Page 1

Instructions for Use

PENTAX Medical Video Upper GI Scope EG29-i10c

Operation

EG29 - i10c

For cleaning, high-level disinfection, and sterilization of the product after use, refer to the

separate Instructions for Use (Reprocessing) with the model name of the endoscope.

Page 2

Page 3

Instructions for Use

This Instructions for Use (hereinafter referred to as “IFU”) contains essential information, such as operating

procedures and handling precautions, on using this endoscope safely and effectively. Before use, fully

understand the contents of, and properly follow, this IFU and the instruction manuals of all equipment that

are going to be used in combination. Do not use this endoscope for any purpose other than its intended

use.

In addition, review and fully understand the contents of the separate IFU for reprocessing (hereinafter

referred to as “IFU (Reprocessing)”). Inappropriate use of the product may result in damage to the

equipment or injuries, including, but not limited to, burns, electric shock, perforation, infection, and

bleeding.

This IFU does not describe specific endoscopic procedures. The specific procedures should be determined

according to the discretion of a medical professional.

If you have any questions or concerns about any information in this IFU, contact your local PENTAX Medical

service facility.

The content of the IFU may be changed without prior notice.

Unauthorized reproduction of any part of this IFU is prohibited.

Keep this IFU and all related instruction manuals in a safe, accessible location.

1

Page 4

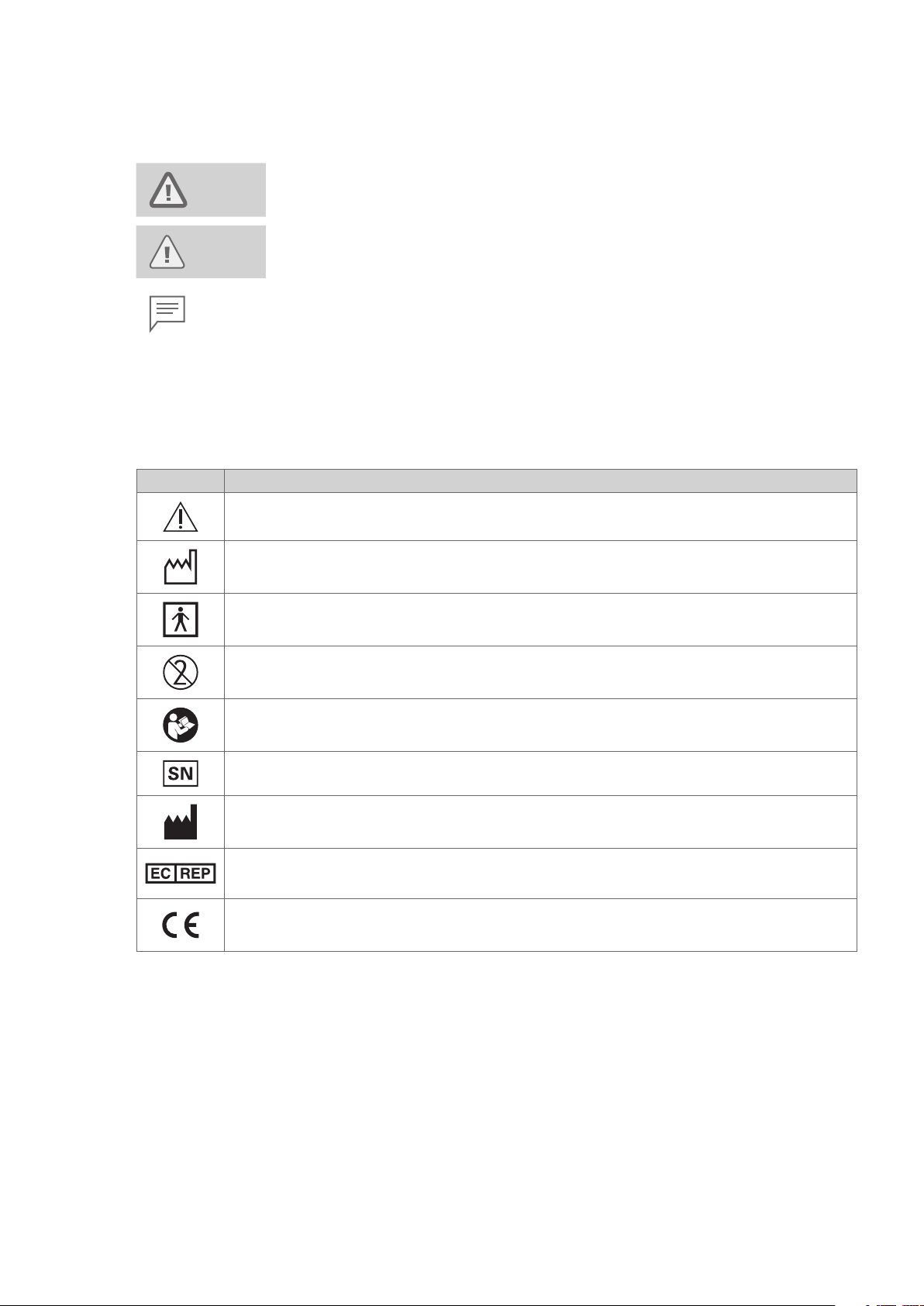

Signal words and symbols

Signal words

The following signal words are used throughout this IFU.

Warning

Caution

Indicates a situation that could result in death or serious injury if not avoided.

Indicates a potentially hazardous situation that could result in minor or moderate

injury or damage to equipment if not avoided.

Note Indicates supplementary or useful information regarding use.

Symbols

Symboles

The meaning(s) of the symbol(s) on the endoscope, accessories, and/or on their packaging are as follows:

Symbol Description

Caution

Attention

Year of Manufacture

Année de fabrication

Type BF applied part

Partie appliquee du type BF

Do not re - use

Ne pas reutiliser

Follow the Instructions for Use

Suivre les instructions d’utilisation

Serial Number

Numero de serie

Manufacturer

Fabricant

Authorized representative in the European Community

Representant autorise dans I’Union europeenne

This product complies with the applicable standards harmonised under the Directive 93/42 / EEC and Directive

2011 / 65EU.

Ce produit est conformé aux normes harmonisées au titre de la Directive 93/42 / CEE et la Directive 2011 / 65EU

2

Page 5

3

Page 6

Contents

Instructions for Use

Signal words and symbols

................................................................................

.......................................................................

Important information: Please read before use

Product summary

Intended use

Application

Classification

Specifications

Compatible products

Reprocessing before initial use/Reprocessing / Storage after use

General warnings and cautions

Maintenance management

.............................................................................................................

1 Package contents

.....................................................................................................

...........................................................................................................

...........................................................................................................

..........................................................................................................

.................................................................................................

....................................................................................

........................................................................................

.............................................................................

.............................................

..........................................

1

2

6

6

6

6

7

7

8

10

12

13

14

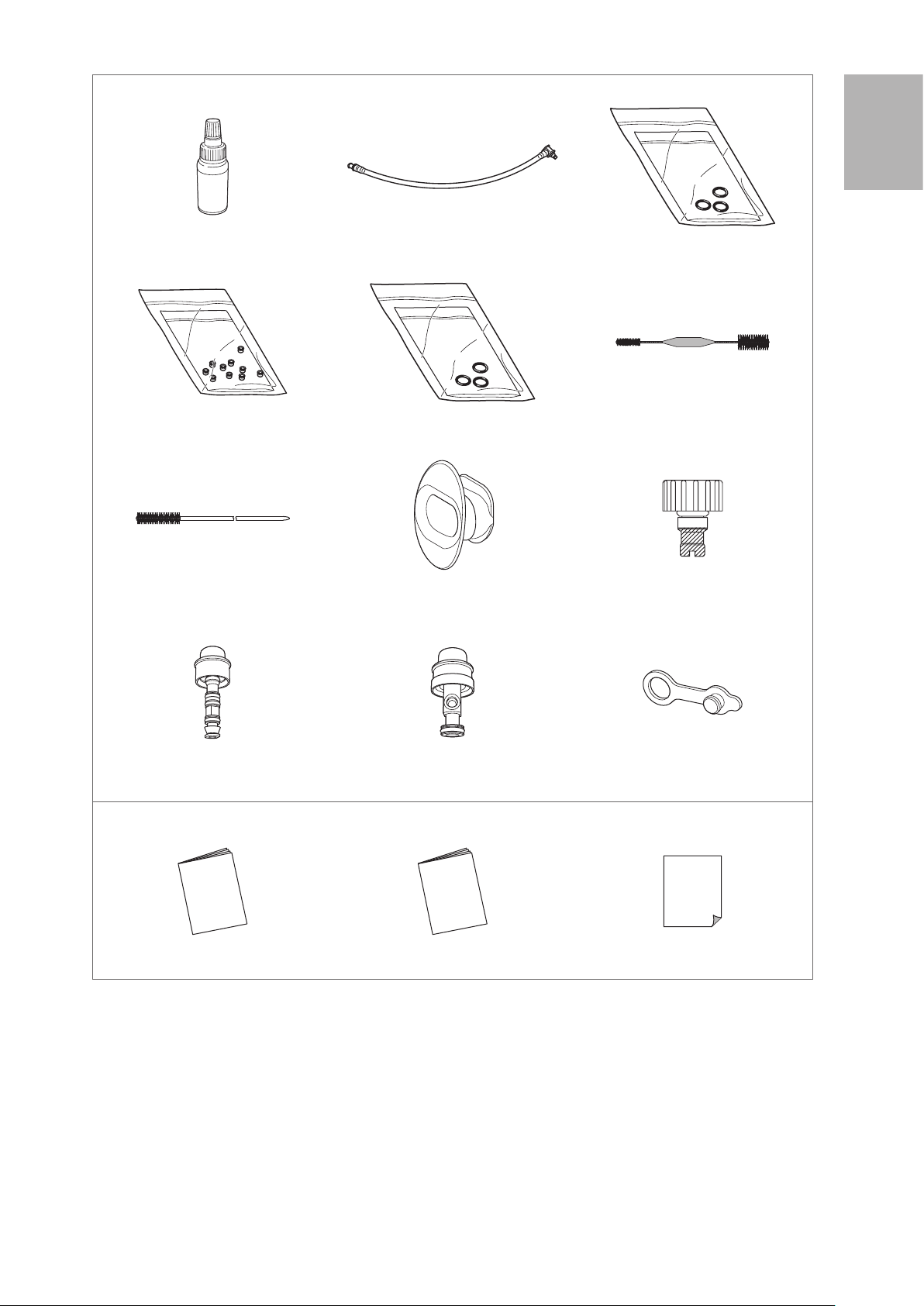

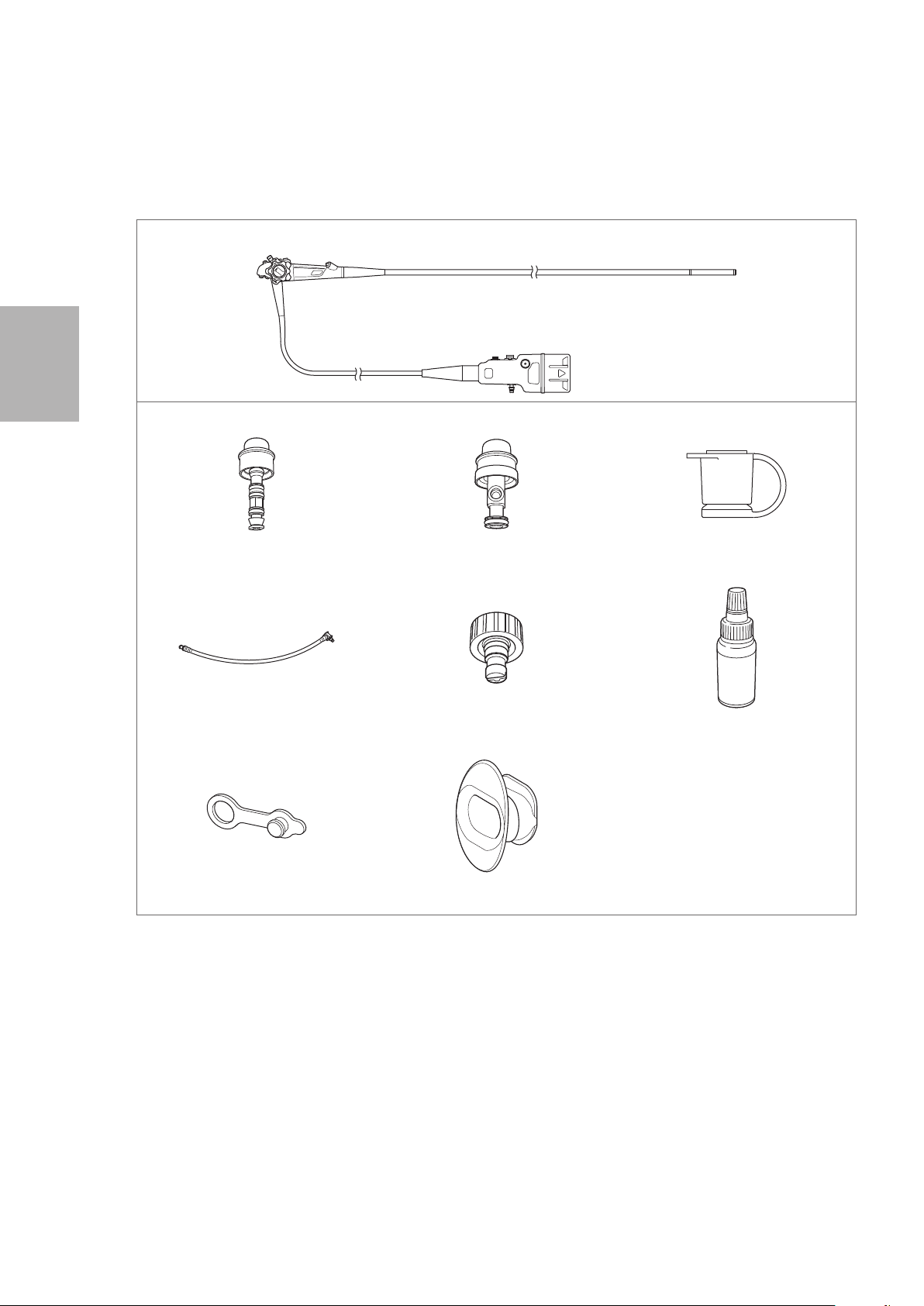

1-1. Package contents

2 Nomenclature and functions

2-1. Control body and insertion portion

2-2. Scope connector

3 Preparation and inspection

3 - 1. Preparation of the equipment

3 - 2. Inspection of the endoscope

3 - 3. Inspection of accessories and attachment to the endoscope

3 - 4. Inspection and connection of ancillary equipment to the endoscope

3 - 5. Inspection of the endoscopic system

4 Directions for use

4 - 1. Preparation immediately before insertion of the endoscope

4 - 2. Insertion and observation

4 - 3. Using an endoscopic device

4 - 4. Using a nonflammable gas

4 - 5. Laser cauterization

4 - 6. Electrosurgery

4 - 7. Withdrawal of the endoscope

4 - 8. Care after use

.............................................................................................

