Page 1

PENTAX VIDEO GI SCOPES

EG-290Kp

OWNER’S MANUAL

EC-380LKp

Page 2

Intended Use (Gastroscope)

These instruments are intended to provide optical visualization of (via a video monitor), and therapeutic access to, the Upper Gastrointestinal Tract.

This anatomy includes, but is not restricted to, the organs; tissues; and subsystems: Esophagus, Stomach, Duodenum and Small Bowel.

The instruments are introduced via the mouth when indications consistent with the need for the procedure are observed in adult and pediatric patient

populations.

Never use the endoscope for any purpose other than that for which it has been designed.

The video endoscopes contained in this manual can only be used with PENTAX video processor, model EPK-1000 and EPK-i.

Intended Use (Colonoscopes)

These instruments are intended to provide optical visualization of (via a video monitor), and therapeutic access to, the Lower Gastrointestinal Tract.

The This anatomy includes, but is not restricted to, the organs; tissues; and subsystems: Large Bowel to the Cecum.

These instruments are introduced via the rectum when indications consistent with the need for the procedure are observed in adult and pediatric patient

populations.

Never use these endoscopes for any purpose other than that for which they have been designed.

These video endoscopes contained in this manual can only be used with PENTAX video processors, model EPK-1000 and EPK-i.

Notes

Read this manual before operating, and save this book for future reference. Failure to read and thoroughly understand the information presented in this

manual, as well as those developed for ancillary endoscopic equipment and accessories, may result in serious injury including infection by cross

contamination to the patient and/or user. Furthermore, failure to follow the instructions in this manual may result in damage to, and/or malfunction of,

the equipment.

This manual describes the recommended procedures for inspecting and preparing the equipment prior to its use and for the reprocessing and

maintenance of the equipment after its use. It does not describe how an actual procedure is to be performed, nor does it attempt to teach the beginner

the proper technique or any medical aspects regarding the use of the equipment.

It is the responsibility of each medical facility to ensure that only well educated and appropriately trained personnel, who are competent and

knowledgeable about the endoscopic equipment, antimicrobial agents/processes and hospital infection control protocol be involved in the use and the

reprocessing of these medical devices. Known risks and/or potential injuries associated with flexible endoscopic procedures include, but are not limited

to, the following: perforation, infection, hemorrhage, burns and electric shock.

Current infection control guidelines require that G.I.scopes and other semi-critical medical devices, that normally come into contact with intact mucous

membranes, such as in the gastrointestinal tract, must at least be high-level disinfected before patient use. Only the user can determine if an instrument

has undergone appropriate infection control procedures prior to each clinical use. It must be recognized that infection control practices involve many

complex and often controversial issues which are constantly evolving. PENTAX strongly recommends that user remain informed of the latest federal

and local regulations, and encourages users to follow infection control guidelines developed by various organizations for health care professionals.

The text contained in this manual is common for various types/models of PENTAX endoscopes and users must carefully follow only those sections and

instructions pertaining to the specific instrument models appearing on the front cover.

If you have any questions regarding any of the information in this manual or concerns pertaining to the safety and/or use of this equipment, please

contact your local PENTAX representative.

Sterility Statement

The instruments identified in this instructional booklet are reusable medical devices. Since they are packaged non-sterile, they must be high-level

disinfected or sterilized BEFORE initial use. Prior to each subsequent procedure, they must be subjected to an appropriate cleaning and either highlevel disinfection or sterilization process.

Conventions

Throughout this manual, the following conventions will be used to indicate a potentially hazardous situation which, if not avoided;

: could result in death or serious injury.

: may result in minor or moderate injury or property-damage.

: may result in property-damage. Also, advises owner/operator about important information on the use of this equipment.

Prescription Statement

Federal (U.S.A) law restricts this device to sale by or on the order of a physician or other appropriately licensed medical professional.

EC REP

Symbol for “MANUFACTURER”

Symbol for “DATE OF MANUFACTURE”

Symbol for “AUTHORISED

REPRESENTATIVE”

Page 3

TABLE OF CONTENTS

1. NOMENCLATURE AND FUNCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1. VIDEO ENDOSCOPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-2. ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-3. VIDEO PROCESSOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2. PREPARATION AND INSPECTION FOR USE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2-1. INSPECTION OF THE VIDEO PROCESSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2-2. INSPECTION OF ENDOSCOPE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2-3. PREPARATION JUST BEFORE INSERTION OF ENDOSCOPE . . . . . . . . . . . . . . . 13

3. DIRECTIONS FOR USE

3-1. PRETREATMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3-2. INSERTION AND WITHDRAWAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3-3. BIOPSY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3-4. LASER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3-5. ELECTRO-SURGERY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4. CARE AFTER USE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4-1. ENDSCOPES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4-1-1 INTERNAL CHANNELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4-1-2 PRE-CLEANING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4-1-3 CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4-1-4 HIGH-LEVEL DISINFECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4-1-5 STERILIZATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4-2. ENDOSCOPIC ACCESSORY INSTRUMENT (EAIs) AND ENDOSCOPE

COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4-2-1 CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4-2-2 DISINFECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4-2-3 STERILIZATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4-3. WATER BOTTLE ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5. POST REPROCESSING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5-1. SERVICING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5-2. CARE AND MAINTENANCE TIPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Page 4

- 1 -

1. NOMENCLATURE AND FUNCTION

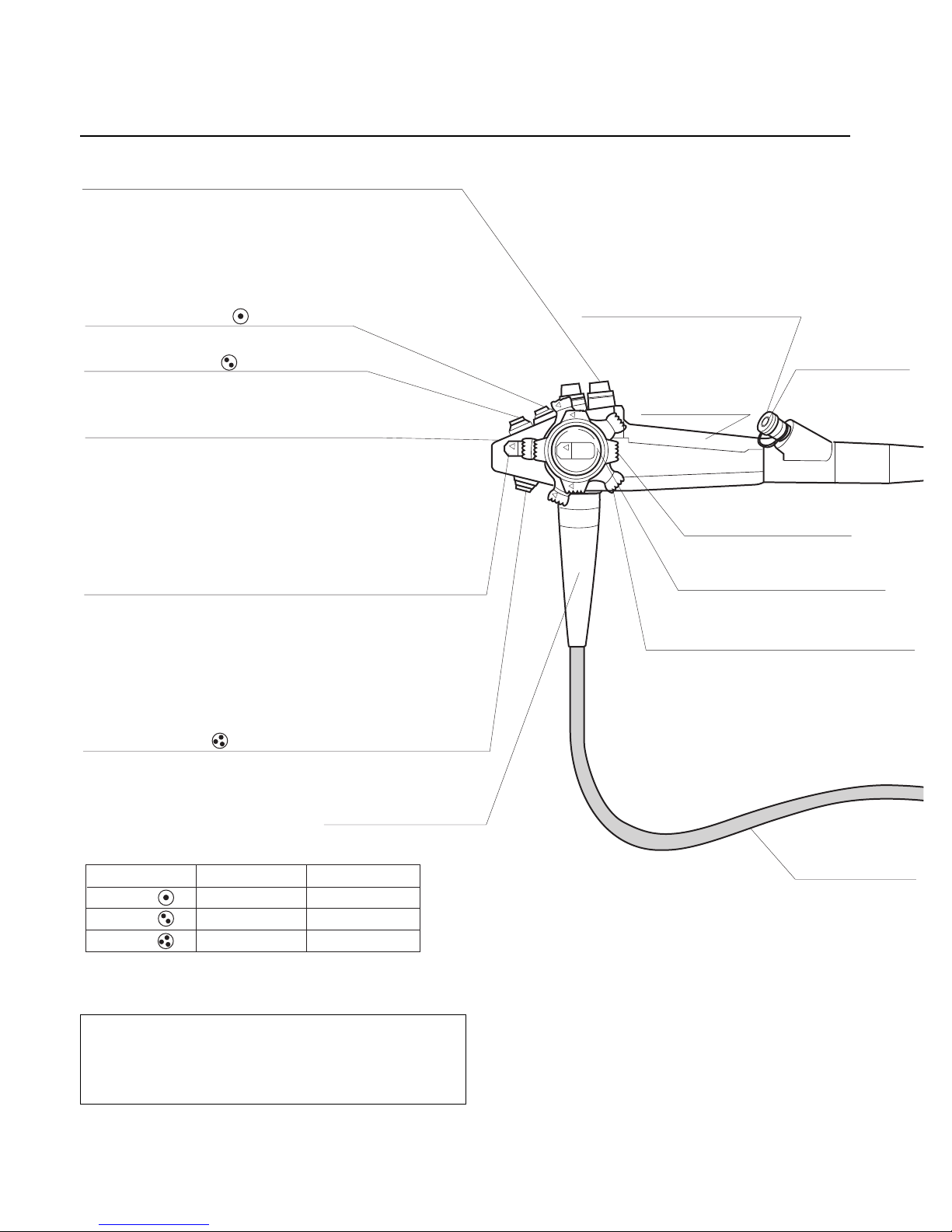

1-1. VIDEO ENDOSCOPE

NOTE:

To avoid damaging the endoscope, do NOT twist,

rotate or bend excessively any of the rubber strain

reliefs.

ENHANCE BUTTON

Push to activate the VCR for recording live procedures.

UP/DOWN DEFLECTION LOCK

When this lever is in the “F” position, turned clockwise,

the bending section moves freely. When turned counterclockwise,

the bending section becomes progressively more stabilized.

UMBILICAL CABLE

RIGHT/LEFT DEFLECTION

CONTROL KNOB

RIGHT/LEFT DEFLECTION LOCK

Functions similar to Up/Down lock

UP/DOWN DEFLECTION CONTROL KNOB

“F” (FREEZE) BUTTON

Push to freeze an image.

“C” (COPY) BUTTON

Push to activate the hardcopy system that

was selected between “FILE” and “HARD COPY”.

MODEL DESIGNATION

SUCTION CONTROL VALVE (OF-B120)

Depress to remove fluids or air through

the instrument channel.

RUBBER INLET SEAL (OF-B190)

Allows passage of accessories while

preventing escape of fluids and air.

INSTRUMENT

CHANNEL INLET

For introduction of

biopsy forceps

and other accessories

CONTROL BODY

AIR/WATER FEEDING VALVE (OF-B121)

Covering of hole in the top of the valve delivers

pressurized air. Covering of the hole and fully

depressing the valve delivers pressurized water.

U

L

R

D

F

F

BUTTON

Freeze

VCR

Hardcopy

BUTTON

BUTTON

EPK-1000

Freeze

VCR

Hardcopy

EPK-i

* The function can be changed. For more details, refer

to the manual supplied with the processor

RUBBER STRAIN RELIEF

Page 5

- 2 -

WARNING:

Note:

Immediately after use, the metal light guide prong and the

electrical contacts/pins of the endoscope may be HOT.

To avoid burns, do not touch these areas immediately

after use. For safer handling after a procedure, grasp the

PVE connector housing.

Ensure that the soaking cap has been securely

attached (by properly rotating it) to prevent the cap from

coming off during reprocessing. Failure to securely

attach the soaking cap can result in scope damage.

