Page 1

APPLICATION

EMM-3U Universal

Electronic MiniZone™ Panel

PRODUCT DATA

FEATURES

• Compatible with single-stage, multi-stage,

conventional or heat pump applications.

• Uses virtually any Honeywell four-wire, single-stage,

multi-stage, or Trol-A-Temp heat pump thermostat.

• Optional Discharge Air Temperature Sensor for

capacity control with adjustable high and low limits.

• System and Zone LEDs indicate system status.

• Automatic zone changeover with 20-minute

changeover timer.

• Individual zone fan control.

• Thermal circuit breaker protects panel and transformer

from damage if miswired.

• Purge timer protects equipment between calls for

heating and cooling.

• Uses spring-open/power-closed, spring-closed/poweropen, and power-open/power-closed dampers.

• Single or dual transformer equipment compatible.

The EMM-3U Universal Electronic MiniZone™ Panel controls

single-stage, multi-stage, conventional or heat pump heat/cool

equipment and is used on two- and three-zone applications.

For Internet access:

www.honeywellzoning.com

For technical support, call 1-800-828-8367.

To download Zoning literature: http://hbctechlit.honeywell.com

Contents

Application ........................................................................ 1

Features ........................................................................... 1

Specifications ................................................................... 2

Ordering Information ........................................................ 2

Installation ........................................................................ 4

Troubleshooting ................................................................ 15

® U.S. Registered Trademark

Copyright © 2002 Honeywell • All Rights Reserved

68-0237-2

Page 2

EMM-3U UNIVERSAL ELECTRONIC MINIZONE™ PANEL

1

SPECIFICATIONS

Input Ratings:

Voltage: 20 - 30 Vac, 50/60 Hz.

Power: 10.75 VA nominal.

Output Ratings:

Equipment Relays and Zone Relays:

1.5A run, 3.5A inrush, 200,000 cycles (30 Vac).

1.5A run, 7.5A inrush, 100,000 cycles (30 Vac).

Humidity Ratings: 5% to 90% RH non-condensing.

Temperature Ratings:

Shipping: -20° to 120°F.

Operating: -40° to 150°F.

LED:

SYSTEM mode LED (5) used to communicate equipment

status:

Red Heat: Heat mode.

Green Cool: Cool mode.

Yellow Purge: Purge mode.

Green Fan: Fan mode.

Red EM Heat: Emergency Heat mode.

Flashing Red Heat: System exceeds high DATS input.

Flashing Green Cool: System exceeds low DATS input.

Flashing Yellow Purge: No DATS or DATS failure.

Off: Idle mode.

ZONE LED (3) used to communicate damper status:

Green: Dampers are opening or open.

No Color: Dampers are closing or closed.

Finish:

Taupe cover.

Gray base.

Dimensions: See Fig. 1.

Mounting: Mounts with four one-inch no. 8 screws (provided)

through holes in cabinet. Wall anchors provided.

Wiring: 18 to 22 gauge wire for all equipment and system

connections.

Wiring Connections:

Thermostat: R-C-E-W1-Y1-G-W2-Y2-O-B-L.

Dampers: M6 (Closed); M4 (Open); M1 (Common).

Discharge Air Temperature Sensor: DATS-DATS.

Transformer: R-C.

Equipment: RC-RH-W1-W2-E-B-O-Y1-Y2-G.

0-3/4

(273)

12-3/4

(273)

1-7/8

(47)

Fig. 1. EMM-3U dimensions in in. (mm).

Approvals:

Federal Communications Commission: Class B.

NEMA DC-3: Not required.

Thermostats (See Table 1):

Most conventional four-wire (R, W, Y, G) thermostats can be

used to control conventional, heat pump, or multi-stage

equipment.

Manual or automatic changeover switching thermostats can

be used.

Multi-stage or select heat pump thermostats can also be used.

M20779A

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone (1-800-468-1502):

1. Your local Automation and Control Solutions Sales Office (check white pages of your phone directory).

2. Honeywell Automation and Control Solutions Customer Care

1985 Douglas Drive North

Golden Valley, MN 55422

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

68-0237-2 2

Page 3

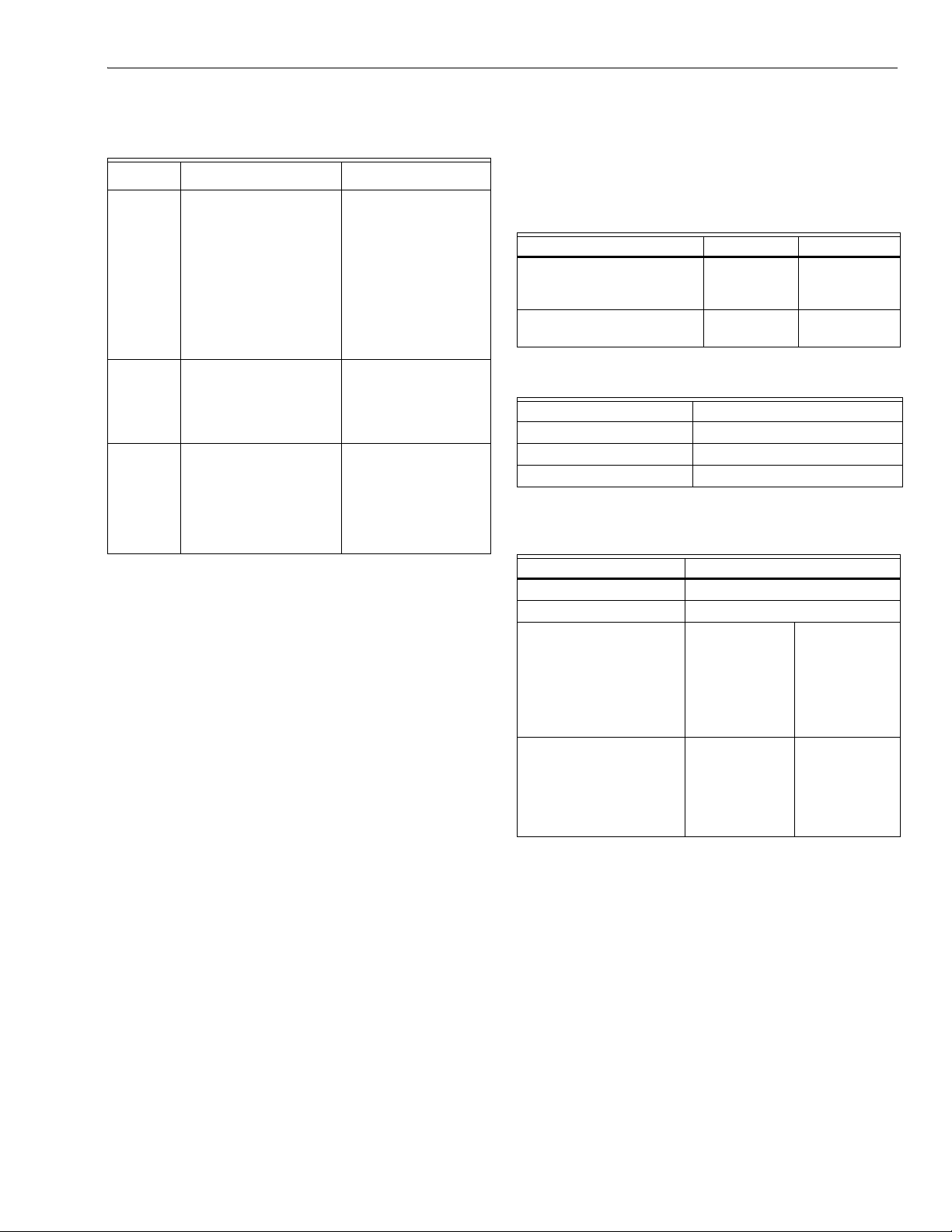

Table 1. Recommended Thermostats.