...............................................................

........................................................................

..............................................................................................

.................................................................

..............................................................................

...............................................................................

.....................................................................

.............................................................................

...................................................................................

................................................................................

..................................................................................

...........................................................................................

.................................................................................................

..............................................................................

.................................................................................................

........................................

..............................

.........................................

14

16

16

18

19

20

22

30

42

46

57

59

60

64

67

69

70

71

72

4

Page 7

5 Troubleshooting

...............................................................................

75

5 -1. Troubleshooting guide

5 -2. Withdrawal of an endoscope with an abnormality

5 - 3. Returning the endoscope for repair

Disposal

.............................................................................................

Electromagnetic compatibility (EMC)

Electromagnetic disturbances

Endoscope specifications

System chart

.......................................................................................

.......................................................................................

.......................................................................

.......................................................

.................................................................

.......................................................................

.....................................................

76

79

80

81

82

85

89

90

5

Page 8

Important information: Please read before use

Product summary

This endoscope is inserted transorally. It visualizes subjects under illumination of the LED (light emitting

diode) at the distal end of the endoscope with a solid -state image sensor located at the distal end of the

endoscope and provides images for observation of the target anatomy through the images reproduced on

the video monitor via the video processor.

It can be used with endoscopic devices which are introduced from the instrument channel inlet of the

control body.

The endoscope also allows for angulation operation of the bending sections via operation of the angulation

control knob; air/ water feeding from the distal end of the endoscope via operation of the air/water feeding

valve; and suction through the channel at the end of the endoscope via operation of the suction control

valve.

Intended use

The PENTAX Medical Video Upper GI Scope EG29 - i10c is intended to provide optical visualization of (via

a video monitor), and therapeutic access to, the upper gastrointestinal tract. This anatomy includes, but is

not restricted to, the organs; tissues; and subsystems: esophagus, stomach, and duodenum.

This endoscope is introduced via the mouth when indications consistent with the need for the procedure

are observed in adult and pediatric patient populations.

Application

Medical purposes Provide images for observation, diagnosis, visualization, and treatment.

Patient population

Intended anatomical area Upper gastrointestinal tract (esophagus, stomach) duodenum

User qualifications

Location of use A medical facility (including the place where the high frequency generator is used)

Patients who are considered suitable for the application of this endoscope by the physicians (pediatric

to adult patients).

Physicians (Experts who have been approved by the endoscopic medical safety administrator at each

medical facility. If the eligibility requirements are defined by an official body, such as a government

entity and / or an academic society, follow such requirements).

Specific training to use this endoscope is not required of personnel who have been trained to use

other endoscopes of this type.

6

Page 9

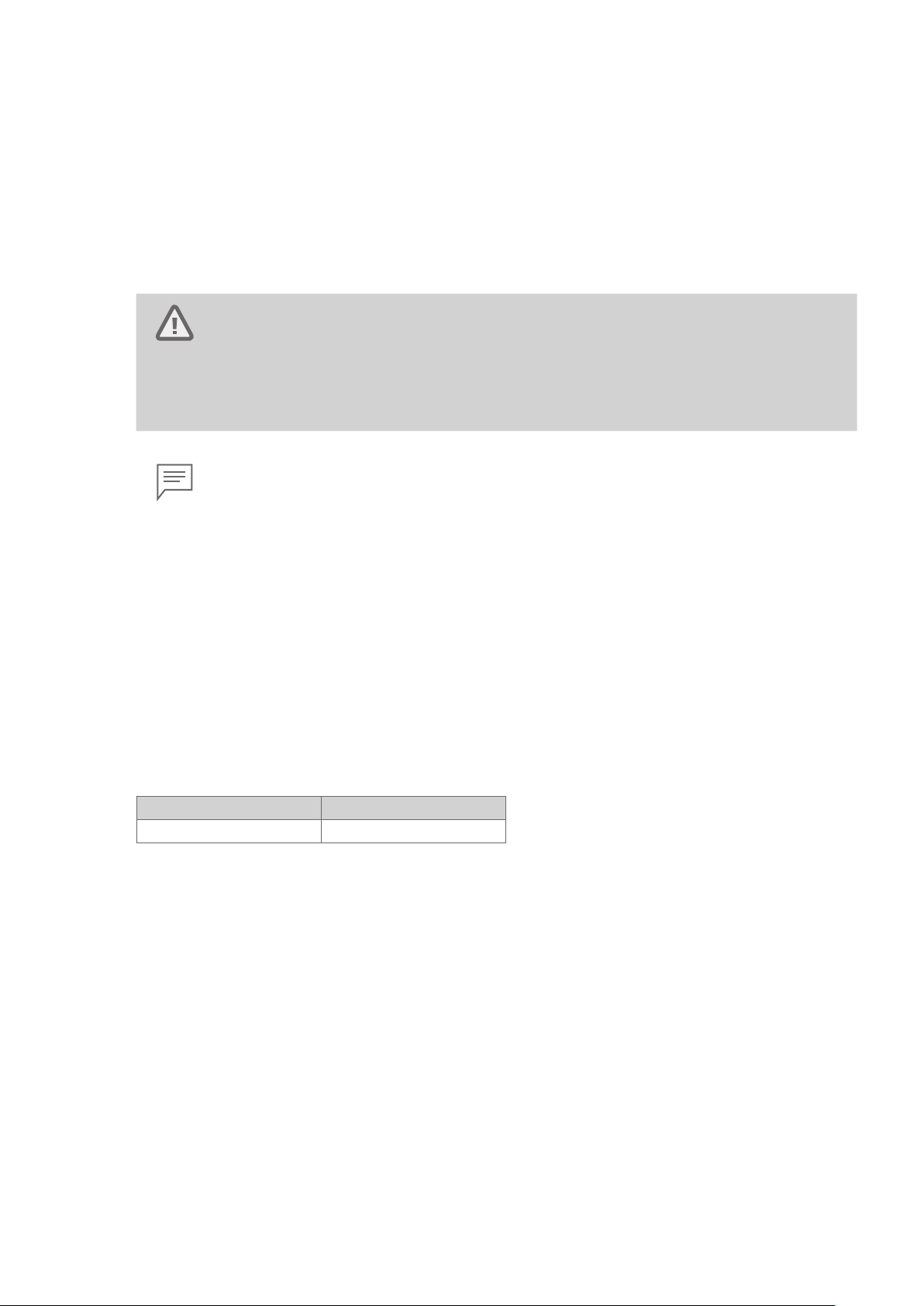

Classification

Degree of protection against electric shock for

the applied parts

Degree of protection against water IPX7

Mode of operation Continuous operation

TYPE BF applied part (when connected to a compatible PENTAX Medical video

processor)

Specifications

█

Environment

Ambient temperature 10 to 40 ºC

Operating environment

Storage / transportation environment

█

Software version

Refer to the back cover for the software version by model(s).

Relative humidity 30 to 85 %RH

Air pressure 700 to 1,060 hPa

Ambient temperature -20 to 60 ºC

Relative humidity 10 to 85 %RH

Air pressure 700 to 1,060 hPa

█

Endoscope specifications

For details, refer to “Endoscope specifications” (p. 89).

7

Page 10

Compatible products

This section describes the equipment that can be used in combination with this endoscope. For more

details, refer to “System chart” (p. 90).

For the equipment used in combination during cleaning/ high - level disinfection/sterilization, refer to the

separate IFU (Reprocessing) of this endoscope.

The combinations of equipment and accessories that can be used with this product are listed below.

Prior to use, the product must be prepared and inspected according to its IFU.

Warning

PENTAX Medical does not warrant compatibility with unlisted products. If products are not

listed, contact the manufacturer of the equipment or accessory to confirm the compatibility and

instructions for use with PENTAX Medical products.

Note

• When this endoscope is used in combination with other equipment, depending on how it is

connected, it may result in malfunction and/or unforeseen events to patients and/or medical

professionals. Pre- use operation checks and risk management associated with such changes

are recommended, particularly when the equipment used in combination is changed, added,

or upgraded.

• Some products are not available depending on the sales region. For details, contact your local

PENTAX Medical service facility.

█

Video processor

Video processor models that can be connected with these endoscopes are shown below. For instructions

on video processor operation, refer to the IFU of the video processor.

Model Name Brand Name

EPK- i5500c PENTAX Medical

8

Page 11

█

Endoscopic device

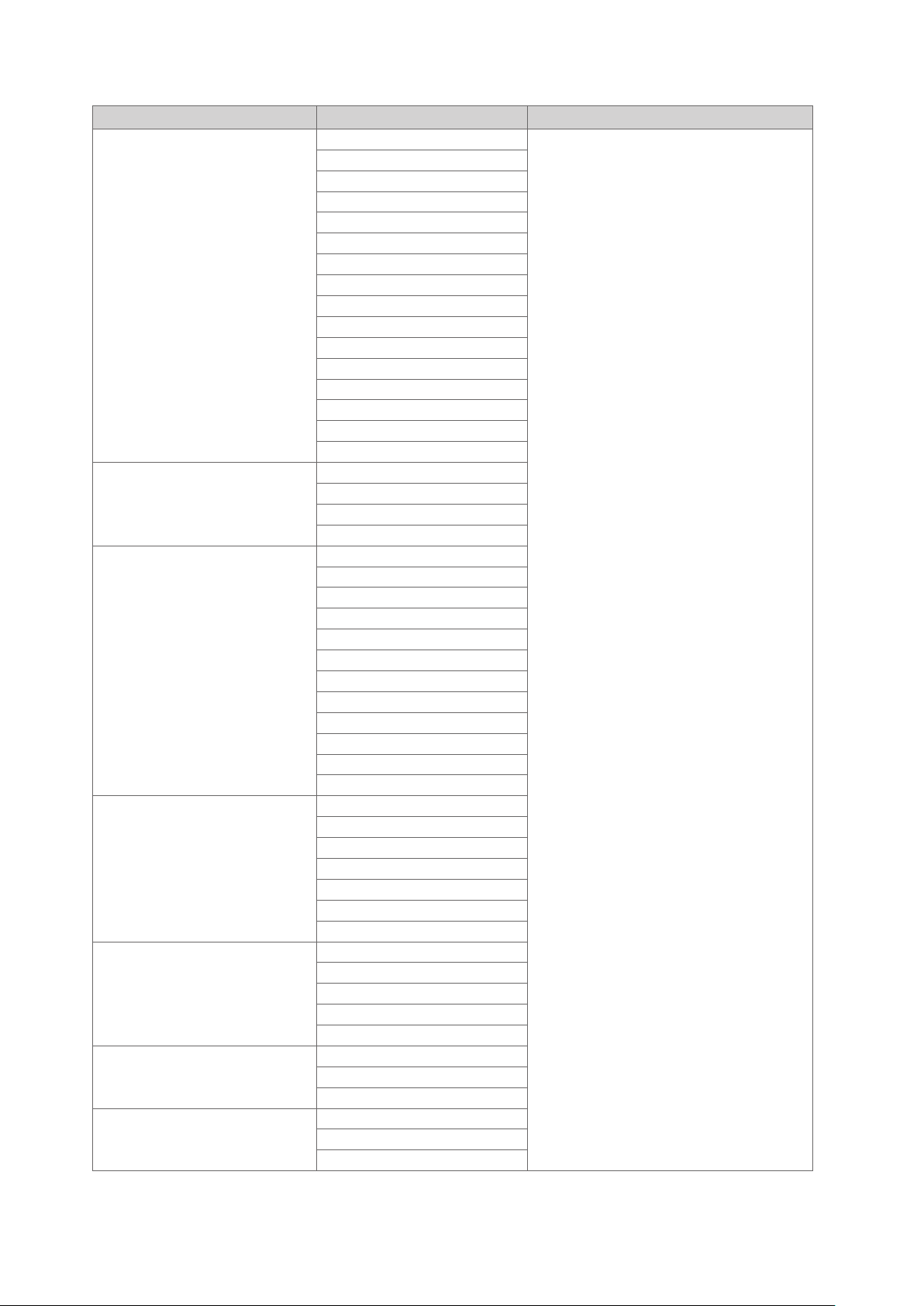

Category Model Name Brand Name

Biopsy Forceps

Retrieval Basket

Injection Needle

Electro - Surgical Snare

Electro - Surgical Knife

Electro - Surgical Hemostasis Forceps

Spray Catheter

KW - D1816

KW - D2416T

KH - D2416T

KA - D2416T

KB - D2416T

KA1815S

KA2415S

KH2415S

KH2418CS

KS1022CS

KW1815S

KW1818CS

KW2215S

KW2218CS

KW2415R

KW2415S

GB - D1819L020

GB - D2415L030

GB - D2419L020

GB - D2423L035

NI - D1816 - T2304

NI - D1816 - T2305

NI - D1816 - T2306

NI - D1816 - T2308

NI - D2416 -T2304

NI - D2416 -T2306

NI - D2423 -T2305

NI - D1816 - T2504

NI - D1816 - T2505

NI - D2416 -T2504

NI - D2416 -T2505

NI - D2416 -T2506

DO - D2416 -15

DO - D2416 -20

DO - D2416 -25

DH - D2416 -15

DH - D2423- 20

DH - D2416 - 25

DO - D2618

DN - D2718A

DC - D2618

DP - D2518

DP - D2622

DN - D2718B

H - S2518

HS - D2618

HDB2418W

TJ - D2418PB

TJ1817WS

TJ2417WS

PENTAX Medical

9

Page 12

█

Other ancillary equipment

For instructions, refer to the respective manual provided with each equipment.

