Page 1

Section 11—Focal-Plane Shutters

ou've seen that the blade-type shutter sits behind the

lens or between lens elements. By contrast, the focal-

Y

plane shutter sits just in front of the camera's film aperture.

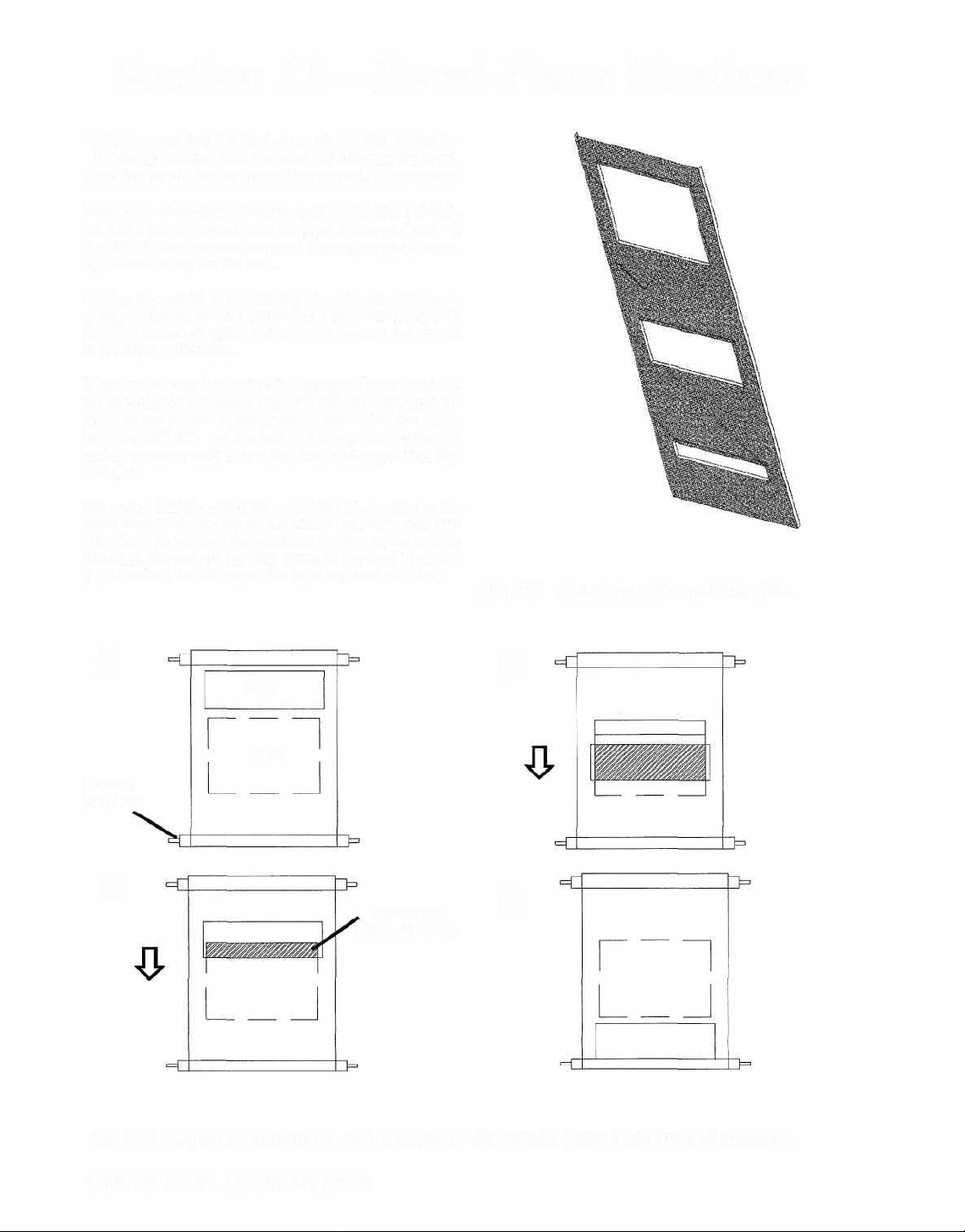

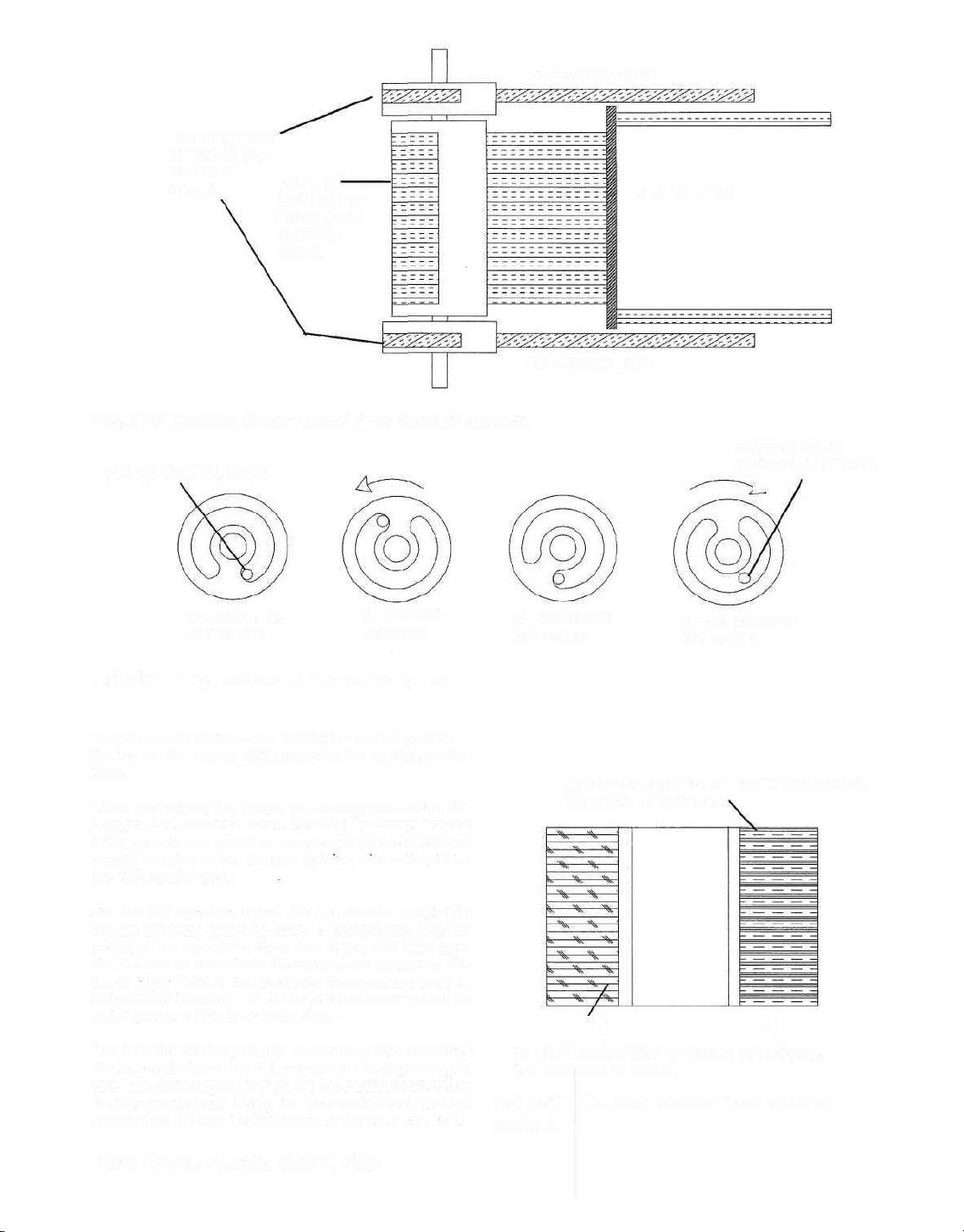

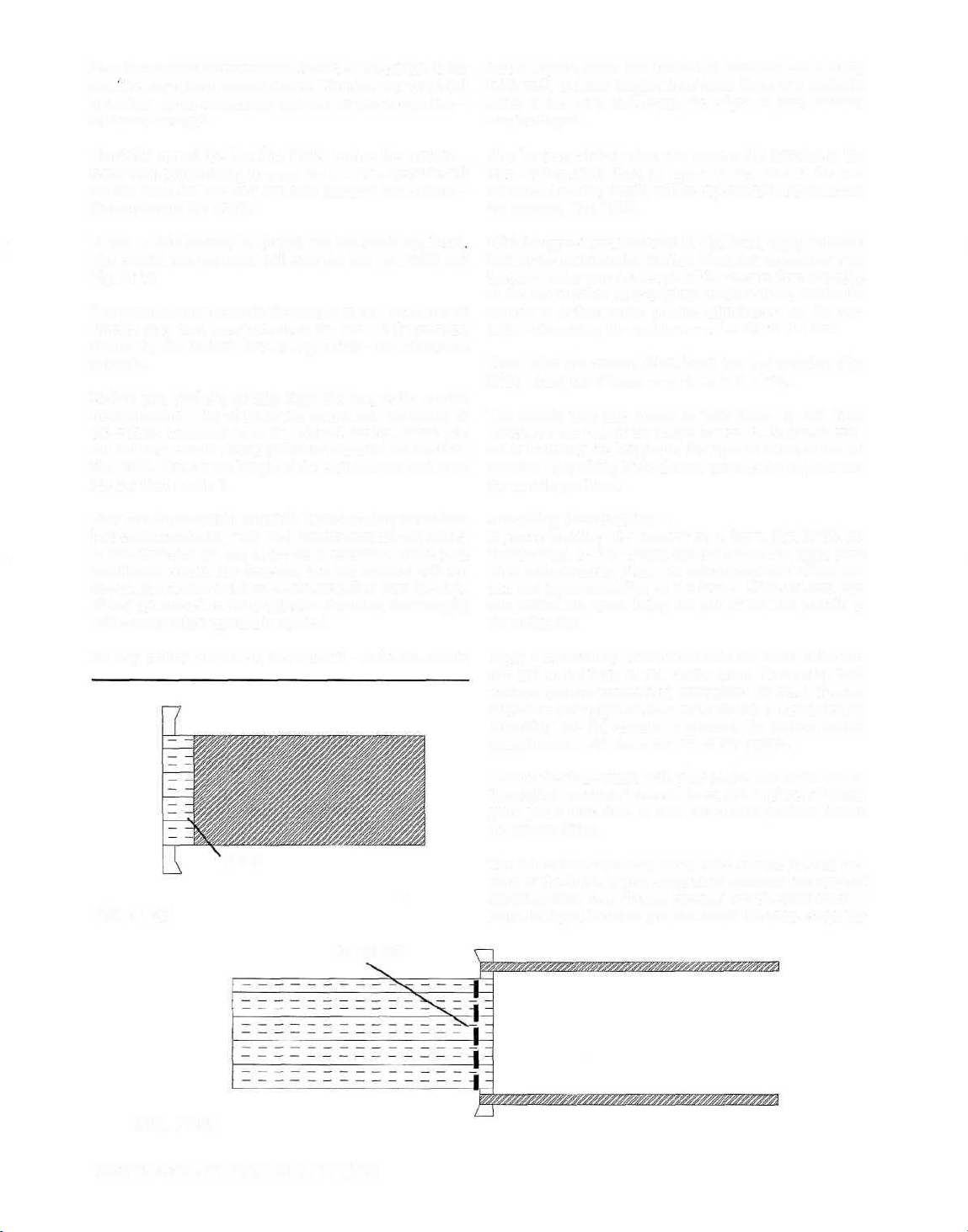

Some early focal-plane designs, such as the Speed Graph-

ics, use a single curtain with multiple openings ("slits" ),

Fig. FP1. Selecting a shutter speed determines which opening is used to expose the film.

