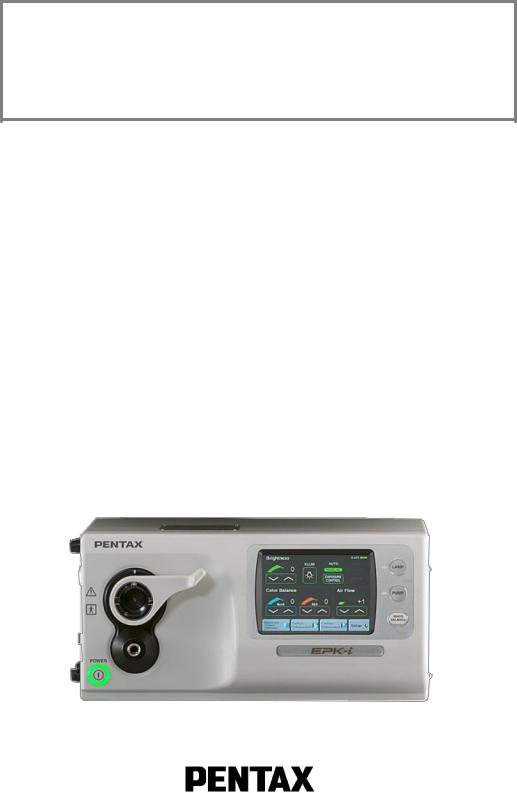

Pentax EPK-i Service manual

SERVICE MANUAL

(Version 03)

High-end Video Processor

PENTAX EPK-i

Medical Instrument Division / Service Technical Group

MNL-045-03 / May 16, 2008

|

|

< CONTENTS> |

|

|

1. |

Specifications |

Page |

1 |

|

2. General explanations |

Page |

2 |

||

|

Feature |

|

|

|

3. |

Functions |

Page |

3 |

|

4. |

Configuration (Main parts) |

Page |

6 |

|

5. |

Precaution |

Page |

7 |

|

6. |

Service |

Page |

8 |

|

|

6.1 |

Lamp block |

|

|

|

6.2 Pump |

Page |

10 |

|

|

6.3 Iris |

Page |

13 |

|

|

6.4 |

Peripheral Board (G700) |

Page |

14 |

|

6.5 |

Process Board (H700) |

Page |

15 |

7. |

Electrical safety test |

Page |

18 |

|

7.1Dielectric strength test

7.2Protective GNDing wire resistance

7.3 Leakage current test |

Page |

19 |

8. Trouble shooting |

Page |

20 |

9. Wiring Diagram |

Page |

21 |

Appendix – Exploded view |

|

|

Parts list |

|

|

Notes for using this Service Manual

1)Up-date of Service Manual will be notified by such information as Notice of Modification, Service Note and so on.

2)When you start repair servicing, be sure to leave service records.

3)This Service Manual voids preceding "New Product Repair Guide" for the same model, if any.

4)Upon request, PENTAX will provide qualified service personnel with further information to service this product provided that the requested information needed within the range of servicing described in this Service manual.