Category Description Model Name Brand Name

Irrigation Pump

CO² Insufflator EGA - 501P

High Frequency Generator VIO Series

EGA Series

EGA - 500P

VIO 300D

VIO 200S

PENTAX Medical

ERBE

Reprocessing before initial use/Reprocessing/Storage after use

█

Reprocessing before the initial use

Warning

The endoscope identified in this IFU is a reusable semi- critical device.

Since it endoscope and accessories are packaged non- sterile, they must be cleaned and high

level disinfected, or cleaned and sterilized according to the separate IFU (Reprocessing) of this

product before initial use as well as after each procedure and after repair. Insufficient reprocessing

may increase the risk of cross contamination.

Note

The wording "high- level disinfection" in this IFU defines the disinfection of the endoscope and the

accessories with a completely virucidal disinfectant.

█

Reprocessing

Warning

When using an endoscope and its accessories on patients with Creutzfeldt- Jakob disease (CJD)

or variant Creutzfeldt- Jakob disease (vCJD), use only dedicated instruments and equipment. The

instruments and equipment used on these patients must be discarded so that they can NOT be

used again on another patient. The pathogenic agents that cause this disease, which are called

“prions”, can NOT be destroyed or inactivated using the cleaning, disinfection, and sterilization

methods presented in this IFU. Please consult the guidelines that apply to your country or region

for more detailed information regarding the handling of prion- contaminated instruments.

10

Page 13

█

Storage after use

Warning

Observe the following guidelines. Failure to do so may result in contamination of the endoscope

with bacteria or pose a risk of infection to patients and/or users.

– Ensure that all removable accessories, such as air/ water feeding valve, suction control

valve, inlet seal, and cleaning adapter are removed from the endoscope when storing.

– Do NOT store the endoscope in areas of high humidity or high temperature.

– Do NOT store the endoscope, its components, and accessories in the carrying case.

– Ensure that the endoscope, its components, and accessories are completely moisture -

free before storage.

– Before the next use, the endoscope, its components, and accessories that have been

stored inappropriately or for a prolonged period of time must be subjected to appropriate

cleaning, high - level disinfection, and / or sterilization processes according to the separate

IFU (Reprocessing).

Caution

Observe the following precautions when storing the endoscopes, its accessories, or device.

Failure to do so may result in damage to property.

– Endoscope insertion portion, umbilical cord, and endoscopic devices should be kept as

straight as possible during storage.

– Keep away from chemicals, direct sunlight, or ultraviolet rays.

– Do NOT store the endoscope and its accessories in such a way that they might be

damaged due to contact with other devices.

Note

It is recommended to store the endoscope hanging down straight in a well- ventilated room or

cabinet dedicated for endoscope storage.

For storage after use, also refer to the separate IFU (Reprocessing) of this endoscope.

11

Page 14

General warnings and cautions

Warning

• The medical facility should determine whether or not to conduct an endoscopic examination

in patients determined to have lowered immunity.

• Do NOT use this endoscope with equipment other than those that have been specified for

combined use. Doing so may result in damage to the endoscope and patient injury.

• Do NOT drop the endoscope onto a hard surface or subject it to severe impact. This applies

particularly to the distal tip lens. Doing so may negatively impact image quality.

• Ensure to attach/connect an appropriate device to the connectors of the scope connector

such suction nipple, air/ water port, water jet port, or venting connector according to the IFU.

Incorrect connection or inappropriate use may result in unforeseen events.

• Always check the endoscopic image during endoscope angulation, air/ water feeding, and

suctioning, use of endoscopic devices, and endoscope insertion and withdrawal. Ensure that

these operations are performed in the normal (non- frozen, non -magnified) mode. Endoscope

peration in the freeze or magnification mode may result in damage to the endoscope and/or

patient injury.

• Do NOT forcefully insert and withdraw the endoscope. Doing so may result in patient injuries,

including bleeding and perforation.

• Do NOT perform retroflexed observations inside a narrow lumen. Doing so may cause patient

injury or make it impossible to withdraw the endoscope.

• After using operational/cleaning accessories (e.g., forceps, needles, snares, brushes, etc.)

with the endoscope, carefully check that all accessories are intact and that no parts have fallen

off and become lodged within the endoscope’s instrument/suction channel. Furthermore,

ensure that any endoscopic devices (e.g., clips, stents, etc.) passed through the channel

are accounted for after use. If the instrument / suction channel becomes blocked or clogged

due to the accumulation of debris, an accessory that can NOT be removed, or other cause,

do NOT attempt to correct the blockage or continue to use the endoscope. In such a case,

contact your local PENTAX Medical service facility to have the endoscope repaired. The use

of an endoscope with a blocked internal channel may result in ineffective reprocessing and/

or the introduction of debris and / or device components into a patient during a subsequent

procedure, posing a risk of cross contamination.

• This product is intended to be used in the electromagnetic environment specified by

"Electromagnetic disturbances". Using the product in an unintended environment may result

in incorrect exposure control of the light emitted from distal end of the endoscope due to

electromagnetic interference.

12

Page 15

Caution

• Users as well as the assisting personnel should always wear protective equipment (e.g.,

gloves, goggles, masks, medical gowns, etc.) to minimize the risk of cross contamination, as

patient's body fluids may be dispersed from instrument components such as the instrument

channel inlet and the suction control valve.

• Do NOT forcefully attach an accessory to the endoscope. Doing so may result in damage to

the endoscope.

• Do NOT excessively twist, rotate, or bend any of the insertion portions, strain relief boots, or

umbilical cord. Doing so may damage the endoscope.

• Do NOT hit the remote buttons with hard objects or pull or twist them. Doing so may cause

internal damage to the endoscope that may lead to water leaks.

• Do NOT attach or remove the scope connector of the endoscope while the power of the

video processor is turned on. Doing so may damage the endoscope.

• Electromagnetic interference may occur with equipment labeled with the following symbol

or near mobile RF communication equipment such as mobile phones. If electromagnetic

interference occurs, reorient or relocate the endoscope or shield the location of use.

Maintenance management

The service life of this endoscope is 6 years after date of shipment with the following conditions.

• Perform inspection before use, care after use, storage, and replacement of consumables according to

this IFU.

• Have a specialist specified by PENTAX Medical perform repairs and at least annual periodic inspections.

13

Page 16

1

1

Package contents

Package contents

1-1. Package contents

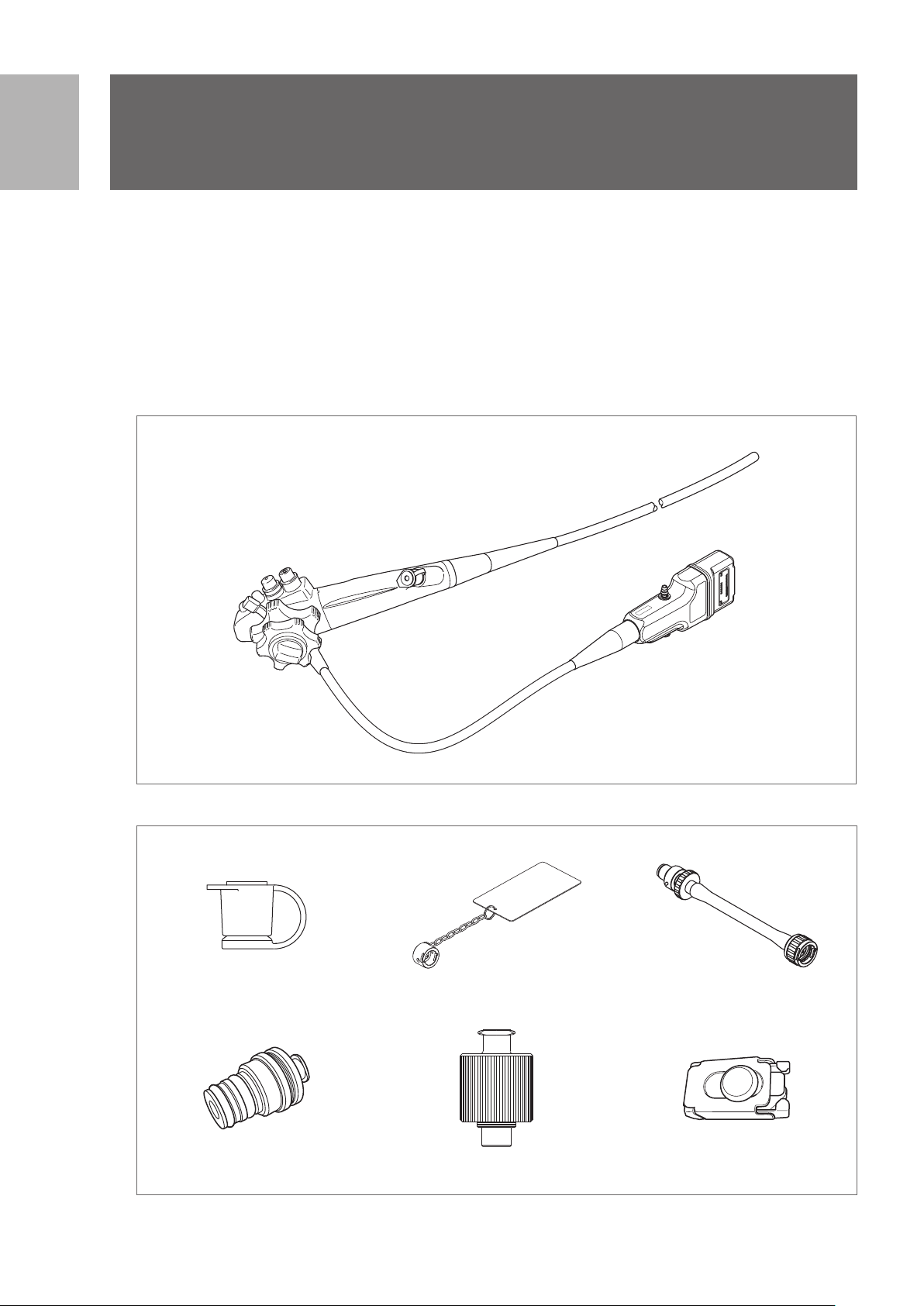

Check the package contents according to the separate Standard Accessories List provided with this

product. For detail picture of the contents/accessories, refer to Figure 1.1 and 1.2.

If there are any damaged or missing components, do not use the endoscope. Immediately contact your

local PENTAX Medical service facility.

Endoscope

EG29 - i10c

Figure 1.1

Accessories

Inlet Seal (OF - B190)

(Installed)

Cleaning Adapter (OF - G17) Cleaning Adapter for Water Jet

Figure 1.2

Ventilation Cap (OE- C28) Venting Connector Adapter (OE- C29)

Connector (OE - C20)

Cleaning Adapter

(OF - B153)

14

Page 17

Accessories

Silicone Oil (OF - Z11) Irrigation Tube (OF - B113) O Ring Set (OF -B192*)

* For Air/ Water Feeding Valve (OF- B188)

1

Package contents

Check Valve Sets (OE- C15) O Ring Set (OF - B127**)

** For Suction Control Valve (OF - B120)

Cleaning Brush (CS5522A) Bite Block (OF-Z5) Water Jet Check Valve Adapter

Air/ Water Feeding Valve (OF - B188)

(Installed)

Others

Suction Control Valve (OF- B120)

(Installed)

Cleaning Brush (CS - C13A)

(OE - C12) (Installed)

Water Jet Connector Cap (OF- B118)

(Installed)

IFU (Operation; this document) IFU (Reprocessing) Standard Accessories List

Figure 1.2

15

Page 18

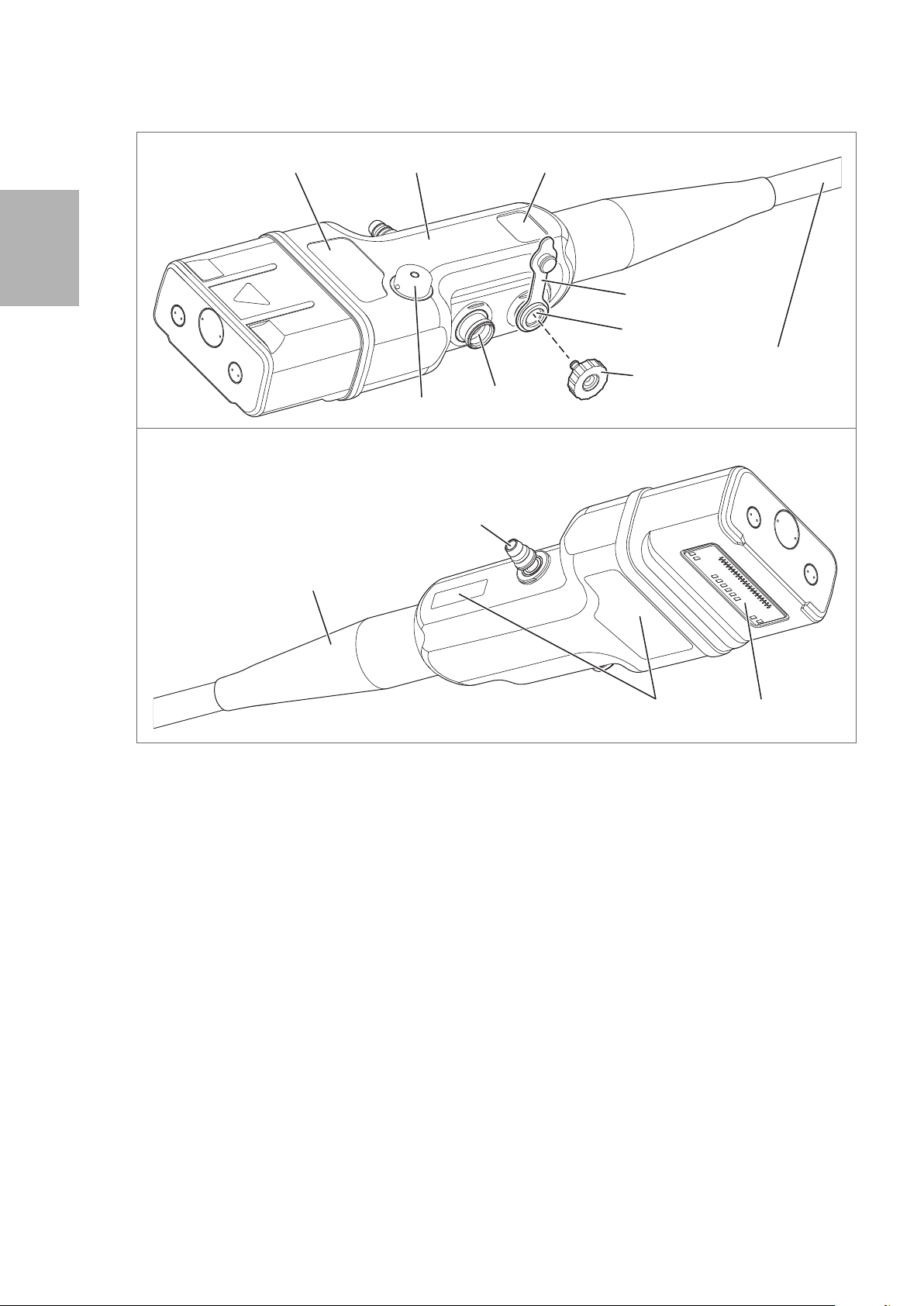

2

7

2

Nomenclature and functions

2-1. Control body and insertion portion

Nomenclature and functions

1

10

3

9

Alternative view

1

2

4

Control Body

13

5

10

12

11

Insertion Portion

(Endoscope

components that

come into direct

contact with the

patient.)

