Page 1

Only For the Americas

INSTRUCTIONS FOR USE

(REPROCESSING)

PENTAX VIDEO BRONCHOSCOPES

EB-1970TK

EB-1170K, EB-1570K

EB-1970K, EB-1575K

EB-1975K, EB-1990i

Page 2

Product Overview

These instruments photograph the subject of observation using a solid-state image sensor located at the endoscope tip under the

light transmitted from the processor/light source. The target of the observation is monitored by the physician using the endoscopic

image displayed on the video monitor. The endoscopic procedure is performed by inserting biopsy forceps and other endoscopic

accessories into the instrument channel inlet on the control body.

The bending section angulates in the intended direction and angle by operating the Angulation Control Lever; and air or fluids can

be suctioned from the distal end of the endoscope by operating the Suction Control Valve.

Indication for Use

The PENTAX Video Bronchoscopes (EB Family) have been designed to be used with a PENTAX Video Processor (including Light

Source), documentation equipment, video monitor, endo-therapy accessories (such as biopsy forceps) and other ancillary

equipment for endoscopy and endoscopic surgery within the airways and tracheobronchial tree.

Application

Medical purpose: Provide images for optical visualization, recording, and/or diagnostic aid.

Patient populations: Adults and lowercase pediatrics who have been determined by the physician to be appropriate candidates for

the use of this instrument.

Intended anatomical area: Airways and tracheobronchial tree

User: Medical doctors (expert approved by the medical safety officer to perform endoscopic examinations at each medical facility)

Place of Use: Medical facillity

Functions Used Frequently

The frequently used functions in these endoscope models are as follows:

Angulation capability using control lever

•

Remote control operation using remote buttons

•

Suctioning function

•

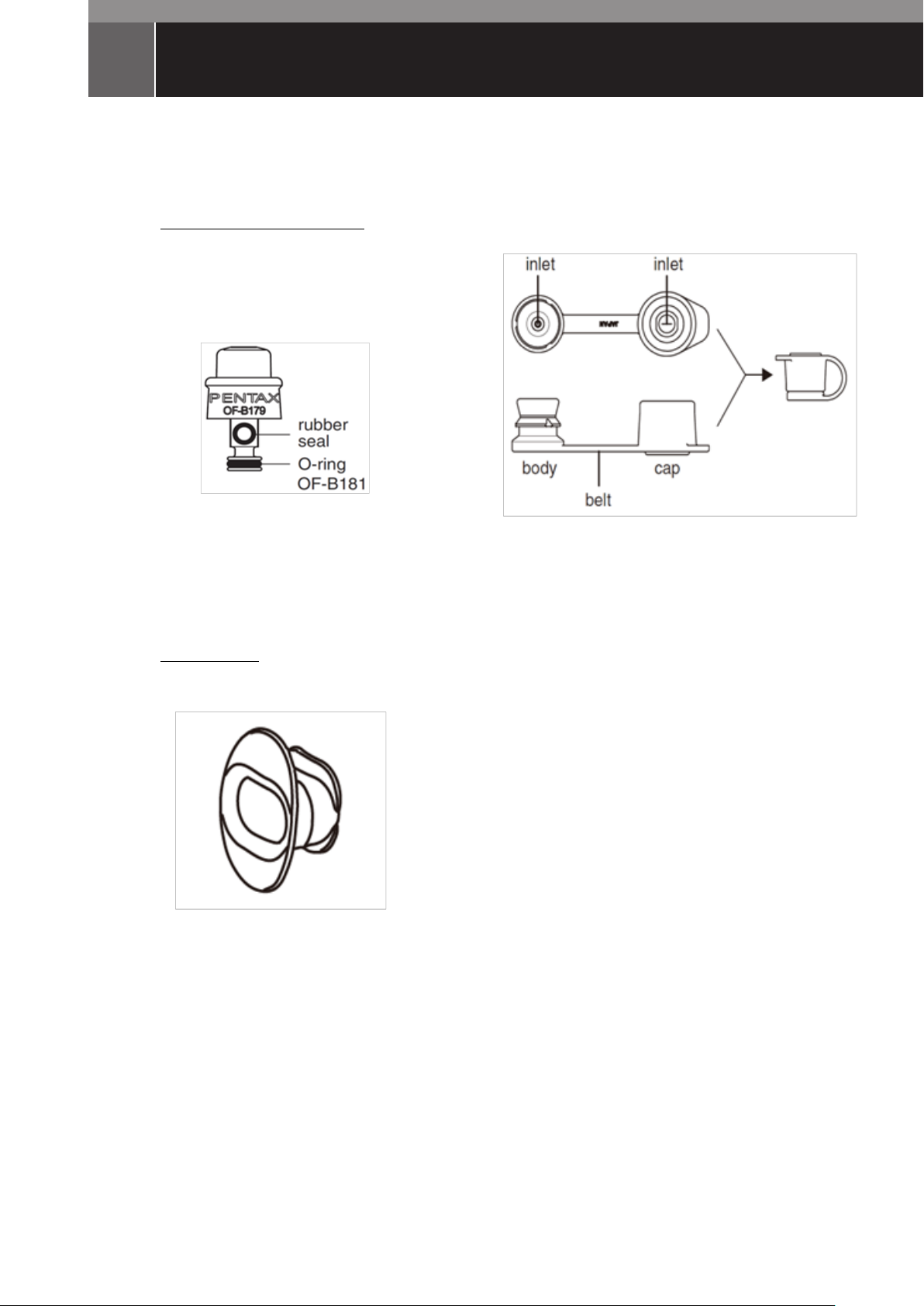

Removable Components

OF-B179

OF-B190

Suction Control Valve

Inlet Seal

Notes

Read this Instructions for Use (IFU) before reprocessing the endoscope, and save this book for future reference. Failure to read and

thoroughly understand the information presented in this IFU, as well as those developed for ancillary endoscopic equipment and

accessories, may result in serious injury, including infection by cross contamination to the patient and/or user. Furthermore, failure

to follow the instructions in this IFU or the companion Instructions for Use (operation) may result in damage to, and/ or malfunction

of, the equipment.

It is the responsibility of each medical facility to ensure that only well hyphen educated and appropriately trained personnel, who are

competent and knowledgeable about the endoscopic equipment, antimicrobial agents/processes, and hospital infection control

protocol be involved in the use and the reprocessing of these medical devices. Known risks and/or potential injuries associated with

flexible endoscopic procedures include, but are not limited to, the following: perforation, infection, hemorrhage, burns, and electric

shock.

This IFU describes the procedures for reprocessing and maintenance of the equipment after its use.

For inspection and preparation prior to its use, please refer to the separate Instructions for Use (Operation).

The text contained in this IFU is common to various types/models of PENTAX endoscopes, and users must carefully follow only

those sections and instructions pertaining to the specific instrument model in question.

If you have any questions regarding any of the information in this IFU or concerns pertaining to the safety and/or use of this

equipment, please contact your local PENTAX representative.

Page 3

Sterility Statement

NOTE

Symbols on Marking

Symboles distinctifs

The endoscopes identified in this IFU are reusable semicritical devices. Since they are packaged non-sterile, they must be highlevel disinfected or sterilized BEFORE inital use. Prior to each subsequent procedure, they must be subjected to appropriate

cleaning and either high-level disinfection or sterilization processes.

Contraindication

Please consult regional and national health authority recommendations and requirements regarding protocols to follow in order to

reprocess and/or destroy endoscopes that will be used or have been determined to have been used (post procedure) on patients

afflicted with Creutzfeldt-Jacob Disease (CJD or vCJD).

Conventions

Throughout this IFU, the following conventions will be used to indicate a potentially hazardous situation which, if not avoided;

WARNING

CAUTION

: could result in death or serious injury.

: may result in minor or moderate injury or property-damage.

: may result in property-damage. Also advises owner/operator about important information on the use of

this equipment.

Prescription Statement

Federal (U.S.A) law restricts this device to sale by or on the order of a physician or other appropriately licensed medical

professional.

Symbols on Marking

Symboles distinctifs

Symbol for “MANUFACTURER”

Symbol for “DATE OF MANUFACTURE”

Symbol for “Authorised Representative in the European Union”

このCEマ ーキ ングは EC指令への適合宣言マークです。

The CE marking assures that this product complies with the requirements of the EC directive for safety.

Das CE Zeichen garantiert, daß dieses Produkt die in der EU erforderlichen Sicherheitsbestimmungen erfüllt.

Le logo CE certie que ce produit est conforme aux normes de sécurité prévues par la Communauté Européenne.

II marchio CE assicura che questo prodotto è conforme alle direttive CE relative alla sicurezza.

La marca CE asegura que este producto cumple todas las directivas de seguridad de la CE.

Attention, consult instructions for use

Attention, consulter le manuel d’utilisation

Type BF applied part (Safety degree specified by IEC 60601-1)

Partie appliquée de type BF (niveau de sécurité spécifié par la norme CEI 60601-1)

Page 4

Page 5

TABLE OF CONTENTS

NOMENCLATURE ............................................................................................................................................ 1

Video Bronchoscopes ..............................................................................................................................1

NOMENCLATURE ............................................................................................................................................ 3

Endoscope Components and Accessories ............................................................................................3

ENDOSCOPE REPROCESSING PROCEDURE FLOW .................................................................................. 5

1 CARE AFTER USE ..................................................................................................................................... 6

1-1. General ............................................................................................................................................... 6

1-1-1. Application ..................................................................................................................6

1-1-2. Important Instructions ................................................................................................ 7

1-1-3. Internal Channels of Video Bronchoscopes ............................................................10

1-1-4. Quick Reference of Injection Volumes for Internal Channel ..................................11

1-1-5. Inspection of Reprocessing Accessories ................................................................12

1-2. Endoscope Reprocessing ................................................................................................................ 14

1-2-1. Pre-Cleaning ................................................................................................................14

1-2-2. Leak Testing ................................................................................................................ 17

1-2-3. Cleaning .......................................................................................................................18

1-2-4. High-Level Disinfection .............................................................................................. 28

1-2-5. Optional Sterilization .................................................................................................. 35

1-3. Endoscope components and accessories .....................................................................................39

1-3-1. Cleaning .......................................................................................................................40

1-3-2. High-Level Disinfection .............................................................................................. 44

1-3-3. Optional sterilization ..................................................................................................47

General

Endoscope

Pre-Cleaning

Leak

Testing

Endoscope

Cleaning

Endoscope

Disinfection

Endoscope

Sterilization

Accessory

Cleaning

2 POST REPROCESSING AND STORAGE ................................................................................................. 50

3 SERVICING ................................................................................................................................................. 51

4 APPENDIX .................................................................................................................................................. 53

4-1. PENTAX Medical Compatible Reprocessing Systems/Agents ..................................................... 53

Accessory

Disinfection

Accessory

Sterilization

Page 6

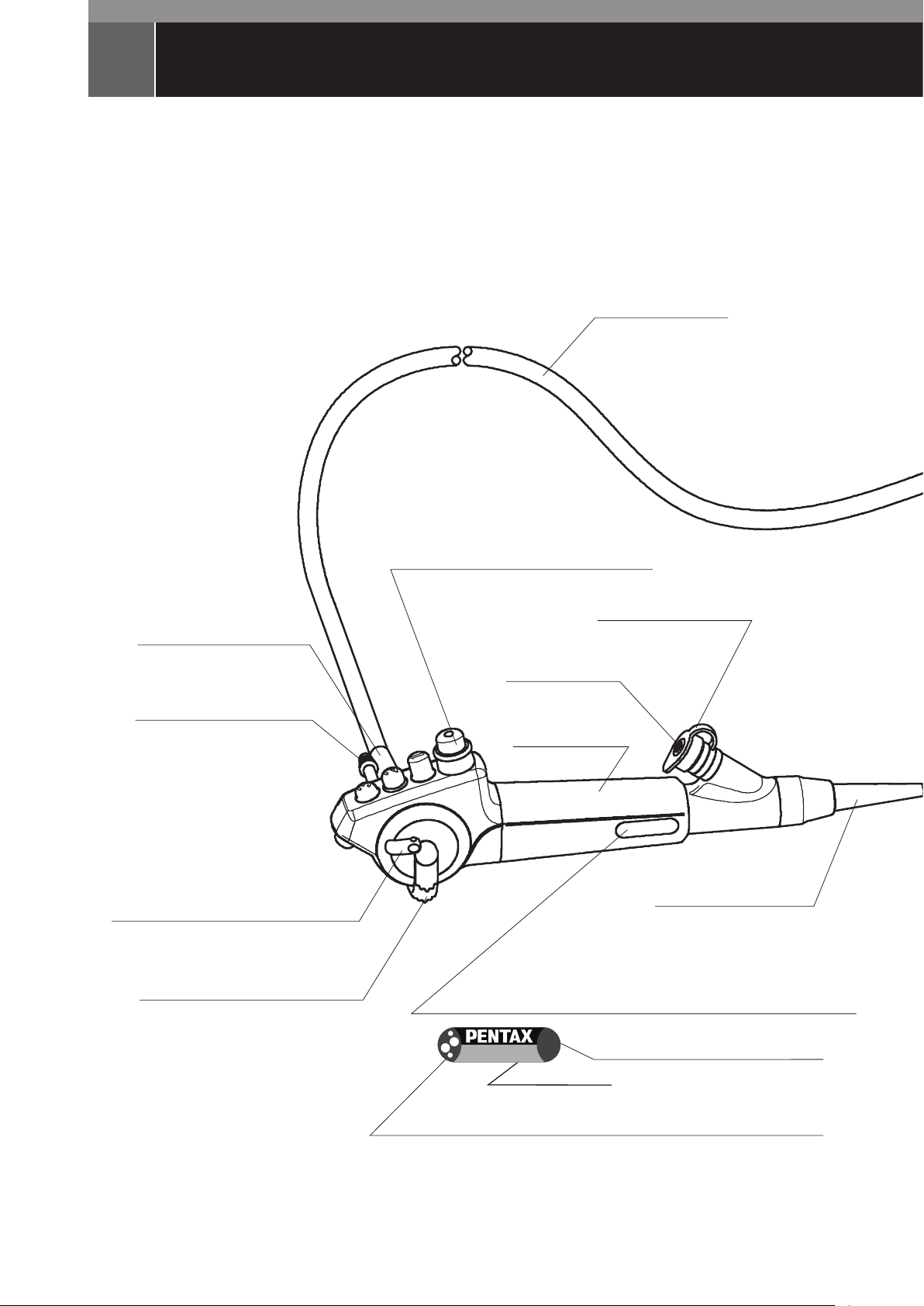

NOMENCLATURE

Video Bronchoscopes

EB-1970TK, EB-1170K, EB-1570K, EB-1970K, EB-1575K,

EB-1975K, EB-1990i

UMBILICAL CABLE

STRAIN RELIEF BOOT

SUCTION NIPPLE

ANGULATION LOCK LEVER

EB-1170K, EB-1570K, EB-1970TK only

ANGULATION CONTROL LEVER

SUCTION CONTROL VALVE (OF–B179)