Moving the curtain in the cocking direction also tensions a

spring—a spring located within the lower roller, Fig. FP2

(A). The tensioned spring is now ready to draw the curtain

in the release direction.

When you release the shutter, the spring pulls the curtain in

the direction of the arrow, Fig. FP2 (B). The film gets exposed as the curtain opening moves across the film opening, Fig. FP2 (C). At the end of the exposure cycle, the

curtain opening rests below the focal-plane aperture, Fig.

FP2 (D).

But notice that the entire frame doesn't get exposed at the

same time. First the top of the film is exposed, Fig. FP2

(D). Then, as the curtain continues moving in the release

direction, the rest of the film frame is exposed, Fig. FP2

(C). In effect, the slit wipes the exposure onto the film.

Fig. FP1 A curtain with multiple slits.

A

SLIT

FILM

LOWER

ROLLER

c

B

EXPOSED

AREA OF FILM

Fig. FP2 Exposure sequence with a multiple-slit curtain (view from front of camera).

D

108/FOCAL-PLANE SHUTTERS

Page 2

Two factors determine the actual exposure time (shutter

speed):

TAPE

1. the width of the opening used to expose the film

2. the speed at which the curtain travels.

For the slowest shutter speed, the curtain opening is as large

as the focal-plane aperture—the top slit in Fig. FPL As the

curtain moves in the release direction, the film is completely

uncovered—now the entire film frame sees the maximum

amount of light. But the curtain continues moving in the

release direction until it completely recovers the film.

As the curtain recovers the film, the top of the film frame

gets cut off first. The bottom of the film frame continues to

see light until the curtain opening moves below the aperture.

The fastest shutter-speed setting uses the smallest open-

ing—the bottom slit in Fig. FP1. Here, only a small section

of film sees light at a given moment.

Selecting a smaller slit decreases the amount of time that

any given film section receives light. Similarly, moving the

curtain at a faster speed decreases the length of time that

the film sees light. Either or both techniques may then be

used to provide different shutter speeds—providing differ-

ent curtain openings or changing the speed at which the

curtain travels.

The way most focal-plane shutters vary the exposure is by

changing the size of the curtain opening. Very few cameras

change the exposure time by speeding up or slowing down

the curtain. Varying the curtain-travel time (curtain speed)

requires changing the tension on the spring—the spring that

draws the curtain in the release direction.

1st CURTAIN

BAR

2nd CURTAIN

TENSION ROLLER

FIG. FP3 Curtains in a two-curtain focalplane shutter.

1st CURTAIN

A—CURTAINS IN RELEASED POSITION (BACK)