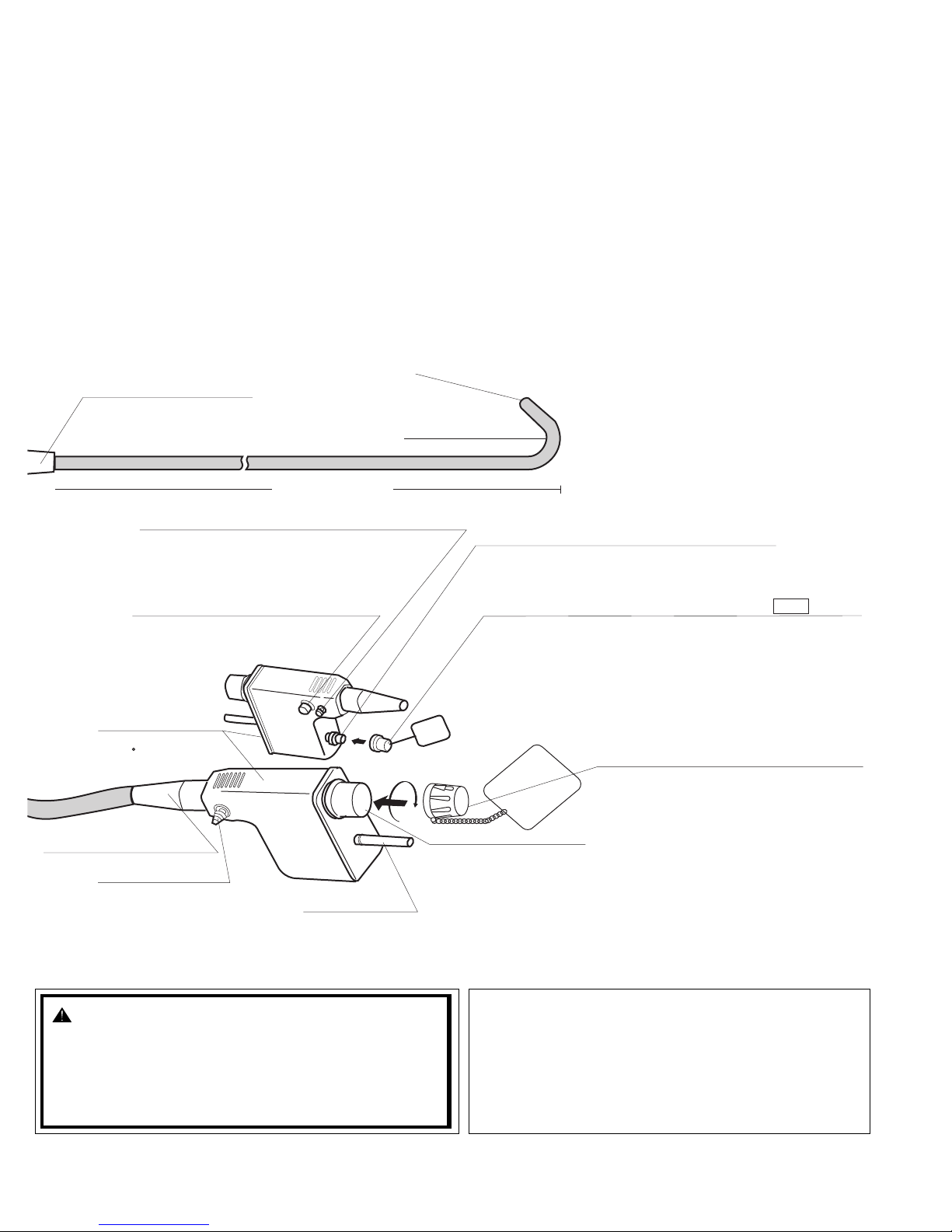

INSERTION TUBE

ELECTRICAL CONTACTS

LIGHT GUIDE

Transmits light from

light source to distal

end of endoscope.

ETO GAS STERILIZATION VENTING CAP OF-C5

Provides venting of endoscope interior to equalize

internal and external pressures. This cap must be

removed before immersion.

NOTE: See important separate section

regarding the use of this cap!

SUCTION NIPPLE

For attachment to

external suction

source

PVE CONNECTOR

Can be rotated within

a 180 range

AIR/WATER PORT

To connect feeding tube from water

bottle assembly.

FEED BACK TERMINAL

Certain manufacturers’ electrosurgical units, such

as older Olympus models, require the connection

of a scope feedback cord (S-cord) to this

feedback terminal.

VENTING CONNECTOR

Accepts “RED” ETO GAS Sterilization Venting cap.

Also accepts Leakage Tester.

PVE SOAKING CAP

OE-C9

BENDING SECTION

RED

This cap must be securely attached before

immersion.

DISTAL END

(Refer to the inside rear cover of this manual)

RUBBER STRAIN RELIEF

RUBBER STRAIN RELIEF

Page 6

- 3 -

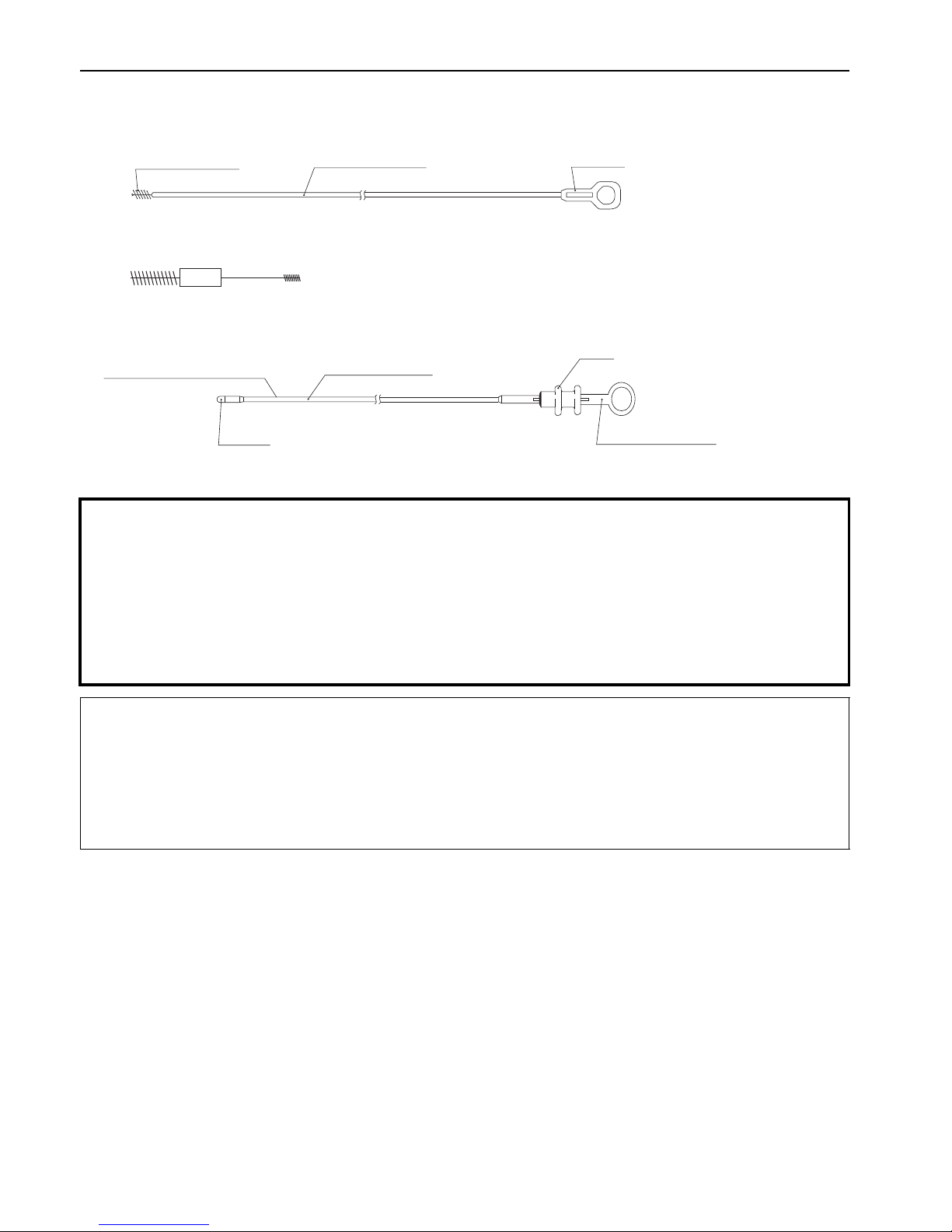

1-2. ACCESSORIES

CAUTION:

• Because of the effect that accessories used through the instrument channel of the endoscope can

have on the performance of the endoscope itself, it is strongly recommended that PENTAX accessories be used with PENTAX endocopes. If a unique or highly specialized accessory is available from

another source, please contact PENTAX to arrange a test of its compatibility before using it through

the PENTAX endoscope.

• Maximum outer diameter of an endoscopic accessory instrument must be at least 0.2 mm less than

the specified instrument channel diameter in PENTAX endoscopes. Working length of an endoscopic

accessory instrument should be approximately 30 cm longer than the endoscope working length.

NOTE:

• Depending upon country and/or local PENTAX distributor, each PENTAX endoscopic accessory may

be an optional accessory.

• For patient contact endoscopic accessories, follow the specific and detailed instructions on use, care

and maintenance supplied with each product.

• To confirm the exact condition of any new accessory device, check the labeling/packaging accompanying the product. Each label/package should clearly identify the contents as either sterile or non-sterile.

HANDLE

(CS6021SN)

FLEXIBLE SHAFT

WHITE BRISTLE

1) Cleaning Brush for Instrument Channel

2) Cleaning Brush for A/W Suction Valve Cylinder

( CS-C5S )

3) Biopsy Forceps

ENHANCED FLEXIBLE

PORTION

CUPS

FLEXIBLE SHAFT

GRIP

HANDLE

Pink handle defines

autoclavable forceps.

Page 7

- 4 -

1-3. VIDEO PROCESSOR

CAUTION:

Please refer to the instruction supplied with the processor.

NOTE:

Do not use the new PENTAX OS-H4 water bottle cap with the older OS-H2 water container/bottle.

Although the cap may appear to fit onto the bottle, air may escape resulting in insufficient pressure and

flow of air and water during the endoscopic procedure. Both the PENTAX water bottle cap and bottle

(container) are identified by their appropriate model designation. Ensure that an OS-H4 cap is used only

with the OS-H4 water container/bottle.

Do not overtighten the bottle cap. Overtighting can cause the bottle cap to break.

WARNING:

The lifetime of the lamp in EPK-i processor is 500 hours. Prior to use, check the lamp life meter on the rear

panel to ensure the lamp life is less than 500 hours. After 500 hours of use, the image quality will

deteriorate. Excessive use of the lamp beyond 500 hours could break the lamp inside the equipment

resulting in damage to the equipment.

WARNING:

The lifetime of the lamp in EPK-i processor is 500 hours. Prior to use, check the lamp life meter on the front

panel to ensure the lamp life is less than 500 hours. After 500 hours of use, the image quality will

deteriorate. Excessive use of the lamp beyond 500 hours could break the lamp inside the equipment

resulting in damage to the equipment.

NOTE:

The lamp life could be affected by frequency of use. In which case, the lamp life might become shorter than

its respective rated hours (EPK-i: 500 hours, EPK-1000 and EPK-100p: 400 hours)

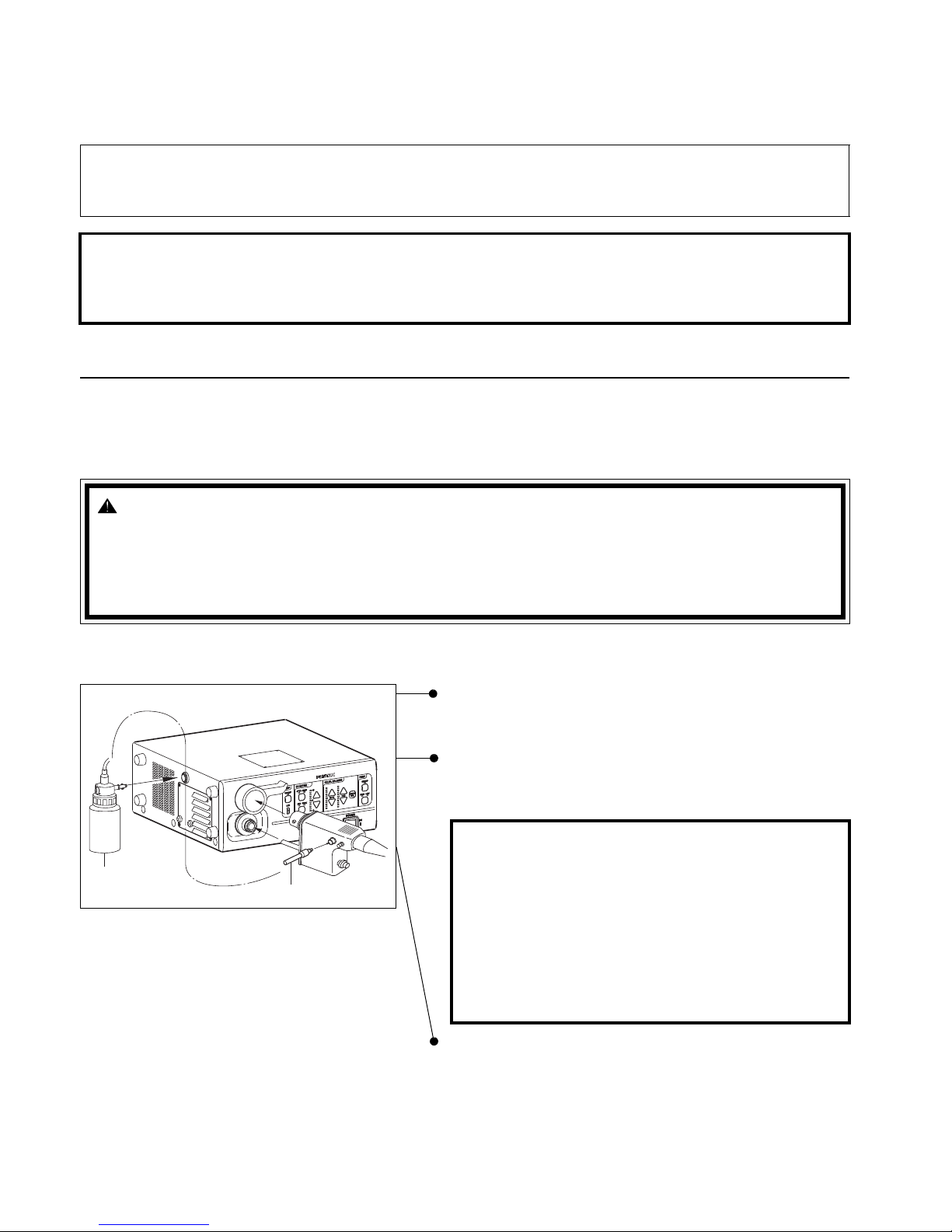

WATER BOTTLE

LAMP SWITCH

AIR PUMP SWITCH

LCD

POWER SWITCH

INTERFACE SOCKET

EPK-1000

POWER SWITCH

I : ON

O: OFF

LAMP SWITCH

INTERFACE

SOCKET

BRIGHTNESS

CONTROLS

AIR PUMP SWITCH

WATER BOTTLE

EPK-i

EPK-1000

Page 8

- 5 -

2. PREPARATION AND INSPECTION FOR USE

Prior to use, the endoscope, video processor and endoscopic accessory instruments must be carefully inspected for

cleanliness and proper function to determine that they are appropriate for patient use:

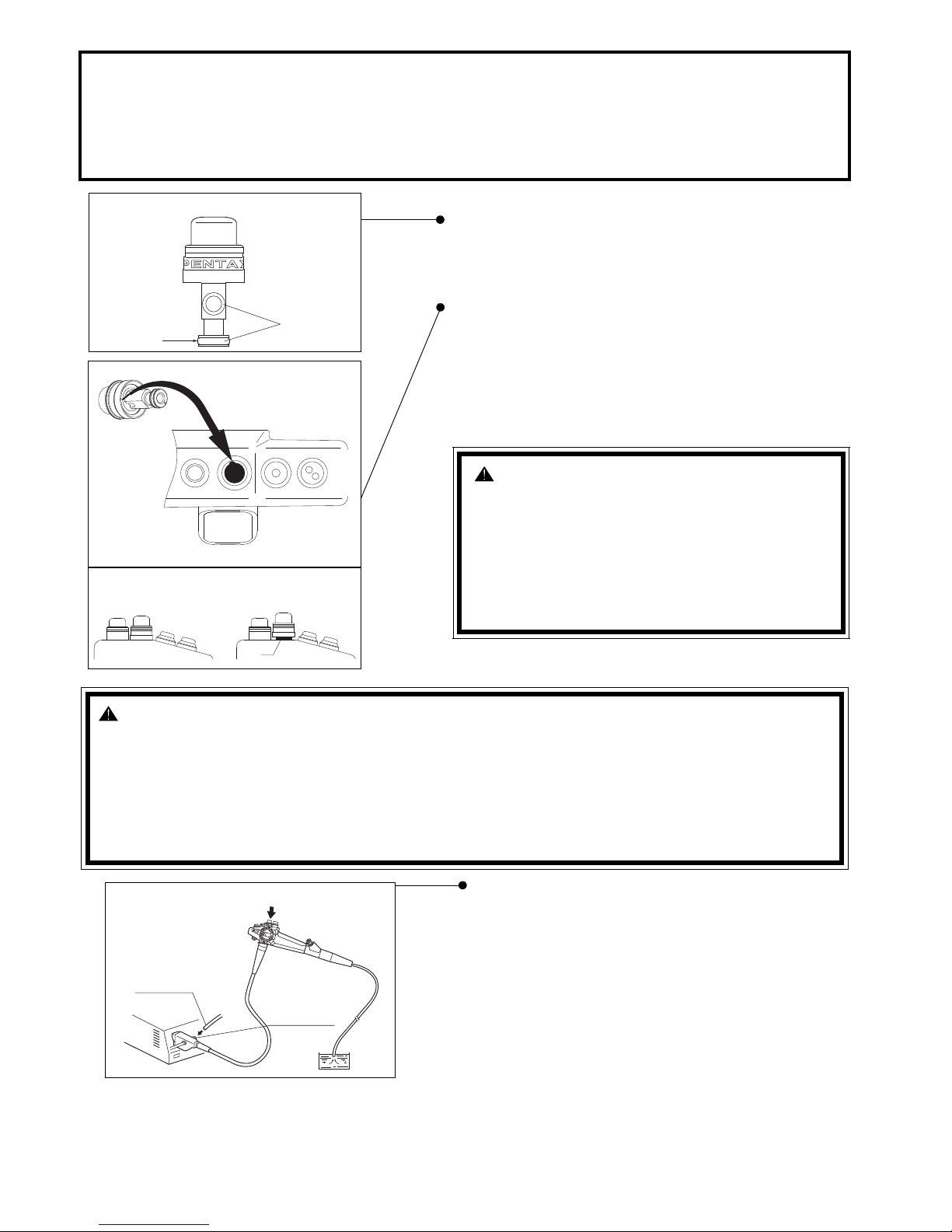

2-1. INSPECTION OF THE VIDEO PROCESSOR

Please refer to the Owner’s Manual of the specific model of PENTAX video processor for complete instructions.

1) Attach water bottle assembly, 2/3 filled with sterile water to the appropriate location on the left side of the

video processor.

2) Set the drain lever on the water bottle assembly to the upright position labeled A/W (air/water).

3) Plug the processor into a properly grounded receptacle with the power switch in the OFF position.

4) Make sure that the PENTAX PVE connector is aligned

with the interface socket on the front panel of the processor.

5) Connect the endoscope to the interface socket on the

processor as illustrated. Rotate the lever of the interface socket clockwise after insertion.

6) Connect the air/water feeding tube from the water bottle assembly to the air/water port on the side of the

PVE connector.

7) Turn the processor and air pump to the “ON” position and check for proper functioning.

8) Press the lamp switch of the processor to ignite the lamp.

NOTE:

PENTAX video endoscopes contained in this manual are only compatible with PENTAX video processor,

model EPK-1000 and EPK-i.

CAUTION:

To avoid discontinuation of endoscopic procedure, have an extra (spare) instrument available as a

standby device. Should any unforeseen event or circumstance render the original instrument inoperable

and/or unsafe for patient.

WARNING:

The addition of defoaming agents to the water supply is NOT recommended. Due to their nature, these

silicone based agents cling tenaciously to surfaces. Unless they are rinsed very thoroughly, a “barrier”

could be created which could reduce the effectiveness of the disinfection/sterilization process. Additionally, repeated use of such defoamers could eventually lead to residual silicone build up resulting in

equipment malfunction such as clogged air and/or water channels.

EPK-1000

WATER BOTTLE

air/water feeding tube

CAUTION

Failure to do so may create a “miscommunication”

between the scope and processor and may result

in the loss of the system’s automatic brightness

control and in excessive light emission from the

scope. Excessive light intensity can in turn

increase the amount of delivered thermal energy

causing heating of the scope tip, specifically the

illumination (LCB) cover glass and/or objects in

contact with the distal cover glass.

Page 9

- 6 -

9) Prior to each procedure, check the endoscope image quality displayed on the monitor. Confirm that the image

quality, color, automatic brightness (iris) functions are acceptable as per the instructions provided with the

PENTAX video processor.

2-2. INSPECTION OF ENDOSCOPE

Before proceeding with inspection of individual functions, PENTAX endoscopes should be tested for the integrity

of their water-tight design (example: tear in the instrument channel). This test is described in another section of

this manual entitled: “Leakage Testing.”

1) Inspection of the Insertion Tube

a) Check the entire surface of the insertion tube for abnormal conditions such as dents, crush marks, wrin-

kles, bumps, buckles, excessive bending, protrusions, bite marks, peeling of outer sheath, cuts/holes or

other irregularities. Any crush or indentation of the flexible shaft of the endoscopes can cause damage to

the internal mechanisms of the endoscopes.

b) Similarly, check the condition of the umbilical cable for outward signs of damage such as buckling, crush

marks, etc.

c) Make sure that the entire endoscope is clean and has been subjected to either a high-level disinfection or

sterilization process before each patient use.

NOTE:

As indicated elsewhere in PENTAX product labeling, endoscopes particularly the quality of the endoscopic image should be checked prior to patient use.

CAUTION:

If the endoscope is intended to be clinically used after testing of individual scope functions (suction, air/

water delivery, water jet, etc.) without further reprocessing, the following precaution should be exercised.

Use “fresh” distilled or sterile water during individual scope function tests to avoid recontamination of the

previously reprocessed instrument by waterborne microorganisms. Tap water, especially that which may

be left idle and uncovered for a prolonged period of time, should not be used during any inspection/testing of the endoscope.

CAUTION:

Various types of endoscope leakage testers exist including manual, electro-mechanical and “automated”

versions, some of which are stand alone units and others which may be integrated into Automated Endoscope Reprocessors (AERs)/Washer-Disinfectors (WDs). It must be recognized that PENTAX does not

evaluate non-PENTAX leak tester systems to satisfy their specific products claims, for their effectiveness

to accurately detect leaks and/or for their compatibility with PENTAX endoscopes. Insufficient pressures

may adversely affect the endoscope, especially if pressurization occurs during automated reprocessing

at elevated temperatures. PENTAX accepts no responsibility for use of non-PENTAX leakage testers.

Users should check with the leakage tester manufacturer and confirm their specific product claims,

including compatibility with PENTAX endoscopes at various temperatures and their ability to detect leaks

with/without fluid immersion and with/without flexing of the scope’s distal bending section.

CAUTION:

To avoid further damage to the endoscope or the possibility of malfunction during a procedure, do not

use an endoscope with any abnormalities or outward signs of damage.

WARNING:

All instruments must be reprocessed prior to first time use, after any repairs/service and before every

patient use. When utilizing chemo-thermal processes for reprocessing the endoscope, the instrument

should be allowed to return to room temperature prior to use and/or further handling.

Page 10

- 7 -

NOTE:

• The distal end of the endoscope as well as the electrical contacts/pins on the PVE connector must be

protected against damage from impact. Never apply excess force such as twisting, or severe bending

to the flexible portion of the endoscope.

• During pre-use inspection, ensure that the distal objective lens and the illumination (LCB) cover glass

are clean and no residues are present on these distal surfaces. If not, crisp images can NOT be displayed. Wipe with a gauze or the like moistened with enzymatic detergent solution.

• As indicated elsewhere in PENTAX product labelling, endoscopes particularly the quality of the endoscopic image should be checked prior to patient use.

• Ideally all patients should be prepped well to maximize visualization of the intended areas of interest.

Patient material and sections should be removed from the area of observation to eliminate the potential

to blur the endoscopic image and/or obscure the illumination system.

• Prior to a procedure, remove debris or secreta from observation area as much as a possible.

• Continuing use of the light guide with sticky debris might cause steam because debris is deprived of

moisture by heat. If steam is found on the light guide during a procedure, stop it immediately and withdraw the scope carefully from a patient.

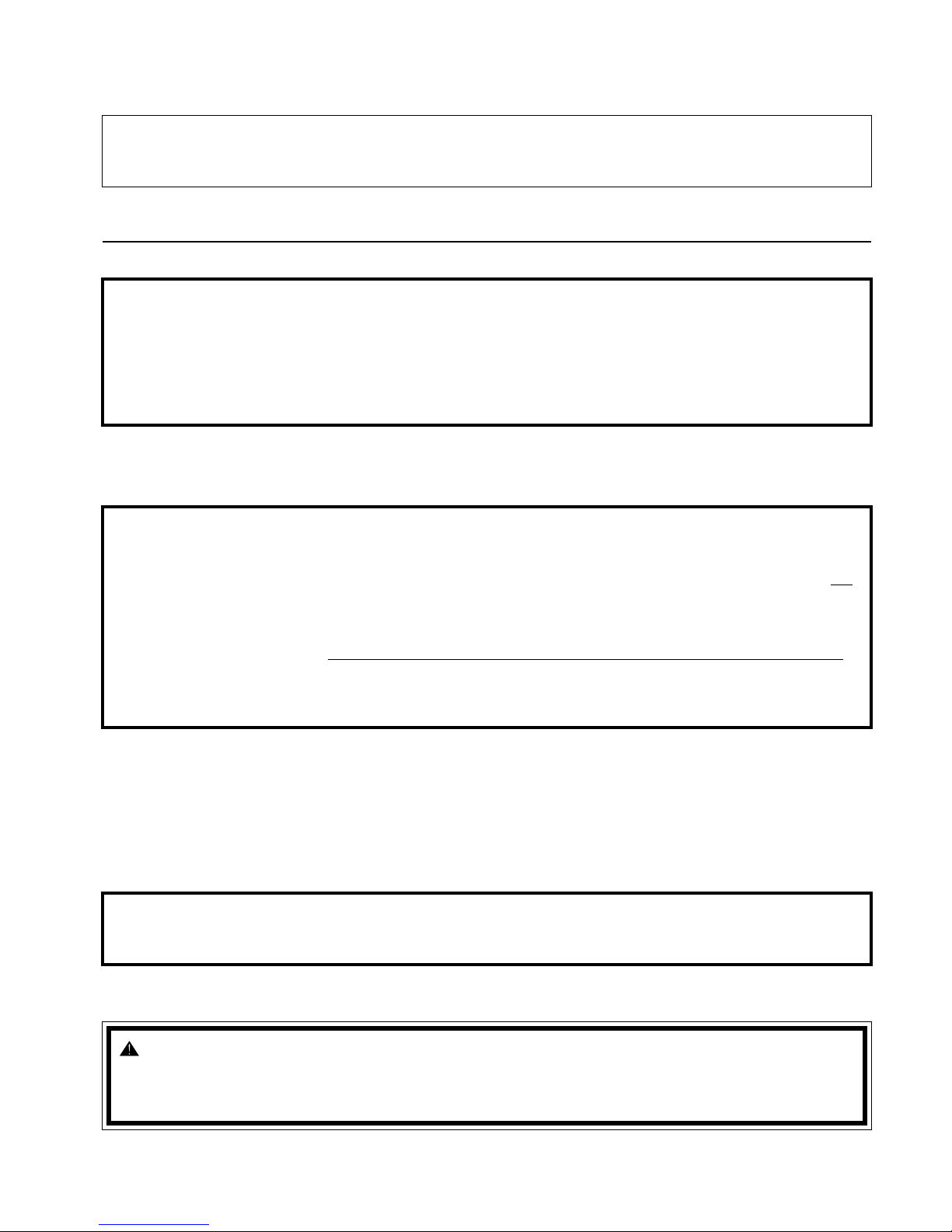

NOTE:

Flexible endoscopes and other sophisticated medical instruments are constructed of special materials,

unique parts and intricate components with strict dimensional tolerances. Specialized assembly techniques

and application of specific sealants and/or adhesives are required to ensure the watertight integrity and

maintain the functionality of these devices. It is therefore imperative that endoscopes be routinely checked

to ensure that parts used in their construction are not loose, missing or compromised that could otherwise

negatively affect the functionality of these devices. Compromised or loose components could result in device

failure, scope damage (via fluid invasion) and/or in incomplete decontamination of used instruments.

PENTAX recommends that prior to use endoscopes should be carefully inspected for their integrity and

checked for any “looseness” in the mating or joining of components including the following parts/areas:

• the channel inlet assembly (biopsy inlet port) (

① )

• the suction nipple/connector (

② )

• the air/water inlet port (

③ )

• any valve cylinder (

④ )

• basically, any inlet or outlet port associated with an internal channel, an indirect patient contact portion of

the endoscope

• rubber strain relief along insertion tube and umbilical cable (rotate clockwise only to tighten)

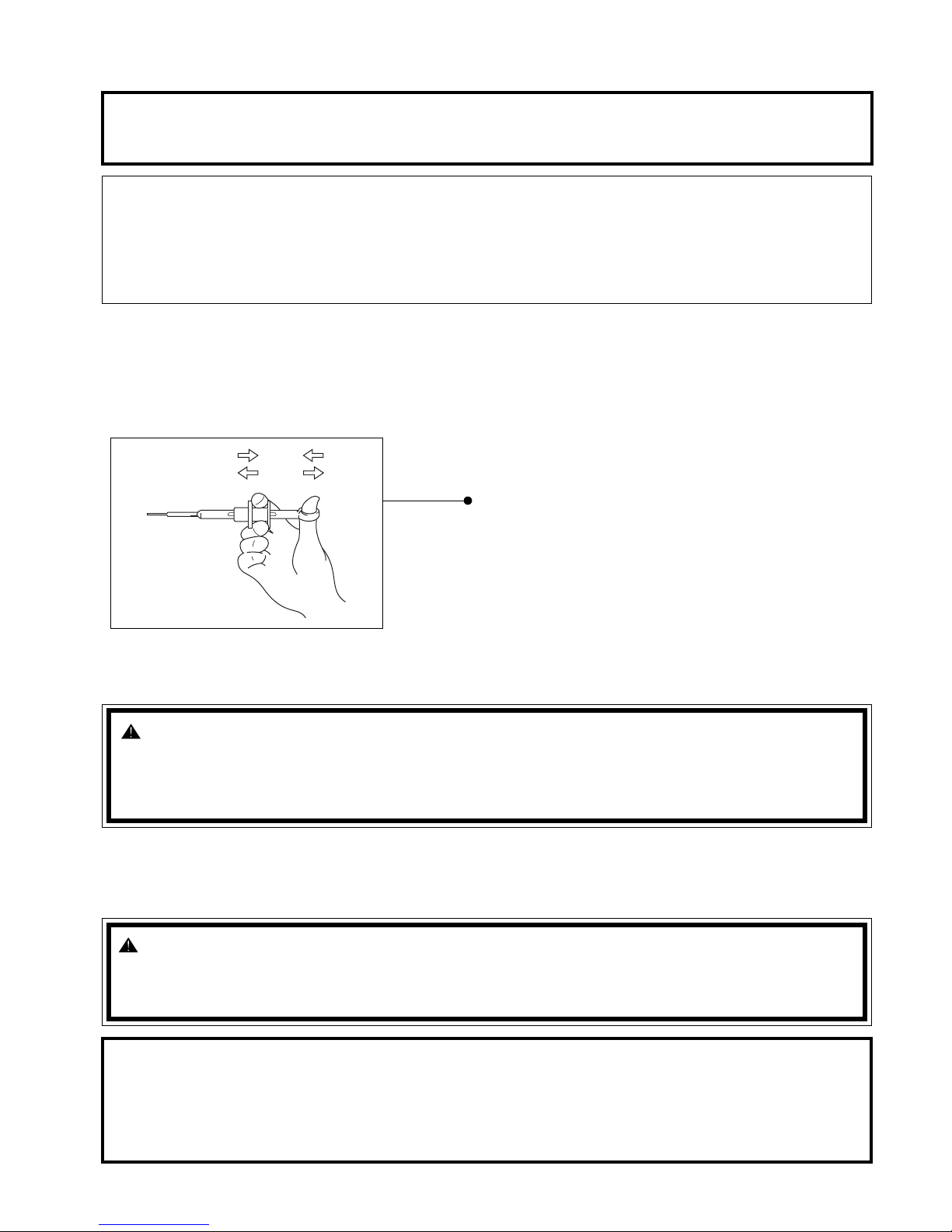

One method to check for looseness is to lightly grip

the exposed part, and while grasping the component

carefully attempt to move it in various directions. Use

of a lintfree gauze while grasping metal parts is

recommended as a protection for one’s fingers.

If any part/component remains loose (after

attempting to tighten) and/or if there is any

indication or suspicion of an abnormality or

outward signs of damage, do NOT use the

endoscope.

Contact your local PENTAX service facility.

Page 11

- 8 -

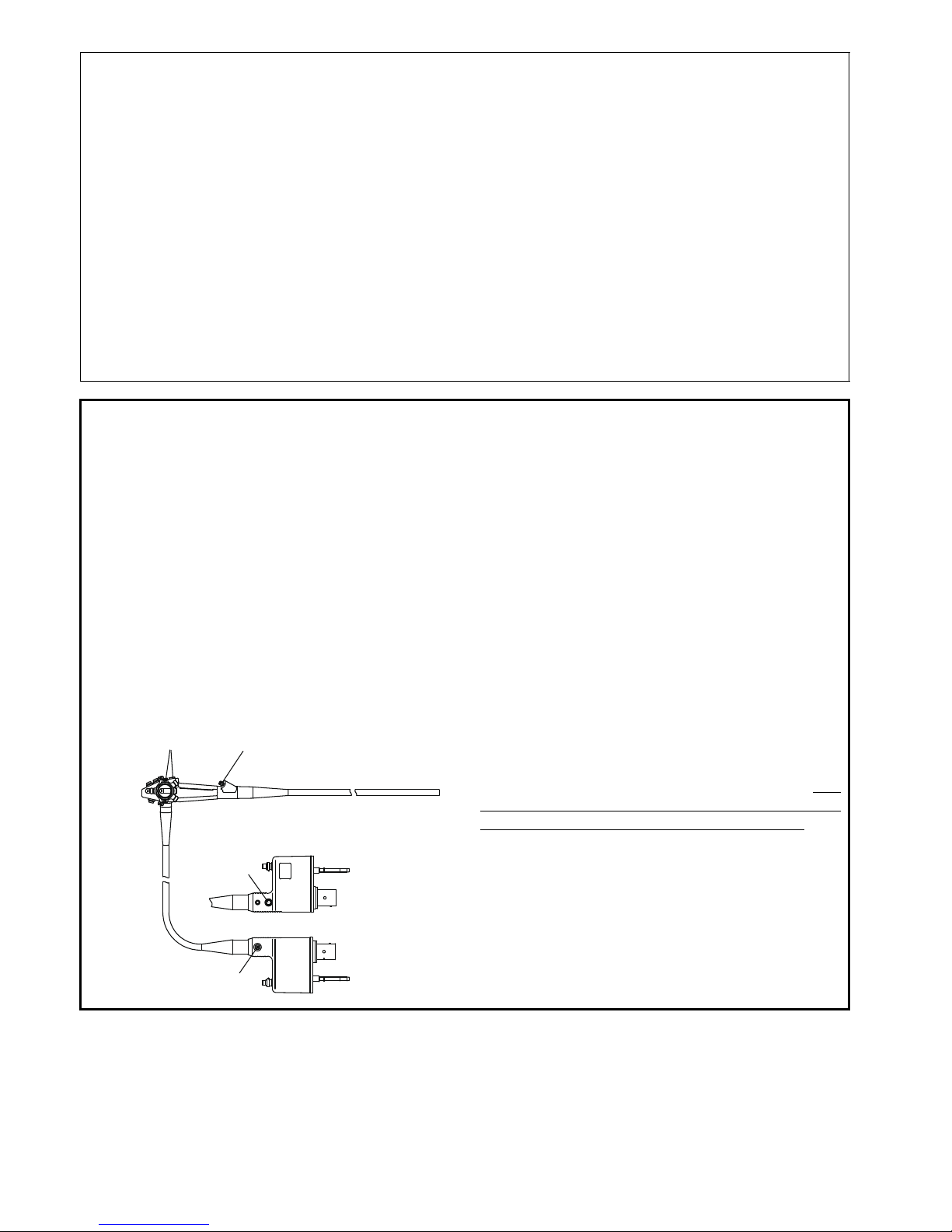

2) Inspection of Deflection Controls and Locks

a) Slowly manipulate the Up/Down and the Right/Left

control knobs to see that they function smoothly. Be

certain that a full and appropriate range of deflection is possible.

b) Engage the deflection locks to be certain that the

position of the deflected tip can be stabilized.

CAUTION:

To avoid damaging the endoscopes, do NOT twist, rotate or bend excessively any of the rubber strain

relief (

①, ②

) during inspection, clinical use, reprocessing or any handling activity. Be particularly cautious for

the insertion tube strain relief (

①

). When wiping the insertion tube and the umbilical cable, use a slow back

and forth motion to wipe them along the tube/cable. Never apply excessive force or torque on these strain

reliefs or slim tubes/cables. During ANY handling of the instrument avoid excess force, twisting, rotation and/

or bending of the actual insertion tubes and umbilical cables to prevent inadvertent damage (crush,

compression, deformity, etc.) to these parts as well as to internal components contained within the

endoscope.

U

L

R

D

F

F

U

L

R

D

F

F

U

L

R

D

F

F

Twisting or Rotating

Bending

RIGHT-LEFT

UP-DOWN

NOTE:

The deflection locks are of the friction type and the degree of friction is adjustable. The degree of locking

friction depends on the rotational position of the lever.

CAUTION:

ANY lack of smooth operation of the deflection controls may be an early indication of internal damage to

and/or part(s) failure within the endoscope’s angulation system. To avoid the possibility of further endoscope damage or the potential for malfunction of the angulation system, do NOT use the endoscope if the

angulation mechanism does not operate properly.

Prior to use ensure that the deflection controls can rotate smoothly, that there is no grinding or excess

friction within the angulation system and that the distal bending section bends freely and smoothly.

NEVER APPLY EXCESSIVE FORCE TO THE DEFLECTION CONTROLS!

When an endoscope exhibits excessive “knob play” or if angulation is lost in any direction, do NOT use

the instrument. Excessive “knob play” can be defined as rotating of the angulation control knob(s) in any

one direction for more than 30 degrees without any corresponding distal tip deflection. The examples

above are indications that service is required to avoid more serious problems with the angulation control

system, including angle or pulley cable/wire breakage and/or the possibility of a “frozen” distal bending

section.

A “frozen” bending section can make instrument extraction from a patient more difficult.