INLET SEAL (OF–B190)

INSTRUMENT

CHANNEL INLET

CONTROL BODY

STRAIN RELIEF BOOT

MODEL DESIGNATION

STERRAD

This symbol denotes an endoscope model's material compatibility with

the STERRAD

Endoscopes that do not have this symbol are incompatible with

the STERRAD

EB-1970TK)

®

NX™ system material compatibility identification symbol

®

®

– 1 –

Model Name

NX™ system. (EB-1575K, EB-1975K, EB-1990i)

NX™ system. (EB-1170K, EB-1570K, EB-1970K,

Minimum Instrument Channel Width

Page 7

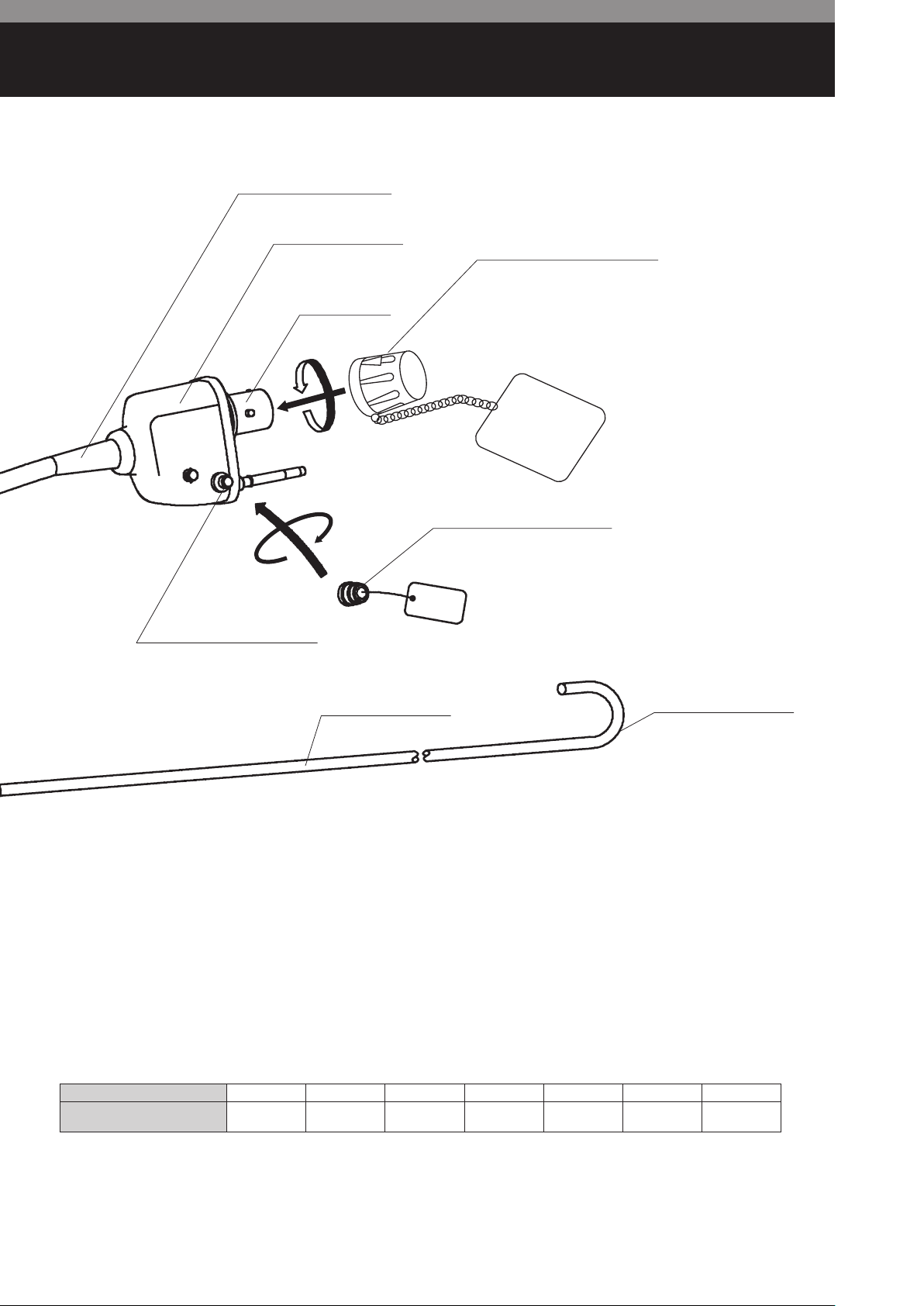

PVE CONNECTOR

STRAIN RELIEF BOOT

VENTING CONNECTOR

PVE SOAKING CAP OE-C9

ELECTRICAL

CONTACTS

VENTILATION CAP OF-C5

INSERTION TUBE

BENDING SECTION

Table of Minimum Instrument Channel Width

Video Bronchoscopes EB-1170K EB-1570K EB-1970K EB-1970TK EB-1575K EB-1975K EB-1990i

Minimum Instrument

Channel Width (I.D.φmm)

1.2 2.0 2.8 3.2 2.0 2.8 1.2

– 2 –

Page 8

NOMENCLATURE

Endoscope Components

・Suction Valve (OF-B179)

・Inlet Seal (OF-B190)

Accessories

・Bite Bock (OF-Z5)

Endoscope Components and Accessories

– 3 –

Page 9

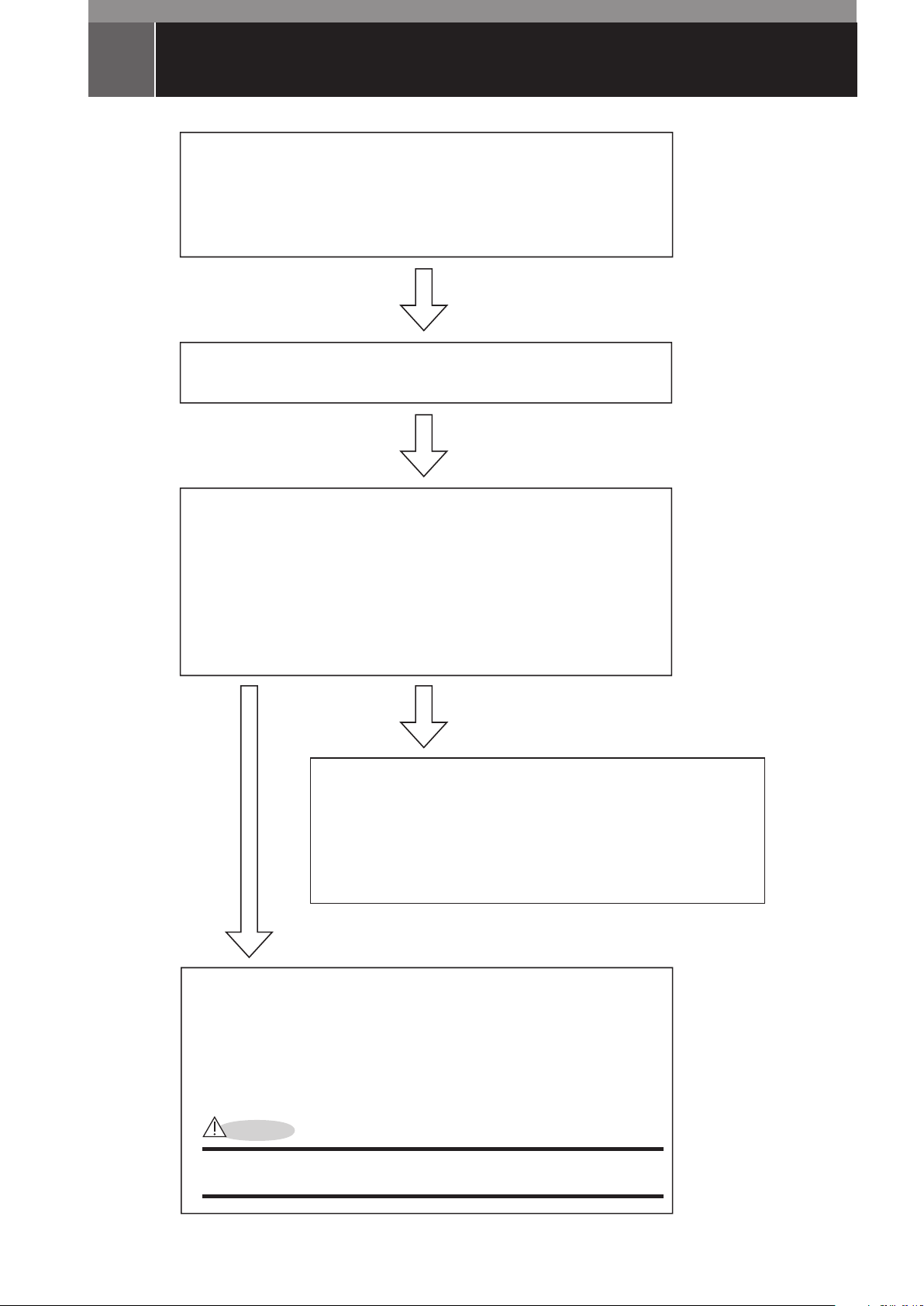

Accessories for Reprocessing

・PVE Soaking Cap (OE-C9)

・Ventilation Cap (OF-C5)

・Cleaning Brush (CS-C3S)

・Cleaning Brush (CS6002SN/CS6015ST/CS3010S)

・Cleaning Adapter (OF-B155)