Distal End

Bending

Section

Figure 2.1

16

6

8

Insertion Tube

Page 19

1. Remote Buttons 1- 4

Functions assigned to each button can be remotely controlled by pressing each of the remote buttons.

Functions of the remote buttons 1- 4 are assigned from the video processor.

Refer to the IFU of the video processor for assignment of functions to each remote button.

2. Up / Down Angulation Control Knob

By turning in the “▲U” direction, the bending section moves upwards.

By turning in the “▲D” direction, the bending section moves downwards.

3. Up / Down Angulation Lock Lever

By turning counterclockwise, upward/downward bending of the bending section is locked.

By turning in the “F ►” direction, the bending lock is released.

4. Right /Left Angulation Control Knob

By turning in the “▲R” direction, the bending section moves to the right.

By turning in the “▲L” direction, the bending section moves to the left.

5. Right /Left Angulation Lock Knob

By turning counterclockwise, right / left bending of the bending section is locked.

By turning in the “F ►” direction, the bending lock is released.

6. Suction Cylinder

Attach the suction control valve (OF- B120).

7. Suction Control Valve (OF- B120)

Attach to the suction cylinder. Depress it to suction fluids or air through the instrument channel of the

endoscope.

8. Air / Water Feeding Cylinder

Attach the air/water feeding valve (OF - B188) or the optionally available gas/ water feeding valve (OF-

B194).

9. Air / Water Feeding Valve (OF-B188)

Attach to the air/water feeding cylinder. Covering the hole on the valve button feeds air to the air/ water

nozzle at the distal end of the endoscope. Depressing the valve button feeds water to the air/ water

nozzle at the distal end of the endoscope.

10. Strain Relief Boot

The strain relief boot protects the connecting parts.

11. Instrument Channel Inlet

The instrument channel inlet is an inlet for endoscopic devices. Attach the inlet seal (OF- B190).

12. Inlet Seal (OF - B190)

The inlet seal is attached to the instrument channel inlet to avoid fluid / air leakage.

13. Model Name Label

The model name label shows the model name, minimum instrument channel width, and other related

information.(Figure 2.2)

2

Nomenclature and functions

EG29-i10c

Figure 2.2

Minimum Instrument Channel Width

3.2

Model Name

17

Page 20

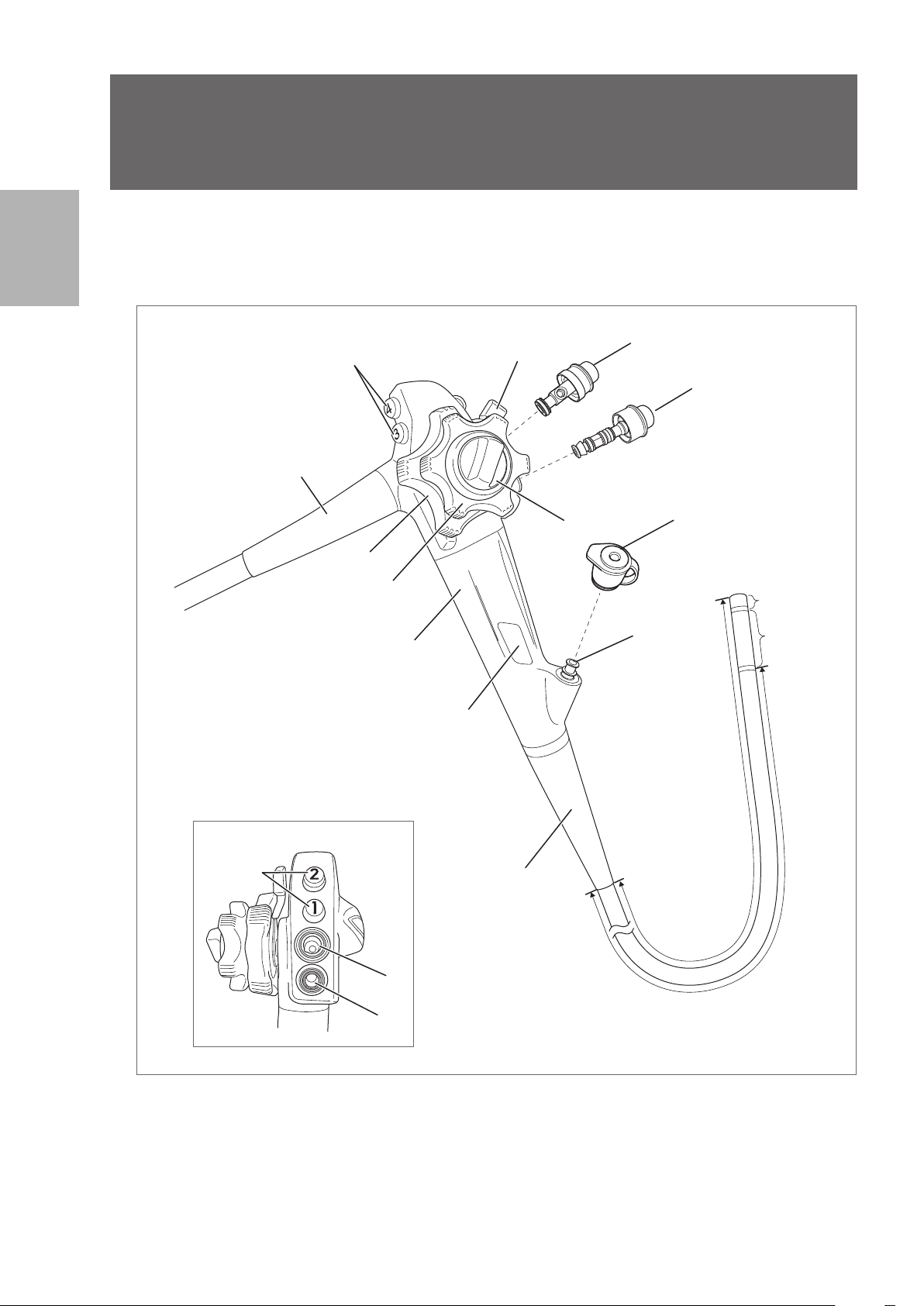

2-2. Scope connector

2

Model Name

Country of Origin

Nomenclature and functions

Alternative view

10

Scope Connector

18

14

Serial Number

Date of Manufacture

Water Jet Connector Cap

(OF - B118)

16

Umbilical Cord

17

15

Electrical ContactsManufacturer Label

Figure 2.3

14. Suction Nipple

Connect the suction tube on the suction source to the suction nipple.

15. Air/ Water Port

Connect the air/ water feeding hose on the water bottle assembly to the air/ water port.

16. Water Jet Port

Attach a water jet check valve adapter (OE- C12).

1 7. Water Jet Check Valve Adapter (OE- C12)

Use it by attaching to the water jet port.

Connect the irrigation tube (OF- B113) to send sterile water from a syringe or irrigation pump to the

water jet nozzle at the distal end of the endoscope.

When an irrigation tube is not connected, close it with the water jet connector cap (OF- B118).

18. Venting Connector

Attach the ventilation cap (OE- C28) or leakage tester via the venting connector adapter (OE - C29)

here.

18

Page 21

3

Before use, the endoscope, accessories, video processor, and other components must be prepared and

carefully inspected according to the IFU. Any equipment used in combination with the endoscope must also

be prepared and inspected according to the respective instruction manuals.

Always perform pre - use inspection before each use.

Preparation and inspection

Refer to “5 -1. Troubleshooting guide” (p. 76) for assistance in diagnosing an endoscope malfunction. If the

problem persists after troubleshooting or there is an apparent failure, do not use the endoscope. Send it for

repair according to “5- 3. Returning the endoscope for repair” (p. 80).

Warning

• Always perform pre - use inspection before each use. NEVER use an endoscope with a suspected

abnormality. Doing so may result in malfunction, endoscope damage, and / or injury to the patient

and / or user.

• Ensure that another endoscope is also prepared to avoid interruption of the procedure due to

endoscope failure or unforeseen events.

3

Preparation and inspection

19

Page 22

3

3-1. Preparation of the equipment

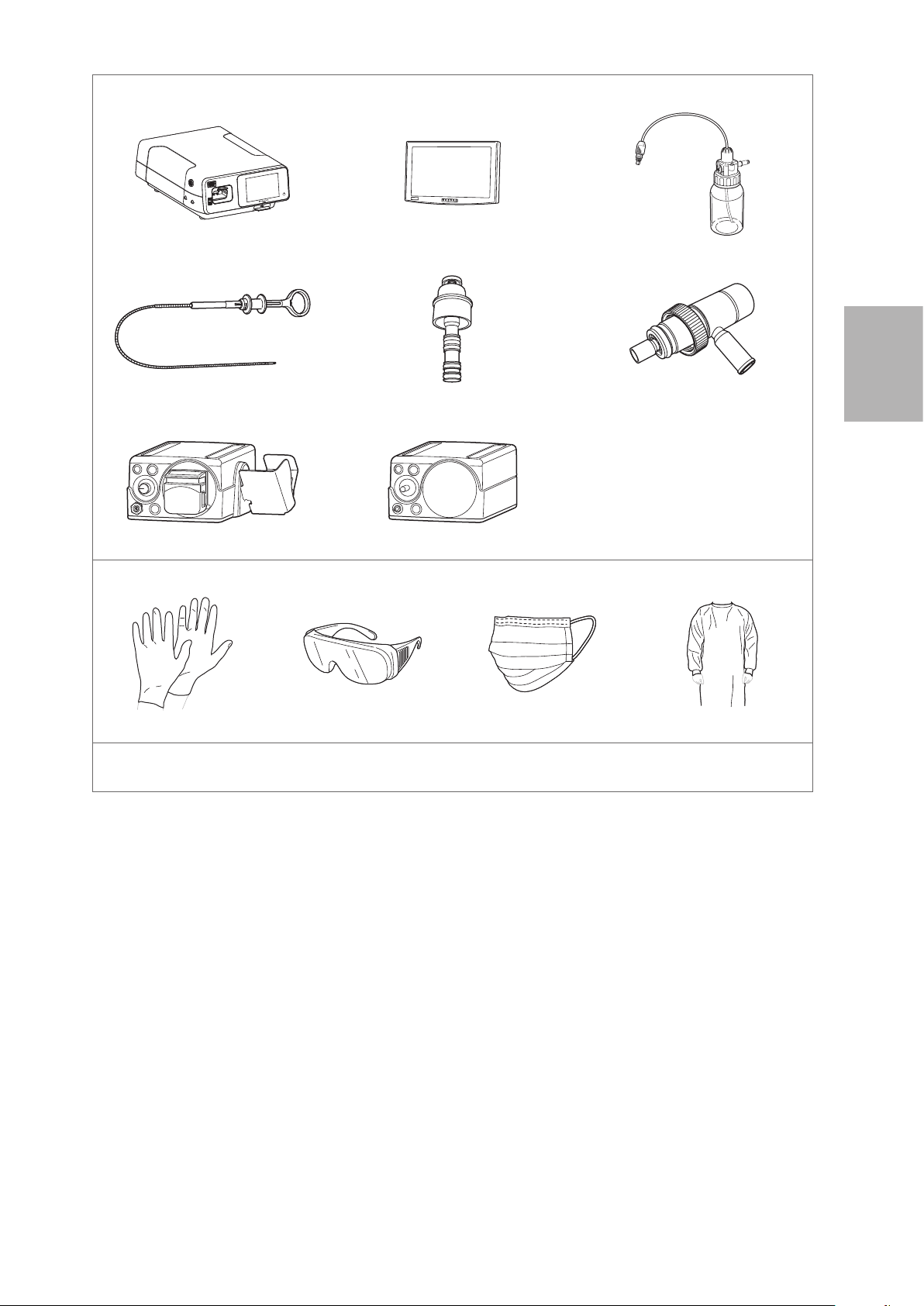

Prepare the endoscope, accessories, ancillary equipment, and protective equipment. Refer to the

“Compatible products” to prepare the ancillary equipment as necessary and to the IFU provided with the

video processor for its inspection.

Endoscope

Accessories

Preparation and inspection

Air/ Water Feeding Valve (OF - B188) Suction Control Valve (OF- B120) Inlet Seal (OF- B190 or OF - B215*)

* Optional item

Irrigation Tube (OF - B113) Water Jet Check Valve Adapter (OE- C12) Silicone Oil (OF- Z11)

Water Jet Connector Cap (OF- B118) Bite Block (OF-Z5)

20

Page 23

Ancillary Equipment

Video Processor Monitor Water Bottle Assembly

Endoscopic Device Gas / Water Feeding Valve (OF- B194*)

* Optional item

3

Gas Adapter (OF - G11*)

* Optional item

Suction Source

Irrigation Pump (EGA- 500P)

Protective Equipment (example)

Gloves Goggles Mask Medical Gown

Other Equipment

Gauze, sterile water, container for sterile water, etc.

Figure 3.1

CO² Insufflator (EGA - 501P)

Preparation and inspection

21

Page 24

3

3-2. Inspection of the endoscope

Prepare an endoscope that has been reprocessed according to the procedure specified in the separate

IFU(Reprocessing) of this endoscope.

