Page 1

PENTAX VIDEO PROCESSOR

EPK-1000

OWNER,S MANUAL

Page 2

Read this manual before operating and save this book for future reference.

This manual describes the recommended procedures for inspecting and preparing the EPK-1000 Video Processor

prior to its use and the care and maintenance after its use. It does not describe how an actual procedure is to be performed,

nor does it attempt to teach the beginner the proper technique or any medical aspects regarding the use of the equipment.

Failure to follow the instructions in this manual may result in damage to and/or malfunction of the equipment.

Do NOT use this device for any other purpose than that for which it has been designed.

If you have any questions regarding any of the information in this manual or concerns pertaining to the safety and/or use

of this equipment, please contact your local PENTAX representative.

CAUTION:

Federal (USA) law restricts this device to sale by, or on the order of a physician or other appropriately licensed medical

professional.

IMPORTANT

このCEマーキングはEC指令への適合宣言マークです。

TheCEmarkingassuresthatthisproductcomplieswiththerequirementsoftheECdirectiveforsafety.

Das CE Zeichen garantiert, daß dieses Produkt die in der EU erforderlichen Sicherheitsbestimmungen

erfüllt.

Le logo CE certifie que ce produit est conforme aux normes de sécurité prévues par la Communauté

Européenne.

IImarchioCEassicurachequestoprodottoè conformealledirettiveCErelativeallasicurezza.

LamarcaCEaseguraqueesteproductocumpletodaslasdirectivasdeseguridaddelaCE.

INTENDED USE:

This electro-medical device (Video Processor) is intended to be used for endoscopic diagnosis and treatment.

Together, this Video Processor and PENTAX video endoscope may provide optical visualization of, and/or therapeutic

access to, various body cavities, organs and canals. Do NOT use this device for any purpose other than that for which it

has been designed.

This device should only be used by physicians who have thoroughly studied all the characteristics of this device and who

are familiar with the proper techniques of endoscopy.

EC REP

Symbol for “MANUFACTURER”

Symbol for “DATE OF MANUFACTURE”

Symbol for “AUTHORISED

REPRESENTATIVE”

Page 3

CONTENTS

1 SAFETY PRECAUTIONS

...............................................................................................................................................................................

1

2 NOMENCLATURE, CONTROLS AND FUNCTIONS

.................................................................................................................................

7

2-1 VIDEO PROCESSOR

.........................................................................................................................................................................

7

(1) MAIN BODY

............................................................................................................................................................................

7

(2) FRONT PANEL

........................................................................................................................................................................

8

(3) REAR PANEL

...........................................................................................................................................................................

9

2-2 WATER BOTTLE ASSEMBLY, MODEL OS-H4

..........................................................................................................................

10

2-3 MONITOR DISPLAY SCREEN

......................................................................................................................................................

11

(1) NORMAL

................................................................................................................................................................................

11

(2) FREEZE (SUB-SCREEN DISPLAY)

.....................................................................................................................................

11

3 PREPARATION AND SAFETY CHECK

.....................................................................................................................................................

12

3-1 PREPARATION

................................................................................................................................................................................

12

(1) SETTING UP THE VIDEO PROCESSOR

............................................................................................................................

12

(2) CONNECTING THE WATER BOTTLE

...............................................................................................................................

12

(3) CONNECTING THE ENDOSCOPE

......................................................................................................................................

13

(4) CONNECTING THE PERIPHERAL EQUIPMENT

.............................................................................................................

13

3-2 PRE-USE SAFETY CHECKLIST

....................................................................................................................................................

14

4 OPERATION

..................................................................................................................................................................................................

16

4-1 PROCESSOR FUNCTIONS

.............................................................................................................................................................

16

(1) MAIN LAMP

...........................................................................................................................................................................

16

(2) AUXILIARY LAMP

...............................................................................................................................................................

16

(3) BRIGHTNESS

.........................................................................................................................................................................

17

(4) COLOR BALANCE

................................................................................................................................................................

17

(5) PUMP

......................................................................................................................................................................................

18

4-2 KEYBOARD FUNCTIONS

..............................................................................................................................................................

19

(1) CONVENTIONAL KEYS

......................................................................................................................................................

19

(2) SPECIAL FUNCTION KEYS

................................................................................................................................................

20

5 MAINTENANCE

...........................................................................................................................................................................................

29

5-1 AFTER EACH PROCEDURE

..........................................................................................................................................................

29

5-2 WATER BOTTLE CLEANING

.......................................................................................................................................................

29

(1) CLEANING

.............................................................................................................................................................................

29

(2) STERILIZATION

....................................................................................................................................................................

30

(3) CARE DURING STORAGE

...................................................................................................................................................

31

5-3 STORAGE

.........................................................................................................................................................................................

31

5-4 CHANGING THE LAMP

.................................................................................................................................................................

31

5-5 RESETING THE BREAKERS

.........................................................................................................................................................

32

6 TROUBLE-SHOOTING GUIDE

...................................................................................................................................................................

33

7 SPECIFICATIONS

.........................................................................................................................................................................................

35

8 ELECTROMAGNETIC COMPATIBILITY

.................................................................................................................................................

36

Page 4

1

1. SAFETY PRECAUTIONS- IMPORTANT

The following precautions should always be exercised with the use of all electro-medical equipment to ensure safety to all

involved parties - user(s), patient(s), etc.

Please carefully read and follow this owner’s manual.

1-1. TRAINING

This equipment should only be used under the supervision of a trained physician in a medical facility. Do NOT use in other

locations or for any other purposes than the intended application.

1-2. INSTALLATION

1. This equipment should NEVER be installed or used in areas where the unit could get wet or be exposed to any environmental

conditions such as high temperature, humidity, direct sunlight, dust, salt, etc., which could adversely affect the equipment.

2. This equipment should NEVER be installed or used in the presence of flammable or explosive gases or chemicals.

3. This equipment should NEVER be installed, used or transported in an inclined position nor should it be subjected to impact

or vibration.

4. For safety reasons, this equipment must be properly grounded. (This equipment should be connected to a three (3) prong

hospital grade receptacle in U.S.A. or Canada.)

5. Ensure that all power requirements are met and conform to those specified on the rating plate located on the rear panel.

6. Do NOT block the air intake vent of this equipment.

7. Do NOT allow the power cord to become twisted, crushed or pulled taut.

8. When using an isolation transformer for any ancillary equipment, ensure that the power requirements of the devices do not

exceed the capacity of the isolation transformer. For further information, contact your local PENTAX distributor.

1-3. PRIOR TO USE

1. Confirm that this equipment functions properly and check the operation of all switches, indicators, etc.

2. To prevent electrical shock when used with endoscopes, this equipment is insulated (type BF electro-medical equipment).

Do NOT allow it to be grounded to other electrical devices being used on the patient. Rubber gloves should always be worn

to prevent grounding through user(s).

3. Confirm that other devices used in conjunction with this equipment function properly and that these other devices will not

adversely affect the operation or safety of this equipment. If any component of the endoscopic system is not properly

functioning, the procedure should not be performed.

4. Check and confirm that all cords or cables are connected correctly and securely.

5. The lamp life when used in this equipment is 400 hours. Prior to use, check the lamp life indicator on the front panel to

ensure the indicator is lit green or yellow. After 400 hours of use, the indicator turns red and the image quality will

deteriorate. Excessive use of the lamp beyond its rated 400 hours (approaching a thousand hours of use or more ) could cause

the lamp to explode resulting in damage to the video processor.

- The lamp life rated at 400 hours, is applicable to the EPK-1000 processor with serial number beginning with UB and

EB.

1-4. DURING USE

1. To prevent electric shock, the endoscope and/or any other ancillary device should NEVER be applied directly to the heart.

2. Make sure that no contact is made between the patient and this equipment.

3. To avoid damage to the luminous display and flat membrane switches, do NOT press any keys with any sharp or pointed

objects.

4. The light emitted by the Xenon lamp is extremely intense. Avoid looking directly at the light exiting the endoscope and/or

this equipment.

NOTE

Page 5

2

5.To protect the users eyes and avoid risk of thermal injury during an endoscopic examination, use only the minimum amount

of brightness required.

6. During clinical procedures, avoid unnecessary prolonged use which could compromise patient/user safety.

7. Continually monitor this equipment and the patient for any signs of irregularities.

8. In the event that some type of irregularity is noted to the patient or this equipment, take the appropriate action to ensure

patient safety.

9. If the operation of any of the components of the endoscopic system fails during the procedure and the visualization of the

procedure is lost or compromised, place the endoscope in the neutral position and slowly withdraw the endoscope.

10. This equipment should only be used according to the instruction and operating conditions described in this manual. Failure

to do so could result in compromised safety, equipment malfunction or instrument damage.

1-5. AFTER USE

1. Refer to the operating instructions supplied with all the components of the endoscopic system to establish the right order in

which components should be turned OFF. Some peripheral devices may have to be turned OFF first to avoid compromising

their operation.

2. Wipe all surfaces clean with gauze slightly dampened with alcohol.

3. Be sure connector interfaces and ventilation ports are not allowed to become wet or splashed with liquids.

1-6. STORAGE

1. This equipment should NEVER be stored in areas where the unit could get wet or be exposed to any environmental

conditions such as high temperature, humidity, direct sunlight, dust, salt, etc., which could adversely affect the equipment.

2. This equipment should NEVER be stored in the presence of flammable or explosive gases or chemicals.

3. This equipment should NEVER be stored or transported in an inclined position, nor should it be subjected to impact or

vibration.

4. Cords, accessories, etc., should be cleaned and neatly stored.

5. This equipment should be maintained in a clean condition during storage and be ready for subsequent use.

1-7. SERVICE

1. Alterations/modifications to the equipment should NEVER be made. Repairs should only be performed by an authorized

PENTAX service facility.

2. When replacing the lamp, use only the lamp recommended by PENTAX and follow all PENTAX instructions provided.

1-8. MAINTENANCE

Periodically this equipment and any applicable accessories should be inspected for operation and safety.

1-9. DISPOSAL

The equipment should be returned for disposal to PENTAX. Contact your local PENTAX representative or service facility.

1-10. FOR THE STATE OF CALIFORNIA, USA ONLY

Perchlorate Material-special handling may apply. See www.dtsc.ca.gov/hazardouswaste/perchlorate.

Perchlorate Material: Lithium battery contains perchlorate.

An information on Disposal for users in the European Union

This product is a medical device. In accordance with European Directive 2002/96/EC on Waste Electrical and Electronic

Equipment, this symbol indicates that the product must not be disposed off as unsorted waste, but should be collected

separately. Contact your local PENTAX distributor for correct disposal and recycling.

By disposing of this product correctly you will help ensure that the waste undergoes the necessary treatment, recovery

and recycling and thus prevent potential negative effects on the environment and human health which could otherwise

arise due to inappropriate waste handling.

