Page 1

INSTRUCTIONS FOR USE

Z845 R22EEG 3670URK,

3870UTK.book

1

ジ

2022年5月30日

月曜日

午後12時59分

ULTRASOUND UPPER GI VIDEO SCOPES

CURVED LINEAR ARRAY TYPE

EG-3870UTK

RADIAL ARRAY TYPE

EG-3670URK

Page 2

Intended Use

WARNING

CAUTION

NOTE

Manufacturer

Fabricant

Date of manufacture

Date de fabrication

Authorized representative in the European Community

Représentant autorisé dans l'Union européenne

Serial number

Numéro de série

This is a UDI (Unique Device Identification) code required by Unique Device Identification System designed to adequately identify devices through distribution

and use. The following information is coded in 2D bar code (GS1 Data Matrix).

- (01) GS1 Commodity code (Global Trade Item Number)

- (11) Production date

- (21) Serial number

Ce code d’UDI (Unique Device Identification, ou identification unique des dispositifs médicaux) est requis par Unique Device Identification System pour identifier

correctement les dispositifs lors de leur distribution et leur utilisation. Les informations suivantes sont contenues dans le code-barres 2D (GS1 Data Matrix) :

- (01) Code de marchandise GS1 (code article international)

- (11) Date de production

- (21) Numéro de série

Attention, consult instructions for use

Attention, consulter le manuel d’utilisation

Type BF applied part

Partie appliquée de type BF

Z845 R22EEG 3670URK,

3870UTK.book

1

ジ

2022年5月30日

月曜日

午後12時59分

PENTAX ultrasound endoscopes are intended to provide optical and ultrasonic visualization of (via a video monitor), and

therapeutic access to, the Upper Gastrointestinal Tract. This anatomy includes, but is not restricted to, the organs; tissues; and

subsystems: Esophagus, Stomach and Duodenum.

These instruments are introduced via the mouth when indications consistent with the need for the procedure are observed in

adult and pediatric patient populations.

NEVER use these endoscopes for any purpose other than that for which they have been designed.

These video endoscopes contained in this Instructions for Use can be used with PENTAX video processors EPK-i5000, EPK-i,

EPK-100p, EPK-1000, or EPK-i7000/i7000(A). See the addendum sheet No.370.

Notes

Read this Instructions for Use (IFU) before operating and save this IFU for future reference. Failure to read and thoroughly

understand the information presented in this IFU, as well as those developed for ancillary endoscopic equipment and

accessories, may result in serious injury including infection by cross contamination to the patient and/or user. Furthermore, failure

to follow the instructions in this IFU may result in damage to, and/or malfunction of, the equipment.

This IFU describes the recommended procedures for inspecting and preparing the equipment prior to its use and for the

reprocessing and maintenance of the equipment after its use. It does not describe how an actual procedure is to be performed,

nor does it attempt to teach the beginner the proper technique or any medical aspects regarding the use of the equipment.

It is the responsibility of each medical facility to ensure that only well educated and appropriately trained personnel, who are competent

and knowledgeable about the endoscopic equipment, antimicrobial agents/processes and hospital infection control protocol be

involved in the use and the reprocessing of these medical devices. Known risks and/or potential injuries associated with flexible

endoscopic procedures include, but are not limited to, the following: perforation, infection, hemorrhage, burns and electric shock.

Current infection control guidelines require that gastroscopes and other semi-critical medical devices, that normally come into

contact with intact mucous membranes, such as in the gastrointestinal tract, must at least be high-level disinfected before clinical

use. Only the users can determine if an instrument has undergone appropriate infection control procedures prior to each clinical

use. It must be recognized that infection control practices involve many complex and often controversial issues which are

constantly evolving. PENTAX strongly recommends that users remain informed of the latest federal and local regulations, and

encourages users to follow infection control guidelines developed by various organizations for health care professionals.

If you have any questions regarding any of the information in this IFU or concerns pertaining to the safety and/or use of this

equipment, please contact your local PENTAX service facility.

Sterility Statement

The instruments identified in this IFU are reusable medical devices. Since they are packaged non-sterile, they must be high-level disinfected

or sterilized BEFORE initial use. Prior to each subsequent procedure, they must be subjected to an appropriate cleaning and either highlevel disinfection or sterilization process. After servicing, these endoscopes and those components must be reprocessed prior to clinical use.

Contraindication

Please consult regional and national health authority recommendations and requirements regarding protocols to follow in order to

reprocess and/or destroy endoscopes that will be used or have been determined to have been used (post procedure) on patients

afflicted with Creutzfeldt-Jacob Disease (CJD or vCJD).

Conventions

Throughout this IFU, the following conventions will be used to indicate a potentially hazardous situation which, if not avoided;

: could result in death or serious injury.

: may result in minor or moderate injury or property-damage.

: may result in property-damage. Also, advises owner/operator about important information on the use of this

equipment.

Prescription Statement

Federal (U.S.A) law restricts this device to sale by or on the order of a physician or other appropriately licensed medical professional

Symbols on Marking

Symbols distinctifs

Page 3

TABLE OF CONTENTS

Z845 R22EEG 3670URK,

3870UTK.book

1

ジ

2022年5月30日

月曜日

午後12時59分

1. NOMENCLATURE AND FUNCTION ................................................................................................ 1

1-1. Video Endoscope .......................................................................................................... 1

1-2. Accessories ................................................................................................................3

1-3. Video Processor ........................................................................................................... 4

2. PREPARATION AND INSPECTION FOR USE ..................................................................................... 7

2-1. Inspection of the Video Processor ..................................................................................... 7

2-2. Inspection of Endoscope ................................................................................................. 9

2-3. Preparation of Ultrasound Scanning Unit ............................................................................21

2-4. Preparation before the Examination ..................................................................................21

2-5. Preparation just before Insertion of Endoscope ....................................................................24

3. DIRECTIONS FOR USE ............................................................................................................26

3-1. Pretreatment ..............................................................................................................27

3-2. Insertion and Withdrawal ...............................................................................................27

3-3. Precise Accessory Control (For EG-3870UTK only) .................................................................31

3-4. Biopsy ......................................................................................................................32

4. CARE AFTER USE .................................................................................................................37

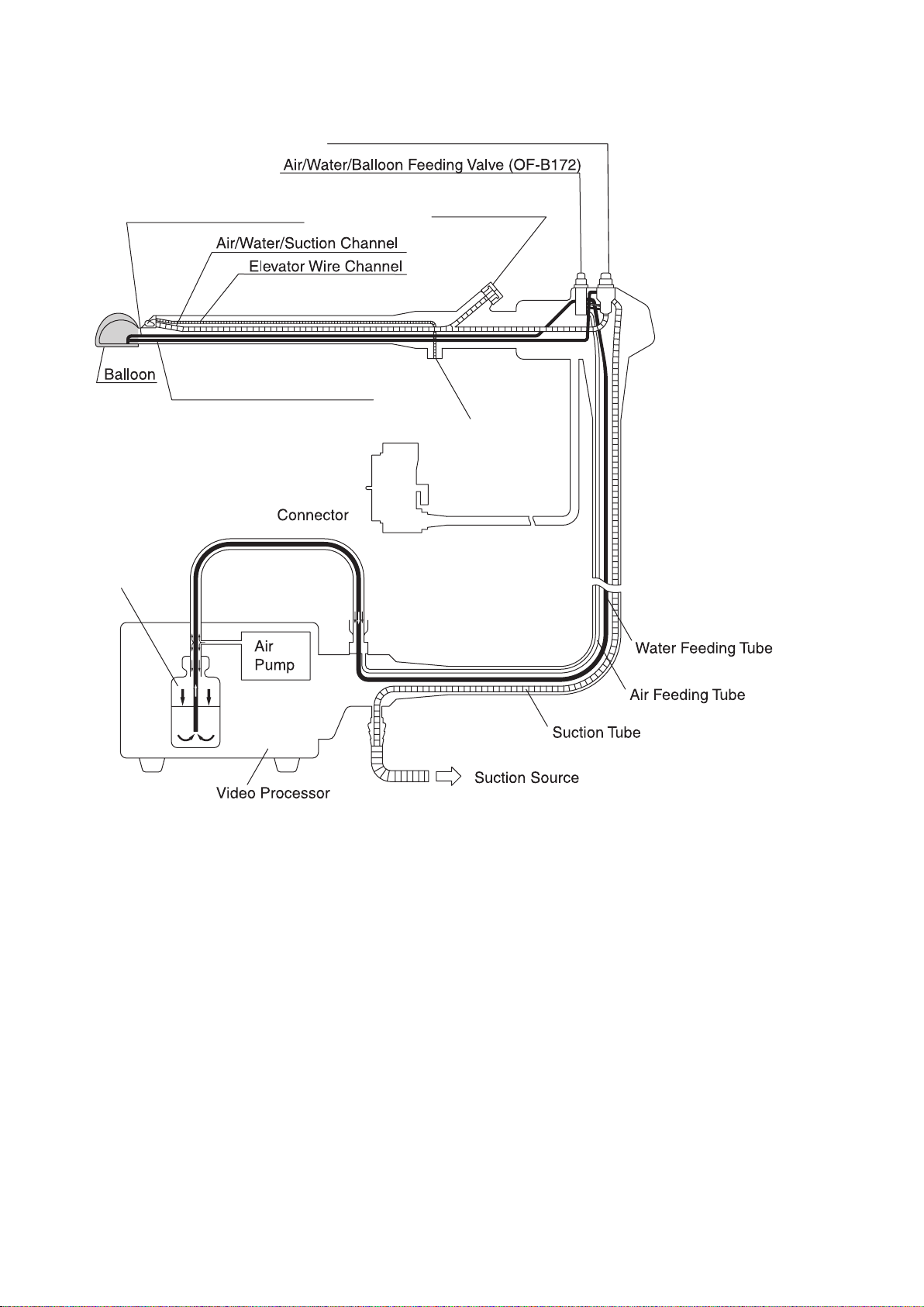

4-1. Internal Channels of PENTAX endoscopes ...........................................................................38

4-2. Reprocessing System ....................................................................................................42

4-3. Endoscopes ...............................................................................................................44

4-3-1. Pre-Cleaning .....................................................................................................44

4-3-2. Leakage Testing ................................................................................................46

4-3-3. Cleaning ..........................................................................................................46

4-3-4. High-Level Disinfection ........................................................................................65

4-3-5. Sterilization ......................................................................................................76

4-4. Endscopic Accessory Instruments (EAIs) and Endoscope Components .........................................78

4-4-1. Cleaning ..........................................................................................................78

4-4-2. High-Level Disinfection ........................................................................................79

4-4-3. Sterilization ......................................................................................................81

4-5. Water Bottle Assembly ..................................................................................................82

5. POST REPROCESSING ............................................................................................................83

5-1. Servicing ...................................................................................................................84

5-2. Care and Maintenance Tips ............................................................................................86

SPECIFICATION....................................................................................................................

89

Page 4

1. NOMENCLATURE AND FUNCTION

RIGHT/LEFT

ANGULATION LOCK KNOB:

Functions similar to Up/Down

Angulation Lock.

UP/DOWN ANGULATION

CONTROL KNOB

SUCTION/BALLOON SUCTION VALVE (OF-B171)

Depress to remove fluids or air through

the instrument channel or

aspirate air or water from the balloon.

For details, refer to “6) Inspection of Suction

Mechanism (on page 17)”.

Push to freeze an image.

REMOTE BUTTON 1

REMOTE BUTTON 2

Push to activate the hardcopy

system that was selected between

“File” and “HARD COPY”.

When this lever is in the “F” position,

turned clockwise, the bending section

moves freely. When turned

counterclockwise, the bending

section becomes progressively

more stabilized.

Push to change the intensity of

enhancement that was previously

assigned.

REMOTE BUTTON 4

REMOTE BUTTON 3

Push to activate the VCR

for recording live

procedures.

STRAIN RELIEF BOOT

AIR/WATER/BALLOON FEEDING VALVE (OF-B172):

To control air/water delivery.

For details, refer to 4) Inspection of Air/Water/Balloon

Feeding Mechanism (on page 14)”.

CONTROL BODY

INLET SEAL

INSTRUMENT CHANNEL INLET

For introduction of biopsy forceps

and other accessories.

STRAIN RELIEF BOOT

CONTROL BODY

(EG-3870UTK)

INLET CAP (OE-B3)

(EG-3870UTK)

ELEVATOR WIRE CHANNEL

CLEANING INLET

The elevator wire and the

elevator wire channel can

easily be reprocessed with

an appropriate solution

administered through

this inlet.

STRAIN RELIEF BOOT

SCANNING UNIT CONNECTOR CABLE

(EG-3870UTK) ELEVATOR CONTROL LEVER

To guide and direct forceps and other accessories.

UMBILICAL CORD

UP/DOWN ANGULATION

LOCK LEVER:

RIGHT/LEFT ANGULATION CONTROL KNOB

NOTE:

Function of each button depends upon the processor. The

function can be changed. For more details, refer to the

Instructions for Use supplied with the processor. The table

below shows the factory setting.

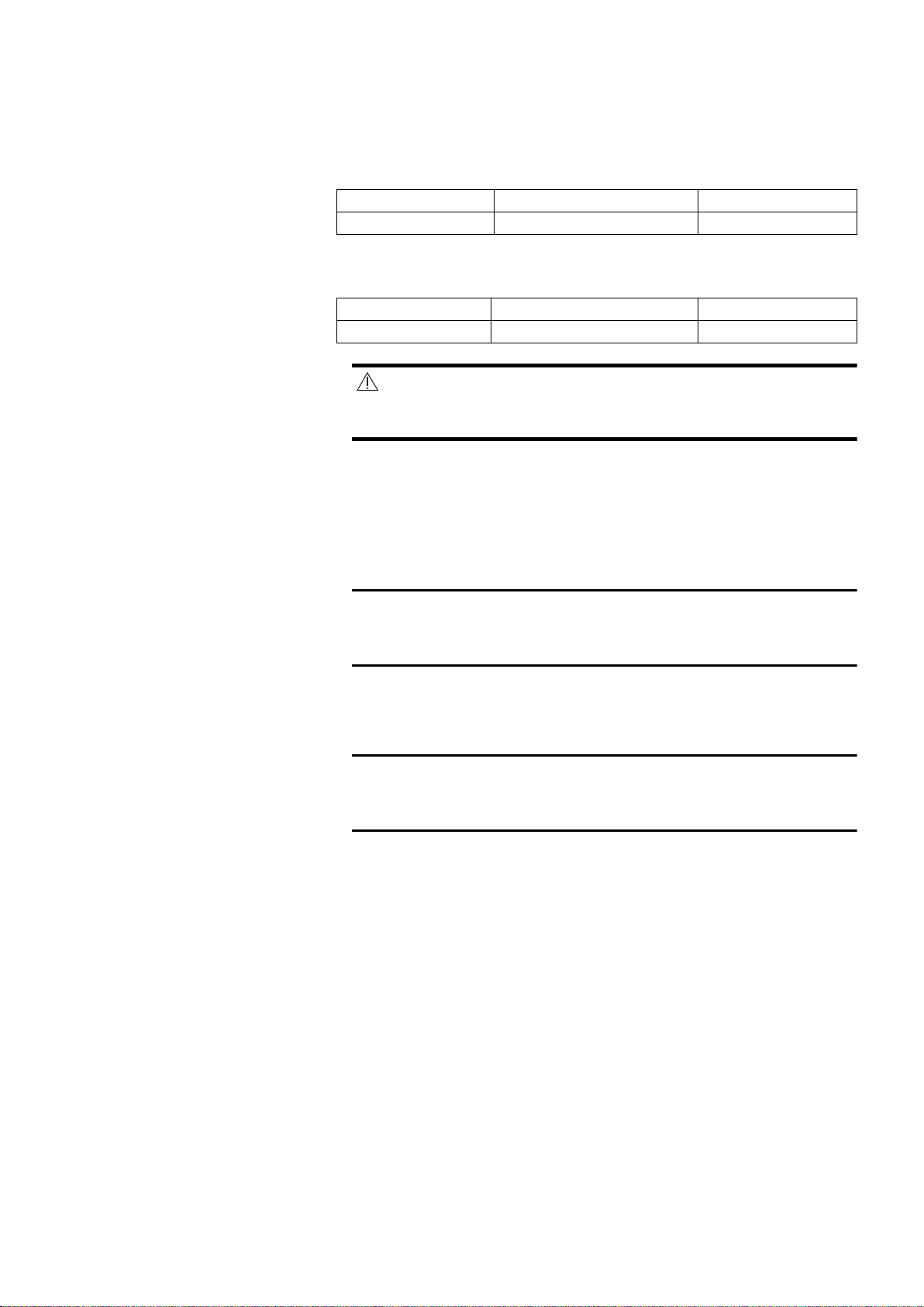

EPK-i5000

EPK-1000 EPK-100p

Remote

Button

1 Freeze Freeze Freeze Freeze

Remote

Button

2 P

eripheral Hard Copy

Remote

Button

3 AV

E/PEAK VCR

VCR (for NTSC)

Enhance

Enhance (for PAL)

Remote

Button

4 Enhance Enhance

Enhance (for NTSC)

AVE/PEAK

AVE/PEAK (for PAL)

EPK-i,

EPK-i7000,

Hard Copy

Hard Copy

EPK-i7000(A)

Z845 R22EEG 3670URK,

3870UTK.book

1

ジ

2022年5月30日

月曜日

午後12時59分

Ultrasound Upper GI Video Scopes EG-3870UTK/EG-3670URK

1-1. Video Endoscope

– 1 –

Page 5

STRAIN RELIEF BOOT

DISTAL END

BENDING SECTION

INSERTION TUBE

SCANNING UNIT CONNECTOR

LOCK LEVER

Securely locks the scanning

unit connector of the PENTAX

endoscope into the

scanning unit (FUJIFILM

Healthcare Corporation) to

ensure proper contact with

and functioning of

the electronic circuitry.

SCANNING UNIT CONNECTOR

SCANNING UNIT CONNECTOR SOAKING CAP

(Model OE-U1)

VENTILATION CAP RED

(Model OF-C5)

AIR/WATER PORT

To connect feeding tube from water

bottle assembly.

PVE CONNECTOR

Can be rotated within

a 180° range.

Provides venting of endoscope interior to equalize

internal and external pressures. This cap must be

removed before immersion.

PVE SOAKING CAP

(Model OE-C9)

VENTING CONNECTOR

Accepts “RED” VENTILATION Cap

and Leakage Tester.

STRAIN RELIEF

BOOT

ELECTRICAL

CONTACTS

FEEDBACK TERMINAL

NOT USED TO

THESE SCOPES

LIGHT GUIDE PLUG

Transmits light from

light source to distal

end of endoscope.

SUCTION NIPPLE

For attachment to

external suction

source.

NOTE:

To avoid damaging the endoscope, do NOT

twist, rotate or bend excessively any of the

strain relief boots.

The strain relief boots of endoscopes with

split (bifurcated) umbilical cord should

never be grasped together or pressed

firmly against each other to avoid the

potential for scope damage in these

areas.

NOTE:

Function of each button can be changed by the

processor. For more details, refer to the

Instructions for Use provided with the processor.

Immediately after use, the metal light guide plug and the electrical contacts/pins of the

endoscope may be HOT. To avoid burns, do NOT touch these areas immediately after use.

For safer handling after a procedure, grasp the PVE connector housing.

NOTE:

Ensure that the soaking caps have been securely attached (by properly rotating them) to

prevent the caps from coming off during reprocessing. Failure to securely attach the soaking

caps can result in endoscope damage.

WARNING:

CAUTION:

Do NOT immerse it without the soaking cap.

CAUTION:

Prior to immersion this cap must be attached

to the scanning unit connector.

NOTE:

See important separate section regarding

the use of this cap! (p.42, 43, 46, 65, 77)

NEVER perform electrosurgery with these

endoscopes.

WARNING:

This cap must be securely atached to the

electrical contact before immersion.

