Page 1

EQUIPMENT PROTECTION SOLUTIONS 2015-03-23

VARISTAR Cooling unit SHX 30

Instruction Manual

60130-716

- Original instruction manual -

Product number:

62139-097

Page 2

VARISTAR Cooling unit SHX 30

2

Produced by

Pentair Equipment Protection

Schroff GmbH

Langenalber Str. 96 - 100

75334 Straubenhardt, Germany

The details in this manual have been carefully compiled and

checked - supported by certified Quality Management System

to EN ISO 9001/2000

The company cannot accept any liability for errors or misprints.

The company reserves the right to amendments of technical

specifications due to further development and improvement of

products.

Copyright © 2013

All rights and technical modifications reserved

Page 3

VARISTAR Cooling unit SHX 30

3

1 Safety ...............................................................................................................................................................5

1.1 General information regarding safety............................................................................................................... 5

1.2 Warning notices ................................................................................................................................................ 6

1.3 Safety of personnel ........................................................................................................................................... 7

1.4 Intended use ..................................................................................................................................................... 8

1.5 Terms of warranty............................................................................................................................................. 8

1.6 Installation site .................................................................................................................................................. 9

1.7 Safety instructions for transport ....................................................................................................................... 9

1.7.1 General information ..................................................................................................................................... 9

1.8 Safety instructions for set-up .......................................................................................................................... 10

1.9 Safety instructions for maintenance ............................................................................................................... 11

1.10 Disclaimer........................................................................................................................................................ 11

2 Description / Overview ...................................................................................................................................12

2.1 General information........................................................................................................................................ 12

2.2 Variants ........................................................................................................................................................... 12

2.3 Mode of operation .......................................................................................................................................... 13

2.4 Air circuit ......................................................................................................................................................... 14

2.5 Water circuit.................................................................................................................................................... 14

2.6 Control method ............................................................................................................................................... 15

2.7 Alarms ............................................................................................................................................................. 16

2.8 Incorrect use ................................................................................................................................................... 16

3 System Layout ................................................................................................................................................18

3.1 Overview ......................................................................................................................................................... 18

3.2 Connections..................................................................................................................................................... 20

3.3 Electrical box ................................................................................................................................................... 22

3.4 Schematic system diagram.............................................................................................................................. 23

3.5 Function overview........................................................................................................................................... 24

3.6 Symbols / labels on the unit ............................................................................................................................ 25

4 Components ...................................................................................................................................................26

4.1 Control valve ................................................................................................................................................... 26

4.2 Control unit ..................................................................................................................................................... 27

4.3 Interface board................................................................................................................................................ 28

4.4 Fuse board....................................................................................................................................................... 30

4.5 Basic electronic system ................................................................................................................................... 31

5 Setting Up .......................................................................................................................................................32

5.1 General information........................................................................................................................................ 32

5.2 Transport and packaging material .................................................................................................................. 34

5.3 Start-up ........................................................................................................................................................... 34

5.4 Installation....................................................................................................................................................... 35

5.5 Connections..................................................................................................................................................... 35

5.6 Electrical connection ....................................................................................................................................... 37

5.7 Antifreeze and anti-corrosion agents.............................................................................................................. 39

5.8 Adjustments .................................................................................................................................................... 40

Page 4

VARISTAR Cooling unit SHX 30

4

5.9 Venting ............................................................................................................................................................ 41

5.10 Removal/installation ....................................................................................................................................... 44

6 Operation .......................................................................................................................................................45

6.1 General information........................................................................................................................................ 45

6.2 Adjustments .................................................................................................................................................... 45

6.3 Switching off the unit ...................................................................................................................................... 46

6.4 Control unit ..................................................................................................................................................... 47

6.4.1 General information ................................................................................................................................... 47

6.4.2 Activating/deactivating functions ............................................................................................................... 48

6.4.3 Selecting and setting values........................................................................................................................ 48

6.4.4 Program overview....................................................................................................................................... 49

6.4.5 Screen contents and descriptions ............................................................................................................... 50