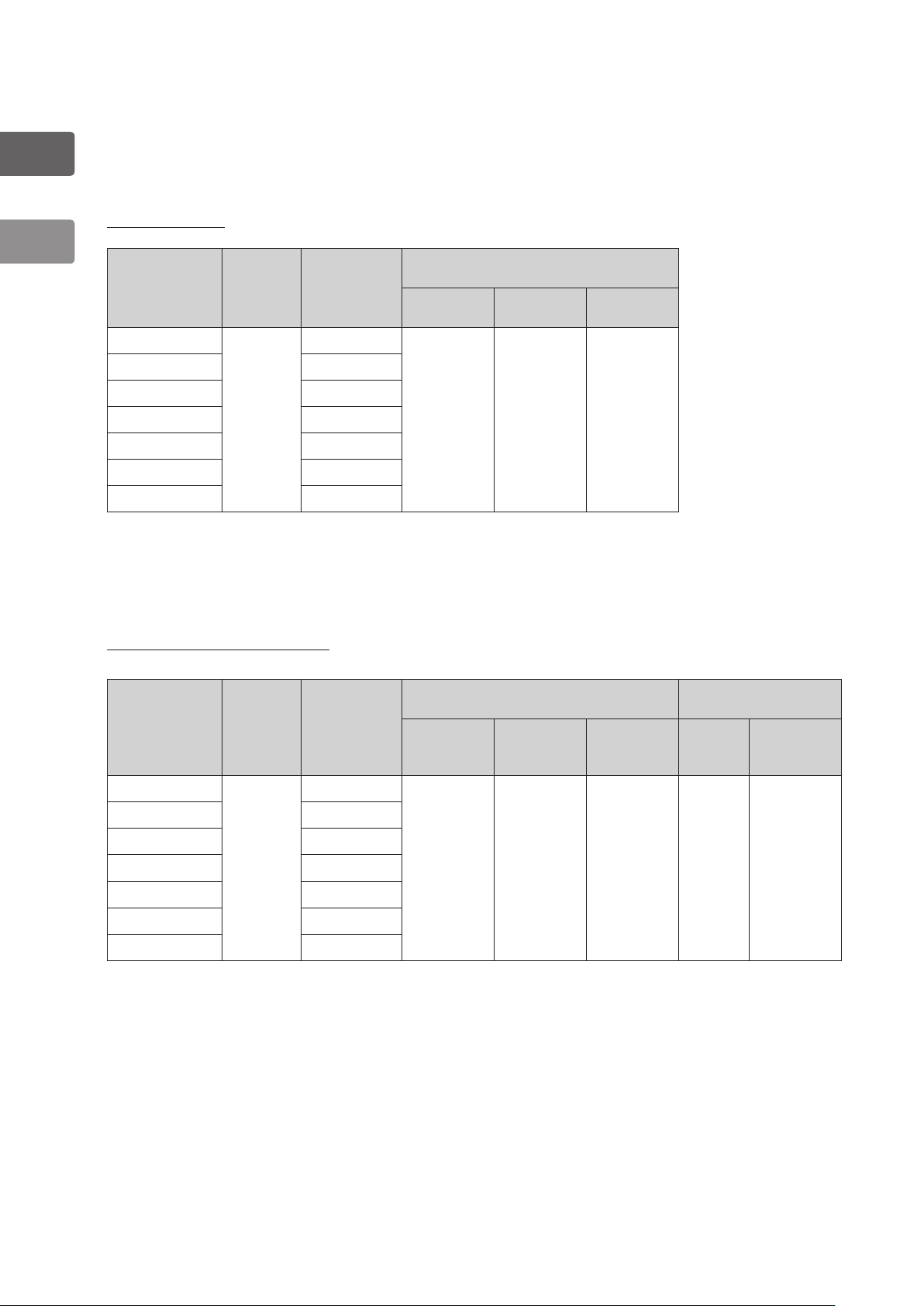

Model Number Appearance of Bristles Length of Shaft Diameter of Bristles

CS6002SN 20cm

CS6015ST 150cm

CS3010S 100cm

– 4 –

φ

φ

φ

6mm

6mm

3mm

Page 10

ENDOSCOPE REPROCESSING PROCEDURE FLOW

Pre-Cleaning

• Preparation

• Wiping of insertion tube

• Aspiration of detergent solution through suction channel

• Transport to cleaning room

Leak Testing

Cleaning

• Preparation

• Cleaning of all external surfaces

• Brushing of suction channel

• Filling of detergent solution into suction channel

• Soaking in detergent solution

• Rinsing

• Drying

High-Level Disinfection

• Preparation

• Filling of disinfecting solution into suction channel

• Soaking in disinfecting solution

• Rinsing

• Drying

Optional Sterilization

Sterilization using STERRAD® NX™ system (EB-1575K,

EB-1975K, EB-1990i only)

• Preparation

• Wrapping

• Sterilization Parameter Selection

CAUTION

STERRAD® NX™ Validation data has not been generated for endoscope

models in this manual other than EB-1575K, EB-1975K, and EB-1990i.

– 5 –

Page 11

NOTE

1 CARE AFTER USE

1-1. General

This Instructions for Use (IFU) has been written in accordance with 21CFR

Part801, ISO 17664, and national guidelines on reprocessing of medical

products.

1-1-1. Application

WARNING

Reprocessing may affect device functionality. Prior to use, always inspect the

endoscope, components, and accessories for proper function to determine

that they are appropriate for patient use.

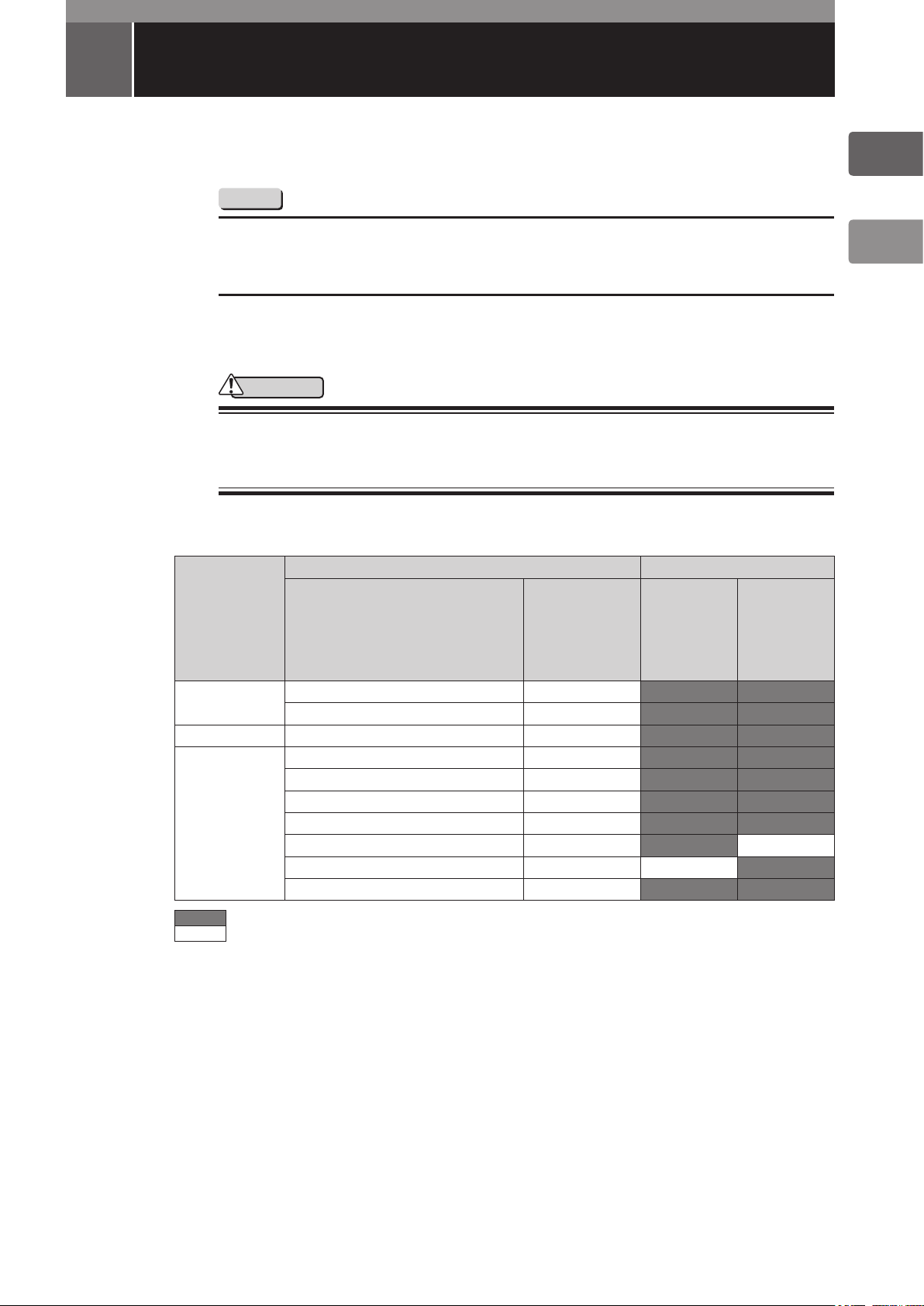

Components and Accessories for Video Bronchoscopes

MODEL Video Bronchoscopes

TYPE

Endoscope

Component

Accessory Bite Block - Adult Size OF-Z5 Y Y

Reprocessing

Accessory

Suction Control Valve OF-B179 Y Y

Inlet Seal OF-B190 Y Y

PVE Soaking Cap OE-C9 Y Y

Ventilation Cap OF-C5 Y Y

Cleaning Adapter OF-B155 Y Y

Cleaning Brush CS6002SN Y Y

Cleaning Brush CS6015ST Y N

Cleaning Brush CS3010S N Y

Cleaning Brush CS-C3S Y Y

Name Number

EB-1570K

EB-1970K

EB-1970TK

EB-1575K

EB-1975K

1

General

EB-1170K

EB-1990i

Y : YES

N : NO

– 6 –

Page 12

1-1-2. Important Instructions

WARNING

1

General

• Reusable Medical Devices that are initially supplied non-sterile require

the end user to disinfect or sterilize them prior to initial use and to

subsequently reprocess them after each subsequent use.

• Proper care of the device after each procedure is extremely important.

Immediately (within one hour) after the completion of a procedure,

the endoscope and its removable components, and accessories should

be both pre-cleaned and mechanically cleaned with detergent solution.

Generally, if these endoscopes and accessories are not precleaned

within 15 minutes and mechanically cleaned within one hour after the

conclusion of the procedure, dried blood, mucus, or other patient debris

may cause damage to the devices or interfere with the ability of the user

to properly reprocess them.

• The use of detergent immediately after each procedure to dissolve and

remove organic contaminants and proteinaceous debris is essential to

the proper care and maintenance of the endoscope. Prior to disinfection

or sterilization, all instruments and components must be meticulously

cleaned. Failure to do so can result in incomplete or ineffective

disinfection or sterilization.

• Always inspect reprocessed endoscopes and accessories prior to use

according to their respective Instructions for Use (IFU).

• During the reprocessing process, always wear protective equipment

(e.g., gloves, gowns, face masks, etc.) to minimize the risk of cross

contamination.

• Contact the manufacturer and follow local regulations regarding safe use,

appropriate handling, and disposal of cleaning and disinfection solutions,

including alcohol and rinse water. Material Safety Data Sheets available

from the cleaning and disinfection solution manufacturer should be

consulted to provide guidance to end users about formulation, hazards,

chemical and physical properties, first aid, handling and storage,

stability, precautions, disposal, etc..

WARNING

Endoscopes are semicritical devices that require cleaning and at least highlevel disinfection. Use only legally marketed solutions and/or automated

endoscope reprocessors (AERs) for which validation testing with PENTAX

products has been performed by their manufacturers. A list of legally

marketed solutions/systems that have been determined to be compatible with

PENTAX brand products is contained in this manual.

– 7 –

Page 13

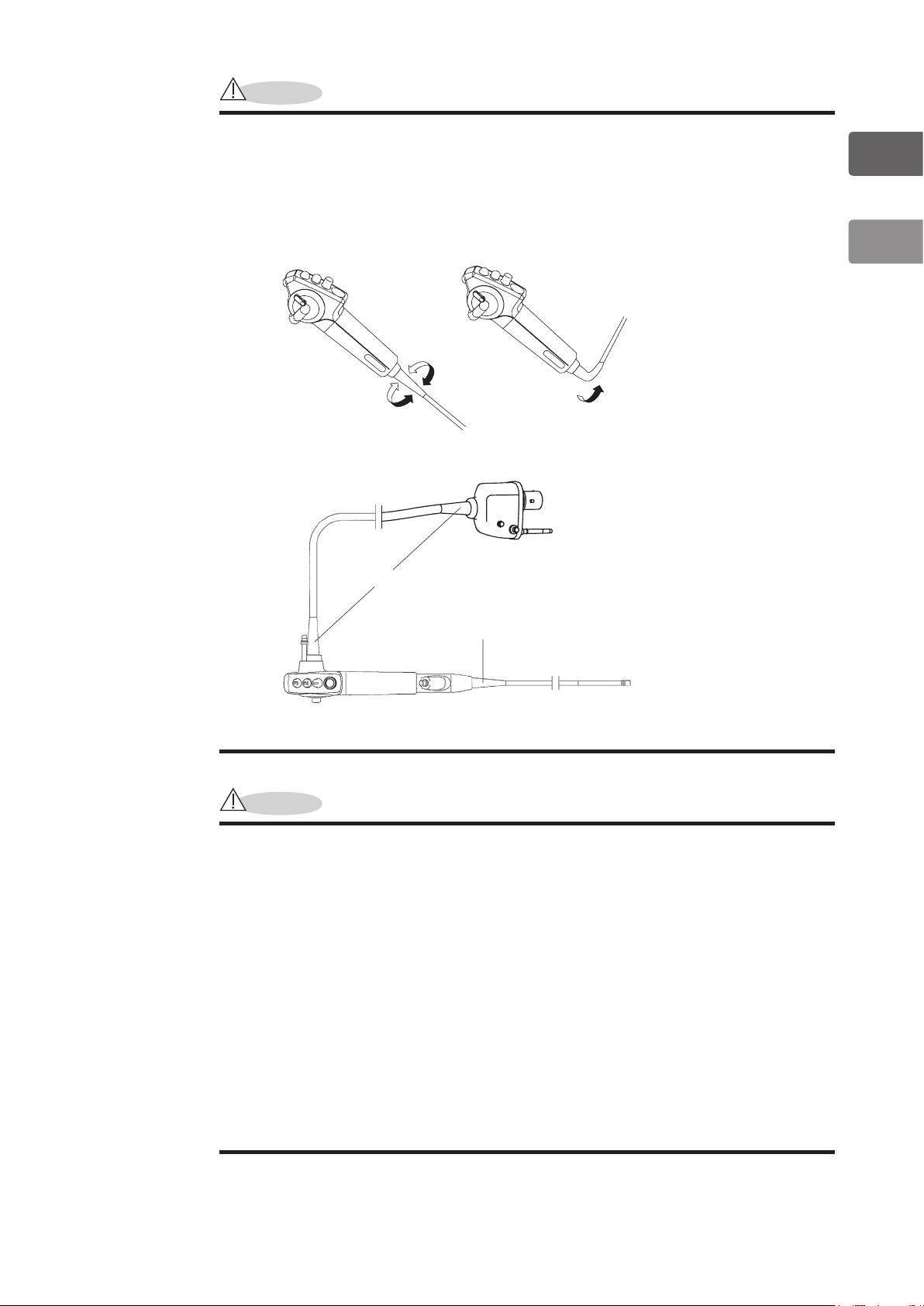

CAUTION

To avoid damaging the endoscope, do NOT twist, rotate or excessively bend

any of the strain reliefs [(1), (2)] during inspection, clinical use, reprocessing,

or any handling activity. Be particularly cautious regarding the insertion tube

strain relief [(1)]. When wiping the insertion tube and the umbilical cable, use

a slow back and forth motion to wipe them along the tube/cable. Never apply

excessive force or torque to these strain reliefs or tubes/cables.