System Non-Programmable Programmable

SingleStag e

T87F1859/Q539A1014

T87F4010/Q539A4026

T8501D1046

T8400C1016

T8400C1040

T8400C1099

T8501D1111

T8601D2027

T8600D2069

T8600D2028

T8601D2019

T8602D2018

T8602D2000

T8000C1002

T8000C1010

T8001C1019

PC8900/W8900A,C

Heat

Pump

MultiStag e

b

b

Y594R1243

Y594G1252

T8411R1002

T8411R1028

T8424D1008

T8424D1016

T8524D1007

T8524D1015

Y594D1347

a,c,d

a,e

f

T8611G2051

T8011R1006

T8011R1014

T8011F1002

T8624D2004

T8624D2012

T8024D1002

T8024D1010

T8024F1007

a

T8524D1015

a

Heat pump thermostat with single Y first-stage terminals. See

Heat Pump Thermostats section and Fig. 6.

b

Multi-stage and heat pump thermostats are not required to

control multi-stage and heat pump systems. They are used

only when second stage or emergency heat control from the

zone thermostat is needed.

c

The Y594R1243 must be wired to the panel using the B ter-

minal for changeover.

d

Cut thermostat second-stage variable heating anticipator

wire (gray).

e

Cut thermostat first-stage fixed heating anticipator wire (bare)

and second-stage variable heating anticipator wire (gray).

f

Cut thermostat second-stage cooling anticipator wire (lowest

bare wire).

EMM-3U UNIVERSAL ELECTRONIC MINIZONE™ PANEL

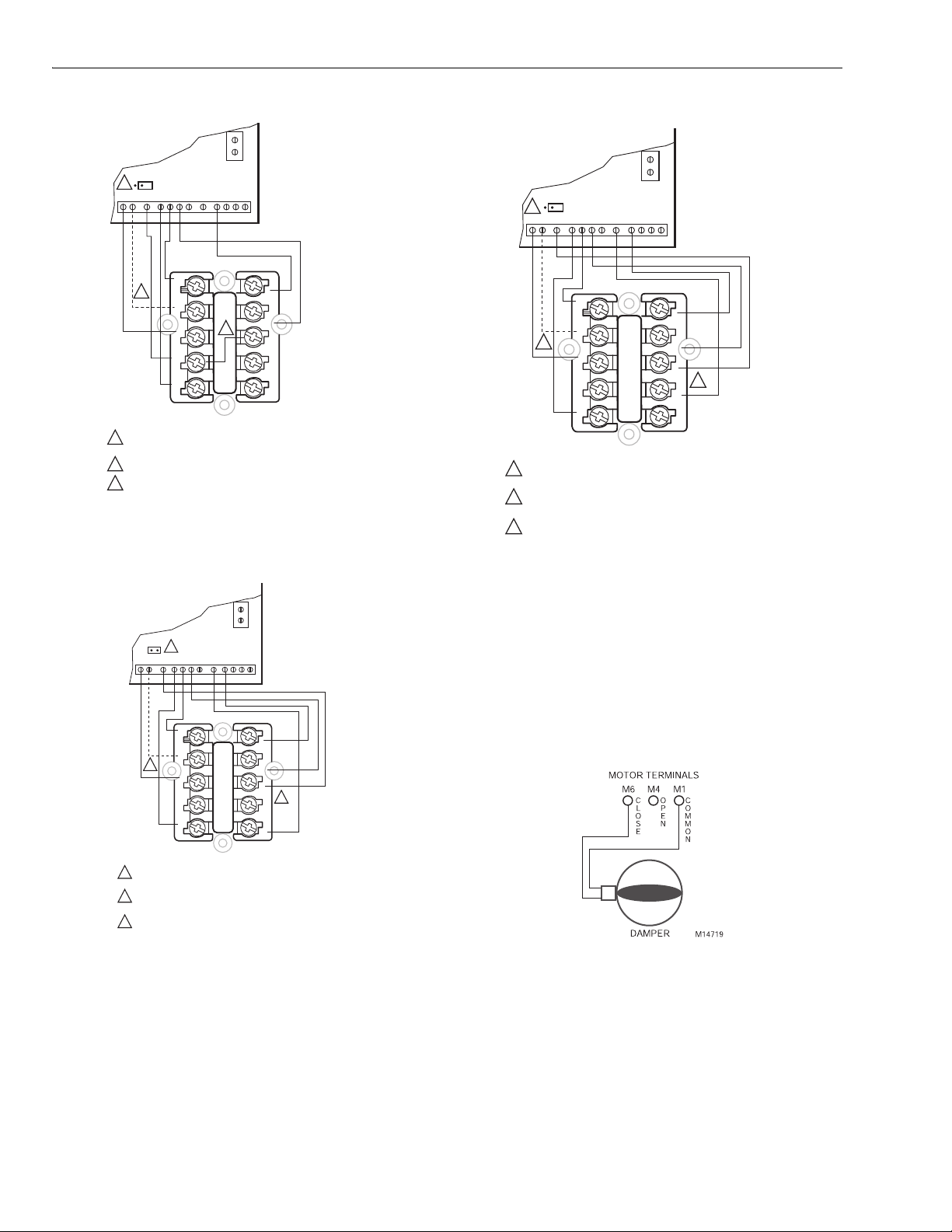

Recommended Dampers (See Table 2):

Five ZD or ARD dampers maximum connected to each panel

and a maximum of five dampers per zone.

Use SDCR for additional dampers required on one zone.

Dampers are connected to M1 Common, M4 Open, and M6

Closed (see Fig. 8-12 for hookups).

Table 2. Recommended Dampers.

Honeywell Damper Type Round Rectangular

Power-open/power closed

(for systems >2000 cfm)

MARD D642 using

ML6161 Motor

Actuator

Spring-open/power-closed

ARD ZD

(for systems </= 2000 cfm)

Damper Connections:

Motor Terminal Damper Action

Common/M1 Common

Open/M4 Power Open

Closed/M6 Power Close

Accessories: For required accessories, see Table 3.

Table 3. Required Accessories.