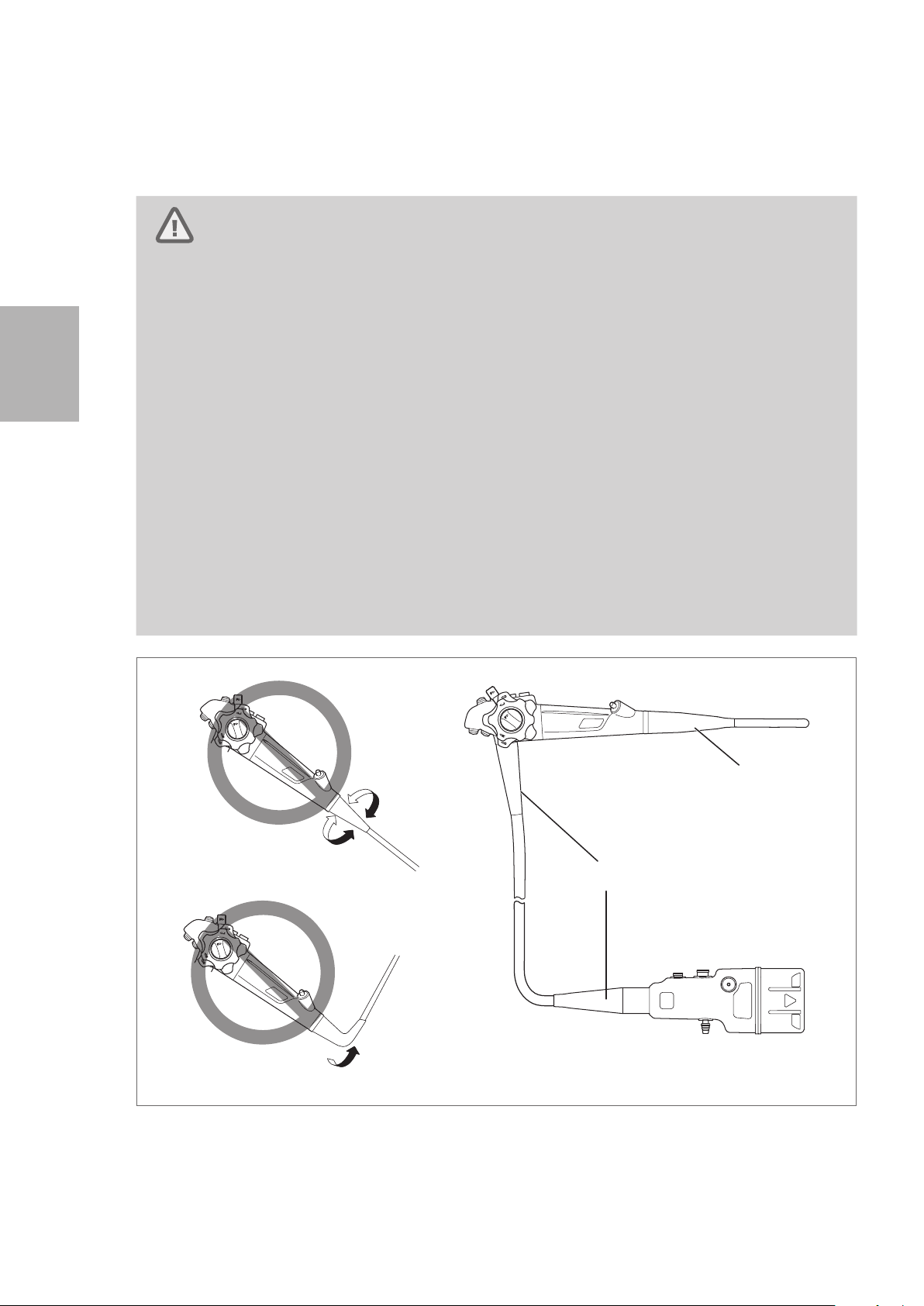

Warning

• NEVER disassemble or modify the endoscope. Doing so may impair its original functionality

and possibly result in serious injury to the patient and /or user.

• NEVER use an endoscope with any abnormality. Doing so may result in endoscope damage,

detachment of parts into the patient’s body cavity, malfunction during use, and / or injury to

the patient and / or user.

• Use only sterile water for inspection. Failure to do so may result in contamination of the

endoscope with waterborne bacteria and other microorganisms. Do NOT use water that has

been left uncovered for a prolonged period of time.

Preparation and inspection

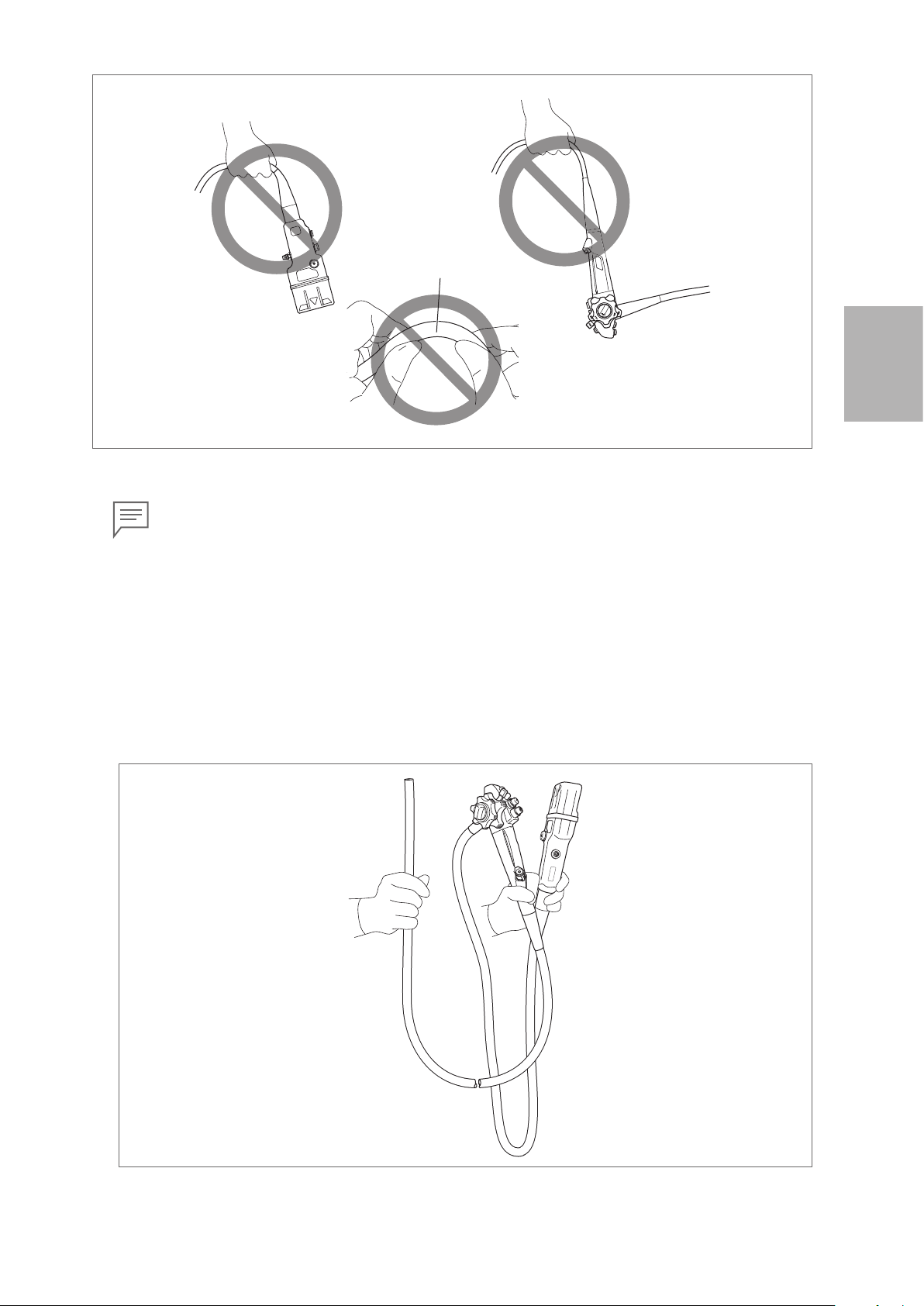

• Do NOT excessively twist, bend, or rotate any of the strain relief boots on the instrument (See

Figure 3.2 (A) and (B)) to identify the strain relief boots). Doing so may result in instrument

damage. Pay special attention to the careful handling of the strain relief boot of the insertion

portion (See Figure 3.2 (A)) of the endoscope, because it has a small diameter and is more

likely to suffer damage due to mishandling.

• When carrying the endoscope, do NOT grasp or carry it only by its umbilical cord or insertion

portion. Moreover, do NOT squeeze or forcefully bend the bending section. (Figure 3.3) Doing

so may result in equipment damage.

Figure 3.2

(A)

Do Not Twist or Rotate

(B)

Do Not Forcefully Bend

22

Page 25

Bending Section

Do Not

Forcefully

Bend

Figure 3.3

Note

In case the endoscope is hot / cold immediately after cleaning, high -level disinfection, and/ or

sterilization, wait until it returns to room temperature before using it. Lens fogging, which will

result in blurry images, might result from abrupt changes in environmental temperature.

█

Carrying the endoscope by hand

When carrying the endoscope by hand, loosely loop the umbilical cord and insertion portion, hold the

control body and the scope connector in gloved hand, and hold insertion portion (near the bending

section) in the other gloved hand as shown in Figure 3.4.

3

Preparation and inspection

Figure 3.4

23

Page 26

3

(1)

(2)

(6)

(5)

Inspection of the entire endoscope

Warning

NEVER use the endoscope with any abnormality in function. Doing so may result in endoscope

damage, detachment of parts into the patient’s body cavity, endoscope malfunction during

use, and / or injury to the patient and / or user.

Caution

Clear images can NOT be obtained if there is any foreign material attached to the objective

lens or light guides. Water vapor from the foreign material may be released in response to

heating by the light passing through these components, obscuring the image.

Preparation and inspection

1. Check the entire surface of the endoscope for any visible adhered material.

2. Check the entire surface of the insertion portion for abnormalities such as wrinkles, scars, sharp

edges, clouding of the surface, dents, catching, protrusions, attachment of foreign materials,

detachment of parts, etc.

3. Check the surface of the adhesive bands on both ends of the bending section for abnormalities

such as scratches, clouding, and peeling. With clean gauze, lightly wipe the surface of the adhesive

bands to ensure that there is no catching and/or attachment of the adhesive to the gauze.

Bending Section

Magnified View

(1)

Figure 3.5

4. Check the case of the distal end of the endoscope (especially around the periphery of the instrument

channel) for any abnormalities such as deformation or chipping.

(1)

(1) Adhesive Bands

24

(1) Objective Lens

(2) Light Guides

(4)

(3)

Figure 3.6

5. Check the objective lens at the distal end of the endoscope and the light guides for any abnormalities

such as attachment of foreign material, scratches, or chipping, and ensure that there is no gap on

the periphery of the lens.

6. Ensure that there are no scratches, clouding, or peeling on the surface of the adhesive glue around

the objective lens at the distal end of the endoscope and that it has a glossy surface.

(2)

(3) Air/ water Nozzle

(4) Case

(5) Instrument Channel

(6) Water Jet Nozzle

Page 27

7. Gently clean the objective lens and light guides with clean gauze or a cotton- tip applicator moistened

(5)

(1)

with 70% – 90% medical grade ethyl or isopropyl alcohol. Check that there is no attachment of the

adhesive to the gauze.

8. Check the air/ water nozzle at the distal end of the endoscope for any abnormalities such as

clogging, dents, deformations, chipping, etc.

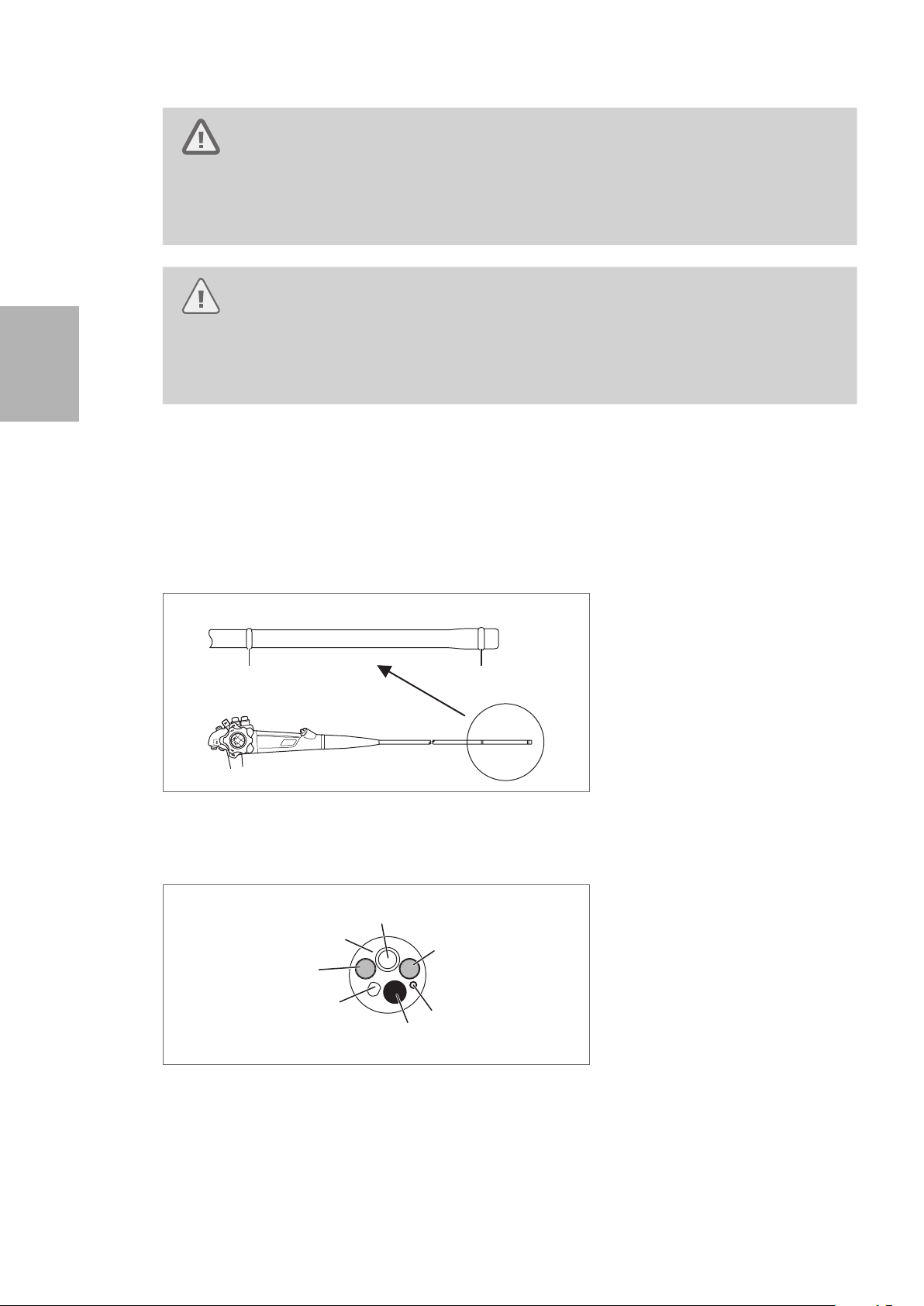

9. Using both hands, form an arch with the insertion tube as shown in Figure 3.7. Slide the insertion

tube in the direction of the arrows in Figure 3.7, and check that the entire insertion tube can be bent

smoothly and easily to form an arch.

