2. Seals shall be installed within 18 in. (450 mm) of the

explosion-proof/ameproof “db” enclosure.

8. The non-metallic membrane touchpad and display is

a potential electrostatic discharge hazard. Use only

water damp cloth and allow to air dry for cleaning

device. Do not use or install in high charge areas.

See IEC 60079-32-1 for further information.

9. In hazardous dust environment, regularly remove dust

from the control unit enclosure to prevent excessive

temperature rise, including the solenoid valve.

10. Only pressure relief vent model EPV-6000-xx-xx

covered under the following certicates can be

used with devices covered by this certicate: For

ATEX applications: Certicate No. DEMKO 15

ATEX 1622X, DEMKO 07 ATEX 0705753X, or SIRA

09ATEX9337X. For IECEx applications: Certicate

No. IECEx UL 15.0147X, IECEx UL 08.0003X or

IECEx CSA 09.0007X. For cULus and cCSAus

applications: UL certication as part of le E184741

or CSA certication as part of 2205652 (LR90178).

11. For all applications, the 6000-TEMP-XX I.S.

temperature hub must be mounted in an enclosure

that is a minimum IP54. In hazardous dust

environment, the 6000-TEMP-xx temperature hub

has to be mounted in an enclosure that is certied

for the area classication. The pressurized enclosure

does not account for this type of enclosure because

power to this device is required before safe operation

within the pressurized enclosure. Maintain separation

of I.S. to non-I.S. wiring as required by local codes.

12. Caution must be used when handling or cleaning

products so there is no static charge buildup. Do not

wipe off the 6000-TSEN-xx sensor with dry cloth

or use in the presence of high charge generating

processes such as ionizers or electrostatic

equipment. See IEC 60079-32-1 for further

information.

13. The 6000 systems may also be provided with

previously certied items (operators, gable glands,

terminal box, etc.) as specied in the test reports.

14. Enclosure 6000-DPE-xx is only for I.S. termination

board 6000-ISB-xx and/or 6000-TEMP-xx.

3. When the purge control unit is mounted to an

enclosure, the complete unit shall be evaluated to

the current revision of IEC/EN 60079-2 or NFPA 496

as applicable. See certicates and/or Declaration of

Conformity for reference to relevant editions of these

standards.

4. The purge control unit has an operating temperature

class of 135 °C (T4 temperature class). This

temperature shall be considered when mounted to an

enclosure.

5. The device must be installed in accordance with the

manufacturer’s installation drawing number 116-B027.

6. Intrinsically safe cables extending from the explosionproof/ameproof "db" enclosure must be provided

with at least 0.25 mm insulation thickness per

conductive core to maintain segregation between

intrinsically safe circuits.

7. The cable entries may be used only in places

where they are protected against the inuence of

mechanical danger.

4

I.S. Termination Board, DIN Mounted:

6000-ISB-xx

1. In hazardous dust environments, the I.S. termination

board, DIN mounted: 6000-ISB-xx must be mounted

in an enclosure that is certied for the area

classication. The pressurized enclosure does not

account for this type of enclosure because power to

this device is required before safe operation within

the pressurized enclosure.

2. Only connect to the 6000 EPCU I.S. termination

connection.

3. All wiring to and from this board is for intrinsically

safe connections and must be properly routed and

managed per international, NEC, local codes, and

applicable standards.

4. See the latest revision of installation drawing 116B027 for other important installation information.

5. The 6000-CBLA-… is not certied to be used in a

Zone 21 location. Use approved cable glands for this

area classication.

Page 9

6000 Series Purge/Pressurization System

Note

I/O Manual

Note:

• Peripheral devices such as optional SRM module and

I.S. solenoid were not evaluated by UL as part of the

intrinsically safe certication.

• When using third-party certication, ensure that you

match the entity parameters for intrinsically safe

devices as shown in control drawing 116-B027.

• SRM module is a simple apparatus and does not

require third-party certication.

EPV-6000 Vent

1. The EPV vent has an operating temperature class of

135 °C (T4 temperature class). This temperature shall

be considered when mounted to an enclosure.

2. When the purge control unit is mounted to an enclosure,

the complete unit shall be evaluated to IEC/EN 600792: 2014 (Ed. 6)

3. Cables used to connect to an EPV- vent must be

provided with at least 0.25 mm insulation thickness

per conductive core to maintain segregation between

intrinsically safe circuits.

4. In hazardous dust environments, regularly remove dust

from the EPV vent to prevent excessive temperature

rise. See certicate for full information.

5. In hazardous dust environments, the connector end of

the vent shall be protected from direct exposure of a UV

light source. See certicate for full information.

The 6000 series system features these main parts:

• Electronic processor (EPCU) housed in an

explosion-proof enclosure

• I.S. electrical/pneumatic manifold assembly

• I.S. user interface for programming and monitoring

the system

• 316L stainless steel (UNS S31603) type4X IP66

enclosure for EPCU and connections

• Pressure relief vent with ow and pressure

monitoring at the exhaust.

The user interface allows programming of up to 4 switch

inputs, temperature modules, enclosure power contacts,

2 auxiliary outputs, and various operational functions.

Through the user interface menus, conguration of the

standard information for setup and operation of a system

(purge time, ow rates, pressures, enclosure size, etc.)

are easily programmed. Additional features allow inputs

for system bypass, enclosure power on/off, temperature

overload and activation of rapid exchange ow for cooling

or auxiliary relay for separate cooling source, delay

power shutdown, and more. The two auxiliary contact

outputs can be congured to activate on most of the

input switches or any of the congured alarm states for

pressure, ows, and temperature.

6. Only EPV-6000-xx-xx vents can be connected to any

certied model 6000 control system.

Purpose

The purpose of the Pepperl+Fuchs 6000 series Type X

& Ex px, Zone 1 enclosure protection system is to allow

the use of general purpose or non-rated electrical or

electronic devices located in general purpose enclosures

instead of explosion-proof/ameproof, Type 7 or 9 / Ex

d enclosures or other means of protection for the rated

area. Other purposes include heat, moisture, and dust

contamination prevention.

Description

The 6000 series Type X & Ex px purge and

pressurization system protects general purpose

equipment mounted in a standard enclosure. This allows

the enclosure to be located and the equipment operated

in a hazardous area. The hazardous area classication

can be Class I, Class II, Division 1 / Zone 1, Zone 21.

The 6000 series operates by controlling and monitoring

compressed instrument air or inert gas through the

protected enclosure(s) so as to remove and prevent the

accumulation of ammable gas, vapors, or dust.

The power for the solenoid valve on the manifold unit,

inputs, the user interface controller (UIC), and EPV-6000

vent are provided by the EPCU through the internal

galvanically isolated intrinsic safety barrier. No additional

I.S. barrier is required.

The adjustable mounting bracket and the universally

mountable vent make the 6000 system easy to install

horizontally or vertically onto the enclosure. A component

kit is available for custom installations that t specic

customer needs.

The 6000 control unit can monitor multiple enclosures

and control and accept inputs from two (2) EPV-6000

vents.

The 6000 series provides a complete system for purging

and pressurizing enclosures for hazardous location

operation.

One (1) operations copy of this manual must be

studied and retained by the system operator in

addition to one (1) permanent le copy. User’s

agents are responsible for transferring this manual

to the user/operator prior to start-up.

5

Page 10

6000 Series Purge/Pressurization System

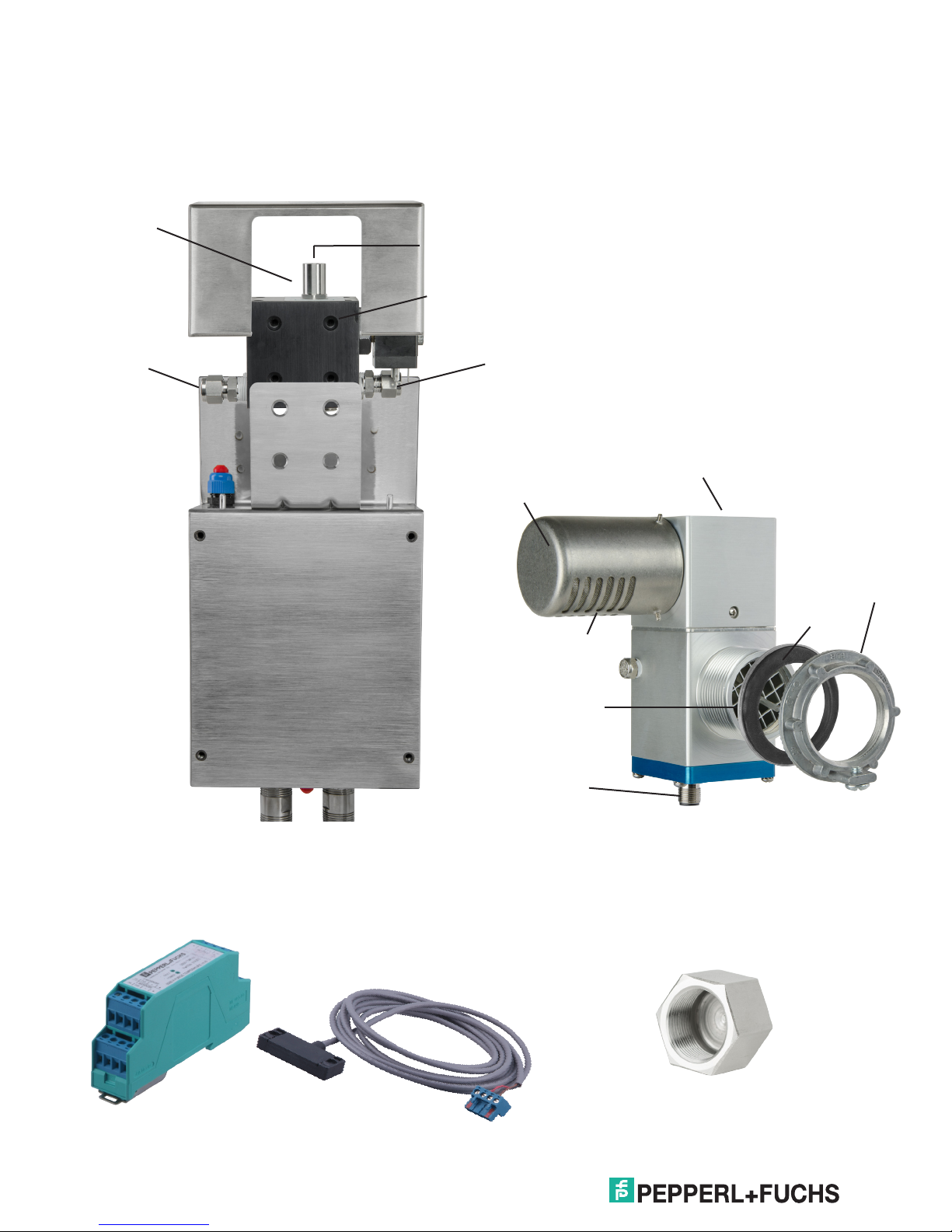

6000 Control Unit

Main unit

I/O Manual

I.S. wiring terminals

User interface controller

(UIC)