Accessory Description

40 VA transformer AT140D1046

Capacity protector C7735A1000

Round static pressure

regulator damper

Rectangular static

pressure regulator

damper

7 SPRD

8 SPRD

9 SPRD

10 SPRD

12 SPRD

14 SPRD

16 SPRD

12 x 8 SPRD

12 x 10 SPRD

12 x 12 SPRD

20 x 8 SPRD

20 x 10 SPRD

20 x 12 SPRD

300 cfm

400 cfm

600 cfm

750 cfm

1200 cfm

1800 cfm

2400 cfm

1000 cfm

1200 cfm

1400 cfm

1600 cfm

2000 cfm

3000 cfm

3 68-0237-2

Page 4

EMM-3U UNIVERSAL ELECTRONIC MINIZONE™ PANEL

U

O

L

INSTALLATION

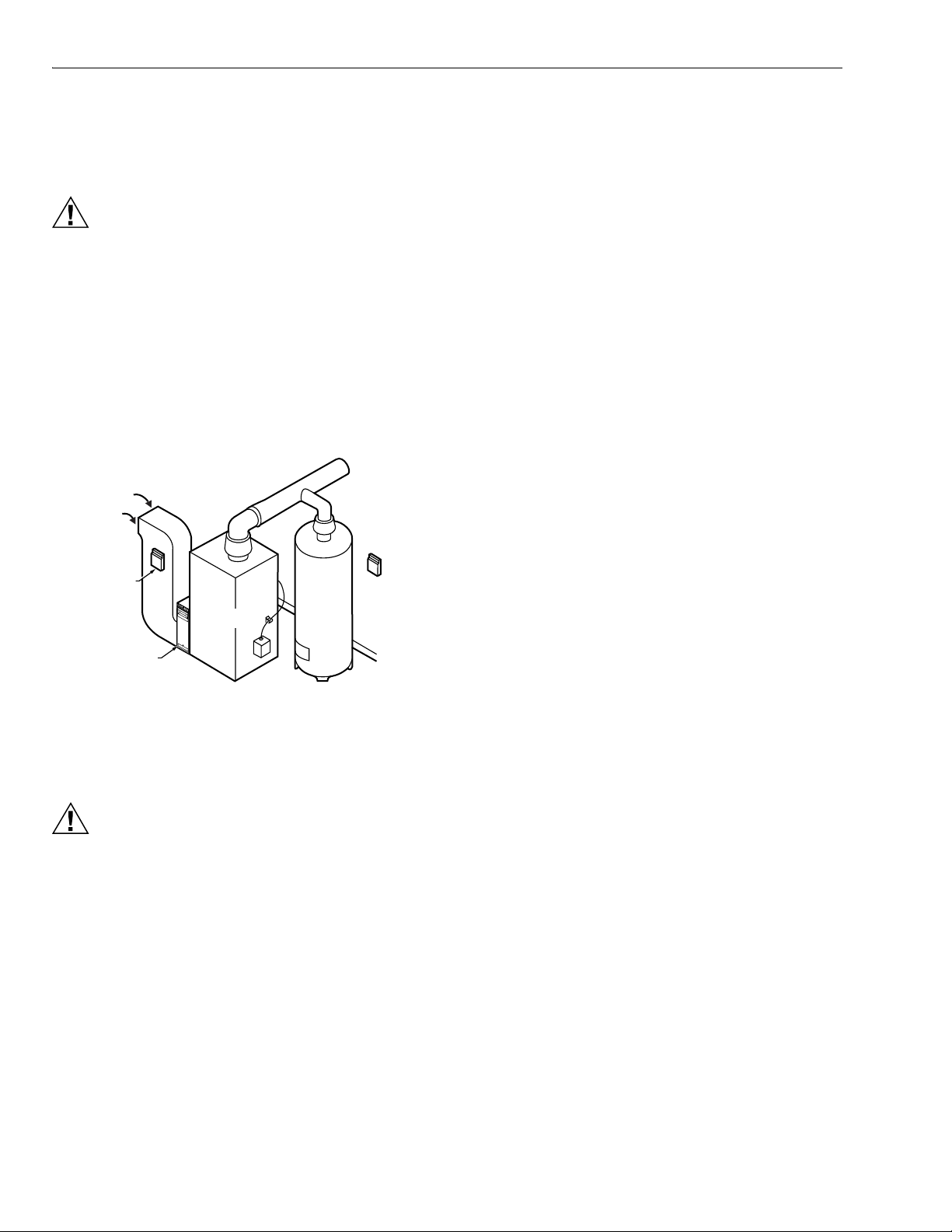

Mounting

CAUTION

Equipment Damage Hazard.

Do not mount EMM-3U inside HVAC equipment.

Mount only on wall or on cold air return.

1. Mount the thermostats in each zone of the living space

using the installation instructions provided with each

thermostat.

2. Mount the dampers in the ductwork using the installation instructions provided with each damper.

3. Mount the EMM-3U zone panel near the HVAC equipment; locate it on a wall or on the cold-air return. See

Fig. 2.

4. Level the EMM-3U for appearance only.

RETURN

AIR

EMM-U3

PTIONAL

OCATION

ELECTRONIC AIR CLEANER

FURNACE

OR BOILER

HIGH

EFFICIENCY

AIR CLEANER

Fig. 2. EMM-3U mounting location.

WATER

HEATER

EMM-3

M14762

Thermostat Wiring

Conventional Equipment

Conventional (RWYG) thermostats can be used to control

conventional, multi-stage and heat pump equipment. When

single-stage thermostats are used, stages are engaged

through the on-board 5 - 60 minute timer. If the equipment is a

heat pump, the EMM-3U panel controls the reversing valve. If

the thermostat has a common terminal, it is wired to C on the

panel, see Fig. 3. Multi-stage conventional (non-heat pump)

thermostats are wired with the second stage of heat and cool

on the thermostat to W2 and Y2 on the panel. Leave the O/B

thermostat jumper on the EMM-3U disconnected.

The PC8900 can be used as a zone thermostat. See Fig. 4 for

hookup. The PC8900 with the W8900A or C controls up to 2

heat and 2 cool stages of conventional equipment. The

PC8900 with the W8900A also controls heat pump

equipment.

Connect a jumper on the W8900 from Rc to Rh as shown.

Wire terminals R and C to a transformer. Alternately, if the

zone control system current draw is within specifications, the

R and C on the W8900 could be connected to R and C on the

EMM-3U. The PC8900/W8900 draws 5 VA.

Heat Pump Equipment

Select a heat pump thermostat from Table 1. If the thermostat

selected has a separate Y1 and W1 wire, connect as shown in

Fig. 5, leaving the zone O/B thermostat type jumper on the

EMM-3U disconnected

If the PC8900/W8900A is used, wire as shown in Fig. 4. This

hookup engages second stage heat based on thermostat

demand, but the Em Heat switch on the panel must be used to

switch the panel to emergency heat.

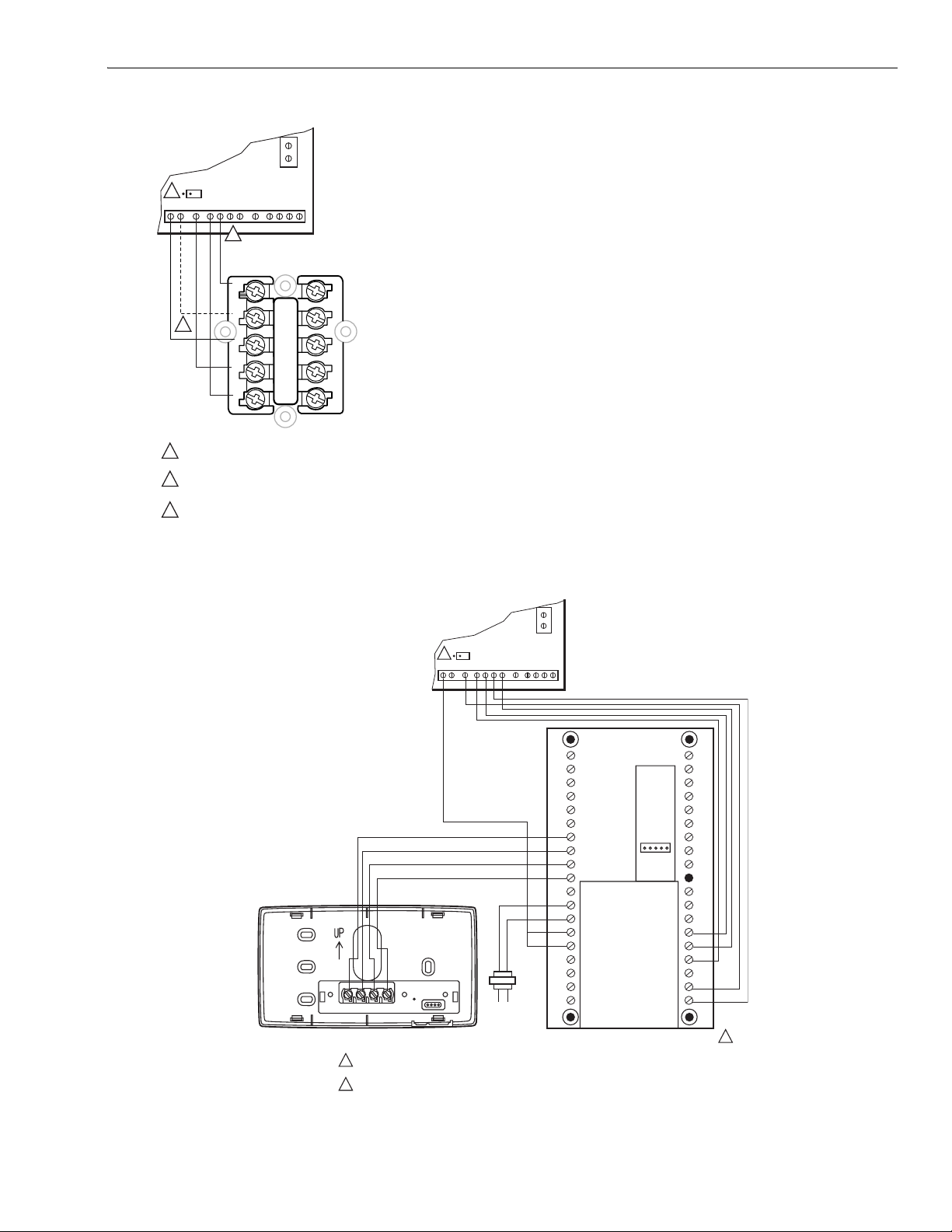

WIRING

NOTE: The thermostat Em Heat switch does not switch the

panel to emergency heat.

If the thermostat selected from Table 1 has a single Y terminal

CAUTION

Voltage Hazard.