7 Maintenance...................................................................................................................................................51

7.1 General information........................................................................................................................................ 51

7.2 Maintenance plan ........................................................................................................................................... 53

7.3 Replacement ................................................................................................................................................... 54

7.3.1 Fans............................................................................................................................................................. 54

7.3.2 Actuator of the control valve ...................................................................................................................... 55

7.3.3 Temperature sensor.................................................................................................................................... 60

7.3.4 Replacement of other components ............................................................................................................ 60

7.4 Antifreeze and anti-corrosion agents.............................................................................................................. 61

7.5 Cooling module ............................................................................................................................................... 62

7.5.1 Rinsing process ........................................................................................................................................... 62

8 Troubleshooting .............................................................................................................................................64

8.1 General information........................................................................................................................................ 64

8.2 Electrical connection ....................................................................................................................................... 65

8.3 Unit-specific .................................................................................................................................................... 65

8.4 Control unit ..................................................................................................................................................... 66

9 Disconnecting the device ................................................................................................................................68

9.1 General information........................................................................................................................................ 68

9.2 Dismantling ..................................................................................................................................................... 68

9.3 Transport and storage..................................................................................................................................... 69

9.4 Recycling.......................................................................................................................................................... 70

10 Technical Data ................................................................................................................................................71

11 Spare Parts .....................................................................................................................................................74

Page 5

VARISTAR Cooling unit SHX 30

Safety 5

Pos:1/Überschriften/1 /Sicherheit @1\mod4_18.docx @ 273 95 @ 1 @ 1

1 Safety

Pos:2.1/Überschriften /1.1/Allge meines zur Sic herheit @ 15\m od_110259039 1724_18.d ocx @ 123085 @2@ 1

1.1 General information regarding safety

Pos:2.2/Sicherheit/Al lgemeines/Stan dard - nur Te xt @ 166\m od_1381297657 816_18.d ocx @ 1659344 @@ 1

Personnel in charge of carrying out work on the unit or system must have read and

understood this manual and in particular the section on safety.

If necessary, in-house instruction should be provided, taking into account the technical

qualifications of the personnel concerned.

Certain components have additional warning plates or labels to enable safer operation.

Plates or labels must not be covered or removed.

Observe all safety instructions. Observation of these instructions is in the interest of

personal safety.

The relevant accident prevention regulations as well as other generally recognised

regulations concerning workplace health and safety must be observed.

Pos:2.3/Sicherheit/Al lgemeines/I nfos zur Aufbew ahrung der Dok u @ 201 \mod_1402910704 999_18.do cx @ 1984090 @@ 1

The manual must be stored so that it is easily available at any time. It must be complete,

kept close to the machine and must be available to all authorized persons.

Pos:2.4/-- leer --/=== ===== @ 1\ mod26_18.do cx @ 27188 @ @1

Page 6

VARISTAR Cooling unit SHX 30

Safety 6

Pos:2.5/Überschriften /1.1/Warnhi nweise @ 159\ mod_1375190 689535_18. docx @ 1617 560 @ 2 @ 1

1.2 Warning notices

Pos:2.6/Sicherheit/Al lgemeines/Dar stellung ANSI -Warnhinweise @166\mod_138129 7890394_18.do cx @ 1659377 @@ 1

Explanation of warning notices used in this manual:

DANGER

Short description of danger

The signal word DANGER identified an immediately threatening danger.

Any non-adherence will result in most serious injuries or death.

WARNING

Short description of danger

The signal word WARNING identified a potential danger.

Any non-adherence may result in most serious injuries or death.

CAUTION

Short description of danger

The signal word CAUTION identified a potential danger.

The non-adherence may result in minor to medium injuries.

Notice

Short description

The signal word Attention identifies a potential risk of property damages.

The non-adherence may cause damages at the unit or at the plant.

Note

The signal word Note identifies further information on the unit or about its use.