1. Specifications

Item |

Description |

Specification |

|||

|

120V model |

|

230V model |

||

|

|

|

|||

Video system |

|

NTSC |

|

PAL |

|

|

Voltage |

120VAC |

|

230VAC |

|

Power requirement |

Frequency |

|

50 - |

60Hz |

|

Power consumption |

Less than 5.4A |

|

Less than 2.8A |

||

|

|

||||

|

Voltage fluctuation |

|

+/- |

10% |

|

Operation environment |

Temperature |

|

10 – 40 |

||

Relative humidity |

|

30 – 85 % |

|||

|

Atmospheric pressure |

700 –1060 hPa |

|||

Storage environment |

Temperature |

|

-20 – 60 |

||

Relative humidity |

|

0 – 95 % |

|||

|

Atmospheric pressure |

700 – 1060 hPa |

|||

|

Lamp |

300W Xenon lamp |

|||

|

Lamp average life span |

Continuous use, Average 500 hours |

|||

Illumination |

Color temperature |

|

6,000K |

||

Iris control |

Automatic / Manual |

||||

|

|||||

|

Brightness control |

Adjustable by +/- 5 steps each |

|||

|

Auxiliary lamp |

3W White LED (IEC60825-1) |

|||

Scope compatibility |

|

PENTAX Color Video Endoscope i-series and K-series |

|||

|

|

(K-series with Y/C output) |

|||

|

|

|

|||

Color correction |

|

Red and Blue each adjustable by +/- 5 steps each |

|||

White balance |

|

Adjustable automatically with “White Bal” button |

|||

|

DVI-D, DVI-A |

DVI x 1 terminal (either DVI-D or DVI-A is assigned) |

|||

|

RGBS output |

9pin D-sub x 2 |

|||

|

Y/C output |

S terminal x 2 |

|||

Video signal |

Composite video output |

BNC connecter x 1 |

|||

DV output |

DV terminal x 1 |

||||

|

Printer output |

N. A. |

|

9pin D-subx1, |

|

|

|

S terminal x1 |

|||

|

|

|

|

||

|

Analog input |

BNC connector x1 |

|

S terminal x1, |

|

|

|

BNC connector x1 |

|||

|

|

|

|

||

Photo-1 New label |

Serial output |

USB A terminal (Female) |

x 2 (for memory, printer) |

||

Digital output |

|

|

|

|

|

LAN |

RJ45 terminal x 1 |

||||

|

|||||

Audio input |

Analog input |

Stereo mini plug x 1 |

|||

|

RS-232c |

9pin D-sub x 1 |

|||

|

Remote |

Stereo mini plug x 3 |

|||

Control signal |

Keyboard |

6-pin Mini-DIN x1 (exclusive or ordinary PC keyboard) |

|||

Footswitch |

4pin Bayonet lock type(Female) x 1 |

||||

|

|||||

|

Water feeder (SA-P2) |

4pin Bayonet lock type(Female) x 1 |

|||

|

Sync signal (Y signal) |

BNC connector x 1 |

|||

|

|

On / Off, Air flow volumes are selectable in 5 steps |

|||

|

|

Level 1: |

2.0 – 2.8 L/min. |

||

|

Control |

Level 2: |

2.9 – 3.4 L/min. |

||

Air feeding |

Level 3: |

3.5. – 4.0 L/min. |

|||

|

|||||

|

|

Level 4: |

4.1 – 4.5 L/min. |

||

|

|

Level 5: |

4.6 – 7.2 L/min. |

||

|

Air pressure |

45 – 70 KPa |

|||

LCD touch screen |

Display |

6.4 inch TFT |

|||

Touch screen |

Pressure-sensitive type |

||||

|

|||||

Classification electro |

Electric shock protection |

|

Class – I |

||

Degree of protection |

|

BF type |

|||

medical equipment |

Degree of explosion |

Do not use in potentially flammable surroundings. |

|||

|

proofing |

||||

|

|

|

|

||

Electromagnetic |

Electromagnetic |

Complied with IEC60601-1-2 Class B |

|||

Interference |

compatibility |

||||

|

|

|

|||

|

Harmonic current |

Complied with IEC60601-3-2 Class A |

|||

|

emissions |

||||

|

|

|

|

||

Medical electrical |

|

UL60601-1 |

|

IEC60601-1 |

|

equipment general |

|

|

|||

requirement for safety |

|

|

|

|

|

Size |

Dimensions |

430mm (W) x 485mm (D) x 205mm (H) |

|||

Weight |

Main body |

|

26.5Kg |

||

Table-1 Specifications

- 1 -

2. General explanations

The PENTAX EPK-i is a high-end Video Processor, which produces High Definition images with a specially developed scope “Mega Scope 90i”. Several image processing methods (advanced enhancement, etc.) that help the user observe precisely and easily have been introduced. At the same time, the EPK-i keeps compatibilities with the former K-series scopes (Y/C signal type). To obtain stiller frozen images, a mechanical structure (rotary shutter etc,) has been built in. A user-friendly manner has been established with several new devices.

Features

1)High Definition image> High Definition images can be created with “Mega Scope 90i” which has a mega pixel CCD. The 90i scope provides the image data in digital signal to the EPK-i. The EPK-i can process the image signal without converting the analog signal. The EPK-i has a DVI (Digital Visual Interface) output port. Therefore non deteriorated image can be seen on the PENTAX LCD monitor (when “DVI-D” port of the monitor is used. / For analog signal, “VGA” port is also available on the monitor). The DVI port can provide either DVI (digital signal) or VGA (analog signal) depending on “DVI Output” setting of the system (refer to the Owner’s Manual). The default setting is “VGA”. When the full digital environment is used, “DVI Output” must be set to “DVI”. Otherwise the image will not appear on the monitor.