Bracket for mounting to the

enclosure

316L stainless steel

(UNS S31603)

Type 4X (IP66) rating

Removable electronics

Explosion-proof/flameproof

enclosure

3/4" conduit for power

connections

Cable glands for I.S. inputs/outputs

6

Page 11

6000 Series Purge/Pressurization System

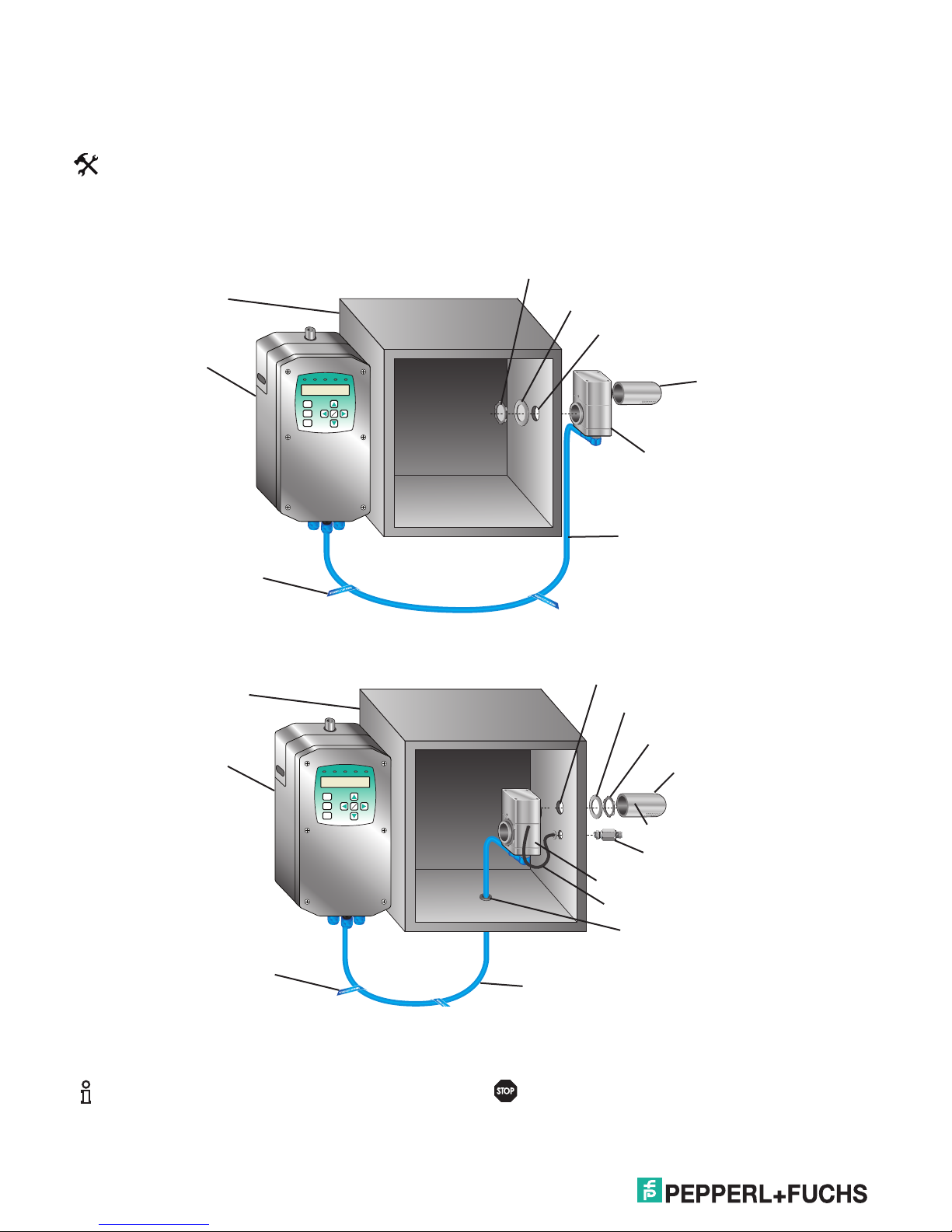

6000 Control Unit

Manifold

I/O Manual

Manifold for

purging and

pressurization

Type 4X (IP66)

ttings for

enclosure ow

Needle valve for

pressurization of enclosure

(requires athead

screwdriver for adjustment)

Manifold with

I.S. solenoid

valve

Connection to

protective gas

supply

Rotating vent cap

Spark arrestor

Vent

The EPV-6000 vent

is required.

Mounts on vertical or horizontal

surface of the enclosure

Lock nut

Seal washer

I.S. temperature hub

Temperature

monitoring/control

accessories

I.S.

temperature

sensor

1.5 " NPT knockout

(Ø 2", 50.8 mm)

M12 (V1) connector

for I.S. connection

to control unit

Conduit plug

7

Page 12

6000 Series Purge/Pressurization System

Warning

Warning

Attention

Warning

Warning

Warning

I/O Manual

Electrical & pneumatic diagrams

Complete 6000 full control unit power

connections (-WH-)

General wiring notes

For power connections to the 6000 control unit and

relay contacts:

1. All applicable local and national wiring codes

MUST be followed when wiring to the unit.

2. Ground wire to be 14 AWG (2.08mm2). Strip

length of ground to mate with pigtail under wire

nut .437" to .5" (11.1mm to 12.7 mm).

3. If a single wire is used, the maximum wire gauge

to the pluggable terminal block is 14 AWG

(2.08mm2).

4. If jumpering from one terminal to another at

pluggable terminal block, the maximum wire

gauge is 16 AWG (1.31mm2) for both wires.

5. Minimum wire gauge to the pluggable terminal

Attention

Warning

Warning

block is 24 AWG (0.20mm2). (Based on

connector, not code. Follow all applicable

codes.)

6. Strip length of wires terminating into the screw

terminals on the pluggable terminal block to be

0.2" to 0.27" (5 mm to 7 mm).

7. Add extra wire length of 1.25" (31.75 mm) past

top of opening in explosion-proof/ameproof box

to pluggable terminal block (allows connector

to be moved out of the way when changing

electronics. Prevents repouring seals).

8. Wires are to be neatly tucked back down past the

lid threads before lid is placed on unit. The wires

must not loop past the high point of the plastic

cover. The wire nut should be tucked in last (If

not, it may be difficult to access when changing

electronics).

9. If using a single conduit seal, the other conduit

on the 6000 control unit will need a cap for

the end of the conduit with appropriate hazloc

certications (A standard 3/4" conduit cap will not

work).

10. Conduit seals with or without the 6000-CC3/4NPT plug must be within 18" (457.2 mm) of

internal explosion-proof/ameproof box, or within

15.25" (387.3 mm) from the end of the conduit

supplied with the 6000 unit.

11. When wiring to the terminal plug, it is easier

to remove the plug, terminate the wires, then

reconnect the plug.

12. When removing the pluggable terminal block, it

is recommended that the electronics module be

supported by pressing down on top of the EPCU

to counteract the lifting force required to remove

the connector.

13. Wire should be copper only, rated 90 °C

Attention

minimum. Minimum of 0.25" (6.3 mm) wire

insulation thickness required.

14. The minimum wire strand in a stranded wire

should have a diameter of 0.1 mm or greater.

15. The 6000-CC-3/4NPT plug is certied to be

used only with the 6000 control unit’s ¾” nipples

coming out of the housing. This plug is not

certied to be used on any other hazardous

location equipment.

16. Ensure that electrical, mechanical, and

pneumatic connections and requirements are

met to operate this system. Please refer to

this manual and applicable standards/codes,

including current editio9n of the EN/IEC 60079-

14. Electrical supply to the purge system shall be

supplied through a switch or circuit breaker and

suitably located and easily reached and must be

marked as the disconnect for the equipment.

1 7. Power must be removed from the system when

the Ex d enclosure cover is off, unless the area is

known to be non-hazardous.

WARNING – To prevent ignition of the ammable

atmospheres, the wiring method must ensure that

if any wire is disconnected and extended to the

opposite terminal, a 2-inch separation must be

maintained.

I.S. wiring notes

For wires going to the explosion-proof/ameproof

box on the I.S. side:

1. The wire strip length is to be between 0.2" and

Attention

0.27" (5 mm and 7 mm).

2. The wire's gauge depends on the number of

connections. Fewer wires allow for heavier

gauge and will still meet the conduit seal ll

requirement. See the applicable standards for ll

requirement.

3. The terminal blocks are rated for a wire size of

16 AWG (1.31 mm2 ) to 28 AWG (0.08 mm2 ).

8

Page 13

6000 Series Purge/Pressurization System

Warning

Warning

Warning

Attention

4. If multiple wires need to land to a single terminal

(e.g., the RS-485 bus), these wires must be

either crimped to a single pin or grouped in an

external junction box with one wire going into the

terminal.

5. The wires must have a minimum insulation

thickness of 0.01" (0.25 mm).