Pos:3/-- leer --/===== === @ 1\m od26_18.docx @ 27188@ @1

Page 7

VARISTAR Cooling unit SHX 30

Safety 7

Pos:4.1/Überschriften /1.1/Sicherh eitshinweise fürdasBe dienpersonal @15\mod_1102592264 898_18.doc x @ 123478 @ 2@1

1.3 Safety of personnel

Pos:4.2/Sicherheit/B edienpersonal/Ter motek - inkl. Beispielfür Sicherheit seinrichtung @165\mod_138114077 0414_18.d ocx @ 16573 43 @ @1

Avoid any working practice that:

• endangers the health and safety of the user or third parties,

• presents a danger to the unit or system or other property,

• impairs the safety or functionality of the unit or system,

• does not comply with the safety instructions.

Maintenance and service should be performed only by suitably qualified persons who are

familiar with the unit and who have been informed concerning the potential hazards.

WARNING

Danger for persons!

There is an increased risk of injury if the safety devices (e.g. fuses) are rendered

inoperative. Do not remove or deactivate any safety devices.

• Check the safety devices daily for correct operation.

• Malfunctions and defects concerning the safety devices must be reported

immediately to the after-sales service.

• The housing must be closed during the operation and may be opened only to

rectify malfunctions or to perform maintenance tasks.

• Repairs to pipe systems and tanks may only be carried out when the system is

depressurised.

• When handling chemicals, observe the applicable safety data sheets and disposal

instructions that are provided by the suppliers, as well as any relevant local safety

regulations. Wear protective clothing!

Any safety devices that have been removed for set-up, maintenance, or repair purposes

must be reinstalled and checked for correct operation immediately upon the completion

of the maintenance and repair work.

In the above case, particular attention must be paid to the general accident prevention

and safety regulations.

Pos:5/-- leer --/===== === @ 1\m od26_18.docx @ 27188@ @1

Page 8

VARISTAR Cooling unit SHX 30

Safety 8

Pos:6.1/Überschriften /1.1/Besti mmungsgemäße Ver wendung @15\mod_1102594725 256_18.d ocx @ 123524 @2@ 1

1.4 Intended use

Pos:6.2/Sicherheit/B estim. Verwen dung/Standard @15\mod_1102586 516803_18.do cx @ 123039 @ @1

The unit or the system is intended solely for the application outlined in the

“Description/Overview” section and only with the components supplied and approved.

Using the unit for purposes other than those mentioned above is considered contrary to

the intended use. The manufacturer cannot be held liable for any damage resulting from

such use. The risk of such misuse lies entirely with the user.

Pos:7/Überschriften/1 .1/Gewährlei stungsbesti mmungen @ 15 \mod_110258 7459161_1 8.docx @ 123 231 @ 2 @ 1

1.5 Terms of warranty

Pos:8/Sicherheit/Gewä hrleistungSt andard @ 166 \mod_13812 98980681_ 18.docx @ 165951 4 @ @1

The manufacturer is not liable for damage resulting from improper use, the failure to

observe this manual, the employment of insufficiently qualified personnel, or

unauthorised modifications. In these cases the manufacturer’s warranty is rendered void.

Notice

Unit function is affected when using incorrect spare parts!

When using components which have not been approved, correct operation can no longer

be guaranteed. Only use spare parts approved by the after-sales service.

Pos:9/Sicherheit/Gewä hrleistung/Vorsi chthinwei s -V erwe ndung von unter schiedlichen M edien - ne utral, ohne Beis piele @ 242\m od_142295884 3671_18.d ocx @ 223548 6 @ @1

Notice

Caution - Loss of warranty!

The use of media that are not approved may result in damage to the unit or to the

system. The warranty will be rendered void. The same shall apply if different media are

mixed.

Use only media that have been approved by the manufacturer.

Pos:10/Sicherheit/Gewä hrleistungHi nweis Typen schild @ 1 66\mod_13812986 75590_18. docx @ 16594 79 @ @1

Note

Removing type plates will make the warranty claim expire.

Pos:11/Sicherheit/Gewä hrleistungHi nweis - eige nmächtige Zerst örung, Verl ust Gewährl eitungsanspru ch @ 166\m od_1381298546 638_18.doc x @ 1659445 @@ 1

Note

The warranty will be rendered void if seals are broken without authorisation.