Do NOT Twist or Rotate Do NOT Bend

1

General

(2)

(1)

Figure 1.1

CAUTION

• EB-1575K, EB-1975K, EB-1990i can be sterilized using the STERRAD®

NX™ system. For more detail, refer to sections 1-2-5-1 and 1-3-3-2 of

this instruction for use.

• Video bronchoscopes other than EB-1575K, EB-1975K, EB-1990i are

incompatible with sterilization using STERRAD® NX™ system.

• After every 100 cycles of STERRAD® NX™ exposure, the endoscope

should be returned to an authorized PENTAX service facility for repair.

Replacement of the insertion tube and bending section will be necessary

and other components may also require service.

• Although STERRAD® NX™ compatible endoscopes are generally capable

of withstanding up to 100 cycles of exposure to STERRAD® NX™, repair/

replacement of components might be necessary prior to 100 cycles,

depending upon the condition of the endoscope.

• Be sure to attach the ventilation cap (OF-C5) to the venting connector

before performing STERRAD® NX™ sterilization.

– 8 –

Page 14

1

NOTE

NOTE

NOTE

General

This IFU contains detailed recommendations on the manual reprocessing of

PENTAX endoscopes using PENTAX supplied cleaning/disinfecting adapters.

AERs may also be used to reprocess flexible endoscopes. However, only

those AERs should be used whose manufacturers provide device-specific

instructions and have validation data to support each AER claim with respect

to PENTAX instruments. AER manufacturers should be consulted for their

specic claims including, but not necessarily limited to:

a) the ability of the AER to provide a cleaned and high-level disinfected (or

sterilized) endoscope and endoscope components (e.g., valves),

b) the identification of any special feature (internal channel) or endoscope

component that cannot be reprocessed and therefore requires manual

reprocessing,

c) the microbial quality of the rinse water,

d) the inclusion of an “automated” alcohol rinse cycle,

e) the inclusion of a terminal drying cycle that removes the majority of water

from within endoscope channels,

f) maintenance procedures for water filter replacement and/or

decontamination of the filtration system to ensure water of suitable

quality,

g) compliance with local regulations and/or guidelines.

PENTAX exible endoscopes should not be exposed to temperatures in excess

of 140oF (60oC) during either reprocessing or storage. During reprocessing

depending upon the detergent used, the endoscope may be damaged even if

the temperature does not exceed 140oF (60oC). A list of detergents that are

compatible with PENTAX endoscopes is contained in this manual.

All of the steps in the validated reprocessing protocol described in this

manual are intended to be performed in rapid succession and as a single,

continual procedure. There should be no breaks in between steps of the

protocol that are of sufficient duration to permit the endoscope to dry to

such an extent that dislodged debris and/or microbial contaminants would be

permitted to dry onto any endoscope surface. In the event that drying of the

endoscope occurs due to an excessive break in the reprocessing procedure,

the procedure should be completely repeated, beginning with the rst pre-

cleaning step.

– 9 –

Page 15

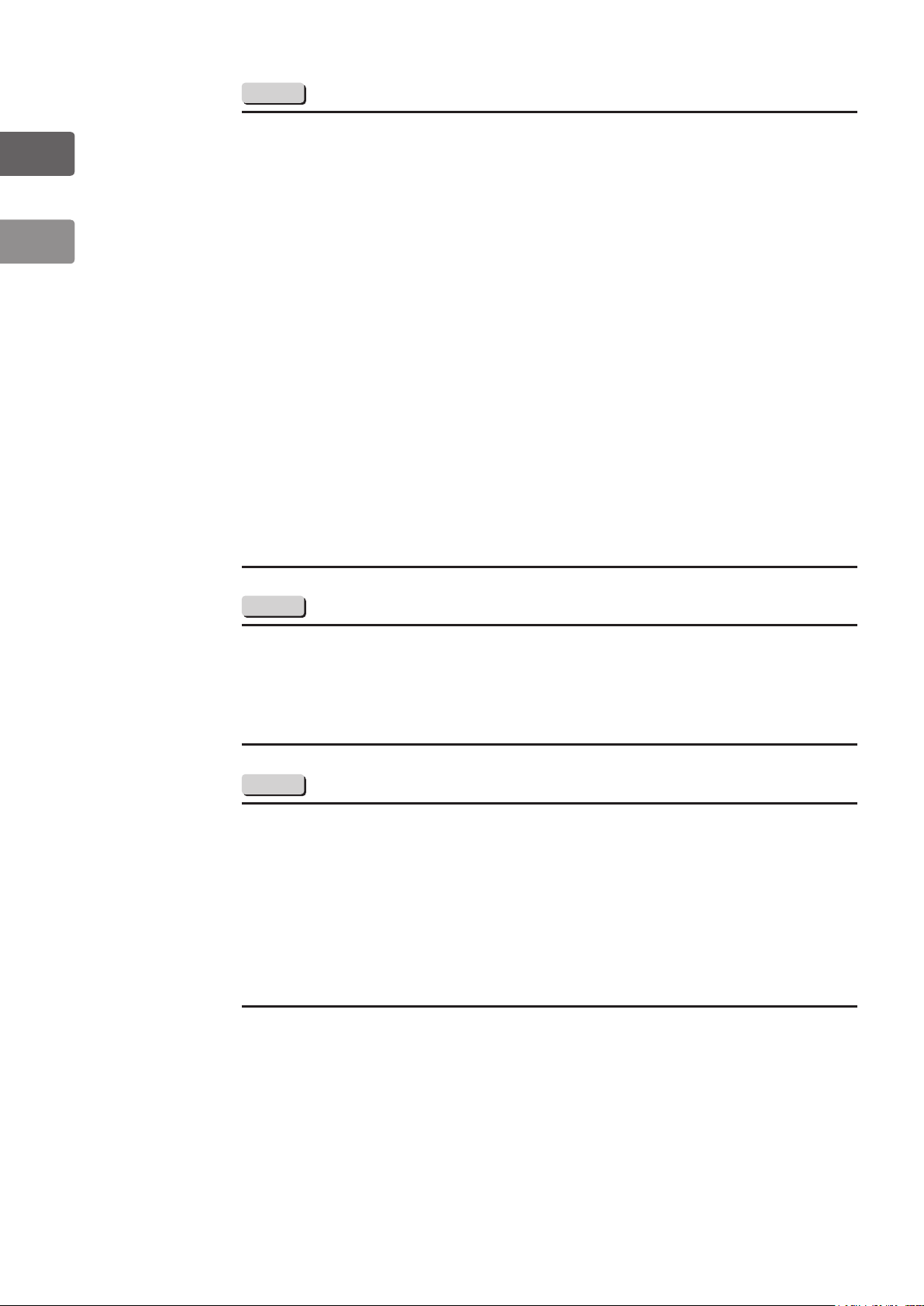

1-1-3. Internal Channels of Video Bronchoscopes

The following internal schematic is designed to help users better understand the intricate

construction of PENTAX endoscopes. Please note that all solution entrance ports and flow

pathways are illustrated below.

(1) Suction Channel

(2) Instrument

(7)

(1)

(6)

(2)

(4)

(5)

(3)

Channel Inlet

(3) Inlet Seal

(OF-B190)

(4) Suction Cylinder

(5) Cleaning Adapter

(OF-B155)

(6) Ventilation Cap

(OE-C5)

(7) PVE Soaking Cap

(OE-C9)

1

General

Figure 1.2

– 10 –

Page 16

1

General

1-1-4. Quick Reference of Injection Volumes for Internal Channel

The following table is designed to to help users better understand the injection volumes for

internal channel of video bronchoscopes.

Cleaning Process

Video

Bronchoscopes

EB-1170K

EB-1570K 6 mL

EB-1970K 8 mL

EB-1970TK 9 mL

EB-1575K 6 mL

EB-1975K 8 mL

EB-1990i 4 mL

①

Injecting from suction nipple

②

Injecting from inlet seal (OF-B190)

Internal

Channel

Suction

Channel

Capacity (mL)

Maximum

Volume

4 mL

Injection Volumes (mL)

Detergent

①

:25 mL

②

:25 mL

Cleaning

Rinse

Water

①

:35 mL

②

:35 mL

①

:35 mL

②

:35 mL

Air

High Level Disinfection Process

Video

Bronchoscopes

EB-1170K

EB-1570K 6 mL

EB-1970K 8 mL

EB-1970TK 9 mL

EB 1575K 6 mL

EB-1975K 8 mL

EB-1990i 4 mL

①

Injecting from suction nipple

②

Injecting from inlet seal (OF-B190)

Internal

Channel

Suction

Channel

Capacity (mL)

Maximum

Volume

4 mL

High Level Disinfection

Injection Volumes (mL)

Disinfectant

①

:25 mL

②

:25 mL

Sterile

Rinse

Water

①

:35 mL

②

:35 mL

Alcohol Rinse

Injection Volumes (mL)

Air Alcohol Air

①

:35 mL

②

:35 mL

①

:15 mL

②

:15 mL

①

:35 mL

②

:35 mL

– 11 –

Page 17

1-1-5. Inspection of Reprocessing Accessories

Before use, inspect reprocessing accessories according to the following procedure.

WARNING

• Replace reprocessing accessory with a new one when inspection of the

device indicates that it is damaged or unable to function properly.

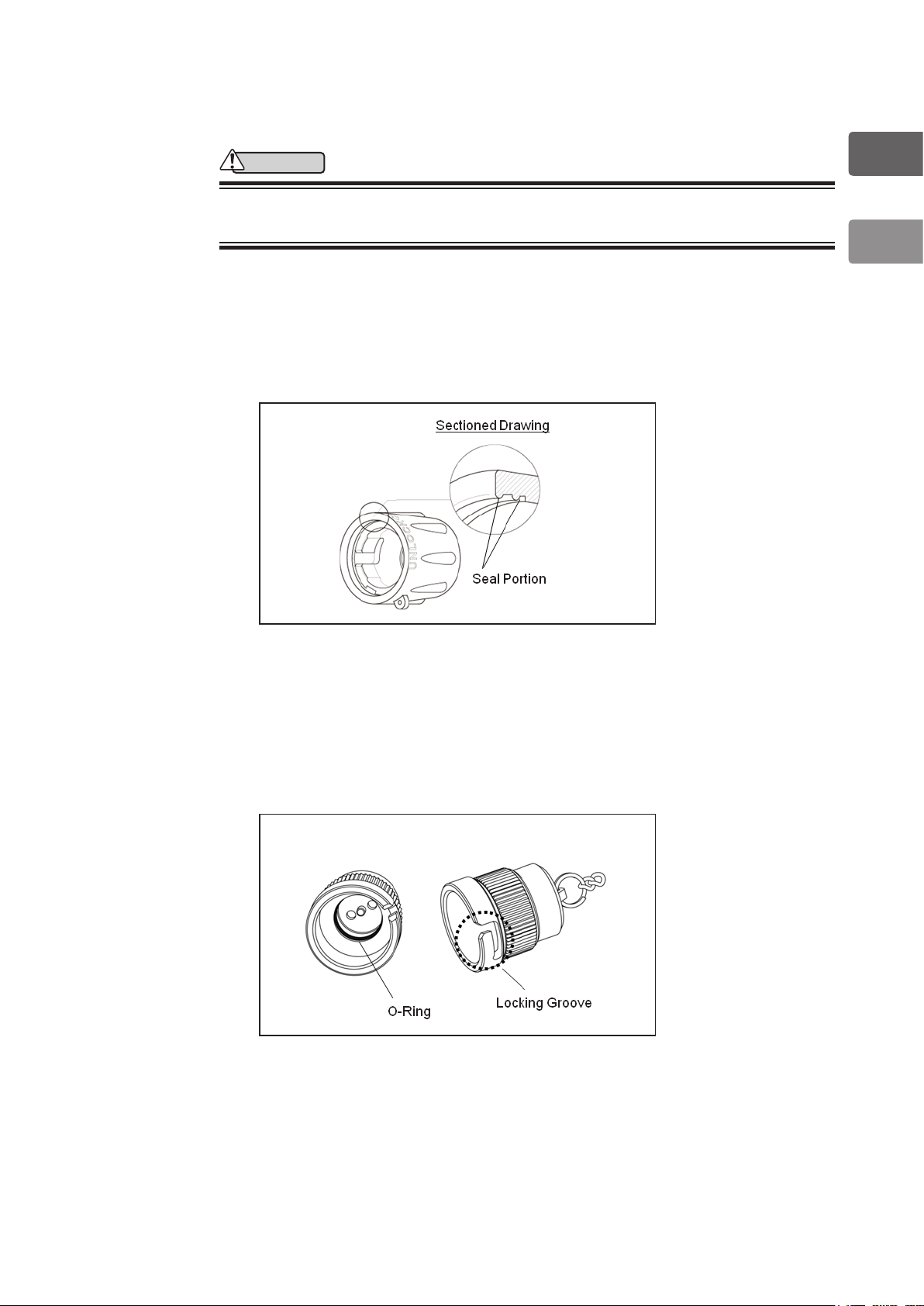

1-1-5-1. Inspection of PVE Soaking Cap (OE-C9)

1) Check that there is no cracking on the outer surface of the PVE Soaking Cap.