COCKING DIRECTION

1st CURTAIN

COVERS FILM

2nd CURTAIN COVERING FILM

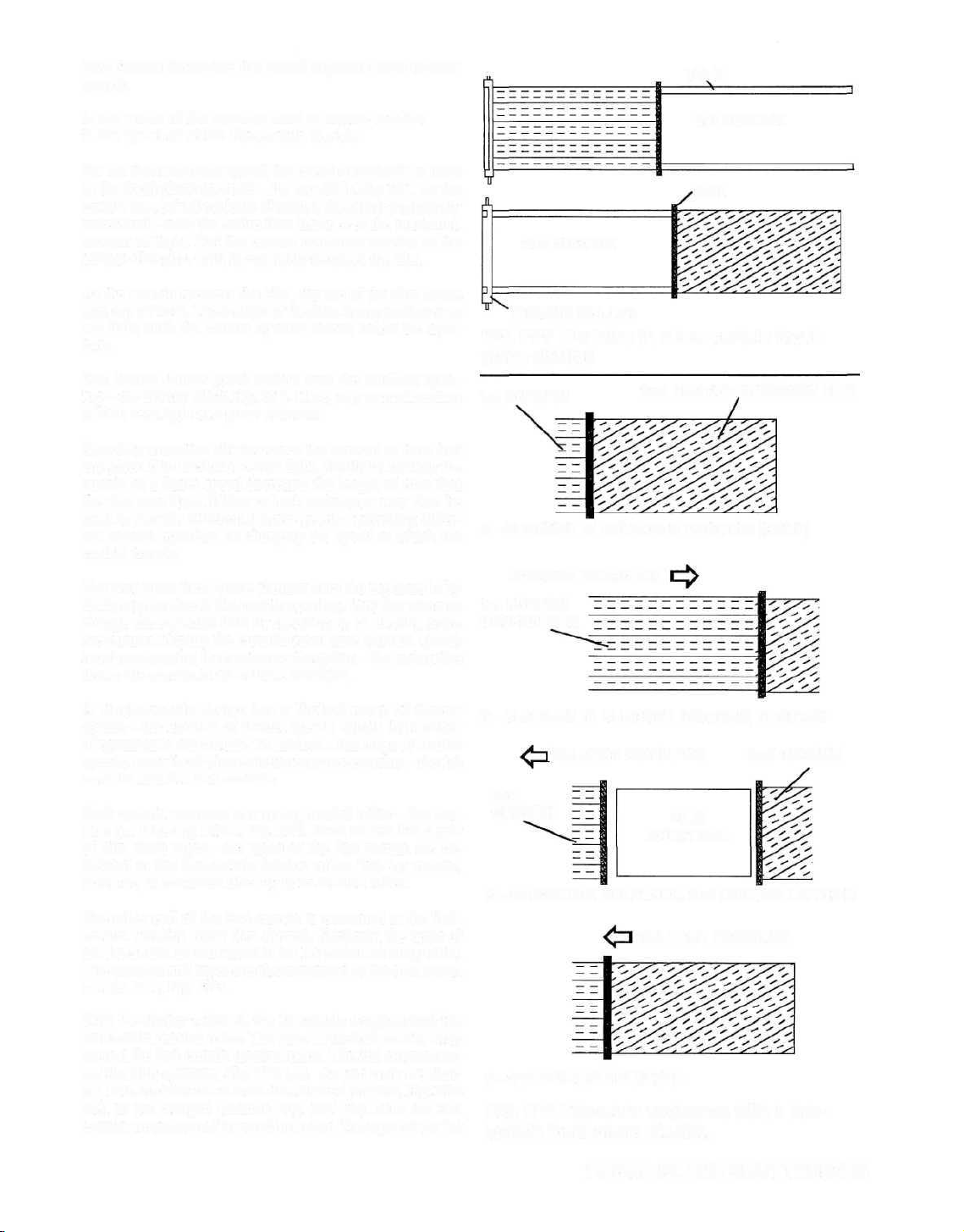

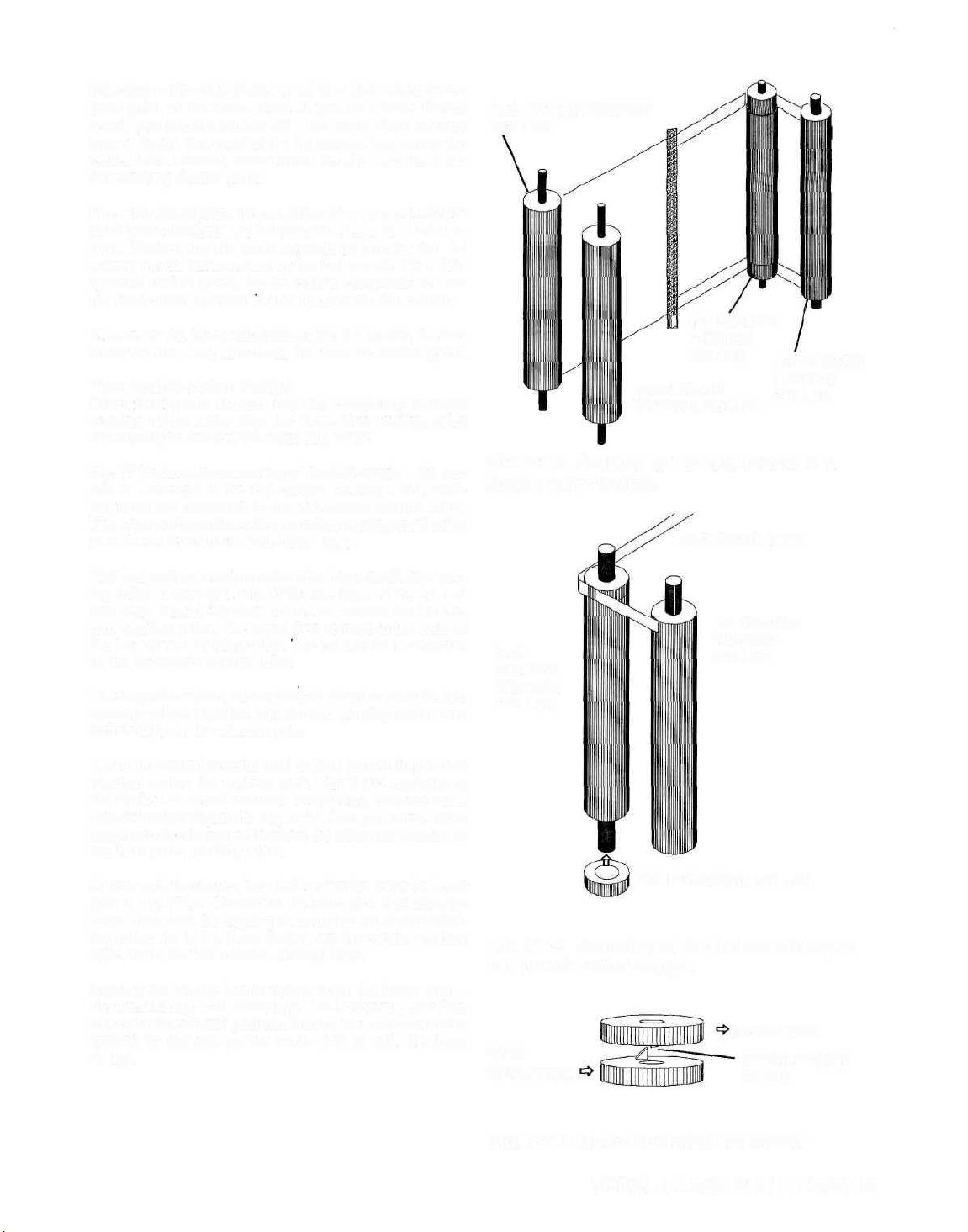

A single-curtain design has a limited range of shutter

speeds—the number of shutter speeds equals the number

of openings in the curtain. To achieve a full range of shutter

speeds, most focal-plane shutters use two curtains—the 1st

curtain and the 2nd curtain.

Each curtain connects to a spring-loaded roller—the ten-

sion (or take-up) roller, Fig. FP3. Each curtain has a pair

of thin cloth tapes—the tapes of the 2nd curtain are ce-

mented to the 2nd-curtain tension roller. The 1st curtain,

however, is cemented directly to its tension roller.

The other end of the 2nd-curtain is cemented to the 2nd-

curtain winding roller (not shown). Similarly, the tapes of

the 1st curtain are cemented to the lst-curtain winding roller.

The curtains and tapes are also cemented to the thin, metal

curtain bars, Fig. FP3.

With the shutter released, the 1st curtain wraps around the

1st-curtain tension roller. The tapes of the 2nd curtain wrap

around the 2nd-curtain tension roller. The 2nd curtain covers the film aperture, Fig. FP4 (A). As you cock toe shutter, both curtains move from the released position, Fig. FP4

(A), to the charged position, Fig. FP4 (B). Now the 2nd

curtain wraps around its winding roller. The tapes of the 1st

B—CURTAINS IN CHARGED (COCKED) POSITION

| RELEASE DIRECTION

1st

CURTAIN

C—1st CURTAIN RELEASED, 2nd CURTAIN LATCHED

d—2nd CURTAIN RELEASED

FILM

APERTURE

RELEASE DIRECTION

2nd CURTAIN

FIG. FP4 Exposure sequence with a twocurtain focal-plane shutter.

FOCAL-PLANE SHUTTERS/109

Page 3

curtain wrap around the lst-curtain winding roller. Notice

that the curtains overlap one another during the cocking

movement. This curtain overlap prevents light from reach-

ing the film.

Now, with the shutter charged, the 1st curtain covers the

film aperture. The springs insided the tension rollers have

been tensioned—both springs want to pull their respective

curtains in the release direction. But each curtain is now

latched—the 1st-curtain latch holds the 1st curtain, and the

2nd-curtain latch holds the 2nd curtain. The latches prevent the springs from pulling the curtains in the release

direction.

RELEASE

DIRECTION

1st CURTAIN

FILM APERTURE

2nd CURTAIN

Releasing the shutter disengages the lst-curtain latch. Now

the 1st curtain moves across the aperture in the release direction, Fig. FP4 (C). Since the 2nd curtain remains latched

by the 2nd-curtain latch, the shutter opens—the film sees

light as the 1st curtain moves.

The right-hand edge of the film in Fig. FP4 (C) sees light

first, The film then gets progressively uncovered as the 1st

curtain moves. Finally, the 1st curtain reaches the other side

of the aperture, completely uncovering the film.

Next the speed-control mechanism of the camera disengages

the 2nd-curtain latch. Now the 2nd curtain moves across

the aperture. The 2nd curtain progressively covers the film,

ending the exposure to each part of the film in turn. Finally,

the 2nd curtain reaches the end of its travel at the other side

of the aperture, Fig. FP4 (D).

The sequence we've just described is called the full-aper-

ture shutter speed—the 2nd curtain is released when the 1st

curtain reaches the closing side of the aperture. For a moinenl, the entire film frame receives light. The full-aperture

shutter speed depends on how fast the curtains travel and

the exact moment that the 2nd curtain is released. In the

classics and antiques, the full-aperture shutter speed is typically around 1/30 to 1/60 second.

For a faster shutter speed, the speed-control mechanism

releases the 2nd curtain before the 1st curtain reaches the

end of the aperture. Consider that the 2nd curtain releases

when the 1st curtain reaches the position shown in Fig. FP5.

The 1st curtain is then still in the aperture—still partially

covering the film—when the 2nd curtain starts its release

movement.

As a result, a slit formed between the two curtains moves

across the film, Fig. FP6. The sooner the 2nd curtain is

released, the narrower this slit becomes—and, as a result,

the faster the shutter speed.

At the fastest shutter-speed setting, the 1st curtain just starts

to move when the 2nd curtain releases. A very narrow slit

then moves across the film. The shutter speed depends on

the actual slit width and the speed that the curtains travel.

Changing the slit width can provide a wide range of shutter

speeds. The classic cameras may provide speeds of 1/60

second (the full-aperture speed), 1/125 second, 1/250 sec-

FIG. FP5 1st curtain released, 2nd curtain

latched.

SLIT

FIG. FP6 Both curtains released and

traveling across film.

ond, and 1/500 second (or 1/1000 second) just by

changing the release point of the 2nd curtain. Modern cameras rely on the same principle to provide

shutter speeds as fast as 1/8000 second.

The two-curtain design also allows shutter speeds slower

than the full-aperture speed. Here, the 1st curtain completely

uncovers the film aperture—just as with the full-aperture

speed. A mechanical speeds governor—similar to the speeds

governor in blade-type shutters—then delays the release of

the 2nd curtain. As a result, the film aperture remains completely uncovered for the length of the exposure time.

With a mechanical speeds governor, the slowest shutter

speed is typically 1 second. The camera may provide shutter speeds of 1/2 second, 1/4 second, 1/15 second, and 1/30

second just by changing the engagement of the speeds governor. Modern cameras again rely on the same principle.

But the electronic controls of today may provide even longer

exposure times—perhaps 30 full seconds.

110/FOCAL-PLANE SHUTTERS

Page 4

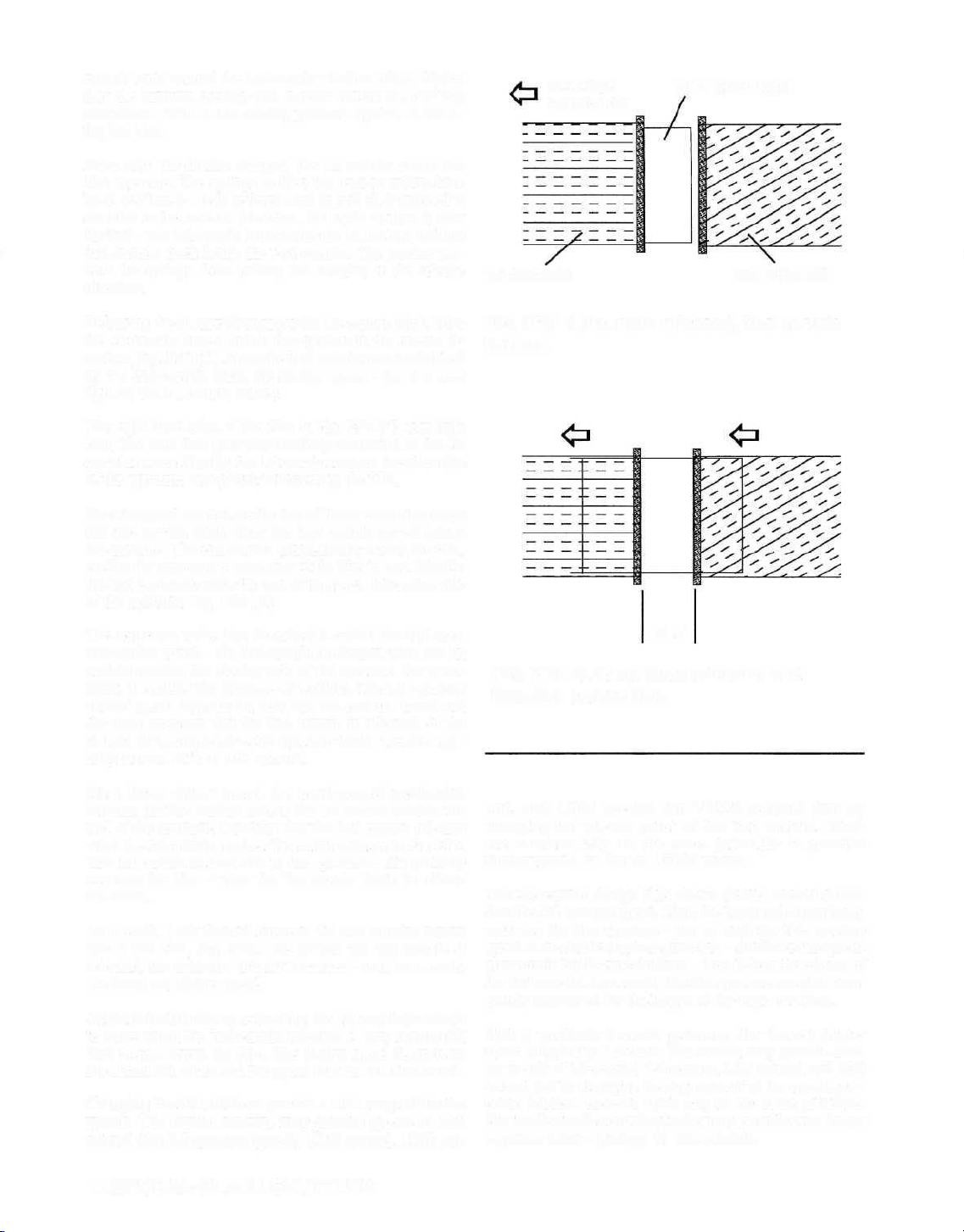

THE CURTAIN ROLLERS

ach curtain has its own spring-loaded tension roller—

when the curtain is released, its tension roller pulls it to

E

the released position. Each curtain also has its own winding roller to draw the curtain to the cocked position.