Page 6

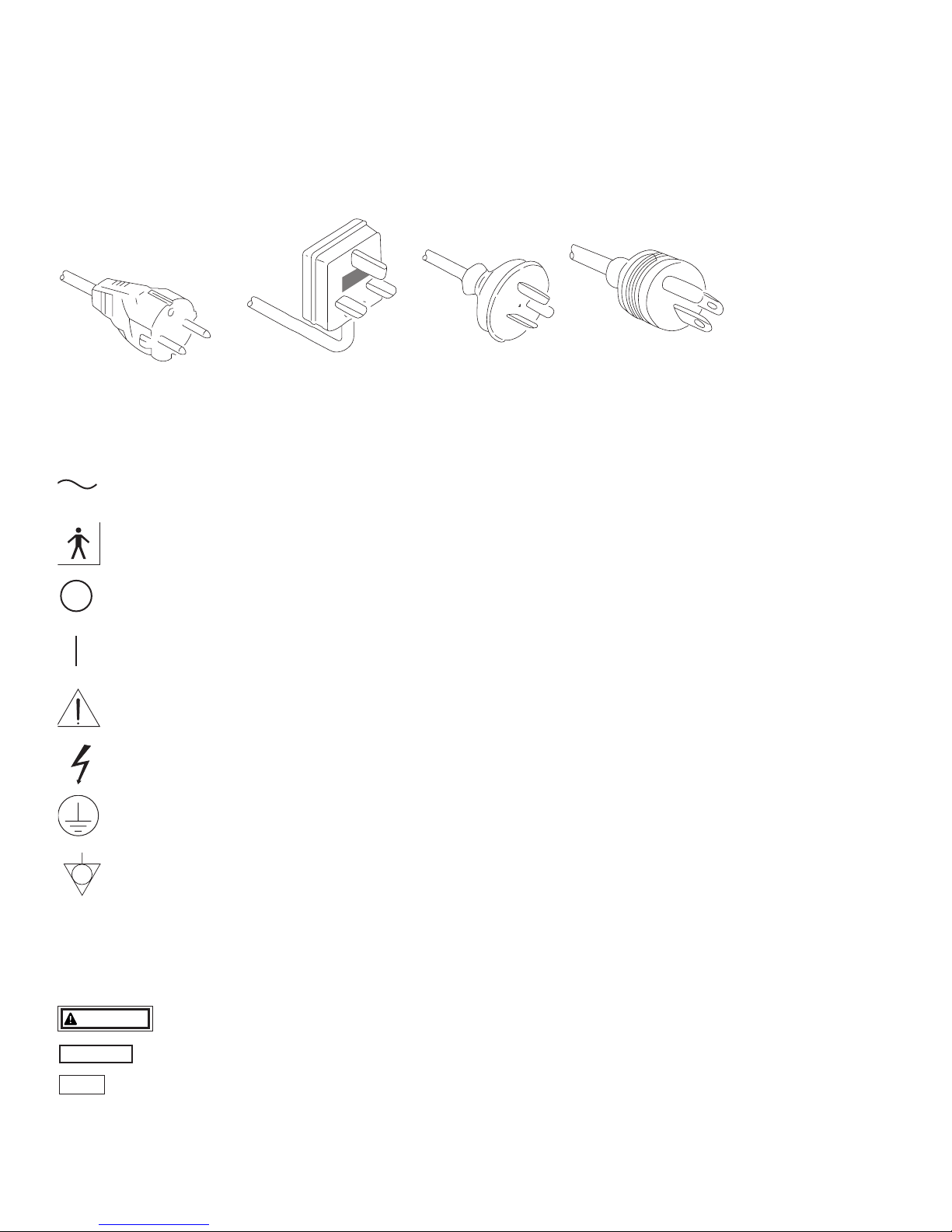

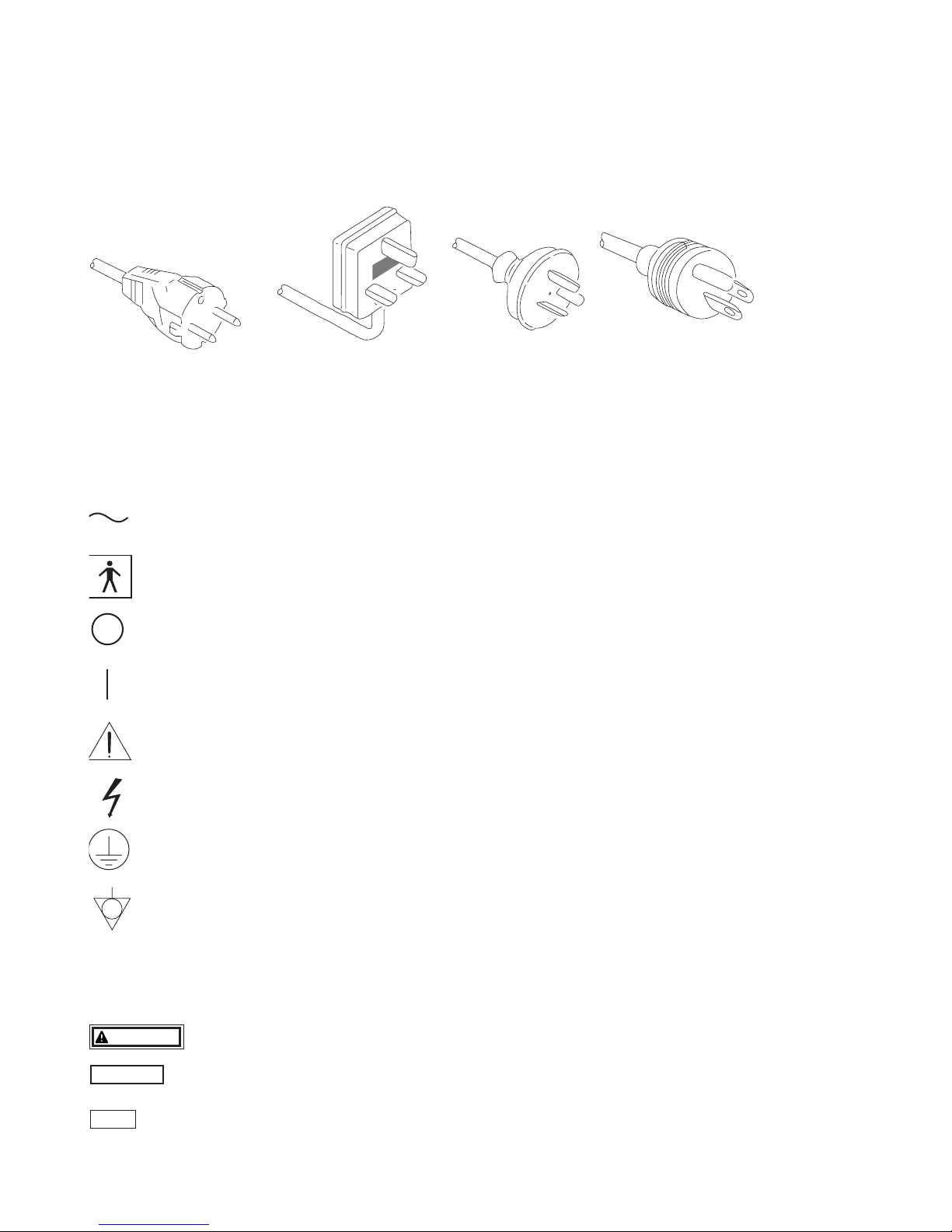

POWER REQUIREMENTS

Check the standard power plug configurations that are used in your country. If the appropriate power cord is not included in your

product, notify your local PENTAX distributor.

SYMBOLS ON MARKING

CONVENTIONS

The following conventions have been established in the text of this manual to aid in the identification of potential hazards of

operation;

: Could result in death or serious injury.

: May result in minor or moderate injury or property-damage.

: May result in property-damage. Also, advises owner/operator about important information on the use of

this equipment.

3

Continental Europe

(Use a SEV approved

plug for Switzerland)

U.K. Australia

and

New Zealand

U.S.A. and

Canada

(Hospital Grade)

Alternating current

Type BF applied part (Safety degree specified by IEC 60601-1)

OFF (Power : disconnection from mains)

ON (Power : connection to the mains)

Attention, consult Owner’s Manual

Dangerous Voltage

CAUTION

NOTE

WARNING

Protective earth (ground)

Equipotentiality

Page 7

4

1. PRECAUTIONS DE SECURITE-IMPORTANT

Les précautions suivantes doivent toujours être obeervées lors de l’utilisation de tout matériel médical électrique susceptible

d’être utilisé avec cet appareil, pour assurer à toutes les personnes concernées (utilisateus, patients, etc...) une sécurité maximale.

Veuillez lire et suivre attentivement les recommandations du manuel d’utilisation.

1-1. FORMATION

L’appareil ne doit être utilisé que sous la surveillance d’un médecin expérimenté, dans un établissement médical. Ne pas utiliser

dans un autre endroit ou pour toute autre application pour laquelle il n’est pas prévu.

1-2. INSTALLATION

1. L’appareil ne doit JAMAIS être placé ou utilisé dans un endroit où il serait mouillé ou exposé à l’humidité, à une température

élevée, à la lumière solaire directe, à la poussière, au sel, etc., qui pourraient l’endommager.

2. L’appareil ne doit JAMAIS être placé ou utilisé en présence de gaz ou de produits chimiques inflammables ou explosifs.

3. L’appareil ne doit JAMAIS être placé, utilisé ou transporté en position inclinée, ni être soumis à des chocs ou des vibrations.

4. Pour des raisons de sécurité, l’appareil doit être correctement relié à la terre (cet appareil doit être branché dans une prise

secteur 3 broches aux normes Hôpital aux U.S.A. et au Canada).

5. Assurez-vous que les spécifications électriques de la prise secteur sont conformes à celles indiquées à l’arrière de l’appareil.

6. Ne pas obturer les orifices de ventilation de l’appareil.

7. Ne pas écraser, plier ou tendre le cordon secteur.

8. Dans le cas ou un transformateur d’isolement est utilisé pour le matériel périphérique, vérifier que la puissance totale de

l’installation ne dépasse pas la capacité du transformateur. Pour de plus amples informations, contacter votre distributeur

PENTAX.

1-3. AVANT UTILISATION

1. Vérifier le fonctionnement de l’appareil et de ses interrupteurs, afficheurs, voyants, etc...

2. Pour prévenir les risques de chocs électriques lorsqu’il est utilisé avec des endoscopes, cet appareil doit être installé comme

“Matériel électrique médical type BF”. Ne pas le relier aux autres appareils électriques utilisés pour le même patient. Les

utilisateurs doivent s’isoler électriquement en portant des gants de caoutchouc.

3. Vérifier le fonctionnement des périphériques utilisés avec l’appareil et s’assurer qu’ils n’en perturbent pas le fonctionnement

et la sécurité. Si l’une des composantes du système endoscopique ne fonctionne pas correctement, interrompre l’utilisation.

4. Vérifier le branchement des différents câbles de liasions (vidéo, secteur, contrôle, etc...).

5. La durée de vie nominale de la lampe est de 400 heures. Avant utilisation, vérifier que le témoin de durée de vie vert ou jaune

est allumé. A partir de 400 heures, le témoin rouge s’allume et la qualité d’image diminue. Une utilisation excessive de la

lampe au-delà de 400 heures (approchant plusieurs milliers d’heures) peut être à l’origine d’une explosion de la lampe

pouvant provoquer des dommages au vidéoprocesseur.