Can cause electrical shock or equipment damage.

Disconnect power before continuing installation.

Wiring must comply with applicable codes, ordinances and

regulations.

1. Connect thermostats as shown in Fig. 3-7.

2. Connect dampers as shown in Fig. 8-12.

3. Connect C7735A1000 Discharge Air Temperature Sen-

sor (DATS) to the DATS terminals. The wires are not

polarized; see Fig. 13.

4. Connect the HVAC equipment to the EQUIP terminals

on the panel; see Fig. 13-18.

for first stage heat and cool, wire as shown in Fig. 6 and 7.

Wire either O or B (not both) from the thermostat to the O/B

terminal on the EMM-3U. Locate the O/B thermostat jumper

on the EMM-3U near each zone thermostat wiring terminal.

Connect the jumper if O is used or leave the jumper

disconnected if B is used. Connect second stage, auxiliary

heat, to W2.

Conventional single stage thermostats can be used to control

a heat pump if wired as shown in Fig. 3. In this case, the panel

operates the reversing valve, the second stage is brought on

by the panel stage timer, and emergency heat is activated by

the EM heat switch on the panel. Leave the O/B thermostat

type jumper disconnected when using conventional

thermostats.

5. Connect a 40 VA, 24 Vac transformer to R (hot) and C

(common). This must be a dedicated transformer. See

Fig. 13.

68-0237-2 4

Page 5

EMM-3U UNIVERSAL ELECTRONIC MINIZONE™ PANEL

A

H

R

C

24VAC

3

G W2Y2 O/B M6M4M1Y1W1/ECR L

40VA

2

EMM-3U THERMOSTAT

CONNECTORS

G

C

1

R

W

Y

TYPICAL SINGLE STAGE

THERMOSTAT WIRING

COMMON (C) TERMINAL IS USED ONLY BY THERMOSTATS

1

THAT REQUIRE A COMMON WIRE.

2

MULI-STAGE THERMOSTATS ARE WIRED SIMILARLY BUT WIT

Y2 AND W2 USED FOR SECOND STAGE COOL AND HEAT.

LEAVE O/B JUMPER ON EMM-3U DISCONNECTED.

3

M20780

Fig. 3. Typical conventional thermostat wiring.

2

O/BW1/E

GW2Y2 M6M4M1Y1CRL

R

C

24VAC

40VA

EMM-3U THERMOSTAT

CONNECTORS

CO

2

1

2

3

4

GND

C

R

RH

RC

HUM

24 VAC

HUM

VNT

120 VAC

1234

VNT

PC8900

W8900A/C IS RECOMMEDED FOR CONVENTIONAL AND HEAT PUMP APPLICATIONS. THE W8900B CANNOT

1

SWITCH THE PANEL TO EMERGENCY HEAT.

2

LEAVE O/B JUMPER ON EMM-3U DISCONNECTED.

S1

S

T1

T

OUT

OUT

LED

G

Y2

Y1

W1

W2

W8900A,C

1

M20781A

Fig. 4. PC89800 with W8900A,C Thermostat wiring.

5 68-0237-2

Page 6

EMM-3U UNIVERSAL ELECTRONIC MINIZONE™ PANEL

A

H

A

T.

A

T.

R

C

24VAC

3

GW2Y2 M6M4M1Y1CRL

40VA

O/BW1/E

EMM-3U THERMOSTAT

CONNECTORS

R

C

24VAC

3

GW2Y2 M6M4M1Y1CRL

40VA

O/BW1/E

EMM-3U

THERMOSTAT

CONNECTORS

G

1

C

R

W1

Y1

COMMON (C) TERMINAL IS USED ONLY BY THERMOSTATS

1

THAT REQUIRE A COMMON WIRE.

2

JUMP E TERMINAL TO W1 FOR EMERGENCY HEAT.

3

LEAVE O/B JUMPER ON EMM-3U DISCONNETED.

L

W2

2

E

B

O

HEAT PUMP THERMOSTAT WIT

SEPARATE W1 AND Y1

THERMOSTAT WIRING

M20782

Fig. 5. Heat pump thermostat with separate W1 and Y1

terminal wiring.

R

C

24VAC

3

GW2Y2 M6M4M1Y1CRL

G

C

1

R

Y1

COMMON (C) TERMINAL IS USED ONLY BY THERMOSTATS

1

THAT REQUIRE A COMMON WIRE.

2

NORMALLY, CONNECT E ON THERMOSTAT TO W1/E ON PANEL.

ALTERNATELY, INSTALL JUMPER FROM E TO Y1 ON THERMOSTA

3

CONNECT O/B TERMOSTAT JUMPER ON EMM-3U PANEL IF

USING O FROM THERMOSTAT; DISCONNECT IF USING B.

40VA

O/BW1/E

EMM-3U

THERMOSTAT

CONNECTORS

L

W2

E

B

O

HEAT PUMP THERMOSTAT WITH

SINGLE Y THERMOSTAT WIRING

2

M20783

G

C

1

R

W1

Y1

COMMON (C) TERMINAL IS USED ONLY BY THERMOSTATS

1

THAT REQUIRE A COMMON WIRE.

2

NORMALLY, CONNECT E ON THERMOSTAT TO W1/E ON PANEL.

ALTERNATELY, INSTALL JUMPER FROM E TO Y1 ON THERMOSTA

3

CONNECT O/B TERMOSTAT JUMPER ON EMM-3U PANEL IF

USING O FROM THERMOSTAT; DISCONNECT IF USING B.

L

W2

E

2

B

O

HEAT PUMP THERMOSTAT WITH

SINGLE Y THERMOSTAT WIRING

M20784

Fig. 7. Heat pump thermostat with single Y1 using B for

changeover thermostat wiring.

Damper Wiring

ARD or ZD Dampers

Wire the ARD or ZD damper to the panel as shown in Fig. 8.

Multiple dampers can be wired in parallel. Use these dampers

on systems up to 2000 cfm.

Fig. 6. Heat pump thermostat with single Y1 using O for

changeover thermostat wiring.

68-0237-2 6

Fig. 8. Wiring ARD or ZD Damper to panel.

AOBD Dampers

Wire the AOBD dampers to the panel as shown in Fig. 9. Two

AOBD can be wired in tandem as shown in Fig. 10. More than

two AOBD dampers require the Slave Damper Control Relay

(SDCR).

Page 7

EMM-3U UNIVERSAL ELECTRONIC MINIZONE™ PANEL

F

7

8

S

S

6

A

MOTOR TERMINALS

M6 M4 M1

4

5 6

123ZX

IELD JUMPER

DAMPER MOTOR

M1906

Fig. 9. Wiring AOBD Damper to panel.

MOTOR TERMINAL

FIELD JUMPER

4 5 6

123ZX

DAMPER MOTORS

M6 M4 M1

4

5 6

123

Z

X

M1906

Fig. 10. Wiring two AOBD dampers in parallel.

ZONE CONTROL PANEL

DAMPER TERMINALS

M6 M4 M1

R8222 RELAY

R

C

ML6161

COM

CCW

CW

M20548

Fig. 12. MARD or ML6161 Damper Motor Actuator using

R8222 Relay wiring.

Discharge Air Sensor Wiring

Wire the C7735 Discharge Air Temperature Sensor (DATS) to

the panel as shown in Fig. 13 -16.

The Purge LED (amber) flashes in all modes except purge if:

1. No DATS is connected to the EMM-3U.

2. There is a problem with the DATS sensor.

3. There is a problem with the DATS wiring.

The zone control panel will continue to operate correctly when

the purge LED is flashing but without the high and low limit

protection.

MARD Dampers or Dampers Using ML6161 Motor

Actuator

Wire the MARD Damper or ML6161 Actuator to the panel as

shown in Fig. 11. These are floating control actuators, but are

controlled as two-position devices on the EMM-3U Panel.

Multiple dampers can be wired in tandem.

The ML6161 Motor causes the damper LED to illuminate

green constantly. Wire a relay as shown in Fig. 12 to restore

damper position indication.

Use the MARD or D642 Damper with the ML6161 on systems

2000 cfm and higher.

ZONE PANEL

CONNECTION

M1 M4

MARD

CW

COM

CCW

Fig. 11. Wiring MARD Damper or ML6161 Actuator to

panel.