6. Add extra wire length of 1.25" (31.75 mm) past

top of opening in explosion-proof/ameproof box

to pluggable terminal block. (Allows connector

to be moved out of the way when changing

electronics. Prevents repouring seals.)

7. Conduit seal on I.S. wiring side must be within

18" (457.2 mm) of the explosion-proof/ameproof

box.

8. Wire should be copper only, rated 90 °C

minimum.

9. The minimum wire strand in a stranded wire

should have a diameter of 0.1 mm or greater.

I/O Manual

For wires going to the I.S. interface board in the main

housing or to the DIN-rail-mount I.S. board:

1. The wire strip length is to be between 0.16" and

0.24" (4 mm and 6 mm).

2. The terminal blocks are rated for a wire size of

16 AWG (1.31 mm2) to 26 AWG (0.081 mm2).

3. The only terminals that might have multiple

connections are the shield connections.

These must be crimped to a single pin before

connection to the board.

4. If cables are used (recommended for

connections to the vents and UIC), it is

recommended that the cables be shielded.

5. The wires must have a minimum insulation

thickness of 0.01" (0.25 mm).

6. Wire should be copper only, rated 90 °C

Attention

minimum.

7. The minimum wire strand in a stranded wire

should have a diameter of 0.1 mm or greater.

9

Page 14

6000 Series Purge/Pressurization System

Note

Note

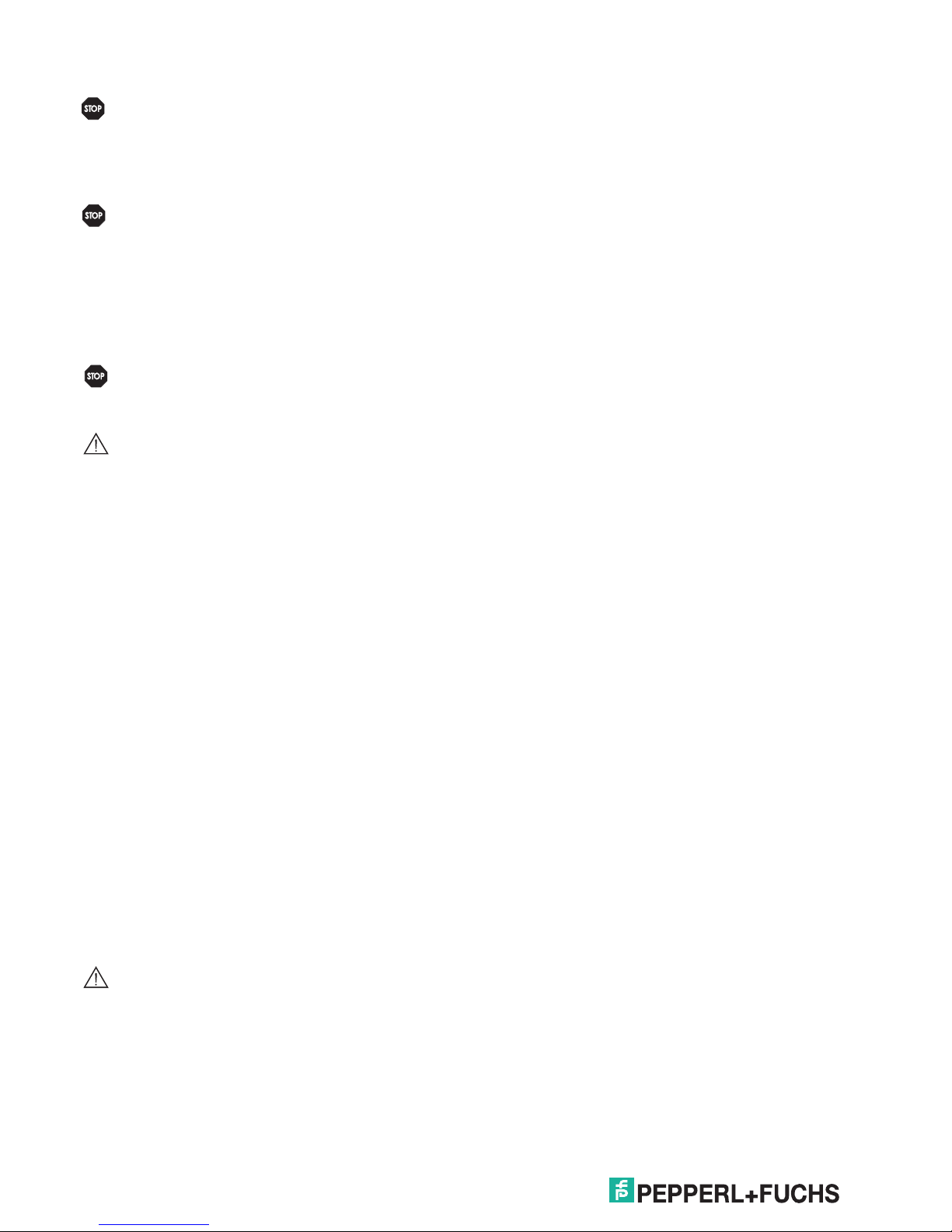

IS PWR 1+

IS PWR 1-

IS DATA 1A

IS DATA 1B

IS 1 SHLD

IS PWR 2+

IS PWR 2-

IS DATA 2A

IS DATA 2B

IS 2 SHLD

IS PWR 3+

IS PWR 3-

IS DATA 3A

IS DATA 3B

IS 3 SHLD

INPUT 1-

INPUT 1+

INPUT 2-

INPUT 2+

INPUT 3-

Temp

Module

Vent 1

Vent 2

Inputs

1 thru 4

Enclosure

Prewired

Electrical installation - power and I.S. wiring

I/O Manual

Power to

EPCU

GND

GND

GND

Prewired

L1

GND

N

BK

OR

GN

WT

BK/WT

BL/WT

RD/WT

GN/WT

OR/BK

BL

RD

WT/BK

RD/BK

User interface

connection

(pre-wired)

EPCU I.S. connector

I.S. solenoid valve

from manifold

(pre-wired)

Temperature module

connection

(when Vent 2 is used)

Vent 1 connection

Vent 2 connection or

Temperature Module

connection

Inputs 1 - 4, 5.0 V DC

Contacts

(2) N.O.

Aux

Output 1

(1) SPDT

Aux

Output 2

(1) SPDT

Connector color code for the user interface,

temperature module, and vent:

PWR + BN (brown)

PWR - BU (blue)

DATA_A WH (white)

DATA_B BK (black)

Requires standard explosion-proof seals to

explosion-proof/ameproof enclosure at a

Warning

maximum distance of 18" (457.2 mm).

When removing the terminal block from the

EPCU stack, place your hand on top of the

plastic to support the stack when lifting the

terminal block off the stack.

10

Manifold connection Vent connection

GND

'A' White

+1

-2

'+' Brown

'B' Black

'-' Blue

The EPCU is prewired to the I.S. terminal board.

Note

Both enclosure power contacts are switched at

the same time.

Page 15

6000 Series Purge/Pressurization System

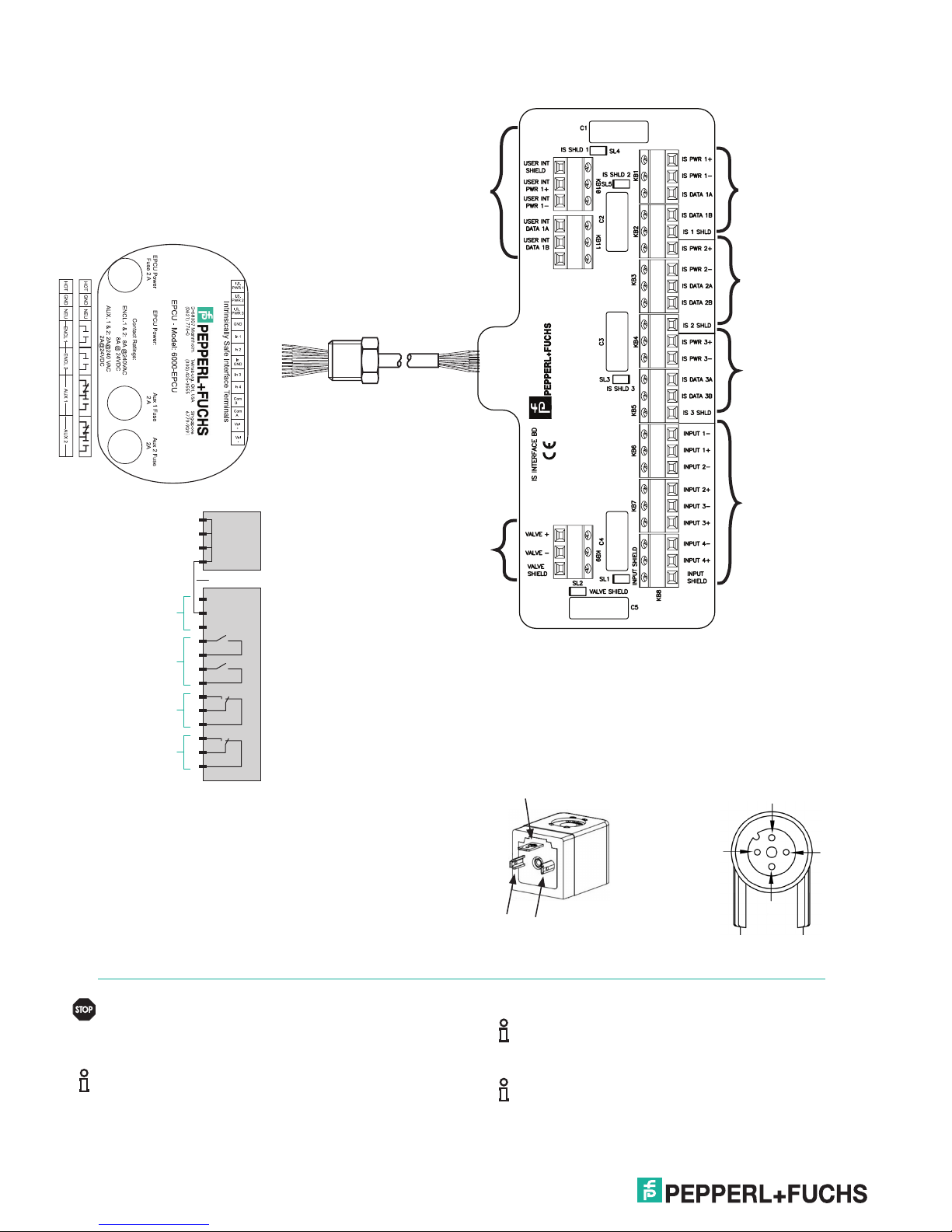

Warning

No wiring is to be in

the area between the

terminals

I/O Manual

I.S. wiring

Non- I.S. wiring

Incoming ground wires

should be terminated into

the supplied wire nut

WARNING: To prevent ignition of the ammable

atmospheres, the wiring method must ensure

that if any wire is disconnected and extended to

the opposite terminal, a 2" (50.8 mm) separation

must be maintained.