Z845 R22EEG 3670URK,

3870UTK.book

2

ジ

2022年5月30日

月曜日

午後12時59分

2022. 06 6217001 Z845 R22

– 2 –

Page 6

1-2. Accessories

CAUTION:

(4)

(5)

(3)

(2)

(1)

(2)

(1)

Z845 R22EEG 3670URK,

3870UTK.book

3

ジ

2022年5月30日

月曜日

午後12時59分

Ultrasound Upper GI Video Scopes EG-3870UTK/EG-3670URK

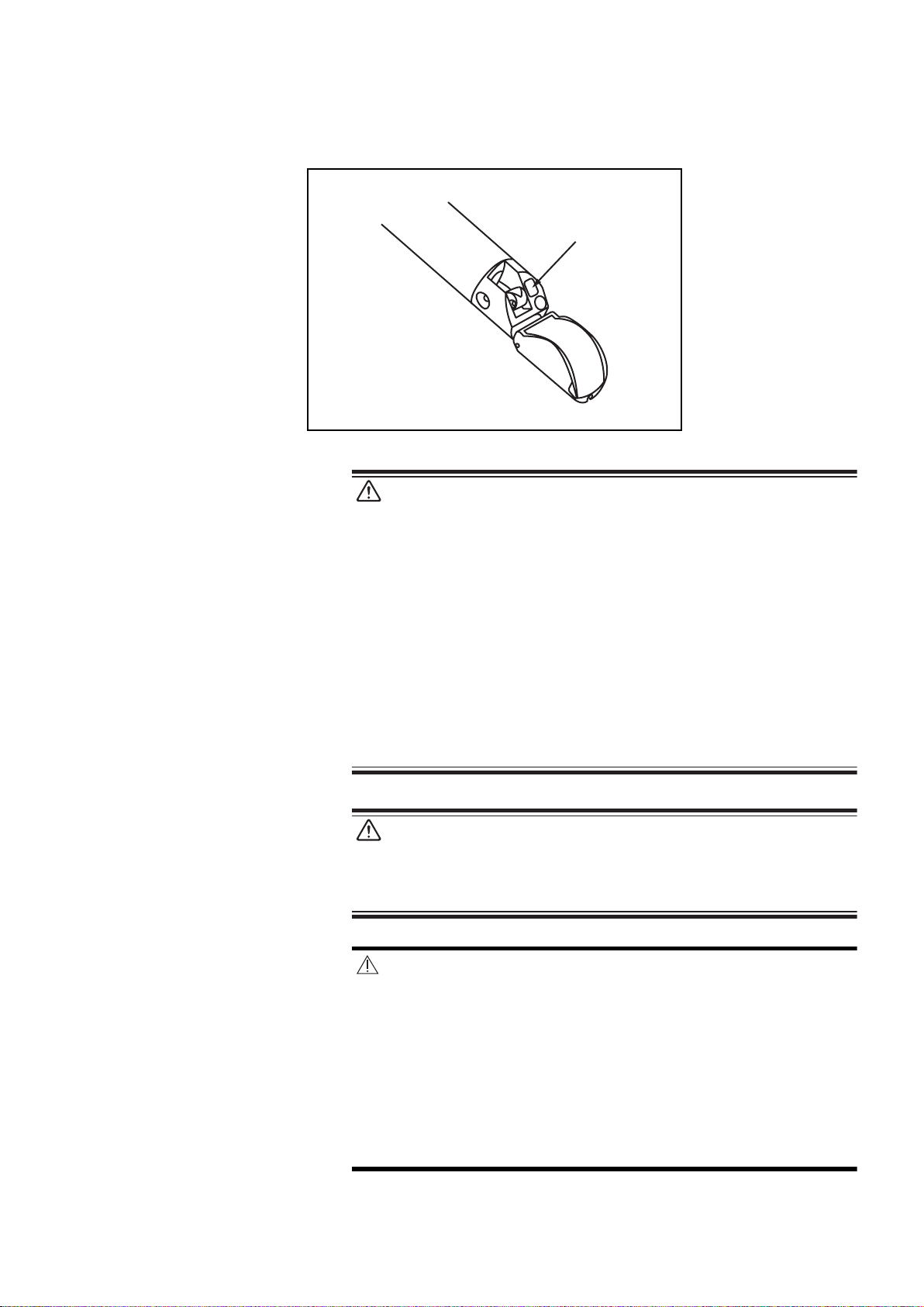

1) Biopsy Forceps

Figure 1.1

2) Aspiration Needle (For EG-3870UTK)

Figure 1.2

3) Channel Cleaning Brush

(1) Enhanced Flexible

Portion

(2) Flexible Shaft

(3) Grip

(4) Handle

(5) Cups/Jaws

(1) Needle

(2) Flexible Shaft

(3) Handle

(4) Proximal End

(5) Luer Lock(Female)

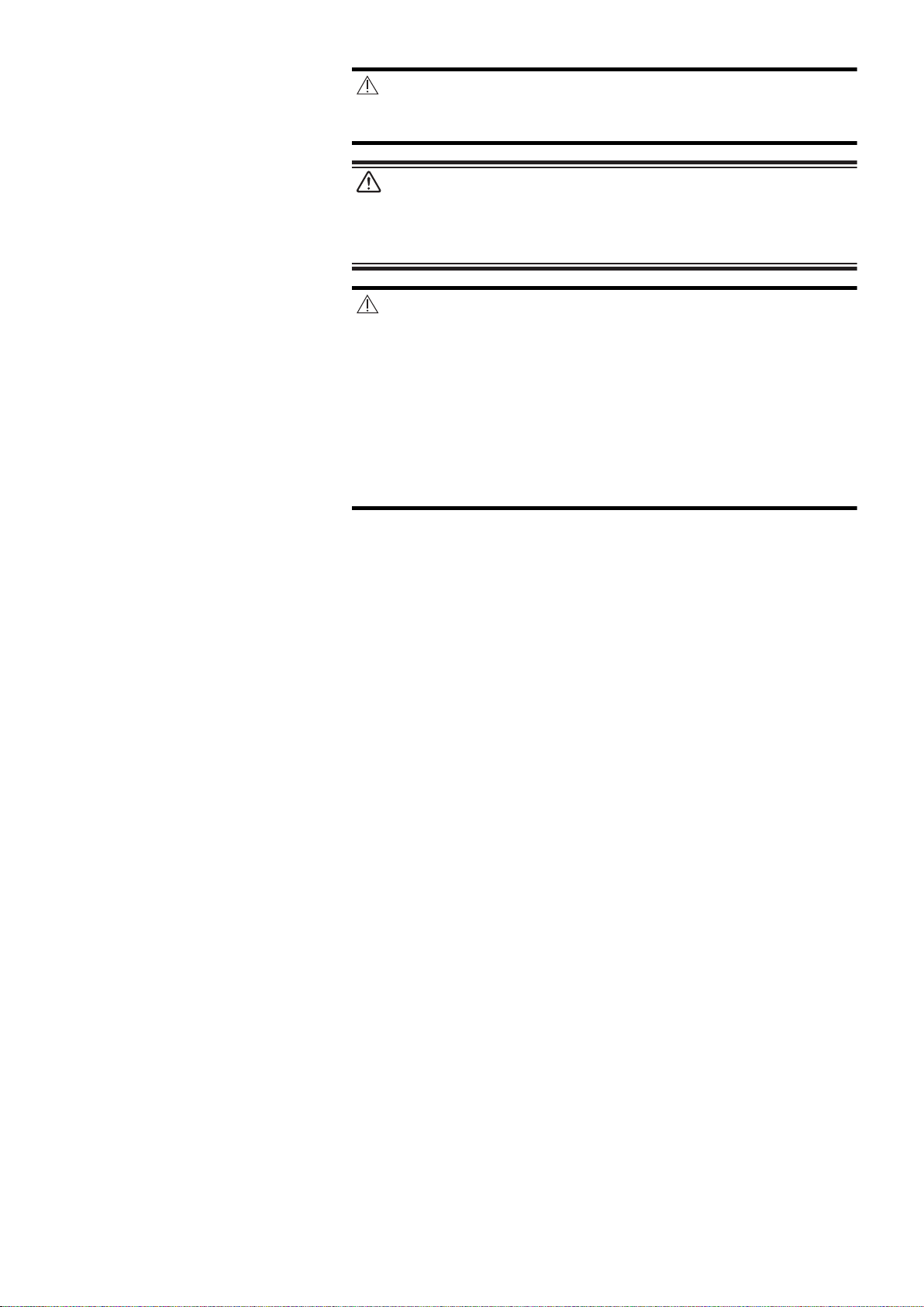

(1) Back End (Blue)

(2) (CS6021T)

Figure 1.3

This brush is provided non-sterile for one time use. NEVER reuse this

disposable brush on more than one instrument.

4) Cylinder Cleaning Brush for Air/Water/Balloon feeding Cylinder and

Suction/Balloon Suction Cylinder

(1) (2)

(3)

Figure 1.4

• Because of the effect that accessories used through the

instrument channel of the endoscope can have on the

performance of the endoscope itself, it is strongly

recommended that PENTAX accessories be used with PENTAX

endocopes. If a unique or highly specialized accessory is

available from another source, the accessory manufacturer

should be consulted to confirm compatibility with PENTAX

endoscopes before use.

• Maximum outer diameter of an endoscopic accessory

instrument must be at least 0.2 mm less than the specified

instrument channel diameter in PENTAX endoscopes. Working

length of an endoscopic accessory instrument should be

approximately 30 cm longer than the endoscope working

length.

(1) Large Bristle

(2) Small Bristle

(3) (CS-C9S)

– 3 –

Page 7

NOTE:

• Depending upon country and/or local PENTAX service facility,

NOTE:

WARNING:

NOTE:

Z845 R22EEG 3670URK,

3870UTK.book

4

ジ

2022年5月30日

月曜日

午後12時59分

2022. 06 6217001 Z845 R22

each PENTAX endoscopic accessory may be an optional

accessory.

• For patient contact endoscopic accessories, follow the specific

and detailed instructions on use, care and maintenance

supplied with each product.

• To confirm the exact condition of any new accessory device,

check the labeling/packaging accompanying the product.

Each label/package should clearly identify the contents as

either sterile or non-sterile.

1-3. Video Processor

Please read the Instructions for Use supplied with the processor.

Do not install, operate or store electro-medical equipment in a

dusty environment. Accumulation of dust within these units may

cause malfunction, smoke, or ignition.

Do NOT use the new PENTAX OS-H4 water bottle cap with the

older OS-H2 water container/bottle. Although the cap may

appear to fit onto the bottle, air may escape resulting in

insufficient pressure and flow of air and water during the

endoscopic procedure. Both the PENTAX water bottle cap and

bottle (container) are identified by their appropriate molded-in

model designation. Ensure that an OS-H4 cap is used only with

the OS-H4 water container/bottle. Do NOT overtighten the bottle

cap. Overtightening can cause the bottle cap to break.

– 4 –

Page 8

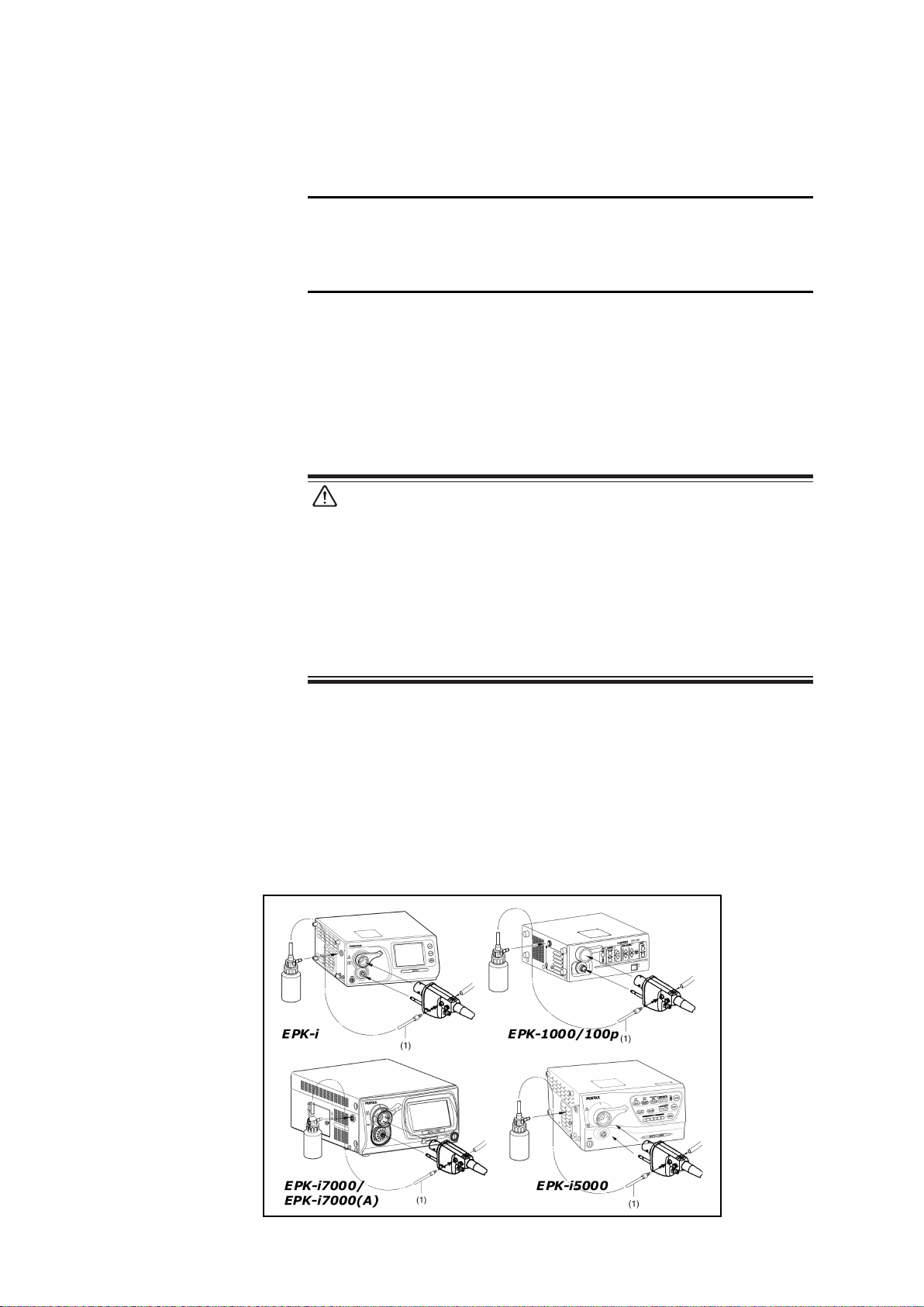

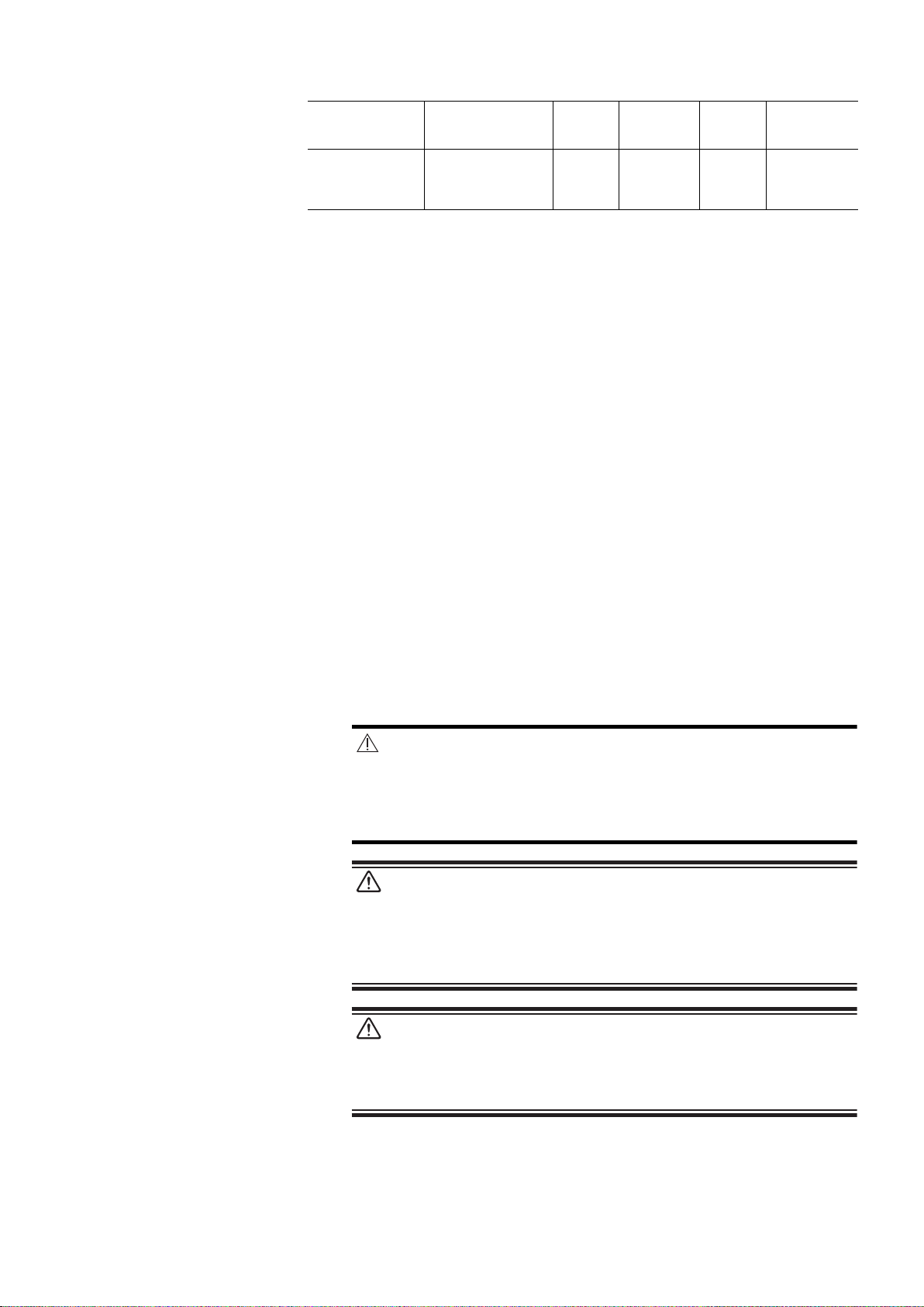

(1) EPK-i5000/EPK-i

WARNING:

NOTE:

WARNING:

Z845 R22EEG 3670URK,

3870UTK.book

5

ジ

2022年5月30日

月曜日

午後12時59分

Ultrasound Upper GI Video Scopes EG-3870UTK/EG-3670URK

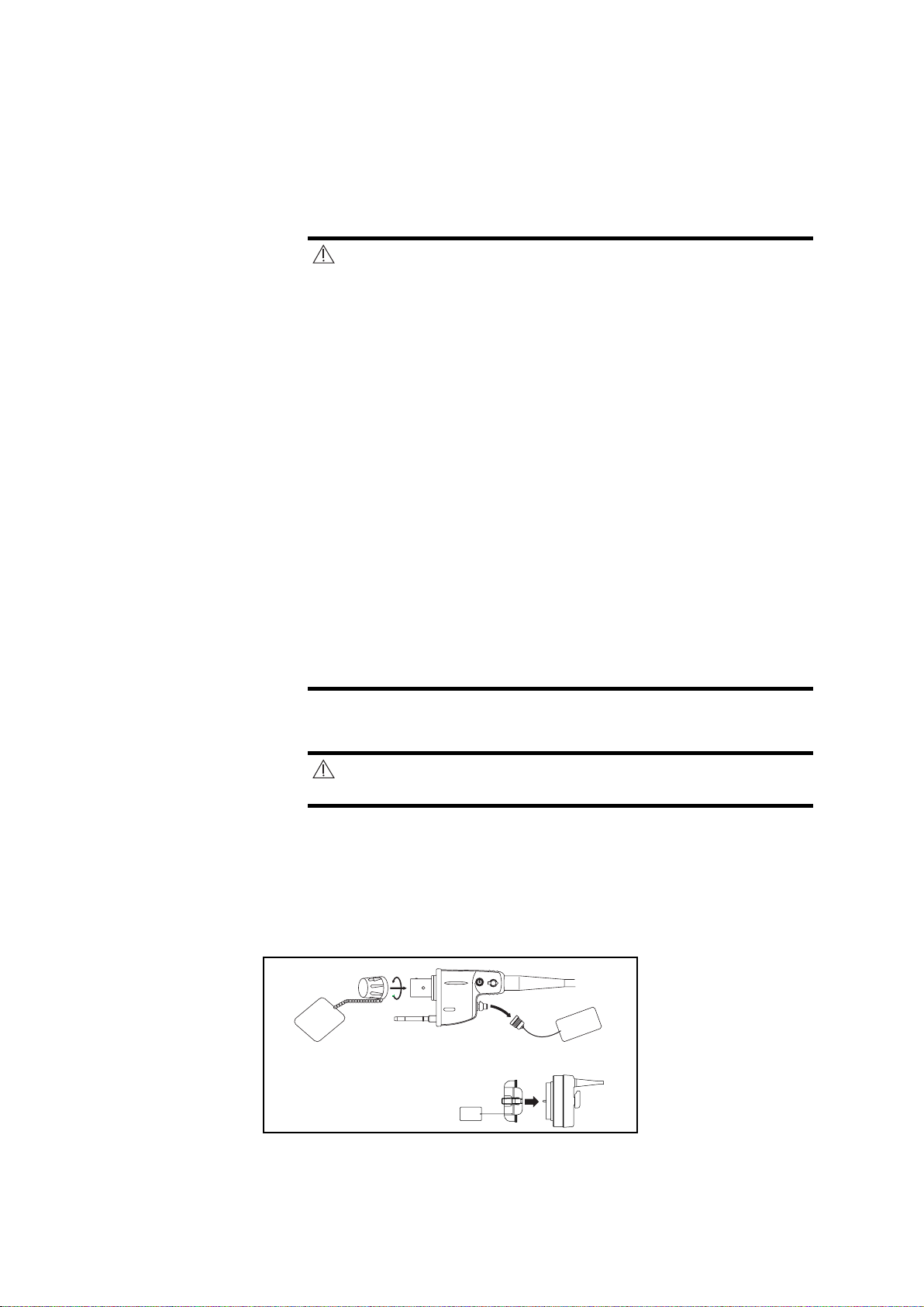

(1) Endoscope

Electrical

(1)

(2)

Connector

(2) Lamp Switch

(3) Light Guide

Receptacle

(4) Power Switch

(5) Water Bottle

Assembly

(5)

Figure 1.5

The lamp life for EPK-i5000 is 500 hours. Check the lamp life

indicator on the touch panel before you use the processor.

Replace the lamp cartridge if one of the bars on the LIFE

indicator lights red and the [Please replace the lamp] message

appears on the monitor. The lamp life could be affected by

frequency of use. In which case, the lamp life might become

shorter than 500 hours.

Software update may be required depending on the software

version of the EPK-i5000 processor. If the software is not

updated, the image will not be displayed. If the images are not

displayed correctly, please contact your local PENTAX service

facility.

(2) EPK-i7000/EPK-i7000(A)

(4)

(3)

(5)

Figure 1.6

The lamp life for EPK-i7000/EPK-i7000(A) is 500 hours. Check

the LIFE indicator (lamp life indicator) on the touch panel before

you use the processor. Replace the lamp cartridge if a red circle

is displayed on the LIFE indicator. The lamp life may not be as

long as 500 hours depending on the method of use and

operating environment.