Page 12

- 9 -

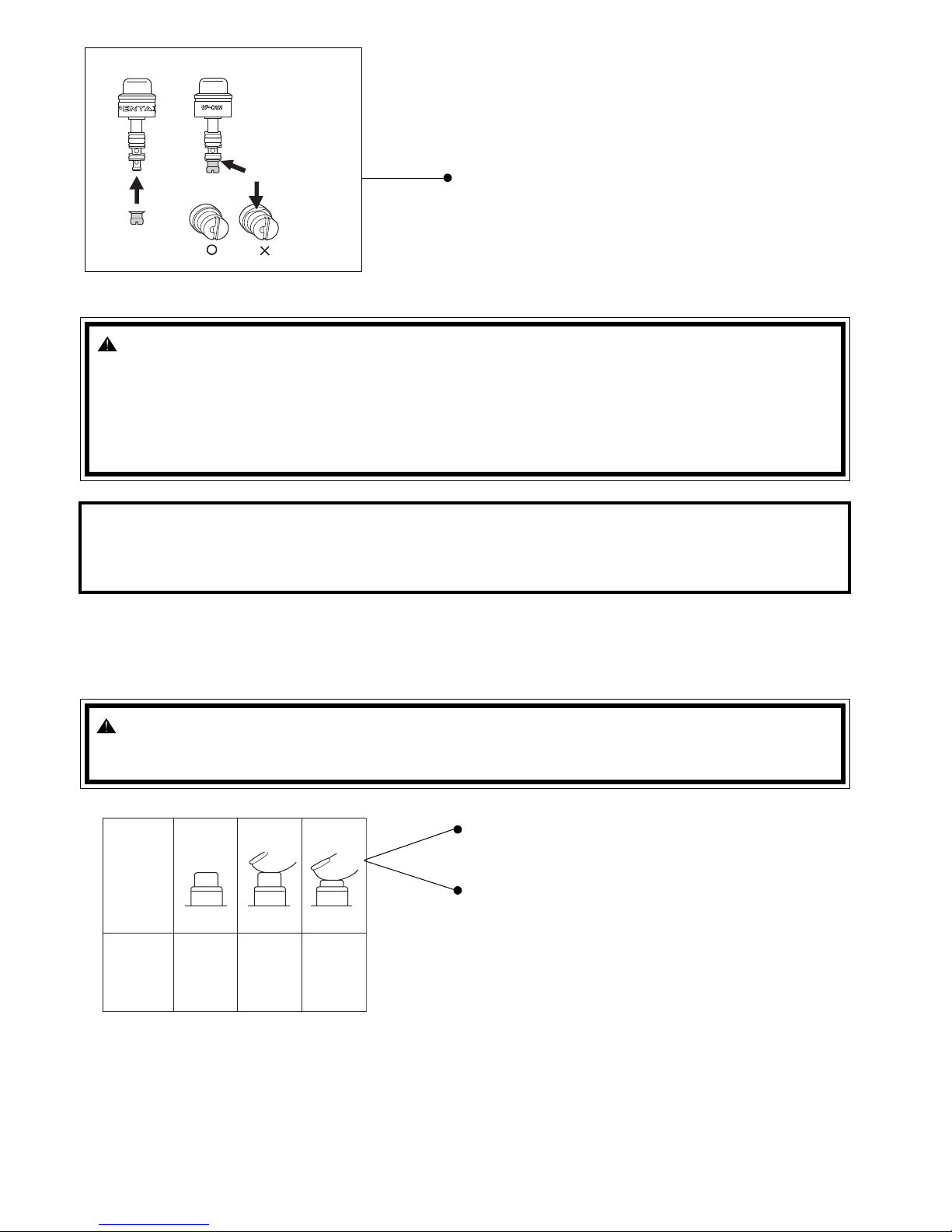

3) Inspection of Air/Water Feeding

a) Prior to use, the air/water feeding valve (OF-B121)

should be inspected. Remove the valve from the

control body and make sure that the black rubber

check-valve (OE-C14) in good condition is properly attached to the bottom of the metal valve stem.

b) If the rubber check-valve is missing or not attached

properly, correctly reposition the check-valve by

turning it several times on the air/water valve stem.

For proper positioning, there should be no clearance (gap) between the rubber check valve and the

metal air/water valve stem

c) To confirm that the check-valve is attached properly, visually inspect the check-valve and install the air/

water valve into the air/water cylinder on the control body. Proceed to test the air delivery function.

d) Connect the scope to the video processor. Turn air pump “ON” to desired pressure setting.

Place the scope distal tip into sterile water and confirm that no air bubbles exit the distal air nozzle.

e) To inspect air delivery, cover the hole at the top of

the air/water valve and confirm that air flows freely

from the air/water nozzle at the scope disital tip.

f) By depressing the air/water feeding valve, the water

delivery system is activated. Water should flow in a

steady stream from the air/water nozzle at the distal

tip of the endoscope. (This may take several seconds on the initial attempt.) USE STERILE

WATER ONLY.

WARNING:

A worn or damaged check-valve should be replaced with a new one which has already been subjected

to a high-level disinfection or sterilization procedure (Check valve set, model OE-C15 is optionally available). For repeated use, always ensure that the check-valve has already been reprocessed. A damaged, worn or missing check-valve could create continous air flow or excessive air insufflation and result

in potential patient injury such as pneumatic perforation. If the check-valve is not attached properly, it

could fall off during the endoscopic procedure and result in potential injury to the patient.

CAUTION:

If there is any doubt as to the suitability for use of the rubber check-valve, replace with a fully reprocessed

one prior to each procedure. A set of 10 pieces of the OE-C14 check-valve are available in a package as

model OE-C15.

WARNING:

If air bubbles are observed during the test, the rubber check-valve MUST BE REPLACED. Repeat the

test procedure with a new check-valve (OE-C14).

OF-B121

OE-C14

Don’t let the skirt

fold under

Action

Result

Air

Feeding

Water

Feeding

–

Page 13

- 10 -

g) Release the air/water valve to determine if the valve

freely returns to its OFF (neutral) position and

delivery of water (and air) ceases.

h) If the air/water valve OF-B121 does not function

properly, does not move smoothly or feels “sticky”,

remove the valve and apply a very small amount of

silicone oil lubricant onto all the O-rings. Do NOT

use excess oil, avoid “blobs”, large drops and/or

squirts of oil directly onto the metal valve stems instead, simply place a small droplet of oil on one’s

sterile gloved forefinger and gently swirl between

thumb and forefinger. Next place the valve with

O-ring in-between thumb and finger and gently rotate the valve so that the oil is evenly applied to the outer

edges of each rubber O-ring. Make sure the oil is applied to all O-rings and wipe off all excess.

Do NOT apply excess oil. Doing so can allow for inadvertent migration of the oil inside channels or other

areas not intended to be lubricated.

i) If air and/or water do not flow properly, NEVER attempt to clear the air or water nozzles with a needle or

any other sharp object. Instead, the following steps should be followed.

1 Disconnect the endoscope from the video processor.

2 Remove the air/water feeding valve.

3 Using a cotton tipped applicator and alcohol, clean the valve recess (receptacle) in the control body thor-

oughly to remove any debris. Do NOT attempt to insert the applicator into the small openings within the

valve receptacle as the cotton or applicator could become lodged within these openings and cause channel

blockage.

4 • Following the section of this manual for cleaning the air and water channel with detergent, flush deter-

gent through both the air and water channel.

Then flush the air several times to force any residual solution out of the channel.

• Remove the adapters and install the air/water feeding valve.

(Alternate) By leaving the air/water valve in the cylinder instead of the adapter, one may direct pressured

fluid (or air) independently to either channel to expel debris from and/or more forcefully flush solution

into either the air or water channel. This should not be attempted on a completely clogged/blocked air or

water channel/nozzle.

5 Test for normal delivery of air and water. It may be necessary to repeat the above procedure if normal air

and water delivery is still not available.

OF-B121

O Ring : OF-B143

NOTE:

Excessive silicone oil (lubricant) should be avoided to prevent occlusion of the internal air or water channels/nozzles and potential impairment of the normally clear endoscopic image.

NOTE:

If blockage of the line is encountered, avoid use of excessive pressure to prevent scope damage.

NOTE:

Do NOT apply excessive force in an attempt to unblock a clogged channel as the channel and/or brush

could become damaged. Whenever channel damage is suspected, the endoscope should be leak tested.

If repeated attempts to flush the air/water system are unsuccessful, do not attempt to use the endoscope

on a patient. Contact the PENTAX service department.

NOTE:

Prior to clinical use, it is important that the entire air channel system be dry. Failure to thoroughly dry the

air system could result in an unclear or blurry image caused by very fine droplets of moisture being swept

over and/or onto the objective lens at the distal end of the scope.

Page 14

- 11 -

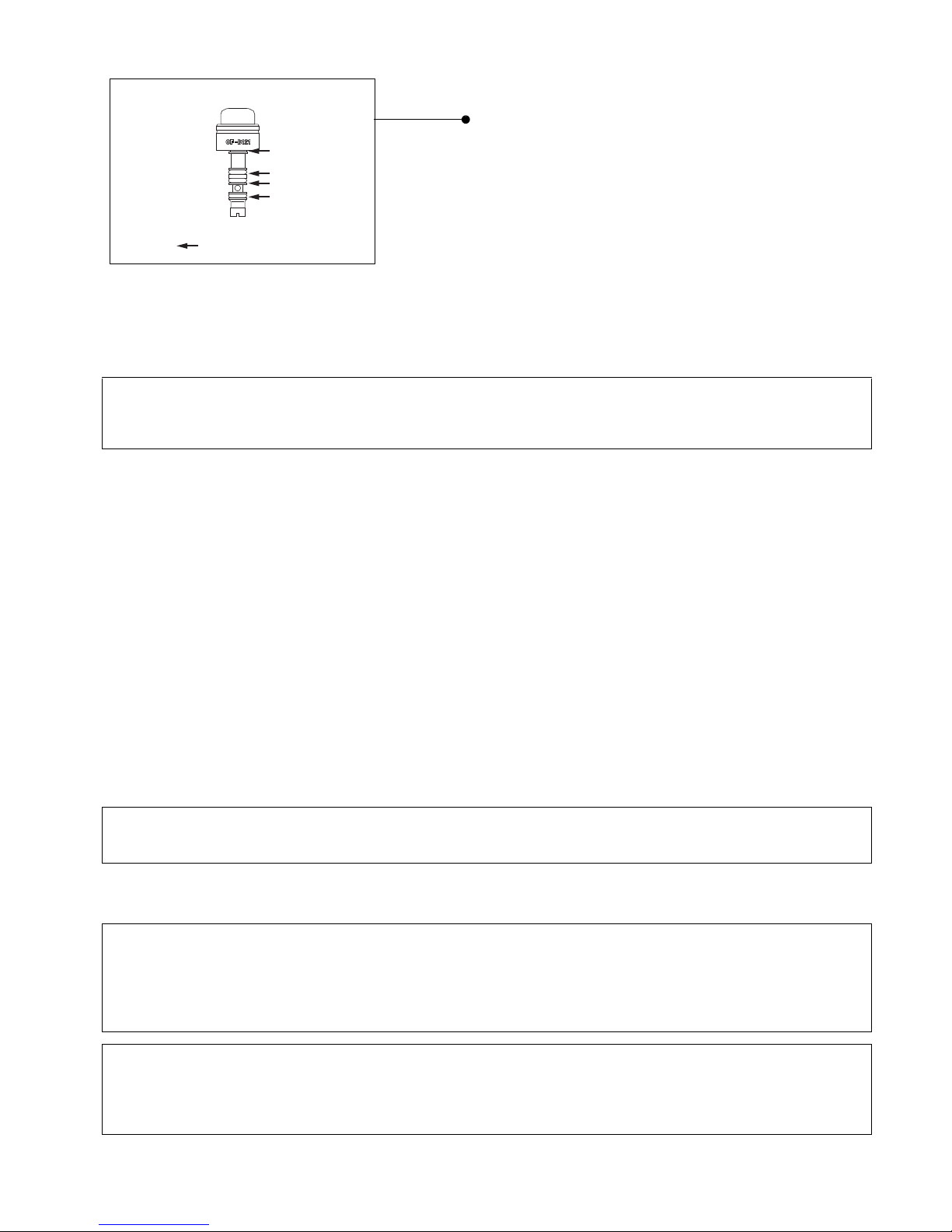

4) Inspection of Suction Mechanism

a) Prior to use suction control valve (OF-B120)

should be inspected. Remove the value from the

control body and make sure that the rubber portion

is not damaged or worn.

b) Position the valve OF-B120 so that the small metal

tab near the base on the valve stem aligns with the

notched suction valve cylinder, also color coded in

orange. Install the valve into the suction cylinder by

gently pushing the valve into the cylinder. Never

apply excessive force to push the valve into the suction cylinder.

c) Connect suction tubing from an external suction

source to the suction nipple located on the PVE

Connector at the end of the umbilical cable. Place

the distal tip of the endoscope in a basin of sterile

water and depress the suction control valve. Water

should be rapidly aspirated into the suction system

collection container.