EPCU

Maintain a minimum space of 2" (50.8 mm)

between the I.S. wiring and the non - I.S. wiring.

Attention

Make sure that the wiring is neatly tucked into

the explosion-proof housing. Use wire ties if

necessary. As a rule, no wires are to be in the

area between the two terminals, as shown

above.

11

Page 16

6000 Series Purge/Pressurization System

Note

I/O Manual

Pneumatic requirements

Protective gas supply

The protective gas supply to the enclosure system must

be a clean, instrument quality compressed air or inert

gas ltered to a minimum of 40 microns. It must contain

no more than trace amounts of ammable gas, vapor, or

dust.

The protective gas supply compressor intake must

originate in a nonhazardous location. The suction

duct passing through a hazardous location and the

protective tubing and piping must be fabricated from

noncombustible materials suitable for the prevailing

hazardous and environmental conditions.

The protective gas supply provided must be able to

handle the ow and pressure requirements for purging

and pressurization (see page 66, Establishing connection

sizes, lengths & bends).

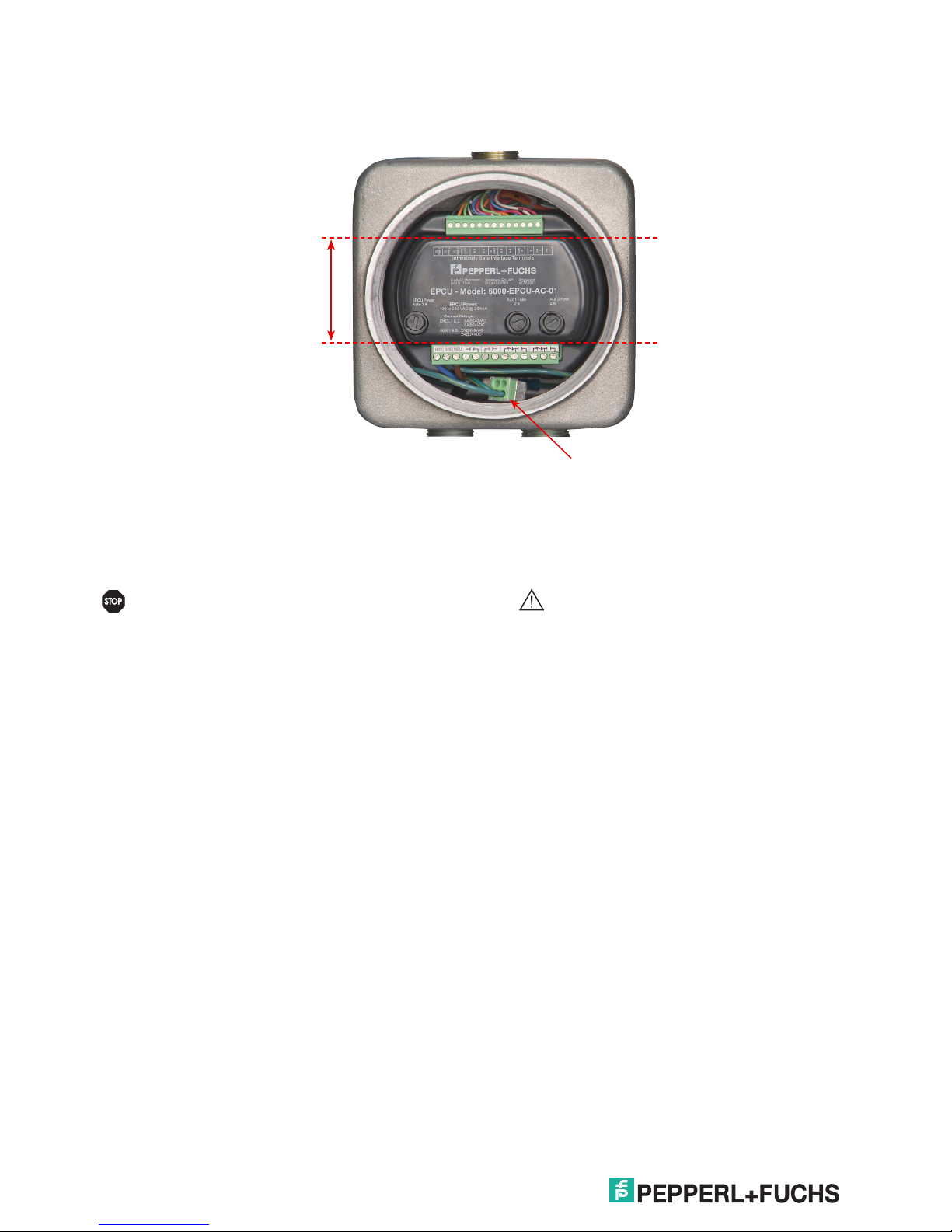

Needle valve

3/8" tubing

Protective

Plug

gas supply

EFC-6-SS

Pneumatic connections

The 6000 series system requires only two pneumatic

connections to the protective enclosure, one for the

exhaust for the vent mounting and the other for the

protective gas supply for purging and pressurization.

The vent requires a single 1 1/2" conduit knockout (Ø2"

[50.8mm]) hole in the enclosure. A lock ring with gasket

for sealing are provided. The control unit for the 6000

series provides a compression tting with a lock ring and

washer connected to a 3/8" tube. All tubing and ttings

are 316L (UNS S31603) stainless steel. A single hole

into the enclosure as noted on the mounting template will

provide the installation for this tting.

For replacement of this tubing use only 3/8" tubing with

wall thickness of 0.035" (0.9 mm).

The 6000 series control unit with the manifold can be

top, bottom, right, or left-hand mounted on the enclosure.

However, the manifold connections may have to be

reversed as shown below.

Needle valve

3/8" tubing

EFC-6-SS

Plug

Protective

gas supply

Plug

Solenoid

valve, EEx io

2/2 way

Supply

to enclosure

Pressurization adjustment

To adjust, use a at head screw driver inserted into the

needle valve of the manifold as shown. Turn clockwise to

decrease the ow, counter-clockwise to increase the ow.

The maximum number of complete rotations allowed is

ve (5).

Diagram shown is without plumbing. See the

diagrams on the following page for plumbing

Note

installation.

Unit must be powered to get a pressure reading.

When delivered, the system is in its default mode

(fully automatic [FA]). It may be easier to adjust

Note

safe pressure in standard (STD) or

semiautomatic (SA) mode so that the system

does not automatically begin purging when

energized.

Supply

to enclosure

MAXIMUM of ve (5) turns

Counterclockwise

rotation

increases ow

6000 control unit

housing

Plug

Solenoid

valve, EEx io

2/2 way

Flathead screwdriver

Clockwise

rotation

decreases ow

Needle valve

in manifold

12

Page 17

6000 Series Purge/Pressurization System

Mounting Instructions

Manifold assembly – left-hand or right-hand mount

Left-hand mount*

*Reverse ttings for

right-hand mount

Protective gas

supply inlet

Protective gas to

enclosure

I/O Manual

3/8" SS tube

(included)

3/8" ferrule tting

(included)

1/4 - 20

at head screws

(4 included)

3/8" SS tube

(included)

3/8" ferrule tting

(included)

Wiring entry

EFC-6-SS

(included)

EFC-6-SS nut

(included)

13

Page 18

6000 Series Purge/Pressurization System

Note

Warning

EPV-6000 vent

Tools:

1 1/2" NPT knockout (Ø 2" [50.8mm] hole ) for

vent

Vent mounted on the outside of the enclosure

Pressurized enclosure

I/O Manual

Locking nut w/grounding screw

(included)

Seal gasket (included)

Ø 2" (50.8 mm)

6000 control unit

I.S. wire tag

(included)

Vent mounted on the inside of the enclosure

Pressurized enclosure

6000 control unit

Vent cap

(included)

EPV-6000

Vent cable (included)

Ø 2" (50.8 mm)

Seal gasket (included)

Locking nut w/o ground

(included)

Vent cap (included)

I.S. wire tag

(included)

Vent is not gravity sensitive and can be installed

in any orientation.

14

Hex screws 0.05"(1.3 mm) (3)

*Bulkhead tting for reference

pressure

EPV-6000

*Reference tube

Cord grip CG-8

(optional)

Vent cable (included)

*Reference tubing and hardware included with EPV-6000-SS models

Cable to the vent is I.S. wiring and must be

properly isolated from other wiring.

