Page 1

®

EQ Series

High Performance Commercial Pump

For commercial and high-end residential

swimming pools and other water

applications. Available in flows to

800 GPM , and from 3 to 15 HP.

®

EQ Series

maximum efficiency and quiet operation in every

detail. They are the only non-corrosive, all

plastic pumps designed exclusively for the

commercial pool and water applications market.

EQ Series Impellers are manufactured for true

breakthrough performance, allowing for lower

loads and longer motor life. Available with and

without strainer pot.

commercial pumps are designed for

Standard Features

• Close coupled for quiet, stable flow operation.

• Lightweight for easy, one-man installation.

• Cam and Ramp™ locking ring design with clear lid

for added service convenience.

• 6" suction and 4" discharge with strainer pot.

• Closed impeller for long life and durability.

• Available in single- and three-phase models.

• Self-priming under NSF standards; NSF listed.

Page 2

EQ Series

®

High Performance Commercial Pump

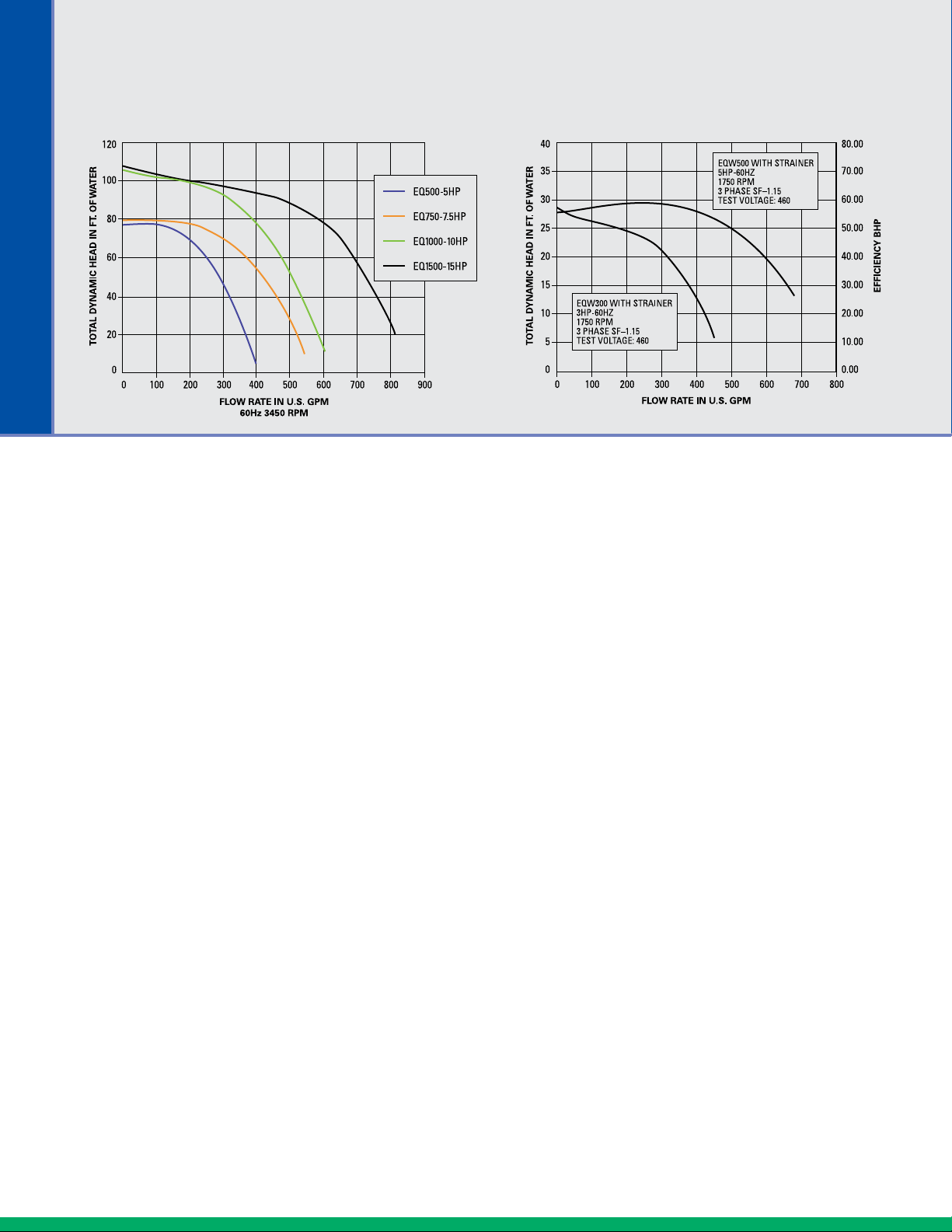

Performance curves

EQ Series

®

MATERIALS AND DESIGN

Pump Body

Performance curve

EQ Series

For detailed efficiency curves for each model, please contact the factory.