(1)

(4)

(2)

(3)

(1) Endoscope

Electrical

Connector

(2) Touch Panel

(3) Power Switch

(4) Light Guide

Receptacle

(5) Water Bottle

Assembly

– 5 –

Page 9

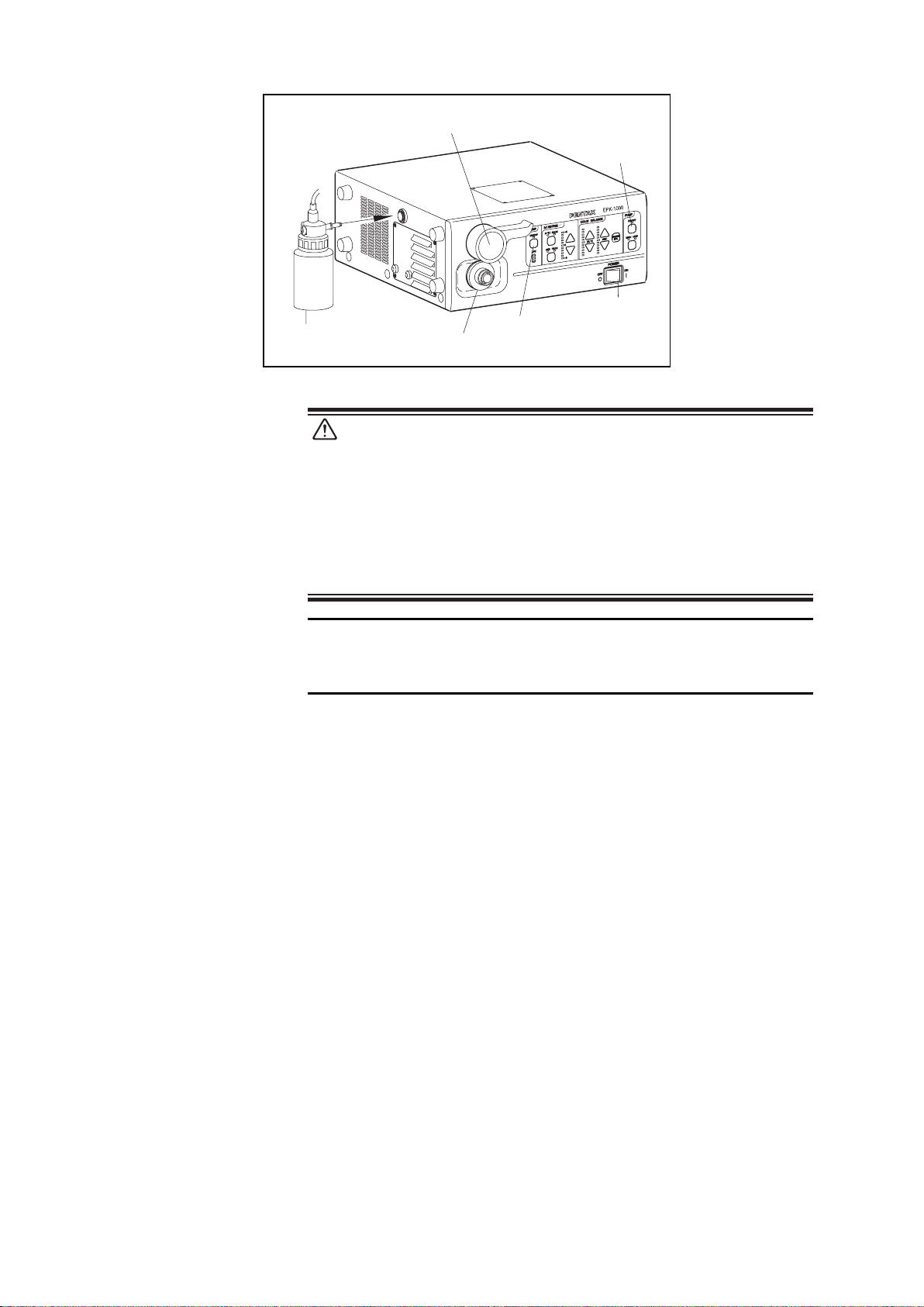

(3) EPK-1000/EPK-100p

WARNING:

NOTE:

(1)

(2)

(3)

(4)

(5)

(6)

Z845 R22EEG 3670URK,

3870UTK.book

6

ジ

2022年5月30日

月曜日

午後12時59分

2022. 06 6217001 Z845 R22

Figure 1.7

The lamp life when used in this equipment is 400 hours. Prior to

use, check the lamp life indicator on the front panel to ensure

the indicator is lit green or yellow. After 400 hours of use, the

indicator turns red and the image quality will deteriorate.

Excessive use of the lamp beyond its rated 400 hours

(approaching a thousand hours of use or more) could cause the

lamp to explode resulting in damage to the video processor.

(1) Endoscope

Electrical

Connector

(2) Air Pump Switch

(3) Power Switch

I : ON

O: OFF

(4) Lamp Switch

(5) Light Guide

Receptacle

(6) Water Bottle

Assembly

The lamp life could be affected by frequency of use. In which

case, the lamp life might become shorter than 400 hours.

– 6 –

Page 10

2. PREPARATION AND INSPECTION FOR USE

NOTE:

WARNING:

Z845 R22EEG 3670URK,

3870UTK.book

7

ジ

2022年5月30日

月曜日

午後12時59分

Ultrasound Upper GI Video Scopes EG-3870UTK/EG-3670URK

Prior to use, the endoscope, video processor and endoscopic accessory

instruments must be carefully inspected for cleanliness and proper function to

determine that they are appropriate for patient use:

PENTAX video endoscopes contained in this Instructions for Use

are compatible with PENTAX video processors, EPK-i, EPK-i5000,

EPK-i7000, EPK-i7000(A), EPK-100p, and EPK-1000.

2-1. Inspection of the Video Processor

Please refer to the Instructions for Use of the specific model of PENTAX video

processor for complete instructions.

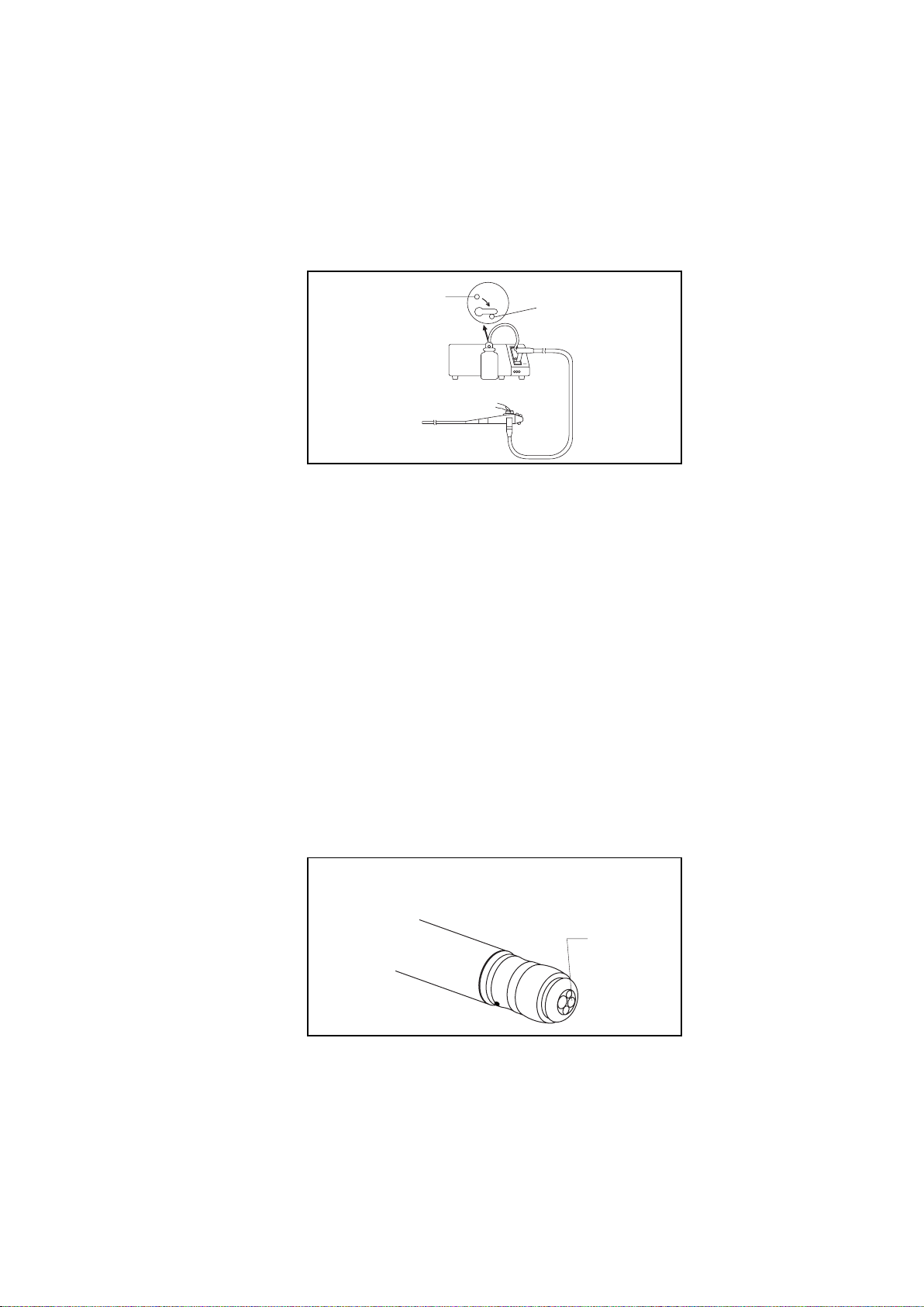

1) Attach water bottle assembly, 2/3 filled with de-aerated sterile water to the

appropriate location on the left side of the video processor.

The addition of defoaming agents to the water supply is NOT

recommended. Due to their nature, these silicone based agents

cling tenaciously to surfaces. Unless they are rinsed very

thoroughly, a “barrier” could be created which could reduce the

effectiveness of the disinfection/sterilization process.

Additionally, repeated use of such defoamers could eventually

lead to residual silicone build up resulting in equipment

malfunction such as clogged air and/or water channels.

2) Set the drain lever on the water bottle cap to the upright position labelled A/

W (air/water).

3) Plug the processor into a properly grounded receptacle with the power

switch in the OFF position.

4) Make sure that the PENTAX PVE connector is aligned with the endoscope

electrical connector on the front panel of the processor.

5) Connect the endoscope to the endoscope electrical connector on the

processor as illustrated.

(1) Air/

Water

Feeding

Tube

Figure 2.1

– 7 –

Page 11

6) Rotate the lever of the endoscope electrical connector clockwise after

CAUTION:

CAUTION:

Z845 R22EEG 3670URK,

3870UTK.book

8

ジ

2022年5月30日

月曜日

午後12時59分

2022. 06 6217001 Z845 R22

insertion.

After connecting the video endoscope to the video processor,

always make sure that the endoscope is firmly secured to the

endoscope receptacle by turning the locking lever to the “lock”

position.

7) Connect the air/water feeding tube from the water bottle assembly to the air/

water port on the side of the PVE connector.

8) Turn the processor and air pump to the “ON” position and check for proper

functioning.

9) Prior to each procedure, check the endoscope image quality displayed on

the monitor. Confirm that the image quality, color, automatic brightness

(iris) functions are acceptable as per the instructions provided with the

PENTAX video processor.

2-2. Inspection of Endoscope

If the endoscope is intended to be clinically used after testing of

individual endoscope functions (suction, air/water delivery, etc.)

without further reprocessing, the following precaution should be

exercised. Use sterile water during individual endoscope function

tests to avoid recontamination of the previously reprocessed

instrument by waterborne microorganisms. Tap water,

especially that which may be left idle and uncovered for a

prolonged period of time, should not be used during any

inspection/testing of the endoscope.

Before reprocessing and/or immersion in any fluids, PENTAX endoscopes

should be tested for the loss of integrity in their watertight construction by using

PENTAX brand leakage testers. For specific details on PENTAX recommended

leakage detection procedures, please refer to the instructions supplied with

PENTAX leakage testers.

– 8 –

Page 12

CAUTION:

Various types of endoscope leakage testers exist including

NOTE:

CAUTION:

Z845 R22EEG 3670URK,

3870UTK.book

9

ジ

2022年5月30日

月曜日

午後12時59分

Ultrasound Upper GI Video Scopes EG-3870UTK/EG-3670URK

manual, electro-mechanical and “automated” versions, some of

which are stand alone units and others which may be integrated

into Automated Endoscope Reprocessors (AERs)/WashersDisinfectors (WDs). It must be recognized that PENTAX does not

evaluate non-PENTAX leakage tester systems to satisfy their

specific product claims, for their effectiveness to accurately

detect leaks and/or for their compatibility with PENTAX

endoscopes. Insufficient pressures may reduce the likelihood for

accurate leak detection, especially if the endoscope’s distal

bending section is not flexed during testing. Excessive pressures

may adversely affect the endoscope, especially if pressurization

occurs during automated reprocessing at elevated temperatures.

PENTAX accepts no responsibility for use of non-PENTAX leakage

testers.

Users should check with the leakage tester manufacturer and

confirm their specific product claims, including compatibility with

PENTAX endoscopes at various temperatures and their ability to

detect leaks with/without fluid immersion and with/without

flexing of the endoscope’s distal bending section.

Do not use a water supply device that can exert 30kPa or

greater of water pressure to the suction channel (suction valve)

during endoscopic examination.

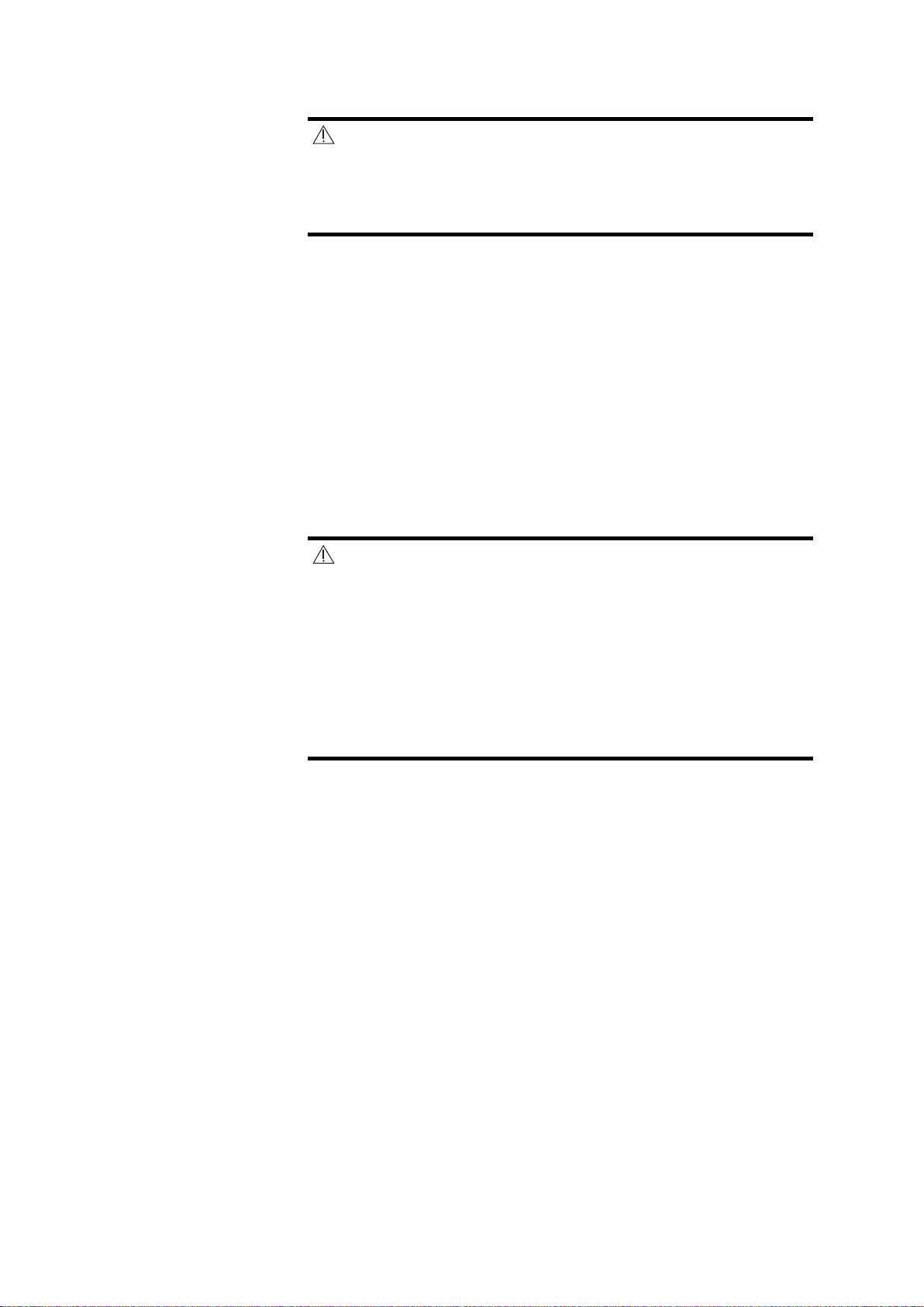

1) Inspection of the Insertion Tube

a) Check the entire surface of the insertion tube for abnormal conditions

such as dents, crush marks, wrinkles, bumps, buckles, excessive

bending, protrusions, bite marks, peeling of outer sheath, cuts/holes or

other irregularities. Any crush or indentation of the flexible shaft of the

endoscopes can cause damage to the internal mechanisms of the

endoscopes.

b) Similarly, check the condition of the umbilical cord for outward signs

of damage such as buckling, crush marks, etc.

c) Also check the condition of the scanning unit cord for any outward

signs of damage.

To avoid further damage to the endoscope or the possibility of

malfunction during a procedure, do NOT use any endoscope with

outward signs of damage.

– 9 –

Page 13

d) These areas [A], [B] should be checked for ANY abnormalities or

WARNING:

NOTE:

CAUTION:

(1)

(2)

(3) (4)

Z845 R22EEG 3670URK,

3870UTK.book

10

ジ

2022年5月30日

月曜日

午後12時59分

2022. 06 6217001 Z845 R22

irregularities. If anything unusual is found including but not limited to

rough textured surfaces, cracks, brittleness, sharp-edges, holes,

peeling, tackiness, etc., the endoscope should NOT BE USED. During

this inspection process check the surface/condition of the adhesive by

applying slight pressure with one's gloved fingers and by slightly

wiping this area with dry gauze. Make sure the glue is not peeling, nor

does it have roughened texture or any sharp-edges.

(1) Bending Section

(2) Close-Up View

(3) Black adhesive band

[A]

(4) Black adhesive band

[B]

Figure 2.2

e) Make sure that the entire endoscope is cleaned and has been subjected

to either a high-level disinfection or sterilization process before each

patient use.

All instruments must be reprocessed prior to first time use, after

any repairs/service and before any patient use. When utilizing

chemo-thermal processes for reprocessing PENTAX endoscopes,

the instruments should be allowed to return to room

temperature prior to use and/or further handling.

2) Inspection of Insertion Tube flexibility

Perform this process as part of the pre-use inspection of the

endoscope.

When performing this inspection, ensure that other components

of the endoscope (Distal End, Control Body, etc.) are not

damaged by impact to surfaces or objects in the area. Do NOT

adjust the Bending Section of the endoscope as part of this

inspection. Maintain the distal end in a straight orientation.

• Hold the Insertion Tube at the junction of the Insertion Tube

and Bending Section,

• Do NOT close your hand around the Bending Section.

– 10 –

Page 14

Inspection Process

Z845 R22EEG 3670URK,

3870UTK.book

11

ジ

2022年5月30日

月曜日

午後12時59分

Ultrasound Upper GI Video Scopes EG-3870UTK/EG-3670URK

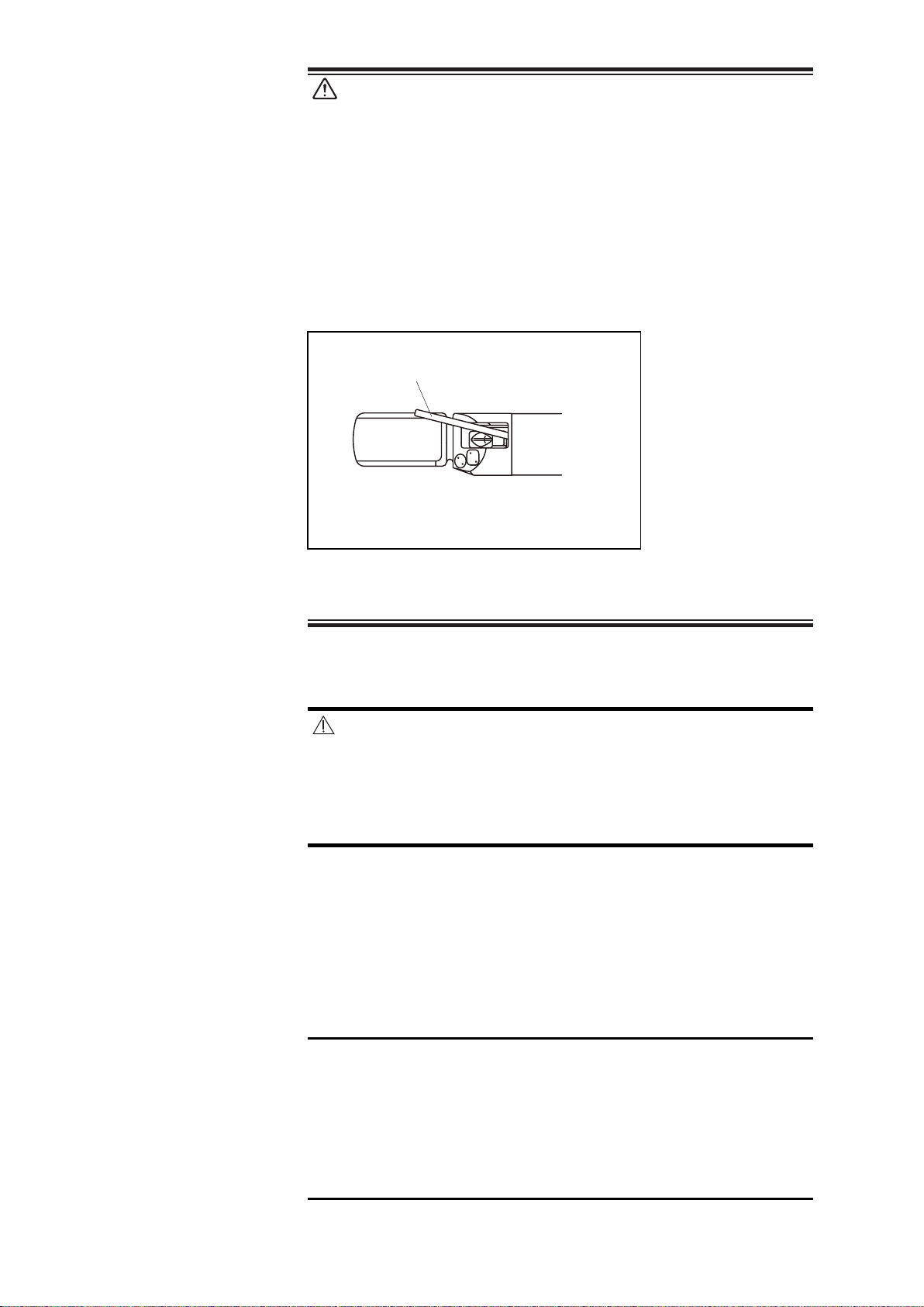

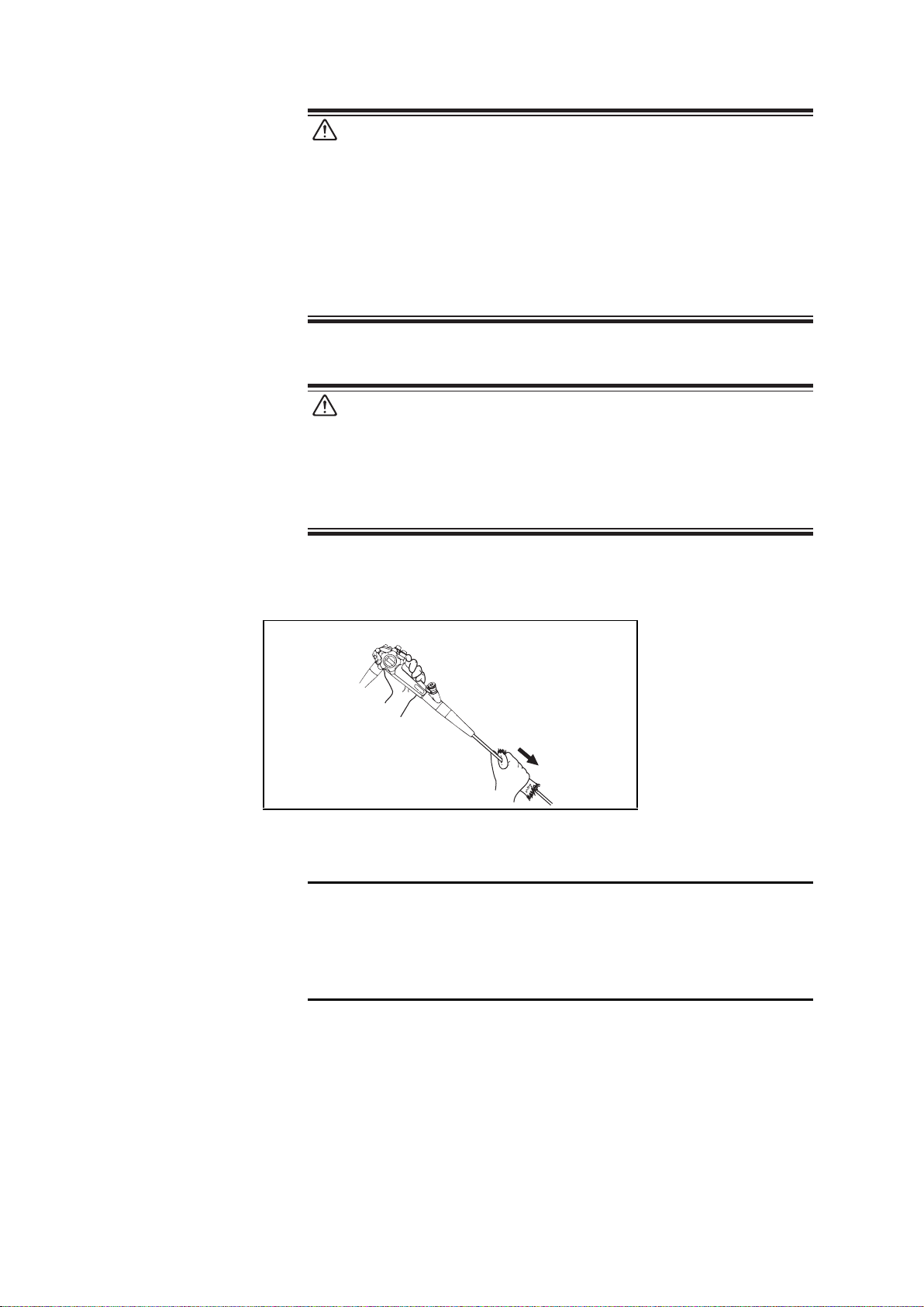

a) Starting at the Bending Section junction, create a 50cm loop of the

Insertion Tube as shown in the figure below.