M

M20136A

Equipment Wiring

Conventional Equipment

Wire the heating and cooling equipment to the equipment

terminals on the EMM-3U Panel as shown in Fig. 17.

Conventional Equipment: Leave DIP switch 4 set to On.

Electric Furnace: Set DIP switch 7 to Off to energize the fan

with a call for heat.

Oil Heat: Wire the oil primary T, T terminals to the Rh and W

equipment terminals. (If the oil primary has powered

terminals, remove the Rh and Rc jumper.) See Fig 15 and 16.

Multi-Stage: Wire the equipment as shown in Fig. 13 using the

W2 for second stage heating, and the Y2 for second stage

cooling.

See the Operation section for stage configuration and other

settings.

7 68-0237-2

Page 8

EMM-3U UNIVERSAL ELECTRONIC MINIZONE™ PANEL

Hot Water Heat Systems

Hydronic Heat

Hydronic heat systems using zone valves or circulator relays

for heating and dampers for cooling can be controlled by the

panel. In this hookup, one thermostat is used per zone to

control both heating and cooling. Use thermostats with

separate Rc and Rh terminals to isolate the heating and

cooling circuits. Connect the thermostat Rh and W to the zone

valve and the Rc, Y and G to the zone control panel. Wire the

thermostats and air conditioning equipment the same as for

conventional equipment; see Fig. 3 and 16.

Hydro Heat

Hydro heat systems using a boiler and hot water coil can be

used with this zone control panel. Wire the zone valve or

circulator relay to equipment terminals Rh and W. The Rc and

Rh jumpers located above the equipment terminals must be

removed if a separate transformer powers the heating and

cooling circuits. Wire the cooling equipment, thermostats, and

dampers the same as for conventional equipment; see Figure

19. Set DIP switch 7 to off if it is necessary for the fan to be

energized on a call for heat. Alternatively, an Aquastat can be

used to engage the blower based on water temperature.

Heat Pump Equipment

See Fig. 17 and 18 for heat pump equipment wiring. Refer to

the manufacturer instructions for additional wiring details and

substitute the EMM-3U equipment terminals for the

thermostat terminals shown.

If the same heat source is used for auxiliary heat and

emergency heat:

• Connect the auxiliary heat to W2.

• Wire a jumper from W2 to E.

• Set DIP switch 12 to Off.

If auxiliary heat is separate from emergency heat:

• Connect the auxiliary heat to W2.

• Connect the emergency heat to E.

• Leave DIP switch 12 set to On.

Connect the changeover relay to the O or B equipment

terminal (O is energized when the panel is in the cool mode, B

is energized when the panel is in the heat mode).

IMPORTANT

Connect the compressor wire to the Y1 terminal. If there is a

2

To control a two-stage heat pump with auxiliary heat, select

the TZ-4 TotalZone Zone Control panel.

Set DIP switch 4 to Off for heat pump operation, and set DIP

switch 7 to Off for fan on a call for heat.

See the Operation section for additional configuration

settings.

Some heat pump manufacturers (such as York and

Trane) use the B terminal as the transformer common. Do not connect the common from the equipment to the zone control panel.

nd

stage compressor, wire it to Y2 with a jumper to W2.

Transformer

Wire a dedicated transformer to the R (hot) and C (common)

terminals on the zone control panel as shown in Fig.13. One

40 VA, 24 Vac transformer powers up to five ARD or ZD

Dampers and the panel.

68-0237-2 8

Page 9

M14763A

Single Transformer

S

T

t

a

F

t

H

I

L

(

L

M14766A

M14764A

Heating/Cooling

systems require a

jumper to be installed

connecting R

(factory installed).

24 Volt Equipment

Transformer(s)

Cooling Transformer

Heating Transformer

First Stage Heat Relay

econd Stage Heat Relay

First Stage Cool Relay

Second Stage Cool Relay

his diagram shows the typical

wo-stage equipment, thermostat,

nd damper motor connections.

or specific wiring for other

hermostats, damper motors, and

VAC Equipment, refer to the

nstallation Instructions.

and R

H

Fan Relay

C

EMM-3U UNIVERSAL ELECTRONIC MINIZONE™ PANEL

HEAT COOL PURGE FAN EM. HEAT ZONE 1 ZONE 2 ZONE 3

LED STATES:

RED HEAT LED HEATING MODE

GREEN COOL LED COOLING MODE

R

C/RH

JUMPER

EQUIPMENT

CRR

1

CW2Y2

Zone 1 Thermostat

YELLOW PURGE LED PURGE MODE

GREEN FAN LED FAN MODE

RED EM HEAT LED EM HEAT MODE

FLASHING RED HEAT LED ZMS SENSOR EXCEEDS HIGH LIMIT IN HEATING

FLASHING GREEN COOL LED ZMS SENSOR EXCEEDS LOW LIMIT IN COOLING

FLASHING YELLOW PURGE LED

ZONE LEDS

R

C

ON (GREEN COLOR) DAMPER IS OPEN OR OPENING

R

OFF (NO COLOR) DAMPER IS CLOSED OR CLOSING

H

W

1

MOMENTARY PUSHBUTTON SWITCHES:

W

2

BOOT USED TO CLEAR THE SYSTEM AND MICROPROCESSOR.

E

PURGE OVERRIDE USED TO BYPASS THE PURGE CYCLE WHILE TROUBLESHOOTING.

B

DIP SWITCH SETTINGS

O

1 STAGE TIMER

Y

2 STAGE TIMER ON OFF

1

3 STAGE TIMER 1 0 TABLE

Y

2

4 SYSTEM TYPE CONV HEAT PUMP

G

5 ZMS HIGH LIMIT 160 F 120 F

6 ZMS LOW LIMIT 40 F 48 F

7 HEAT FAN HVAC PANEL

8 PURGE FAN HVAC PANEL

9 PURGE DAMPER NO CHG OPEN

10 PURGE TIME 2.0 MIN 3.5 MIN

11 EM HEAT FAN HVAC PANEL

12 2ND STAGE EM HEAT YES NO

SEE

TABLE

ZONE 1

O/BW1/E O/BW1/E O/BW1/E

GW2Y2 M6M4M1

GY1Y1W1

Power-open

Power-closed

(Opposed Blade

Damper Motors)

L

456Z

123X

NO ZMS SENSOR INSTALLED OR ZMS SENSOR FAILUR

#1 #2 #3 TIME

1 1 1 5 MIN

1 1 0 10 MIN

1 0 1 15 MIN

1 0 0 20 MIN

0 1 1 30 MIN

0 1 0 45 MIN

0 0 1 60 MIN

0 0 0 NO TIMER

ZONE 2

CRR

GW2Y2 M6M4M1

1 12 2 2

GY1Y1W1

CW2Y2

Zone 2 Thermostat

Power-closed

Spring-open

(Model ZD)

L

BOOT PURGE

O

N

1

2 3 4 5 6 7 8 9 101112

222

CRR

CW2Y2

Zone 3 Thermostat

OVERRIDE

E

DATS

DATS

ZONE PANEL

TRANSFORMER

EM

HEAT

R

C

24V AC

ZONE 3

GW2Y2 M6M4M1

GY1Y1W1

Power-closed

Spring-open

(Model ARD)

L

ON

OFF

(See C7735

Installation

Instructions

for further

information.)

40VA

24 Volt 40VA

Transformer

ZONE

THERMOSTATS

1 C terminal

connection is not

required on battery

powered, power

stealing, or some

electromechanical

thermostats.

2 Leave jumper

disconnected for

conventional

thermostats.

ZONE DAMPER MOTORS

M1 - common

M4 - power open

M6 - power closed

Discharge Air

Temperature

Sensor

CR

Fig. 13. EMM-3U System wiring diagram.

1

TRANSFORMER

HOT)

2

Fig. 14. Conventional single-stage single transformer

LEAVE FACTORY INSTALLED RH TO RC JUMPER IN PLACE

1

FOR SINGLE TRANSFORMER SYSTEM.

COOLING

CONTACTOR

HEAT

RELAY

FAN

RELAY

system wiring diagram.