- La duré de vie de la lampe estimée à 400 heures s’applique aux processeurs EPK-1000 dont le numéro de série

commence par UB et EB.

NOTE

Page 8

1-4. PENDANT L’UTILISATION

1. Pour éviter les risques de choc électrique, l’endoscope et/ou tout autre périphérique utilisé conjointement avec l’appareil ne

doivent JAMAIS être placés directement sur le coeur.

2. Ne pas mettre le patient en contact avec l’appareil.

3. Pour conserver l’afficheur et le clavier souple en bon état, ne pas presser les touches du tableau avec un objet pointu ou

tranchant.

4. Eviter de regarder directement la lumière sortant de l’endoscope et/ou de l’appareil du fait de la forte luminosité émise par la

lampe Xénon.

5. Pour protéger l’utilisateur et éviter toute blessure thermique pendant l’examen, régler la luminosité au minimum nécessaire.

6. Eviter une utilisation prologée de l’appareil si elle n’est pas indispensable, pour ne pas compromettre la sécurité du patient

et de l’utilisateur.

7. Surveiller en permanence l’appareil et le patient pour prévenir tout signe de dysfonctionnement.

8. En cas de problème avec le patient ou l’appareil, prendre toutes les mesures nécessaires pour préserver la sécurité du patient.

9. Si un problème de fonctionnement survient sur l’un des appareils du système endoscopique et que l’image est interrompue

ou altéree, placer l’endoscope en position neutre et retirer doucement.

10. Cet appareil doit toujours être utilisé selon les instructions et conditions de fonctionnement décrites dans ce manuel. Ne pas

les suivre peut compromettre la sécurité, le fonctionnement du matériel, ou endommager l’appareil.

1-5. APRES UTILISATION

1. Veuillez vous référer aux instructions fournies avec chaque composante du système endoscopique afin d’éteindre les

composantes dans l’ordre adéquat. Certains périphériques peuvent devoir être éteints d’abord pour ne pas compromettre leur

fonctionnement.

2. Essuyer les appareils avec une compresse légèrement imbibée d’alcool.

3. Vérifier que les connecteurs et les orifices de ventilation sont à l’abris des projections de liquides.

1-6. STOCKAGE

1. L’appareil ne doit JAMAIS être rangé à l’humidité, à température élevée, à la lumière solaire directe, la poussière, le sel, etc.,

qui pourraient l’endommager.

2. L’appareil ne doit JAMAIS être rangé en présence de gaz ou de produits chimiques explosifs.

3. L’appareil ne doit JAMAIS être rangé en position inclinée ni être soumise à des chocs ou des vibrations.

4. Les accessoires et les câbles doivent être nettoyés et rangés correctement.

5. L’appareil doit être maintenu en parfait état de propreté durant le stockage, et tenu prêt pour l’utilisation suivante.

1-7. SERVICE

1. Ne JAMAIS modifier ou altérer l’appareil. Les réparations éventuelles ne doivent être effectuées que par un service aprés-

vente PENTAX.

2. Le remplacement de la lampe ne doit être effectué que par une lampe agréée par PENTAX et en sulvant les instructions

fournies par PENTAX.

1-8. MAINTENANCE

Périodiquement, cet appareil et tous les périphériques associés doivent être vérifiés en fonctionnement et en sécurité.

1-9. ÉLIMINATION

Ce matériel doit être retourné à PENTAX pour élimination. Contacter PENTAX ou votre Agence PENTAX locale.

5

Information concernant l’élimination des produits dans l’Union européenne.

Ce produit est un dispositif médical. En conformité avec la Directive européenne 2002/96/CE relative aux déchets d’équipements électriques et

électroniques, ce symbole indique que le produit ne doit pas être éliminé comme un déchet non trié, mais qu’il doit faire l’objet d’une collecte

sélective. Contactez votre distributeur PENTAX local pour avoir des informations concernant la procédure correcte d’élimination et de recyclage.

En éliminant ce produit correctement, vous contribuerez à garantir que ce déchet est soumis au traitement, à la valorisation et au recyclage

nécessaires, empêchant ainsi les effets négatifs potentiels pour l’environnement et la santé des personnes qui résultent de la gestion

inappropriée des déchets.

Page 9

6

ALIMENTATION NECESSAIRE

Vérifier le type de prise de courant utilisé dans votre pays. Si le cordon secteur approprié n’est pas fourni avec votre appareil,

contactez votre distributeur PENTAX.

SYMBOLES UTILISES:

CONVENTIONS

Les conventions suivantes ont été adoptées dans le texte de ce manuel, afin d’aider á l’identification des risques potentiels liés à

l’utilisation;

: Peut causer la mort ou une blessure grave

: Peut causer une blessure légère à modérée ou des dégâts au materiel

: Peut causer des désgâts au matériel. Donne aussi à l’utilisateur des informations sur les appareils

Europe Continentale Royaume - Uni Australie

et

Nouvelle Zélande

USA et Canada

(Normes Hôpital)

Courant alternatif

Élément type BF (Niveau de sécurité spécifié par la norme IEC60 601-1)

“OFF” (Alimentation : déconnectée du secteur)

“ON” (Alimentation : connectée au secteur)

Attention : consulter le manuel d’utilisation

Voltage dangereux

Mise à la terre de protection

Equipotentialité

(Utiliser une tiche homologuée

SEV pour la Suisse)

CAUTION

NOTE

WARNING

Page 10

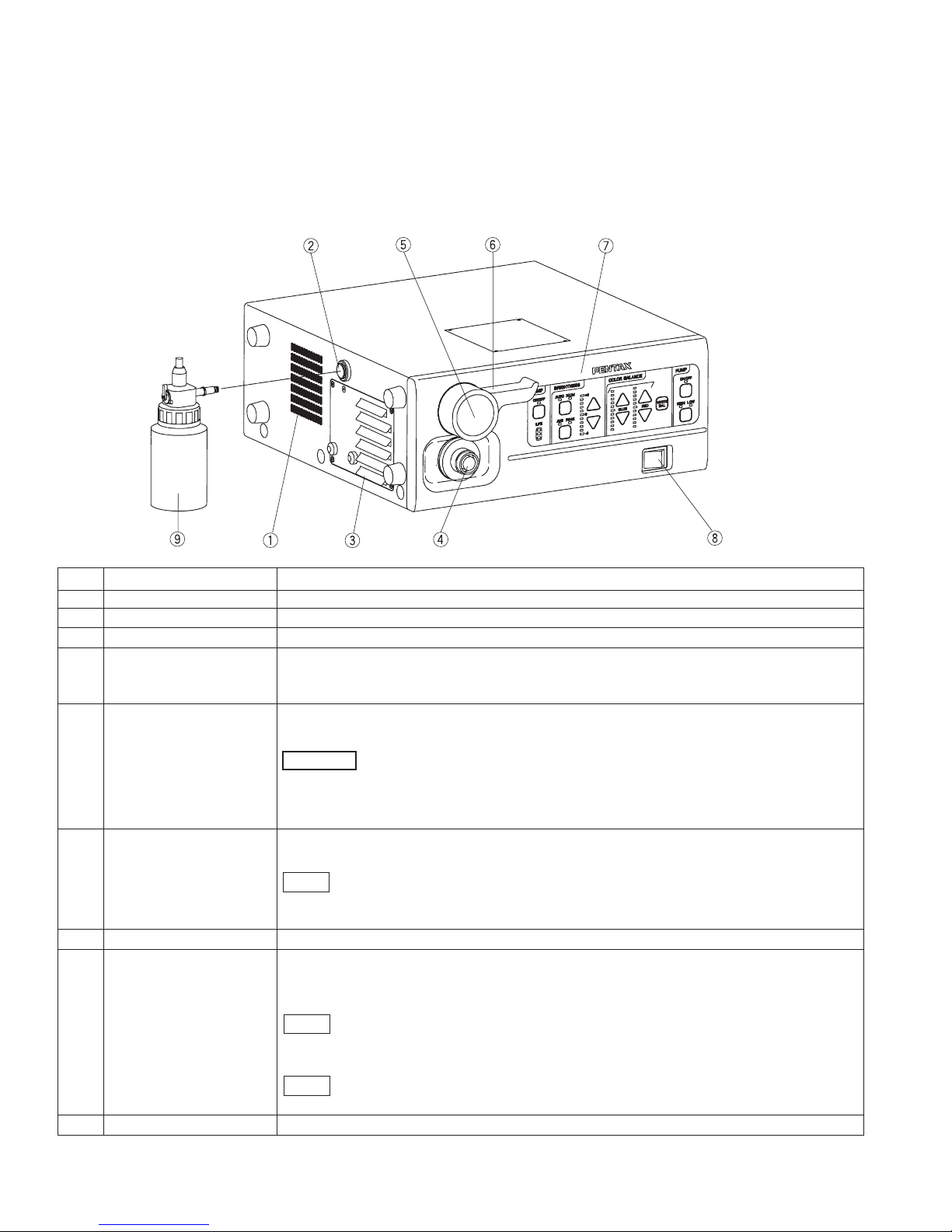

7

2. NOMENCLATURE, CONTROLS AND FUNCTIONS

2-1 VIDEO PROCESSOR

(1) MAIN BODY

No. NAME FUNCTION

1 Ventilation Grid allows for adequate ventilation and cooling lamp/unit. Do NOT block the grids.

2 Water Bottle Receptacle accepts air pipe from PENTAX water bottle assembly.

3 Lamp Housing Cover provides access to replace lamp cartridge.

4 Light Guide Attachment AE-P1 adapter for standard PENTAX endoscopes. Port accepts video endoscope or

fiberscope light guide. Adapter can be changed for use as light source for other

manufacturer’s endoscopes or for use with fiberscope video adapter module.

5 Endoscope Electrical accepts Color video endoscope electrical connector or fiberscope video adapter module

Connector electrical connector.

- Always turn ON the power switch after connecting an endoscope. Also,

remove the endoscope from the processor after turning OFF the power switch.

- When you take the light guide out of this socket, the sleeve of the light guide might be hot.

Take the light guide out of the socket with caution.

6 Scope Locking Lever Open the lever before setting or removing an endoscope.

After connecting the endoscope to the processor, close the lever.

- After connecting the endoscope to the EPK-1000 video processor, always make

sure that the endoscope is firmly secured to the scope receptacle by turning the locking

lever to the “lock” position.

7 Front Panel See the section 2-1- (2)

8 Power Switch The processor is turned | : ON, or O : OFF.

Switch lights green when switched ON. Switch should not be hit with objects like

endoscope light guides, when being switched ON or OFF.

- Always turn ON the power switch after connecting an endoscope. Also, remove

the endoscope from the processor after turning OFF the power switch.

- Before turning the EPK-1000 power ON, ensure the air flow vents are not obstructed.

-Aside from the pre-use inspection of the equipment, the lamp in the video

processor should be turned OFF when the video system is not clinically used.