Figure 2.3

b) Gently raise/lower the left/right hands alternately and confirm equal

flexibility for the length of the loop. Do NOT use the endoscope if

there are any:

• extraordinarily rigid portion which do not bend as easily as the rest

of the loop or

• extraordinarily flexible portions which bend much more than the rest

of the loop.

Figure 2.4

Figure 2.5

– 11 –

Page 15

c) Repeat steps a and b above until the inspection of the entire insertion

NOTE:

Z845 R22EEG 3670URK,

3870UTK.book

12

ジ

2022年5月30日

月曜日

午後12時59分

2022. 06 6217001 Z845 R22

tube is complete. If the endoscope fails the inspection above: Do NOT

use the endoscope and Contact your PENTAX service facility.

• The distal end as well as the electrical contacts/pins on the

PVE connector and scanning unit connector of the endoscope

must be protected against damage from impact. NEVER apply

excess force such as twisting, or severe bending to the

flexible portion of the endoscope.

• As indicated elsewhere in PENTAX product labelling,

endoscopes particularly the quality of the endoscopic image

should be checked prior to patient use. Similarly the quality

of the ultrasound image should be checked.

• During pre-use inspection, ensure that the distal objective

lens and the illumination (LCB) cover glass are clean and no

residues are present on these distal surfaces. If not, crisp

images can NOT be displayed. Wipe them with a gauze or the

like moistend with 70-90% medical grade ethyl or isopropyl

alcohol.

• Ideally all patients should be prepped well to maximize

visualization of the intended areas of interest. Patient

material and secretions should be removed from the area of

observation to eliminate the potential to blur the endoscopic

image and/or obscure the illumination system.

• Prior to a procedure, remove debris or secreta from

observation area as much as possible.

• Continued use of the endoscope’s light guide lens system

covered with adhering patient material might cause a visible

steam-like vaporization associated with moisture loss from

heated organic material clinging to the distal LCB lens

surface. If this vapor is observed during a procedure, stop it

immediately, withdraw the endoscope from patient and clean

off any foreign material clinging to the endoscope lens/end.

– 12 –

Page 16

CAUTION:

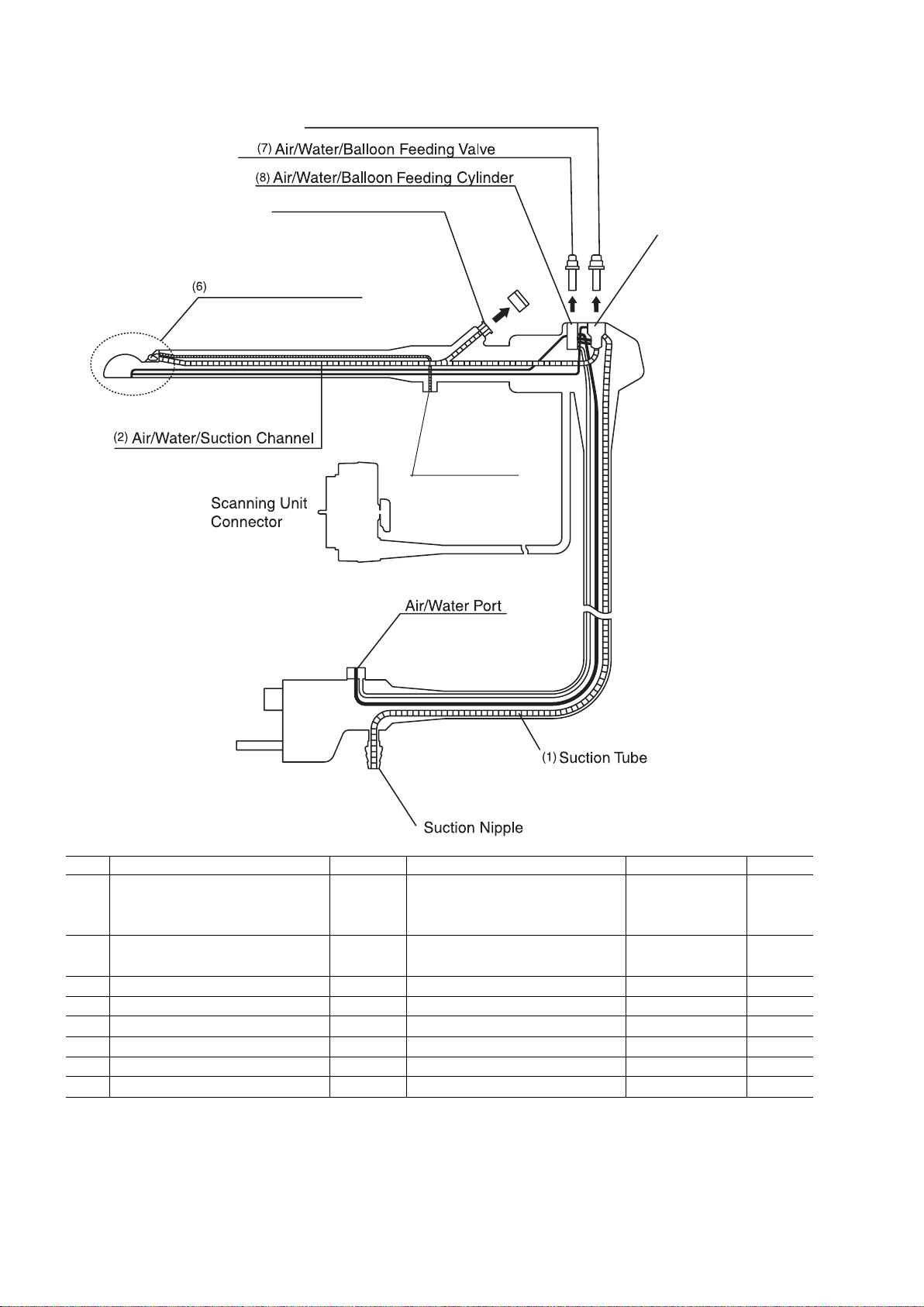

Flexible endoscopes and other sophisticated medical instruments

(1)

(4)

(5)

(3)

(2)

Figure 2.6

Z845 R22EEG 3670URK,

3870UTK.book

13

ジ

2022年5月30日

月曜日

午後12時59分

Ultrasound Upper GI Video Scopes EG-3870UTK/EG-3670URK

are constructed of special materials, unique parts and intricate

components with strict dimensional tolerances. Specialized

assembly techniques and application of specific sealants and/or

adhesives are required to ensure the watertight integrity and

maintain the functionality of these devices. It is therefore

imperative that endoscopes be routinely checked to ensure that

parts used in their construction are not loose, missing or

compromised that could otherwise negatively affect the

functionality of these devices. Compromised or loose

components could result in device failure, endoscope damage

(via fluid invasion) and/or in incomplete decontamination of

used instruments. PENTAX recommends that prior to use

endoscopes should be carefully inspected for their integrity and

checked for any “looseness” in the mating or joining of

components including the following parts/areas:

• the channel inlet assembly (Instrument Channel Inlet) (1)

• the suction nipple (2)

• the air/water port (3)

• any valve cylinder (4)

• the elevator wire channel cleaning inlet (5) (For EG-3870UTK)

• basically, any inlet or outlet port associated with an internal channel, an

indirect patient contact portion of the endoscope

One method to check for looseness is to lightly grip the exposed

part, and while grasping the component carefully attempt to

move it in various directions. Use of lint-free gauze while

grasping metal parts is recommended as a protection for one's

fingers.

If any part/component remains loose (after attempting to

tighten) and/or if there is any indication or suspicion of

an abnormality or outward signs of damage, do NOT use

the endoscope. Contact your local PENTAX service facility.

– 13 –

Page 17

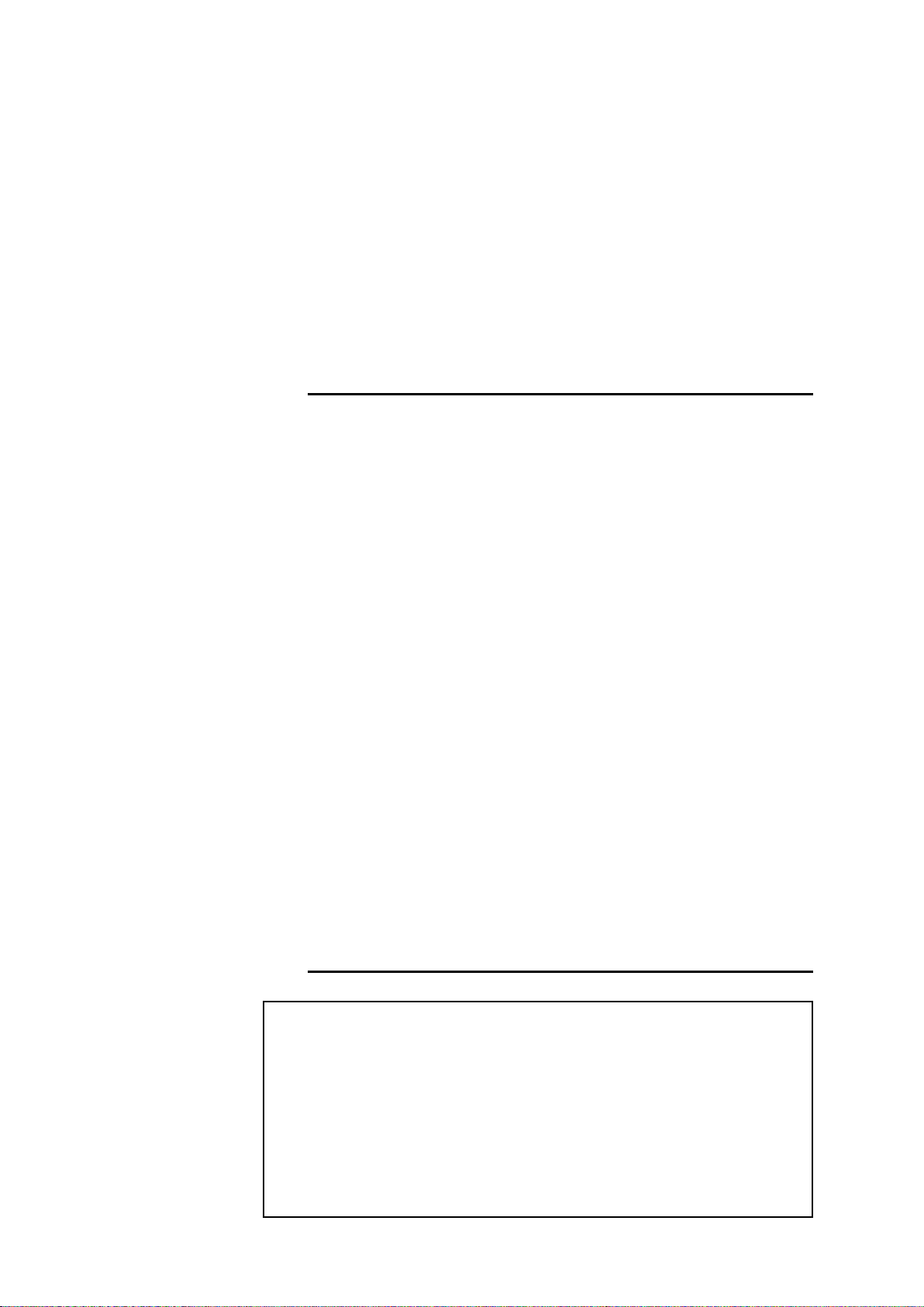

CAUTION:

To avoid damaging the endoscopes, do NOT twist, rotate or bend

NOTE:

Do NOT Twist or Rotate

Do NOT Bend

(1)

(2)

(2)

Figure 2.7

Z845 R22EEG 3670URK,

3870UTK.book

14

ジ

2022年5月30日

月曜日

午後12時59分

2022. 06 6217001 Z845 R22

excessively any of the strain relief boot (1), (2) during

inspection, clinical use, reprocessing or any handling activity. Be

particularly cautious for the insertion tube strain relief boot(1).

When wiping the insertion tube and the umbilical cord, use a

slow back and forth motion to wipe them along the tube/cord.

Never apply excessive force or torque on these strain relief

boots or slim tubes/cords.

3) Inspection of Angulation Controls and Locks

a) Slowly manipulate the Up/Down and the Right/Left control knobs to

see that they function smoothly. Be certain that a full and appropriate

range of angulation is possible.

b) Engage the angulation lock knob/lever to be certain that the position of

the angulated distal end can be stabilized.

The angulation lock knob/lever are of the friction type and the

degree of friction is adjustable. The degree of locking friction

depends on the rotational position of the lock knob/lever.

– 14 –

Page 18

CAUTION:

ANY lack of smooth operation of the angulation controls may be

WARNING:

Z845 R22EEG 3670URK,

3870UTK.book

15

ジ

2022年5月30日

月曜日

午後12時59分

Ultrasound Upper GI Video Scopes EG-3870UTK/EG-3670URK

an early indication of internal damage to and/or part(s) failure

within the endoscope’s angulation system. To avoid the

possibility of further endoscope damage or the potential for

malfunction of the angulation system, do NOT use the

endoscope if the angulation mechanism does not operate

properly. Prior to use, ensure that the angulation controls can

rotate smoothly, that there is no grinding or excess friction

within the angulation system and that the distal bending section

bends freely and smoothly. NEVER APPLY EXCESSIVE FORCE TO

THE ANGULATION CONTROLS! When an endoscope exhibits

excessive “knob play” or if angulation is lost in any direction, do

NOT use the instrument. Excessive “knob play” can be defined

as rotating of the angulation control knob(s) in any one direction

for more than 30 degrees without any corresponding distal end

angulation. The examples above are indications that service is

required to avoid more serious problems with the angulation

control system, including angle or pulley wire breakage and/or

the possibility of a “frozen” distal bending section.

A “frozen” bending section can make instrument extraction from

a patient more difficult.

(1)

(2)

Figure 2.8

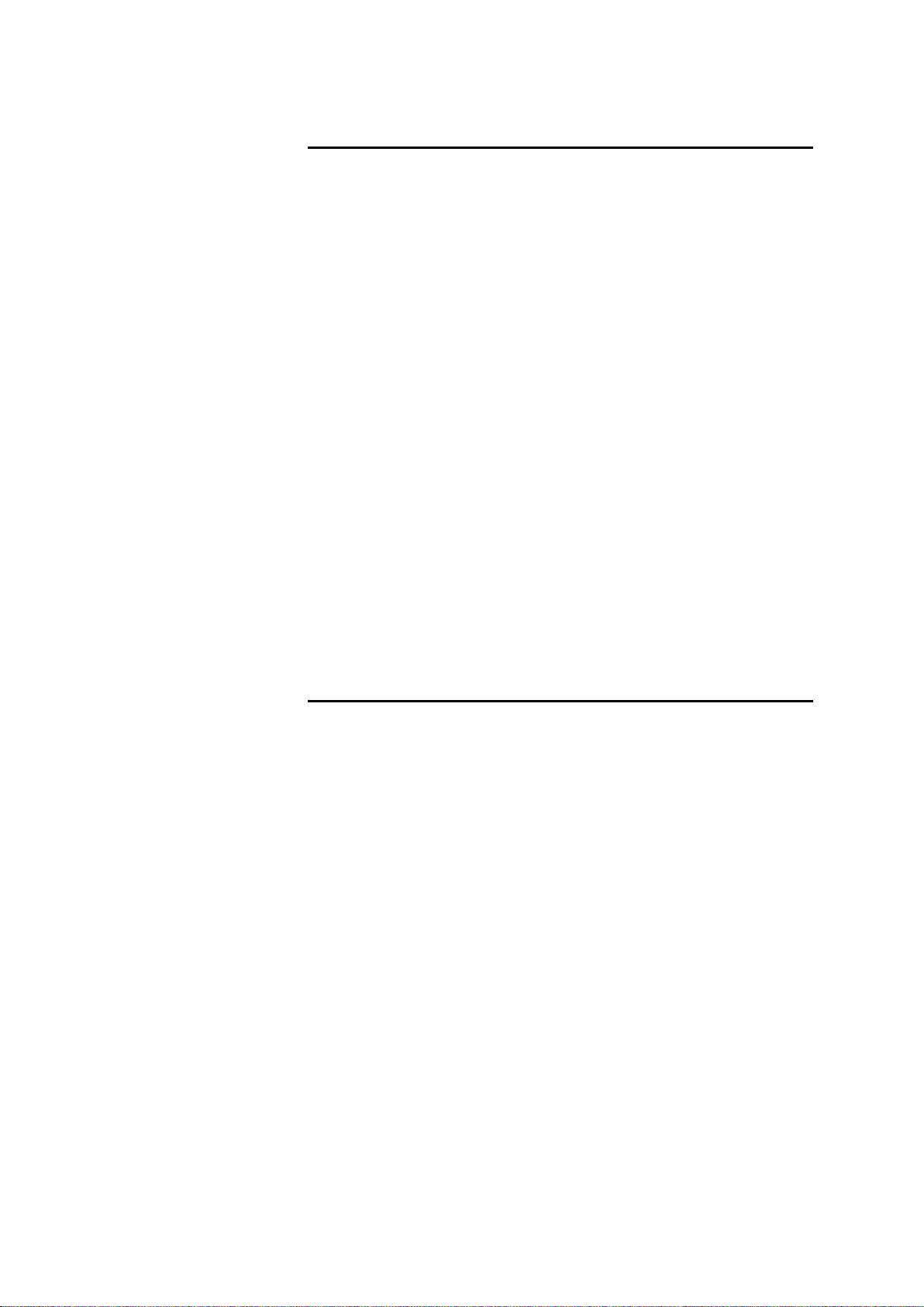

(1) OF-B172

(2) O-ring Set

(OF-B191)

4) Inspection of Air/Water/Balloon Feeding Mechanism

a) Prior to use, the air/water/balloon feeding valve, OF-B172, should be

inspected. Remove the valve from control body. Make sure that O-

rings are in good condition and are properly attached and lubricated

with a small amount of OF-Z11 silicone oil.

A worn or damaged valve and/or O-rings should be replaced

with a new one. The entire valve mechanism should be

subjected to a high-level disinfection or sterilization procedure

prior to use (O-ring set, model OF-B191, is optionally available).

For repeated use, always ensure that the valve and/or O-rings

have already been reprocessed. A damaged or worn valve and/

or O-rings could create continuous air flow or excessive air

insufflation and result in potential patient injury such as

pneumatic perforation or could create a risk of cross

contamination to the end user due to the potential for reflux

(spit-back) of patient fluids out of the valve.