Approx. 30 cm

Approx. 20 cm

Figure 3.7

3

10. Check the entire surface of the umbilical cord for abnormalities such as wrinkles, scars, sharp

edges, clouding of the surface, catching, protrusions, attachment of foreign materials, detachment

of parts, etc.

11. Check the control body, scope connector, and electrical contacts for abnormalities such as

scratches, deformities, loose parts, etc. Pay special attention when checking the parts shown in

the Figure 3.8. Using a clean lint- free cloth, gently hold these parts and move them in various

directions to ensure that there are no abnormalities such as looseness.

(2)

(4)

(3)

(1) Suction Cylinder & Air/ Water

Feeding Cylinder

(2) Instrument Channel Inlet

(3) Water Jet Port

(4) Air/ Water Port

(5) Suction Nipple

Preparation and inspection

Figure 3.8

25

Page 28

12. Check the electrical contacts for any attachment of foreign materials such as residual chemical

solution, water deposit, sebum, dust and gauze lint, etc.

Note

In case there are any attachment of foreign material or the endoscope has been left unused

for a prolonged period of time, wipe the electrical contacts with gauze moistened with

70% – 90% medical grade ethyl or isopropyl alcohol. After wiping, dry the electrical contacts

sufficiently.

13. Ensure that the electrical contacts are sufficiently dry.

3

Inspection of the angulation mechanism

Ensure that there is nothing near the bending section that would hinder its operation, and inspect the

angulation mechanism while the insertion portion is kept straight.

Preparation and inspection

█

Inspection of bending function

Warning

Do NOT use an endoscope that can NOT be smoothly angulated, can NOT be fully angulated

in any direction, or has excessive play in the angulation control lever. Use of an endoscope

with any of these conditions may result in damage to the device, malfunction during use,

and / or patient injury.

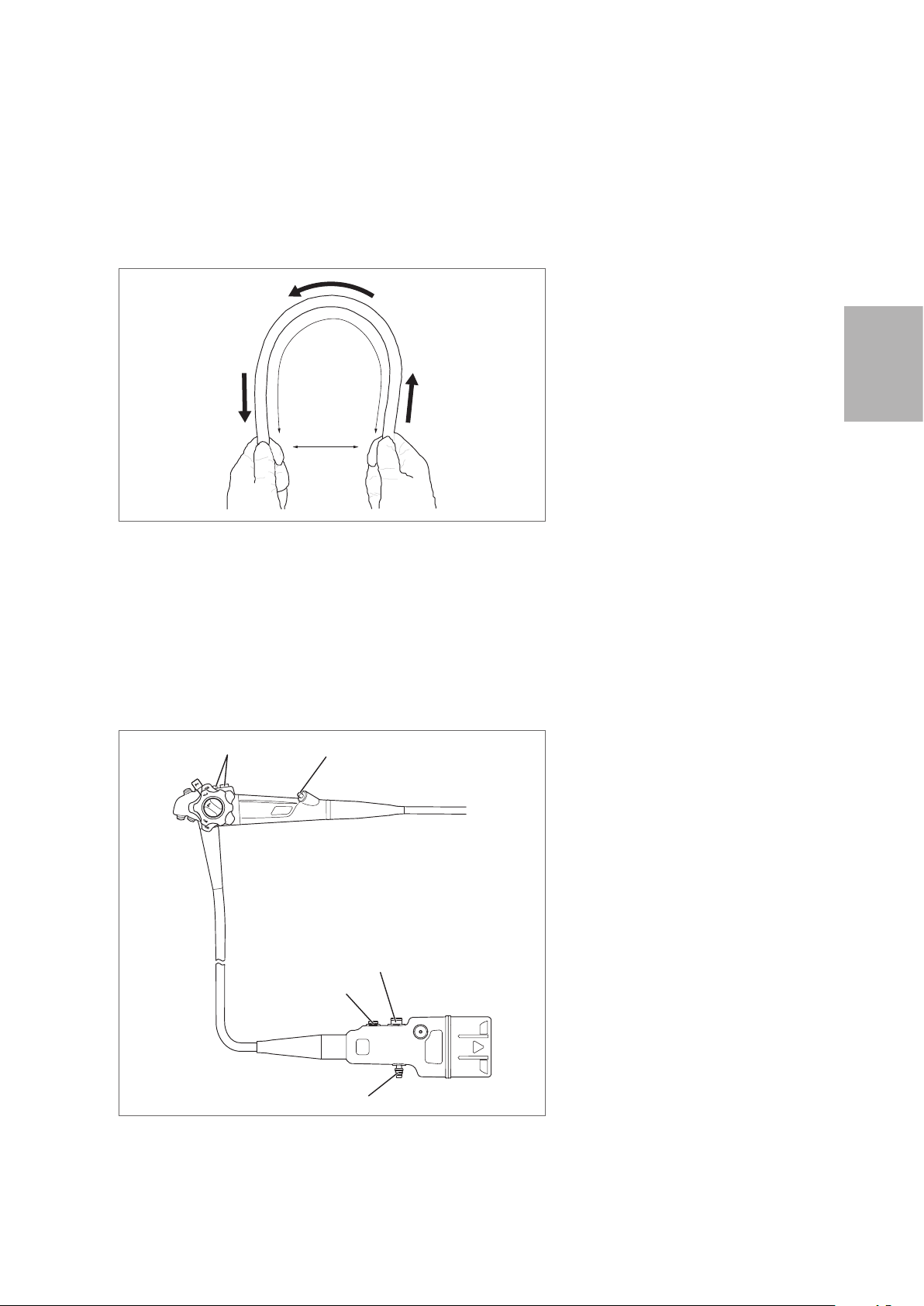

1. Turn the up / down angulation lock lever and right / left angulation lock knob in the “F ►” direction

until they stop to release the lock of the angulation control knobs.

26

Figure 3.9

Page 29

2. Turn the up/down and right/ left angulation control knobs slowly in each direction until they stop,

and return them to their original position. Check that the angulation control knobs operate smoothly

with no roughness or catching.

Figure 3.10

3. Check that the bending section angulates in the direction in which the angulation control knobs are

turned and that the maximum angulation can be achieved.

UP

RIGHT

Figure 3.11

4. Turn the angulation control knobs back to the neutral position. Check that the bending section

returns to a straight orientation.

DOWN

LEFT

DOWN LEFT

Neutral Position

UP RIGHT

3

Preparation and inspection

Figure 3.12

27

Page 30

█

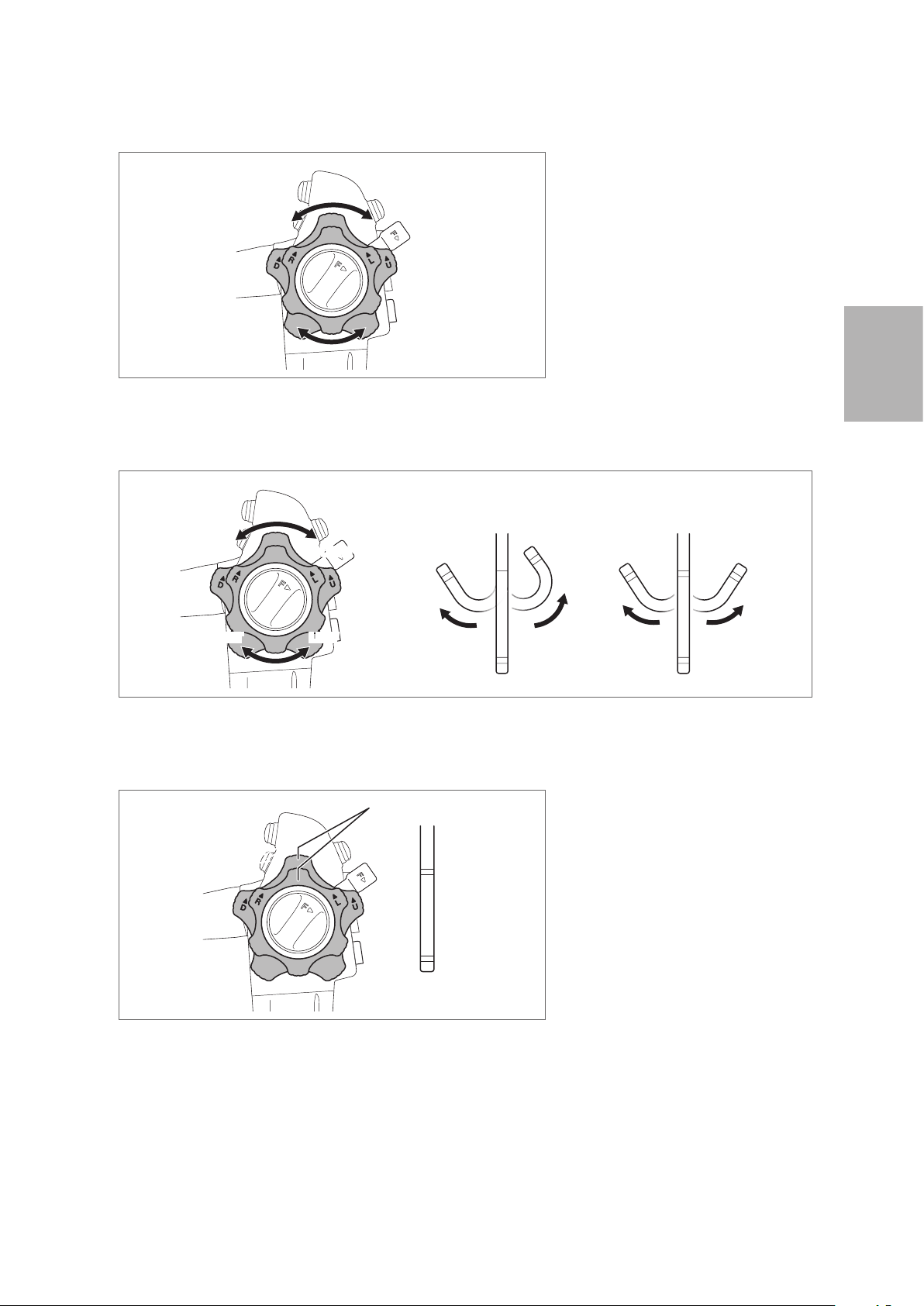

Inspection of the up/down bending lock mechanism

1. Turn the up / down angulation lock lever counterclockwise until it stops.

3

Figure 3.13

2. Turn the up/down angulation control knob slowly in the “▲U” or “▲D” direction until it stops.

Preparation and inspection

Figure 3.14

3. Check that the curved form of the bending section is fixed when releasing the angulation control

knob.

4. Turn the up/down angulation lock lever in the “F ►” direction until it stops to release the lock.

Check that the bending section returns to a straight orientation.

28

Figure 3.15

Page 31

█

Inspection of the right / left bending lock mechanism

1. Turn the right /left angulation lock knob counterclockwise until it stops.

Figure 3.16

2. Turn the right/ left angulation control knob slowly in the “▲R” or “▲L” direction until it stops.

Figure 3.17

3. Check that the curved form of the bending section is fixed when releasing the angulation control

knob.

4. Turn the right/ left angulation lock knob in the “F ►” direction until it stops to release the lock.

Check that the bending section returns to a straight orientation.

3

Preparation and inspection

Figure 3.18

29

Page 32

3

3-3. Inspection of accessories and attachment to the endoscope

When using reusable accessories, ensure that they have been cleaned, high- level disinfected, and/or

sterilized according to the separate IFU (Reprocessing) for this endoscope.

Warning

NEVER disassemble or modify the accessories and endoscopic devices. Doing so may impair

their original functionality and possibly result in serious injury to the patient and /or user.

Preparation and inspection

30

Page 33

Inspection of the air/water feeding valve (OF-B188)

(3)

(1)

(2)

Warning

Replacement O - rings are NOT sterilized or disinfected before shipment. Perform cleaning

and high - level disinfection and/or sterilization of the air/ water feeding valve after O - ring

replacement.

Caution

• If any abnormality is detected with the check valve of air/ water feeding valve (OF - B188)

(Figure 3.19), replace the air/ water feeding valve with a new one. Use of an air/ water

feeding valve with abnormalities can result in continuous air feeding into the patient,

posing a risk of pain and / or perforation. Dispersal of patient material into the environment

can also occur, posing a risk of infection to healthcare providers.

• The O - ring of the air/ water feeding valve is a consumable. If any abnormality is detected

with the O - ring, stop using it immediately and replace it with a new one. Use the

compatible O - ring set for replacement. Using an O - ring with abnormalities or non -

compatible O - ring could lower the function of air/ water feeding, cause unintended

continuous air feeding, and pose a risk of pain to the patient. Dispersal of patient material

into the environment can also occur, posing a risk of infection to healthcare providers.

3

Note

• Use O ring set (OF - B192) to replace the O- ring of air / water feeding valve (OF- B188).

• For details on the O - ring replacement method, refer to the IFU provided with the O ring

set (OF - B192).