9 Water Bottle See the section 2-2.

NOTE

NOTE

NOTE

CAUTION

Page 11

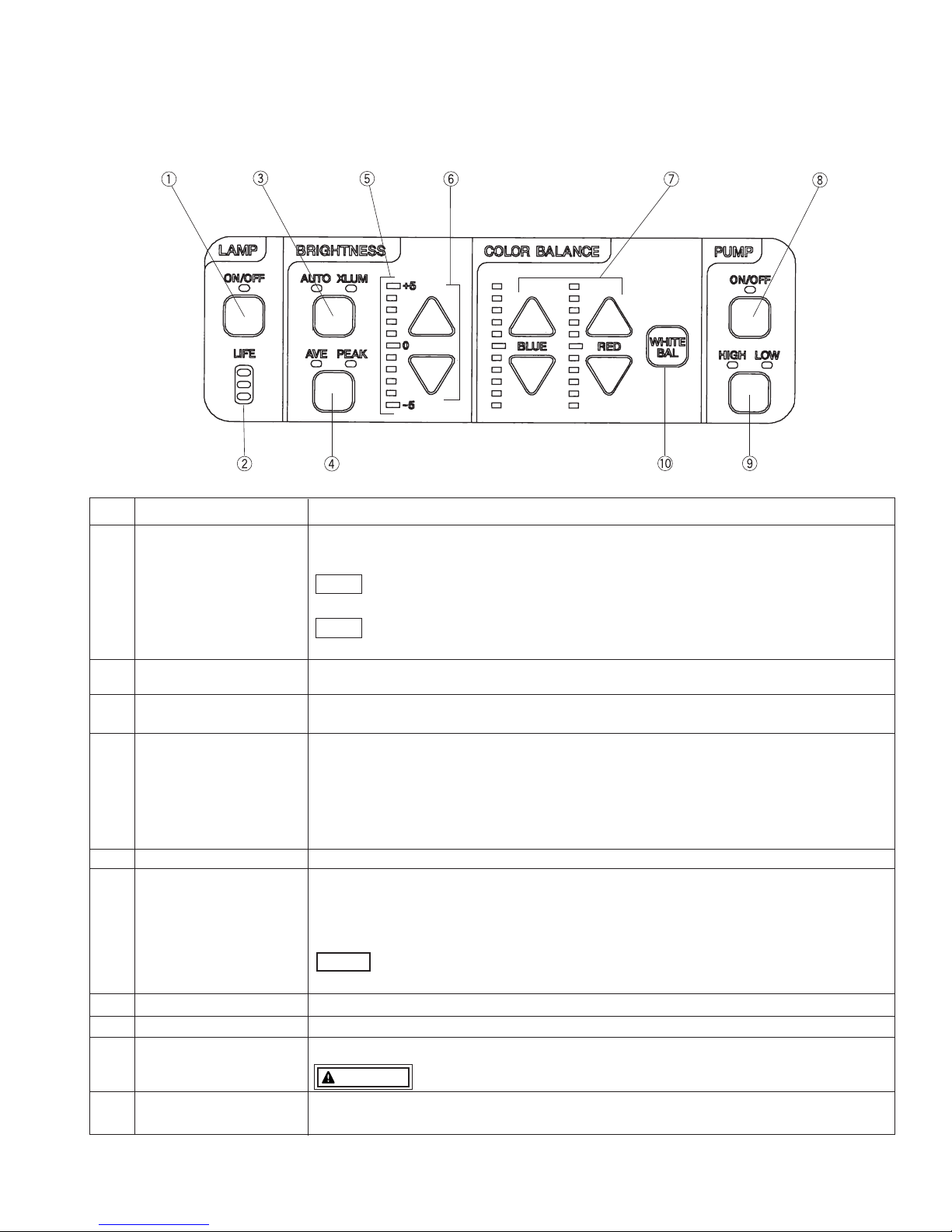

8

(2) FRONT PANEL

No. NAME FUNCTION

1 Lamp Switch ignites the main lamp. The LED lights green when switched ON. When the main lamp

fails to ignite, the LED flashes. Press the lamp switch again to ignite the auxiliary lamp.

-Aside from the pre-use inspection of the equipment, the lamp in the video

processor should be turned OFF when the video system is not clinically used.

-The auxiliary lamp is incorporated to the processor with serial number beginning

UB and EB.

2 Lamp Life Indicator indicates hours for Xenon lamp installed in video processor. If the indicator lights red, a lamp

should be replaced before beginning the next procedure.

3

AUTO/XLUM Select Switch

selects AUTO (automatic) or XLUM (manual) brightness control mode. AUTO or XLUM

indicators will light to indicate which is selected.

4

AVE/PEAK Select Switch

Selecting AUTO will require selection of light measuring method, AVERAGE or PEAK.

AVE or PEAK indicator lights to indicate which is selected.

AVERAGE: the brightness level is adjusted with respect to an averaging of the brightness

of the video signal.

PEAK: the brightness level is adjusted with respect to the brightness of the peak of

the screen.

5 Brightness Indicator indicates the brightness level settled by the user.

6 Brightness controls the brightness level.

Up or Down button will change the brightness level as shown on the brightness indicator.

Adjustment

△

increases the brightness level.

Switch

▽

descreases the brightness level.

-Minimum reguired brightness should be used at all times to avoid risk of injury

to the patient.

7 Color Balance Switch adjusts the video image color, Blue or Red by +/- 5 steps.

8 Pump on/off controls air pumps on/off. LED on the switch will light when switched ON.

9 Pump high/low LED on the switch indicates the pump output pressure level, High/Low.

WARNING -When selecting HIGH pressure, be careful not to deliver too much air.

10 White Balance Switch adjusts the white balance of the video endoscope. After adjustment, “WB OK!” is

displayed for about 3 seconds.

NOTE

NOTE

NOTE

Page 12

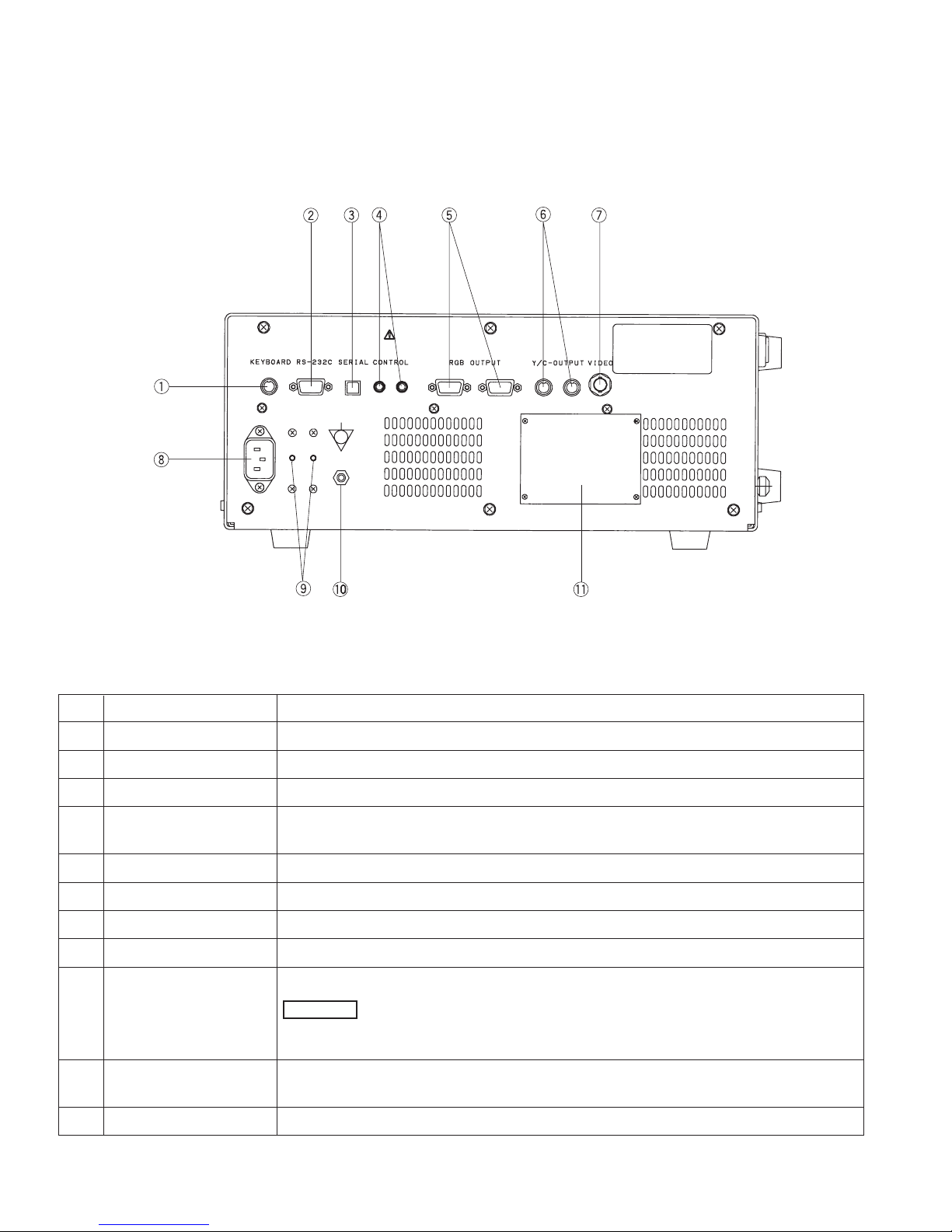

9

(3) REAR PANEL

No. NAME FUNCTION

1 Keyboard Connector accepts the keyboard supplied by PENTAX.

2 Interface Connector RS-232C serial interface connector.

3 Serial Bus NTSC or PAL Serial Digital Video out connector for a still-frame video image .

4 Control is activated by either the endoscope control buttons (C, V) or the keyboard copy key to

control peripherals.

5 RGB Video Output NTSC or PAL RGB video out connectors, 9-pin D-sub Female connectors.

6 Separated Video Output Y/C video out connector (4-pin S connector)

7 Composite Video Output NTSC or PAL composite video out connector, BNC type connector.

8 Power Input Socket accepts AC power cord.

9 Breaker activates with a red button sticked out when abnormal current flows.

-When the breaker is activated, try to reset first. If the breaker activates

again when the processor is turned ON, do NOT use the processor and return it to

PENTAX.

10

Potential equalization terminal

For safety purposes, this terminal is connected to a potential equalization busbar of the

electrical installation.