CAUTION:

The instrument, Air/Water channel systems are made of stainless steel, poly phenylene oxide and fluorine-contained polymers. When any fluids are used with this scope, please read carefully and follow all

instructions in the manual supplied with the fluids for use and pay special attention to any reactions with

the materials identified in the intended fluid path. Only the user can determine if the fluids are appropriate

for patient use.

Silicone oil

O-Ring

OF-B127

OF-B120

Incorrect

Correct

metal

OF-B120

OF-B120

WARNING:

Improperly installed valves may not function as

originally intended. Such valves may not return

to their neutral (released) positions and/or they

may provide continuous suction. Continuous

aspiration can cause loss of air/fluid, difficulty in

maintaining proper insufflation and/or inadvertent

suctioning of tissue into the distal instrument

channel opening.

WARNING:

A worn or damaged value and/or O-ring should be replaced with a new one. The entire value mechanism should be subjected to a high-level disinfection or sterilization procedure prior to use (O-ring set,

model OF-B127, is optionally available). Failure to do so could result in continuous aspiration which in

certain clinical situation can suction tissue into the distal channel opening at the scope tip and/or create

a loss of insufflated air via the suction system.

A compromised valve could also result in the potential for reflux or spit-back of patient fluids that may

present infection control risks.

SUCTION

TUBE

DEPRESS

SUCTION

NIPPLE

Page 15

- 12 -

d) Release the suction control valve to determine if the valve freely returns to its OFF position and the aspira-

tion of water ceases.

e) If the suction valve does not move smoothly or feels “sticky”, remove the valve from the suction cylinder

on the control body of the endoscope. Apply a small amount of silicone oil lubricant, OF-Z11, onto rubber

part and rubber the O-ring. Place a small droplet of oil on one’s sterile gloved forefinger and gently swirl

between thumb and forefinger. Next place the valve with O-ring in-between thumb and finger and gently

rotate the valve so that the oil is evenly applied to the outer edges of the rubber O-ring.

Remove/wipe off excess lubricant with a soft gauze. Do not use excessive silicone oil.

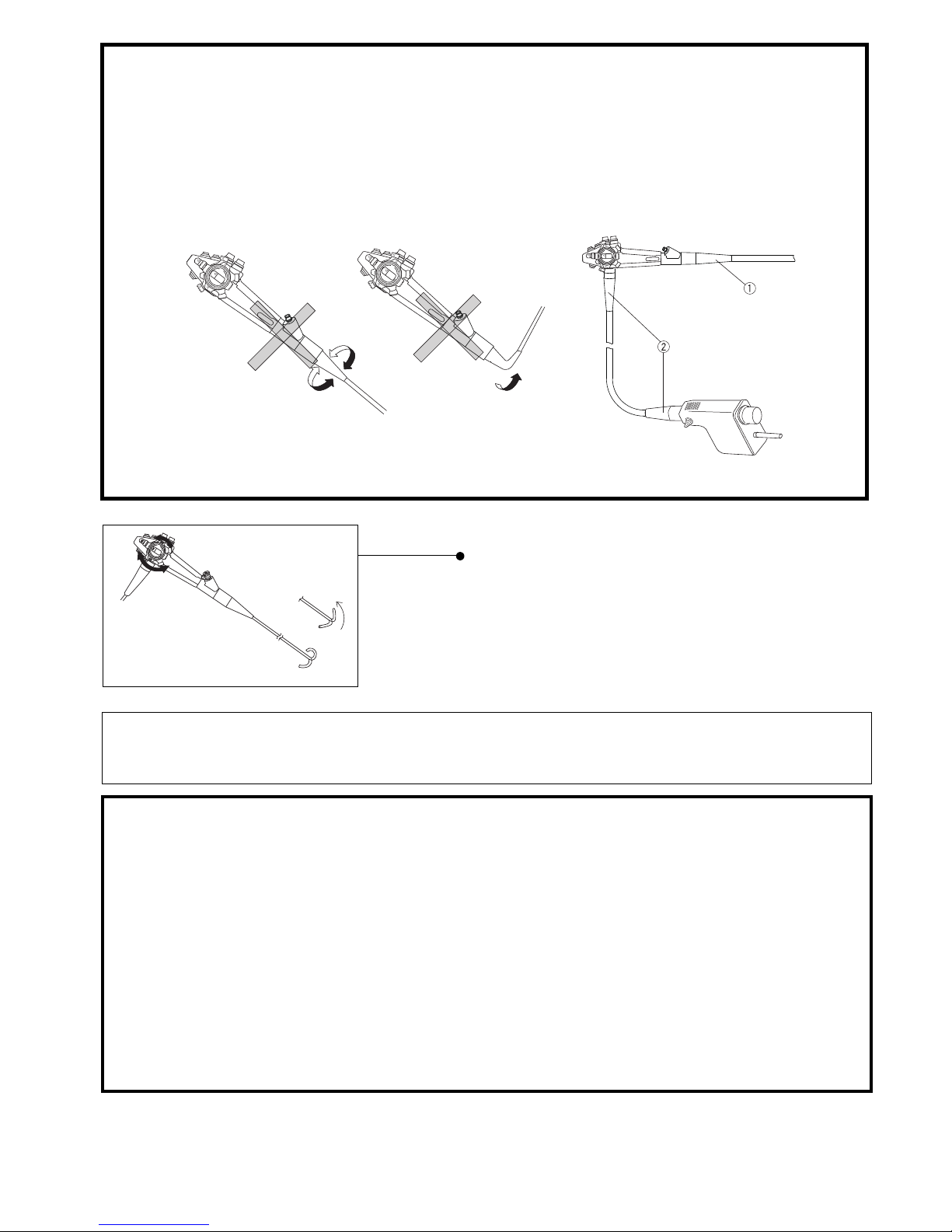

5) Inspection of Biopsy Forceps and Instrument Channel

a) Make sure there are no kinks in the flexible shaft of

the biopsy forceps.

b) The jaws of the forceps must be free of any residual

debris. Any debris must be cleaned from the forceps before they are used. Use only sterile forceps.

c) The handle mechanism on the forceps should be

operated to open and close the jaws. This mechanism should operate freely.

d) Close and inspect the jaws of the forceps to make

sure the cups are in proper alignment. If the forceps

has a spike, the spike must be completely straight

and fully within the cups.

e) Any accessory should be slowly inserted through the instrument channel inlet with the endoscope in a

straight position. There should be no resistance encountered. If resistance is encountered, do not attempt

to introduce the accessory further. The instrument channel may be damaged and the endoscope should not

be used. Contact the PENTAX service department.

CAUTION:

If the instrument is to be used immediately after the inspection, use only “fresh” distilled or sterile water.

To avoid recontamination of a previously reprocessed endoscope, avoid use of idle/uncovered tap water.

NOTE:

A rubber inlet seal in good condition must be on the instrument channel inlet to prevent the loss of suction

and a risk of cross contamination to the end user due to the potential for reflux (spit-back) of patient fluids. Worn seal will result in leakage and should be replaced. To ensure maximum performance of these

sealing mechanisms, consider replacing the rubber inlet seal with a new fully reprocessed one for each

procedure.

WARNING:

The use of any forceps or accessory that shows any sign of damage or difficulty of operation must be

avoided. Any malfunction of a forceps or accessory during a patient procedure could result in serious

injury to the patient. Also, the use of damaged forceps or accessories may result in serious and costly

damage to the endoscope.

WARNING:

All patient contact accessories must be thoroughly cleaned and subjected to an appropriate high-level

disinfection or sterilization process before being used for the first time and subsequently after each clinical use.

CAUTION:

The instrument, Air/Water channel systems are made of stainless steel, poly phenylene oxide and fluorine-contained polymers. When any fluids are used with this scope, please read carefully and follow all

instructions in the manual supplied with the fluids for use and pay special attention to any reactions with

the materials identified in the intended fluid path. Only the user can determine if the fluids are appropriate

for patient use.

CLOSE

OPEN

Page 16

- 13 -

2-3. PREPARATION JUST BEFORE INSERTION OF ENDOSCOPE

1) If the endoscope has just recently been reprocessed, has been prepared or stored properly and passed all preprocedure inspections, the instrument should be ready to use. If necessary, the scope’s insertion tube may be

wiped down with a gauze dampehed with 70-90% ethyl or isopropyl alcohol.

2) Gently wipe the insertion tube with a gauze moistened with 70-90% ethyl or isopropyl alcohol.

3) Gently clean the objective lens with a cotton-tip applicator moistened with 70-90% ethyl or isopropyl alcohol. A lens cleaner (anti-fogging agent) may also be applied via gauze or other applicator.

4) Check the endoscopic image and confirm that it is of acceptable quality for clinical use. Refer also to the

owner’s manual supplied with the PENTAX video processor for inspection of the image quality.

5) (SCOPES TO BE INTRODUCED TRANSORALLY)

Prior to trans-oral insertion of the endoscope, place a bite-block (mouthpiece) into the patient’s mouth to protect the endoscope from damage during the procedure. Failure to do so can result in scratches, tears and/or

crushing of the insertion portion of the endoscope.

6) Apply a medical grade water soluble lubricant to the insertion tube. Do not use petroleum based lubricants.

NOTE:

Accessories should always be inspected and checked with the particular endoscope prior to each

procedure.

WARNING:

Do NOT clinically use the endoscope if any irregularity or abnormality is suspected. If there is any doubt

as to the suitability of use for any endoscope component, replace it with a new fully reprocessed one. An

instrument irregularity may cause scope damage and/or compromise patient or user safety.

WARNING:

Every endoscope should be properly disinfected or sterilized before being used for the first time. The

endoscope should have been properly cleaned, disinfected or sterilized after any previous use and after

being returned for any repairs/service.

Refer to the companion manual describing in detail PENTAX reprocessing instructions.

WARNING:

Current infection control guidelines require that endoscopes and their patient contact accessories either

be sterilized or at the least be subjected to high-level disinfection. Accessories which ENTER STERILE

TISSUE or THE VASCULAR SYSTEM must be sterilized before patient use. It is recommended that any

accessory intended for use in the biliary tract be subjected to an appropriate sterilization process. Only

the user can determine if an instrument has undergone appropriate infection control procedures prior to

each clinical use.

NOTE:

Contact the manufacturer and follow local regulations regarding safe use, appropriate handling and disposal of alcohol products. Material Safety Data Sheets (Health and Safety Data Sheets or similar documents depending upon country) available from the alcohol manufacturer should provide guidance to end

users about composition, hazards, chemical and physical properties, first aid, handling and storage, stability, precautions, disposal, etc. associated with alcohol solution.

Page 17

- 14 -

NOTE:

• The objective lens and the light guide must be kept free of the lubricant and excess lens cleaner.

• Prior to a procedure, remove debris or secreta from observation area as much as possible.

WARNING:

Never drop this equipment or subject it to severe impact as it could compromise the functionality and/or

safety of the unit. Should this equipment to be mishandled or dropped, do not use it. Return it to an

authorized PENTAX service facility for inspection or repair.

Page 18

- 15 -

3. DIRECTIONS FOR USE

3-1. PRETREATMENT

1) The patient should be prepared in your normal endoscopy regimen.

3-2. INSERTION AND WITHDRAWAL

1) Slowly insert the scope under direct vision.

2)

(SCOPES TO BE INTRODUCED TRANSORALLY)

When the distal end of the scope is passed through the

pharynx, the patient should be gently biting down on the

bite block to maintain the bite block’s position during the

procedure.

3) Adjust the intensity of the video processor to obtain a

brightness level suitable for observation.

4) The deflection controls should be used as needed to position the scope. The deflection of the tip should be

done under direct vision in a gentle and deliberate manner.

5) Insufflation can be controlled by the combined use of the air valve or CO2 valve to increase the amount of

insufflation and the suction control to decrease the level of insufflation. The user may elect to use CO

2 deliv-

ery in lieu of air delivery by using the CO

2 gas adapter (OF-G11) in combination with a special CO2/water

valve. (OF-B130)

WARNING:

This instrument should only be used by physicians who have thoroughly studied all the characteristics of

this instrument and who are familiar with the proper techniques of endoscopy. During the procedure,

always wear protective garments such as gloves, gowns, face masks, etc. to minimize the risk of cross

contamination.

BITE BLOCK

WARNING:

The light emission from the endoscope could cause thermal injury. To minimize the risk, use only the

minimum amount of brightness and avoid close stationary viewing and unnecessary prolonged use.

CAUTION:

ANY lack of smooth operation of the deflection controls may be an early indication of internal damage to

and/or part(s) failure within the endoscope’s angulation system. To avoid the potential for malfunction of

the angulation system, do NOT use the endoscope if the angulation mechanism does not operate properly.

Ensure that the deflection controls can rotate smoothly, that there is no grinding or excess friction within

the angulation system and that the distal bending section bends freely and smoothly.