2) Check that there are no scratches, cracking, or chipping of the sealing surfaces inside

the PVE Soaking Cap

.

1

General

Figure 1.3

1-1-5-2. Inspection of Ventilation Cap (OF-C5)

1) Make sure that of the Locking Groove Potion of the Ventilation Cap is not deformed.

2) Check that there are no scratches, cracking, or chipping of the O-ring inside the

Ventilation Cap.

Figure 1.4

– 12 –

Page 18

1

General

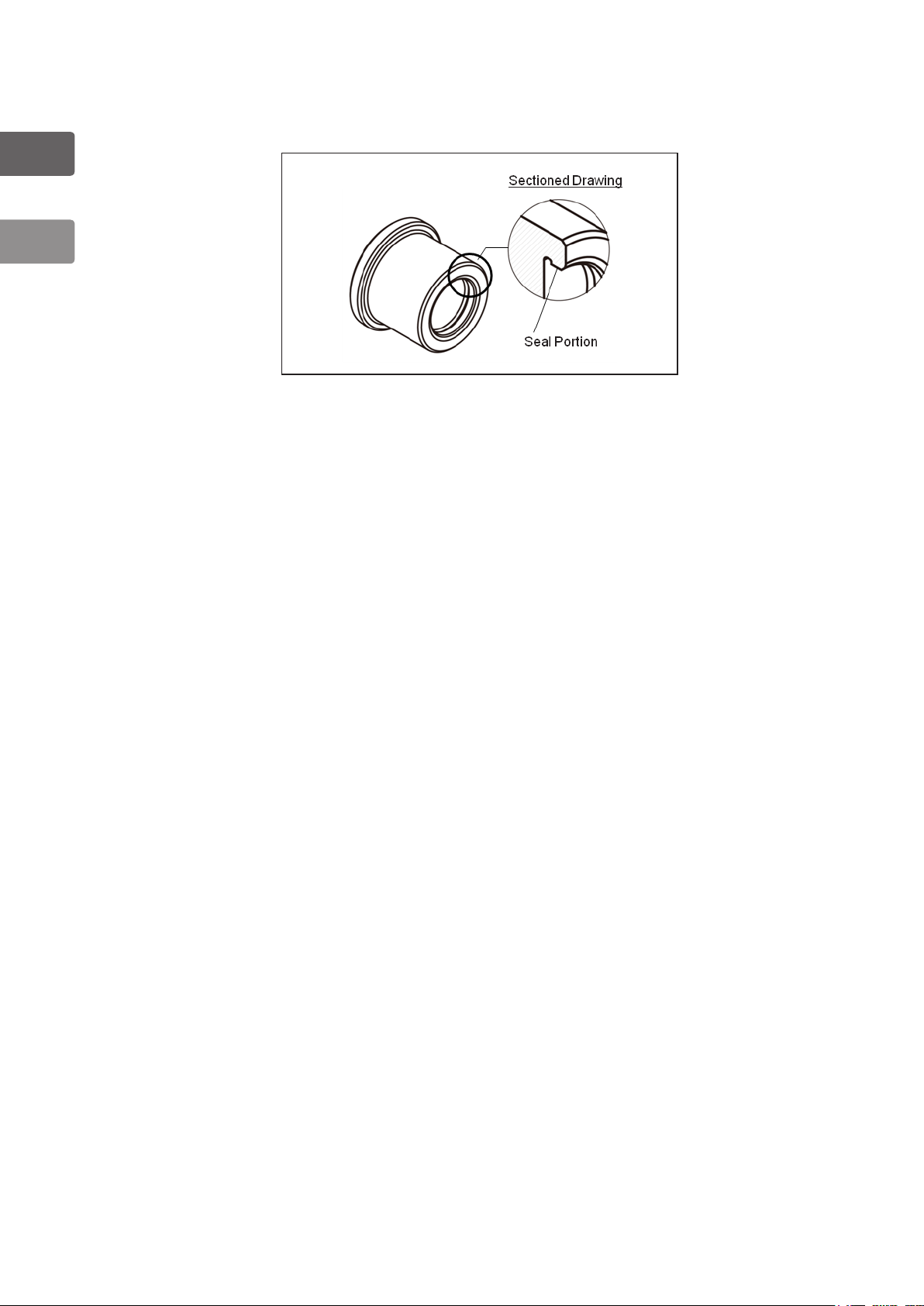

1-1-5-3. Inspection of Cleaning Adapter (OF-B155)

1) Check that there are no scratches, cracking, or chipping of the sealing surfaces inside

the Cleaning adapter.

Figure 1.5

1-1-5-4. Inspection Cleaning Brushes

(CS-C3S/CS6002SN/CS6015ST/CS3010S)

1) Make sure that there are no missing bristles on Cleaning Brushes.

2) Check that there is no kinking or bending of the Cleaning Brush Shaft.

– 13 –

Page 19

1-2. Endoscope Reprocessing

Video bronchoscopes can be subjected to the following cleaning, disinfection, and optional

sterilization process.

Video

Bronchoscopes

EB-1170K Y N Y N N

EB-1570K Y N Y N N

EB-1970K Y N Y N N

EB-1970TK Y N Y N N

EB-1575K Y N Y N Y

EB-1975K Y N Y N Y

EB-1990i Y N Y N Y

Y : YES

N : NO

Manual Ultrasonic

Cleaning

High-Level

Disinfection

1-2-1. Pre-Cleaning

WARNING

Optional Sterilization

Steam

Sterilization

STERRAD

NX™ system

®

1

Endoscope

Pre-Cleaning

• During reprocessing, always wear protective equipment (e.g., gloves,

gowns, face masks, etc.) to minimize the risk of cross contamination.

• Pre-cleaning is intended to remove visible debris from the endoscope

immediately after its withdrawal from the patient, in order to withdrawal

subsequent cleaning procedure. Endoscopes that are from the patient

are soiled with debris such as blood, tissues, and mucus. When such

debris dries, it cannot be adequately removed in the subsequent cleaning

procedure. It should be noted that pre-cleaning cannot substitute for the

mechanical cleaning process. Always mechanically clean the endoscope

after pre-cleaning.

• During pre-cleaning, never wipe the insertion tube with alcohol or

disinfecting solution. These solutions may x organic contaminants and

proteinaceous debris to the instrument and have an adverse effect on

endoscope functionality and proper reprocessing.

• When using detergent, use only legally marketed brands that have been

tested and found to be compatible by PENTAX. A list of detergents that

are compatible with PENTAX endoscopes is contained in this manual.

CAUTION

• Immediately after use, the metal light guide plug and electrical contacts/

pins of the endoscope may be HOT. To avoid burns, do not touch these

areas immediately after use. For safer handling after a procedure, grasp

the PVE connector housing.

• Prior to pre-cleaning the endoscope, leave the PVE connector attached to

the video processor

• In order to prevent damage to the endoscope, do not place any objects

other than Inlet Seal (OF-B190) and Suction Control Valve (OF-B179)

with the endoscope in the closed container used for transport to the

reprocessing area.

.

– 14 –

Page 20

NOTE

1

Endoscope

Pre-Cleaning

CAUTION

In order to avoid damaging the endoscope, never subject it to suction in

excess of 66kPa

If the use of detergent solution is not permitted in the procedure room,

remove the endoscope from the procedure room and perform pre-cleaning

solution in another location.

.

1-2-1-1. Items required

• Protective equipment such as gloves, gowns, face masks, etc., to minimize the

risk of cross contamination.

• Detergent solution, Endozime (Ruhof Corporation)

• External suction source

• 500 mL basin

• Lint-free gauze

• 30 mL luer lock syringe

• Inlet seal (OF-B190)

• Suction control valve (OF-B179)

1-2-1-2. Preparation

1) Wear personal protective equipment.

2) Prepare a 500 mL basin with detergent solution per manufacturer's instructions

(temperature, concentration). In the case of ENDOZIME, add 30 mL of ENDOZIME

concentrate to 3.8 L (1 gallon) of clean potable water at 20°C~30°C (68°F~86°F).

1-2-1-3. Wiping of the insertion tube

1) Turn off the lamp switch of the video processor.

2) Immediately after removing the endoscope from the patient, gently wipe the entire

length of the insertion tube three times using lint-free gauze soaked with detergent

solution.

Figure 1.6

– 15 –

Page 21

1-2-1-4. Aspiration of detergent solution through the suction channel

1) Connect inlet seal (OF-B190) and suction control valve (OF-B179) to the endoscope.

2) Connect a suction tube from an external suction source to the endoscope suction

nipple.

3) Turn on the external suction source.

4) Place the distal end of the endoscope into a basin, and aspirate detergent solution

through the suction channel by pressing suction control valve (OF-B179) for 10

seconds.

1

(1) OF-B190

(2) OF-B179

(3) External Suction Source

(3)

Figure 1.7

(2)

(1)

5) Take the distal end out of detergent solution, and aspirate air through the suction

channel by pressing suction control valve (OF-B179) for 10 seconds.

6) Turn off the external suction source.

7) Disconnect tubing from the endoscope suction nipple.

1-2-1-5. Transport to cleaning room

1) Turn off the power to the video processor, and detach the PVE connector from the

video processor.

2) Transport the pre-cleaned endoscope to the cleaning room in a closed container.

Endoscope

Pre-Cleaning

– 16 –

Page 22

1

Leak

Testing

1-2-2. Leak Testing

Before reprocessing and/or immersion in any uids, PENTAX endoscopes should be tested for

the loss of integrity in their watertight construction by using a leakage tester.

CAUTION

Various types of manual and automated endoscope leakage testers

exist. Some manual and automated are stand-alone units, and others

may be integrated into an AER. PENTAX does not evaluate non-PENTAX

leakage testers to verify their specific product claims with respect to their

effectiveness to accurately detect leaks and/or their compatibility with

PENTAX endoscopes. Insufficient pressures may reduce the likelihood for

accurate leak detection, especially if the endoscope’s distal bending section

is not flexed during testing. Also, excessive pressures may adversely

affect the endoscope, especially if pressurization occurs during automated

reprocessing at elevated temperatures. PENTAX accepts no responsibility for

use of non-PENTAX Leakage testers. Users should check with the leakage

tester manufacturer and confirm their specific product claims, including

compatibility with PENTAX endoscopes at various temperatures and their

ability to detect leaks with/without uid immersion and with/without exing

of the endoscope’s distal bending section.

– 17 –

Page 23

1-2-3. Cleaning

WARNING

• During reprocessing, always wear protective equipment (e.g., gloves,

gowns, face masks, etc.) to minimize the risk of cross contamination.

• In order to ensure thorough cleaning, be sure to perform all cleaning

steps. The effectiveness of each cleaning step will influence the

effectiveness of subsequent steps. Failure to properly follow the cleaning

steps described may result in incomplete or ineffective cleaning,

disinfection, and/or sterilization of endoscope, and may pose a crossinfection risk.

• Immediately (within one hour) after the completion of a procedure,

the endoscope and its components should be thoroughly and carefully

cleaned with detergent solution. If the endoscope and its components

are left uncleaned for an excessive time after use, dried blood, mucus,

or other patient debris may cause damage or interfere with the ability of

the user to properly reprocess the device.

• For cleaning, use only legally marketed detergents that have been

tested according to the instructions of the manufacturer and found to

be compatible by PENTAX. A list of detergents that are compatible with

PENTAX endoscopes is contained in this manual.

• Fresh detergent solution must be used for each endscope that is

reprocessed.

1

Endoscope

Cleaning

CAUTION

• PVE soaking cap (OE-C9) must be properly secured over the electrical

contacts. Failure to do so could result in water invasion and damage

to the endoscope. If an endoscope is cleaned without the soaking cap

attached, do not use the endoscope, and contact your local PENTAX

service facility or sales representative.