The drum design

Some focal-plane shutters combine the two winding rollers

into a single curtain drum, Fig. FP7. The classic screwmount and M-series Leicas use the curtain drum. Another

classic—the Nikon F—also uses the drum.

The center section of the curtain drum, Fig. FP7, turns independently of the end sections. But the end sections turn

together as one unit.

Fig. FF8 shows the construction of the drum. A shaft joins

the two end sections. But the center section can rotate freely

around the shaft.

One curtain—the 2nd curtain—is cemented to the center

section of the curtain drum, Fig. FP9. The tapes of the 2nd

curtain then cement to the 2nd-curtain tension roller.

The tapes of the 1st curtain are cemented to the end sec-

tions of the curtain drum, Fig. FP9. The 1st curtain is then

cemented to the lst-curtain tension roller.

Note that the two end sections of the drum are slightly larger

in diameter than the center section, Fig, FP9. The larger

diameter of the end sections provides a slight separation

between the curtains.

END

SECTIONS

FIG. FP7The curtain drum.

CENTER (2nd-CURTAIN)

DRUM

CENTER

SECTION

As you cock the shutter, the curtain drum rotates as a unit—

the center section is locked to the end sections. The 2nd

curtain wraps around the center section of the drum. At the

same lime, the tapes of the 1 st curtain wrap around the end

sections of the drum. As the drum rotates, it draws both

curtains to the cocked position—against the tension of the

tension rollers.

Fig. FP10 shows how the two sections of the drum are locked

together during the charge cycle. Note the pin on top of the

center drum, Fig. FP8. The pin passes through a cutout in

the top section of the lst-curtain drum, Fig. FP10.

As you cock the shutter, the cocking mechanism turns the

lst-curtain drum as shown by the curved arrow, Fig. FP10

(B). The lst-curtain drum then comes against the pin on the

center drum. So, as the lst-curtain drum turns counterclock-

wise, it turns the center drum in the same direction.

Both curtains now move to the cocked position. The cur-

tains overlap to prevent light from reaching the film. When

the curtains reach the cocked position, a latch—the 2nd-

curtain latch—engages and holds the center drum (you'll

see the 2nd-curtain latch in the next section). The 2nd-cur-

tain latch prevents the 2nd-curtain tension roller from pull-

ing the 2nd curtain to the released position.

2nd CURTAIN

1st-CURTAIN

DRUM

TAPES OF

1st CURTAIN

FIG. FP8 Construction of the curtain drum.

FOCAL-PLANE SHUTTERS/111

Page 5

END SECTIONS

OF DRUM (1stCURTAIN

DRUM)

CENTER

SECTION OF

DRUM (2ndCURTAIN

DRUM)

FIG. FP9 Curtain drum viewed from front of camera.

PIN ON CENTER DRUM

1st-CURTAIN TAPE

2nd CURTAIN

1st-CURTAIN TAPE

CENTER DRUM

REMAINS LATCHED

A

A—SHUTTER

RELEASED

B—DURING

CHARGE

FIG, FP10 Top section of 1st-curtain drum.

The lst-curtain drum is also held in the cocked position—

the lst-curtain drum is still engaged to the cocking mechanism.

When you release the shutter, the cocking mechanism disengages the lst-curtain drum. Now the 1st-curtain tension

roller pulls the 1st curtain to the released position. The 2nd

curtain remains in the charged position—it's still held by

the 2nd-curtain latch.

For the full-aperture speed, the 1st curtain completely

crosses the focal-plane aperture. A disengaging lever attached to the lst-curtain drum then strikes and disengages

the 2nd-curtain latch. Now the center drum can rotate. Notice in Fig. FP10 (D) that the center drum can turn freely in

a clockwise direction—its pin no longer comes against the

upper section of the lst-curtain drum.

But for a slit-width speed, the center drum releases before

the 1st curtain has completely crossed the focal-plane aperture. The disengaging lever on the lst-curtain drum strikes

(the 2nd-curtain latch during the lst-curtain travel. The 2nd

curtain then follows the 1st curtain as shown in Fig. FP11.

C—CURTAINS

CHARGED

(1) OUTER SECTION OF DRUM RELEASES,

1st CURTAIN TRAVELS

(2) CENTER SECTION OF DRUM RELEASES,

2nd CURTAIN TRAVELS

D—1st CURTAIN

RELEASED

FIG. FP11 Curtains viewed from front of

camera.

112/FOCAL-PLANE SHUTTERS

Page 6

Selecting a slit-width shutter speed then determines the release point of the center drum. If you set a faster shutter

speed, you select a smaller slit—the center drum releases

sooner during the travel of the 1st curtain. The sooner the

center drum releases, the narrower the slit—and the faster

the resulting shutter speed.

From this description, we can determine a general rule for

focal-plane shutters: The 1st curtain releases the 2nd curtain. Further, the slit width depends on how far the 1st

curtain travels before releasing the 2nd curtain. For a fullaperture shutter speed, the 1st curtain completely crosses

the focal-plane aperture; it then releases the 2nd curtain.

The sooner the 1st curtain releases the 2nd curtain, the narrower the slit—and, as a result, the faster the shutter speed.

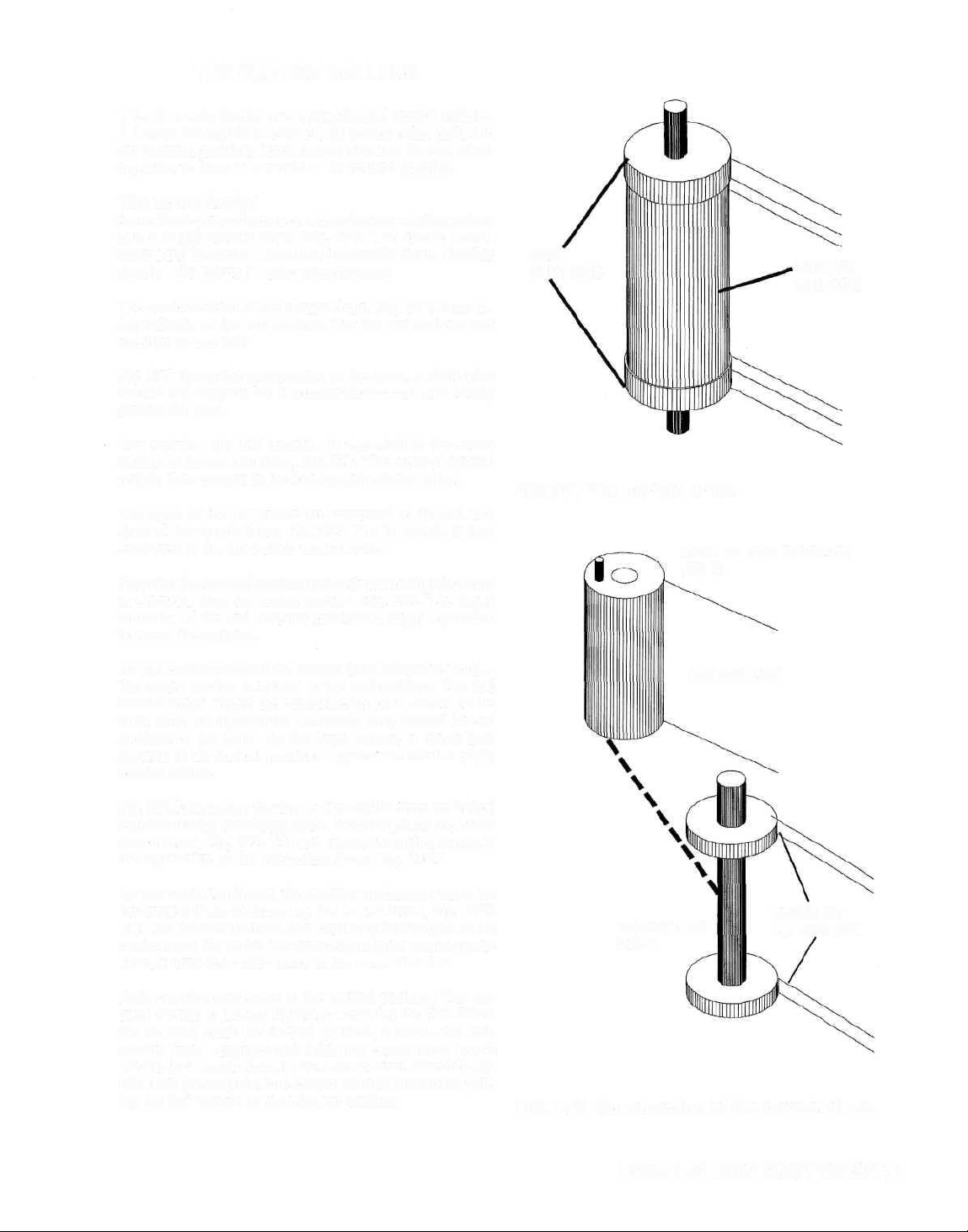

The double-roller design

Other focal-plane shutters use two completely separate

winding rollers rather than the drum. One winding roller

sits directly in front of the other, Fig. FP12.

Fig. FP12 shows the mounting of the 2nd curtain—the curtain is cemented to the 2nd-curtain winding roller, while

the tapes are cemented to the 2nd-curtain tension roller.

The 1st-curtain tension roller has a free-turning small roller

at each end to route the 2nd-cutain tapes.

The 2nd-curtain winding roller also has a small free-turning roller at each end, Fig. FP13. The tapes of the 1st curtain wrap around the small rollers en route to the Ist-curtain winding roller. The tapes then cement to (the ends of

the lst-curtain winding roller. The 1st curtain is cemented

to the 1st-curtain tension roller.

To charge the shutter, the cocking mechanism turns the two

winding rollers together. But the two winding rollers turn

individually on the release cycle.

2nd-CURTAIN WINDING

ROLLER

1st-CURTAIN

TENSION

ROLLER 2nd-CURTAIN

1st-CURTAIN

WINDING ROLLER

TENSION

ROLLER

FIG. FP12 Position of the 2nd curtain in a

double-roller design.