11 Rating Plate displays unit model number, serial number and power requirements.

CAUTION

Page 13

10

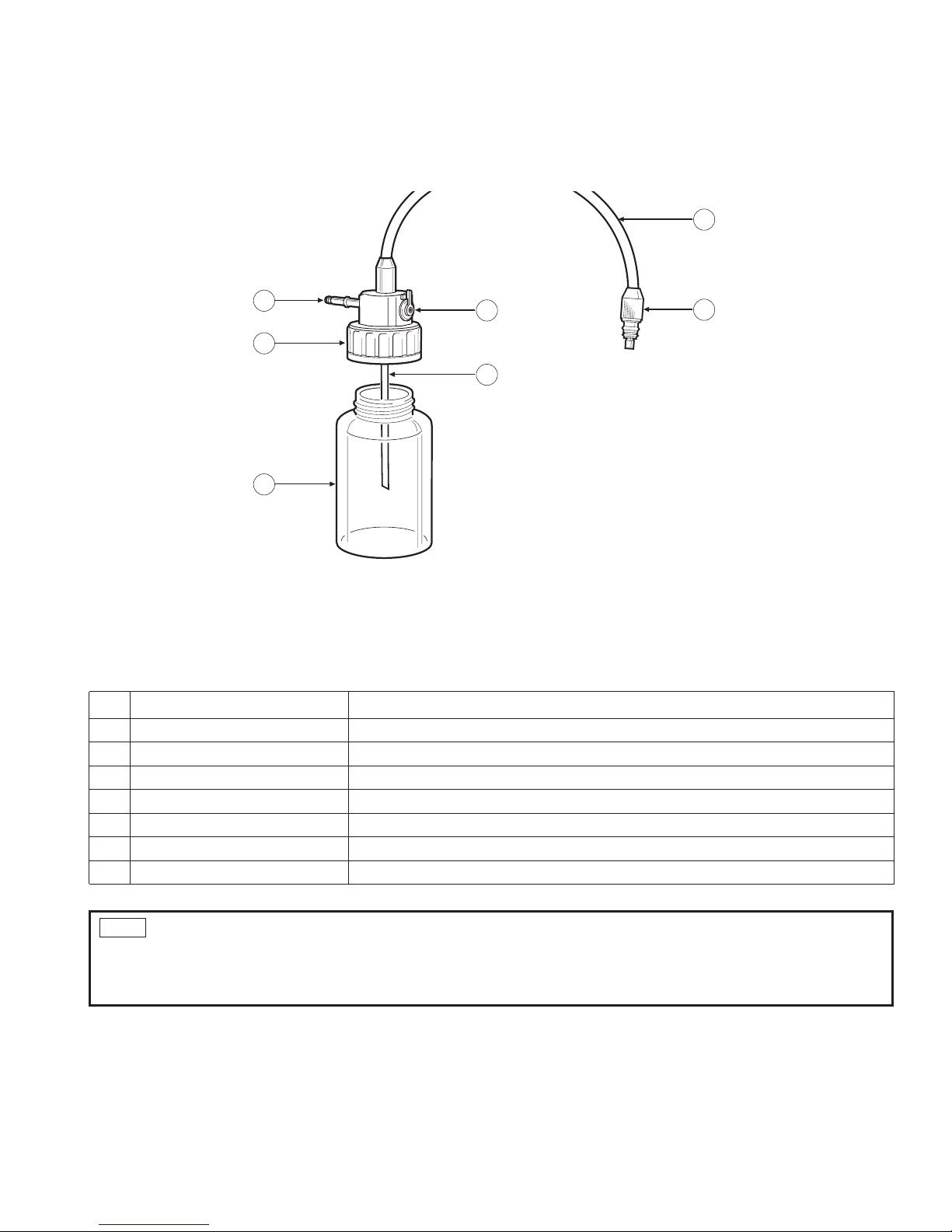

2-2 WATER BOTTLE ASSEMBLY, MODEL OS-H4

No. NAME FUNCTION

1 Bottle holds sterile water for procedure. (use up to 2/3’s full)

2 Water Bottle Cap Assembly

must be firmly secured to bottle to prevent air leakage. Do NOT overtighten the bottle cap.

3 Air Pipe Stem inserts into video processor water bottle receptacle.

4 Air/Water Hose contains (2) independent tubes - 1 for air, 1 for water.

5 Air/Water Connector inserts into Air/Water socket of endoscope umbilical connector.

6 Air/Water- Drain Lever must be set to upright (A/W) position for delivery of air and water.

7 Water Feeding Stem channel for water to be displaced from bottle and into scope.

1

2

3

6

7

4

5

- If the water bottle assembly has been handled roughly, the water feeding tube inside the Air/Water hose may be

disconnected at the A/W connector for the endoscope. To test, remove the cap assembly and using a syringe, inject water into

the water feeding stem. If the water comes out of both the center hole of the A/W connector and the series of holes around the

center hole, the water feeding tube is disconnected. Use another water bottle assembly.

NOTE

Page 14

11

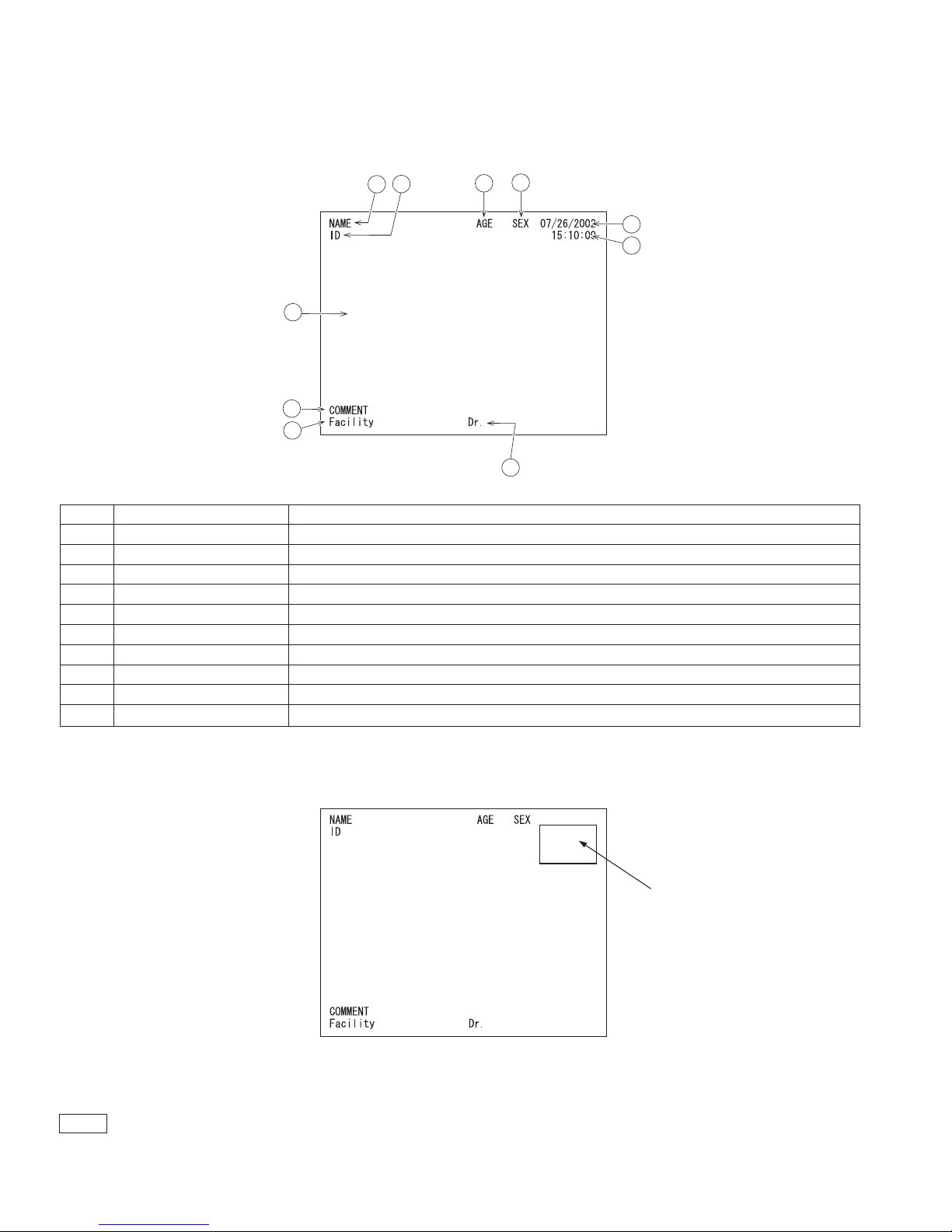

2-3 MONITOR DISPLAY SCREEN

(1) NORMAL

(2) FREEZE (SUB-SCREEN DISPLAY)

Endoscopic image will be displayed to this area of the monitor screen when freeze function is activated.

NOTE - Appearance of sub-screen covers Date and Clock.

2

4

5

3

7

10

6

9

8

1

No. NAME FUNCTION

1 NAME Alpha-numeric field, 24 characters long.

2ID Alpha-numeric field, 12 characters long.

3AGE Alpha-numeric field, 3 characters long.

4 SEX Alpha-numeric field, 1 character long.

5 Date Numeric field

6 Clock Military format, Hours: Minutes: Seconds.

7 Doctor’s Name Alpha-numeric field, 12 characters long.

8 Facility Alpha-numeric field, 12 characters long.

9 COMMENT Alpha-numeric field, 40 characters long.

10 Main Screen Endoscopic image will be displayed on the monitor screen.

Sub-Screen Display

Page 15

12

2. Make sure the power switch is OFF.

3. Plug the power cord into the power source

using the three (3) prong plug supplied with the unit.

4. Ensure the keyboard is connected properly.

WARNING

• To reduce the potential for the electric shock, connect the power cord

of the following peripheral components into the medical isolation

transformer supplied.

– Any peripheral components connected to the PENTAX Processor.

– Any peripheral components connected to the PENTAX Endoscope.

– NEVER connect other components to the isolation transformer.

• Check that the total power consumption of all connected devices does

not exceed the isolation transformers’ power rating.

• Make sure that outputs are in compliance with IEC 60601-1-1.

• Make sure that the power cord is connected to the main with a three (3)

prong plug (In the U.S.A use UL 2601-1 rated isolation transformers

and/or power strips only).

(2) CONNECTING THE WATER BOTTLE

1. Fill the water bottle approximately 2/3 full with sterile water.

2. Screw the water bottle cap assembly to the water bottle snugly.

-Do NOT overtighten the water bottle cap

3. Set the Air/Water- Drain lever to A/W position.

4. Insert the water bottle air pipe stem into the video processor water

bottle receptacle and press until the water bottle ‘clicks’ into

position.

-Do NOT press the water bottle too forcefully into the video

processor. Rough handling may cause water to leak onto/into the

video processor.

5. Insert the Air/Water connector into the holder on the water bottle

cap assembly until the endoscope is connected

-Always disconnect the water bottle before moving the

processor into a position not common to normal use.

Always disconnect the water bottle before packing the video

processor for shipment.

EPK-1000

SAT-1300

Peripheral

A/W

DRAIN

NOTE

NOTE

NOTE

●

●

3. PREPARATION AND SAFETY CHECK

3-1 PREPARATION

WARNING - PENTAX video processors are electro-medical devices incorporating delicate

components and sophisticated circuitry that should not be subjected to harsh conditions,

including excessive vibrations and/or severe impact. NEVER drop this equipment or subject it to

severe impact as it could compromise the functionality and /or safety of the unit. Should this

equipment be mishandled or dropped, do NOT use it. Return it to an authorized PENTAX service

facility for inspection and repair.

(1) SETTING UP THE VIDEO PROCESSOR

1. Place the video processor on a stable and level surface (cart, counter, stand,etc..).

• Avoid places where the video processor may be splashed with liquid.