• Ventilation cap (OF-C5) must be taken OFF during reprocessing. Failure

to do so can result in damage to the endoscope. If an endoscope is

cleaned with the ventilation cap attached, do not use the endoscope,

and contact your local PENTAX service facility or sales representative.

• During cleaning, never twist, rotate, or bend the insertion portion and

umbilical cable excessively.

• Never subject the endoscope to ultrasonic cleaning methods.

• In order to prevent damage to the endoscope, do not place any objects

other than the reprocessing accessories listed in section 1-2-3-1 of this

instruction for use with the endoscope when immersing it in a cleaning

basin.

– 18 –

Page 24

1-2-3-1. Items required

Endoscope component

• Inlet seal (OF-B190)

1

Reprocessing accessory

• PVE soaking cap (OE-C9)

• Cleaning brush (CS6002SN)

• Cleaning brush (CS6015ST) for EB-1570K, EB-1970K, EB-1970TK,

EB-1575K and EB-1975K

• Cleaning brush (CS3010S) (EB-1170K and EB-1990i only)

• Cleaning brush (CS-C3S)

• Cleaning adapter (OF-B155)

Other Equipment

Endoscope

Cleaning

• Protective equipment such as gloves, gowns, face masks, etc., to minimize the

risk of cross contamination.

• Detergent solution, Endozime (Ruhof Corporation)

• Clean potable water

• Basin sufcient in size to immerse the entire endoscope (at least 50 cm in width

x 40 cm in depth x 15 cm in height)

• Lint-free gauze

• 30 mL luer slip syringe

1-2-3-2. Preparation

1) Wear personal protective equipment.

2) Attach PVE soaking cap (OE-C9) to the endoscope

3) Detach Ventilation Cap (OF-C5) from the endoscope.

(1)

(1) OE-C9

(2) OF-C5

(2)

Figure 1.8

4) Fill a basin with a sufcient volume of detergent solution to completely immerse the

endoscope. Prepare the detergent in accordance with the manufacturer’s instructions

(temperature, concentration). In the case of ENDOZIME, add 30 mL of ENDOZIME

concentrate to 3.8 L (1 gallon) of clean potable water at 20°C~30°C (68°F~86°F).

– 19 –

Page 25

1-2-3-3. Cleaning of all external surfaces

(1)

CAUTION

• Do not squeeze or severely bend the insertion tube.

• Do not use any abrasive materials.

• Be careful to avoid damage to the distal lenses.

1) Fully immerse the endoscope with the components attached in detergent solution.

2) Detach the inlet seal (OF-B190) and suction control valve (OF-B179) from the

endoscope.

(2)

(1)

Figure 1.9

(1) OF-B190

(2) OF-B179

3) Open the cap of inlet seal (OF-B190) and place it in the detergent solution.

(1) OF-B190

1

Endoscope

Cleaning

Figure 1.10

4) Reprocess suction control valve (OF-B179) separately from the endoscope. (see

Section 1-3 “Endoscope components and accessories”)

5) While still immersed in detergent solution, wash the entire surface of the endoscope

and OF-B190 three times with a lint-free gauze.

6) Visually inspect the entire surface of the endoscope to insure that no soil is present,

paying special attention to areas such as the distal end, and control body, which are

the most likely regions to retain visible soil.

7) If any soil is still present on the endoscope, remove it by wiping the area in question

with lint-free gauze until it has been completely removed.

– 20 –

Page 26

1-2-3-4. Brushing of the suction channel

WARNING

1

Endoscope

Cleaning

• Do not use cleaning brushes other than those that are specied in this

instructions for use. Failure to do so could result in endoscope damage

or incomplete or ineffective cleaning.

• Prior to use, ensure that cleaning brushes are not damaged (e.g., kinked

shaft or bent or missing bristles).

• In order to prevent the dispersal of patient debris that might still be in

the endoscope channel into the environment, always withdraw brushes

slowly.

CAUTION

• In order to avoid damage to the endoscope, never attempt to insert a

cleaning brush into the endoscope distal tip.

• Never apply excessive pressure to introduce or withdraw the brush. This

can result in damage to the endoscope and/or the brush.

Always fully immerse the endoscope during brushing.

1) Insert cleaning brush (CS6002SN), into the opening of the suction nipple, and gently

push it until it appears in the suction cylinder.

(1) CS6002SN

(1)

(2)

(3)

Figure 1.11

(2) Suction Nipple

(3) Suction Cylinder

2) Gently withdraw the brush, and remove from debris from the brush head by rubbing

it with gloved ngers.

3) Repeat steps 1 and 2 three additional times.

4) Insert cleaning brush (CS6002SN) into the opening at bottom of the suction cylinder

and advance it for about 15 cm until resistance is felt. DO NOT USE EXCESSIVE

FORCE.

(1)

(2)

(1) CS6002SN

(2) Suction Cylinder

Figure 1.12

5) Gently withdraw the brush, and remove debris from the brush head by rubbing it

with gloved ngers.

– 21 –

Page 27

6) Repeat steps 4 and 5 three additional times.

7) Insert cleaning brush (CS3010S for EB-1170K and EB-1990i/CS6015ST: for all

other scopes) into the instrument channel inlet, and gently advance it until it exits the

distal end of the endoscope.

(1) CS3010S (for EB-

(1)

(2)

Figure 1.13

1170K and EB-1990i)

CS6015T (for all other

scopes)

(2) Instrument Channel

Inlet

8) Remove debris from the brush head by rubbing it with gloved ngers and then gently

withdraw the brush.

9) Repeat steps 7 and 8 three additional times.

10) Insert cleaning brush (CS-C3S) into the suction cylinder, and rotate it for 30 seconds.

Do not insert the brush excessively.

(1) CS-C3S

(2) Suction Cylinder

(1)

(2)

1

Endoscope

Cleaning

Figure 1.14

11) Withdraw the brush. Remove debris from the brush head by rubbing it with gloved

ngers.

12) Repeat steps 10 and 11 three additional times.

– 22 –

Page 28

1-2-3-5. Filling the suction channel with detergent solution

WARNING

1

Endoscope

Cleaning

• While injecting detergent solution through the channels, avoid the

introduction of air. The presence of air bubbles can prevent contact of

the detergent solution with channel surfaces.

• Always fully immerse the endoscope while flushing detergent solution

into the endoscope channel.

• It is imperative that the cleaning adapter (OF-B155) and Inlet Seal (OF-

B190) be securely attached to the endoscope. Failure to properly mount

and secure the cleaning adapter and inlet seal can result in ineffective

and incomplete reprocessing.

CAUTION

In order to avoid damage to the endoscope, never apply excessive force if

resistance is encountered while ushing detergent solution into channels. Do

not use the endoscope, and contact your local PENTAX service facility or sales

representative.

Always immerse the endoscope, components, and accessories in detergent solution during

cleaning.

Attaching components and accessories to the endoscope

1) Attach inlet seal (OF-B190) and cleaning adapter (OF-B155) to the endoscope.

(2)

(1)

Figure 1.15

(1) OF-B190

(2) OF-B155

Filling the suction channel with detergent solution

2) Attach a 25 mL syringe lled with the detergent solution to the suction nipple, and

inject 25 mL of detergent solution into the suction channel.

(1) Suction Nipple

(1)

Figure 1.16

– 23 –

Page 29

3) Check to conrm that detergent solution ows out from the suction channel opening

(2)

on the distal end of the endoscope.

4) Insert a syringe lled with detergent solution to inlet seal (OF-B190), and inject 25

mL of detergent solution into the suction channel.

(1) OF-B190

(1)

Figure 1.17

5) Detach the inlet seal cleaning adapter inlet seal (OF-B190), and cleaning adapter

(OF-B155) from the endoscope, and leave them to soak along with the endoscope in

detergent solution. Open the cap of inlet seal (OF-B190).

1

Figure 1.18

(1)

(1) OF-B190

(2) OF-B155

Endoscope

Cleaning

– 24 –

Page 30

1-2-3-6. Soaking in detergent solution

WARNING

1

Endoscope

Cleaning

• The detergent solution must remain in contact with ALL internal channels

and external endoscope surfaces for the time period recommended by

the manufacturer of the detergent.

• Adhere to the conditions (temperature, concentration, time) specified

by the detergent manufacturer to accomplish effective and complete

cleaning. Use of the detergent solution under conditions that fall outside

the manufacturer's directions might damage the endoscope. Use of

a timer or audible alarm is recommended in order not to exceed the

recommended soaking time.

• During immersion, detach the cleaning adapter (OF-B155) and inlet

seal (OF-B190) from the endoscope to ensure contact of all endoscope

surfaces with the detergent solution.

CAUTION

Never subject the endoscope to ultrasonic cleaning methods.

1) While fully immersing the endoscope, inlet seal (OF-B190), and cleaning adapter

(OF-B155), ensure that there are no air bubbles on the endoscope surfaces, distal

end, and acessories. If any air bubbles are detected, ush them away with detergent

solution using a 30 mL syringe.

2) Soak the endoscope, inlet seal (OF-B190), and cleaning adapter (OF-B155)

under conditions (temperature, concentration, time) specified by the detergent

manufacturer. In the case of Endozime, the immersion time is 3 minutes.

Figure 1.19

3) After soaking, ultrasonically clean inlet seal (OF-B190), and cleaning adapter (OFB155) according to Section 1-3 “Endoscope components and accessories”.

Purging detergent solution the from suction channel

4) After ultrasonic cleaning, attach inlet seal (OF-B190) and cleaning adapter (OFB155) to the endoscope. (Figure 1.15, p23)

5) Attach a syringe lled with air to the suction nipple, and ush the suction channel

with at least 35 mL of air to purge as much residual detergent solution as possible.

(Figure 1.16, p23)

6) Insert a syringe lled with air to inlet seal (OF-B190), and ush the suction channel

with at least 35 mL of air to purge as much residual detergent solution as possible.

(Figure 1.17, p24)

7) Remove the endoscope (with inlet seal (OF-B190) and cleaning adapter (OF-B155)

attached) from the detergent solution.

– 25 –

Page 31

1-2-3-7. Rinsing

WARNING

It is important that all internal channels, external endoscope surfaces,

and components be thoroughly rinsed with clean water to remove residual

detergent solution. Failure to do so can result in ineffective or incomplete

disinfection and sterilization.

First rinse

1) Place the endoscope with the inlet seal (OF-B190), and cleaning adapter (OF-B155)

attached in a basin of clean water that is of sufcient volume to completely immerse

the endoscope.

2) Detach inlet seal (OF-B190), and cleaning adapter (OF-B155) from the endoscope. Open

the cap of inlet seal (OF-B190). (Figure 1.18, p24)

3) Wipe all exterior surfaces of the endoscope, inlet seal (OF-B190), and cleaning adapter

(OF-B155) one time with a lint-free gauze in order to remove residual detergent solution.

4) While still completely immersed in water, grasp the distal end and control body of the

scope and PVE connector with two hands, and agitate them under the water by moving

them from side to side repeatedly for one minute.

1

Endoscope

Cleaning

Figure 1.20

5) Similarity, agitate inlet seal (OF-B190), and cleaning adapter (OF-B155) under the

water by moving them from side to side repeatedly for at least one minute.

6) Attach inlet seal (OF-B190), and cleaning adapter (OF-B155) to the endoscope.

(Figure 1.15, p23)

7) Attach a syringe lled with water to the suction nipple, and ush the suction channel

with 35 mL of water. (Figure 1.16, p23)

8) Insert a syringe filled with water into inlet seal (OF-B190), and flush the suction

channel with 35 mL of water. (Figure 1.17, p24)

9) Remove the endoscope with inlet seal (OF-B190), and cleaning adapter (OF-B155)

attached from the water.

10) Attach a syringe lled with air to the suction nipple, and ush the suction channel

with 35 mL of air to expel residual water. (Figure 1.16, p23)

11) Insert a syringe lled with air to the inlet seal, and ush the suction channel with 35

mL of air. (Figure 1.17, p24)

– 26 –

Page 32

1

Endoscope

Cleaning

Second rinse

12) Fill a basin with clean water and repeat steps 1-11 to perform a second rinse.

Third rinse

13) Fill a basin with clean water and repeat steps 1-11 to perform a third rinse.

Forth rinse

14) Fill a basin with clean water and repeat steps 1-11 to perform a fourth rinse.

15) Detach inlet seal (OF-B190), and cleaning adapter (OF-B155) from the endoscope.

(Figure 1.18, p24)

1-2-3-8. Drying

1) Gently wipe and dry all external surfaces of the endoscope, inlet seal (OF-B190),

and cleaning adapter (OF-B155) with a new lint-free gauze.

– 27 –

Page 33

1-2-4. High-Level Disinfection

Prior to high-level disinfection, the end user should confirm the minimum effective

concentration (MEC) of reused disinfectant as per the manufacturer’s instructions.

WARNING

• During the reprocessing process, always wear protective equipment

(e.g., gloves, gowns, face masks, etc.) to minimize the risk of cross

contamination.

• Prior to disinfection, it is imperative that any solutions previously used in

the cleaning process be thoroughly rinsed and dried. Failure to do so can

result in ineffective or incomplete disinfection.