Pos:12/-- leer --/=== ===== @ 1\m od26_18.do cx @ 27188 @ @1

Page 9

VARISTAR Cooling unit SHX 30

Safety 9

Pos:13/Überschriften/ 1.1/Standort wahl @ 15\m od_110259117 9197_18.d ocx @ 123412 @2@ 1

1.6 Installation site

Pos:14/Sicherheit/St andort/Term otek - Schrof f-Kühler @ 158\ mod_137361 8767274_18.do cx @ 1605212 @@ 1

When selecting an installation site, observe the following instructions:

• Keep the specified escape routes clear.

• Ensure firm support and a horizontal position of the unit.

• Comply with the data stated in the “Technical Data” section concerning the

ambient temperature for operation, transport, and storage when the unit is

completely empty.

• Ensure sufficient space for operating, maintaining, and cleaning the unit.

• Keep the air inlets and outlets free.

Comply with the relevant technical and building regulations.

Lay the hoses and electrical cables so that there is no danger of tripping and that they are

protected from damage.

When selecting an installation site, the applicable safety regulations and manufacturer

instructions concerning any substances that are used for, or located near, the machine

must be observed.

Pos:15.1/Überschrifte n/1.1/Sicher heitshinweise zu m Transport @15\mod_110623522 9266_18.doc x @ 13328 4 @ 2 @ 1

1.7 Safety instructions for transport

Pos:15.2/Überschrifte n/1.1.1/Allg emein @ 15\m od_1105356965 484_18.d ocx @ 128601 @3@ 1

1.7.1 General information

Pos:15.3/Sicherheit/Tran sport/War nung - Verletzu ngsgefahr dur ch unsa chgemäßen Trans port @ 222\m od_141353945 3644_18.d ocx @ 209963 1 @ @1

WARNING

Danger for persons!

Increased risk of injuries through improper transport.

The transport of the unit should be carried out only by suitably qualified persons who are

familiar with the unit and who have been informed as to potential hazards.

Pos:15.4/Hinweise/Vorsi cht / Ac htung - GerätA chtung - Bes chädigung dur ch unsachge mäßen Transport 4Pkt.@ 16 6\mod_13813 00412030_ 18.docx @ 1 659717 @ @1

Notice

Damaging of unit!

Damage due to improper transport.

• Make sure to follow signs (if attached) at unit when transporting unit.

• Transport units with suitable lifting gear only.

• Transport the unit only when it is empty.

• Transport on suitable and secured transporting pallet.

Pos:16/Hinweise/Warn ung Person enWarnung -Kippgefahr (schmales Gerät ) @ 190\m od_1396607317 081_18.d ocx @ 190473 9 @ @1

WARNING

Danger of overturning!

Due to the slim set-up of the unit, there is a higher risk of injury when the unit tips over.

Ensure that the unit is sufficiently secured during the transport.

Pos:17/-- leer --/=== ===== @ 1\m od26_18.do cx @ 27188 @ @1

Page 10

VARISTAR Cooling unit SHX 30

Safety 10

Pos:18.1/Überschrifte n/1.1/Sicher heitshinweise zur Inbetriebnahme@ 1 5\mod_11062 36513563_ 18.docx @ 1 33452 @ 2 @ 1

1.8 Safety instructions for set-up

Pos:18.2/Sicherheit/I nbetriebnah me/Standard (inkl . Warnung /Achtung/Hi nweis) @ 166\ mod_138130 2032471_18.do cx @ 1660042 @@ 1

WARNING

Danger through faulty commissioning!

There is an increased risk of injury to persons who perform tasks for which they are not

suitably qualified or trained.

• The commissioning of the system shall only be carried out by persons familiar with

the system and instructed with respect to dangers and risks involved, also having

the required qualifications.

• Fulfil all safety-relevant conditions before commissioning.

• The location of the unit or of the system must correspond to the regulations

according to Chapter "Safety, Choice of Location".