– 15 –

Page 19

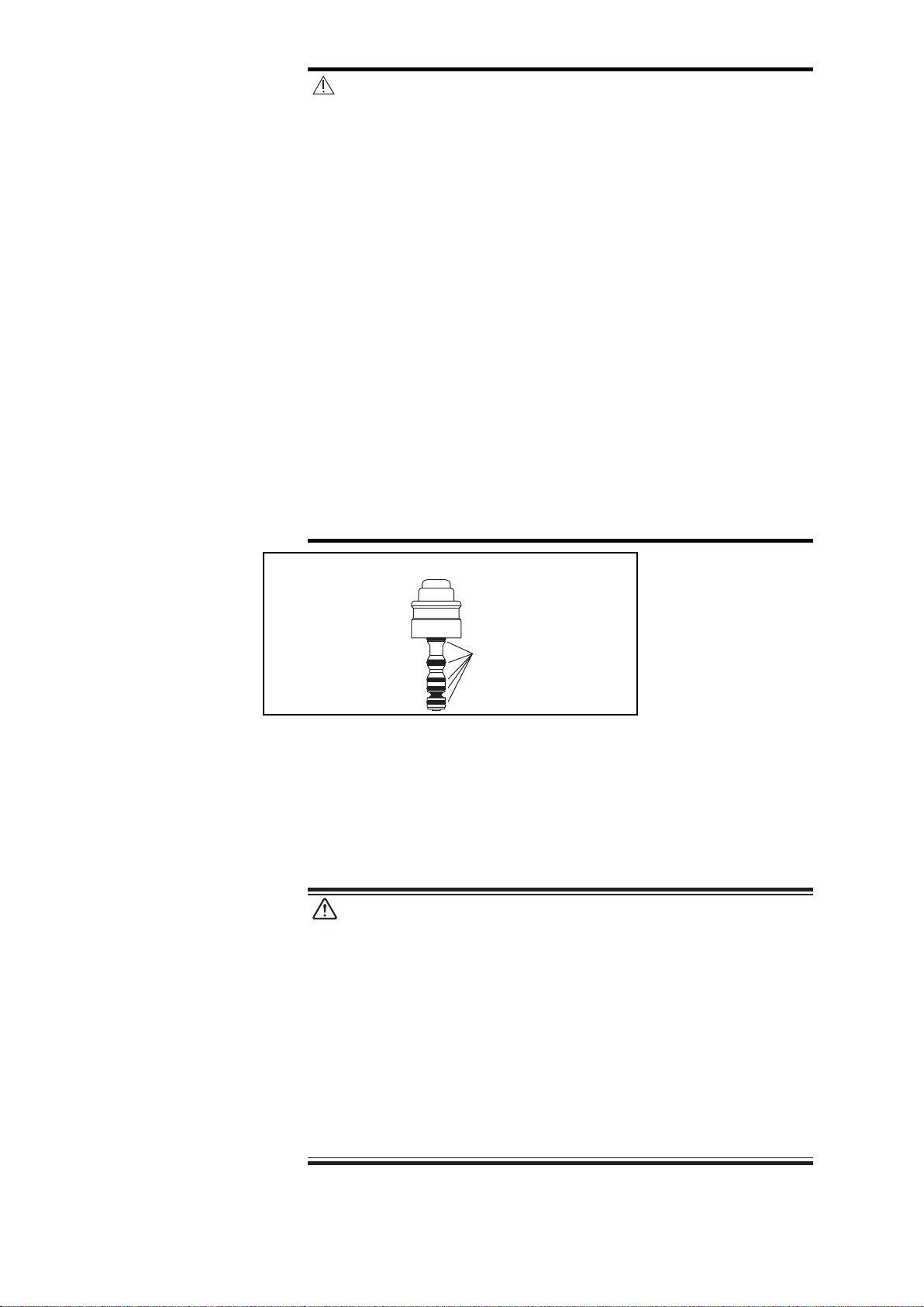

b) To inspect air delivery, cover the hole at the top of the OF-B172 and

NOTE:

Z845 R22EEG 3670URK,

3870UTK.book

16

ジ

2022年5月30日

月曜日

午後12時59分

2022. 06 6217001 Z845 R22

confirm that air flows freely from the endoscope distal end.

c) By depressing the top button of OF-B172, the water delivery system is

activated. Water should flow in a steady stream from the distal end of

the endoscope. (This may take several seconds on the initial attempt.)

USE STERILE WATER ONLY.

d) By fully depressing both buttons of OF-B172, the delivery system to

fill the balloon with water is activated. Water should flow in a steady

stream from the balloon injection nozzle at the distal end of the

endoscope (this may take several seconds on the initial attempt).

e) Release the air/water/balloon feeding valve to determine if the valve

freely returns to its OFF (neutral) position and delivery of water (and

air) ceases.

f) If the air/water/balloon feeding valve does not move smoothly, remove

the valve and apply a small amount of silicone oil lubricant onto all the

O-rings. Remove/wipe off excessive lubricant with a soft gauze. Do

NOT use excessive silicone oil.

Excessive silicone oil (lubricant) should be avoided to prevent

occlusion of the internal Air/Water/Suction channel and potential

impairment of the normally clear endoscopic image.

g) If air and/or water do not flow properly, NEVER attempt to clear any

of the distal channel openings with a needle or any other sharp object.

Instead, the following steps should be followed.

[1] EG-3670URK

[a] Disconnect the endoscope from the video processor.

[b] Remove the air/water/balloon feeding valve (OF-B172).

[c] Using a cotton tipped applicator and alcohol, clean the valve

recess (receptacle) in the control body thoroughly to remove any

debris. Do NOT attempt to insert the applicator into the small

openings within the cylinder as the cotton or applicator could

become lodged within these openings and cause channel

blockage.

[d] Clean the air/water/balloon feeding valve (OF-B172) assembly

thoroughly and rinse well.

– 16 –

Page 20

NOTE:

CAUTION:

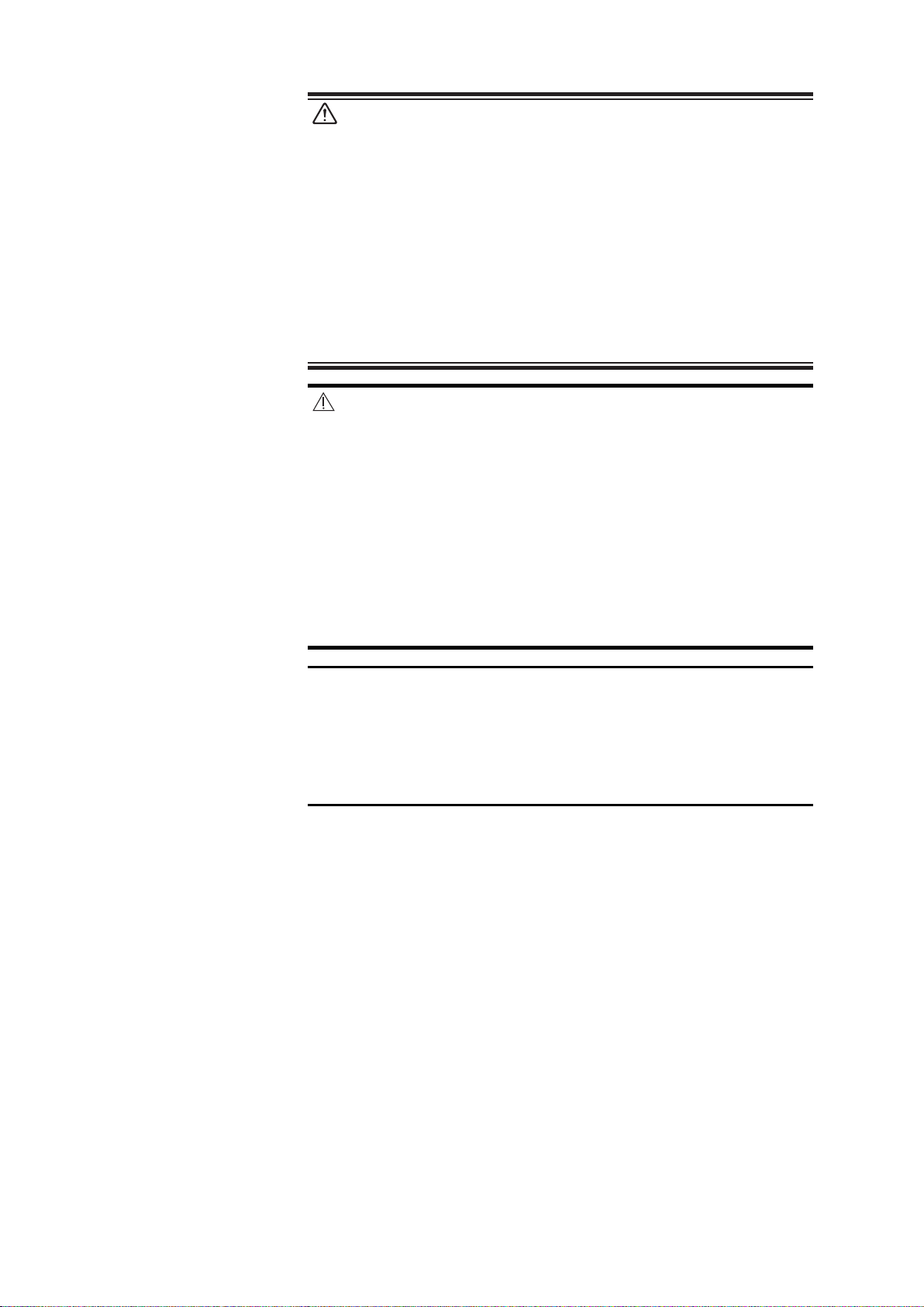

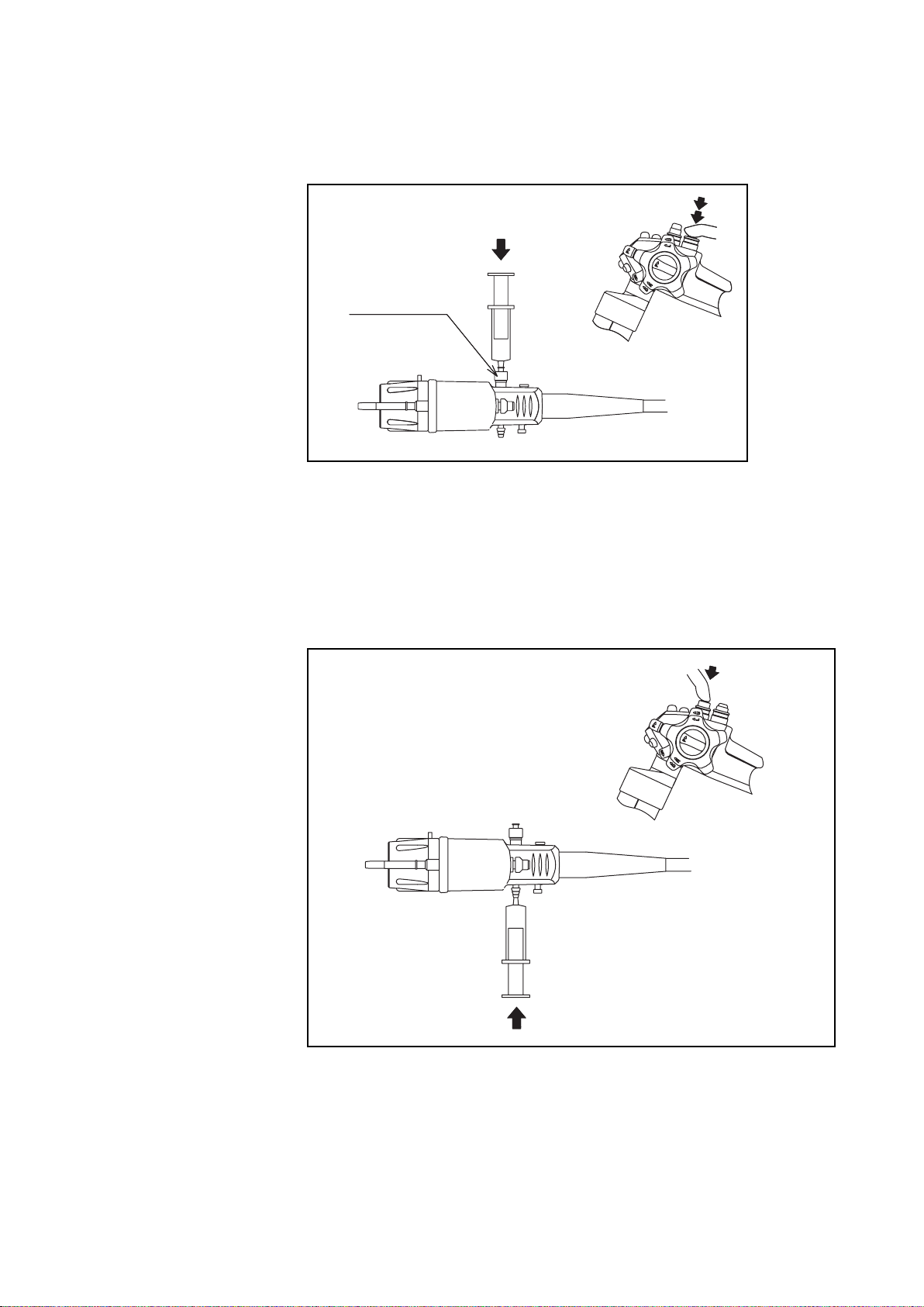

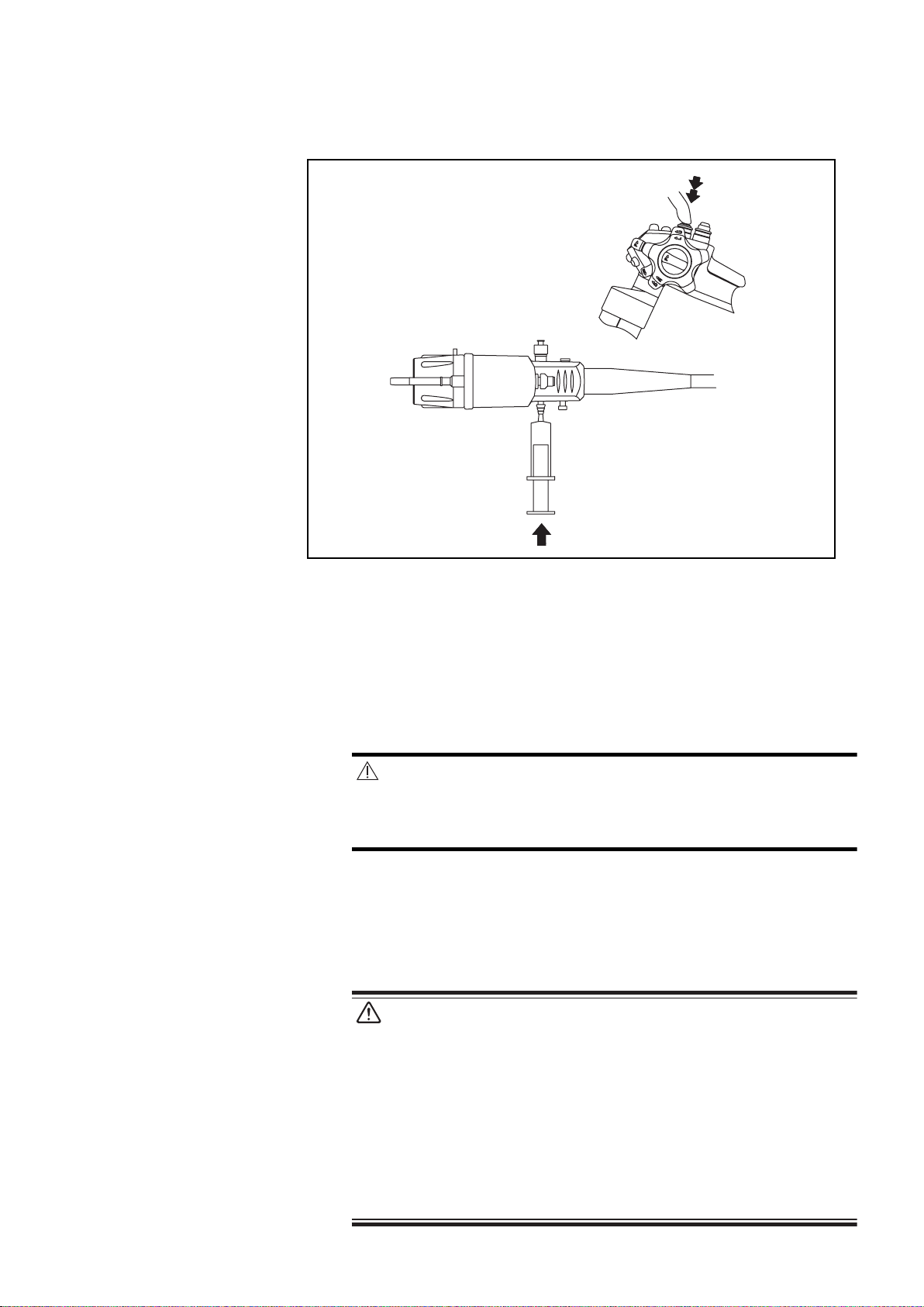

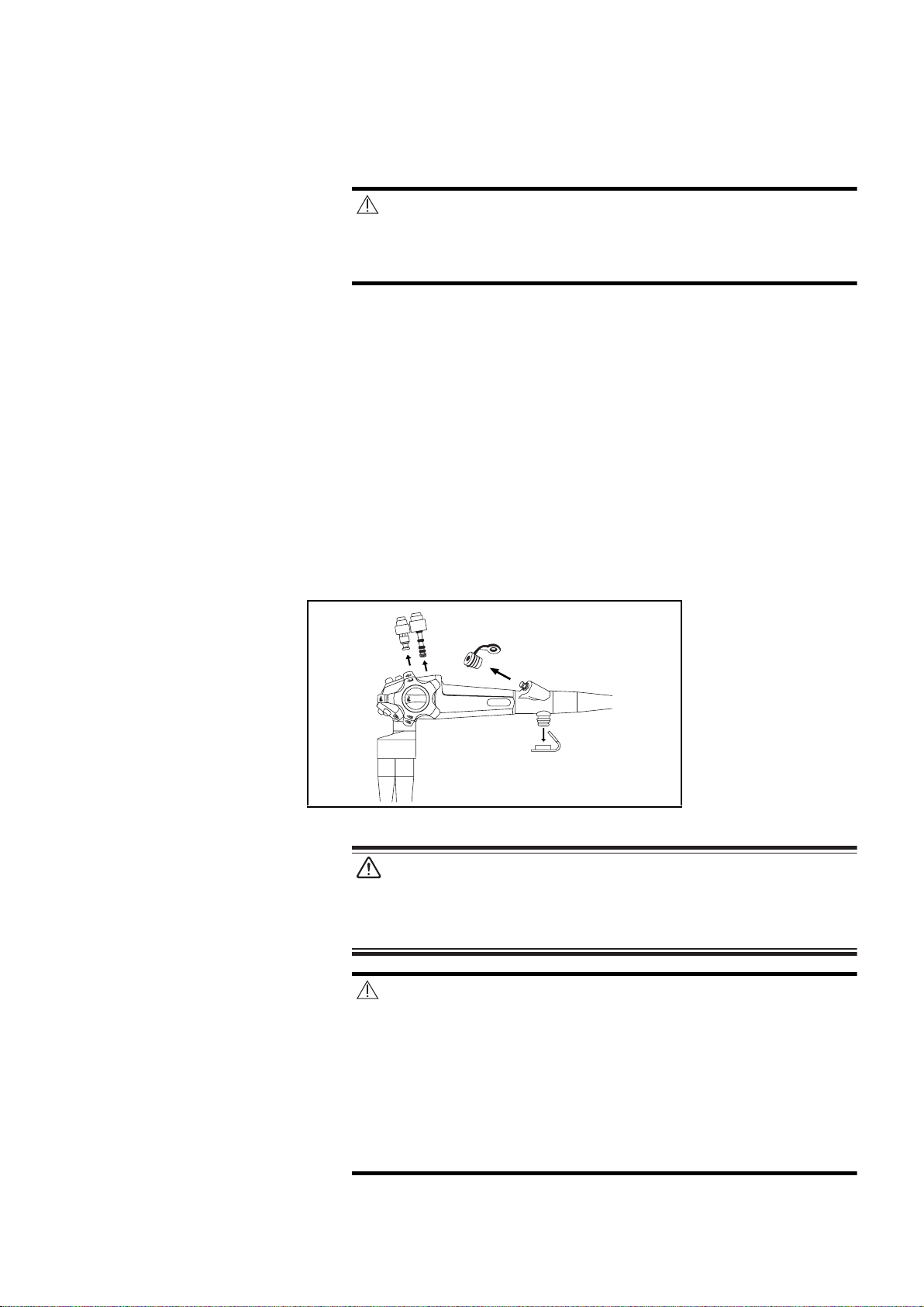

Figure 2.9

(1)

(2)

Z845 R22EEG 3670URK,

3870UTK.book

17

ジ

2022年5月30日

月曜日

午後12時59分

Ultrasound Upper GI Video Scopes EG-3870UTK/EG-3670URK

Thoroughly dry the air and water channels of the endoscope. 7090% medical grade ethyl or isopropyl alcohol followed by

compressed air, not greater than 165 kPa (1.69 kg/cm

PSI), may be used to facilitate drying via the adapter.

(2)

(1)

(1) Cleaning Adapter

(OE-C5)

(EG-3670URK only)

(2) Cleaning Adapter

(OF-B153)

(EG-3670URK only)

[e] Remove the suction/balloon suction valve, and install the

adapters as illustrated.

[f] After attaching the adapters as illustrated, follow the section of

this Instructions for Use for cleaning the Air/Water/Suction

channel.

2

, 24

[g] Remove the adapters used in step [f] and install the air/water/

balloon feeding valve. Test for normal delivery of air and water.

It may be necessary to repeat the procedure outlined in steps [e]

& [f] if normal air and water delivery is still not available.

[2] EG-3870UTK

Follow the reproc

essing instructions as described in section 4.

CARE AFTER USE.

If repeated attempts to flush the air/water system are

unsuccessful, do NOT attempt to use the endoscope on a

patient. Contact the PENTAX service facility.

5) Inspection of elevator (EG-3870UTK only)

This is the control that will guide and direct either the biopsy forceps or

other accessory during a procedure. To inspect, push the elevator control

knob forward with thumb of the left hand. The elevator in the distal end

should elevate in proportion to the distance the control knob is moved. The

motion of the elevator and the knob should be smooth and easy without any

“play” involved.

Figure 2.10

(1) Elevator

(2) Elevator Control knob

– 17 –

Page 21

WARNING:

As with all other internal channels of the endoscope, the elevator

WARNING:

(2)

(1)

(3)

(3)

(2)

(4)

(1)

Z845 R22EEG 3670URK,

3870UTK.book

18

ジ

2022年5月30日

月曜日

午後12時59分

2022. 06 6217001 Z845 R22

wire channel must have been properly cleaned and subjected to

an appropriate high-level disinfection or sterilization process

before each use.