Page 19

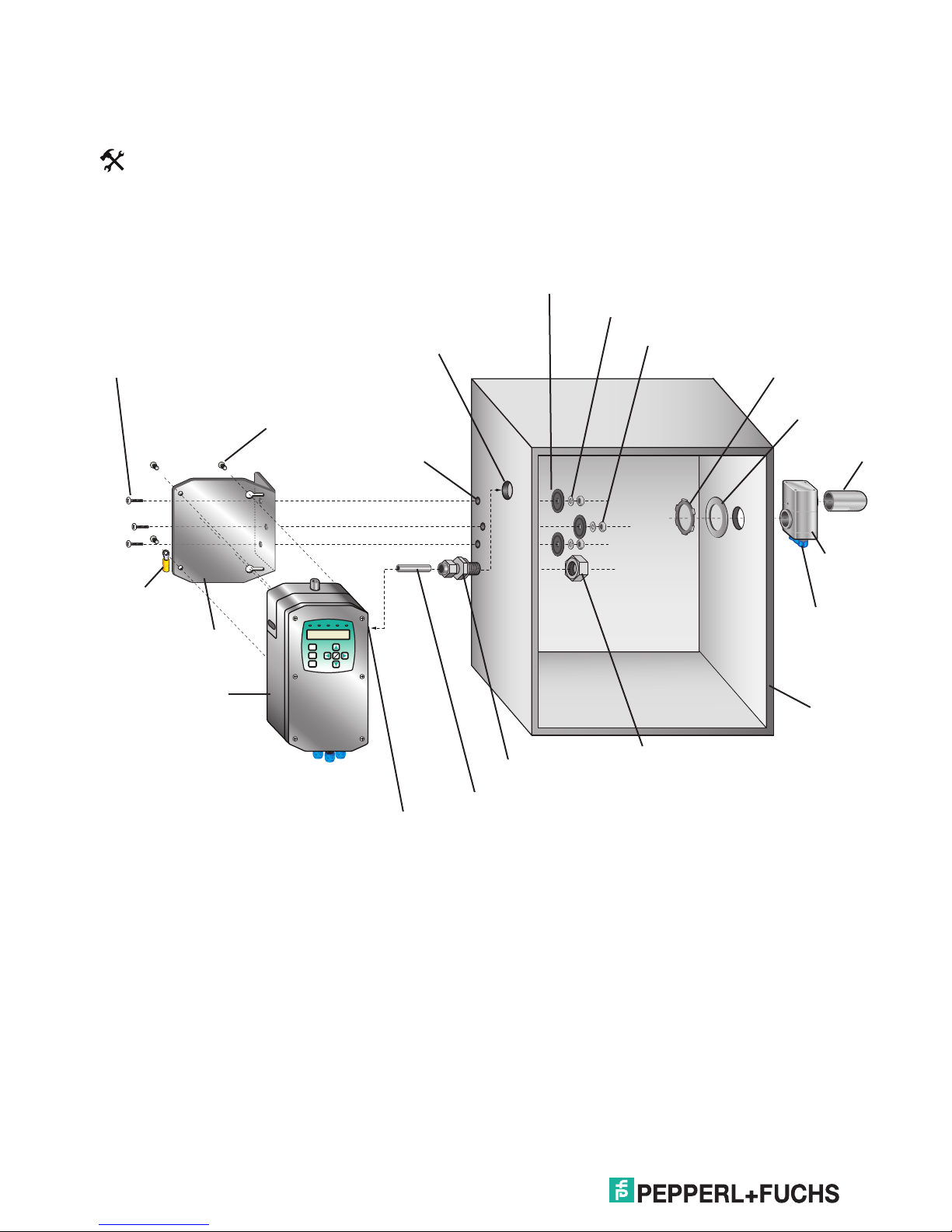

6000 Series Purge/Pressurization System

6000 Control unit with housing "WH"

Tools:

Appropriate sized drill bits or knockout holes

1 1/16" open end box wrench

Bolts: 1/4-20 (provided),

hole clearance = 0.27" (6.86 mm) diameter

EFC-6-SS (provided):

hole clearance = 0.61" (15.54 mm) diameter

I/O Manual

Seal washer (3 included)

Lock washer (3 included)

1/4-20 pan head bolts

(3 included)

Grounding lug

(included)

Mounting bracket

(included)

6000 control unit

1/4-20 pan head

w/lock washer screws

(4 included)

Ø 0.61" (15.54 mm) hole

Ø 0.27" ( 6.86 mm)

hole (3x)

1/4-20 nuts (3 included)

Locking nut

w/grounding screw

(included)

Seal gasket

(included)

Vent cap

(included)

EPV-6000

Vent cable

(included)

Enclosure

EFC-6-SS nut (included)

EFC-6-SS (included)

1. Drill holes using template. Check the scale if

printing an electronic version.

2. Assemble tubing and tting to control unit. Install

on the "Out" port of the correct side.

3. Bolt mounting plate to the enclosure. Type 4X

washers must be mounted inside the enclosure.

Tighten to 60 – 80 in-lb (16.38 – 18.08 Nm).

3/8" stainless steel tube, 2.5" (65 mm) long (included)

3/8" ferrule tting (included)

4. Put 2 of the mounting screws in the back of the

control unit to align with the key holes in the

mounting plate.

5. Hang the control unit onto the plate. Slide the unit

towards the enclosure so that the EFC-6-SS tting

is in the proper location.

6. Tighten the 2 bolts. Put the other two mounting

bolts in place and tighten.

7. Place the EFC-6-SS bolt in position and tighten.

15

Page 20

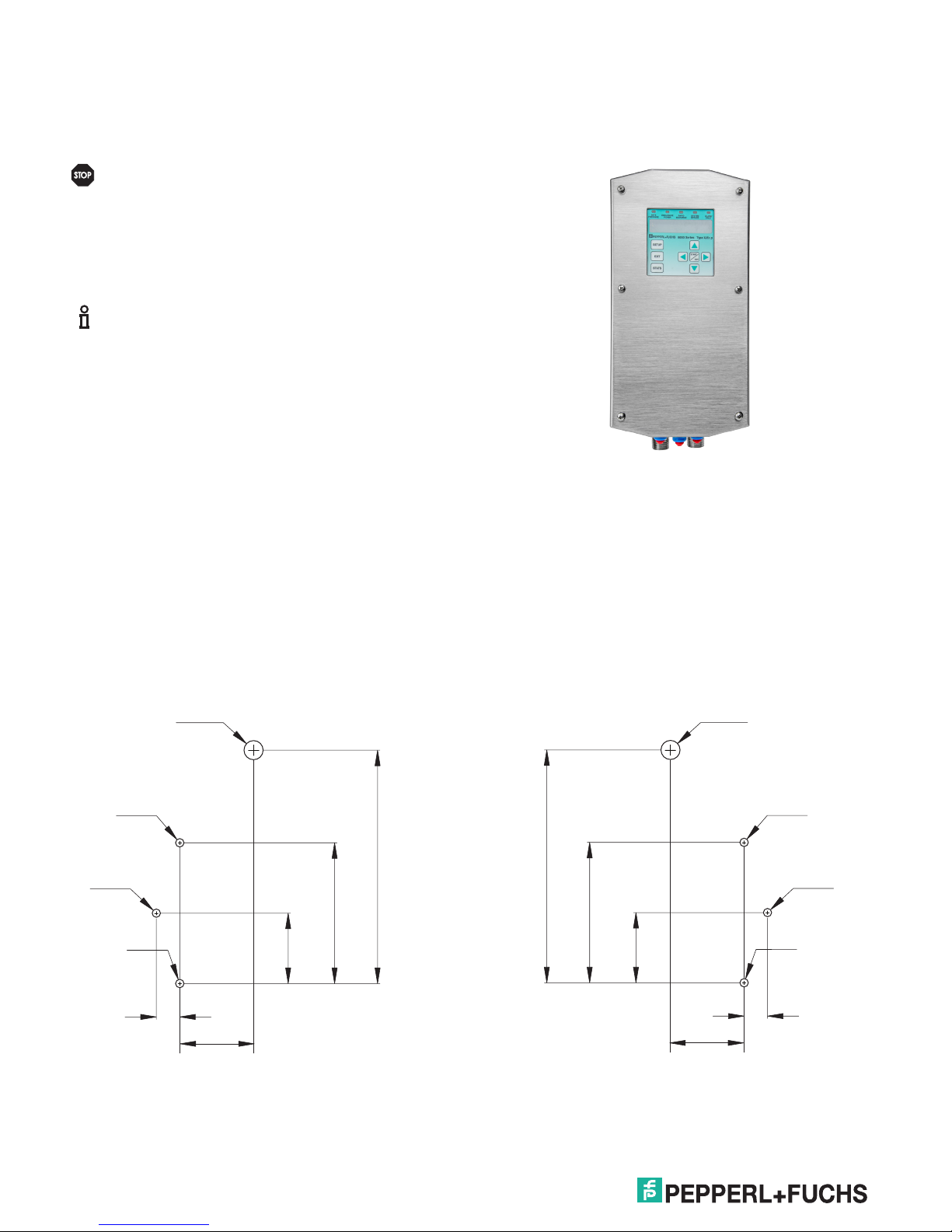

6000 Series Purge/Pressurization System

(2.5")

Warning

Tightening unit cover plate

The screws on the unit cover plate must be

tightened in the order shown on the diagram to

the right. The cover plate to the main housing

has positive stops so that the gasket is not over

tightened. Torque screws at 12 in-lb (1.36 Nm).

When rotating the UIC, torque down the 4 screws

at 4 in-lb (0.46 Nm) using a crisscross pattern.