NEVER APPLY EXCESSIVE FORCE TO THE DEFLECTION CONTROLS!

If during a procedure angulation is lost in any direction such as when “cables snap” (broken pulley wire,

broken angle wire, etc.), do NOT continue to use the instrument and do NOT rotate the deflection controls. Should the angulation system fail for any reason, stop the procedure, release the lock lever and

carefully withdraw the endoscope under direct visualization.

The examples above are indications that service is required to avoid more serious problems with the

angulation control system, including the possibility of a “frozen” distal bending section.

A “frozen” bending section can make instrument extraction from a patient more difficult.

Page 19

- 16 -

6) Procedures involving poorly prepped patients should be avoided as excessive patient material can negatively

affect certain scope channel functions as well as the ability to maintain a clear endoscopic view.

7) Mucous, fluids and/or other patient material should be aspirated via the instrument/suction channel and suction control valve to improve visualization. Maintain a clear view during aspiration, avoid prolonged suction

time and use the minimum level of negative pressure required to perform the clinical procedure.

8) The objective lens may be cleaned during the procedure by alternately using the air/water and suction control

valves.

9) Image capture, hard copy documentation, video recording, etc. may be carried out as necessary.

10) Before withdrawing the scope, trapped air should be suctioned to reduce patient discomfort.

11) When attempting to withdraw the scope, return the deflection locking levers to their free position. Always

withdraw the scope under direct visualization.

NOTE:

Be careful not to deliver too much air.

WARNING:

It must be recognized that variations in air flow (pressure and volume) for patient insufflation may exist

from one manufacturer’s equipment (processor and/or scope type) to another. It is, therefore, important

to closely monitor the patient at all times and to aspirate excessive air to prevent overinsufflation and

potential pneumatic perforation.

WARNING:

Do not apply excessive negative pressures (high suction settings) and/or prolonged contact of the distal

instrument channel opening (scope tip) against mucosal surfaces to avoid “suction polyps”, bleeding

and/or other trauma to the patient. During aspiration keep as clear as possible an endoscopic view of

patient anatomy and maintain some distance from scope tip to tissue to avoid suctioning of mucosa

onto/into the distal channel opening.

NOTE:

Continuing use of the light guide with sticky debris might cause steam because debris is deprived of

moisture by heat. If steam is found on the light guide during a procedure, stop it immediately, and withdraw the scope carefully from a patient.

NOTE:

Should debris on the objective lens be difficult to clean, one can temporarily use the HIGH air pressure

setting on the processor and simultaneously press the air/water and suction control valves. Return air

pressure setting to original selection before proceeding.

UP/DOWN DEFLECTION LOCK

RIGHT/LEFT

DEFLECTION LOCK

FREE POSITION

(LOCK RELEASED)

FREE POSITION

(LOCK RELEASED)

LOCK POSITION

LOCK POSITION

WARNING:

If for any reason, the image is lost due to power

shortage, lamp or processor failure, etc. the

deflection locking levers should be released, the

scope tip should be straightened to its neutral

position, and the insertion tube should be carefully and slowly withdrawn from the patient.

Page 20

- 17 -

3-3. BIOPSY

1) Insert the forceps through the slit in the rubber inlet seal. Be certain to hold the forceps handle in such a way

to ensure that the jaws of the forceps are in a fully closed position during insertion.

2) When a portion of the cups of the forceps becomes

visible in the viewing field, carefully advance the forceps onto the target area.

3) Open the forceps cups and advance the forceps against

the target area. Carefully squeeze the forceps handle to

close the cups and obtain a specimen within the cups.

Always maintain a view of accessory during advancement.

4) Withdraw the forceps slowly with the cups closed.

CAUTION:

For ALL types of endoscopic accessory instruments, always maintain a view of the accessory during

advancement, use and withdrawal of the device.

WARNING:

For safety reasons, always insert and advance the accessory in the standard, non-magnified mode.

Magnified vision reduces the depth of the viewing field making it difficult to maintain a clear view of the

accessory.

5 cm

NOTE:

When the cups are first passed through the inlet

seal, a temporary resistance will be encountered.

Hold the shaft tightly at about 5cm from the cups

and push it through.

NOTE:

During insertion, if the forceps are found hard to advance further due to resistance, decrease the deflection of the bending section to a level suitable for smooth insertion and insert the forceps again.

CAUTION:

Never apply excessive pressure when introducing

any accessory since the instrument channel may

be damaged. Malfunction of the scope as well as

costly repairs may result.

NOTE:

Because of the effect accessories used in the instrument channel of the endoscope can have on the performance of the endoscope itself, it is strongly recommended that only PENTAX accessories be used

with PENTAX endoscopes. If a unique or highly specialized accessory is available from another source,

please contact PENTAX to arrange a test of its compatibility before using it through the PENTAX endoscope.

WARNING:

Accessories which ENTER STERILE TISSUE or THE VASCULAR SYSTEM must be sterile.

Accessories intended for use in the biliary tract should be sterilized before patient use.

Page 21

- 18 -

3-4. LASER

Laser equipment should only be used by physicians who have thoroughly studied all the characteristics of the

equipment and who are familiar with the proper techniques of endoscopic laser therapy. The user must carefully

read and follow all instructions in the operating manual supplied with the Laser equipment. The Laser equipment

should be carefully and thoroughly inspected and calibrated. Only the user can determine if the condition of the

Laser equipment is suitable.

1) The user has the option of using a non-explosive gas

for insufflation. Non-explosive gas from a pressureregulated and flow-rate controlled source can be connected to the provided or optionally available gas

adapter, Model OF-G11, as illustrated.

2) The gas adapter, which can be secured to the air/water port on the PVE connector, has a luer receptacle to

accept tubing from an external source of non-explosive gas. As long as the air/water feeding tube from a

PENTAX water bottle assembly is connected to the gas adapter and the air pump in the video processor is

turned OFF, non-explosive gas can be delivered.

3) Flow of gas from the nozzle at the distal end of the scope can be checked by placing the tip of the scope under

water and covering the hole on the top of the CO

2/water valve. The flow rate of gas should be no greater than

the rate of air delivery when the air feeding valve on the control head of the scope is covered.

4) The water delivery system is activated by depressing the CO2/water feeding valve.

WARNING:

The PENTAX endoscopes identified in this manual are compatible with Nd:YAG laser (wavelength

1064 nm) and Diode Laser (wavelength 800 nm ~ 1000 nm) only

. Do not use these endoscopes with

other types of laser such as KTP, He-Cd, or Excimer Laser Systems. It could result serious injury to the

patient.

LIGHT GUIDE PLUG

CO2 GAS

CYLINDER

CO2 GAS

ADAPTER

OF-G11

PROCESSOR

NOTE:

Never connect an unregulated source of gas to the

PENTAX endoscope.

NOTE:

Set the pressure below 49 kPa (0.5 kg/cm2, 7.1 PSI) and the flow rate at about 1 liter/min.

CAUTION:

Open the valve of the CO2 gas cylinder only AFTER turning off the pump switch of the processor. Failure

to do so will apply excessive pressure to the processor and can cause damage to the air pump.

NOTE:

It should be noted that as long as the valve of the CO2 gas cylinder is OPEN and the hole at the top of the

A/W feeding valve is NOT covered, CO

2 gas will constantly be vented through the A/W valve into the

room. To reduce excessive CO

2 concentrations, it is, therefore, recommended to close the CO2 gas cylin-

der valve, work in a well ventilated room, and use air delivery whenever possible during examinations

which are lengthy or in very confined quarters. As an alternative, the optionally available gas/water valve,

Model OF-B130, may be used in place of the standards air/water valve. OF-B130 is a closed two-stage

valve mechanism. Pressing the first stage delivers CO

2 gas and fully depressing the second stage acti-

vates water delivery.

When using the OF-B130 valve, there will be no venting of CO

2 gas into the room.

Replace OF-B130 with the air/water valve OF-B121 after using the CO

2 gas.

Page 22

- 19 -

5) The operator and assistant(s) should wear surgical gloves to avoid burns during use of Laser equipment.

6) The laser probe should be introduced through the endoscope in the same manner as described for biopsy forceps in section 3-3.

7) The position of the active portion of the laser probe should always be clearly visualized before Laser equipment is activated.

8) It should be recognized that a variety of factors can effect the quality of the video endoscope image during

laser use. Intensity of the aiming beam, high power setting of the laser, close distance of laser fiber to scope

tip, excessive tissue burning, can each adversely influence image quality. To obtain optimum results, it is recommended that the power settings of the aiming beam and laser be adjusted to minimal levels capable of

achieving the desired clinical effect.

9) Follow standard hospital protocol regarding safe-use of lasers, including the wearing of safety eyewear.

10) Should the distal tip of the endoscope be moved closer

than 20 mm from the irradiated tissue surface, the aiming beam may create a “smear” in the image as shown

at left. If this smear affect becomes too severe and distorts the visual field, the intensity of the aiming light

should be decreased.

11) When activating the laser at high power (about 100 W

for Yag Laser and 60 W for Diode Laser.) and/or if the

endoscope tip comes to within 10 mm of the irradiated

tissue, flare may appear at the corners of the image as

shown at left.

NOTE:

One may choose to leave the OF-G11 adapter attached to the endoscope during conventional air insufflation using the standard air/water valve. However, the luer sideport of the OF-G11 must be capped.

Similarly, for normal water delivery, the air pump must be turned ON and the plastic luer lock cap must be

secured to the OF-G11 adapter.

WARNING:

Prior to activation of the laser, make sure that the laser fiber exits the distal channel opening of the

endoscope. Failure to do so can result in scope damage and possible ignition/burning of the endoscope.

NOTE:

It is normal for the aiming light to appear white in the video scope image.

IRRADIATE

AREA

SMEAR

PROBE

PROBE

FLARE

WARNING:

Activation of the laser at high power settings may

cause patient injury or thermal damage of the

endoscopes tip.

Avoid use of high power.

Page 23

- 20 -

3-5. ELECTRO-SURGERY

1) The user has the option of using a non-explosive gas

for insufflation. Non-explosive gas from a pressureregulated and flow-rate controlled source can be connected to the provided or optionally available gas

adapter, Model OF-G11, as described for Laser in section 3-4.

2) The electrosurgical accessories should be introduced

through the endoscope in the same manner as

described for biopsy forceps in section 3-3.

WARNING:

Please refer to the operating manual provided with the electrosurgical unit. Electrosurgical systems may

be of the floating type (BF type, CF-type) or non-floating (B type). To avoid patient and user burn, use

only the floating type ESU (such as ERBOTOM ICC 200) /accessory systems. Do not use the non-floating (B type) electrosurgical systems. The electrosurgical generator and any electrosurgical accessory

should be carefully and thoroughly inspected. Only the user can determine if the condition of the electrosurgical generator and the electro-surgical accessory are suitable.

LIGHT GUIDE PLUG

CO2 GAS

CYLINDER

CO2 GAS

ADAPTER

OF-G11

LIGHT

SOURCE

WARNING:

To avoid patient and user burn, follow the instruction below before electrosurgical energy is delivered.

1) Use only the electrosurgical generator with the floating grounding type (BF or CF Type). Do not use

the non-floating (B type) electrosurgical systems.

2) Wear rubber gloves and face masks.

3) The position of the target area, the insulated distal portion of the electrosurgical accessory and the

active portion of the electrosurgical accessory, should be visible.

4) The active portion of the electrosurgical accessory should not touch the surrounding tissue directly or

via fluids.

5) The head of any lesion such as polyp should not touch the surrounding tissue directly or via fluids.

6) Physicians and assisting personnel should avoid contact with the patient while high frequency

energy is delivered.

7) Electro-surgical energy should be delivered for as short a time period as necessary to accomplish

the desired clinical effect.

8) Select a high frequency output power setting suitable for the particular intended procedure in order to

avoid thermal invasion of the tissue or insufficient coagulation resulting in excessive bleeding.

9) To avoid the risk of thermal injury, use only insulated accessories.

Never use non-insulated devices while performing endoscopic electrosurgical procedures.

CAUTION:

It should be recognized that the use of electro-surgical accessory devices employing high frequency current may interfere with the normal endoscopic image and this interference is not indicative of a malfunction of the video endoscope system. PENTAX has developed an earth cable, model OL-Z3 intended to

reduce potential RF interference and electronic noise that may appear in the endoscope image when

using electro-surgical devices. Ensure to always correctly connect cable OL-Z3 between the endoscope

and video processor as described in the instructions provided with the OL-Z3

to endoscope

to video processor

Page 24

- 21 -

4. CARE AFTER USE

IMPORTANT INSTRUCTIONS

Cleaning-Disinfection-Sterilization: PENTAX Endoscopes

To maintain maximum performance and a long service life of the endoscope, proper care after each procedure is extremely important. Immediately after the completion of a procedure, the endoscope and its components should be thoroughly and carefully cleaned. If the endoscope or its components are left uncleaned

for some time after use, dried blood, mucous, contrast material or other patient debris may cause damage

to the instrument (component) or may interfere with the ability of the user to properly reprocess the endoscope or component

NOTE:

This manual has been written having regard to ISO 17664 and national guidelines on reprocessing of medical

products (e.g. RKI, DGS/DHOS).