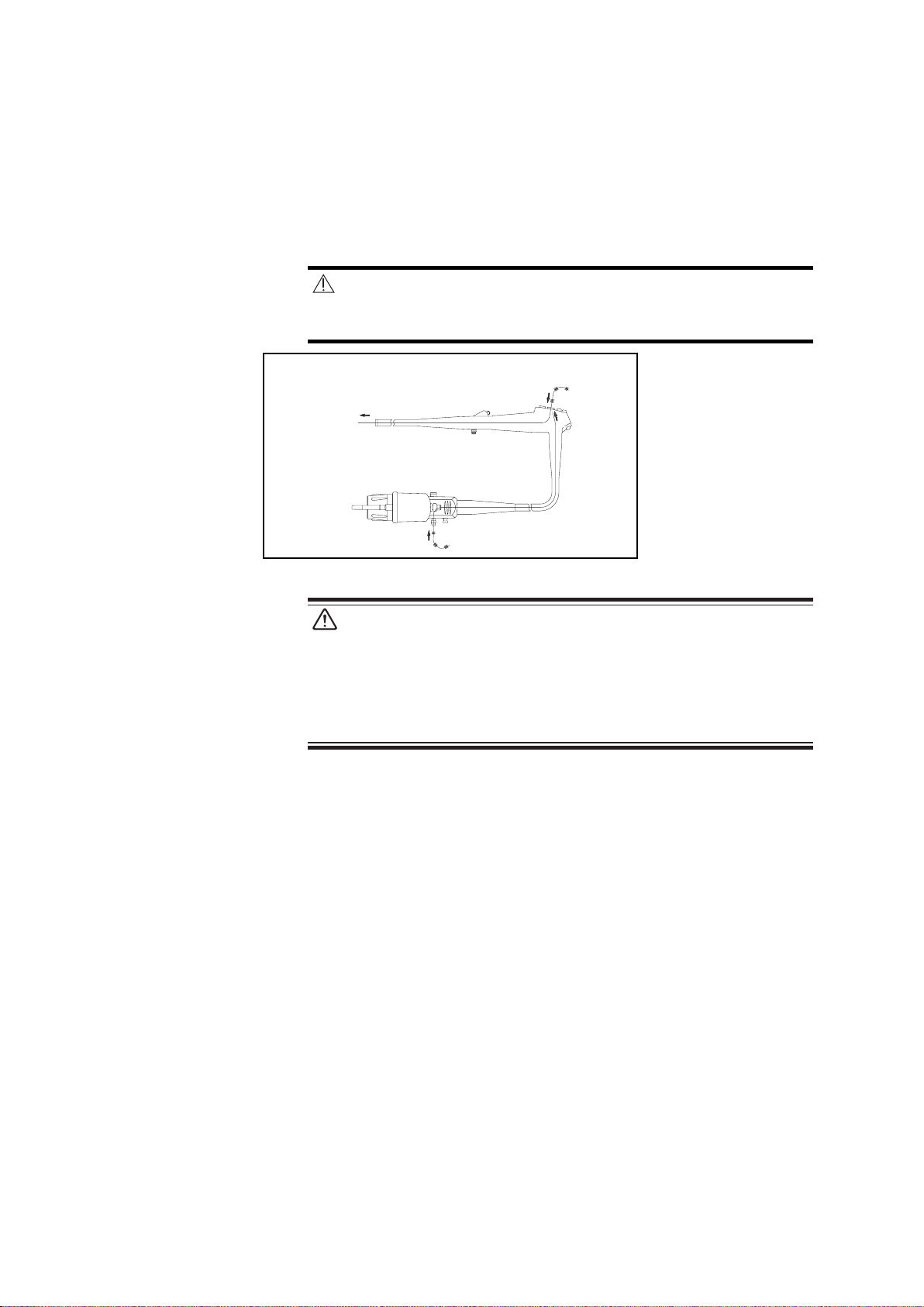

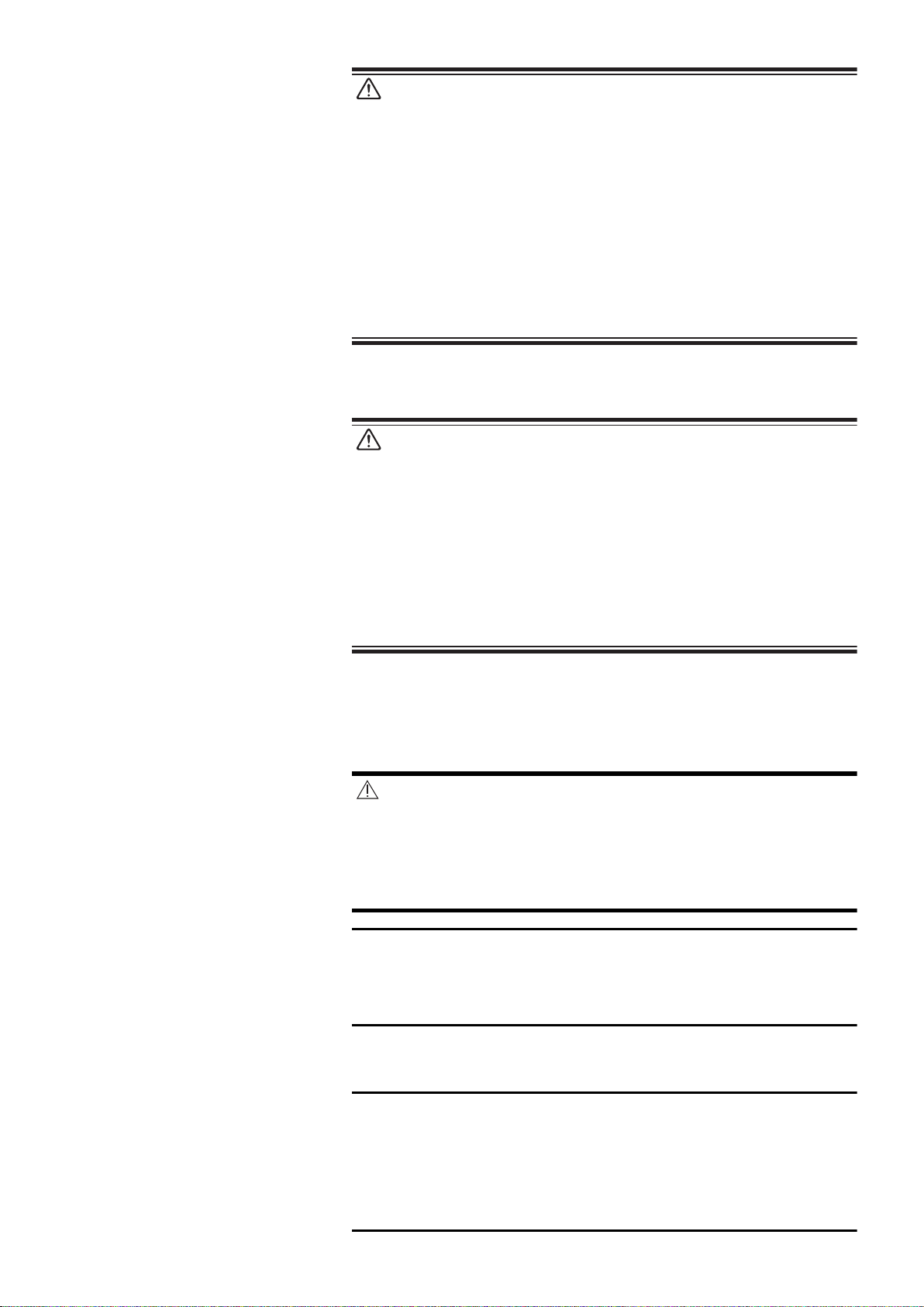

6) Inspection of Suction Mechanism

(1) Depress

(2) Suction Tube

(3) Suction Nipple

Figure 2.11

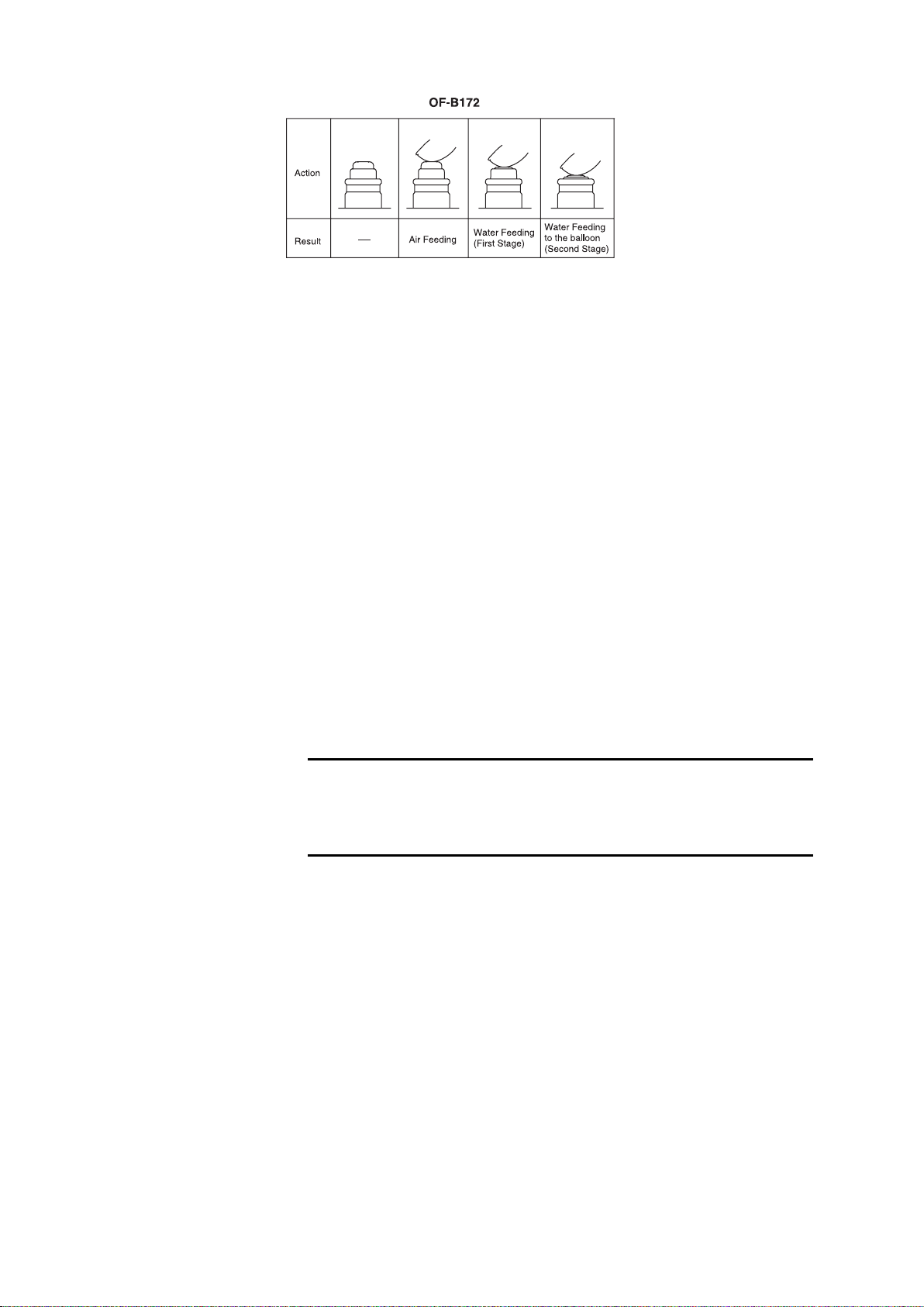

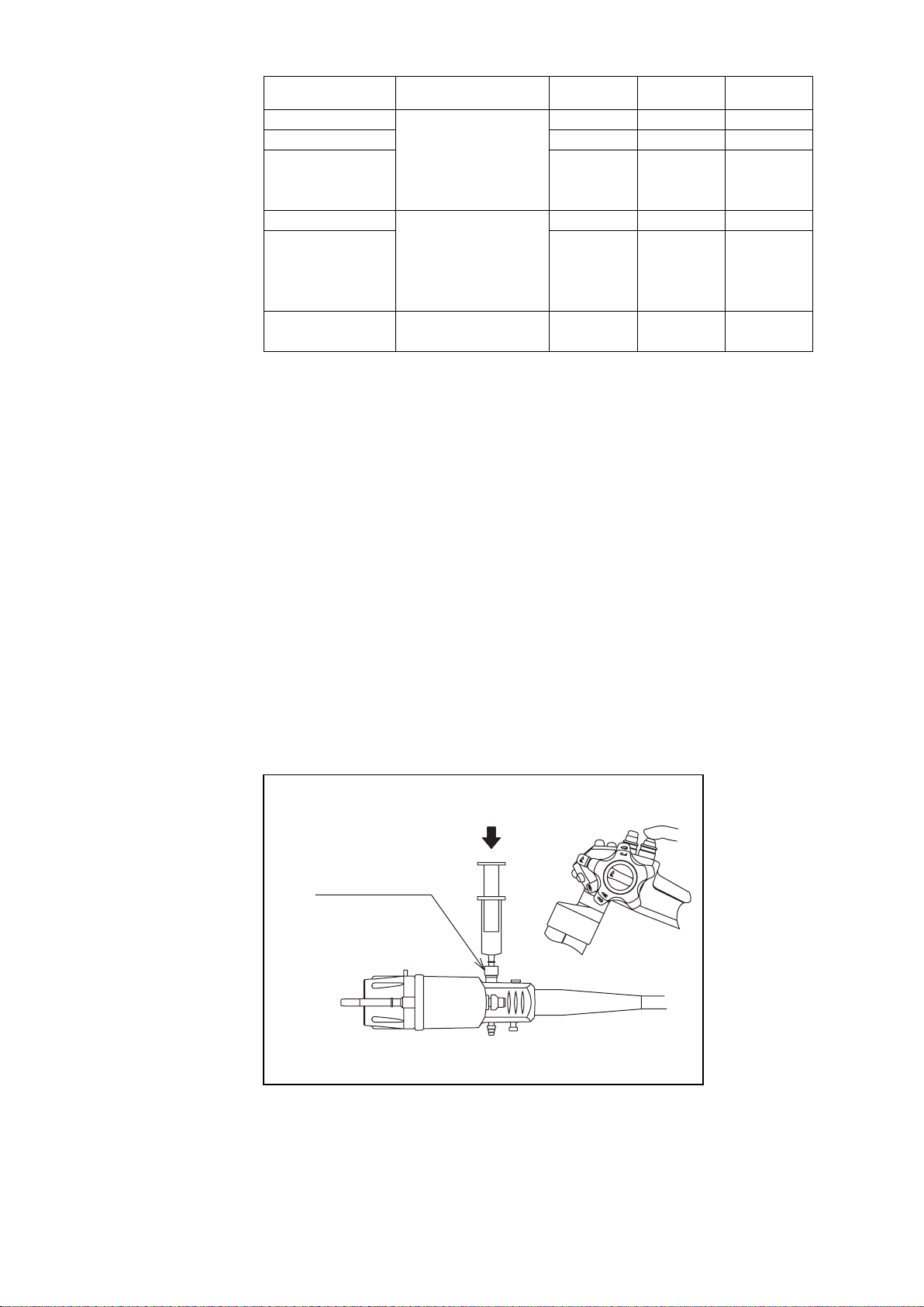

a) Prior to use, the suction/balloon suction valve, OF-B171 should be

inspected. Remove the valve from the control body and ensure that O-

rings are in good condition and properly attached and are lubricated

with a small amount of OF-Z11 Silicone Oil.

Figure 2.12

A worn or damaged valve and/or O-rings should be replaced

with a new one. The entire valve mechanism should be

subjected to a high-level disinfection or sterilization procedure

prior to use (O-ring set, model OF-B187, is optionally available).

Failure to do so could result in continuous aspiration which in

certain clinical situation can suction tissue into the distal channel

opening at the distal end and/or create a loss of insufflated air

via the suction system. A compromised valve could also result in

the potential for reflux or spit-back of patient fluids that may

present infection control risks.

(1) OF-B171

(2) O-Ring (Large)

(3) O-Ring (Small)

(4) O-Ring Set

(OF-B187)

b) Connect suction tubing from an external suction source to the suction

nipple located on the PVE Connector at the end of the umbilical cord.

Place the distal end of the endoscope in a basin of sterile water.

– 18 –

Page 22

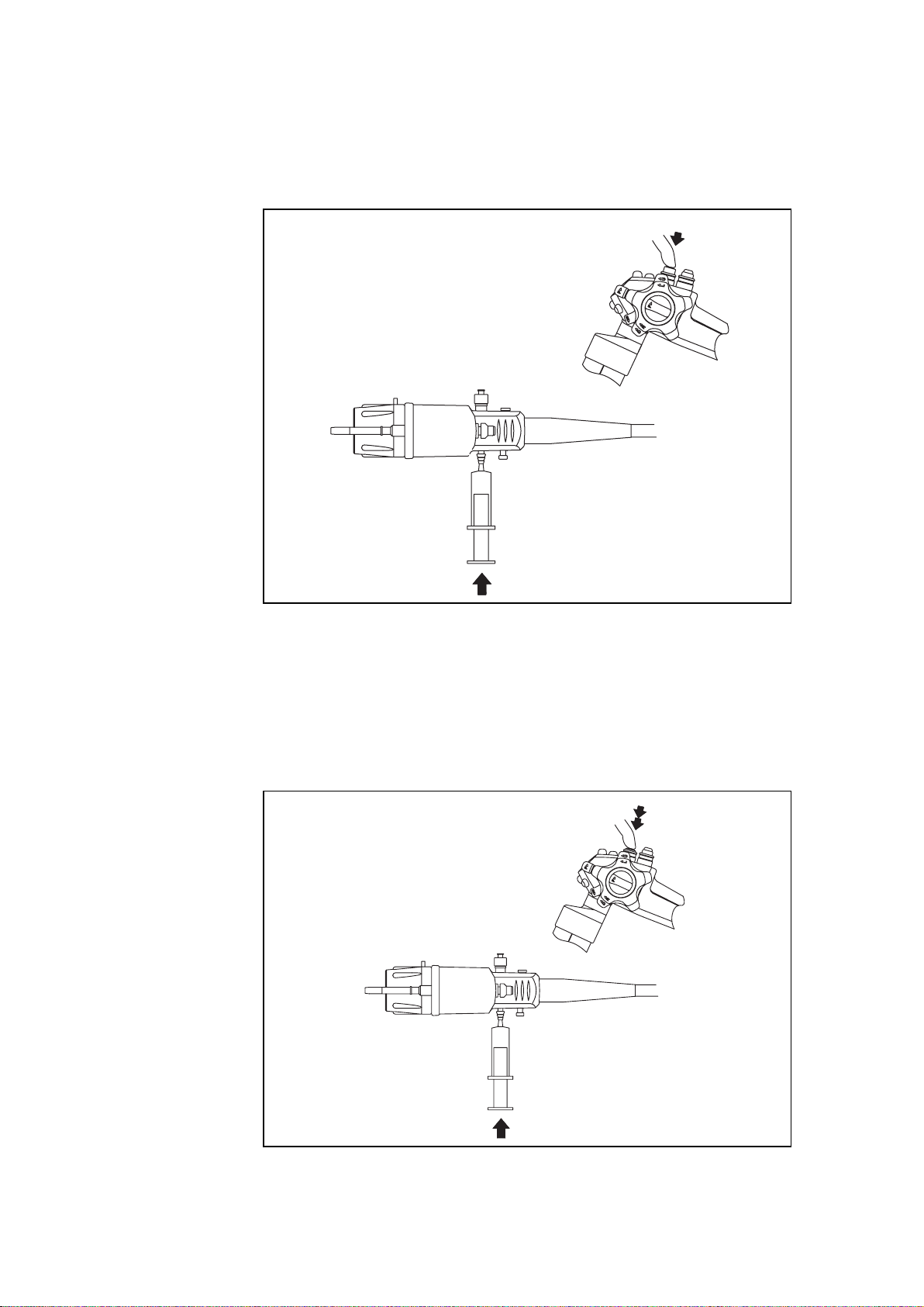

c) Fully depress and then release the suction/balloon suction valve to

CAUTION:

NOTE:

Z845 R22EEG 3670URK,

3870UTK.book

19

ジ

2022年5月30日

月曜日

午後12時59分

Ultrasound Upper GI Video Scopes EG-3870UTK/EG-3670URK

determine if the valve freely returns to its OFF position and the

aspiration of water ceases.

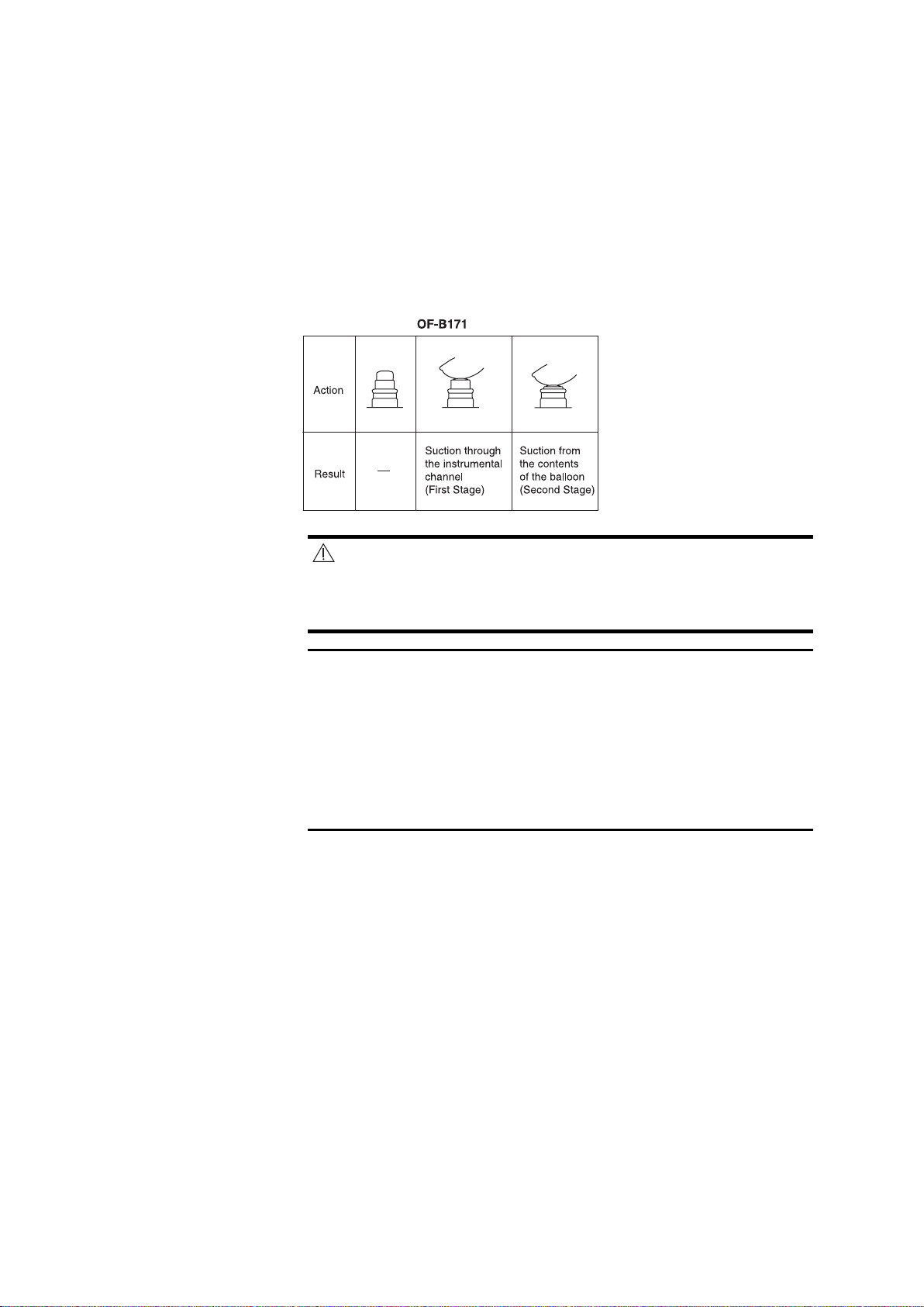

d) Pressing the suction/balloon suction valve halfway down to its 1st

stage will start suctioning through the biopsy/instrument channel

system.

e) Fully depressing the suction/balloon suction valve down to its 2nd

stage will initiate suctioning of and empty the contents of the balloon

through the balloon suction channel.