Notice

Damage to components!

Danger of damage due to improper operation. Observe the description of additional

components, if included.

Note

Check all hoses and hose connections for leaks when commissioning the unit.

Pos:19/-- leer --/=== ===== @ 1\m od26_18.do cx @ 27188 @ @1

Page 11

VARISTAR Cooling unit SHX 30

Safety 11

Pos:20.1/Überschrifte n/1.1/Sicher heitshinweise zur Wartung@ 15\ mod_110623676 6737_18.doc x@ 1 33521 @ 2 @1

1.9 Safety instructions for maintenance

Pos:20.2/Sicherheit/ Wartung/Standar d @ 166\ mod_138130274 4553_18.d ocx @ 16601 54 @ @1

WARNING

Carry out instructed maintenance works only!

There is an increased risk of injury to persons who perform tasks for which they are not

suitably qualified or trained.

• Maintenance works should be carried out only by suitably qualified personnel who

are familiar with the unit and who have been informed as to potential hazards.

• Repairs to pipe systems and tanks may only be carried out when the system is

depressurised.

WARNING

Connections alive!

Negligence can lead to electric shock.

Observe the following points when carrying out maintenance work on the electrical

system:

1. Disconnect the unit from the power supply in order to deenergise it.

2. Secure the unit so that it cannot be switched on again accidentally.

3. Check whether the unit is properly disconnected from power and absolutely

voltage-free

4. Earth and short-circuit the unit.

5. Cover any adjacent live parts and secure the danger area.

Notice

Damage to electronic components!

Take suitable measures (ESD protection measures) to prevent the electronic components

from being damaged due to electrostatic discharge.

Pos:21/Sicherheit/Haft ungsauss chluss/Fa. Schrof f @ 156\ mod_137208054857 4_18.do cx @ 1587750 @ 2 @1

1.10 Disclaimer

Schroff shall not be held liable for any errors that may be included in this documentation.

Liability for direct and indirect damage that occurs in connection with the supply or use of

this documentation is excluded to the extent permitted by law.

Schroff reserves the right to change this document, including the disclaimer of liability, at

any time and Schroff shall not be liable for the potential consequences of these changes.

Pos:22/-- leer --/=== ===== @ 1\m od26_18.do cx @ 27188 @ @1

Page 12

VARISTAR Cooling unit SHX 30

Description / Overview 12

Pos:23.1/Überschrifte n/1/Beschreib ung/Überbli ck @ 1\mod5_1 8.docx @ 280 16 @ 1 @ 1

2 Description / Overview

Pos:23.2/Beschreib ung/Kühlgerät/Ter motek/G erätespezifis ch/LHX 30 @ 242 \mod_14229 57055816_ 18.docx @ 223502 6 @ 2222222 @1

2.1 General information

The cooling modules that are described in this instruction manual are part of a cooling unit

for the Schroff VARISTAR cabinet platform. In combination with the corresponding

VARISTAR cabinets, the cooling units are used to set up an enclosure.

Note

For the start-up of the cooling system, the cooling module must be connected to an

external re-cooling system (e.g. water chiller).

The unit is suitable for the use of water-glycol mixtures (33% glycol max.).

The power supply is ensured via a power supply unit. The power supply unit transforms

the mains voltage (AC, alternating voltage) into a direct voltage (DC) and it supplies

various components with power, including the control system and fans.

Since the fans are intended for a supply voltage of 48 V (DC), the cooling module can also

be used in telecommunications environments.

Note

See the circuit diagram.

2.2 Variants

The cooling modules are supplied as part of a Schroff VARISTAR cooling unit. The variants

and dimensions of the cooling units are configured based on the customer requirements

and VARISTAR cabinets that are used.

The following variants of the cooling modules are available:

• 60714-067: Cooling module, water connection at the bottom

• 60714-068: Cooling module, water connection at the bottom, redundant power

supply

• 60714-077: Cooling module, water connection at the top

• 60714-078: Cooling module, water connection at the top, redundant power supply

Note

• Cooling modules with a redundant power supply are equipped with two power

supply units and mains power inputs. They can be supplied with power via two

independent mains power sources.