• Absolutely do NOT use in any environment with explosive or flammable gases.

• Avoid places where the unit could be exposed to high temperature, humidity, direct sun light, etc.

• Do NOT install, operate or store electro-medical equipment in a dusty environment.

Accumulation of dust within these units may cause malfunction, smoke, or ignition.

• Do NOT block the venting grids on the sides of the processor.

• When moving the video processor, do NOT hold the scope locking lever.

NOTE

●

Page 16

13

(3) CONNECTING THE ENDOSCOPE

- Always turn ON the processor after connecting an endoscope. Also, remove the endoscope from the processor after

turning OFF the power switch.

1. Check to ensure that the appropriate light guide adapter is mounted to the video processor. The adapter, AE-P1 is already

attached to the video processor.

- Connecting a video endoscope without a light guide adaptor in place will reduce light output at the endoscope distal

end. Attempting to connect a fiberscope without a light guide adapter and/or an appropriate light guide sleeve in place will

damage the fiberscope and the video processor.

2. Check to ensure that the scope locking lever is open.

3. Connect the scope firmly into the processor until it clicks

into position.

4. Close the scope locking lever

- After connecting the endoscope to the EPK-1000

video processor, always make sure that the endoscope is firmly

secured to the scope receptacle by turning the locking lever to

the “lock” position.

- If using the fiberscope video adaptor module, make

sure the eyepiece of the fiberscope is properly connected to the

module (use adapters as required). Connect the electrical

connector of the module to the electrical connector of the video

processor, lining up the red dots on each.

5. Connect the water bottle Air/ Water connector to the

Air/Water receptacle on the endoscope’s umbilical connector.

6. Connect the suction tube of the suction device to the suction

nipple on the umbilical connector of the endoscope.

(4) CONNECTING THE PERIPHERAL EQUIPMENT

1. Referring to the rear panel diagram, connect a TV monitor

and other required equipment such as hard copy equipment,

VCR, etc., to the processor.

- When used in clinical or residential areas near

radio and TV receiver units, this equipment may be subjected

to radio interference.

- To reduce electromagnetic interference, do NOT keep turning

ON the main POWER SWITCH of the equipment while a

videoscope is connected but not ready for use.

- To avoid and resolve adverse electromagnetic effects, do NOT

operate this equipment near the RF energy equipment.

: FOR EUROPE

- This equipment is a Class B Medical Equipment (specified

EN55011) and is intended for hospital or health care districts.

- Use the connection cables as specified below.

Composite Video Cable (1.5m), RGB Video Cable (1.5m), Y/C Video Cable (1.5m), Control (1,2) Cable (1.5m), RS-232C

Cable (1.5m), Serial Bus Cable (1.5m).

- Do NOT connect a printer simultaneously to RS232C and Control terminal located on rear panel of the processor.

- Do NOT connect two or more processors to a computer.

CAUTION

CAUTION

CAUTION

NOTE

NOTE

NOTE

●

●

●

●

CAUTION

CAUTION

Page 17

14

3-2 PRE-USE SAFETY CHECKLIST

WARNING - Before every use the following points should be checked. If any function or device in the video endoscope system

does not perform properly, do NOT perform the endoscopic examination. Contact the manufacturer of the device, your PENTAX

sales representative or a PENTAX service center before using the equipment for an endoscopic examination.

1. Ensure that power switch is OFF.

2. Ensure that video processor is placed in stable and level position.

3. Ensure that water bottle is properly prepared and connected.

4. Ensure that endoscope (and fiberscope video adaptor module if applicable) is connected properly.

- After connecting the endoscope to the EPK-1000 video processor, always make sure that the endoscope is firmly

secured to the scope receptacle by turning the locking lever to the “lock” position.

5. Ensure that keyboard is connected properly.

6. Turn ON monitor and other peripheral devices.

7. Turn ON video processor power switch. Ensure that switch is lighted green and the sound of the ventilation fans can be heard.

WARNING - After 400 hours of use, the image quality will deteriorate. Excessive use of the lamp beyond 400 hours

(approaching a thousand hours of use or more) could cause the lamp to explode resulting in damage to the video processor.

-The lamp life rated at 400 hours, is applicable to the EPK-1000 processor with serial number beginning with UB and EB.

8. Ensure that video processor lamp life indicator lights green or yellow. If red, replace the lamp.

- Always turn ON the processor after connecting an endoscope. Also, remove the endoscope from the processor after

turning OFF the power switch.

-Power function switches should not be activated by contact with objects like endoscope light guides when being switched ON

or OFF. Before turning the video processor power ON, ensure the air flow vents are not obstructed.

9. Turn on the lamp switch to ignite the lamp. If lamp fails to ignite, turn video processor OFF, wait 60 seconds and repeat steps

7 and 9.

-If lamp fails to ignite, do NOT attempt to perform an endoscopic examination, contact your PENTAX service facility.

10. With lamp lit and endoscope connected, check for live endoscopic image on the monitor.

NOTE:

It should be recognized that the use of electro-surgical accessory devices employing high frequency current

may interfere with the normal endoscopic image and this interference is not indicative of a malfunction of the

video endoscope system. PENTAX has developed an earth cable, model OL-Z3 intended to reduce potential

RF interference and electronic noise that may appear in the endoscope image when using electro-surgical

devices. Ensure that cable OL-Z3 is correctly connected between the endoscope and video processor as

described in the instructions provided with the OL-Z3.

NOTE

NOTE

NOTE

NOTE

CAUTION

to endoscope

to video processor

Page 18

15

11. Exercise the endoscope’s automatic iris. Bring the tip of the

endoscope within 1 cm off the palm of your hand and move

it to about 5 cm away from the palm. Watch the image on

the monitor to ensure the brightness at both distances is

similar. Lift the distal end of the endoscope to the room

lights, the light being emitted at the distal end of the scope

should lower significantly (dependent on the ambient light

levels in the room). Return the distal end of the endoscope

to point at the palm and ensure that the light is being emitted

from the distal end of the endoscope.

12. Check the endoscope control buttons positioned on the

control body of the endoscope.

-In combination with PENTAX 70K/72K/80K/81K/85K

series endoscopes, the function of each button can be selected

with the scope buttons key on the keyboard.

13. Select brightness control auto or XLUM. If selecting

AUTO, also select light measurement mode, average or

peak. And exercise the brightness control switches to ensure

that the brightness indicator and controls are functioning.

14. Exercise the color adjustment as described below.

Cup the distal end of the endoscope loosely in your hand. Ensure

that the monitor displays a natural color. Exercise the color adjust

switches (Red Up and Down and Blue Up and Down) to ensure

that the changes are recognizable in the image of your hand.

15. If XLUM is intended to be used during the procedure,

exercise the XLUM function. Upon selecting the switch,

LED will light and maximize the brightness level.

16. Turn ON the air pump on/off switch. The switch LED will

light and the sound of the air pump should be heard.

Select desired level, Low or High.

17. Exercise Air/Water delivery through the endoscope.

Covering air venting hole on top of Air/Water button

lightly should deliver air at the distal end of the endoscope

by submerging the distal end in enough water to cover the

tip, air flow will be demonstrated by a trail of bubbles.

Pressing the button all the way down should deliver water

through the tip of the endoscope.

-Use only “fresh” distilled or sterile water for testing

of the endoscope air/water delivery functions.

If all items above appear to function satisfactorily, then the

endoscopic procedure may be performed. If any functionality

above is compromised, do NOT attempt to perform the

endoscopic procedure.

●

●

●

●

●

Air

Feeding

Water

Feeding

NOTE

NOTE

F

U

L

R

D

Page 19

16

4. OPERATION

4-1 PROCESSOR FUNCTIONS

-Check the lamp life indicator on the front panel. If red, a lamp should be replaced before beginning a procedure.

-Before turning the processor ON, ensure the air flow vents are not obstructed.

WARNING - After 400 hours of use, the image quality will deteriorate. Excessive use of the lamp beyond 400 hours

(approaching a thousand hours of use or more) could cause the lamp to explode resulting in damage to the video processor.

-The lamp life rated at 400 hours, is applicable to the EPK-1000 processor with serial number beginning with UB and EB.

(1) MAIN LAMP

Turn ON the lamp switch to ignite main lamp and the LED on the lamp switch. The light will be emitted from the distal end of

the endoscope. When the procedure is completed, turn OFF the lamp. If the lamp fails to ignite and the LED flashes, do NOT

attempt to perform an endoscopic procedure.

-Aside from the pre-use inspection of the equipment, the lamp in the video processor should be turned OFF when the

video system is not clinically used.

(2) AUXILIARY LAMP

If the LED on the lamp switch is flashing , it indicates that main lamp is burnt out or there is a lamp failure. The message

“PUSH LAMP SWITCH” will be displayed on the monitor screen. While this error message is displayed, all function keys

(except the lamp switch) are deactivated. To ignite the lamp, press the “LAMP SWITCH” - do NOT push the “POWER

SWITCH” - while the LED is flashing. The auxiliary lamp and the LED will light.

Do NOT attempt to perform an endoscopic examination with auxiliary lamp. The auxiliary lamp is intended to assist in the safe

withdrawal of the endoscope in the event that the main lamp fails to ignite during a procedure. After igniting the auxiliary lamp,

return the endoscope to the neutral position and slowly withdraw the endoscope under controlled visualization by the auxiliary lamp.

The auxiliary lamp can be turned OFF by pressing the switch or by turning the processor OFF.

WARNING - The auxiliary lamp is intended to provide sufficient visualization to withdraw the endoscope, should the main

lamp fail. Do NOT attempt to perform an endoscopic examination with the auxiliary lamp.

-The auxiliary lamp is incorporated to the processor with serial number beginning with UB and EB.

- The auxiliary lamp in the EPK-1000 incorporates a LED which is recognized as a class 2 laser product by

IEC60825-1. Emission from the endoscope distal tip into the human body is at a level lower than class 2 as long as the lamp and

all associated finished products are used properly according to provided instructions. To protect user’s eyes, avoid looking

directly at the light exiting the endoscope and/or the processor.

Use of controls or adjustments or performance of procedures other than those specified herein may result in hazardous

radiation exposure.

NOTE

NOTE

CAUTION

NOTE

NOTE

Page 20

17

(3) BRIGHTNESS

Select the desired brightness control mode, AUTO or XLUM, using the brightness control switch.

AUTO = Automatic brightness control, where the video signal of the endoscope will automatically maintain the brightness level

selected by the brightness adjustment switches. The switch will beep when pressed and the AUTO indicator will light when the

AUTO mode is selected.

If the AUTO brightness mode is selected, select the desired brightness level and the light measurement method, AVE or PEAK,

using the light measurement switch on the front panel or the endoscope control buttons.

AVE = The brightness level is automatically adjusted with respect to an averaging of the brightness of the video signal.

PEAK= The brightness level is automatically adjusted with respect to a peak (maximum) value of the brightness of the video signal.

The switches will beep when pressed and the AVE or PEAK label will light when either is selected.