PANEL

1

R

C

R

H

W

1

W

2

E

B

O

Y

1

Y

2

G

L1

OIL PRIMARY

(HOT)

T T

L2

COOLING

L1

(HOT)

L2

1

24V

REMOVE FACTORY INSTALLED RH TO RC JUMPER.

CONTACTOR

FAN

RELAY

PANEL

1

R

C

R

H

W

1

W

2

E

B

O

Y

1

Y

2

G

Fig. 15. EMM-3U oil heating wiring diagram.

9 68-0237-2

Page 10

EMM-3U UNIVERSAL ELECTRONIC MINIZONE™ PANEL

L

(

L

L

(

A

L

(

L

A

.

L

(

L

A

.

PANEL

HEATING

1

TRANSFORMER

HOT)

L2

COOLING

1

TRANSFORMER

HOT)

2

REMOVE FACTORY INSTALLED RH TO RC JUMPER.

1

HEAT

RELAY

COOLING

CONTACTOR

FAN

RELAY

1

R

C

R

H

W

1

W

2

E

B

O

Y

1

Y

2

G

M14765

Fig. 16. Two-transformer system wiring diagram.

PANEL

1

TRANSFORMER

HOT)

2

SECOND STAGE

HEAT RELAY

EM HEAT

RELAY

COOLING

CHANGE OVER

VALVE

FIRST STAGE

COMPRESSOR

RELAY

1

R

C

R

H

W

1

W

2

E

B

O

Y

1

Y

2

G

PANEL

1

TRANSFORMER

HOT)

2

LEAVE FACTORY INSTALLED RH TO RC JUMPER IN PLACE

1

SECOND STAGE

HEAT RELAY

COOLING

CHANGE OVER

VALVE

FIRST STAGE

COMPRESSOR

RELAY

FAN

RELAY

R

C

R

H

W

1

W

2

E

B

O

Y

1

Y

2

G

M14767

1

Fig. 18. Single-stage heat pump with auxiliary heat wiring

diagram.

FAN

RELAY

LEAVE FACTORY INSTALLED RH TO RC JUMPER IN PLACE

1

M14767

Fig. 17. Single-stage heat pump with separate auxiliary

and emergency heat wiring diagram.

68-0237-2 10

Page 11

EMM-3U UNIVERSAL ELECTRONIC MINIZONE™ PANEL

M20888

T

a

h

u

s

F

t

HEAT COOL PURGE FAN EM. HEAT ZONE 1 ZONE 2 ZONE 3

24 Volt Equipment

R on Fan Center for AC

Compressor Relay

Fan Relay

his diagram shows the typical

ir conditioning system and

ydronic zone valve hookup

sing common dampers and

ingle stage thermostats.

or specific instructions, refer

o Installation Instructions.

R

C/RH

JUMPER

EQUIPMENT

R

C

R

H

W

1

MOMENTARY PUSHBUTTON SWITCHES:

W

2

BOOT USED TO CLEAR THE SYSTEM AND MICROPROCESSOR.

E

PURGE OVERRIDE USED TO BYPASS THE PURGE CYCLE WHILE TROUBLESHOOTING.

B

DIP Switches (see Installation Instructions for details):

O

1, 2, 3: Set to off for 1 stage heat and cool

Y

1

4: Set to on for conventional equipment

Y

5: Set to on for 160°F high limit

2

6: Set to on for 40°F or off for 48°F

G

7: Set to on

8: Set to on for no purge fan after call for heat or cool

9: Set to on

10: Set to on

11: Set to on

12: Set to on

ZONE 1

CRcR

Rh RcRh Rc Rh

Zone 1 Thermostat

Yellow Leads

V8043E

Power-open

Power-closed

(Opposed Blade

Damper Motors)

O/BW1/E O/BW1/E O/BW1/E

GW2Y2 M6M4M1

GY1YW

L

456Z

123X

ZONE 2

GW2Y2 M6M4M1

CRL

GY1YW

Zone 2 Thermostat

Th/Tr

Th

V8043F V8043F

Power-closed

Spring-open

(Model ZD)

DATS

DATS

EM

HEAT

R

C

24 VAC

ON

OFF

40VA

BOOT PURGE

OVERRIDE

O

N

1

2 3 4 5 6 7 8 9 101112

ZONE PANEL

TRANSFORMER

111

Th

ZONE 3

GW2Y2 M6M4M1

CRL

GY1YW

Zone 3 Thermostat

Th/Tr

Power-closed

Spring-open

(Model ARD)

Discharge Air

Temperature

Sensor

(See C7735

Installation

Instructions

for further

information.)

CR

24 Volt 40 VAC

Transformer

1 Leave this jumper

disconnected.

ZONE DAMPER MOTORS

M1 - common

M4 - power open

M6 - power closed

Fig. 19. EMM-3U with Air Conditioning Zoned with Dampers and Hydronic Heat Using V8043 Zone Valves.

STARTUP AND CHECKOUT

5. Verify that the heat LED is red and the zone one damper

remains green while the other damper LEDs turn off.

6. Raise zone two setpoint to call for heat. Lower zone one

After the installation is complete, verify correct operation:

1. Place the Em Ht switch in the Off (down) position.

2. Verify that DIP switches are set correctly.

3. Turn on power to the EMM-3U Panel and set the ther-

mostats so no zones are calling.

a. EMM-3U enters the Purge Mode, opening all damp-

ers and operating the fan for two or three and onehalf minutes (configurable). In Purge, damper LEDs

setpoint to stop the call for heat to that zone.

7. Verify that zone one LED turns off and zone two LED

turns green.

8. Repeat for zones two and three.

9. Alternately, set the System switch to Cool, and lower the

setpoint to call for cooling.

10. Verify that the green cool LED illuminates.

are green to indicate the dampers are open.

NOTE: If a Discharge Air Temperature Sensor is not con-

nected to the panel, the purge LED flashes in all

modes other than Purge.

b. Press the Purge Override button on the panel to exit

the Purge mode early.

4. Set the zone one thermostat to heat and raise the set-

OPERATION

Identifying DIP Switches

This panel has one bank of 12 DIP switches numbered

starting with 1 on the left. The switches are shipped in the On

(Up) position. See Fig. 13 and Tables 4 and 5.

point to call for heat.

11 68-0237-2

Page 12

EMM-3U UNIVERSAL ELECTRONIC MINIZONE™ PANEL

Sequence of Operation

• When there is no call for heat, cool, or fan, the EMM-3U is

in the Idle mode. No system LEDs are illuminated and the

damper LEDs are green to indicate open.

• On a call for heat, cool, or fan, the calling zone damper

stays open, and the other zone dampers close:

— Panel energizes the HVAC equipment and conditioned

air is delivered to the calling zone.

— Heat LED (red), cool LED (green), or fan LED (green)

illuminates to indicate equipment operation.

— Fan LED illuminates only during a call for circulation; it

does not illuminate during a call for heat or cool.

• When the call is satisfied, the system enters the Purge

mode. After Purge, all dampers return to the Open position

• Any zone thermostat can call for heating or cooling. If there

are co-existing calls for heat and cool, the panel accepts

the first call.

• Once a call is satisfied, or a maximum of 20 minutes has

elapsed, the panel switches to allow the opposite call after

completing Purge mode.

Purge Mode

• At the end of every call for heat or cool, the panel enters a

Purge mode that holds open the calling zone damper for

two minutes (default) or three and one-half minutes.During

this time, the panel or the HVAC equipment can be

configured to operate the fan.

• The Purge LED lights to signal that the system is in the

Purge mode. Pressing the purge override button overrides

the Purge mode.

• Unless there is a new call for heat or cool during the Purge

mode, all dampers are moved to the Open position at the

end of Purge.

• The panel can be configured to open all dampers during

purge mode.See Table 4 to configure the Purge mode

using DIP switches 8, 9 and 10.

Individual Zone Fan Control

• The fan switch of each thermostat controls the fan

operation for that zone.

• When the Fan switch is in the On position, the fan is

energized, and dampers close to zones where the Fan

switch is in Auto position.

• During a call for heat or cool at this time, the circulation

mode ceases, and the heat or cool call is honored.

• When the zone calling is satisfied, the circulation call

resumes.

Single- and Multi-Stage Operation

The panel can control up to two stages of heat and cool:

• First stage is energized by the thermostat

• Second stage of heating or cooling can be energized by

the thermostat or timer.