1st-CURTAIN TAPE

1st-CURTAIN

2ndCURTAIN

WINDING

ROLLER

WINDING

ROLLER

There are several systems used to lock the winding rollers

together during the cocking cycle. You'll see examples in

the studies of actual cameras. Frequently, cameras use a

pair of interlocking studs, Fig. FP14. One gear in Fig. FP14

couples to the charge mechanism; the other gear couples to

the 1st-curtain winding roller.

As you cock the shutter, the wind mechanism turns the lower

gear in Fig. FP14. The stud on the lower gear then turns the

upper gear. And the upper gear turns the 1st-curtain wind-

ing roller. As in the drum design, the 1st-curtain winding

roller turns the 2nd-curtain winding roller.

Pushing the release button moves down the lower gear—

the interlocking studs disengage. The 1st curtain, now free,

moves to the released position. But the 2nd curtain remains

latched by the 2nd-curtain latch—just as with the drum

design.

FREE-TURNING ROLLER

FIG. FP13 Mounting of the 1st curtain tapes

in a double-roller design.

1st CURTAIN

WIND

MECHANISM

INTERLOCKING

STUDS

FIG. FP14 Gears that wind 1st curtain.

FOCAL-PLANE SHUTTERS/113

Page 7

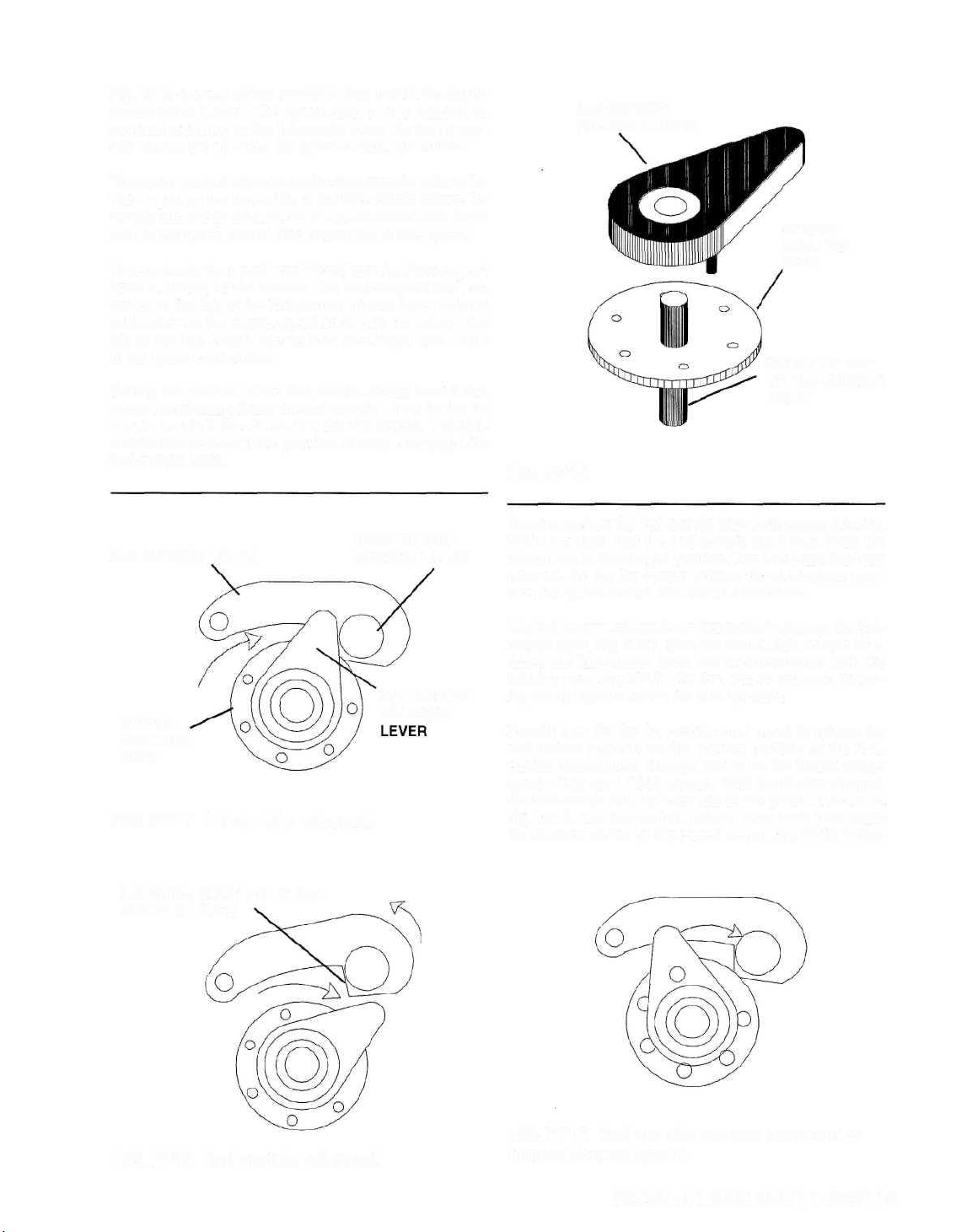

SPEED CONTROL IN THE FOCAL-PLANE

SHUTTER

o control the release point of the 2nd curtain, we'll first

add the latching system—the mechanism that latches

T

the 2nd curtain in the charged position. In Fig. FP15, we've

added a latching cam to the top pivot of the 2nd-curtain

winding roller. Remember, the 2nd-curtain winding roller

winds on the 2nd curtain during the cocking cycle.

We now need a latch—the 2nd-curtain latch—to engage

the latching cam. Fig. FP16 shows the top view of the latching cam and the 2nd-curtain latch. In Fig. FP16 A, the curtains are in the released position. As you cock the shutter—

and the 2nd-curtain winding roller winds on the 2nd curtain—the latching cam rotates as shown in Fig. FP16B.

As the latching cam nears the charged position, it pushes

aside the 2nd-curtain latch, Fig. FP16B. The latching cam

travels slightly further to the position shown in Fig. FP16C—

the 2nd-curtain latch then drops into engagement with the

latching cam.

Now the 2nd-curtain tension roller tries to pull the 2ndcurtain winding roller in the release direction, Fig. FP16C.

But the 2nd-curtain latch holds the latching cam, preventing the 2nd-curtain winding roller from turning.

Releasing the shutter disengages the 1st curtain—the 2nd

curtain remains held by the 2nd-curtain latch, Fig. FP16C.

Remember that the release point of the 2nd curtain depends

on how far the 1st curtain has traveled. Consequently, the

part that releases the 2nd curtain typically moves with the

1st curtain. For the full-aperture speed, the 1 st curtain com-

pletely crosses the focal-plane aperture. The part rotating

with the lst-curtain winding roller then strikes the 2nd-cur-

tain latch.

LATCHING

CAM

2nd-CURTAlN

WINDING

ROLLER

2nd CURTAIN

FIG. FP15 Top of 2nd-curtain winding roller.

2nd-CURTAIN

LATCH

LATCHING

CAM

A—SHUTTER

RELEASED

Disengaging the 2nd-curtain latch frees the 2nd curtain. As

the 2nd curtain moves across the aperture, the latching cam

rotates as shown in Fig. FP16D.

For a faster shutter speed, the 1st curtain disengages the

2nd-curtain latch sooner—before the 1st curtain has completely crossed the focal-plane aperture. The sooner the 1st

curtain disengages the 2nd-curtain latch, the smaller the

slit width—and the faster the exposure time.

114/FOCAL-PLANE SHUTTERS

B—DURING COCKING

CYCLE

C—2nd CURTAIN

LATCHED

D—2nd CURTAIN

RELEASED

FIG. FP16 Latching sequence for 2ndcurtain winding roller.

Page 8

Fig. FP16 shows a system similar to that used in the classic

screw-mount Leicas. The speed-control disc attaches to

the shaft at the top of the lst-curtain drum. As the 1st curtain crosses the aperture, the speed-control disc rotates.

The speed-control disc carries the 2nd-curtain release lever—a pin on the underside of the 2nd-curtain release le-

ver fits into one of the holes in the speed-control disc. Each

hole in the speed-control disc relates to a shutter speed.

To select a shutter speed, you lift and turn the shutter-speed

knob at the top of the camera. The shutter-speed knob at-

taches to the top of the 2nd-curtain release lever. Align a

calibration on the shutter-speed knob with the index—the

pin on the 2nd-curtain release lever then aligns with a hole

in the speed-control disc.

Setting the position of the 2nd-curtain release lever deter-

mines the release point of the 2nd-curtain—how far the 1st

curtain travels before it releases the 2nd curtain. The 2ndcurtain release lever is the part that actually disengages the

2nd-curtain latch.

2nd-CURTAIN

RELEASE LEVER

SPEEDCONTROL

DISC

SHAFT ON TOP

OF 2nd-CURTAIN

DRUM

FIG. FP16

2nd-CURTAIN LATCH

SPEEDCONTROL

DISC

POST ON 2ndCURTAIN LATCH

FIG. FP17 1st curtain released.

LATCHING SURFACE OF 2ndCURTAIN LATCH

2nd-CURTAIN

RELEASE

You can see how the 2nd-curtain latch is disengaged in Fig.

FP17. Consider that the 2nd-curtain latch now holds the

2ndcurtain in the charged position. The 1st curtain has been

released. As the 1st curtain crosses the focal-plane aperture, the speed-control disc rotates clockwise.

The 2nd-curtain release lever then strikes a post on the 2ndcurtain latch, Fig. FP17. Now the 2nd-curtain release lever

drives the 2nd-curtain latch out of engagement with the

latching cam, Fig. FP18. The 2nd curtain releases, following the 1st curtain across the film aperture.

Exactly how far the 1st curtain must travel to release the

2nd curtain depends on the starling position of the 2ndcurtain release lever. Perhaps you've set the fastest shutter

speed—let's say 1/1000 second. With the shutter charged,

the 2nd-curtain release lever sits at the position shown in

Fig. FP19. The 2nd-curtain release lever must then rotate

the distance shown by the curved arrow, Fig. FP 19, before

FIG. FP18 2nd curtain released.

FIG. FP19 2nd-curtain release lever set to

fastest shutter speed.