• In the case of cooling modules with a water connection at the top, the condensate

outlet is also located at the top. These cooling modules are equipped with an

integrated condensate pump.

Page 13

VARISTAR Cooling unit SHX 30

Description / Overview 13

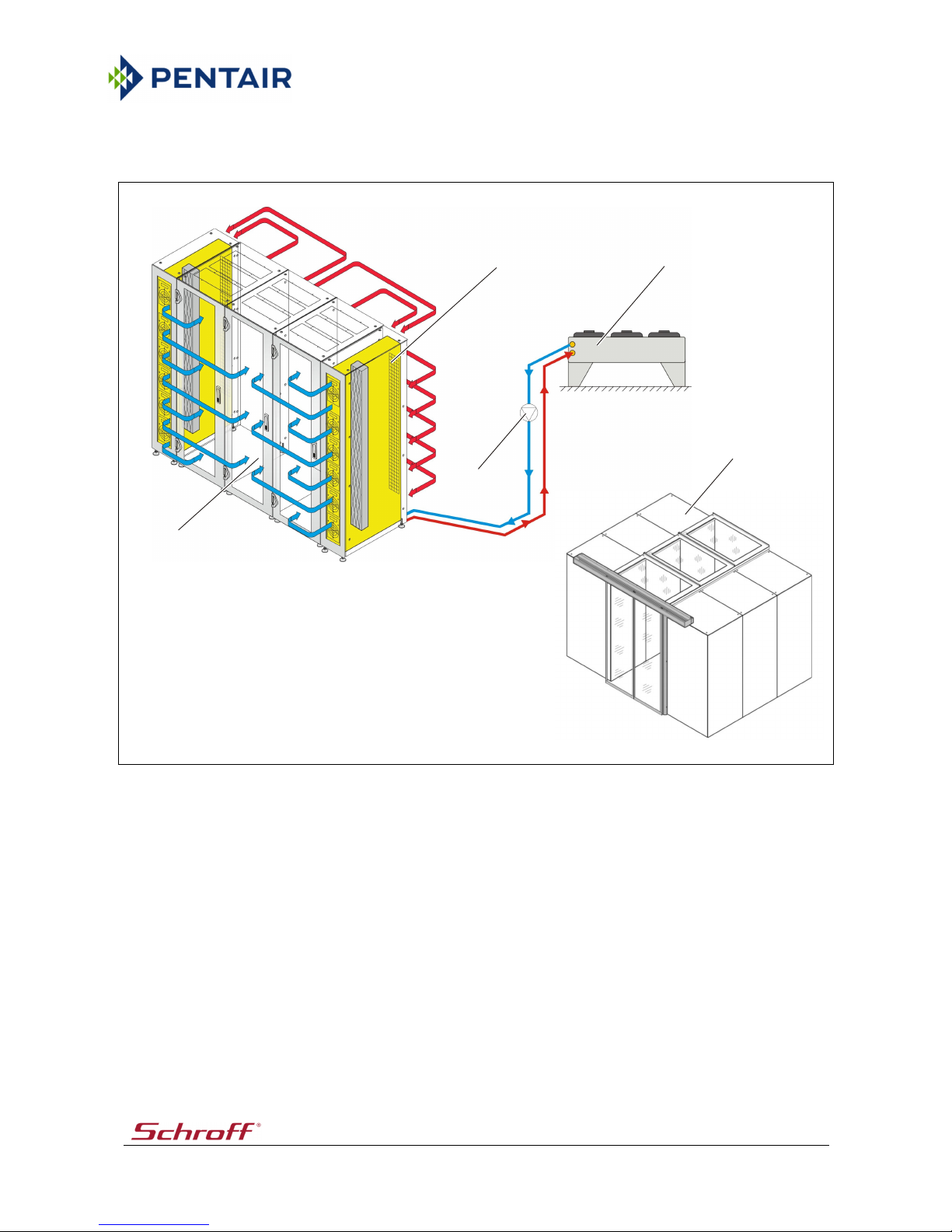

2.3 Mode of operation

Fig. 1: Mode of operation of the cooling module (principle)

1 Cooling module

2 External recooler *)

3 Pump *)

4 Enclosure

*) (not included in the scope of supply)

The cooling units are positioned between the VARISTAR cabinets in an enclosure.