Single-Stage

Select a single stage thermostat, see Table 1. Set DIP

switches 1, 2, and 3 to Off to disable the stage timer.

Multi-Stage

THERMOSTAT-CONTROLLED STAGES

• Select a multi-stage thermostat, see Table 1, that

energizes W2 and Y2 for second stage of heat and cool.

• Configure DIP switches 1, 2 and 3 to Off to disable the

stage timer.

Timer Controlled Stages

• The panel stage timer energizes the second stage of heat

or cool after the first stage has been calling for a specified

amount of time.

• Second stage remains energized until the call for heat or

cool is satisfied.

• See Table 5 for stage timer configuration.

Heat Pump Operation

The panel can control single or two stage heat pumps with or

without auxiliary heat:

• Set DIP switch 4 to Off for heat pump control. This

energizes the Y1 on a call for first stage heat or cool.

• Set DIP switch 7 to Off to engage the fan with a call for

heat.

Thermostat Controlled Stages

• Select a thermostat from Table 1. Configure DIP switches

1,2, and 3 to off to disable the stage timer.

— When thermostat calls for first stage, panel energizes

Y1, G and the correct reversing valve terminal.

— When the thermostat calls for second stage heat on

W2, the panel energizes the equipment W2 terminal.

• Recommended heat pump thermostats can switch the

panel to emergency heat:

— In this mode, Y1 equipment terminal is disabled and E

is energized on a call for heat.

— If the same source of heat is used for emergency heat

and auxiliary heat, W2 and E equipment terminals

must be jumpered.

• Emergency heat can be energized by the Em Heat switch

on the panel.

• If the equipment is a two-stage heat pump, W2 and Y2

equipment terminals must be jumpered and wired to the

second stage compressor contactor.

• If the equipment is a two-stage heat pump with auxiliary

heat, select the TZ-4 TotalZone™ panel.

Timer Controlled Stages

If single-stage thermostats are used, the EMM-3U can

energize second stage using stage time:

• The timer can be set to engage second stage heat or cool

after the first stage has been calling for the specified length

of time.

• See Table 5 for DIP switch configuration.

Thermostat Operation

Conventional Thermostats

Conventional (R,W,Y,G) heat/cool thermostats can be used

with the EMM-3U to control single or multi-stage gas, electric,

or oil systems and heat pumps with or without auxiliary heat.

• For two stage heat or cool equipment, configure the stage

timer with DIP switches 1, 2 and 3. See Table 5. This

enables the panel to engage second stage after stage one

has been calling for the specified length of time.

68-0237-2 12

Page 13

EMM-3U UNIVERSAL ELECTRONIC MINIZONE™ PANEL

• Heat pumps can be controlled by conventional thermostats

because the EMM-3U controls the reversing valve based

on whether the panel is in heat or cool.

— It controls auxiliary heat through the stage timer.

— For heat pump applications, set DIP switch 4 to Off.

• In all cases, when a conventional thermostat is used, the

O/B thermostat type jumper located next to each

thermostat connection must remain disconnected.

Heat Pump Thermostats

Heat pump thermostats that have a single Y terminal for first

stage heat and cool and those with separate Y1 and W1 can

be used with the EMM-3U. Thermostats of either type can be

used on any zone. Set DIP switch 4 to Off for heat pump

control.

HEAT PUMP THERMOSTATS WITH SINGLE Y OUTPUT

Thermostats with a single Y wire for first stage heat and cool

can be connected to the EMM-3U. O/B thermostat type

jumpers must be set correctly:

— If the thermostat uses O for changeover, connect it to

the O/B thermostat terminal on the panel and connect

the O/B jumper on the panel. (There is one jumper for

each zone.)

— If B is used, leave the jumper disconnected.

HEAT PUMP THERMOSTATS WITH SEPARATE Y1 AND W1

TERMINALS

• Heat pump thermostats with separate Y1 and W2 terminals

for first stage can be used to control a heat pump.

• On these installations, it is not necessary to connect O or B

from the thermostat.

• Leave the O/B thermostat type jumper disconnected.

Manual and Automatic Changeover

Thermostats

Manual or automatic changeover thermostats can be used.

• The panel determines the call for heat or cool based on

which was called for first.

• Subsequent calls for heat or cool are honored when the

initial call is satisfied, or 20 minutes has elapsed.

Rebooting the Microprocessor

To reset the panel, press and release the Boot button. The

system reboots and enters the Purge mode.

Discharge Air Temperature Sensor

The C7735A1000 Discharge Air Temperature Sensor is a

supply-duct-mounted temperature probe used to control

capacity and prevent high limit or coil icing.

• The sensor attaches to the two DATS terminals on the

panel.

• When a high or low limit is reached, the panel shuts off the

equipment and keeps the fan operating for 2-1/2 minutes.

• After this time, it re-energizes the equipment after the

discharge air temperature recovers by ten degrees.

• When the DATS exceeds the high or low limit, the Heat

(red) or Cool (green) LED flashes.

• Set the temperature to 120°F for heat pump systems or

160°F for fossil fuel. The low limit can be set to 40°F or

48°F.

See Table 4 to configure high and low limit using DIP switches

5 and 6.

Emergency Heat Control

NOTE: Emergency heat is defined as using an auxiliary heat

source without using the heat pump. When the Em

Heat switch is in the Em Ht position, the heat pump is

locked out and calls for heat are sent to the E equipment terminal.

• A recommended heat pump thermostat (see Table 1) can

also switch the board to the emergency heat mode. When

one or more thermostats is in emergency heat, the board

locks out the heat pump.

• When the same source of heat is used for auxiliary heat

and emergency heat, the W2 and E equipment terminals

are jumpered together. Set DIP switch 12 to the Off

position.

• When a different source of heat is used for Auxiliary Heat

and Emergency Heat, Auxiliary Heat is wired to W2 and

Emergency Heat is wired to E. Set DIP switch 12 to On.

When the EMM3-U is then set to Emergency heat, it first

engages equipment terminal E on a call for heat and the

second stage of emergency heat is then W2.

Multi-Stage Thermostats

Use multi-stage thermostats to control up to two stages of

heat or cool with the Y2 and W2 thermostat terminals on the

panel.

IMPORTANT

Be sure the Discharge Air Temperature Sensor

wiring does not run parallel with line voltage wiring

unless more than 12 inches of separation exists or

shielded cable is used.

NOTE: The yellow purge LED flashes in all modes other

than purge when there is a DATS failure, a wiring

problem, or when no DATS is connected to the

panel.

The zone control panel will continue to operate correctly when

the purge LED is flashing but without the high and low limit

protection.

Circuit Breaker Protection

A built-in thermal circuit breaker protects the panel against

shorts in the thermostat and damper wiring:

• When the circuit breaker is tripped, none of the LEDs

illuminate and the yellow rectangular component located

left of the R and C terminals is hot when touched.

• Remove power to the panel for at least five minutes to

allow the breaker to cool and reset.

• To eliminate the short, verify damper and thermostat wiring.

Fan On In Heat

The system blower can be set to come on with a call for heat

as required for hydro-air or electric heat systems:

• Setting DIP switch 7 to Off configures the blower to engage

with a call for heat.

13 68-0237-2

Page 14

EMM-3U UNIVERSAL ELECTRONIC MINIZONE™ PANEL

Table 4. DIP Switch Settings and Functions.

DIP Switch Function On (Default) Off

1 Stage Timer See Table 5.

2 Stage Timer See Table 5.

3 Stage Timer See Table 5.

4 System Type Conventional Heat Pump

5 DATS High Limit 160 120

6 DATS Low Limit 40 48

7 Heat Fan HVAC controls fan in heat Panel engages fan in heat

8 Purge Fan Purge Fan controlled by

HVAC

9 Purge Damper Purges into last zone calling Purges into all zones

10 Purge Time Two minutes 3-1/2 minutes

11 EM Heat Fan HVAC controls fan in EM

heat

12

Time (Minutes) DIP Switch 1 DIP Switch 2 DIP Switch 3

5 On On On

10 On On Off

15 On Off On

20 On Off Off

30 Off On On

45 Off On Off

2nd Stage Em Heat

Table 5. Stage Timer Configuration.