FOCAL-PLANE SHUTTERS/115

Page 9

CHECKING AND ADJUSTING SHUTTER SPEEDS WITH A FOCAL-PLANE SHUTTER

camera-repair shop uses a specialized electronic tester

to check shutter speeds. If you're in the business of

A

restoring antiques and classics, you may want to invest in

such equipment. But if restoring antiques is a hobby, you

probably can't justify the expense.

As with blade-type shutters, however, the important thing

with antique focal-plane shutters may be proper operation—

not point-blank accuracy. You should be able to visually

detect a difference in the slow speeds. At the 1-second setting, the 2nd curtain should run smoothly through the slowspeed governor.

You can also visually check the fast speeds with a focalplane shutter. Open the camera back and remove the lens.

Now hold the lens opening to a light source. Watch through

the focal-plane aperture at the back of the camera as you

release the shutter.

As you change the shutter speeds in the slit-width range,

you should be able to detect a difference—the light flash

appears darker at each faster shutter-speed setting.

If you use a fluorescent lamp, you can even get a visual

indication as to the accuracy of the shutter. The pulses of

the fluorescent light capture the slit in different positions.

At 1/1000 second, you should see three slits, Fig FP23. At

1/500 second, you should see two slits.

FIG. FP23 Exposure with a fluorescent lamp at

1/1000 second.

Full aperture1/60 second

Another technique you can use is to watch the flash expo-

sure at the slit-width shutter speeds. With electronic flash,

you'll see only the portion of the aperture that's uncovered

when you fire the flash. Point the electronic-flash unit to-

ward a white wall. Set the camera to X sync, and watch the

wall through the back of the focal-plane aperture as you

release the shutter.

At the full-aperture shutter speed, you should see the full

focal-plane aperture, Fig. FP24. But at each faster shutter

speed, you should see only part of the aperture—a smaller

portion illuminated at each faster shutter speed. At 1/500

second and 1/1000 second, you may see no flash through

the aperture at all.

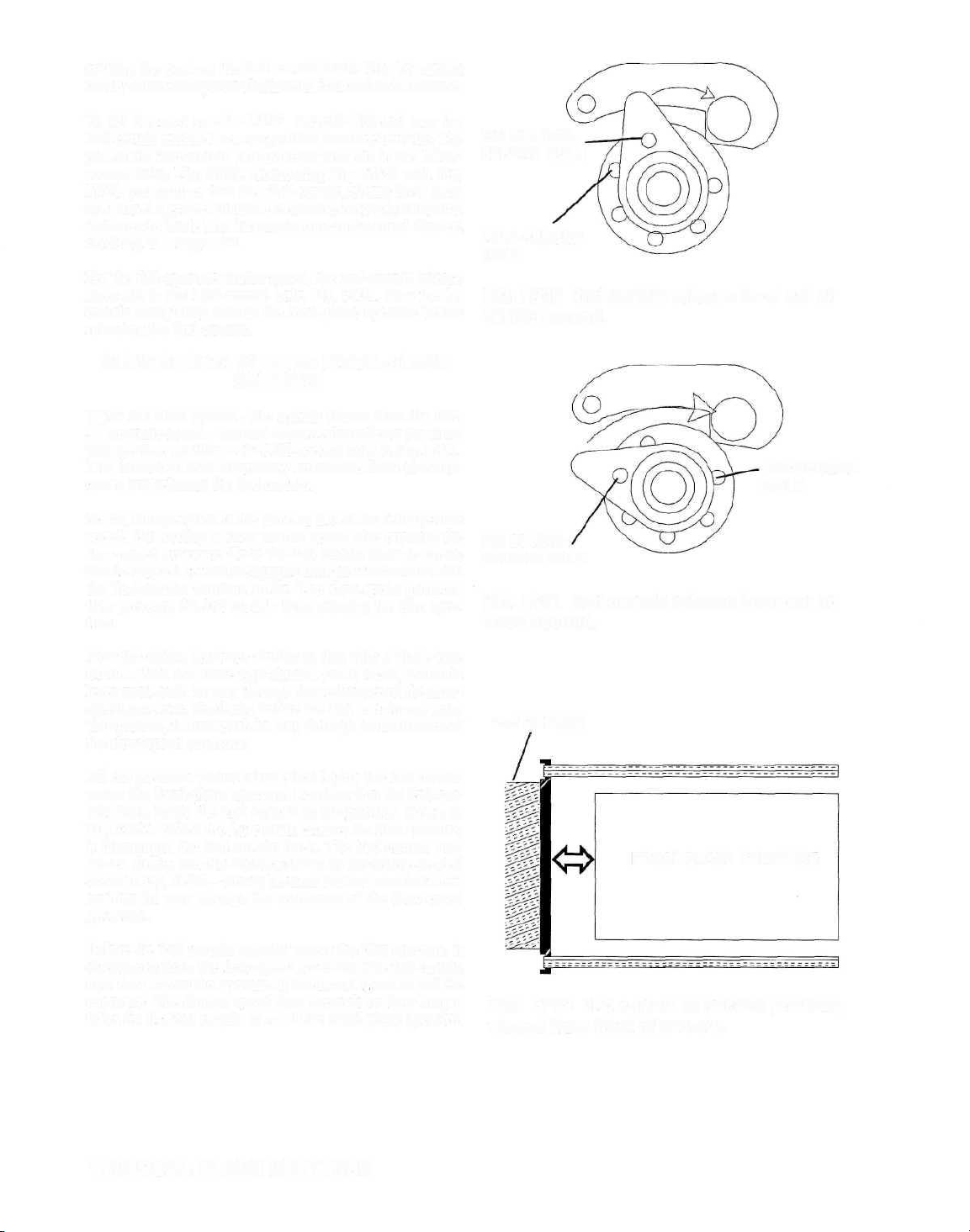

Checking and adjusting curtain tensions—

Focal-plane shutters have individual tension adjustments

for each curtain. The two curtains should be traveling at the

same speed.

If the 1st curtain is traveling faster than the 2nd curtain, the

slit gets wider as it crosses the aperture. The exposure on

the closing side of the aperture is then longer than the exposure at the opening side of the aperture. The effect of the

error is the most severe at the fastest shutter speed—the

shutter speed with the narrowest slit.

The problem may even worse if the 2nd curtain travels faster

than the 1st curtain. The slit then gets narrower as it crosses

1/125 second

1/250 second

FIG. FP24 Exposure with an electronic-flash

unit—curtain travel is from right to left.

FOCAL-PLANE SHUTTERS/117

Page 10

striking the post on the 2nd-curtain latch. The 1st curtain

barely enters the aperture before the 2nd curtain is released.

To set the next speed—1/500 second—lift and turn the

2nd-curtain release lever one position counterclockwise. The

pin on the 2nd-curtain release lever now fits in the 1/500second hole, Fig. FP21. Comparing Fig. FP20 with Fig.

FP21, you can see that the 2nd-curtain release lever must

now travel a greater distance clockwise before it strikes the

2nd-curtain latch. The 1st curtain travels that much further,

resulting in a larger slit.

For the full-aperture shutter speed, the 2nd-curtain release

lever sits in the 1/30-second hole, Fig. FP21. Now the 1st

curtain completely crosses the focal-plane aperture before

releasing the 2nd curtain.

SLOW SPEEDS WITH THE FOCAL-PLANE

SHUTTER

or the slow speeds—the speeds slower than the full-

aperture speed—the 2nd-curtain release lever sits at the

F

full-aperture position—the 1/30-sccond hole in Fig. FP21.

The 1st curtain then completely crosses the focal-plane aperture and releases the 2nd curtain.

So far, the operation is the same as it is at the full-aperture

speed. But setting a slow shutter speed also engages the

slow-speed governor. Once the 2nd curtain starts to move,

the slow-speed governor engages some part that rotates with

the 2nd-curtain winding roller. The slow-speed governor

then prevents the 2nd curtain from entering the film aper-

ture.

PIN IN 1/1000-

SECOND HOLE

1/500-SECOND

HOLE

FIG. FP20 2nd-curtain release lever set at

1/1000 second.

1/30-SECOND

HOLE

PIN IN 1/500SECOND HOLE

FIG. FP21 2nd-curtain release lever set at

1/500 second.

Now the action becomes similar to that with a blade-type

shutter. With the blade-type shutter, you'll recall, the main

lever must push its way through the resistance of the slow-

speed governor. Similarly, before the 2nd curtain can enter

the aperture, it must push its way through the resistance of

the slow-speed governor.

All the governor action takes place before the 2nd curtain

enters the focal-plane aperture. Consider that the 2nd-cur-

tain latch holds the 2nd curtain at the position shown in

Fig. FP22. When the 1st curtain crosses the film aperture,

it disengages the 2nd-curtain latch. The 2nd curtain now

moves slowly over the distance shown by the double-headed

arrow in Fig. FP22—slowly because the 2nd curtain is now

pushing its way through the resistance of the slow-speed

governor.

Before the 2nd curtain actually enters the film aperture, it

disengages from the slow-speed governor. The 2nd curtain

now fires across the aperture at its normal speed to end the

exposure. The shutter speed then depends on how long it

takes for the 2nd curtain to reach the focal-plane aperture.

2nd CURTAIN

FOCAL-PLANE APERTURE

FIG. FP22 2nd curtain in latched position,

viewed from front of camera.

116/FOCAL-PLANE SHUTTERS

Page 11

the aperture. And the exposure time is shorter on the closing side of the aperture.

But if the 2nd curtain travels much faster than the 1st curtain, the slit may close completely. The 2nd curtain catches

the 1st curtain—before the curtains have completely crossed

the aperture.

Check at the fastest shutter speed. Hold the lens opening to

a light source and watch through the back of the focal-plane

aperture. When you release the shutter, make sure that you're

getting an exposure all the way across the aperture. If you

get an exposure at one side of the aperture—but not at the

other side—the 2nd curtain is catching the 1st curtain.

For example, consider in Fig. FP25 that the curtains are

traveling from right to left. And you get the result shown in

Fig. FP25—exposure at the right side of the aperture, but

nothing at the left side. The 2nd curtain is catching the 1st

curtain—in Fig. FP25, the 2nd curtain catches the 1st curtain around half way across the aperture.

If you get light all the way across the aperture, you at least

know that the slit isn't closing. But you still don't know if

the curtains are traveling at uniform speeds. The fluorescent light source gives you a better indication. In Fig. ,

notice that the three light slits are the same width—that

means the curtains are traveling at the same speed. If the

light slits are uneven in width, the curtains are traveling at

different speeds.