(1) O -ring

(2) Check Valve

(3) Hole

Air/ Water Feeding Valve (OF - B188)

Figure 3.19

1. Check the air/ water feeding valve (OF- B188) for any abnormalities such as attachment of foreign

materials, deformation, cracks, or hole blockage.

2. Check that the O- ring is properly attached and that there is no chipping, breaks, or peeling in the

O - ring or check valve.

Preparation and inspection

31

Page 34

3

(1)

(3)

(2)

Inspection of the suction control valve (OF-B120)

Warning

• If any abnormality is detected with the rubber seal of suction control valve (OF- B120)

(Figure 3.20), replace the suction control valve with a new one. Use of a suction control

valve with any abnormality can result in continuously weak aspiration, which may hinder

the procedure. Dispersal of patient material into the environment can also occur, posing

a risk of infection to healthcare providers.

• The O - ring of the suction control valve is a consumable. If any abnormality is detected

with the O - ring, stop use immediately and replace it with a new one. Use the compatible

O - ring set (OF - B127) for O - ring replacement. Using an O -ring with abnormalities or

non - compatible O - ring could result in unintended continuous suction and may hinder

the examination. It could also pose a risk of infection to the user as a result of reflux or

dispersal of patient’s body fluids from the suction control valve.

Preparation and inspection

• Replacement O - ring is NOT sterilized or disinfected before shipment. Perform cleaning

and high - level disinfection, and/or sterilization of the suction control valve after O - ring

replacement.

Note

Use the O ring set (OF - B127) to replace the O- ring of the suction control valve (OF - B120).

(1) Rubber Seal

(2) O - ring

(3) Hole

Suction Control Valve (OF- B120)

Figure 3.20

1. Check the suction control valve (OF - B120) for any abnormalities such as attachment of foreign

materials, deformation, cracks, or hole blockage.

2. Check that the O- ring is properly attached and that there is no chipping, breaks, or peeling in the

O - ring or the rubber seal (Figure 3.20).

32

Page 35

Inspection of the inlet seal (OF- B190)

(1) (2)

(4)

Warning

NEVER use an inlet seal (OF - B190) that has any abnormality. Replace it with a new one.

Inlet seals are consumables. Using a damaged and / or worn inlet seal may result in lowered

suction function and potential reflux or dispersal of patient’s body fluids, posing a risk of

infection to the user.

1. Check the slit in the cap of the inlet seal (OF- B190) and the hole of the body of the inlet seal for

any abnormalities such as cracks, wear, chipping, and attachment or presence of foreign materials.

Check that the light does not shine through the slit of the cap.

(3)

Inlet Seal (OF - B190)

Figure 3.21

2. Close the inlet seal as depicted in Figure 3.22.

(1) Hole

(2) Slit

(3) Body

(4) Cap

3

Preparation and inspection

Figure 3.22

PENTAX Medical PROfILE Single Use Endoscope Inlet Seal (OF- B215) can also be used. For

details on the inspection method, refer to the IFU provided with the inlet seal (OF- B215).

Correct Incorrect

Note

33

Page 36

3

(2)

(3)

Inspection of the water jet check valve adapter (OE- C12)

Warning

Replacement check valve sets (OE- C15, a packed set of multiple check valves) are NOT

sterilized or disinfected before shipment. Perform cleaning and high- level disinfection or

sterilization of the water jet check valve adapter after check valve replacement.

Caution

NEVER use a check valve of the water jet check valve adapter (OE- C12) that has any

abnormality. Replace it with a new one. Check valves are consumables. Using a damaged

check valve may result in potential reflux or dispersal of patient’s body fluids, posing a risk of

infection.

Preparation and inspection

Note

Use the check valve set (OE- C15, a packed set of multiple check valves) for replacement.

(1) O -ring

(2) Hole

(1)

Water Jet Check Valve Adapter (OE- C12)

Figure 3.23

1. Check the water jet check valve adapter for any abnormalities such as attachment of foreign

materials, deformation or cracks, or hole blockage.

2. Ensure that the check valve is attached correctly to the water jet check valve adapter without any

gaps or pinching.

(3) Check Valve

Figure 3.24

3. Check the O- ring and check valve for any abnormalities such as cracks, breaks, and peeling.

34

Page 37

Inspection of the irrigation tube (OF- B113)

Warning

NEVER use the irrigation tube (OF- B113) when an abnormality is suspected in inspection.

Replace it with a new one. Using the OF- B113 with abnormality in the process of cleaning,

high level disinfection, or sterilization may cause leaking of detergent from the connection

part and detachment of the OF- B113. The cleaning, high -level disinfection or sterilization may

not be effective due to the insufficient reprocessing.

(1) Luer Connector

(1)

(2)

(2) Hole

(3) Connector

(4) Hole

(5) O - ring

3

(3)

(4)

(5)

Irrigation Tube (OF - B113)

Figure 3.25

1. Check the entire surface of the irrigation tube (OF- B113) for abnormalities such as bending/

breakage/ looseness of the connector, cut / chip of the O - ring, buckling/deterioration / hardening

of the tube, and/or broken luer.

2. Attach a syringe filled with the sterile water to the luer connector of the irrigation tube (OF- B113)

and flush sterile water through the tube.

3. Check that sterile water flows in a steady stream from the connector of the irrigation tube (OF -

B113).

Preparation and inspection

35

Page 38

3

Inspection of the bite block (OF-Z5)

Caution

NEVER use a bite block with any abnormality. Replace it with a new one.

Using a bite block with an abnormality may result in endoscope damage and injury to the oral

cavity of patients.

Check the bite block for any abnormalities such as attachment of foreign materials, cracks, deformity,

chipping, and discoloration.

Preparation and inspection

Bite Block (OF-Z5)

Figure 3.26

36

Page 39

Inspection of the endoscopic devices

For details on the inspection of each endoscopic device, refer to the instruction manual provided

with the specific endoscopic device. For reusable endoscopic devices, prepare ones that have been

cleaned and sterilized by following the instruction manual for the respective endoscopic device.

Warning

• NEVER use an endoscopic device with signs of damage and/or operational abnormality.

Doing so may result in malfunction during use, endoscope damage, and/or patient injury.

• Use endoscopic devices specified by PENTAX Medical whose compatibility has been

confirmed. Using endoscopic devices whose compatibility has not been confirmed may

result in endoscope damage and / or patient injury caused by failure during use.

This section describes the use of a biopsy forceps.

1. Check the entire surface of the forceps for any visible adhered material.

2. Check the insertion portion and control body of the biopsy forceps for abnormalities such as

wrinkles, scars, sharp edges, clouding of the surface, dents, catching, protrusions, attachment of

foreign materials, falling of parts, etc.

Control Body

Insertion Portion

Figure 3.27

3. Check that the cups of the biopsy forceps open/ close smoothly by operating its handle.

CLOSE

CLOSE

OPEN

3

Preparation and inspection

OPEN

Figure 3.28

37

Page 40

4. Form a loop with a diameter of 20 - 30 cm with the flexible shaft at approximately 20 - 30 cm from

the tip of the insertion portion of the biopsy forceps. Check that the cups of the biopsy forceps

open / close smoothly by operating its handle.

20cm - 30cm

20cm - 30cm

3

Figure 3.29

5. Check that the cups align with each other when closed.

Preparation and inspection

Figure 3.30

38

Page 41

Attachment of accessories

(1)

(2)

Warning

Attach the accessories properly to the endoscope. Failure to do so may result in lowered

function and potential reflux or dispersal of patient’s body fluids, posing a risk of infection to

the user.

█

Attachment of the air/water feeding valve (OF - B188) and suction control valve (OF- B120)

Warning

• Ensure to apply silicone oil lubricant (OF - Z11) onto the O- ring of each valve and the

rubber seal of the suction control valve (OF- B120). Using the valves without applying the

oil or applying a silicone oil other than the specified one could deteriorate the functions

and may result in damage to the endoscope and/or patient injury.

• Attach the air/water feeding valve (OF - B188) and suction control valve straight into

their respective valve cylinders. Inserting them into their valve cylinders at an angle may

damage valve O- rings and rubber seals.

(1) O -ring

(2) Rubber Seal

(1)

Air/ Water Feeding Valve

(OF - B188)

Figure 3.31

1. Apply a minimal amount of silicone oil lubricant (OF-Z11) to the O- rings of the air / water feeding

valve (OF- B188) and the O - ring and rubber seal of the suction control valve (OF- B120). In order to

apply the silicone lubricant, place a small droplet of oil onto a sterile gloved forefinger, gently swirl

the oil between the thumb and the forefinger, and apply it onto the necessary parts. Wipe off the

excess lubricant with soft gauze.

2. Attach the air/ water feeding valve to the air/ water feeding cylinder of the endoscope.

Suction Control Valve

(OF - B120)

3

Preparation and inspection

Figure 3.32

39

Page 42

3. Ensure that the air/ water feeding valve (OF- B188) is firmly attached. Press down the air/ water

(1) (2)

feeding valve a few times to ensure that it moves smoothly.

Figure 3.33

3

4. Align the metal tab on the shaft of the suction control valve with the notch on the suction cylinder

of the endoscope.

(1) Notch

Preparation and inspection

Figure 3.34

5. Attach the suction control valve (OF- B120) to the suction cylinder of the endoscope.

(2) Metal Tab

Figure 3.35

6. Check that the suction control valve is firmly attached. Press down the suction control valve a few

times to ensure that it moves smoothly.

Figure 3.36

40

Page 43

█

Attachment of the inlet seal (OF - B190 or OF - B215 (option))

1. Attach the inlet seal (OF - B190 or OF- B215 (option)) to the instrument channel inlet.

Figure 3.37

2. Ensure that the inlet seal is tightly attached to the instrument channel inlet without gaps.

Correct

Figure 3.38

█

Attachment of the water jet check valve adapter (OE- C12) and water jet connector cap (OF - B118)

1. Attach the water jet connector cap (OF- B118) and water jet check valve adapter (OE- C12) to the

water jet port of the endoscope.

Incorrect

Gap

3

Preparation and inspection

Figure 3.39

2. Ensure that the water jet check valve adapter is fi rmly attached to the water jet port without gaps.

(Close the lid of the water jet connector cap.)

Figure 3.40

41

Page 44

3

3-4. Inspection and connection of ancillary equipment to the endoscope

Inspect the ancillary equipment prepared in “3 -1. Preparation of the equipment”, such as the video

processor, monitor, and suction source, according to their respective IFU.

Video processor

Monitor

Suction source

Endoscopic device

Water bottle assembly

Irrigation pump

CO² Insufflator, etc.

Inspection of the video processor

Preparation and inspection

Only use compatible PENTAX Medical video processors.

For compatible video processors, refer to “Compatible products” (p. 8) or “System chart” (p. 90).

For details on the preparation and inspection of the video processor, refer to the IFU of the respective

video processor.

42

Page 45

Connection of the endoscope and ancillary equipment

█

Connection to the video processor

Warning

Ensure that the scope connector is securely attached to the video processor. Failure to do so

may result in an abnormality such as disappearance of the image which may cause patient

injury.

Caution

Ensure that the scope connector (including the electrical contacts) is sufficiently dry before

connecting it to the video processor. In addition, check the electrical contacts for any

attachment of foreign materials (such as residual chemical solution, water deposit, sebum,

dust and gauze lint, etc.) before connecting. Failing to do so may result in the endoscope’s

malfunction or failure.

Note

When connecting the scope connector to the video processor, hold the video processor with

one hand. It may become difficult to connect if the video processor moves.

1. Ensure that all ancillary equipments are turned off.

2. Hold the scope connector as shown in Figure 3.41, and turn the scope connector's Connector UP

index ("▲") upward and push the scope connector into the video processor receptacle until it clicks.

(1) UP index

(1)

3

Preparation and inspection

Figure 3.41

43

Page 46

█

Connection of the water bottle assembly, suction tube, and irrigation tube (OF - B113)

Warning

• Use only sterile water in the water bottle assembly. Failure to do so may pose a risk of

infection.

• Do NOT use defoaming agents in the water bottle assembly. These agents attach to the

internal lumen of the air/ water channel and may block the channel and/or damage the

endoscope. They are also extremely difficult to remove during subsequent cleaning and

can interfere with proper endoscope reprocessing.

3

Caution

Connect the suction tube of the suction source firmly to the suction nipple. Failure to do

so may result in disconnection of the suction tube during use and pose a risk of cross

Preparation and inspection

contamination to the user as a result of reflux or dispersal of patient’s body fluids.

Note

Turn off the air/ water feeding pump of the video processor beforehand.

1. Attach the water bottle assembly correctly according to the IFU of the video processor.

2. Insert the air/ water connector of the water bottle assembly into the air/water port of the endoscope

until it clicks.

44

Figure 3.42

Note

Failure to connect the water bottle assembly correctly not only lowers the air/ water feeding

function, but may also cause insufficient cleaning of the objective lens.

Page 47

3. Connect the suction tube of the suction source to the suction nipple of the endoscope.

Figure 3.43

4. Remove the lid of the water jet connector cap (OF - B118) and push the irrigation tube (OF - B113)

into the water jet check valve adapter (OE- C12) until it clicks.

Figure 3.44

Caution

Do NOT orient the irrigation tube (OF- B113) at an angle when attaching it to or removing it

from the water jet check valve adapter (OE- C12). Doing so may break the irrigation tube.

3

Preparation and inspection

Note

Do not use the irrigation tube (OF- B113) if you have any difficulty in attaching it, or if you do

not feel it clicking into place when attaching it to the endoscope. The use of damaged luer

connector may result in water leakage from the connected part or tube disconnection.

45

Page 48

3-5. Inspection of the endoscopic system

Inspection of the endoscopic image

Caution

Do NOT look directly at the light emitted from the distal end of the endoscope. The intense light

may cause eye injuries. Turn off the lamp when looking directly at the distal end of the endoscope.

Note

3

The following instructions regarding the operation of a video processor are general in nature. For

specifi c information regarding your video processor model, refer to the IFU provided with the

video processor.

Preparation and inspection

1. Turn on the main power switch on the video processor.

2. Press and hold the On/ Standby switch on the lower right of the front panel on the video processor for

2 to 3 seconds.