®

Waterfall™ Pump

Pump Maximum Limits

Volute type, back pull-out design.

• Port Size

6" – ANSI 150 bolted flange suction port.

4"– ANSI 150 bolted flange discharge port.

• Material - Volute & Motor Adapter

Noryl®.

• Impeller

®

enclosed design.

Noryl

• Base

6061 Aluminum design, slotted for mounting ease.

• Corrosion Prevention

All-plastic pump for maximum hydraulic performance

and corrosion prevention.

1

1

Hair and Lint Strainer

• Material

Separate bolt-on Noryl® body with plastic

basket, Lexan® lid, and stainless steel bolts.

• Size

6" ANSI 150 bolted flange suction and

discharge ports.

Liquid Temperature: 104º F

Ambient Air Temperature: 104º F

Motor

Standard JM type.

• Frame Size

NEMA “C” flange. 230/460V are open

drip-proof design.

• Shaft

303 Stainless steel construction.

• Design

3 to 15 HP, 3500 RPM, JM open drip-proof, continuous

duty, three-phase and single-phase (5 and 7½ HP only).

• Bearings

Double shielded, single row, deep groove type,

permanently lubricated.

• Thermal Overload Protection

All models require external thermal overload protector.

Electrical

• Power Supply Required

Three-phase pumps are 208 – 230/460. 3, 5 and 7½ HP

single-phase models are available in 230V, 60 Hz. only.

1

Use ANSI class 150 plastic flange and 1⁄8" thick class 150 full flange

gasket to make connection.

Page 3

EQ Commercial Pump With Strainer Pot 6" x 4" EQ Commercial Pump Without Strainer Pot

FASTENERS AND 0-RING ARE INCLUDED

2

WITH PENTAIR POOL PRODUCTS EQ

6X6 STRAINER TO CONNECT STRAINER

DIRECTLY TO EQ SERIES PUMP. IF PUMP

IS TO BE INSTALLED WITHOUT

STRAINER MAKE BOTH CONNECTIONS

PER NOTE 1.

USE ANSI CLASS 150 PLASTIC FLANGE

1

AND 1/8" THICK CLASS 150 FULL FLANGE

GASKET TO MAKE CONNECTION.

FASTENERS AND 0-RING ARE INCLUDED WITH PENTAIR POOL

2

PRODUCTS EQ 6X6 STRAINER TO CONNECT STRAINER DIRECTLY

TO EQ SERIES PUMP. IF PUMP IS TO BE INSTALLED WITHOUT

STRAINER MAKE BOTH CONNECTIONS PER NOTE 1.

USE ANSI CLASS 150 PLASTIC FLANGE AND 1/8" THICK CLASS

1

150 FULL FLANGE GASKET TO MAKE CONNECTION.

THIS DIAMETER FITS INSIDE 6" SCH 40 PIPE. DO NOT USE

3

SCH 80 PIPE AS FINAL PIPE SIZE WHEN MAKING THIS

FLANGE CONNECTION.

EQ Commercial Pump With Strainer Pot 6" x 4"

Part # Description Voltage Amps Phase HP Wt Dim. A Dim. B Dim. C Dim. D

340026 EQW 300 Waterfall 115/230 38/19 1 3 97 26.62 10.03 7.5 43.590

340027 EQWK 300 Waterfall 208

340028 EQW 500 Waterfall 230 23.4 1 5 126 26.62 13.18 9.7 43.590

340029 EQWK 500 Waterfall 208

340030 EQ500 230 19.6 1 5 97 26.62 10.03 7.5 43.590

340031 EQK500 208

340032 EQ750 230 30.4 1 7.5 132 27.53 10.78 8.5 44.590

340033 EQK750 208

340034 EQK1000 208

340035 EQK1500 208

– 230/460 8.4 – 7.9/3.9 3 3 77 23.12 10.16 7.5 40.094

– 230/460 13.6 – 12.7/6.4 3 5 106 23.12 13.31 9.7 40.094

– 230/460 13.5 – 12.3/6.2 3 5 77 23.12 10.16 7.5 40.094

– 230/460 20.1 – 18.3/9.1 3 7.5 87 24.50 10.16 7.5 41.560

– 230/460 27.1 – 24.3/12.2 3 10 117 26.31 10.78 8.5 43.290

– 230/460 40.0 – 36.0/17.8 3 15 132 26.31 10.78 8.5 43.290

340013 Strainer Pot Assembly including Strainer, Lid, Basket, and Hardware

EQ Commercial Pump Without Strainer Pot 6" x 4"