Note

I/O Manual

45

1 2

63

Left-hand mounting template

ø15.5 mm

(.60")

ø 7. 0 mm

(.25")

ø 7. 0 mm

(.25")

ø 7. 0 mm

(.25")

19.0 mm

(.75")

60.0 mm

2.35"

Right-hand mounting template

ø 15.5 mm

(.60")

ø 7. 0 mm

(.25")

189.5 mm

(7.45")

(7.45")

114.5 mm

(4.50")

57.0 mm

(2.25")

189.5 mm

(4.50")

114.5 mm

(2.25")

57.0 mm

2.35"

60.0 mm

(2.5")

ø 7. 0 mm

(.25")

ø 7. 0 mm

(.25")

19.0 mm

(.75")

16

Page 21

6000 Series Purge/Pressurization System

Attention

Attention

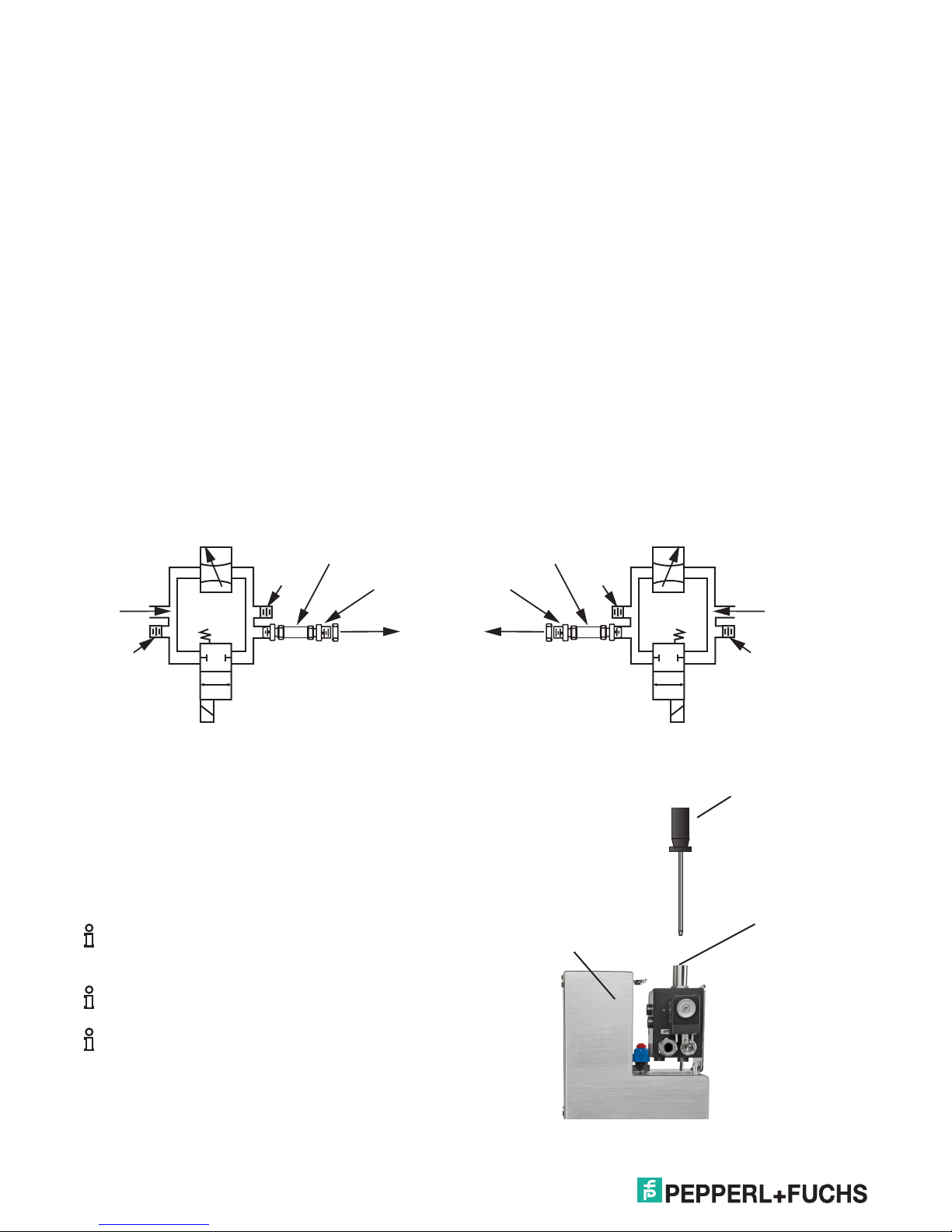

6000 Series component kit

Identication of components

I/O Manual

Optional pneumatic manifold

User interface (Included)

Cannot be mounted in a

hazardous dust environment.

with solenoid (Included)

EPV-6000 vent: required for 6000 control unit / component kit

Atmospheric reference kit (6000-ACC-514482)

for mounting vent inside the enclosure

EPV-6000

The EPV-6000 vent is required.

The reference kit comes with the EPV-6000-SS

vent but must be ordered when mounting the

EPV-6000-AA vent inside the enclosure.

Control unit and explosion-proof/

ameproof enclosure (Included)

6000 series component kit accessories

6000-DPE-01-xxx (Not Included)

Dust-proof enclosure to house the

6000-ISB-01 and 6000-TEMP-01 devices

6000-ISB-01 (Not Included)

DIN-mounted I.S. termination board.

See data sheet for specications

6000-CBLA-ISB-xxxt (Not Included)

Cable assembly for connection from the

6000 EPCU to the 6000-ISB-01. See

data sheet for specic lengths.

17

Page 22

6000 Series Purge/Pressurization System

Warning

Warning

Warning

Warning

Warning

Warning

Warning

Attention

Warning

Warning

I/O Manual

Electrical diagrams

General wiring notes for component kit design

For power connections to the control unit and relay

contacts:

1. All applicable local and national wiring codes

MUST be followed when wiring to the unit.

2. Protective earth wire to be 14 AWG (2.08 mm2).

Strip length of earth to mate with pigtail under

wire nut .437" to .5" (11.1mm to 12.7 mm).

3. If a single wire is used, the maximum wire gauge

to the pluggable terminal block is 14 AWG

(2.08mm2).

4. If jumpering from one terminal to another at

pluggable terminal block, the maximum wire

gauge is 16 AWG (1.31 mm2) for both wires.

5. Minimum wire gauge to the pluggable terminal

Attention

block is 24 AWG (0.20 mm2). (Based on

connector, not code. Follow all applicable codes.)

6. Strip length of wires terminating into the screw

terminals on the pluggable terminal block to be

0.2" to 0.27" (5 mm to 7 mm).

12. When removing the pluggable terminal block, it

is recommended that the electronics module be

supported by pressing down on top of the EPCU

to counteract the lifting force required to remove

the connector.

13. Wire should be copper only, rated 90 °C

minimum.

14. The minimum wire strand in a stranded wire

should have a diameter of 0.1 mm or greater.

15. The 6000-CC-3/4NPT plug is certied to be

used only with the 6000 control unit’s ¾” nipples

coming out of the housing. This plug is not

certied to be used on any other hazardous

location equipment.

16. Ensure that electrical, mechanical, and

pneumatic connections and requirements are

met to operate this system. Please refer to

this manual and applicable standards/codes,

including current editio9n of the EN/IEC 60079-

14. Electrical supply to the purge system shall be

supplied through a switch or circuit breaker and

suitably located and easily reached and must be

marked as the disconnect for the equipment.

7. Add extra wire length of 1.25" (31.75 mm) past

top of opening in explosion-proof/ameproof box

to pluggable terminal block. (Allows connector

to be moved out of the way when changing

electronics. Prevents repouring seals.)

8. Wires are to be neatly tucked back down past the

lid threads before lid is placed on unit. The wires

must not loop past the high point of the plastic

cover. The wire nut should be tucked in last (if

not, it may be difficult to access when changing

electronics).

9. If using a single conduit seal, the other conduit

on the 6000 control unit will need a cap for

the end of the conduit with appropriate hazloc

certications. (A standard 3/4" conduit cap will

not work.)

10. Conduit seals or the 6000-CC-3/4NPT plug must

be within 18" (457.2 mm) of internal explosionproof/ameproof box, or within 15.25" (387.3 mm)

from the end of the conduit supplied with the

6000 unit.

11. When wiring to the terminal plug, it is easier

to remove the plug, terminate the wires, then

reconnect the plug.

1 7. Power must be removed from the system when

the Ex d enclosure cover is off, unless the area is

known to be non-hazardous.

I.S. wiring notes

For wires going to the explosion-proof/ameproof

box on the I.S. side:

1. The wire strip length is to be between 0.2" and

Attention

0.27" (5 mm and 7 mm).

2. The wire's gauge depends on the number of

Attention

connections. Fewer wires allow for heavier

gauge and will still meet the conduit seal ll

requirement. See the applicable standards for ll

requirement.

3. The terminal blocks are rated for a wire size of

16 AWG (1.31 mm2 ) to 28 AWG (0.08 mm2 ).

4. If multiple wires need to land to a single terminal

(e.g., the RS-485 bus) these wires must be

either crimped to a single pin or grouped in an

external junction box with one wire going in to

the terminal.

5. The wires must have a minimum insulation

thickness of 0.01" (0.25 mm).

18

Page 23

6000 Series Purge/Pressurization System

Warning

Warning

6. Add extra wire length of 1.25" (31.75 mm) past

top of opening in explosion-proof/ameproof box

to pluggable terminal block. (Allows connector

to be moved out of the way when changing

electronics. Prevents repouring seals.)

7. Conduit seal on I.S. wiring side must be within

18" (457.2 mm) of the explosion-proof/ameproof

box.

8. Wire should be copper only, rated 90 °C

Attention

For wires going to the I.S. interface board in the

main housing or to the DIN-rail-mount I.S. board:

minimum.

9. The minimum wire strand in a stranded wire

should have a diameter of 0.1 mm or greater.

1. The wire strip length is to be between 0.16" and

0.24" (4 mm and 6 mm).

I/O Manual

2. The terminal blocks are rated for a wire size of

16 AWG (1.31 mm2) to 26 AWG (0.081 mm2)

3. The only terminals that might have multiple

connections are the shield connections.

These must be crimped to a single pin before

connection to the board.

4. If cables are used (recommended for

connections to the vents and UIC), it is

recommended that the cables be shielded.

5. The wires must have a minimum insulation

thickness of 0.01" (0.25 mm).

6. Wire should be copper only, rated 90 °C

Attention

minimum.

7. The minimum wire strand in a stranded wire

should have a diameter of 0.1 mm or greater.

WARNING – The 6000-ISB I.S. termination board

and 6000-TEMP are not certied to operate in

dust-hazardous locations. The 6000-DPE is a

dust-proof enclosure designed only to house

either or both the I.S. termination board and 6000

temperature hub. No other devices are allowed

in the enclosure. This does not apply to the 6000

control unit with housing, a complete unit.