Note: PENTAX LCD monitor will be launched soon.

A summery for the monitor connector, exclusive cable and “DVI Output” setting are shown in the table below:

Connector on LCD monitor |

Connector of cable |

DVI Output setting |

DVI-D |

|

DVI |

|

|

|

VGA |

|

VGA |

|

|

|

Note: The connectors shown in the table are male.

Because DVI signal is very fast, the DVI cable is limited to 3m. With a longer cable, the image becomes noisy as opposed to the image on the analog CRT monitor becoming darker with an analog longer cable.

2)Advanced Enhancement> In addition to the ordinary image enhancement (Edge enhancement), Surface Enhancement and Contrast Enhancement are available. Both enhancement modes cannot be used simultaneously. The other one will be disabled.

3)Still and Fine Freeze> Thanks for the progressive scan method on the mega pixel CCD and the rotary shutter of the EPK-i, stiller and finer images can be captured. Because of the progressive scanning the captured image is real as opposed to the compensated or interpolated image from the field scanning. The finer image is attributed to the progressive scanning. Meanwhile the rotary shutter controls the exposure time. The shorter the exposure time is, the stiller the frozen image becomes. However as the side effect the image becomes darker. Together with the ordinary iris, the rotary shutter controls the exposure time as short as possible and so that the luminance becomes enough for the acceptably brighter and stiller image. During the progressive scan, the next light comes through the hole of the rotary shutter. Thus another mechanical shutter interrupts the light. This shutter is driven by a solenoid motor and momentarily closes. As a result of the stiller freeze, mechanical parts are increased. However no adjustment or it is easy if any.

4)LCD Touch panel>As an operational panel, an LCD touch screen panel has been introduced. The EPK-i has a single board computer inside. Thus it takes about one and half minutes by the LCD touch panel is ready for the operation. The LCD touch panel reacts by pressure, which is a sensitive device. Do not operate it with a sharp edge. The lamp, pump and white balance switches are independent from the single board computer. It means the lamp can be turned on and the pump works with level-1 before the system has been up and running. The LCD touch screen has a function that an image put from “VIDEO IN” port is displayed.

5)SA-P2 port>The exclusive port for the water jet supplier SA-P2 is available on the back panel of the EPK-i. When the scope button or the foot switch assigned with function “WJ” is pressed, an open-collector, active-low signal is sent to the SA-P2 to turn on and off.

6)Lamp>The lamp (300W xenon lamp) can be replaced by a lamp cartridge (OL-X25) by the user (refer to the Owner’s Manual). The door of the lamp house can be opened without any special tool. This door activates the interlock switch for AC power of the unit when it is completely closed. The lamp cartridge consists of the lamp, two heat sinks and IR cut filter. Trained service engineers are allowed to replace the lamp itself (The Service manual for the EPK-i will be issued soon. Please refer to it in detail).

-2 -

7)Pump>Air feed volume can be changed in five levels with the touch screen panel. The air feed volumes of each level are set with the special Set up menu (It is a hidden menu to customers). When the peripheral board (G700) is replaced for the pump function repair, the former setting value can be reused without measuring the air feed volume with an air flow meter. When the pump is replaced, the air feed volumes of each level will be adjusted with the menu by measuring the air feed volume with the air flow meter. The peripheral board is attached with a small tube from the pump. It has been prepared for the precise air feed control, however it is not currently working. But if it is detached, the air must leak at this point. As a result, the air won’t be fed from the air outlet.

8)Auxiliary lamp>3W while light LED has been introduced as an auxiliary lamp. When the main lamp ignition failure continues for about 8 seconds, the auxiliary lamp automatically comes into the light axis by the solenoid motor.

9)DC Power supply for patient circuit>The DC power supply unit for the patient circuit exists independently from the DC power supply unit for the secondary circuits. However the input of the DC power supply unit for the patient circuit is connected to the DC output of the DC power supply unit for the secondary circuits. The reason why the DC power supply units individually exist is just due to limited spaces of the EPK-i unit inside.

10)Lamp power supply unit>The main unit and the igniter exist individually. Of course they are connected each other. However they can be treated as a spare part independently.