If the instrument is to be used immediately after the inspection,

use only sterile water. To avoid recontamination of a previously

reprocessed endoscope, avoid use of idle/uncovered tap water.

Inlet seals in good condition must be on the instrument channel

inlet to prevent the loss of suction and a risk of cross

contamination to the end user due to the potential for reflux

(spit-back) of patient fluids. Worn seals will result in leakage and

should be replaced. To ensure maximum performance of these

sealing mechanisms, consider replacing the inlet seal with a new

fully reprocessed one for each procedure.

f) If the suction/balloon suction valve does not move smoothly or feels

“sticky”, remove the valve from the suction/balloon suction cylinder

on the control body of the endoscope.

Apply a small amount of silicone oil lubricant, OF-Z11, onto rubber

part and rubber O-rings. Remove/wipe off excess lubricant with a soft

gauze. Do NOT use excessive silicone oil.

– 19 –

Page 23

7) Inspection of Biopsy Forceps/Accessory and Instrument Channel

WARNING:

WARNING:

CAUTION:

(1)

(2)

Z845 R22EEG 3670URK,

3870UTK.book

20

ジ

2022年5月30日

月曜日

午後12時59分

2022. 06 6217001 Z845 R22

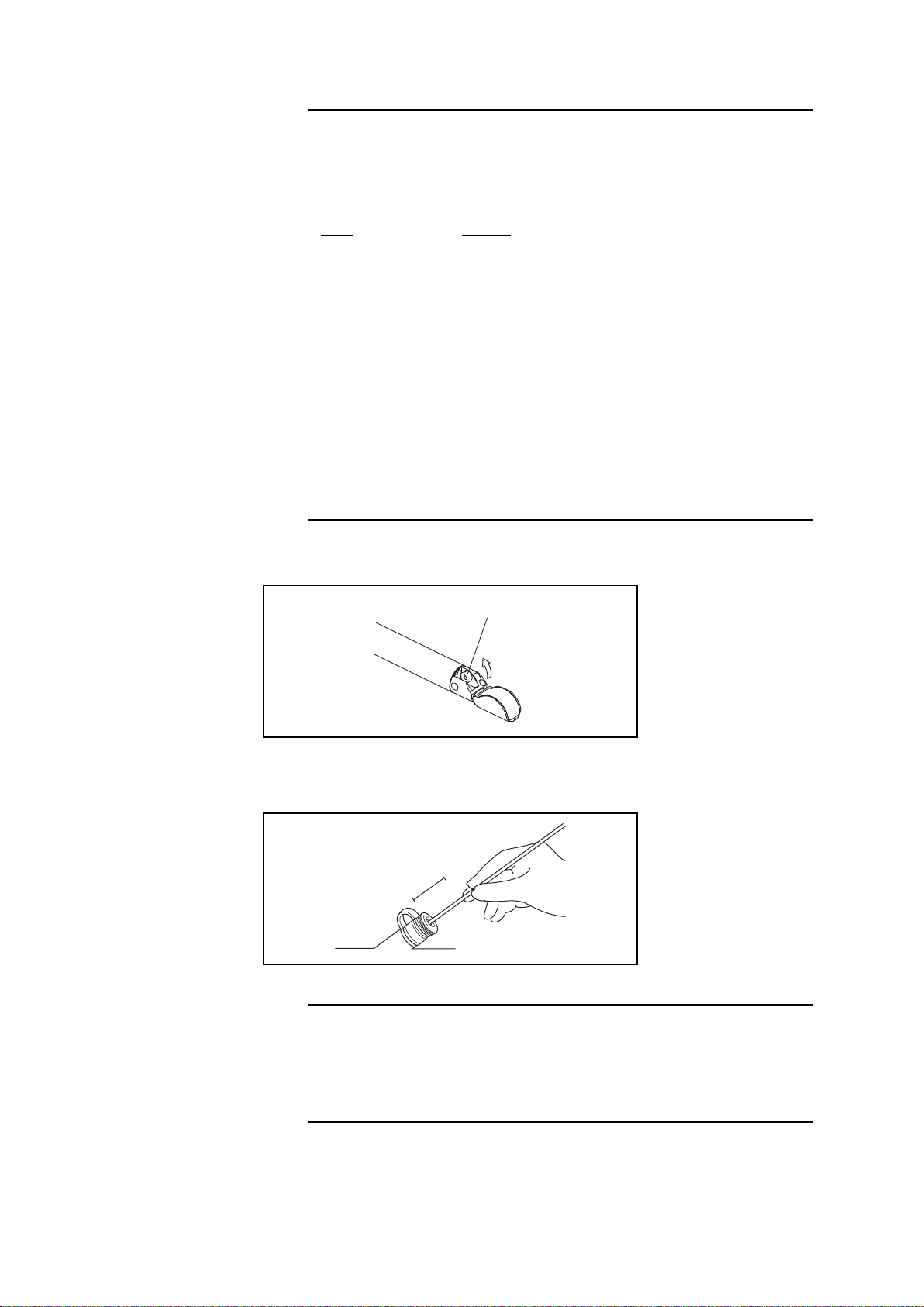

a) Make sure there are no kinks in the flexible shaft of the biopsy forceps.

(1) Close

(2) Open

Figure 2.13

b) The cups/jaws of the forceps must be free of any residual debris. Any

debris must be cleaned from the forceps before they are used. Use only

sterile forceps.

c) The handle mechanism on the forceps should be operated to open and

close the cups/jaws. This mechanism should operate freely.

d) Close and inspect the cups/jaws of the forceps to make sure the cups/

jaws are in proper alignment. If the forceps has a spike, the spike must

be completely straight and fully within the cups/jaws.

The use of any forceps or accessory that shows any sign of

damage or difficulty of operation must be avoided. Any

malfunction of a forceps or accessory during a patient procedure

could result in serious injury to the patient. Also, the use of

damaged forceps or accessories may result in serious and costly

damage to the endoscope.

e) Any accessory should be slowly inserted through the instrument

channel inlet with the endoscope in a straight position. There should be

no resistance encountered. If resistance is encountered, do NOT

attempt to introduce the accessory further. The instrument channel

may be damaged and the endoscope should not be used. Contact your

local PENTAX service facility.

All patient contact accessories must be thoroughly cleaned and

subjected to an appropriate high-level disinfection or

sterilization process before being used for the first time and

subsequently after each clinical use.

The instrument channel system is made of stainless steel, Noryl

and fluorine-contained polymers. When any fluids are used with

this endoscope, please read carefully and follow all instructions

in the Instructions for Use provided with the fluids and pay

special attention to any reactions with the materials identified in

the intended fluid path. Only the user can determine if the fluids

are appropriate for patient use.

– 20 –

Page 24

NOTE:

Accessories should always be inspected and checked with the

WARNING:

NOTE:

WARNING:

NOTE:

Z845 R22EEG 3670URK,

3870UTK.book

21

ジ

2022年5月30日

月曜日

午後12時59分

Ultrasound Upper GI Video Scopes EG-3870UTK/EG-3670URK

particular endoscope prior to each procedure.

Do NOT clinically use the endoscope if any irregularity or

abnormality is suspected. If there is any doubt as to the

suitability of use for any endoscope component, replace it with a

new fully reprocessed one. An instrument irregularity may cause

endoscope damage and/or compromise patient or user safety.

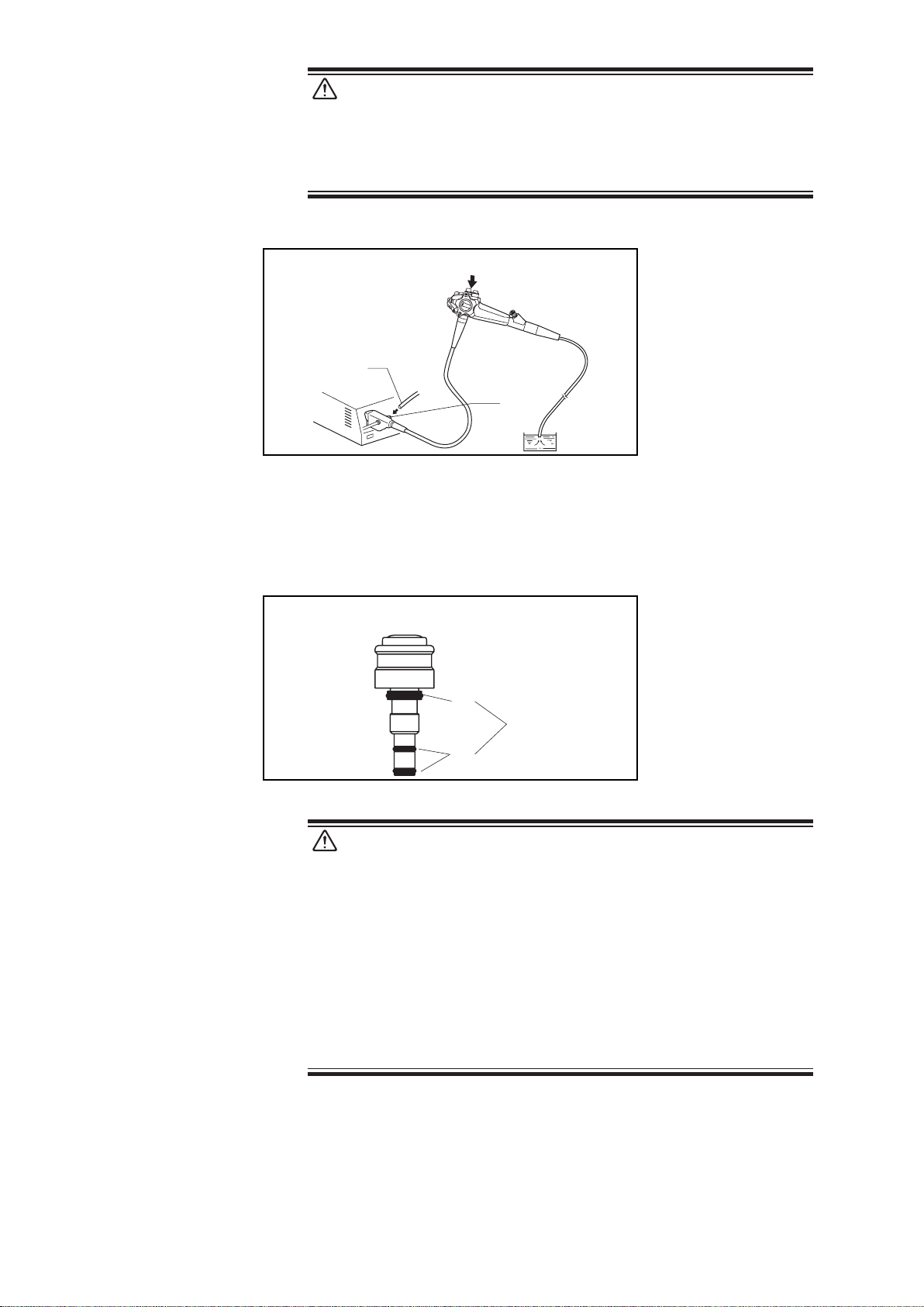

2-3. Preparation of Ultrasound Scanning Unit

1) The ultrasound scanning unit made by FUJIFILM Healthcare Corporation

listed on the addendum sheet F370 is currently compatible with these

PENTAX ultrasound endoscopes.

2) For complete details on the handling, operation, care and maintenance, etc.

of the ultrasound scanning units, refer to the Instructions for Use provided

with each unit.

2-4. Preparation before the Examination

The latex balloons and their O-Rings are disposable. They are

provided sterile for single patient use.

Please be advised that PENTAX balloons, Model OF-A67 for EG3870UTK and Model OE-A51 for EG-3670URK supplied for

endoscopic ultrasound applications are made of latex material.

Appropriate precautions are therefore recommended. Due to the

potential severe allergic reactions to medical devices containing

latex (natural rubber), healthcare professionals are encouraged

to identify latex sensitive patients and be prepared to treat

allergic reactions promptly.

A. Procedures using Balloon Method

When attaching or removing the latex balloon, be careful not to

damage the endoscope, especially the sensitive transducer,

optical lenses or bending section at the distal portion.

1) Ensure that the endoscope is connected properly to the video processor.

2) Connect the scanning unit connector of the endoscope to the ultrasound

scanning unit.

– 21 –

Page 25

3) Fully depress the air/water/balloon feeding valve (OF-B172) until the water

NOTE:

(2)

(1)

(3)

Z845 R22EEG 3670URK,

3870UTK.book

22

ジ

2022年5月30日

月曜日

午後12時59分

2022. 06 6217001 Z845 R22

exits the distal end of the endoscope.

4) Prior to attempting to secure the latex balloon to the endoscope, moisten

both balloon and distal end with sterile water. This will create a more

slippery surface to allow easier sliding of the balloon over the transducer at

the distal end of the endoscope.

5) Carefully attach the balloon provided onto the distal end. Gently slide the

balloon over the distal end of the endoscope.

(1)

(5)

Figure 2.14

(2)

(2)

(3)

(4)

(6)

(1) EG-3670URK

(2) Balloon Attachment

Groove

(3) Balloon (OE-A51)

(4) Balloon Band

(5) EG-3870UTK

(6) Balloon (OF-A67)

6) (EG-3670URK) see Figure 2.15

lace the balloon band into the balloon attachment groove at the endoscope

P

distal end.

7) (EG-3870UTK) see Figure 2.16

S

lide the larger Balloon Band onto the balloon installation device (OF-A37)

.

(1) EG-3870UTK

(2) Balloon Installation

Device (OF-A37)

(3) Large Balloon Band

Figure 2.15

(Optional method) Instead of using the provided rubber bands to secure the

distal balloon, the user may opt to use suture thread to secure attachment.

Balloon O-Ring Kit, OF-A67, is available. The kit consists of:

• Balloon

• 2 pieces of Large Balloon Bands (O-Rings)

• Small Balloon Band* (O-Ring)

*The small Balloon Band is not used for this endoscope.

– 22 –

Page 26

8) To check the integrity of the balloon, inflate it with water in the following

NOTE:

NOTE:

(2)

(3)

(4)

(1)

Z845 R22EEG 3670URK,

3870UTK.book

23

ジ

2022年5月30日

月曜日

午後12時59分

Ultrasound Upper GI Video Scopes EG-3870UTK/EG-3670URK

manner.

Automated Balloon Filling with air/water/balloon feeding valve (OF-

B172) and water bottle

a) Ensure that the water bottle assembly for the video processor has been

filled (2/3 full) with de-aerated sterile water. Connect the bottle tube to

the endoscope.

b) Fully depressing the air/water/balloon feeding valve all the way down

should activate water delivery to the balloon.

Do NOT overfill the balloon with water. Since an excessive

volume of water may literally burst the balloon, the amount of

sterile water injected should be kept down to a minimum.

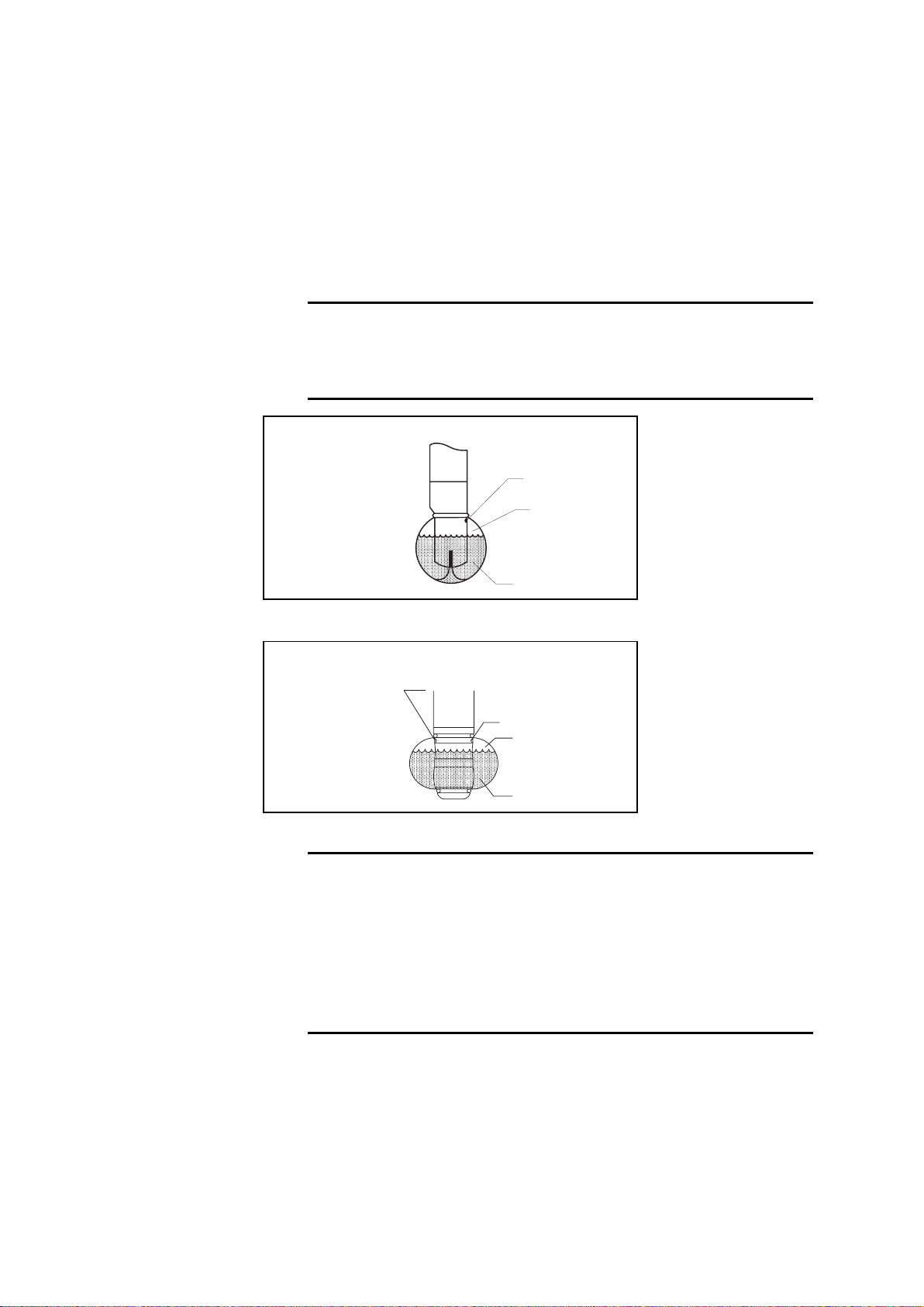

(1) EG-3870UTK

(2) Balloon Injection/

Evacuation Nozzle

(3) Air

(4) Sterile Water

Figure 2.16

Figure 2.17

If any air remains trapped within the balloon, it may be removed

as follows:

1) Position the endoscope distal end so that the entrapped air

2) Proceed to evacuate the excess air as described in the next

(1)

(2)

(3)

(4)

(1) EG-3670URK

(2) Balloon Injection

Nozzle

(3) Balloon Evacuation

Nozzle

(4) Air

(5) Sterile Water

(5)

rises above the water surface and is in contact with the

balloon evacuation nozzle. (Figure 2.19, 2.20)

section.

9) Emptying the balloon

a) To evacuate the contents of the balloon, connect tubing from a

regulated source of suction to the suction nipple located on the PVE

connector at the end of the umbilical cord.

b) When the suction/balloon suction valve (OF-B171) is depressed fully,

the contents of the balloon will be removed.

– 23 –

Page 27

10) Volume of water for distension of balloon

NOTE:

WARNING:

WARNING:

Z845 R22EEG 3670URK,

3870UTK.book

24

ジ

2022年5月30日

月曜日

午後12時59分

2022. 06 6217001 Z845 R22

Since an excessive volume of water may literally burst the balloon, the amount

of de-aerated sterile water injected should be kept down to a minimum.

NEVER reuse the LATEX balloons and their O-rings. They are

provided sterile for single patient use.

B. Procedures Using Water Immersion Method

1) Connect the scanning unit connector of the endoscopes to the ultrasound

scanning unit.

2) Via the instrument channel inlet located just below the control body, sterile

water can be injected to completely fill the stomach.

2-5. Preparation just before Insertion of Endoscope

Every endoscope should be properly disinfected or sterilized

before being used for the first time. The endoscope should have

been properly cleaned and disinfected or sterilized after any

previous use and after being returned for any repairs/service.

Current infection control guidelines require that endoscopes and

their patient contact accessories either be sterilized or at the

least be subjected to high-level disinfection.

Accessories which ENTER STERILE TISSUE or THE VASCULAR

SYSTEM must be sterilized before patient use. It is

recommended that any accessory intended for use in the biliary

tract be subjected to an appropriate sterilization process.

Only the user can determine if an instrument has undergone

appropriate infection control procedures prior to each clinical

use.

1) If the endoscope has just recently been reprocessed, has been prepared or

stored properly and passed all pre-procedure inspections, the instrument

should be ready for use. If necessary, the endoscope’s insertion tube may be

wiped down with a gauze dampened with 70-90% medical grade ethyl or

isopropyl alcohol.

2) Gently clean the objective lens with a cotton-tip applicator moistened with

70-90% medical grade ethyl or isopropyl alcohol. A lens cleaner (anti-

fogging agent) may also be applied via gauze or other applicator.

3) Check the endoscopic image and confirm that it is of acceptable quality for

clinical use. Refer also to the Instructions for Use provided with the

PENTAX video processor for inspection of the image quality.