19

Page 24

6000 Series Purge/Pressurization System

Note

Warning

Note

Warning

Enclosure

IS Solenoid

1

2

3

4

5

6

7

8

9

10

11

12

13

Electrical installation - power and I.S. wiring

GND

GND

GND

Temp

Module

(BN)

1

2

3

(BU)

4

5

6

7

8

9

(BK)

10

(WH)

11

12

13

1

Vent 1

2

Vent 2

3

(BU)

4

5

6

7

8

9

(BK)

10

(WH)

11

12

13

Power to

EPCU

Contacts

(2) N.O.

Aux

Output 1

(1) SPDT

Aux

Output 2

(1) SPDT

Prewired

L1

GND

N

IS PWR 1

IS PWR 2

IS PWR 3

GND

In 1

In 2

In GND

In 3

In 4

Com B

Com A

Val +

Val -

Connections from EPCU to eld devices

Connection of the 6000 EPCU to the 6000-ISB-01 DIN-mounted I.S. termination board.

Vents

(BN)

(BN)

I/O Manual

1

2

3

4

5

6

7

8

9

10

11

12

13

User

Inputs 1-4

1

2

3

4

5

6

7

8

9

10

11

12

13

Interface

(BN)

1

2

3

(BU)

4

5

6

7

8

9

(BK)

10

(WH)

11

12

13

BKBK I.S.PWR 1I.S.PWR 1

OROR I.S.PWR 2I.S.PWR 2

GNGN I.S.PWR 3I.S.PWR 3

WTWT GNDGND

BK/WTBK/WT In 1In 1

BL/WTBL/WT In 2In 2

RD/WTRD/WT In GNDIn GND

GN/WTGN/WT In 3In 3

OR/BKOR/BK In 4In 4

BLBL Com BCom B

RDRD Com ACom A

WT/BKWT/BK Val +Val +

RD/BKRD/BK Val -Val -

I.S. Te rmination board connectorEPCU I.S. connector

Valve

1

2

3

4

5

6

7

8

9

10

11

(BN)

12

(BU)

13

Requires standard explosion-proof seals to

explosion-proof/ameproof enclosure at a

maximum distance of 18" (457.2 mm).

When removing the terminal block from the

EPCU stack, place your hand on top of the

plastic to support the stack when lifting the

terminal block.

20

The maximum distance between the control

unit and the termination board is 3 meters.

6000-ISB-… must be installed within an IP20

enclosure. See “conditions of safe use” when

mounting in a dust environment.

Page 25

6000 Series Purge/Pressurization System

Note

Warning

Warning

Note

Component kit installation

User interface

Panel mount (internal mount, for hazardous

area installation, NOT to be used in

Dust, Class II/Zone 21 areas)

Cutout

3.40" x 3.40"

86 mm x 86 mm

Gasket (provided)

User interface

(provided)

I/O Manual

Customer's

enclosure

Mounting bracket

Use a crisscross pattern to tighten the

screws for the UIC bracket. Tighten bolts

3 to 4 in-lb (0.4 Nm). For a good seal,

ensure that the bracket bottoms out on

the enclosure.

Mount the explosion-proof enclosure and valve as

desired. Follow all applicable electrical codes when

required.

When installing panel mount conguration, the

installation must be evaluated for Type 4x rating

by a third party NRTL authorized

certication agency.

1" #6-32 standoff

Enclosure must be made of metal and grounded.

Cutout must be no larger than dimensions

specied in above drawing.

The user interface must be mounted inside the

pressurized enclosure to maintain the

Note

environmental ratings.

21

Page 26

6000 Series Purge/Pressurization System

83.0 mm

I/O Manual

User Interface mounting template (panel mount)

53.5 mm

(2.10'')

86.5 mm

(3.40'')

16.5 mm

(0.65'')

4 x

ø 3.5 mm (0.15'')

(0.95'')

24.5 mm

(3.40'')

86.5 mm

(0.95'')

24.5 mm

16.5 mm

(0.65'')

User interface mounting template (external mount)

User

interface

(reference)

(3.25'')

ø4.5 mm (0.15'')

mounting

hole

ø4.5 mm (0.15'')

mounting

hole

51.5 mm (2.05'')

41.5 mm

(1.65'')

ø16.0 mm (0.65'')

connector

clearance

EPCU mounting template

(3.40'')

86.0 mm

(6.75'')

171.5 mm

120.5 mm

(4.75'')

C

L

60.5 mm

(2.40'')

Solenoid mounting template

22.0 mm

(0.85")

38.0 mm

(1.50")

38.0 mm

(1.50")

30.0 mm

(1.20")

10.5 mm

(0.40")

(0.50")

12.5 mm

(1.50")

38.0 mm

19.0 mm

(0.75")

(0.85")

22.0 mm

(0.85")

22.0 mm

(0.80")

20.5 mm

(2.10")

53.5 mm

22

Page 27

6000 Series Purge/Pressurization System

Sequence of events

Turning on power to the enclosure

Door open

input off or

not used

No door

open

I/O Manual

Immediate

shutdown

input off or

not used

Overload/temp

input off or

not used

No immediate

shutdown

No

overload/temp

Vent pressure

>

minimum overpressure

<

maximum pressure

Vent flow

>

flow rate

Good vent

communications

No system

fault

Purge

settings

not changed

progress

Purge

Lock 1

on or

unused

Purge

in

timer

Enable

timer

Timer = 0

Control

power

relay

Lock 2

on or

unused

Door

secure

T

u

r

n

p

o

w

e

r

o

n

Aux relay 1

lock door

Aux relay 1

energized

Aux relay 2

lock door

Aux relay 2

energized

23

Page 28

6000 Series Purge/Pressurization System

Turning off power to the enclosure

Control power

relay input

broken/shorted

Control power

relay input

off

Door open

input

broken/shorted

Door open

input on

I/O Manual

Control

power

relay

Door

open

Overload/temp

input

broken/shorted

Overload/temp

input on

Vent pressure

<

safe pressure

Lost vent

communications

Overload/

temp

Unsafe

pressure

System

fault

Immediate shutdown

input

broken/shorted

Immediate shutdown

input on

Shutdown

timer

Volume

changed

Number of

exchanges

changed

Environment

changed

Timer = 0

Immediate

shutdown

Bypass

is

off

Purge

settings

changed

No bypass

T

u

r

n

p

o

w

e

r

o

f

f

24

Flow rate

changed

Page 29

6000 Series Purge/Pressurization System

Note

I/O Manual

Operation of the 6000 series and component

kit

Operation

The 6000 series consists of the control unit and user

interface mounted in a 316L (UNS S31603) stainless

steel Type 4X (IP66) enclosure with the pneumatic

solenoid valve mounted on the unit. The EPV-6000 series

relief vent is separate and is mounted to the enclosure.

The 6000 series control unit is also available as a kit. The

kit consists of the key components of the system, the

control unit, and the user interface. It does not include

the enclosure. The manifold is an optional item. The

user interface includes a panel-mount bracket so that it

can be panel mounted to the customer’s enclosure. The

pneumatic valve for the protective gas can be supplied by

the customer. The EPV-6000 relief vent is still required.

The components of the 6000 series control unit, with

'-WH-' housing, are listed below:

• EPCU mounted in an explosion-proof/ameproof

enclosure

• I.S. user interface with display and cable

• I.S. termination board (not included with "CK" kit

version)

• Manifold with I.S. solenoid valve (not included with

"CK" kit version)

• Flush mount Type 4X IP66 tting for protective gas

supply to enclosure with tube attached

• Type 4X cable glands for I.S. wiring to I.S. inputs,

vents, and temperature modules

• 3/4" pipe nipples for power wires

The components of the 6000 series component kit are

listed below:

• Control unit and explosion-proof/ameproof

enclosure

• 6000-UIC-01 user interface

• SMK-600-CK mounting hardware for 6000-UIC-01

• One 5m (16.5 ft.) quick disconnect cable for 6000UIC-01

• 6000-MAN-DV-01 pneumatic manifold w/ solenoid

(optional)

• EFC-6-SS ush mount connector

The 6000 series control unit and vent can be universally

mounted to the customer's enclosure. Top, bottom, right-,

or left-side mounting can be completed with only one

control unit and vent. Mounting conguration does not

need to be designated when ordering. One unit is used

for enclosure sizes up to 450 ft3 (12.7 m3).

Optional accessories are available to make the

component kit easier to install. The 6000-ISB-01 I.S.

DIN-mounted termination board and 6000-CBLA-ISB-xxx

cable harness allow easy connection to the EPCU of the

control unit.

Electronic power control unit – EPCU

The EPCU houses the redundant microprocessors,

enclosure power contacts, (2) auxiliary contacts, power

supply module, galvanically isolated barriers for the

inputs, vent(s), and temperature modules. The EPCU

is easy to remove and install into the explosion-proof

enclosure that houses it.

• 316L (UNS S31603) stainless steel Type 4X

enclosure for the 6000 series controller. (Not

included with the component kit.)

The components of the EPV-6000 vent:

• EPV-6000 vent with stainless steel spark arrestor

screen

• 1½" lock nut with grounding lug and gasket for

attachment of vent to customer’s enclosure

• One 5m (16.4 ft.) quick disconnect cable; for

connection to I.S. termination board inside 6000

series control unit.

If ordering a stainless steel vent, an atmospheric

reference kit is included for internal mount.

The EPCU is available in 20 ... 30 VDC or

100...250 VAC units. The enclosure power contacts are

force-guided safety relays. The auxiliary contacts can be

user congured for different functions, depending on user

requirements.

User interface controller – UIC

The 6000 series is user programmable for many of the

congurable options available. This is done with the

intrinsically safe user interface on the face of the unit,

which can also be remote mounted. The user interface

contains a 2 x 20 LCD that allows programming through

a set of buttons on the menu-driven unit. All conguration

and options are programmed through this unit. There are

also (5) LEDs for easy visual indication of operation:

• Safe pressure – This turns on (blue) when safe

pressure is achieved inside the enclosure.

25

Page 30

6000 Series Purge/Pressurization System

Note

Note

I/O Manual

• Enclosure power – This is (red) when the

enclosure power is off, and (green) when

enclosure power is on. The enclosure power can

be on only after a successful purge and a safe

pressure is achieved. The bypass option allows

power to remain on if safe pressure is lost.