Figure 3.45

3. Tap a Lamp icon on the touch panel of the video processor.

4. Check that the distal end of the endoscope emits light.

Figure 3.46

5. Check that the endoscopic image is clear and is displayed normally.

46

Page 49

Note

If the image is not clear, gently clean the endoscope objective lens with clean gauze moistened

with 70% – 90% medical grade ethyl or isopropyl alcohol.

6. On the touch panel of the video processor, check that the exposure control is set to [Average] or [Peak].

7. Place the distal end of the endoscope at a distance of approximately 1 cm from the palm of your hand

and then move it approximately 5 cm away from your palm. Watch the image displayed on the monitor

to ensure that the brightness at both distances is similar.

Figure 3.47

3

Caution

Do NOT directly touch the distal end of the endoscope (particularly the light guide) for a prolonged

period of time when the light is being emitted. Doing so may result in burn injury.

8. While checking the image displayed on the monitor and following the IFU of the video processor,

adjust the brightness level as appropriate.

9. Operate the angulation control knobs of the endoscope to move the bending section, and check that

the image is traveling along with the direction of the angulated distal tip of the endoscope. Also check

for abnormalities such as appearance of noise in the endoscopic image or disappearance of the image.

Preparation and inspection

Figure 3.48

47

Page 50

3

Inspection of the remote buttons

Warning

Always inspect the remote buttons even if they are NOT expected to be used. During a procedure,

the endoscopic image may freeze or other abnormalities may occur, which may result in patient

injury.

Alternative view

Remote Button 1

Remote Button 2

Remote Button 4

Preparation and inspection

Figure 3.49

1. Press each remote button.

2. Check that the function assigned to each remote button is operating normally.

Remote Button 3

48

Page 51

Inspection of the air/water feeding function

Warning

Use sterile water for inspection of the air/ water feeding function. Failure to do so may pose a

risk of infection.

Note

Refer to the separate IFU of water bottle assembly for details of the operating procedure.

1. Set the A / W- drain lever of the water bottle assembly at the “A / W” position.

A/W

DRAIN

Figure 3.50

2. Tap the pump icon on the touch panel of the video processor.

3. Set the pump level to "5" by moving an adjustment slider on the pump level menu.

4. Insert the distal end of the endoscope into a container filled with sterile water, and check that air

bubbles are not continuously discharged from the air/ water nozzle at the distal end of the endoscope.

3

Preparation and inspection

Figure 3.51

49

Page 52

3

Caution

If air bubbles are continuously discharged from the air/ water nozzle at the distal end of the

endoscope when the hole on the top of the air/ water feeding valve is NOT closed, stop use

immediately and replace the air/ water feeding valve with a new one. Continuous use of an air/

water feeding valve with abnormalities could cause unintended continuous air feeding and pose

a risk of pain to the patient.

5. Block the hole in the top of the air/ water feeding valve. Confirm that a steady stream of air bubbles is

being released from the air/ water nozzle on the distal end of the endoscope.

Preparation and inspection

Figure 3.52

6. Check that the discharge of air bubbles stops when you remove your finger from the hole in the button

of the air/ water feeding valve.

Figure 3.53

7. Pull the endoscope out of the container, and depress the air/ water feeding valve. Check that a certain

amount of water flows out from the air/ water nozzle. (It takes a few seconds until water comes out

the first time.)

Figure 3.54

50

Page 53

8. Remove your finger from the air/ water feeding valve. Check that the air/ water feeding valve returns

smoothly to the original position and that the flow of water from the air/ water nozzle stops when you

remove your finger from the hole in the valve.

Figure 3.55

Caution

Do NOT attempt to clear the air or water nozzles with a needle or any other sharp object if

nozzle blockage is suspected. This may result in suboptimal performance and/or damage to the

endoscope.

3

Note

Perform the procedure described in “How to deal with the blockage in the air/ water nozzle or

channel” (p. 77) of the endoscope is suspected.

Preparation and inspection

51

Page 54

3

Inspection of the irrigation function

Warning

Use sterile water for inspection of the irrigation function. Failure to do so may pose a risk of

infection.

1. Fill a syringe with sterile water.

2. Put the distal end of the endoscope to the clean container, and insert a syringe filled with sterile water

into the inlet seal (OF - B190) as shown in Figure 3.56.

Preparation and inspection

Figure 3.56

3. Infuse sterile water into the instrument channel and check to ensure that it flows from the instrument

channel opening on the distal tip of the endoscope. Ensure that the effluent is free of foreign materials.

4. Remove the syringe from the inlet seal (OF- B190).

5. Fill the syringe with air and insert it into the inlet seal.

6. Flush the sterile water remaining inside the channel by pressing the syringe.

7. Remove the syringe from the inlet seal.

52

Page 55

Inspection of the suction function

Warning

Use sterile water for inspection of the suction function. Failure to do so may pose a risk of

infection.

Note

Before inspecting the suction function, close the cap of the inlet seal (OF- B190). Failure to do so

may result in a decrease in suction strength.

1. Turn on the suction source and adjust it to a moderate suction setting.

2. Insert the distal end of the endoscope into a container filled with sterile water and press the suction

control valve (OF- B120). Check that water is being suctioned up.

Figure 3.57

3. Check that when the suction control valve is released, it smoothly returns to the initial position and the

suctioning stops.

3

Preparation and inspection

Figure 3.58

4. Repeat steps 2 and 3 several times to check that there is no water leakage from the suction control

valve or the inlet seal.

5. Pull the distal end of the endoscope out of the container. Press the suction control valve, and suction

air in order to remove the water remaining inside the instrument channel.

53

Page 56

Inspection of the instrument channel

Use a biopsy forceps for inspection of the instrument channel.

Prepare a biopsy forceps which has been cleaned and sterilized according to the manual provided with that

product and ensure to perform a pre - use inspection.

Warning

Do NOT use the endoscope if you feel a significant resistance when inserting a biopsy forceps.

It may result in damage to the inside of the channel and unforeseen events to patients and/or

medical professionals.

3

Caution

• Slowly and gently insert and withdraw the forceps from the inlet seal (OF- B190). Applying

strong force may cause endoscope damage.

Preparation and inspection

• Keep the endoscope bending section as straight as possible when inserting the forceps, as it

may not be possible to pass the forceps through a highly angulated bending section.

1. Close the biopsy forceps cups by operating its handle.

CLOSE

OPEN

CLOSE

Figure 3.59

54

Note

Do not close the biopsy forceps cups tightly. Doing so may make its insertion into the instrument

channel difficult.

Page 57

2. Insert the biopsy forceps into the inlet seal (OF - B190). When the cups are first passed through the

inlet seal, temporary resistance will be encountered.

3. Hold the shaft at approximately 5 cm from the inlet seal and slowly advance the biopsy forceps, and

check that the tip exits the distal tip of the endoscope. In addition, check that no foreign materials were

pushed out of the instrument channel by the biopsy forceps.

5cm

Figure 3.60

4. Check that the biopsy forceps can be smoothly withdrawn from the inlet seal.

Inspection of the water jet feeding function

3

Warning

Use sterile water for inspection of the water jet feeding function. Failure to do so may pose a risk

of infection.

1. To use the irrigation pump, prepare to feed sterile water by following the instructions for use for the

irrigation pump.

2. Check the entire surface of the irrigation tube (OF- B113) for abnormalities such as bending/ breakage /

looseness of the connector, cut / chip of the O - ring, buckling/deterioration/ hardening of the tube, and /

or broken luer.

3. Open the water jet connector cap (OF - B118), connect the irrigation tube (OF - B113) to the water jet

check valve adapter (OE- C12) until it clicks into position.

Note

Do not use the irrigation tube (OF- B113) if you have any difficulty in attaching it, or if you do not

feel it clicking into place when attaching it to the endoscope. The use of damaged luer connector

may result in water leakage from the connected part or tube disconnection.

Preparation and inspection

55

Page 58

4. Feed sterile water using the irrigation pump or syringe filled with sterile water attached to the luer

connector of the irrigation tube (OF- B113).

3

(1)

(2)

(3)

Figure 3.61

Note

Preparation and inspection

When the irrigation tube (OF- B113) is connected with locking type of luer connector, ensure that

the luer connectors are properly locked. Do not use irrigation tube (OF- B113) if its luer connector

is damaged and / or if it is not properly connected.

5. Check that a certain amount of water flows out forward from the water jet nozzle at the distal end of

the endoscope. (It takes a few seconds until water comes out the first time.)

(1) Water Jet Connector Cap

(OF - B118)

(2) Irrigation Tube (OF - B113)

(3) Water Jet Check Valve Adapter

(OE - C12)

Figure 3.62

6. Check that there is no water leakage from the connection between the water jet port of the endoscope

and the water jet check valve adapter (OE- C12), or from the connection between the water jet check

valve adapter and the irrigation tube (OF - B113).

Figure 3.63

56

Page 59

4

This endoscope should only be used by a physician authorized by the medical safety administrator at each

medical facility to perform endoscopy.

The device should never be used by individuals who are not licensed medical professionals or used at facilities

other than medical facilities.

This section describes essential information, such as operating procedures and handling precautions, on using

this endoscope safely and effectively. This IFU does not describe specific endoscopic procedures. The specific

procedures should be determined according to the discretion of a medical professional.

Warning

Directions for use

• Do NOT withdraw the endoscope while the bending section is locked. Doing so may result in

patient injury.

• Always check the endoscopic image during endoscope angulation, air/ water feeding, and

suctioning, use of endoscopic devices, and endoscope insertion and withdrawal. Ensure that

these operations are performed in the normal (non- frozen, non -magnified) mode. Endoscope

operation in the freeze or magnification mode may result in damage to the endoscope and patient

injury.

• Ensure that the released energy from the high - frequency does not affect the peripheral device

such as pacemaker and to use the minimum necessary output level of high - frequency when

using it near the heart. It may stimulate the heart.

• Do NOT forcefully insert and withdraw the endoscope. Doing so may result in patient injury.

• Do NOT perform retroflexed observations inside a narrow lumen. Doing so may cause patient

injury or make it impossible to withdraw the endoscope.

• Immediately stop the endoscopic procedure if the endoscopic image disappears unexpectedly

because of blackout and / or damage to the lamp, video processor, and/or endoscope. Slowly

withdraw the endoscope following the instructions in “5 -2. Withdrawal of an endoscope with an

abnormality” (p. 79). Continuing to use the endoscope may result in patient injury.

4

Directions for use

57

Page 60

4

Caution

• Users as well as the assisting personnel should always wear protective equipment (e.g., gloves,

goggles, masks, medical gowns, etc.) to minimize the risk of infection, as the patient’s body fluids

may be dispersed into the environment from endoscope components such as the instrument

channel inlet and the suction control valve.

• Do NOT look directly at the light emitted from the endoscope or direct it at the eyes of other

individuals, as the intense light may cause eye injuries.

• Set the brightness to the minimum necessary. Maintain an appropriate distance between the

distal end of the endoscope and the mucosa in order to avoid prolonged illumination of the

mucosa. The temperature at the distal end of the endoscope may exceed 41°C and even reach

50°C due to the light emitted from it. This may result in mucosal injury to the patient.

• Do NOT use the endoscope when adherence of patient materials (e.g., blood, other body fluids)

is suspected, as this will darken the image. This will also cause the temperature of the distal tip

to increase, which might lead to mucosal injury to the patient.

• Use the minimum pressure necessary for suctioning. Do NOT suction from the mucosa for a

prolonged period of time. Doing so may result in patient injury.

• Do NOT excessively pull the umbilical cord or give shocks such as objects or people hitting the

scope connector. Doing so could cause temporary disappearance of endoscopic images. If any

abnormality occurs in the images, connect the scope connector again to the video processor.

Directions for use

Note

• Prior to a procedure, remove as much debris as possible from the observation area in order to

obtain a clear image.

• The objective lens may be cleaned during a procedure by performing air/ water feeding and

suctioning either alternately or simultaneously.

58

Page 61

4-1. Preparation immediately before insertion of the endoscope

Perform appropriate patient preparation for endoscopy as necessary.

Warning

Do NOT spray or wipe the surface of the endoscope insertion portion with an anesthetic

(particularly anesthetic sprays containing alcohol) or non- medical lubricants (such as petroleum

jelly). Doing so could cause cracking or peeling of the external surface of the insertion portion and

may result in endoscope damage.

1. Apply a medical grade lubricant to the insertion portion, as necessary.

2. Place a bite block (OF-Z5) into the patient’s mouth.

Note

• Do not apply lubricants to the objective lens for getting clear observation images.

• When using lens cleaner, ensure to follow the instructions of that product.

4

Directions for use

59

Page 62

4

4-2. Insertion and observation

Insertion of the endoscope

Warning

Do NOT severely and/or forcefully bend the strain relief boot as shown in Figure 4.1. Doing so

may result in endoscope damage.

Caution

Clear images can NOT be obtained if any foreign material is attached to the objective lens or

the light guide. Continued use of the light guide with any foreign material attached to it might

cause visible steam - like vaporization associated with water vaporization of the organic material

heated by the light. If this vapor is observed, stop the procedure immediately and withdraw the

endoscope from the patient. Using clean gauze, clean off any foreign material that has attached

and then resume endoscopy.

Directions for use

Figure 4.1

1. Slowly and cautiously insert the endoscope.

2. Adjust the brightness as appropriate for observation with the video processor.

60

Page 63

Angulation operation

Warning

Immediately stop the endoscopic procedure and slowly and cautiously withdraw the endoscope

when an abnormality, such as an inability to smoothly angulate the endoscope, is experienced.

NEVER forcefully turn the angulation control knob as it may result in endoscope damage and/ or

patient injuries, including bleeding and perforation.

1. Slowly and cautiously operate the angulation control knobs in order to adjust the position of the distal

end of the endoscope.

2. Turn the up/down angulation lock lever and right/ left angulation lock knob to hold the bending angle of

the distal end of the endoscope, as necessary.

Air/Water feeding

Caution

Be careful NOT to feed too much air and to properly control air insufflation into the body cavity.

Excessive air insufflation into the patient’s body cavity may pose a risk of pain to the patient.

1. Set the appropriate pump level using the pump level menu on the touch panel of the video processor.

2. Cover the hole on top of the air/ water feeding valve with your finger to feed air through the air/ water

nozzle at the distal end of the endoscope.

3. Depress the air/ water feeding valve to feed water from the air/ water nozzle onto the objective lens.

4

Directions for use

61

Page 64

4

Suction

Warning