-Halation is defined as the appearance of a halo around an area of extreme brightness. Halation may occur if the AVE mode

and PEAK mode are selected. If halation is observed and if it distorts the endoscopic image, one should reduce the brightness level.

XLUM= Manual brightness control, the user will select the brightness level by using the brightness adjustment switches.

The switch will beep when pressed and the XLUM label will light when manual mode is selected.

WARNING - To protect users eyes and avoid risk of thermal injury, select the Auto mode. When the processor is used as a

light source, select the XLUM mode with the minimum required brightness. When the procedure is suspended for a while, turn

OFF the lamp switch or select the XLUM mode with the lowest brightness.

There are eleven (11) brightness levels. The brightness level will be displayed as a value -5 to +5 on the brightness indicator on

the front panel.

To change the brightness level;

Press the Up switch (△) to increase the level.

Press the Down switch (▽) to decrease the level.

The switches will beep when pressed and the brightness level indicator will change accordingly.

- To protect the users eyes and avoid risk of thermal injury during an endoscopic examination, use only the

minimum amount of brightness required.

-The video processor has a battery backup memory and will retain the last selected brightness value even if the unit is

turned OFF or disconnected from the power outlet.

(4) COLOR BALANCE

There are eleven (11) color levels for both Red and Blue hue.

They will be displayed as a value -5 to +5 on the monitor display at either end of the color bar.

All the switches described above will beep when pressed.

-The video processor has battery backup memory and will retain the last selected color balance levels even if the unit is

turned OFF or disconnected from the power outlet.

The white balance function adjusts the white balance of each endoscope. Proper

white balance requires the use of the white balance adjuster attached to the PENTAX

System Cart. Contact your local PENTAX service center for the details if required.

1) Put the distal end of the video endoscope into the white balance adjuster which

is supplied with the processor.

2) Watching the monitor, adjust the position of the distal end of the scope in the

adjuster so that the circle at the bottom of the white balance adjuster can be

recognized on the full screen.

3) Press the white balance switch while keeping the scope distal end stationary in

the adjuster more than three seconds.

If the white balance is established, “WB OKI” is displayed on the screen.

NOTE

NOTE

+

●

NOTE

CAUTION

Page 21

18

(5) PUMP

To turn the air pump On, press the Air Pump ON/OFF switch. The switch will beep when pressed. Then the LED on the switch

will light and the sound of the air pump will be heard. To turn the air pumps OFF, press the ON/OFF switch again. The switch will

beep and the LED on the switch will turn OFF.

There are two (2) air pump levels, LOW and HIGH. The switches will beep when pressed and the LED on the level switch will light

to indicate the selected level. The air pump level will control the pressure of both the air and water delivery.

- Regardless of pump level setting selected, avoid delivering too much air to minimize the potential for pneumatic

perforation or barotrauma.

-Should debris on the objective lens be difficult to clean, one can temporarily use a higher pump level setting on the

video processor or light source. While doing so, simultaneously activate the air and suction control valves to minimize air

insufflation. After the lens has been cleared return the air pressure to its original setting for routine use. Regardless of pump

level setting selected, avoid delivering too much air.

CAUTION

NOTE

Page 22

19

4-2 KEYBOARD FUNCTIONS

(1) CONVENTIONAL KEYS

No. NAME FUNCTION

1 Function Keys Refer to FUNCTION KEY INDEXES.

Esc (Escape) Key stops data entry or function menu. Returns to the normal mode.

2 Alpha-Numeric Keys include keys for letters, numbers and special characters (brackets, commas, etc.) as well

as command keys (Control, Shift, Enter etc.).

3 Back Space Key moves cursor leftward and delete the character.

4 Caps Lock Key Caps Lock indicator will light to show Caps Lock selected. When Caps Lock is ON, all

alphabet keys will be typed to the monitor screen as capitals.

5 Enter Key moves cursor to the next field or to store selected data.

6 Shift Keys When Caps Lock is OFF, holding the Shift key and pressing alpha - numeric key will

be typed to the monitor screen as a capital letter or the special character pictured on the

key.

7 Ctrl (Control) Keys is used to access function menus.

8 Space Bar gives a space and deletes a previously typed character.

9 Cursor Movement Keys Up, Down, Left and Right arrows move the cursor to each direction.

Page 23

20

(2) SPECIAL FUNCTION KEYS

No. Function Keys Function

1 Patient makes up Patient List

2 New Patient inputs patient information

3 Clear Patient deletes patient data

4 User makes up User List

5 Scope Buttons assign function to each scope control button

6 Scope SW

select two controls (output terminals) on the rear panel

(Ctrl+Scope Buttons)

7 Enhance Level selects enhance level

8 Color Adj

adjust color

(Ctrl+Enhance Level)

9 Shutter Mode changes shutter speed automatically

10 Freeze Mode

selects freeze image Frame or Field

(Ctrl+Shutter Mode)

11 Clear Screen displays items once removed from the screen

12 Color Bar

remove or display color bar

(Ctrl+Clear Screen)

13 Character Off clears all screen information

14 Date

set date and clock

(Ctrl+Character Off)

15 PC selects peripheral equipment to RS232C terminal

16 Init initializes all data

17 Clear Counter initializes the film counter

18 Stopwatch activates stopwatch

19* Multi Picture sets number of split screens on video printer

20* Print Quant sets number of prints with video printer

21* Delete Image clears images currently stored in video printer

22* Print prints data already stored in video printer

23 Pointer shows a small arrow ( pointer ) on the normal screen

24 Editor enables input freely without any format restriction

25 VTR activates output peripheral such as VTR

26 Freeze activates freeze function

27 Copy activates output peripheral such as copy

28 Capture transmits a “frozen” endoscopic image to the PC connected to the processor.

29 Scope Model displays model name and serial number of endoscope.

* applicable only when certain brand and model printers are connected to the PENTAX Video System.

Page 24

21

Operation of Function Keys

1. Patient Key

-If the Enter key is pressed during display of the normal

screen, “Patient Information” is displayed without operation of

the below (1), (2) & (3).

1) Press the key to get “Patient List 1-10” .

2) Press the key repeatedly to scroll the list up to 11-20, 21-30.

3) Press Up/Down arrow key to move the cursor to the desired

patient.

4) Press Right arrow key to get to “Patient Information” of the

selected patient.

4-1) Press Up/Down arrow key to move the cursor to the

desired selection.

4-2) Press alpha-numeric keys to input/change information.

-While Capture function is activated, do NOT use the

following special characters to input patient information such

as patient name, patient ID.

/ . * ? “ < >

4-3) Select ESC and press Enter key ( or ESC key ) to get

back to “Patient List”.

5) Press Up/Down arrow key to move the cursor to the desired

patient.

6) Press Enter key to get back the normal screen of the selected

patient.

2. New Patient Key

1) Press the key to get “Patient Information” .

2) Press Up/Down arrow key to move the cursor to desired

selection.

3) Press alpha-numeric keys to input information.

4) Select ESC and press Enter key ( or ESC key) to get back to

the normal screen of the patient.

3. Clear Patient Key

Function: Delete data on all patients when “Patient List” is

displayed.

Delete data on one particular patient when “Patient

Information” is displayed.

1) Press the key to be asked for confirmation.

2) Press Up/Down arrow key to move the cursor to the desired

selection.

3) Press Enter Key to make selection.

3-1) in case of Patient List

• If Yes, data on all patients is deleted.

• If No, the list retains the previous data.

3-2) in case of Patient Information or normal screen

• If Yes, data on the selected patient is deleted.

• If No, the data on all patients is retained.

4) Select ESC and press Enter key ( or ESC key) to exit the

menu.

●

●

●

●

●

NOTE

NOTE

Page 25

22

4. User Key

1) Press this key to get “User List 1-10”.

2) Press this key to scroll the list up to 11-20... 41-50.

3) Press Up/Down arrow key to move the cursor to the desired

selection.

4) Press Right arrow key to get “User Setup”.

4-1) Press Up/Down arrow key to the desired selection.

4-2) Press alpha-numeric keys to input information.

4-3) Press Right arrow key at “Display Item Setup” to get

“Display Item Setup”.

4-3-1) Press Up/Down arrow key to the desired selection

4-3-2) Press Right/Left arrow key to select On or Off.

4-3-3) Select ESC and press Enter key ( or ESC key ) to

get back User Setup.

4-4) At “User Setup”, select ESC and press Enter key ( or

ESC key) to get back to “User List”.

5) Press Up/Down arrow key to move the cursor to the desired

selection.

6) At “User List”, press the Enter key to return to the original

User List screen selected by the user.

5.

Scope Buttons Key (70K/72K/80K/81K/85K Series Endoscopes)

Function: Assign function to scope control buttons

1) Press this key to get the menu.

2) Press Up/Down arrow key to move the cursor to the desired

button

3) Press Right/Left arrow key to assign function to the each

selected button

• Right arrow key: 0 → 1 → 2 → 3 → 4 → 5 → 6 → 7 →

8 → 0

• Left arrow key: 8 → 7 → 6 → 5 → 4 → 3 → 2 → 1 →

0 → 7 → 8

4) Select ESC and press Enter key ( or ESC key ) to get back to

the normal screen.

●

●

●

●

Page 26

23

6. Scope SW

- NEVER assign a PC or printer using the Scope

Switch menu while a computer or a printer has been disconnected

from the processor

.

1) Press this key to get the menu.

2) Press Up/Down arrow key to move the cursor to the desired

selection

3) Press Right/Left arrow key to assign function to the each

selection

• Film Counter: None

→ Out1 → Out2 → Printer* → None

• Copy Function: None

→ Out1 → Out2 → Out1,2 → PC →

PC & Out1 → PC & Out2 → PC & Out1,2 → Printer* →

Printer & Out1* → Printer & Out2* → Printer & Out1, 2*

→ Printer & PC* → Printer & Out1 & PC* → Printer &

Out2 & PC* → Printer & Out1,2 & PC* → None

• VTR Function: None → Out1 → Out2 → Out1,2 → PC →

PC & Out1 → PC & Out2 → PC & Out1,2 → Printer* →

Printer & Out1* → Printer & Out2* → Printer & Out1, 2*

→ Printer & PC* → Printer & Out1 & PC* → Printer &

Out2 & PC* → Printer & Out1,2 & PC* → None

*Appears only when PC key selects Sony Video Printer UP-50.

• Freeze Release: On → Off → On

• Counter Type: 1 to 99 (1, 2... 98, 99, 1...)

→ 1/2 (1/2, 2/2, 1/2, 2/2... )

→ 1/4 (1/4, 2/4, 3/4, 4/4, 1/4...)

→ 1/8 (1/8, 2/8... 7/8, 8/8, 1/8...)

→ 1/16 (1/16, 2/16... 15/16, 16/16, 1/16...)

→ Off

→ 1 to 99 (1, 2... 98, 99, 1...)

-“Printer followed” is displayed when PC key selects

Sony Video Printer UP-50 and when film counter selects

“printer”.

4) Select ESC and press Enter key ( or ESC key ) to get back to

the normal screen.

7. Enhance Level

1) Press this key to display the message for about 3 seconds.