FIG. FP25 Results of the 2nd curtain

overtaking the 1st curtain—curtain travel is

from right to left.

SETSCREWS

WORM GEARS

But the best way to check curtain speeds is with a commercial shutter-speed tester. Most shutter-speed testers provide

a function for measuring the curtain speeds—the curtaintravel time. The shutter-speed tester may show you both

curtain-travel times simultaneously. You can then check to

see that the travel times are the same. The readings of the

travel times are in milliseconds.

Camera manufacturers now provide specifications for the

curtain-travel times. For example, the manufacturer may

specify 12ms as the curtain-travel time for a particular

model. Both curtains should then cross the focal-plane ap-

erture in 12ms. But it's more critical that both curtains are

traveling at the same speed—even if that speed doesn't exactly match the manufacturer's specification.

You'll usually find the curtain-tension adjustments at the

bottom of the camera, Fig. FP26. The camera in Fig. FP26

uses worm-gear adjustments. To adjust the curtain travel

time, you first loosen the locking setscrew at the top of the

worm housing. You then turn the worm—and the worm turns

the worm gear to increase or decrease the spring tension of

the tension (take-up) roller.

Other focal-plane shutters may use ratchet gears to set the

curtain-travel times In Fig. FP27, you can turn the ratchet

gear freely in one direction—the direction that adds tension. To let off tension, hold the ratchet gear and disengage

the locking spring. Allow the tension-roller spring to unwind slightly.

1st-CURTAIN 2nd-CURTAIN

ADJUST ADJUST

FIG. FP26 Bottom of Nikon F.

The curtain-adjustment positions in Fig. FP26 and FP27

are typical of focal-plane shutters—the 2nd-curtain adjustment is closer to the back of the camera. So, if the 2nd

curtain is catching up with the 1st curtain, you can add

tension to the 1st curtain—the 1st curtain then travels faster.

You could get the same results by letting off some of the

tension from the 2nd curtain. However, a curtain tends to

slow down as the camera ages due to spring fatigue. If the

2nd curtain is catching the 1st curtain, then, it's more likely

that the 1st curtain is traveling too slowly.

118/FOCAL-PLANE SHUTTERS

Page 12

If you have a way to actually measure the curtain-travel

times, you can set the curtains according to the

manufacturer's specifications. For example, if the manufacturer specifies 12ms, adjust each curtain to travel at 12ms.

ADJUSTING SHUTTER SPEEDS WITH

THE FOCAL-PLANE SHUTTER

he curtain tensions do affect the shutter-speed accu

racy—the faster the curtains travel, the faster the expo-

T

sure time. But the slit width has a greater effect on the exposure time.

Most of the old focal-plane shutters provide an adjustment

on the 2nd-curtain latch, Fig. FP28. The adjustment—usually an eccentric—determines when the 1st curtain releases

the 2nd curtain. The sooner the 1st curtain releases the 2nd

curtain, the narrower the slit—and the faster the exposure

time.

The adjustment for the slow speeds is on the slow-speed

governor. An eccentric or screw adjustment increases or

decreases the retard-lever engagement. If you increase the

retard-lever engagement, it takes longer for the 2nd curtain

to run through the slow-speed governor—a slower shutter

speed.

There may also be an adjustment on the pallet engagement.

The adjustment for the pallet engagement may affect I second, 1/2 second, and 1/4 second. You would then use the

retard-lever adjustment for 1/30 second. And use the pallet

adjustment for the three slowest shutter speeds.

FRONT OF CAMERA

1st-CURTAIN

RATCHET

2nd-CURTAIN

RATCHET

LOCKING

SPRINGS

FIG. FP27 Bottom of camera with ratchet-

type adjustments.

ECCENTRIC ON 2nd-CURTAIN LATCH

FIG. FP28 Top of drum-type focal-plane

RETARD ECCENTRIC

PALLET ECCENTRIC

shutter.

FIG. FP29 The slow-speed governor is at the top, release-button end of the Minolta SR-T

101, a classic with a double-roller focal-plane shutter.

FOCAL-PLANE SHUTTERS/119

Page 13

MAKING AND REPLACING SHUTTER

CURTAINS

Removing the old curtains—

With old cameras, you'll frequently find that the curtains

have deteriorated. Curtains may have a rubber-like coaling

on one side. The rubber-like material deteriorates with age,

falling away in flakes.

Or you may find pin holes in the curtain. If you then hold

the curtain to a light source, you'll see light passing through

the curtain in several places. You may even find that the

curtain has torn loose from the bar.

If the camera won't be used to take pictures, curtain damage may not be a problem. But damaged curtains do detract

from the "perfection" of the camera—often a factor with

collectors.

You probably won't be able to purchase replacement curtains. So, if you want to restore the camera to mint condition, you'll have to make new curtains.

SCRIBE

2nd

curtain

FIG. FP30 Front view of the curtain drum.

Some companies do still provide curtain material—bulk

material from which you can cut new curtains. Curtain

material may be rubberized on one side. Or there may be

no rubber-like coating. But you want to use a material that

matches the original curtain.

Curtains aren't especially difficult to make. The problem is

that you have to almost completely disassemble the camera

to replace the curtains—a major job. You probably should

not attempt such a restoration until you're intimately familiar with the particular camera.

Disassemble the camera far enough to reach the rollers—it

may not be necessary to remove the rollers from the body.

However, in some cameras, the position at which the. curtains cement to the rollers or drum is critical—the position

at which you cement the curtain and tapes may be your

only adjustment for the curtain positions. With other cameras, you can adjust the curtain positions by adjusting gear

timing.

If the camera has a drum-type focal-plane shutter, you can

be certain that the curtain positions are critical—both the

position at which the curtain cements to the inner drum and

the positions at which the tapes cement to the outer drum,

Fig. FP30. The positions may also be critical in the doubleroller design. But with many double-roller designs, you can

change the gear timing to adjust the curtain positions.

Fig. FP31 shows the critical timing on the 2nd curtain—the

distance between the curtain bar and the lead edge of

the focal-plane aperture when the 2nd curtain is latched

in the open position. The critical timing on the 1st curtain is the curtain overlap—how far the curtains overlap

one another during the cocking cycle. Typically, the overlap is one bar. But that's not always the case.

inside of the focal-plane aperture to note the edge of the

2nd-curtain bar, Fig. FP31.

Check the curtain overlap during the cocking stroke. Advance the curtains until they are around half way across the

aperture. Then make a note of the overlap.

Also make careful notes and sketches of the curtain positions. Does the rubberized side face the front or the back of

the camera? Which curtain sits to the front of the camera—

the 1st curtain or the 2nd curtain? You might also mark the

old curtains to note which is the 1st curtain and which is

the 2nd curtain—depending on the camera, the two curtains may be identical or slightly different.

You can now let off the curtain tensions. But count the turns

as you let off the tension. You then have a starting point for

reassembly.

2nd CURTAIN

SCRIBE HERE

FOCAL-PLANE APERTURE

It helps to check both timing points before you remove the

curtains. Hold open the shutter on bulb. Then scribe the

120/FOCAL-PLANE SHUTTERS

FIG. FP31 2nd curtain in latched position,

viewed from front of camera.

Page 14

For example, with the design shown in Fig. FP26, use your

screwdriver to hold the ratchet gear in place. Then hold the

lock spring away from the ratchet gear. Allow (he ratchet

gear to rotate slowly clockwise as you count the turns of

initial tension.

With the worm-gear design, Fig. FP25, loosen the setscrew

that locks the worm. Hold the worm gear in place with your

screwdriver. Now push the worm out of its housing. Count

the turns on the worm gear as the tension-roller spring un-

winds.

The starting positions of the curtain and tapes on the ten-

sion rollers aren't critical—there's no timing on the tension

rollers. But it's very critical that the curtain and tapes are

square to the tension rollers. If they aren't square to the

rollers, the slit will be tapered as it moves across the aperture, Fig. FP32. In Fig. FP32, the top of the film frame

receives more exposure than the bottom of the film frame.

You can use a straightedge to scribe the tension rollers—

use the scribe line to align the end of the 1st curtain and to

make sure both 2nd-curtain tapes start at the same position.

Or you can scribe the old lst-curtain edge and the old 2ndcurtain tapes before you remove them. Then peel the 1st

curtain and the 2nd-curtain tapes from the tension rollers.

FIG. FP32 Tapered slit resulting from one

curtain not being square to its roller.

Also scribe the positions of the old curtains and tapes before you remove them from the drum. With some drum designs, you can see the edge of the 2nd curtain, Fig. FP30,

with the shutter released—scribe the center drum along the

2nd-curtain edge. You can normally see the 2nd-curtain edge

in shutters that use titanium (metal) curtains.

But with drum-type shutters using cloth curtains, the 2nd

curtain usually wraps over the edge. Reaching the edge of

the 2nd curtain may then require that you remove the drum—

something you want to avoid if possible. Fortunately, there's

a shortcut you can use. Here's the shortcut:

First pec) the curtain and tapes from the tension rollers.

Then, with the shutter in the released position, place a

straightedge against the 2nd curtain and the drum—at

the position of the 2nd-curtain edge in Fig. FP30). Using

a sharp hobbyist knife, cut the 2nd curtain along the

straight edge.

Work from the cut to peel the 2nd curtain from the drum.

You can now remove the 2nd curtain from the camera.

But the end of the 2nd curtain remains cemented to the

drum—leave this material in place.

Use the 2nd curtain you just removed as a pattern. Cut

the replacement 2nd curtain to the same length. You can

then slide the replacement 2nd curtain around the hack

of the drum, Fig. FP30. Bring the end of the replacement 2nd curtain against the cut end of the 2nd curtain

that remains on the drum—that end of the old 2nd curtain serves as your scribe line.

You also want to scribe the ends of the lst-curtain tapes,

Fig. FP30. But you won't be able to reach the ends without

FIG. FP33 FIG. FP34

unwrapping the tapes from the outer drum.

With the 1st curtain peeled loose from its tension roller,

you can unwrap the tapes. Or you can use the same technique as described for cutting the 2nd curtain—cut the old

tapes and leave the ends cemented to the center drum. Be

sure to cut the new tapes to the same lengths as the tapes

remaining on the old 2nd curtain.