11)Scope detector>A limit switch has been attached just beside the scope connector assembly. When the scope handle is turned clockwise to lock the scope connector, the switch is activated and the system recognizes that the scope has been connected completely.

12)Processor ID>The processor model name “EPK-i” and its serial number have been stored as ID. These information must be necessary for the LAN environment.

13)Serial and LAN port>Using an USB memory device or LAN, system modification can be done easily.

14)XLUM and Manual mode>Both modes act as an iris manual mode. On the basis of the concepts that “XLUM” is for confirming the location of the scope distal tip and “Manual” is for observing the specific parts in vivo in iris manual mode, these modes are available independently.

3.Functions

1)Preprocess Board (J700)

1)-1 Image signal processing> Because the EPK-i can accept all types of the K-series scopes, Preprocess board has a function that can process the three kinds of the image signals such as R-Y/B-Y color differential signal (old 30/40 series), Y/C signal (30/40 or 70/80 series ) and LVDS signals (90K and 90i series).

R-Y/B-Y and Y/C signals (analog) are converted into 10 bit YUV signal with the video decoder/ADC (U16).

The 20 bit YUV signal is sent to the FPGA (U23) and converted into 12 bit YCbCr signal.

Finally the 12 bit YCbCr signal is sent to Process board (H700) through the connector CN13 on Mother board(E700).

As for LVDS signal, DO+/DO- (LVDS: Low Voltage Differential Signal) is sent to the serializer/deserializer (U42) to be serialized into 12 bit (90i scope) or 8 bit (90K scope) LVDS signal.

The LVDS signal is sent to the also the FPGA (U23) to be converted into 12 bit YCbCr signal.

Finally the 12 bit YCbCr signal is sent to Process board (H700) through the connector (CN13) on Mother board(E700) as well.

With 90i scope, the white balance is adjusted with the FPGA (U23). With the other scopes, the white balance is adjusted with the control board in the scope.

1)-2 Iris signal> Depending on a scope, there are three kinds of signals from the scope that is used for the iris control – “YIRIS” (90K scope), “Yout” (30/40, 70/80K scope) and “DO+/DO-“ (90i scope). And there are two types of processing the iris control signals.

“YIRIS” or “Yout” signal is converted into 12 bit iris control signal with the AD converter (U56).

“DO+/DO-“ is converter into 12 bit iris control signal with the FPGA (U23).

Both converted signals are sent to Peripheral board (G700) through the connector (CN13) on Mother board (E700).

1)-3 Patient circuit> Because Preprocess board that is directly connected to the scope exchanges signals with the scope, it has digital isolators that divides Preprocess board into the patient circuit and the ordinary circuit.

2) Process Board (H700)

2)-1 Image signal processing>This board receives 12 bit YCbCr signal from Preprocess board (J700) through Mother board (E700).

- 3 -

The 12 bit YCbCr signal is processed by enhancing or changing color with the front panel operation with the FPGA (U2).

The processed YCbCr image signal is converted in to 10 bit RGB signal with the DSP (U2), and sent to the FPGA (U39).

The 10 bit RGB signal is sent to Video process board (I700) through the connector (CN8) on Mother board (E700) after gamma compensation with the FPGA (U39).

Meanwhile the same 10 bit RGB signal is converted into 8 bit RGB signal with the FPGA (U39).

The 8 bit RGB signal is sent to the digital display processor (U51) to be superimposed with characters.

The 8 bit RGB signal with characters is sent to the two ways. One is to the panel link transmitter (U56) to be converted into the image signal for DVI. And the image signal for DVI is sent to I/O-1 board (L700) with the internal cable (B521).

The other one is sent to D/A converter (U59) to be converted into RGB analog signal for VGA. And the RGB analog signal is sent to I/O-1 board (L700) with the internal cable (B522).

The digital display processor (U51) has function to zoom up the image or to make a sub screen.

2)-2 Character generation>The FPGA (U2) handles the keyboard operation.

The FPGA (U2) detects the character inputs and sends the instructions to the digital display processor (U51) to create the characters.

The digital display processor (U51) generates the characters and merges them to the image signal.

The fixedly displayed texts like “Age” are stored in the memories connected to the FPGA (U2). These texts are also merged to the image signal with the digital display processor (U51).

The FPGA (U2) also sends the instruction to the digital image processor on Video Board (I700) in order to create appropriate characters to meet the different display resolution.