• For high-level disinfection, use an appropriate disinfecting solution

according to the instructions of the disinfectant manufacturer

(temperature, concentration, time). Adhere to the instructions to

accomplish effective and complete disinfection. The endoscope may be

damaged if exposed to a disinfectant under conditions other than those

specied by the disinfectant manufacturer.

• Use only a legally marketed disinfectant that has been tested according

to the instructions provided by the manufacturer and found to be

compatible by PENTAX. A list of disinfectants that are compatible with

PENTAX endoscopes is contained in this manual.

• It is imperative that ALL internal channel surfaces be in contact with

the disinfecting solution for the time period recommended by the

manufacturer of the solution.

• Ideally, all final rinses should be performed with sterile water, clean

potable water, or water that meets the requirements of the health care

facility.

• Regardless of the quality of the rinse water used, it is essential to

perform a nal alcohol rinse followed by forced air in order to completely

dry the endoscope channels and prevent bacterial colonization and/or

infections associated with waterborne microorganisms.

• The basin that is used to perform disinfectant immersion must be

thoroughly cleaned prior to lling it with disinfectant solution.

1

Endoscope

Disinfection

– 28 –

Page 34

CAUTION

• Prior to disinfection, attach PVE soaking cap (OE-C9). Failure to do

1

so can result in water invasion and damage to the endoscope. If the

endoscope is disinfected without the soaking cap attached, do not use

the endoscope, and contact your local PENTAX service facility or sales

representative.

• Prior to disinfection, detach the ventilation cap (OF-C5). Failure to do so

can result in damage to the endoscope. If the endoscope is disinfected

with the ventilation cap attached, do not use the endoscope, and contact

your local PENTAX service facility or sales representative.

• During disinfection, never twist, rotate, or bend the insertion tube and

umbilical cable excessively.

• To prevent damaging the endoscope, do not place any objects other

than the reprocessing accessories described in section 1-2-4-1 with the

endoscope when immersing the endoscope in the disinfection basin.

1-2-4-1. Items required

Endoscope component

Endoscope

Disinfection

• Inlet seal (OF-B190)

Reprocessing accessory

• PVE soaking cap (OE-C9)

• Cleaning adapter (OF-B155)

Other equipment

• Protective equipment such as gloves, gowns, face masks, etc., to minimize the

risk of cross contamination.

• Disinfecting solution, Cidex Activated Dialdehyde Solution (Johnson &

Johnson).

• Sterile water (preferred) or clean potable water

• 70-90% medical grade ethyl or isopropyl alcohol

• Basin sufcient in size to immerse the entire endoscope (at least 50 cm in width

x 40 cm in depth x 15 cm in height)

• Sterile gauze

• 30 mL luer slip syringe

– 29 –

Page 35

1-2-4-2. Preparation

1) Wear personal protective equipment.

2) Attach the PVE soaking cap (OE-C9) to the endoscope.

3) Ensure that the ventilation cap (OF-C5) is detached from the endoscope.

(1) OE-C9

(1)

(2)

Figure 1.21

(2) OF-C5

4) Prepare a basin with a sufficient volume of disinfecting solution to completely

immerse the endoscope.

1-2-4-3. Filling the suction channel with disinfecting solution

WARNING

1

• When lling endoscope channels with disinfectant, avoid the introduction

of air. The presence of air bubbles can prevent contact of the disinfectant

with channel surfaces.

• Always immerse the endoscope while filling endoscope channels with

disinfectant.

• It is imperative that cleaning adapter (OF-B155) and Inlet Seal (OF-B190)

be securely attached to the endoscope. Failure to properly mount and

secure the cleaning adapter and inlet seal can result in ineffective and

incomplete reprocessing.

Always fully immerse the endoscope, components, and accessories in disinfecting

solution during disinfection.

Attaching components and accessories to the endoscope

1) Fully immerse the endoscope in disinfecting solution, and attach inlet seal (OF-B190)

and cleaning adapter (OF-B155) to the endoscope.

(2)

(1)

(1) OF-B190

(2) OF-B155

Endoscope

Disinfection

Figure 1.22

– 30 –

Page 36

Filling the suction channel with disinfecting solution

(2)

2) Attach a syringe lled with disinfecting solution to the suction nipple, and inject 25

mL of disinfecting solution into the suction channel.

1

Endoscope

Disinfection

(1) Suction Nipple

(1)

Figure 1.23

3) Conrm that disinfecting solution ows out from the suction channel opening on the

distal end.

4) Insert a syringe lled with disinfecting solution into inlet seal (OF-B190), and inject

25 mL of disinfecting solution into the suction channel.

(1) OF-B190

(1)

Figure 1.24

5) After injecting disinfecting solution into the suction channel, detach inlet seal (OF-

B190), and cleaning adapter (OF-B155) from the endoscope, and leave them with

the endoscope in the disinfecting solution. Open the cap of inlet seal (OF-B190).

(1) OF-B190

(1)

Figure 1.25

(2) OF-B155

– 31 –

Page 37

1-2-4-4. Soaking in disinfecting solution

WARNING

• The disinfecting solution must remain in contact with ALL internal channels

and external endoscope surfaces for the time period recommended by

the disinfectant manufacturer.

• Adhere to the conditions (temperature, concentration, time) specified

by the disinfectant manufacturer to accomplish effective and complete

disinfection. Disinfectant solution use under conditions that fall outside

the manufacturer's directions might damage the endoscope. Use of

a timer or audible alarm is recommended in order not to exceed the

recommended soaking time.

• During immersion, detach the cleaning adapter (OF-B155) and inlet

seal (OF-B190) from the endoscope to ensure contact of all endoscope

surfaces with the disinfecting solution.

1) Fully immerse the endoscope, inlet seal (OF-B190), and cleaning adapter (OF-

B155) to ensure that there are no air bubbles on the endoscope surfaces, distal end,

and accessories. If any air bubbles are detected, ush them away with disinfecting

solution using a syringe.

2) Soak the endoscope, inlet seal (OF-B190), and cleaning adapter (OF-B155) under

the conditions (temperature, concentration, time) specified by the disinfectant

manufacturer. In the case of Cidex Activated Dialdehyde Solution, the immersion

time is 45 minutes at 25°C.

1

Endoscope

Disinfection

Figure 1.26

Purging of disinfecting solution from suction channel

3) After soaking, attach inlet seal (OF-B190) with the cap closed, and cleaning adapter

(OF-B155) to the endoscope. (Figure 1.22, p30)

4) Attach a syringe lled with air to the suction channel, and ush the suction channel

with at least 35 mL of air to purge as much residual disinfecting solution as possible.

(Figure 1.23, p31)

5) Insert a syringe lled with air to inlet seal (OF-B190), and ush the suction channel

with at least 35 mL of air to purge as much residual disinfecting solution as possible.

(Figure 1.24, p31)

6) Remove the endoscope with inlet seal (OF-B190) and cleaning adapter (OF-B155)

attached from the disinfecting solution.

– 32 –

Page 38

1-2-4-5. Rinsing

WARNING

1

Endoscope

Disinfection

• Ideally, all nal rinses should be performed with sterile water. However,

if sterile water is not used, use potable water or the water that meets

the requirements of the health care facility.

• The basin that is used to perform rinsing of the endoscope and

accessories must be thoroughly cleaned prior to lling it with rinse water.

• The rinse volumes recommended for removing residual disinfectant

from channels are sufcient for 14-day glutaraldehydes (Cidex Activated

Dialdehyde Solution). If extended shelf-life glutaraldehydes or other FDAcleared, commercially available high level disinfectants are used, consult

with the disinfectant manufacturer for details regarding recommended

rinse water volumes.

First rinse

1) Place the endoscope with the inlet seal (OF-B190) and cleaning adapter (OF-B155)

attached in a basin of sterile water that is of sufcient volume to completely immerse

the endoscope.

2) Detach inlet seal (OF-B190), and cleaning adapter (OF-B155) from the endoscope.

Open the cap of inlet seal (OF-B190).

3) Wipe all exterior surfaces of the endoscope, inlet seal (OF-B190), and cleaning

adapter (OF-B155) at least two times with a sterile gauze in order to remove residual

disinfecting solution.

4) While still completely immersed in water, grasp the distal end and control body of

the scope and PVE connector with two hands, and agitate them under the water by

moving them from side to side repeatedly for at least one minute.

Figure 1.27

5) Similarity, grasp inlet seal (OF-B190) and cleaning adapter (OF-B155) and agitate

them under water by moving them from side to side for at least one minute.

6) Attach inlet seal (OF-B190) and cleaning adapter (OF-B155) to the endoscope.

(Figure 1.22, p30)

7) Attach a syringe lled with water to the suction nipple, and ush the suction channel

with at least 35 mL of water. (Figure 1.23, p31)

8) Insert a syringe filled with water to inlet seal (OF-B190) and flush the suction

channel with at least 35 mL of water. (Figure 1.24, p31)

– 33 –

Page 39

9) Take the endoscope with inlet seal (OF-B190) and cleaning adapter (OF-B155)

attached out of the water.

10) Attach a syringe lled with air to the suction nipple, and ush the suction channel

with at least 35 mL of air to expel residual water. (Figure 1.23, p31)

11) Insert a syringe lled with air into the inlet seal, and ush the suction channel with

35 mL of air. (Figure 1.24, p31)

Second rinse

12) Fill a basin with sterile water and repeat steps 1-11 in order to perform a second

rinse.

Third rinse

13) Fill a basin with sterile water and repeat steps 1-11 in order to perform a third rinse.

Forth rinse

14) Fill a basin with sterile water and repeat steps 1-11 to perform a fourth rinse.

15) Remove the endoscope and its component from the basin of water and place them on

a clean, dry, lint-free cloth.

1-2-4-6. Drying

1

WARNING

Regardless of the quality of the rinse water used, it is essential to perform

a final alcohol rinse followed by forced air in order to completely dry the

endoscope channels and prevent bacterial colonization and/or infections

associated with waterborne microorganisms.

Flushing the channels with alcohol

1) Attach a syringe lled with 70-90% medical grade ethyl or isopropyl alcohol to the

suction nipple, and ush the suction channel with 15 mL of alcohol. (Figure 1.23,

p31)

2) Insert a syringe lled with 70-90% medical grade ethyl or isopropyl alcohol into the

inlet seal (OF-B190), and ush the suction channel with 15 mL of alcohol. (Figure

1.24, p31)

Purging of alcohol from channel

3) Attach a syringe lled with air to the suction nipple, and ush the suction channel 35

mL of air to expel residual alcohol. (Figure 1.23, p31)

4) Insert a syringe lled with air to inlet seal (OF-B190), and ush the suction channel

with 35 mL of air to expel residual alcohol. (Figure 1.24, p31)

5) Ensure no alcohol exits the endoscope end. If any, repeat steps 3 and 4.

6) Detach inlet seal (OF-B190) and cleaning adapter (OF-B155) from the endoscope.

(Figure 1.25, p31)

Endoscope

Disinfection

Drying of all external surfaces

7) Gently dry all external surfaces of the endoscope, inlet seal (OF-B190), and cleaning

adapter (OF-B155) with a sterile gauze.

– 34 –

Page 40

1-2-5. Optional Sterilization

WARNING

1

Endoscope

Sterilization

• Please note that PENTAX Medical has not validated any sterilization

methods for exible endoscopes othet than STERRAD® NX™ system.

• During the reprocessing process, always wear protective equipment

(e.g., gloves, gowns, face masks, etc.) to minimize the risk of cross

contamination.

• Sterilization efcacy and material compatibility depend on the following

factors:

- thorough cleaning of the device

- load of the devices to be sterilized

- wrapping of the devices to be sterilized

- sterilizer cycle parameters

- quality of rinse water

• Prior to sterilization, clean and dry the endoscope thoroughly. Failure to

do so can result in ineffective or incomplete sterilization.

• Use a chemical indicator (CI) and/or biological indicator (BI) to control

the sterilization process and ensure sterilization efcacy.

• The manufacturer of the sterilizer should be consulted to confirm that

test data exists to substantiate that no harmful levels of any residues

(active/inert ingredients, their by-products or derivatives of the

processed devices) remain on any instrument that may pose a risk to

patients and users.

• After sterilization, ensure that the package is intact. If there are any

signs of abnormalities such as stains, tears, or any other indications that

the packaging has been damaged or opened, repeat the sterilization

process with new packaging.

CAUTION

• Due to the heat sensitive nature and/or the specific biocompatible

materials used in the construction of flexible endoscopes, some

sterilization systems/processes/solutions may have detrimental effects

on flexible endoscopes. To avoid the potential for instrument damage

and/or endoscope failure, confirm the compatibility of such systems/

solutions with your local PENTAX dealer prior to use with any PENTAX

products. Also, confirm the specific claim(s) of any sterilization

methods/processes with the sterilizer manufacturer to ensure that they

have performed microbiological validation studies to support their claims

of achieving sterilization of device specic exible endoscope models and

endoscope components.

• NEVER place the endoscope in a steam sterilizer!

– 35 –

Page 41

1-2-5-1. Sterilization using STERRAD® NX™ System (EB-1575K,

EB-1975K, EB-1990i only)

CAUTION

• PENTAX video bronchoscopes other than EB-1575K, EB-1975K, EB-1990i

are incompatible with the STERRAD® NX™ system.