You may not have to scribe the old curtains in a doubleroller design. If you can remove the wind gears (the gears

that engage the winding-roller pinions), you can adjust the

curtain timing—regardless of the starting position of the

curtains. But if you can't remove the wind gears, scribe the

2nd-curtain winding roller to note the lead edge of the 2nd

curtain. Scribe the lst-curtain winding roller to note the

lead edge of each lst-curtain tape.

The scribe marks are useful even if the curtain positions

aren't critical. As mentioned earlier, you can often adjust

gear timing to correct the curtain positions. But you still

want to make sure that the 2nd curtain is square to its winding roller. And the end of each lst-curtain tape must be on

a straight line. If a curtain isn't square to the winding rollers, the curtain will sit at an angle as shown in Fig. FP32.

Making the curtains—

If possible, try to save the old curtain bars—just so you

don't have to make new bars. Each curtain bar may be shaped

similar to the one in Fig. FP33. The end of the curtain then

fits inside the bar. And the bar is pressed closed to sandwich the curtain.

FOCAL-PLANE SHUTTERS/121

Page 15

Here the manufacturer cements the end of the curtain to the

bar. The bar is then pressed closed. Dimples may be added

to the bar—punch marks into both the bar and the curtain—

for added strength.

Carefully spread the bar, Fig. FP33, to free the curtain— Also be very critical when you cement the curtains to the

remember, you're going to reuse the bar. Then peel the old bars—the curtains must be square to the bars. If the curcurtain from the bar. You can now measure the curtain— tains aren't square, the slit will be tapered as it moves across

the length and the width. the aperture, Fig. FP32.

cuts as square, clean, and straight as possible. Use a sharp

knife such as a new single-edged razor blade or a hobbyist

knife. If the knife isn't sharp, the edges of your curtains

may be frayed.

Or the curtain bar may be shaped like the one in Fig. FP34

The curtain and the tapes fold over the bar, Fig. FP35 and

Fig. FP36.

The manufacturer cements the curtain to the bar. A row of

stitches may then be added along the bar—at the position

shown by the dashed line in Fig. FP36—for additional

strength.

Before you peel the curtain from the bar, make careful

measurements—the width of the curtain and the length of

the curtain measured from the edge of the bar. When you

cut the new curtain, leave sufficient material for the fold,

Fig. FP35. But it's the length of the curtain measured from

the bar that's critical.

Now check the curtain material. If you're using the rubber-

ized curtain material, you'll find that the material will stretch

in one direction but not in the other direction. Make your

lengthwise cuts in the direction that the material will not

stretch. Remember that the curtains are pulled from the ends.

If they can stretch in the lengthwise direction, their lengths

will change when tension is applied.

Be very critical as you cut the material—make the curtain

With the type of curtain shown in Fig. FP36, apply Pliobond

both to the curtain and to (the bar. Then fold the curtain over

the bar—make sure the length of the curtain from the edge

of the bar matches your original measurement. While the

cement is drying, make precise adjustments on the curtains—remember, the curtains must be 90° to the bars.

Then, after the cement dries, hand sew the curtains, Fig.

FP36—keep the stitches very close to the bars,

The curtain tape also comes in bulk form—a roll from

which you can cut off the length you need. Be just as critical in matching the lengths of the tapes to those of the old

curtains—especially if the shutter provides no adjustments

for curtain positions.

Installing the curtains—

If you're installing the curtains on a drum, Fig. FP30, remember that the 2nd curtain and the lst-curtain tapes must

align with the scribe lines—or with the cut ends of the curtain and tapes remaining on the drum. Slide the 2nd curtain behind the drum. Bring the end of the 2nd curtain to

the scribe line.

Apply a smooth coat of Pliobond both the back of the cur-

tain and to the front of the center drum. Cementing both

surfaces {contact cementing) strengthens the bond. You can

determine how much of the curtain should be cemented by

examining the old curtain. In general, the cement should

extend around 1/4" from the end of the curtain.

FOLD

FIG. FP35

STITCHES

FIG. FP36

122/FOCAL-PLANE SHUTTERS

Line up the 2nd curtain with your scribe line or the end of

the original curtain and cement the curtain in place. Pliobond

gives you a little time to shift the curtain position before

the cement dries.

The lst-curtain tapes may wrap twice around the end sec-

tions of the drum. If you completely removed the tapes of

the old curtain, wrap the new tapes around the outer drum—

leave the tapes loose so you can reach the ends. Align the

Page 16

tape ends with your scribes and cement them to the outer

drum.

If you left the ends of the old tapes on the drum, you don't

have to wrap the tapes twice around the drum ends—just

bring the ends of the new tapes against the cut ends of the

old tapes.

You can determine if the curtains are in their proper positions before you cement them to the tension rollers. Let the

cement dry for a few minutes. Then hold both curtains toward the tension-roller end of the camera—apply just

enough pressure to remove the slack from the curtain and

tapes. Then slowly cock the shutter. The drum turns, wrapping on the curtains.

As the curtains move to the cocked position, they should

overlap—the overlap should be the amount you noted be-

fore removing the curtains (normally one bar). If there's a

space gap between the curtain bars, you probably didn't

wrap the lst-curtain tapes enough times around the drum

ends. But if the overlap is excessive, you may have wrapped

the tapes loo many times around the drum ends.

Next route the 1st curtain and the 2nd-curtain tapes to the

tension rollers. Follow the same procedures to cement the

curtain and tapes. Here the starting positions aren't critical.

But it's very critical that the curtains are square to the ten-

sion rollers.

After the cement dries, you can put a couple of turns of

tension on the tension rollers—just enough tension to draw

the curtains taut. You can now check the curtain alignment

to see if the curtains are square to their rollers.

Look from the back of the focal-plane aperture as you turn

the center drum in the winding direction—you're now winding on the 2nd curtain. When the 2nd curtain enters the

aperture, you can judge if it's straight, Fig. FP37. Use the

end of the focal-plane aperture as a straight edge.

FIG. FP37 Here the 2nd curtain is square to

the roller.

FIG. FP38 The 2nd curtain is not square to

the roller—the upper end of the curtain must

be pulled from right to left.

around the 2nd-curtain tension roller to hold your tape

"shim" in place.

The extra chunk of tape increases the diameter of the tension roller at the top end. The result—the top end of the

curtain is pulled a little further toward the tension rollers.

Use a similar technique to determine if the 1st curtain is

straight. Cock the shutter. Then hold the drum and release

the shutter. Allow the drum to turn slowly until the 1st cur-

tain to just enter the aperture. Again use the end of the aperture as a straight edge to determine if the 1st curtain is

straight.

If a curtain isn't square, you may be able to make a correc-

tion without removing and recementing that curtain—unless the error is severe. For a slight error, you can use extra

curtain tape to "shim" the curtain.

For example, suppose you're looking at the hack of the

focal-plane aperture. And you can see that the 2nd curtain

isn't quite square—you need to move the upper end of the

curtain toward the tension rollers, Fig. FP38.

Unwrap the upper end of the 2nd-curtain tape from the end

of the tension roller—just enough so you can reach the tape

end. Now insert a small section of tape at the end of the

upper 2nd-curtain tape. Allow the 2nd-curtain tape to wrap

Again check the alignment of the 2nd curtain. If the 2nd

curtain is now straight, your tape "shim" is the right size.

But you may decide you need a slightly larger shim—or a

slightly smaller shim. Once you've determined the proper

size, cement your tape shim to the tension roller.

If the 1st curtain isn't straight, you can use a similar shimming procedure—but this time, shim the lst-curtain tapes

where the tapes cement to the drum ends.

ADJUSTING CURTAIN TIMING

We mentioned that many double-roller designs allow you

to adjust the curtain timing. The upper ends of the winding

rollers engage the winding gears—the gears that rotate to

wind on the curtains. If you can change the timing of these

wind gears, you can adjust the curtain positions.

First adjust the timing of the 2nd-curtain wind gear—the

gear that turns the 2nd-curtain winding roller. Remember

FOCAL-PLANE SHUTTERS/123

Page 17

that the 2nd-curtain latch should hold the 2nd curtain in a

certain position—the curtain bar should be a certain distance from the lead edge of the focal-plane aperture. You

noted that distance before removing the curtains. Many

cameras have factory scribe marks to note the 2nd-curtain

position.

Wind on the 2nd curtain to the cocked position. And engage the 2nd-curtain latch with the 2nd-curtain wind gear.

Now check the position of the 2nd curtain—the lead edge

of the 2nd-curtain bar should be aligned with the scribe

mark. Change the timing between the 2nd-curtain wind gear

and the 2nd-curtain winding roller until the curtain is in the

proper position.

2nd-CURTAIN

WIND GEAR

PINION ON

TOP OF 2ndCURTAIN

WINDING

ROLLER

Adjust the timing of the 1st curtain for the proper overlap.

Start with both curtains in the released position. Then slowly

cock the shutter. Check the curtain overlap as the curtains

move to the cocked position. If the overlap isn't right, change

the timing between the lst-curtain wind gear and the lstcurtain winding roller.

For example, Fig. FP39 and Fig FP40 show the sequence

in an early Pentax double-roller design, the H3v. The lstcurtain wind gear sits on top of the 2nd-curtain wind gear.

You would then first install the 2nd-curtain wind gear, Fig.

FP39. Wind on the 2nd curtain to the charged position. And

engage the 2nd-curtain wind gear with the 2nd-curtain latch.,

Fig. FP39. Now adjust the timing between the 2nd-curtain

wind gear and the 2nd-curtain winding roller until the cur-

tain is held the proper distance from the focal-plane aper-

ture, Fig. FP31.

Disengage the 2nd-curtain latch to release the 2nd curtain.

Then install the lst-curtain wind gear, Fig. FP40. As you

2ndCURTAIN

LATCH

FIG. FP39 Adjusting the timing of the 2nd

curtain.

turn the lst-curtain wind gear, the lst-curtain wind gear

turns the 2nd-curtain wind gear. Both curtains travel simultaneously to the cocked position.

Turn the 1st-curtain wind gear until the two curtains are

around half way across the aperture. Then check the curtain overlap. In the Pentax, the curtains should overlap by

one bar—one curtain bar sits directly in front of the other

curtain bar. Adjust the overlap by changing the timing between the lst-curtain wind gear and the lst-curtain wind-

ing roller.

1st-CURTAIN WIND

GEAR

FIG. FP40 Adjusting the timing of the 1st curtain.

124/FOCAL-PLANE SHUTTERS

PINION ON TOP OF

1st-CURTAIN

WINDING ROLLER

Loading...

Loading...