Part # Description Voltage Amps Phase HP Wt

340014 EQW 300 Waterfall 115/230 38/19 1 3 97

340016 EQWK 300 Waterfall 208

340017 EQW 500 Waterfall 230 23.4 1 5 97

340018 EQWK 500 Waterfall 208

340019 EQ500 230 19.6 1 5 97

340020 EQK500 208

340021 EQ750 230 30.4 1 7.5 132

340022 EQK750 208

340023 EQK1000 208

340024 EQK1500 208

– 230/460 8.4 – 7.9/3.9 3 3 77

– 230/460 13.6 – 12.7/6.4 3 5 77

– 230/460 13.5 – 12.3/6.2 3 5 77

– 230/460 20.1 – 18.3/9.1 3 7.5 87

– 230/460 27.1 – 24.3/12.2 3 10 117

– 230/460 40.0 – 36.0/17.8 3 15 132

Page 4

EQ Series® Pumps

High Performance Commercial Pumps

ENGINEERING SPECIFICATIONS

EQ Series® Pump

• Recirculation pump shall be Pentair EQ Series Model No.______

___self-priming centrifugal pump,____ phase, 60 Hz.

General Notes

• Install pump in a cool, dry, well vented location away from pool

heaters, and chemical storage.

• Pump should be firmly mounted with pipe supported to prevent

vibration and undue operational noise.

• Allow 12" minimum clearance behind motor for servicing.

• Motor overheating may be caused by a voltage drop or

excessive voltage. Be sure that wire size and voltage input is

properly regulated.

Specifications

• The pump motor shall be a ___ HP, ___ phase, 60 Hz, 3450 RPM

for service on a ___ volt electric supply. The pump shall be rated

for ______ GPM at ____ TDH. The pump shall be tested and

certified by a nationally recognized testing laboratory to conform

to National Sanitation Foundation Standard 50.

• The recirculation pump shall be a self-priming, centrifugal

design with a hair and lint strainer as shown in the plans.

• The pump body, seal plate, and attached hair and lint strainer

shall be constructed of non-corrosive Noryl

close-coupled to an electric motor by means of an adaptor of the

same material. The pump body shall have a single suction port

with a 6" ANSI 125 bolt flange to the hair and lint strainer.

A centerline discharge port of 4" ANSI 125 bolt flange and a

winterizing drain port of ¼" NPT shall be a part of the design.

• The pump shall be a back pull-out design to allow servicing

without disturbing piping. The pump shall have a Noryl

to aid in priming and it shall contain a replaceable bronze wear

ring for the impeller. The impeller shall be of the closed type and

Noryl®, non-overloading at any point on the performance curve.

The mechanical shaft seal shall be constructed of ceramic and

carbon seal faces, with stainless steel, brass and Buna N

materials in the spring bellows portion. The impeller shall be

secured to the motor shaft by means of a stainless steel key

and locking screw into the end of the motor shaft. The pump

shall be capable of operating at up to 50 psi, 104° F continuous

water temperature.

®

materials, and

®

diffuser

Hair and Lint Strainer

• The pump strainer shall consist of a Noryl® body, Lexan® cover

with O-ring seal, and Cam and Ramp™ locking ring, and a strainer

basket of mineral reinforced polypropylene material.

• The strainer body shall be 6" ANSI 150 bolt flanged suction and

discharge ports. The strainer body shall have a removable drain

plug for winterizing.

• The strainer basket shall be securely positioned below the suction

inlet of the trap, with access for inspection and cleaning through

a removable trap body lid. The trap body lid shall be secured

by means of a Cam and Ramp™ locking ring. The strainer

basket shall have a perforation which in total open area is 98

square inches.

• The electric motor coupled to the pump shall be of the NEMA

series JM construction with stainless steel shaft inside a

removable shaft sleeve of 300 series stainless steel. The motor

shall be of an open, drip-proof design (unless otherwise

specified) with double shielded, single row, deep groove ball

bearings. Motors shall be continuous duty rated at 40° C

(or better) ambient and be suitable for outdoor installation.

9/08 Part #P1-353

1620 Hawkins Avenue

Sanford, NC 27330

Phone: 800-831-7133 Fax: 800-284-4151

www.pentairpool.com

©2008 Pentair Water Pool and Spa, Inc. All rights reserved.

Loading...

Loading...