• When sterilizing the endoscope, do not place any objects other than inlet

seal (OF-B 190) and suction control valve (OF-179) into the sterilization

tray.

• After every 100 cycles of STERRAD® NX™ exposure, the endoscopes

should be returned to an authorized PENTAX service facility for repair.

Replacement of the insertion tube and bending section will be necessary,

and other components may also require repair or replacement.

• Although STERRAD® NX™ compatible endoscopes are capable of

withstanding STERRAD® NX™ sterilization for up to 100 cycles, repair/

replacement of parts might be necessary prior to reaching 100 cycles,

depending upon the condition of the endoscope.

1-2-5-1-1. Items required

• protective garments such as gloves, gowns, face masks, etc. to minimize the risk

of cross contamination.

• APTIMAX Instrument Tray ( 270 mm in width, 576 mm in length, 100 mm in height)

1

• APTIMAX Instrument Tray Mat ( 254 mm in width, 546 mm in length)

• instrument wrap recommended by STERRAD® for use of STERRAD® NX™

system

• tape recommended by STERRAD® for use of STERRAD® NX™ system

• Ventilation cap (OF-C5)

Endoscope

Sterilization

– 36 –

Page 42

1-2-5-1-2. Preparation

WARNING

1

Consult the manufacturer of the sterilization tray regarding its directions for

use.

CAUTION

Prior to the sterilization using STERRAD® NX™ system, ensure that Ventilation

cap (OF-C5) is attached to the scope. Failure to do so can result in bursting of

the bending rubber.

1) Detach cleaning adapter (OF-B155) and the inlet seal (OF-B190) are detached from

the scope.

(1)

(2)

Figure 1.28

(1) OF-B155

(2) OF-B190

Endoscope

Sterilization

2) Detach PVE soaking cap (OE-C9) from the scope.

3) Attach ventilation cap (OF-C5) to the scope

(1) OF-C5

(2) OE-C9

(2)

(1)

Figure 1.29

4) Lay the APTIMAX Instrument Tray Mat on APTIMAX Instrument Tray

5) Place the scope onto the mat as shown below

Figure 1.30

6) Cover the tray with the lid.

– 37 –

Page 43

1-2-5-1-3. Wrapping

WARNING

• Contact the manufacturer regarding directions for use of instrument

wrap and tape.

• Scope components may be wrapped and sterilized together with

the scope. However, do not attach any components other than the

ventilation cap to the scope

• Secure the wrapping with a length of tape that is sufcient to prevent the

wrapping from peeling away from package. Failure to do so can result in

removal of the tape and ineffective sterilization.

1) Wrap the tray containing the scope.

2) Apply the tape lengthwise across the three sides of the wrapped container.

1-2-5-1-4. Sterilization Parameter Selection

WARNING

Contact Johnson & Johnson regarding directions for use of the STERRAD®

NX™ system

1) Set the tray containing the scope into the sterilization chamber.

1

STERRAD® NX™ :

Select "Advanced" cycle and operate the sterilizer according to the instructions supplied

with the STERRAD® NX™.

Endoscope

Sterilization

– 38 –

Page 44

1-3. Endoscope components and accessories

NOTE

Endoscope components and accessories can be subjected to the following cleaning, disinfection,

and sterilization processes.

1

Model Cleaning

High-Level

Name Number Manual Ultrasonic

Endoscope

Component

Accessory Bite Block OF-Z5 Y Y Y Y N

Reprocessing

Accessory

Suction

Control Valve

Inlet Seal OF-B190 Y Y Y Y Y

PVE Soaking

Cap

Ventilation

Cap

Cleaning

Adapter

Cleaning

Brush

Cleaning

Brush

Cleaning

Brush

Cleaning

Brush

OF-B179 Y Y Y Y Y

OE-C9 Y* N Y* N N

OF-C5 N N N N Y**

OF-B155 Y Y Y Y N

CS6002SN Y Y Y Y N

CS6015ST Y Y Y Y N

CS3010S Y Y Y Y N

CS-C3S Y Y Y Y N

Disinfection

Optional Sterilization

Steam

Sterilization

STERRAD®

NX™

system

Accessory

Cleaning

Y : YES

N : NO

* : The PVE Soaking Cap (OE-C9) should be attached to the endoscope during cleaning and

disinfection procedures.

** : The ventilation cap (OF-C5) should be attached to the endoscope during the STERRAD®

sterilization.

Automated Endoscope Reprocessor (AER) manufacturers may not make

specific claims or provide special instructions for reprocessing all of the

removable endoscope components and accessories that are integral to the

safe and effective operation of flexible endoscopes. Therefore, should the

AER manufacturer's instructions not specically address reprocessing of any

particular endoscope component (suction valve, inlet seal, etc.) reprocess

those components manually as described in this manual. Prior to use, check

with the AER manufacturer regarding their specific claims with respect to

reprocessing individual endoscope components.

– 39 –

Page 45

1-3-1. Cleaning

WARNING

• During the reprocessing process, always wear protective equipment

(e.g., gloves, gowns, face masks, etc.) to minimize the risk of cross

contamination.

• Endoscope components and accessories should be thoroughly and

carefully cleaned with detergent solution within one hour after the

conclusion of an endoscopic procedure. If they are left uncleaned for

greater than one hour after use, dried blood, mucus or other patient

debris may cause damage to them or interfere with the ability of the

user to properly reprocess them.

• For cleaning, use only legally marketed detergents which have been

tested and found to be compatible by PENTAX. A list of detergents that

are compatible with PENTAX components and accessories is contained in

this manual.

• Fresh detergent solution must be used for each set of endoscope

components and accessories.

1-3-1-1. Items required

• Protective equipment such as gloves, gowns, face masks, etc., to minimize the

risk of cross contamination.

1

• Detergent solution, Endozime (Ruhof Corporation)

• Clean potable water

• Basin (at least 25 cm in width x 20 cm in depth x 15 cm in height )

• Lint-free gauze

• 10 mL luer slip syringe

• Ultrasonic cleaner (frequency range: 44 kHz +/-6%)

1-3-1-2. Cleaning procedure

Preparation

1) Wear personal protective equipment.

2) Prepare a basin with detergent solution per manufacturer’s instructions (temperature,

concentration). In the case of ENDOZIME, add 30 mL of ENDOZIME concentrate

to 3.8 L (1 gallon) of clean potable water at 20°C~30°C (68°F~86°F).

3) Fully immerse the components and accessories, and keep them immersed in

detergent solution during the following cleaning procedure.

Accessory

Cleaning

– 40 –

Page 46

4) Open the cap of inlet seal (OF-B190) during cleaning.

1

Figure 1.31

Cleaning of all external surfaces

5) Wash all surfaces of components and accessories three times with a lint-free gauze.

Cleaning of brushes

6) Wash the brush heads of cleaning brushes (CS6002SN, CS6015ST, CS3010S, CS-

C3S) by rubbing them with gloved ngers for 30 seconds.

Manipulating of valve mechanisms

7) While fully immersed, manipulate the suction control valve (OF-B179) mechanism

four times.

Accessory

Cleaning

Figure 1.32

Filling of lumens with detergent solution

8) Using a syringe lled with detergent solution, inject 4 mL of the detergent solution

directly into the lumen of the suction control valve (OF-B179).

Figure 1.33

Soaking in detergent solution

9) While fully immersed, ensure there are no air bubbles on the surfaces of components

and accessories. If any bubbles are detected, ush them away with detergent solution

using a syringe.

10) Soak components and accessories in detergent solution according to the instructions

(temperature, concentration, time) specified by the detergent manufacturer. In the

case of Endozime, the immersion time is at 3 minutes

11) Remove the components and accessories from the detergent solution.

– 41 –

Page 47

1-3-1-3. Ultrasonic Cleaning

WARNING

All components and accessories must be ultrasonically cleaned prior to highlevel disinfection or sterilization.

CAUTION

DO NOT use caustic or abrasive solutions in the ultrasonic cleaner.

1) Prepare detergent solution per the manufacturer’s instructions (temperature,

concentration). In the case of ENDOZIME, add 30 mL of ENDOZIME concentrate

to 3.8 L (1 gallon) of clean potable water at 20°C~30°C (68°F~86°F).

2) Immerse the components and accessories in detergent solution.

3) Using a syringe lled with detergent solution, inject detergent solution directly into

each lumen of the suction control valve (OF-B179).

4) Perform ultrasonic cleaning under the following conditions:

Frequency Range: 44 kHz +/- 6 % Time: 5 minutes

5) After completion of the ultrasonic cleaning process, remove the components and

accessories from the ultrasonic cleaner.

1

1-3-1-4. Rinsing

WARNING

All residual detergent solution must be removed from the components and

accessories. Residual detergent solution may interfere with subsequent

disinfection and sterilization processes.

First rinse

1) Prepare a basin with clean water, and fully immerse the components and accessories.

2) Wipe all exterior surfaces of the components and accessories at least two times with

a lint-free gauze in order to remove residual detergent solution.

3) While still completely immersed in water, agitate them under the water by moving

them from side to side for at least one minute.

4) Manipulate the suction control valve (OF-B179) mechanism at least four times in the

water, and using a syringe lled with water, ush the lumen of the valve with at least

5 mL of water. (see Figure 1.32, p41 and Figure 1.33, p41)

5) Discard the water.

Second rinse

6) Fill a basin with clean water and repeat steps 2-5 to perform a second rinse.

Accessory

Cleaning

– 42 –

Page 48

Third rinse

7) Fill a basin with clean water and repeat steps 2-5 to perform a third rinse.

Forth rinse

1

8) Fill a basin with clean water and repeat steps 2-5 to perform a fourth rinse.

9) Remove all components and accessories from the water.

Purging of water from lumens

10) Using a syringe lled with air, ush the lumen of the suction valve (OF-B179) to

purge residual water. (see Figure 1.33, p41)

1-3-1-5. Drying

1) Wipe all surfaces of components and accessories gently with a lint-free gauze.

Accessory

Cleaning

– 43 –

Page 49

1-3-2. High-Level Disinfection

WARNING

• During the reprocessing process, always wear protective equipment

(e.g., gloves, gowns, face masks, etc.) to minimize the risk of cross

contamination.

• Prior to disinfection, all components and accessories must be

meticulously cleaned. Failure to do so can result in incomplete or

ineffective disinfection.

• For high-level disinfection, use disinfecting solution according

to instructions of the disinfectant manufacturer (temperature,

concentration, time). Use only legally marketed disinfecting solutions

that have been tested and found to be compatible by PENTAX. A list of

disinfectant solutions that are compatible with PENTAX components and

accessories is contained in this manual.

• Adhere to the instructions specified by the disinfectant manufacturer

to accomplish effective and complete disinfection. Failure to do so may

result in damage to the endoscope components and accessories.

• Ideally, all nal rinses should be performed with sterile water. However,

if sterile water is not used, use clean potable water that meets the

requirements of the health care facility.

• Regardless of the quality of the rinse water used, it is essential

to perform a final alcohol rinse followed by forced air in order to

completely dry the lumens of components and accessories and prevent

bacteria colonization and/or infections associated with waterborne

microorganisms.

• The basin that is used to perform disinfectant immersion must be

thoroughly cleaned prior to lling it with disinfectant solution.

• Verification that the potency of the liquid chemical germicide is at or

above its Minimum Effective Concentration (MEC) (using recommended

test strips or similar methods) is required to ensure that high-level

disinfection/sterilization can be achieved.

1

1-3-2-1. Items required

• Protective equipment such as gloves, gowns, face masks, etc., to minimize the

risk of cross contamination.

• Disinfecting solution, Cidex Activated Dialdehyde Solution (Johnson &

Johnson)

• Sterile water (preferred) or clean potable water

• 70-90% medical grade ethyl or isopropyl alcohol

• Basin (at least 25 cm in width x 20 cm in depth x 15 cm in height )

• Sterile gauze

• 10 mL luer slip syringe

Accessory

Disinfection

– 44 –

Page 50

1-3-2-2. Disinfection procedure

Preparation

1) Wear personal protective equipment.

1

2) Prepare a basin of disinfecting solution per manufacturer’s instructions (temperature,

concentration).

3) Fully immerse the components and accessories, and keep them immersed in

disinfecting solution during the following disinfection procedure.

4) Open the cap of inlet seal (OF-B190) and fully immerse it in disinfecting solution.

(see Figure 1.31, p41)

Manipulating the valve mechanism

5) While fully immersed, manipulate the suction control valve (OF-B179) mechanism

four times. (see Figure 1.32, p41)

Filling of disinfecting solution into the lumens

6) Using a syringe filled with disinfecting solution, inject at least 4 mL of the

disinfecting solution directly into the lumen of suction control valve (OF-B179). (see

Figure 1.33, p41)

Soaking in disinfecting solution

7) While fully immersed, ensure there are no air bubbles on the surfaces of components

and accessories. If any air bubbles are detected, ush them away with disinfecting

solution using a syringe.

8) Soak them in disinfecting solution according to the in stru c t ion s ( t e m per a t ure ,