3)Video Board (I700)

3)-1 Image signal processing-1>This board receives 10 bit RGB signal from Process board (H700) through Mother board (E700).

The 10 bit RGB signal is converted into the 8 bit RGB signal and sent to the digital display processor (U100, 102) to be merged with characters.

The 8 bit RGB with characters is sent to the digital video encoder (U303) through the FPGA (U301) and encoded into RGB analog signal. Finally the signal is sent to the RGB port x2 on the back panel through I/O-1 board (L700).

Also the 8 bit RGB with characters is sent to the digital video encoder (U310) through the FPGA (U301) and encoded into Y/C analog signal. Finally the signal is sent to the Y/C port x2 on the back panel through I/O-1 board (L700).

The same 8 bit RGB signal with characters is corrected with the FPGA (U301) in order to meet the required printer color. The look-up-table in the FPGA (301) is used for the color compensation. The corrected RGB signal is converted into RGB and Y/C analog signal with the digital video encoder (U317 and U324) and sent to the RGB or Y/C printer port on the back panel through I/O-2 board

(M700). Note: This port is not available with 120V model.

3)-2 Image signal processing-2>This board creates DV format image signal.

The 10 bit RGB signal is converted into the 8 bit RGB signal and sent to the digital display processor (U100) to be merged with characters.

The 8 bit RGB with characters is sent to the DV encoder (U411) through the FPGA (U301) and encoded into DV signal. Finally the signal is sent to the DV port on the back panel through I/O-2 board (M700). Audio picked up by the microphone attached to “Audio IN” port on the back panel is

converted into 4 bit digital signal and sent to the DV encoder (U411) to merge to the DV signal. 3)-3 Image signal processing-3>This board receives the outer video signal to superimpose it on the main

image.

Outer video image is accepted from “COMPOSITE-IN” port through I/O-2 board (M700).

The outer video signal is converted into 8 bit rec656 format signal with the video decoder (U208) and sent to the digital display processor (U100).

The outer video signal is processed as picture-in-picture data with the digital display processor (U100) and merged to the main image.

4)Peripheral Board (G700)

4)-1 Iris control> With every type of scope, the luminance signal is converted into the 12 bit iris signal on Preprocess board(J700).

The 12 bit iris signal is sent to the FPGA (U19) to measure if the current iris position is adequate against the brightness set by the front panel.

The digital signal controller (U12) creates the iris reference signal (analog) by referring to the results measured with the FPGA (U19). The iris reference signal is sent to the iris analog circuit to control the iris.

-4 -

4)-2 Rotary shutter control> To obtain a stiller frozen image, it is necessary to control an exposure time of light. It is accomplished by adjusting the hole on Rotary shutter (M4). The parts related to Rotary shutter consist of Rotary shutter (M4), Space motor (M6), Photo interrupter (PI1) and Shutter (M3). These are controlled with Peripheral Board (G700).

4)-3 Pump control> The pump control signal (Pump ON-OFF, Air flow level 1-5) are sent from the front panel to Peripheral Board (G700) through Process Board (H700) to turn the pump ON-OFF.

The pump control signal is sent to the micro controller (U32) to turn the pump ON-OFF.

After the micro controller (U32), a part of the pump control signal is sent to the digital potentiometer to set the air flow level.

4)-4 Auxiliary lamp control> The lamp power supply unit sends the lamp failure signal to Peripheral Board (G700) when the lamp ignition fails or the main lamp turns off unexpectedly.

The lamp failure signal from the lamp power supply unit is detected by Peripheral Board (G700) and sent to the FPGA (U19).

The FPGA (U19) sends signals to Auxiliary lamp to move its LED lamp into the light axis and turn on the LED lamp.

5)SBC Board (F700 / SBC: Single Board Computer)

5)-1 Touch Panel and LCD Display control> To control the capacitive type touch panel and manage the various operation buttons and menu tabs.

5)-2 USB Memory control> When the image is captured with the setting that the image output has been assigned to “SERIAL OUT1, 2” port, the captured image will be sent to the USB memory connected to the port.

5)-3 Patient Data management> To provide the graphical user interface for the patient data and store the data.

5)-4 Serial port control> To control the RS-232C port for “ENDONET” database software. 5)-5 LAN control> To control the port for a local area network.

- 5 -

Loading...

Loading...