4) Prior to trans-oral insertion of the endoscope, place a bite-block

(mouthpiece) into the patient’s mouth to protect the endoscope from

– 24 –

Page 28

damage during the procedure. Failure to do so can result in scratches, tears

NOTE:

WARNING:

WARNING:

Z845 R22EEG 3670URK,

3870UTK.book

25

ジ

2022年5月30日

月曜日

午後12時59分

Ultrasound Upper GI Video Scopes EG-3870UTK/EG-3670URK

and/or crushing of the insertion portion of the endoscope.

5) Apply a medical grade water soluble lubricant to the insertion tube. Do

NOT use petroleum based lubricants.

The objective lens must be kept free of the lubricant and excess

lens cleaner.

Ensure that only sterile water is used for water delivery (lens

washing) and balloon filling. Do NOT use tap water.

NEVER drop this equipment or subject it to severe impact as it

could compromise the functionality and/or safety of the unit.

Should this equipment to be mishandled or dropped, do NOT use

it. Return it to an authorized PENTAX service facility for

inspection or repair.

– 25 –

Page 29

3. DIRECTIONS FOR USE

WARNING:

CAUTION:

CAUTION:

Z845 R22EEG 3670URK,

3870UTK.book

26

ジ

2022年5月30日

月曜日

午後12時59分

2022. 06 6217001 Z845 R22

This instrument should only be used by physicians who have

thoroughly studied all the characteristics of this instrument and

who are familiar with the proper techniques of endoscopic

ultrasonography. During the procedure, always wear protective

garments such as gloves, gowns and face masks, etc. to

minimize the risk of cross contamination.

(Curved Linear Array Type : EG-3870UTK)

The PENTAX ultrasound endoscopes identified above are special

instruments that house a distal, precision transducer for

ultrasonic imaging. It must be recognized that compared to

conventional endoscopes, the distal end of these ultrasound

endoscopes contain a longer distal rigid section. This design

combined with its forward oblique optics in the distal end results

in the image not being in full endoscopic view. Only medical

professionals appropriately trained in EUS technique should

operate these devices and special care should be exercised when

using these instruments. Use caution during any movement or

angulation of the endoscope distal end and/or elevator (where

applicable) to avoid patient trauma, tissue damage and/or

perforation. NEVER apply excessive pressure of the endoscope

distal end against patient tissue.

(Radial Array Type : EG-3670URK)

The PENTAX ultrasound endoscopes identified above are special

instruments that house a distal, precision transducer for

ultrasonic imaging. It must be recognized that compared to

conventional endoscopes, the distal end of these ultrasound

endoscopes contain a longer distal rigid section. Only medical

professionals appropriately trained in EUS technique should

operate these devices and special care should be exercised when

using these instruments. Use caution during any movement or

angulation of the endoscope distal end to avoid patient trauma,

tissue damage and/or perforation. NEVER apply excessive

pressure of the endoscope distal end against patient tissue.

– 26 –

Page 30

3-1. Pretreatment

WARNING:

WARNING:

F

U

L

R

D

Z845 R22EEG 3670URK,

3870UTK.book

27

ジ

2022年5月30日

月曜日

午後12時59分

Ultrasound Upper GI Video Scopes EG-3870UTK/EG-3670URK

The patient should be prepared in your normal endoscopy regimen.

Please be advised that PENTAX balloons, supplied for endoscopic ultrasound

applications are made of latex material and thiuram and appropriate precautions,

are therefore, recommended.

Due to the potential severe allergic reactions to medical devices

containing latex (natural rubber), healthcare professionals are

encouraged to identify latex sensitive patients and be prepared

to treat allergic reactions promptly.

3-2. Insertion and Withdrawal

1) Slowly insert the endoscope under direct vision.

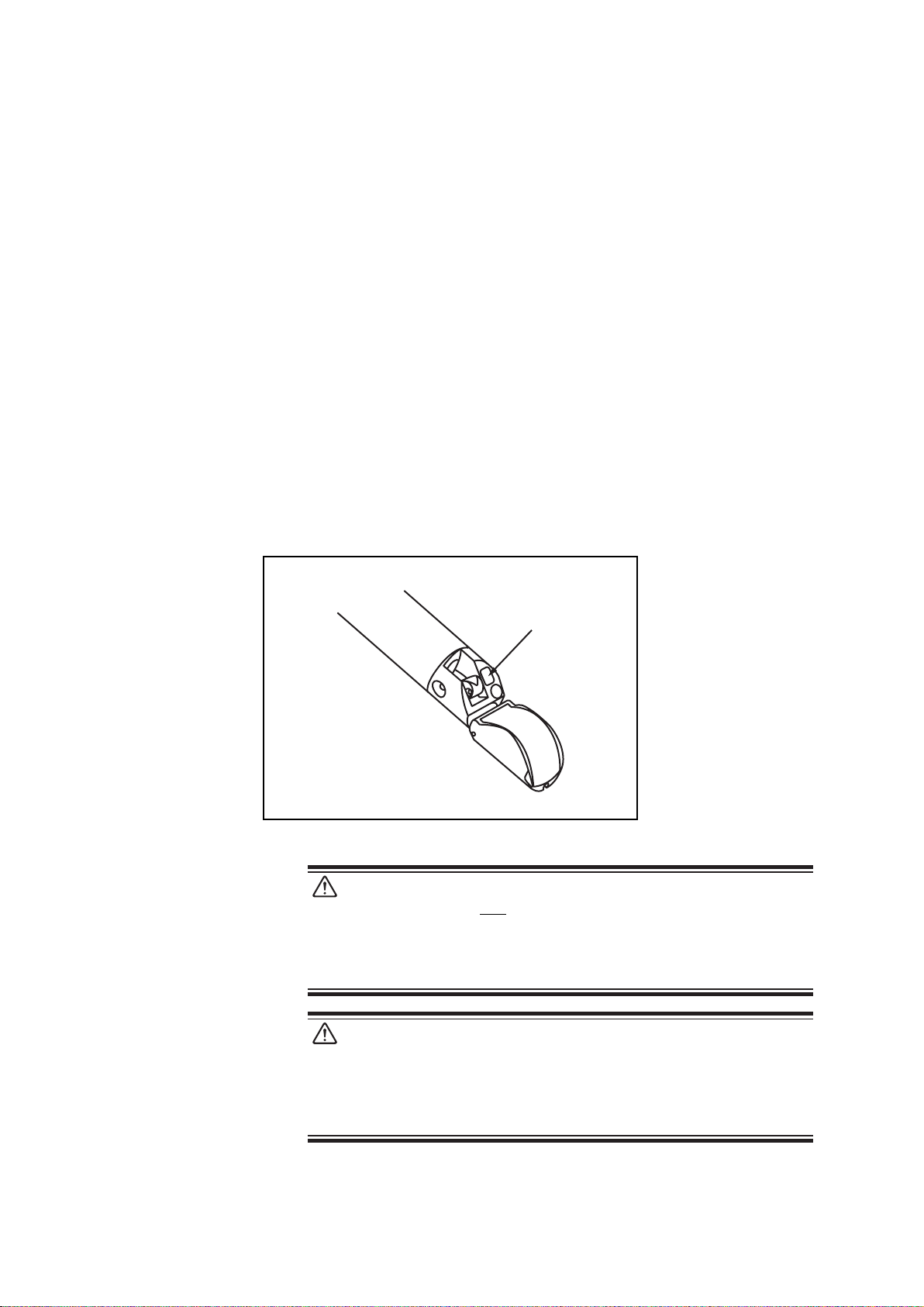

(1) Bite Block

(1)

Figure 3.1

2) When the distal end of the endoscope is passed through the pharynx, the

patient should be gently biting down on the bite block to maintain the bite

block’s position during the procedure.

3) Adjust the intensity of the video processor to obtain a brightness level

suitable for observation.

The light emission from the endoscope could cause thermal

injury. To minimize the risk, use only the minimum amount of

brightness and avoid close stationary viewing and unnecessary

prolonged use.

4) The angulation controls should be used as needed to position the endoscope.

Angulation of the distal end should be performed under direct vision in a

gentle and deliberate manner.

– 27 –

Page 31

CAUTION:

ANY lack of smooth operation of the angulation controls may be

NOTE:

WARNING:

WARNING:

Z845 R22EEG 3670URK,

3870UTK.book

28

ジ

2022年5月30日

月曜日

午後12時59分

2022. 06 6217001 Z845 R22

an early indication of internal damage to and/or part(s) failure

within the endoscope’s angulation system. To avoid the potential

for malfunction of the angulation system, do NOT use the

endoscope if the angulation mechanism does not operate

properly. Ensure that the angulation controls can rotate

smoothly, that there is no grinding or excess friction within the

angulation system and that the distal bending section bends

freely and smoothly.

NEVER APPLY EXCESSIVE FORCE TO THE ANGULATION

CONTROLS!

If during a procedure angulation is lost in any direction such as

when “cords snap” (broken pulley wire, broken angle wire, etc.),

do NOT continue to use the instrument and do NOT rotate the

angulation controls. Should the angulation system fail for any

reason, stop the procedure, release the lock lever/knob and

carefully withdraw the endoscope under direct visualization. The

examples above are indications that service is required to avoid

more serious problems with the angulation control system,

including the possibility of a “frozen” distal bending section. A

“frozen” bending section can make instrument extraction from a

patient more difficult.

5) Insufflation should be controlled by the combined use of the air/water/

balloon feeding valve (OF-B172) to increase the amount of insufflation and

the suction/balloon suction valve (OF-B171) to decrease the level of

insufflation.

Be careful not to deliver too much air.

It must be recognized that variations in air flow (pressure and

volume) for patient insufflation may exist from one

manufacturer’s equipment (light source, video processor and/or

endoscope type) to another. It is, therefore, important to closely

monitor the patient at all times and to aspirate excessive air to

prevent over insufflation and potential pneumatic perforation.

6) Mucous, fluids and/or other patient material should be aspirated via the

instrument/suction channel and suction/balloon suction valve (OF-B171) to

improve visualization. Maintain a clear view during aspiration, avoid

prolonged suction time and use the minimum level of negative pressure

required to perform the clinical procedure.

Do not push button down all the way (to second stage). This

would activate the Balloon Suction Channel and pull patient

fluids into it. The Instrument Channel must be used to perform

such aspiration.

– 28 –

Page 32

WARNING:

Do not apply excessively negative pressures (high suction

NOTE:

Z845 R22EEG 3670URK,

3870UTK.book

29

ジ

2022年5月30日

月曜日

午後12時59分

Ultrasound Upper GI Video Scopes EG-3870UTK/EG-3670URK

settings) and/or prolonged contact of the distal instrument

channel opening (distal end) against mucosal surfaces to avoid

“suction polyps”, bleeding and/or other trauma to the patient.

During aspiration keep as clear as possible an endoscopic view

of patient anatomy and maintain some distance from endoscope

distal end to tissue to avoid suctioning of mucosa onto/into the

distal channel opening.

The endoscope has a single, common channel for air/water

delivery and suction. Since all three functions occur within a

single channel, the following may be experienced when

alternating between these functions:

• A slight delay in air delivery with subsequent residual water

(fluid) flow may occur immediately after switching from water

(or from suction) to air activation. This flow of fluid is due to

the purging (emptying) of residual fluid from the common

internal channel.

• A slight delay in water delivery may occur if activated

immediately after air delivery (or after suction) due to filling

of the empty common internal channel occupied by air.

7) Image capture, hard copy documentation, video recording, etc. may be

carried out as necessary.

8) Guide the endoscope distal end to the area to be observed sonographically.

a) Balloon Method

In this method of sonographic imaging, sterile water-filled balloon is

placed in contact with the target area to be observed. Inflate the

balloon with de-aerated sterile water as previously explained in section

2-4 of this Instructions for Use entitled “PREPARATION BEFORE

THE EXAMINATION”.

b) Water Immersion Method

In this method of sonographic imaging, the distal end is placed in de-

aerated sterile water which acts as the transmission medium for the

ultrasonic signals. Via the instrument channel inlet, de-aerated sterile

water can be injected through the endoscope to completely fill the

stomach.

9) Following the Instructions for Use provided with the ultrasound scanning

unit, observe the sonographic image on the monitor, and obtain desired

photographic and/or video documentation as necessary.

– 29 –

Page 33

10) Relationship between direction of the ultrasound endoscope and the

(1)

EG-3670URK

(3)

(2)

(1)

(2)

(5)

(4)

(3)

Z845 R22EEG 3670URK,

3870UTK.book

30

ジ

2022年5月30日

月曜日

午後12時59分

2022. 06 6217001 Z845 R22

orientation mark on the image is shown below:

Figure 3.2

Figure 3.3

EG-3870UTK

(1)

(2)

(1) Orientation Mark Side

(2) Right-Left Orientation

Mark

(1) UP

(2) Orientation Mark Side

(3) Up-Down Orientation

Mark

(1) Up/Down Angulation

Lock Lever

Free Position (Lock

Released)

(2) Right/Left Angulation

Lock Knob

Free Position (Lock

Released)

(3) Lock Position

(4) Lock Position

(5) Top spoke of

Figure 3.4

angulation knobs in

this position

corresponds to neutral

distal end orientation

11) Before withdrawing the endoscope shrink the balloon by fully depressng

OF-B171 and then trapped air should be suctioned to reduce patient

discomfort by allowing OF-B171 to rise back up to its 1st stage position

(halfway up), thereby suctioning through the Instrument Channel.

– 30 –

Page 34

12) When attempting to withdraw the endoscope, return the angulation lock

WARNING:

NOTE:

CAUTION:

WARNING:

Z845 R22EEG 3670URK,

3870UTK.book

31

ジ

2022年5月30日

月曜日

午後12時59分

Ultrasound Upper GI Video Scopes EG-3870UTK/EG-3670URK

lever/knob to their free position. Always withdraw the endoscope under

direct visualization.

If for any reason, the image is lost due to power shortage, lamp

or processor failure, etc. the right/left angulation lock knob and

the up/down angulation lock lever should be released, the

endoscope distal end should be straightened to its neutral

position, and the insertion tube should be carefully and slowly

withdrawn from the patient.

3-3. Precise Accessory Control (For EG-3870UTK only)

The combination of endoscopic forward oblique optics, linear array ultrasound

imaging and a distal elevator gives users the ultimate control for precise

accessory applications. This unique capability allows users to maintain a view

(both endoscopic and sonographic) for pinpoint guidance of accessories such as

the aspiration needle. Once the accessory exits the distal instrument channel

opening, the accessory can be guided by the elevator, located on the proximal

control section of the endoscope.

Should resistance in passing the accessory be encountered at

the distal portion of the scope, gently pull back the accessory,

reduce the angle of the elevator, then re-advance the accessory.

If the elevator is not deflected at all, the accessory may not be

seen in the field of view since this instrument has 45° forward

oblique optic. It is recommended that the elevator be slightly

deflected so that the accessory exits the distal scope end and

advanced only under full view.

For ALL types of endoscopic accessory instruments, always

maintain a endoscopic view and sonographic view of the

accessory during advancement, use and withdrawal of the

device Otherwise it could result in patient injury such as

perforation.

– 31 –

Page 35

3-4. Biopsy

NOTE:

NOTE:

(1)

Z845 R22EEG 3670URK,

3870UTK.book

32

ジ

2022年5月30日

月曜日

午後12時59分

2022. 06 6217001 Z845 R22

Since these PENTAX video endoscopes in this Instructions for

Use contain a single channel (within the insertion tube) serving

as a common channel for delivery of air or water as well as

suction capability, it is recommended that water delivery should

NOT

be attempted WHILE an endoscopic accessory instrument is

inserted into the instrument/working channel. Under the

conditions described above, it is possible for fluid or water to

leak from the inlet seal/instrument channel inlet area. This is

due to the fact that the accessory device occupies the vast

majority of channel volume leaving very little open space

between accessory and channel for flow of water. If one insists

on activating water delivery while an accessory device is in the

channel, caution must be exercised as this expelled fluid may

contain patient material. As always for endoscopic procedures,

personal protective equipment should be worn and additional

protection such as covering the channel inlet with gauze or

similar means should be used to prevent potential exposure to

expelled fluids.

1) (For EG-3870UTK) Raise the elevator.

(1)

Figure 3.5

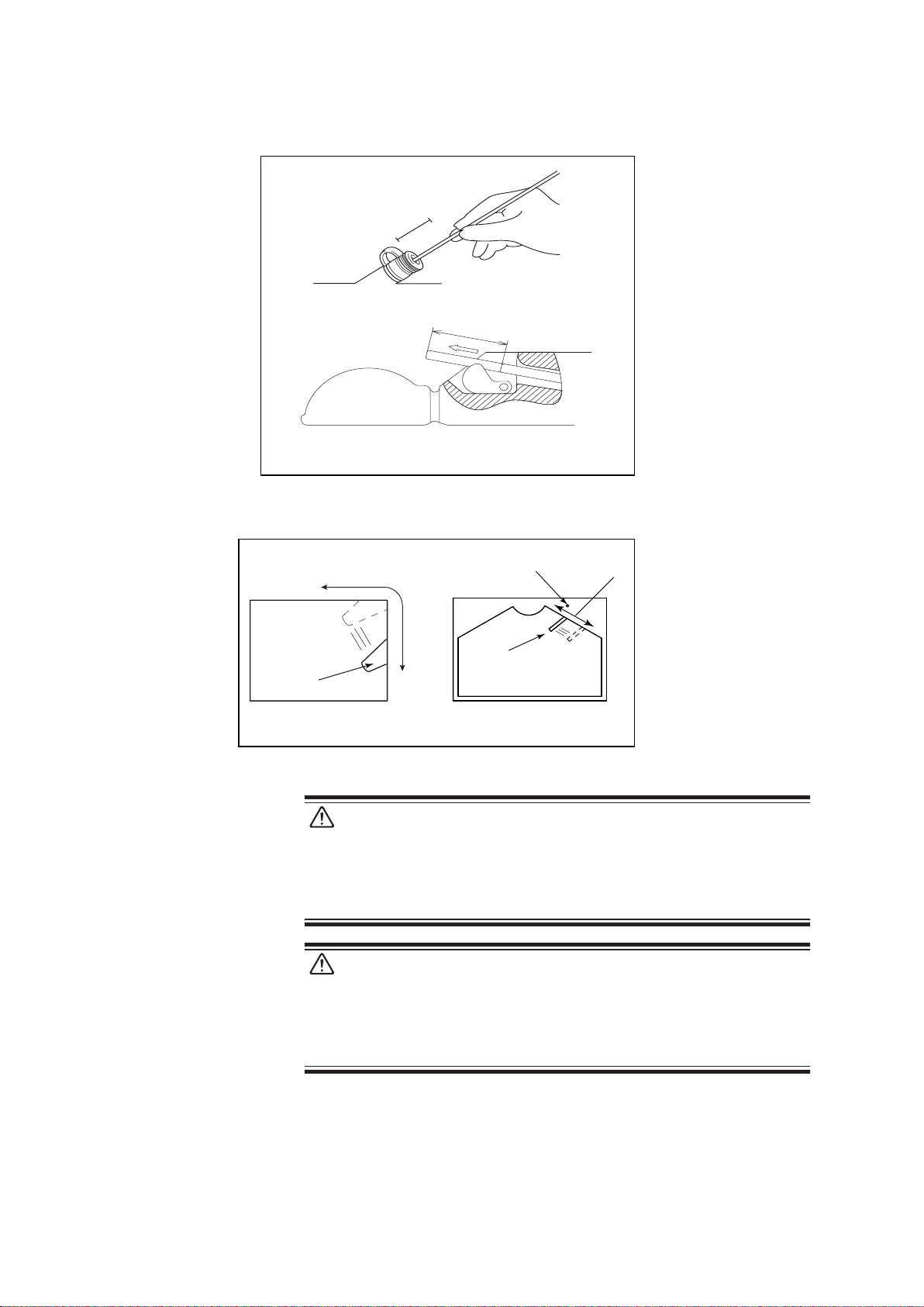

2) Insert the accessory through the slit in the inlet seal.

Figure 3.6

(1) Elevator

(1) 50 mm

When the tip of the accessory is first passed through the inlet

seal, a temporary resistance will be encountered. Hold the shaft

tightly at about 50mm from the tip of the accessory and push it

through.

– 32 –

Page 36

NOTE:

During insertion, if the accessory is found hard to advance

NOTE:

CAUTION:

(1)

(2)

(3)

(1)

(2)

(3)

Z845 R22EEG 3670URK,

3870UTK.book

33

ジ

2022年5月30日

月曜日

午後12時59分

Ultrasound Upper GI Video Scopes EG-3870UTK/EG-3670URK

further due to resistance, decrease the angulation of the

bending section to a level suitable for smooth insertion and

insert the accessory again.

Be certain to hold the forceps handle in such a way to ensure

that the cups/jaws of the forceps are in a fully closed position

during insertion.

NEVER apply excessive pressure when introducing any accessory

since the instrument channel may be damaged. Malfunction of

the endoscope as well as costly repairs may result.

3) (For EG-3870UTK) Insert accessory until reaching the elevator.

(1) Elevator

(2) Tip of the Accessory

(3) Cross section view of

the distal end

Figure 3.7

4) (For EG-3870UTK) The elevator should be lowered to allow accessory

advancement.

(1) Elevator

(2) Tip of the Accessory

(3) Cross section view of

the distal end

Figure 3.8

– 33 –

Page 37

5) When the tip of accessory extends about 10mm from the distal of the

WARNING:

WARNING:

(2)

(1)

(7)

(3)

(6)

(4)

(5)

Z845 R22EEG 3670URK,

3870UTK.book

34

ジ

2022年5月30日

月曜日

午後12時59分

2022. 06 6217001 Z845 R22

endoscope, the accessory appears in a endoscopic view and sonographic

view (See Figure 3.9, 3.10).

(1) about 10 mm

(2) Cross-section view of

the distal end

(1)

(1)

(2)

Figure 3.9

()

Figure 3.10

(1) Accessory appearence

area

(2) Tip of Accessory

(3) Endoscopic view

(4) Orientation mark side

(5) Tip of Accessory

(6) Sonographic view

(7) Accessory appearence

area

For ALL types of endoscopic accessory instruments, always

maintain endoscopic view and sonographic view of the accessory

during advancement, use and withdrawal of the device.

Otherwise it could result in patient injury such as perforation.

If the accessory doesn’t appear in endoscopic view and

sonographic view when the accessory is advanced over 15mm, it

may be necessary to repeat the procedure from step 1).

Otherwise it could result in patient injury such as perforation.

– 34 –

Page 38

WARNING:

Some kinds of accessories could be derailed from the elevator

CAUTION:

NOTE:

(1)

(2)

Z845 R22EEG 3670URK,

3870UTK.book

35

ジ

2022年5月30日

月曜日

午後12時59分