• Rapid Exchange® – The rapid exchange or purging

ow rate turns on (blue) when the ow rate is

measuring proper ow.

• System bypass – This turns on (yellow) when the

system bypass is active. This should be used only

when the area around the enclosure is known to

be safe.

• Alarm fault – The (red) LED blinks when any alarm

input is detected and is solid when there is an

internal system fault.

Pneumatic manifold with I.S. solenoid

• Manifold with I.S. solenoid valve: The manifold

system is mounted on the 6000 control unit

providing a needle valve to set enclosure pressure

and an I.S. solenoid valve that is used for purging

(Rapid Exchange). Power for the I.S. solenoid

valve is provided by the EPCU and is galvanically

isolated. Regulated instrument-grade air or

nitrogen is required.

rate measurement from the EPV-6000 vent is 7 SCFM

(198l/m), the EPCU will use 5 SCFM (141l/m) as the

ow rate for evaluation. The ow rate measurement steps

and corresponding enclosure pressures are as follows:

EPV-6000-XX-01, 02

5 SCFM @ 1.5” wc, (141 l/min @ 3.7 mbar)

12 SCFM @ 2.0” wc, (340 l/min @ 5.0 mbar)

20 SCFM @ 2.7” wc, (565 l/min @ 6.7 mbar)

30 SCFM @ 4.1” wc, (850 l/min @ 10.2 mbar)

EPV-6000-XX-03, 04

5 SCFM @ 2.1” wc, (141 l/min @ 5.2 mbar)

12 SCFM @ 2.6” wc, (340 l/min @ 6.5 mbar)

20 SCFM @ 4.1” wc, (565 l/min @ 10.2 mbar)

30 SCFM @ 5.3” wc, (850 l/min @ 13.2 mbar)

EPV-6000-XX-05, 06

5 SCFM @ 1.5” wc, (141 l/min @ 4.5 mbar)

12 SCFM @ 2.9” wc, (340 l/min @ 7.3 mbar)

The following parameters must be entered for

the purge time:

• Enclosure volume

• Number of exchanges.

Minimum purge time is 2 min

The 6000 series unit can be ordered without the manifold

so that customers can use their own method or valves

for purging and pressurization. If a third-party electronic

valve is used, the valve must be certied and installed in

accordance with the hazardous location where the unit is

operating. The use of the 6000 series manifold unit allows

easy and correct installation of the system.

Requirements for purging/pressurization

Certications allow the 6000 series to be used on

enclosures in gas, dust, or both gas and dust hazardous

atmospheres. Gas atmospheres require the purging of

the enclosure. Dust atmospheres require the physical

removal of all the dust that collects inside. Both gas and

dust atmospheres require the following: 1) removing the

dust, 2) sealing the enclosure, and then 3) purging the

enclosure.

After these sequences, the pressure within the enclosure

is above the minimum level. The equipment within the

enclosure can then be energized.

Purge timing

When using the 6000 series in a gas or gas and dust

location, the time for purging an enclosure can be based

either on a known purge rate and time (xed purge

time), or based on the ow rate being measured from

the vent (dynamic purge time). Both methods base the

time on the ow measurement at the vent, and complete

the process in steps. The EPCU will take the readings

from the vent and use the appropriate reading (listed

below) as the usable ow rate. For example, if the ow

Fixed purge time

If the purge time must be held to a specic time, then this

time is based on the known enclosure volume, number

of volume exchanges, and ow rate through the vent.

If the ow rate is below the required minimum, then the

purging cycle will reset and will not start until the ow

rate is above the selected rate. This setup does not

allow purge ow to go below the value required and will

not recalculate the time for purging if it goes above the

required purge rate. This measurement method is the

same type as was used in our previous system, the 4000

series. The actual time is calculated by the EPCU.

Dynamic purge time

Dynamic purge time allows the purge time to be updated

based on the purge ow through the vent. This method is

not dependent on a constant ow from the protective gas

source. It bases the purge time on the measured ow and

not a set ow. This is very useful when the protective gas

supply pressure varies throughout the purging cycle or

when it may vary from one installation to another.

The purge time will be based on the measurement of

the vent and evaluation of this measurement from the

EPCU. This allows recalculation of the time based on

this measurement. During the dynamic purge time, the

user interface will display the purge time in a percentage

starting with 0% and ending with 100% (purge time

complete).

26

Page 31

6000 Series Purge/Pressurization System

Note

Note

Note

I/O Manual

Purging modes

Purging start-up can be set in 3 different modes:

• STD – Standard mode requires the operator to

engage the manifold solenoid valve manually

when purging and manually disengage when a

successful purging is complete.

• SA – Semi-automatic mode requires the operator

to engage the manifold solenoid valve manually

when purging. The EPCU will automatically

disengage when a successful purging is complete.

• FA – Fully-automatic mode will automatically

engage the manifold solenoid valve when safe

pressure is detected and will automatically

disengage when a successful purging is complete.

This is the factory default setting.

The minimum purge time is 1 minute.

During the purging cycle, when the enclosure

pressure reaches 0.25" wc [(6.4 mm wc),

(0.625 mbar), (62 pa)] or higher, there will be

a 5 second delay before the rapid exchange

solenoid valve is activated. If the ow is enough

through the vent to satisfy the required ow rate

setting, then the timer will begin after 1 min.

The update of the timer is in increments of 1 min

in the Fixed Purge Time and % completed in the

Dynamic Purge Time.

Pressure as Input

In the programming menu under "INPUT SETTINGS"

for the optional pressure control. The pressure control is

achieved within the enclosure by opening and closing a

digital valve or manifold on the 6000 control unit. These

two internal pressure set points can be controlled by the

manifold or an outside source for pressure. The pressure

function can manage the control outputs 1 or 2, or the

control valve (manifold valve).

• The "ON PRESSURE" is the lowest pressure you

want in the enclosure and will start the control

action on when pressure goes below this value.

• The "OFF PRESSURE" is when the valve shuts

off. When the pressure is between these two

values, nothing will happen.

• The "ON PRESSURE" function is active until the

"OFF PRESSURE" is reached

This function does not operate during purging

cycle and only operates after purging and

pressurization.

The "ON PRESSURE" always has to be lower

than the "OFF PRESSURE". This cannot

be reversed.

PRESSURE AS INPUT

on

Control action

time

off

Control action

OFF PRESS

Set PRESS

ON PRESS

off

Control action

I.S. Inputs 1 - 4

There are (4) intrinsically safe inputs for activation

of various outputs and actions by the EPCU. These

inputs only accept a dry contact for activation and are

supplied by the EPCU’s galvanically isolated barrier. The

congurations of the inputs for various actions are done

through the user-interface controller. Only one function

can operate per input. The intrinsically safe inputs can

be congured through the UIC to activate the auxiliary

relays, energize the Rapid Exchange valve, de-energize

the enclosure contacts, and shut the system down, as

well as other actions and outputs. To monitor wiring, the

SRM-6000 (sensor resistor module, not required, ordered

separately) can be added to detect shorts or breaks in

the inputs' wiring to the contacts.

Outputs

Enclosure 1 and Enclosure 2

There are (2) normally open dry contacts for the

enclosure power that can be energized only after a

successful purging and a minimum enclosure pressure

is maintained. Loss of pressure will cause the contacts

to de-energize unless the shutdown timer is activated or

bypass mode is implemented. These contacts operate

simultaneously.

Auxiliary 1 and Auxiliary 2

Also available are the Auxiliary 1 and Auxiliary 2 SPDT

dry contact outputs. The auxiliary outputs are user

congurable using the user-interface controller and can

control various inputs or various conditions such as low

pressure, loss of pressure, bypass implemented, rapid

exchange valve on, enclosure above maximum pressure

setting, etc. Both enclosure contacts and auxiliary

contacts are forced-guided safety relays for functional

safety.

27

Page 32

6000 Series Purge/Pressurization System

Warning

Warning

Note

Note

Note

I/O Manual

Do not use auxiliary contact for power to

enclosure(s).

If powering auxiliary equipment with

auxiliary1 or auxiliary2 outputs, the wiring

methods used must be suitable for the

hazardous area.

Temperature Inputs

The 6000-TEMP-01 temperature hub and 6000-TSEN-01

external temperature sensor(s) are designed to work only

with the 6000 purge and pressurization system.

An averaging or maximum temperature input reading

from the sensor(s) is used to control a solenoid valve or

activate the auxiliary relay to cool or heat the enclosure,

or warn of temperature problems.

In the programming menu, under "SENSOR SETUP",

"EXT SENSOR COUNT", you can congure up to 3

sensors per temperature hub. Each temperature hub has

one embedded temperature sensor. In the programming

menu under "INPUT SETTINGS" you will select the

"HUB". This must be selected if you want to include the

hub as a sensor input.

You may not want to include the temperature as

an input if the sensor is not located near the

device or process you are tracking the

temperature of.

Once a "CONTROL ACTION" is selected, then select

"SETPOINT TYPE" for the "AVERAGE" or "SINGLE PT".

If using more than one (1) sensor, you may want

the control action to occur during the peak or

average temperature of the sensors.

"ON SET POINT" and "OFF SET POINT" are the

temperatures for the control action.

The "ON SET POINT" can be greater than the

"OFF SET POINT"

TEMPERATURE INPUT

on

Control action

time

off

Control action

MAX

Temperature

MIN

off

Control action

High Temperature Control

EPV-6000 I.S. relief vent

The EPV-6000 vent exhausts excess pressure from the

enclosure when the enclosure pressure exceeds the

breaking pressure of the vents relief mechanism. This

pressure and ow is measured during operation. The

6000 series vent has a pressure transducer and thermal

ow sensor that is connected to the 6000 EPCU and is

intrinsically safe through the galvanic isolation barrier

within the EPCU. The measurement of the ow is always

at the exhaust of the pressurized enclosure; therefore,

the vent is located on the enclosure(s) such that it is

venting to the atmosphere.

When using the complete 6000 series system, the

vent is connected to the I.S. termination board using

the M12 (V1) connector and cable that come with the

vent. If using the 6000 series component kit, the vent is