NOTE:

This owner’s manual contains detailed recommendations on the manual reprocessing of PENTAX

endoscopes using PENTAX supplied cleaning/disinfecting adapters. Automated endoscope reprocessors (AER) may provide a means of reprocessing flexible endoscopes, including PENTAX instruments.

Only those Automated Endoscope Reprocessors (AERs) should be used whose manufacturers provide

device-specific instructions and have validation data that support each AER claim with respect to PENTAX model instruments.

AER manufacturers should be consulted for their specific claims including but not necessarily limited to

a) the ability of the AER to provide a cleaned and high-level disinfected (or sterilized) endoscope and

scope components (ex. valves),

b) the identification of any special feature area (internal channel) or scope component that can not be

reprocessed and therefore requires manual reprocessing,

c) the microbial quality of the rinse water,

d) the inclusion of an “automated” alcohol rinse cycle.

e) the inclusion of a terminal drying cycle that removes the majority of water/fluid within scope channels,

f) maintenance procedures for water filter replacement and/or decontamination of the filtration system to

ensure the microbial claim of water, etc.

g) compliance with local regulations and/or guidelines

Summary of PENTAX Reprocessing Instructions

PENTAX reprocessing instructions can be broken down into seven basic steps.

1) Internal Channels Section 4-1-1

2) Pre-Cleaning (in the Examination Room) Section 4-1-2

3) Leakage Testing (in a designated Decontamination Area) Section 4-1-3

4) Cleaning (in a designated Decontamination Area) Section 4-1-4

5) High-Level Disinfection or sterilization (in a designated Decontamination Area) Section 4-1-5, 4-1-6

6) Endoscopic Accessory Instruments (EAIs) and Endoscope Components Section 4-2

7) Post Reprocessing Section 5

Page 25

- 22 -

CAUTION:

(Automated Reprocessing) Unless the AER/WD has validated channel monitoring capability for device-

specific scope model.

• prior to “automated reprocessing” check and confirm the patency of any lumens/channels to ensure

that all internal channels are unblocked and/or unclogged

• prior to use of any AER/WD confirm the integrity of all channel tubes and recommended channel cleaning adapters

• once tubing sets are connected to the appropriate channels, check the tubing to confirm that there are

no kinks or crimps that could restrict flow of solution throughout the endoscope

• (if the unit allows) during reprocessing check and confirm that reprocessing solutions are exiting

expected channel ports

Failure to adhere to the above recommendations could result in inadequate cleaning, disinfection (or

sterilization) of and/or improper removal of residues from all instrument channels/surfaces.

Page 26

- 23 -

4-1. ENDSCOPES

4-1-1 INTERNAL CHANNELS

The following internal schematics have been provided as a service to help users better understand the intricate construction of PENTAX endoscopes. Knowledge of the various internal channels and tubes within an instrument and

their relation to each other allows one to care for and reprocess the endoscope more easily and with greater confidence.

Much time and effort has been expended into designing endoscopes and their cleaning/disinfecting components

so that reprocessing of the instruments before each patient use can be effectively and efficiently performed by either manual methods or automated processes.

Connectors on all PENTAX cleaning/disinfecting adapters and scope inlet ports incorporate standard size luerlock and/or luer-slip fittings to easily accommodate reprocessing devices or systems available from other manufacturers.

As can be seen from these internal schematics, the PENTAX cleaning system promotes efficient unidirectional

flow of solution beginning from connections at the light guide plug, traveling up tubings in the umbilical cable to

the valve cylinders in the control body, passing through the channels in the insertion tube and finally exiting nozzles or channel openings at the distal tip of the scope.

The elimination of multiple branching of channels, combined with a direct and straightforward pathway for solutions to travel maximizes flow efficiency and ensures contact of detergent/disinfectant/sterilant with all internally

exposed channel surfaces.

WARNING: (in the U.S.A. or other countries adhering to FDA regulations)

It is imperative that flexible endoscopes and other semi-critical devices be reprocessed using at least

high-level disinfection with a legally marketed sterilant/disinfectant. Only legally marketed endoscope

automated reprocessing devices/systems whose device specific claims have been validated by the AER

manufacturer and/or anti-microbial agents which have been tested and found to be compatible by Pentax should be used with PENTAX products.

Generally speaking, “2%” and “3.2%” alkaline glutaraldehyde solutions which have been FDA cleared

with High-Level Disinfection and/or Sterilization claims are recommended. It should be noted that the

actual percentage of active ingredient (glutaraldehyde) in these solutions, as per their product label,

may vary from the generic and traditional terms “2% glutaraldehyde” and/or “3.2% glutaraldehyde”.

For specific brands of compatible disinfectants/sterilants, please contact your local PENTAX service

facility or sales representative. Please also refer to the inside front cover of this manual regarding infection control.

Items required for reprocessing:

•10 mL Syringe

•50 mL Syringe

• Tray/Reprocessing basin (at least 40 cm by 40 cm/16 in × 16 in)

• Soft Sponge

• Personal Protective Equipment (PPE) including gloves, face mask, etc.

• Soft Sterile Gauze

• PVE Soaking Cap OE-C9

• Air/Water Channel Cleaning Adapter OF-G17

• Rubber Inlet Seal

• Cleaning Brush CS6021SN

• Cleaning Brush CS-C5S

• Air/Water/Instrument Channel Cleaning Adapter OF-B115

• Suction Control Valve OF-B120

• Air/Water Feeding Valve OF-B121

• Detergent

• Disinfectant

• Alcohol

• Source of compressed/forced air

Page 27

- 24 -

(1) INTERNAL CHANNEL

The illustration above shows the actual routes taken by air, water, and suction through single biopsy/instrument

channel PENTAX videoscopes with forward optics.

EG-290Kp/EC-380Kp

Water Feeding Channel

Air/Water Valve

Channel Inlet

Rubber Inlet Seal

Suction Valve

Suction Tube

Air Feeding Tube

Water Bottle

Water Feeding Tube

Suction Source

Video Processor

Air Feeding Channel

Instrument Channel

Air/Water Nozzle

#KT

2WOR

Page 28

- 25 -

(2) REPROCESSING SYSTEM

To reprocess a PENTAX single-channel videoscope, first an enzymatic detergent and then a high-level disinfectant

or sterilant must be exposed to all internal lumens as well as to all external instrument surfaces and scope components

(air/water valve, suction valve, etc.). Exposure times of detergent and disinfectant/sterilant must be strictly adhered

to as recommended by each respective manufacuturer.

Please note that all solution entrance ports and flow pathways are illustrated above.

CAUTION:

BEFORE IMMERSING:

a) The ‘Red’ ETO gas sterilization venting cap must be taken OFF.

b) The PVE Soaking cap should be securely ON the electrical contacts.

NOTE:

Prior to exposure of all internal channels to an enzymatic detergent and high-level disinfectant (or sterilant), all brushable channels should be manually cleaned with cleaning brushes.

EG-290Kp/EC-380Kp

Water Feeding Channel

Rubber Inlet Seal

Channel Inlet

A/W Instrument Channel Cleaning Adapter OF-B115

Air/Water Channel

Cleaning Adapter OF-G17

PVE Soaking Cap

(ATTACH)

ETO Cap

(REMOVE)

Air Feeding Tube

Water Feeding Tube

Suction Tube

Suction Nipple

Luer-Slip Syringe

with

Cleaning/Disinfectiing

Solution

Luer-Slip Syringe

with

Cleaning/Disinfectiing

Solution

Air Feeding Channel

Instrument Channel

Air/Water Nozzle

Page 29

- 26 -

4-1-2 PRE-CLEANING

1) Immediately after removing the endoscope from the

patient, gently wipe all debris from the insertion tube

with a gauze or the like moistened with an enzymatic

detergent solution.

2) Place the distal end of the endoscope into detergent

solution and aspirate through the channel for 5 ~ 10

seconds. Alternate aspiration of solution and air several times to create agitation for better pre-cleaning.

3) Set the lever on the water bottle to the drain position.

With the air pump of the video processor ON and set

to the HIGHEST pressure setting (if applicable),

depress the air/water valve of the scope fully until all

water has been discharged from the scope. Alternate

covering of the hole in the valve and depressing the

valve to forcefully expel mucous, debris, etc. which

may have entered the air and water nozzles.

4) Place removable scope components in enzymatic

detergent solution to pre-soak.

WARNING:

The importance of meticulous mechanical cleaning of the endoscope and its removable components

cannot be overemphasized.

Prior to disinfection or sterilization, all instruments and components must be scrupulously cleaned.

Failure to do so could result in incomplete or ineffective disinfection and sterilization.

During the reprocessing process, always wear protective garments such as gloves, gowns, face masks,

etc. to minimize the risk of cross contamination.

Page 30

- 27 -

4-1-3 CLEANING

1) Prepare a basin with warm water and a mild enzymatic detergent per detergent manufacturer’s instructions.

The solutions must be enzymatic detergents or other cleaning agents specially formulated to clean flexible

endoscopes. For specific brands of compatible solutions, please contact your local PENTAX service facility

or sales representative.

2) Immerse the endoscope and its components in fresh

detergent solution. Then thoroughly (but gently) wash

the entire surface of the endoscope and its components.

Make sure that the recessed areas such as the channel

openings, valve cylinders, etc are brushed clean using

the provided or similarly effective cleaning brushes.

3) Allow all items to soak in an enzymatic solution for a time period recommended by the manufacturer of the

enzymatic detergent.

PVE

Soaking Cap

ETO Cap

CAUTION:

BEFORE IMMERSING:

a) The ‘Red’ ETO gas sterilization venting cap

must be taken OFF.

b) The PVE Soaking cap should be securely

ON the electrical contacts.

WARNING:

Immediately after use, the metal light guide prong and the electrical contacts/pins of the endoscope may

be HOT. To avoid burns, do not touch these areas immediately after use. For safer handling after a procedure, grasp the PVE connector housing.

air/water

feeding valve

Suction

control

valve

⑤

PVE Soaking Cap

Inlet seal

①

②

③

④

ETO cap

① Suction Control Valve OF-B120

② Air/Water Feeding Valve OF-B121

③ Rubber Inlet Seal OF-B190

④ ETO venting cap OF-C5

⑤ Soaking cap OE-C9

CAUTION:

The use of an enzymatic detergent immediately

after each procedure to dissolve and remove

organic contaminants and proteinaceous debris

is essential to the care and maintenance of the

endoscope from the standpoints of infection

control and functionality.

NOTE:

Detergent refers to an enzymatic detergent or other cleaning solution specifically formulated for use and

compatible with flexible endoscopes.

NOTE:

• Do not squeeze or severely bend the insertion tube.

• Do not use any abrasive materials.

• Be careful to avoid damage to the distal lenses.

Page 31

- 28 -

4) Manual Cleaning of Suction System by Brush

CAUTION:

1) It is highly recommended that only PENTAX cleaning brushes specified in our manuals should be used to clean

PENTAX endoscopes.

2) PENTAX cleaning brushes have been specially designed to clean various PENTAX internal channel systems and

valves, ports or cylinders. Validation studies have been performed supporting the use of PENTAX supplied

brushes and cleaning adapters for cleaning PENTAX scopes following PENTAX manual reprocessing instructions.

3) Over the years some other manufacturers’ cleaning brushes/devices have been found to damage PENTAX

scopes and/or create the need for servicing as some cleaning devices can become lodged (“stuck”) inside various

lumens of PENTAX scopes. The likelihood for scope damage or servicing increases if a cleaning device does not

have a protective tip (or contains any sharp-edged surface), if its flexible shaft uses a flimsy plastic material that is

not firm enough to allow for easy accessory advancement and/or if the proper sequence and/or direction of channel cleaning is not followed as described in PENTAX manuals.

4) The cleaning brushes should be always inserted as described in this manual.

5) It is recommended that cleaning brushes should be grasped about 5 cm (2 inches) from any channel ports/openings while advancing/withdrawing a brush. To avoid scope and brush damage, do not use force.

6) To prevent excess friction between brush and channel, do NOT tightly coil the scope while brushing. Keep the

insertion tube and umbilical cable as straight as possible and never attempt to pass the cleaning brush through a

fully angulated scope. Failure to follow these instructions could result in scope or brush damage.

7) Cleaning brushes/devices, especially those with metal coiled flexible shafts should NOT be inserted into the distal

exit/opening of channels. Doing so can damage the endoscopes.

Fig. Place Brush Entrance Exit Fig.

①

Suction Tube CS6021SN Suction Nipple Suction Cylinder 4-a)

②

Suction Channel CS6021SN Suction Cylinder

—

4-b)

③