Yes No

Panel engages Purge Fan.

Panel engages fan with heat

60 Off Off On

No Timer Off Off Off

68-0237-2 14

Page 15

EMM-3U UNIVERSAL ELECTRONIC MINIZONE™ PANEL

.

TROUBLESHOOTING

The primary diagnostic tools are the System and Zone damper status LEDs and BOOT and PURGE OVERRIDE buttons. See

Fig. 20 and 21 for troubleshooting flowcharts.

Start

The board may have been damaged.

Is there

24 vac at R and C on

the transformer

contacts?

Yes

Is there

24 vac on all the zones

at R-C?

Yes

Is the

thermostat calling

for cool?

Yes

Are you

using heat pump

or conventional

thermostats?

Conventional

Check for

24 vac at Y1-C on

the zone calling for cooling.

You should have

24 vac?

Yes

Is there

continuity at Rc-Y1 and

Rc-O on the equipment

contacts of the EMM-3U

board?

Check the transformer

No

No

No

Yes

Do you

have the correct volt

reading at O/B-C on

the board?

Yes

No

No

Yes

for 24 vac.

The

thermal fuse has

tripped because of a high amp

draw. Remove the R wire on

the transformer contacts from the board

for 5 minutes and allow the board to reset. Take

the thermostat and damper wires off from

each zone before you re-attach the

transformer R wire. Is there

voltage at R-C on all

of the zones?

Thermostat may be in a

5 min delay in cooling.

Make sure thermostat is

calling for cooling.

Heat pump

No

No

Is

24 vac at R-Y or Y1

and R-O/B on the

thermostat?

Remove all wires from the board except R and C (power from the transformer)

the thermostat) on one of the zones. If the COOL light does not come on,

No

Do you have

a DATS sensor hooked

to the board?

Yes

Check for 24 vac at Y1-C on the zone that is calling for

cooling. Check for 24 vac at the O/B-C on that zone.

shunt jumper across the two pins. If you are using B,

pins or completely off. If you are using O then you will

It could be a bad wire. If you have voltage

on the panel at R-Y1 (and R-O/B if there is a

wire on O/B) but not at the thermostat, it is a bad

wire. Check for voltage at R-W or W1, G on the

thermostat. If there is voltage there then it

is a bad Y or Y1 (or O/B if you are using O/B) wire.

If no voltage at R-any other terminal on the

Yes

Reboot the board. Jumper R-Y1 (and R-O/B if you are using O from

Yes

The cooling equipment should be

working but the COOL light is not

Take the transformer R wire off again

for 10 minutes. After 10 minutes reattach that R wire and press the BOOT

button. Check voltage at R-C on all

the zones. If no voltage at R-C then

call Honeywell Zoning hotline,

No

Re-attach each zone thermostat wire. Attach

each zone separately, checking after each

zone is attached if the thermal fuse

has tripped by checking voltage across R

and C on that zone. After attaching the

thermostat wires, attach each zone motor

wires, again checking the thermal fuse to

see if it trips. This step-by-step process

should help you identify what is tripping the

Are you using O or B on the thermostat? If you are

using O on the thermostat, you need to place the

you need to place that jumper on just one of the

have 24 vac at O/B-C. If you are using B on the

thermostat, you will not have 24 vac at O/B-C.

thermostat then it is a bad R wire.

Jumper the R wire to the Y or Y1 (and O/B if you have

jumper R-Y or Y1 on the thermostat and the COOL

light does not come on, you may have a bad wire.

call Honeywell Zoning hotline, 800-828-8367.

Remove the DATS wires from

the board. Reboot the board.

Return to "Is the thermostat

calling for COOL" part of the

troubleshooting from that point.

on. Seems like the board is

coming on. Call Honeywell

Zoning hotline, 800-828-8367.

800-828-8367.

thermal fuse on the board.

a wire on O/B) wire on the thermostat. If the

COOL light comes on, you have a bad

thermostat. Replace thermostat. If you

Try another set of wires or check continuity.

flowchart and begin

END

M14827A

Fig. 20. Thermostat is calling for cooling but the Cool LED is not turning green to show a cool call.

15 68-0237-2

Page 16

EMM-3U UNIVERSAL ELECTRONIC MINIZONE™ PANEL

t

Start

Is there

24 vac at R and C on

the transformer

contacts?

Yes

Is there

24 vac on all the zones

at R-C?

Yes

Is the

thermostat calling

for heat?

Yes

Are you

using heat pump

or conventional

thermostats?

Conventional

Yes

Check for

24 vac at W1-C on

the zone calling for heating.

You should have

24 vac?

Yes

Is there

continuity at Rh-W1 (or Y1

for heat pump) and Rh-B on the

equipment contacts of the

EMM-3U board?

Yes

Check the transformer

No

No

No

Heat pump

Do you

have the correct volt

reading at O/B-C on

the board?

No

a DATS sensor hooked

No

for 24 vac.

thermal fuse has

tripped because of a high amp

draw. Remove the R wire on

the transformer contacts from the board

for 5 minutes and allow the board to reset. Take

the thermostat and damper wires off from

each zone before you re-attach the

transformer R wire. Is there

voltage at R-C on all

Make sure thermostat is

calling for heat. Raise

the setpoint and verify the

thermostat is calling for heat.

No

Is

24 vac at R-W1 and

R-O/B on the

thermostat?

No

Do you have

to the board?

The board may have been damaged.

Take the transformer R wire off again

for 10 minutes. After 10 minutes reattach that R wire and press the BOOT

button. Check voltage at R-C on all

the zones. If no voltage at R-C,

call Honeywell Zoning hotline,

The

of the zones?

No

Remove all wires from the board except R and C (power from the transformer).

Reboot the board. Jumper R-W or W1* (and R-O/B if you are using B from

No

Yes

Re-attach each zone thermostat wire. Replace

each zone separately, checking after each

zone is attached if the thermal fuse

has tripped by checking voltage across R

and C on that zone. After attaching the

thermostat wires, replace each zone motor

wires, again checking the thermal fuse to

see if it trips. This step-by-step process

should help you identify what is tripping the

Check for 24 vac at W1-C on the zone that is calling for

heat. Check for 24 vac at the O/B-C on that zone.

Are you using O or B on the thermostat? If you are

using O on the thermostat, you need to place the

shunt jumper across the two pins. If you are using B,

you need to place that jumper on just one of the

pins or take it completely off. If you are using O then you

will not have 24 vac at O/B-C. If you are using B on the

thermostat, you will have 24 vac at O/B-C.

It could be a bad wire. If you have voltage

on the panel at R-W or W1* (and R-B if there is a

wire on B) but not at the thermostat, it is a bad

wire. Check for voltage at R-Y or Y1, R-G on the

thermostat. If there is voltage, it is a bad W or W1*

or (B if you are using B) wire. If there is

no voltage at R-any other terminal on the

thermostat, it is a bad R wire.

Jumper the R wire to the W or W1* (and O/B, if your thermostat uses it

for heat changover) wire on the thermostat. If the HEAT light comes

Yes

jumper R-W or W1* (and O/B if you have a wire on O/B) on the thermosta

and the HEAT light does not come on, you may have a bad wire.

the thermostat) on one of the zones. If the HEAT light does not come on,

call Honeywell Zoning hotline, 800-828-8367.

Remove the DATS wires from

the board. Reboot the board.

calling for HEAT" part of the

Yes

troubleshooting from that point.

800-828-8367.

thermal fuse on the board.

on, you have a bad thermostat. Replace thermostat. If you

Try another set of wires or check continuity.

Return to "Is the thermostat

flowchart and begin

The heating equipment should be on.

*NOTE:

When using a heat pump thermostat with a single Y for first stage

heating and cooling, in the troubleshooting chart, substitute Y for W1.

Yes

Fig. 21. Thermostat is calling for heating but the Heat LED is not turning red to show a heat call.

Call Honeywell Zoning hotline,

800-828-8367.

END

M14828A

Automation and Control Solutions

Honeywell Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Scarborough, Ontario

68-0237-2 G.H. Rev. 11-02 www.honeywell.com/yourhome

M1V 4Z9

Printed in U.S.A. on recycled

paper containing at least 10%

post-consumer paper fibers.

Loading...

Loading...