2) During the display, press the key to move to Off → Low →

Med → High → DFLT → Off.

-DFLT is displayed when special level is previously

assigned to the scope. When the scope is disconnected from the

processor with setting of DFLT , the DFLT remains on the

memory. When the scope is disconnected with setting other than

DFLT , the DFLT will not remain on the memory.

- This menu can only be displayed if an endoscope is

connected to the processor.

8. Color Adjustment

1) Put the distal end of the endoscope into the white balance

adjuster supplied with the video processor.

2) Watching the monitor, adjust the position of the distal end of

the scope in the adjuster so that the grains inside the adjuster

can be recognized on the full screen. If any halation is

recognized on the screen, lower the brightness level so that

the grains inside the adjuster can be recognized clearly.

●

●

●

NOTE

NOTE

NOTE

CAUTION

CAUTION

Page 27

24

3) Press this key to get the menu.

4) Press Up/Down arrow key to move the cursor to “White Balance”.

5) Press Enter key and remove the distal end from the adjuster.

After adjustment, “WB OK!”, is displayed for about 3

seconds.

6) If fine-tuning is necessary, press Up/Down key to the desired

selection, blue or red.

7) At blue or red, press Right/Left arrow key to change the value.

8) Select ESC and press Enter key ( or ESC key ) to exit the

menu.

- This menu can only be displayed if an endoscope

is connected to the processor.

9. Shutter Mode

- When activated (“Shutter On”), the shutter speed is

automatically increased during close viewing to obtain very

sharp “frozen” images. This function applies only to 70K/72K/

80K/81K/85K-series endoscopes.

1) Press this key to display the message for about 3 seconds.

2) During the display, press the key to toggle between Shutter

On and Shutter OFF.

- This menu can only be displayed if an endoscope

is connected to the processor.

10. Freeze Mode

• Field Freeze: for a more stabilized frozen image.

• Frame Freeze: for a higher resolution.

1) Press this key to display for about 3 seconds.

2) During the display, press the key to toggle between Field and

Frame.

11. Clear Screen

1) Press this key to show the data once deleted with setting of

User key.

2) Press the clear screen key again to remove the data

12. Color Bar

1) Press this key to get the color bar on the screen.

2) Press this key to remove the color bar from the screen.

13. Character Off

1) Press this key to remove all screen information. When an

endoscope is not connected, “Scope not connected” is

displayed.

2) Press this key again to get the information back on the

screen.

●

●

●

●

NOTE

NOTE

CAUTION

CAUTION

Page 28

25

14. Date

1) Press this key to get the menu.

2) Press Up/Down arrow key to move the cursor to the desired

selection.

3) Press Enter key to make selection and to get the cursor under

the first field.

4) Input numeric data in each field.

5) Press Right arrow key to advance through a field without

changing the information.

6) Press Enter key or ESC key to exit the menu.

15. PC

1) Press this key to get the menu.

2) Press Up/Down arrow key to move the cursor to the desired

selection.

3) Press Enter key to make selection. The selected one turns

green.

4) Select ESC and press Enter key (or ESC key) to remove the

menu.

- The selection depends upon country and/or local

PENTAX distributor.

16. Init

1) Press this key to be asked for confirmation if “Reset all

processor data? No/Yes”

2) Press Up/Down arrow key to move the cursor to the desired

selection.

3) Press Enter key to make selection

• If Yes: all data is reset.

• If No: the question is removed without resetting any data.

NOTE

●

●

●

●

●

Page 29

26

17. Clear Counter

- This key is not valid when scope SW selects “NONE”

for film counter.

1) Press this key to initialize the value already set with scope

SW.

18. Stopwatch

1) Press this key to get the menu

2) Press Up/Down arrow key to move the cursor to the desired

selection.

3) Press Enter key to make selection

• Start: displays and runs the stopwatch

• Stop: stops the stopwatch and displays the last value

• Restart: restarts the stopwatch from the last value

• Reset: stops the stopwatch and resets the display to

(00:00:00)

• ESC: exit the menu. When it is on “Reset”, the stopwatch

will be removed from the normal screen. In the other

cases, the stopwatch will remain on the normal

19. Multi Picture

- This function is valid on condition that;

• Copy function is activated with scope switch

• PC key selects Sony Video Printer UP-50

• Sony Video Printer UP-50 is connected to RS-232C output

terminal

1) Press this key to display number of split screens already set

for about 3 seconds

2) Press this key repeatedly to change it to 1 → 2 → 4 → 8 →

16 → 1.

- Press this key to start printing provided the video

printer already contains previously stored images (and

provided that before printing, the cursor is not positioned on

the first image). After printing, multi-picture images change

according to the pre-selected setting.

- While menus for other functions are displayed on

the screen, this function key will not work. Return to the live

screen and then press the key to activate this function.

20. Print Quant

- This function is valid only on condition that;

• Copy function is activated with scope switch

• PC key selects Sony Video Printer UP-50

• Sony Video Printer UP-50 is connected to RS-232C output

terminal

1) Press this key to display for three seconds the quantity of

prints required

2) Press the key repeatedly to change it to 1

→ 2 → 3 ... 9 → 1

- While menus for other functions are displayed on

the screen, this function key will not work. Return to the live

screen and then press the key to activate this function.

NOTE

NOTE

NOTE

NOTE

●

●

●

●

●

CAUTION

CAUTION

Page 30

27

21. Delete Image

- This function is valid only on condition that;

• Copy function is activated with scope switch

• PC key selects Sony Video Printer UP-50

• Sony Video Printer UP-50 is connected to RS-232C output

terminal

1) Press this key to display “ Delete Image?” for about 3

seconds.

2) During the display, press this key to delete the images

currently stored.

3) If the monitor is connected to a video printer, “Delete

Image? ” is not displayed. Instead, this cursor moves from a

split screen to another as shown below to delete each image.

- While menus for other functions are displayed on

the screen, this function key will not work. Return to the live

screen and then press the key to activate this function.

22. Print

- This function is valid only on condition that;

• Copy function is activated with scope switch

• PC key selects Sony Video Printer UP-50

• Sony Video Printer UP-50 is connected to RS-232C output

terminal

1) Press this key to display “Print OK?” for about 3 seconds

2) During the display, press the key to start printing

- While menus for other functions are displayed on

the screen, this function key will not work. Return to the live

screen and then press the key to activate this function.

23. Pointer

1) Press this key to call the pointer.

2) Press Up/Down/Right/Left arrow key to change the position.

3) Press ESC key or the pointer key again to remove the pointer

●

●

●

●

NOTE

NOTE

CAUTION

CAUTION

Page 31

28

24. Editor

- Date and clock remain unchanged.

1) Press this key to be asked for confirmation.

2) Press Up/Down arrow key to move cursor to desired

selection.

3) Press Enter key to make selection

• If “No” is selected, data, clock and previous editor data are

displayed.

• If “Yes” is selected, data and clock are displayed ( previous

editor data is deleted.)

4) Press Up/Down/Right/Left arrow key to move cursor to

desired position.

5) Press alpha-numeric key to input ( except date and clock )

6) Press ESC key, Editor key or other function keys to exit the

menu.

25. VTR

- This function is valid only on condition that;

• VTR function is activated with scope switch

• PC key selects Sony Video Printer UP-50

• Sony Video Printer UP-50 is connected to RS-232C output

terminal

1) Press the key to activate output peripheral such as VTR

according to the setting with the scope switch key.

26. Freeze

1) Press this key to get a still endoscopic image frozen on the

main screen and the endoscipic live image on the sub-screen

activate freeze function.

2) Press the key again to release the main screen from the still

image and remove the sub-screen.

27. Copy

- This function is valid only on condition that;

• Copy function is activated with scope switch

• PC key selects Sony Video Printer UP-50

• Sony Video Printer UP-50 is connected to RS-232C output

terminal .

1) Press this key to activate output peripheral such as copy

according to the setting with the scope switch key.

28. Capture

- The PC Capture function will work ONLY when;

The special software, Endoimage OS-I1, is installed onto the

PC connected to the processor.

1) Press this key to transmit a “frozen” endoscopic image to the

PC.

Alternatively, instead of using this button on the keyboard,

the same PC Capture function can be activated via one of the

remote control buttons that have previously been assigned

for this specific function (70K/80K Series Endoscopes only)

29. Scope Model

The model name and serial no. of the scope are displayed for

about 1 minute when pressing any character key during the

normal screen display. Press any character key again to remove

the data.

●

●

sub-screen

●

●

NOTE

NOTE

NOTE

NOTE

Page 32

29

5. MAINTENANCE

5-1 AFTER EACH PROCEDURE

1. Turn OFF the power switch.

-Some peripheral devices may have to be turned OFF

BEFORE the EPK-1000 to avoid compromising their operation.

Refer to the operating instructions supplied with all the components

of the video endoscopy system to establish the right order in which

each component should be turned OFF in due course.

2. Disconnect the power plug, endoscope and water bottle .

-Always turn OFF the processor BEFORE disconnecting

the endoscope.

3. Wipe all surfaces with gauze slightly dampened with alcohol.

-NEVER allow liquids to be splashed on the EPK-1000.

Be sure connector interfaces and ventilation ports are not

allowed to become wet. To avoid processor damage, do NOT

allow harsh chemicals or cleaning agents to contact the front

panel membrane. Wipe with alcohol only.

5-2 WATER BOTTLE CLEANING

-Be careful when handling the water bottle. Do NOT

carry the water bottle by the Air/Water connector or Air/Water

hose. When the cap assembly has been separated from the

bottle, be careful in handling the water feeding stem.

Water bottles should be sterilized at least on a daily basis.

Like all endoscopic accessories, the water bottle assembly must

be thoroughly cleaned. Failure to do so could result in

incomplete or ineffective sterilization.

(1) CLEANING

1. Immediately after use, the entire water bottle assembly

(bottle, cap assembly and tubing) should be washed with

fresh detergent solution and dampened gauze or scrub brush.

Complete immersion in an enzymatic detergent solution

should be used for soiled items.

Internal surfaces of the water bottle assembly may be exposed

to the detergent by injecting the detergent into the air pipe

stem (opposite the A/W-Drain lever on the water bottle cap)

using a syringe. The A/W-Drain lever should be set to the

A/W position to ensure contact with all internal tubes.

2. Ultrasonic cleaning of the entire water bottle assembly is

recommended to access difficult to reach areas. Use an operating

frequency of 44 kHz ± 6% for a period at least 5 minutes.

3. After washing with the cleaning solution, all surface areas of

the water bottle assembly should be thoroughly rinsed and

dried. Use gauze or lint-free cloth to wipe dry most surfaces.

Compressed air and 70% alcohol may be used to facilitate

drying of hard to reach areas.

NOTE

NOTE

NOTE

NOTE

PENTAX

EPK-700

COPE

RED

BLUE

AUTO

MAN

XLUM

SERVICE

AVE

CENT

CONTROL

COLOR BALANCE

BRIGHTNESS

LAMP

FREEZE

+5

-5

0

AIR PUMP

POEWR

O

FF

OFF

ON

ON

12345

6

●

●

Page 33

30

(2) STERILIZATION