The fans of the cooling unit suck the warm air in at the back and guide it through an

air/water heat exchanger. The air will be cooled and blown out at the front.

The cooling system comprises an air circuit and a water circuit. In the air/water heat

exchanger, the thermal energy of the warm air is transferred to the water.

The air/water heat exchanger is connected to an external recooler (not included in the

scope of supply) that cools the heated water.

12366

1 2

3

4

4

Page 14

VARISTAR Cooling unit SHX 30

Description / Overview 14

2.4 Air circuit

Example "cold aisle containment":

The fans of the cooling unit withdraw the heated air from the room and guide it through

an air/water heat exchanger. During this process, the thermal energy is transferred to the

water circuit. The cool air then fed into the cold aisle. A demister removes any condensate

that may have formed.

The condensate is collected in a condensate tray and discharged via the condensate pipe

at the top or bottom of the cooling module.

The fans that are distributed vertically over the entire cabinet height ensure a

homogeneous temperature stratification. As a result, the temperature difference can be

reduced and the efficiency of the cooling system can be increased.

Components of the air circuit:

• Air/water heat exchanger

• Demister

• Fans

• Temperature sensor (air)

2.5 Water circuit

The chilling medium of the external recooler (not included in the scope of supply) flows

through the air/water heat exchanger of the cooling modules and heats up. Then, it flows

back into the recooler. The temperature is controlled via an electric powered control valve

that controls the chilling medium flow based on the required cooling power.

Components of the water circuit:

• Control valve

• Air/water heat exchanger

• Water temperature sensor

Note

• The control valve in the water circuit of the cooling module is a straight-way valve

(2-way valve). The advantage of this solution is that only the quantity of water that

is required for cooling flows through the air/water heat exchanger. The circulation

pump can be operated with constant pressure and a variable quantity of water.

• For cooling systems that required three-way functionality, the cooling module can

also be supplied with a 3-way valve upon request.

Page 15

VARISTAR Cooling unit SHX 30

Description / Overview 15

2.6 Control method

The fans and the control valve of the water circuit are actuated by a closed loop and open

loop control unit. A closed loop control circuit controls the flow of water through the

air/water heat exchanger as a function of the air outlet temperature of the cooling

module.

The cooling module has four temperature sensors; two in the air outlet at the top and at

the bottom as well as two temperature sensors in the air inlet at the top and at the

bottom. In addition, an external temperature sensor (option) can be connected. The

output signal of these sensors is used as the reference value for the control system. The

reference sensor can be selected in the settings menu.

In order to compensate for temperature stratifications, the air outlet temperature is

measured by two temperature sensor on different levels. The average value of these

temperature sensors is the control variable for the opening characteristics of the control

valve.

Under normal operating conditions, the fans run at constant speed.

In order to ensure sufficient air circulation in the cabinet, the factory setting is 80% of the

nominal speed. The operator can set this value within a range of 30% to 100% via the

settings menu.

If the set temperature is exceeded by 4°C (factory setting), the system will switch to

maximum cooling power, i.e. the control valve will open by 100% and the fan speed will be

increased to 100% of the nominal speed.

If the actual value falls below the set temperature by 3°C, the normal mode will be

resumed.

Note

The control characteristic is defined at the factory. However, it can be changed and

adapted by the service department of Schroff or by a licensed service partner.

Page 16

VARISTAR Cooling unit SHX 30

Description / Overview 16

2.7 Alarms

The electronic control system can detect various malfunctions (e.g. cable break of a

temperature sensor, temperatures exceeding the limit values) and indicate them via the

display or interface.

In order to issue a visual alarm, there is an LED (red) above the control unit on the cooling

module.

The following error messages will be signalled:

• The actual fan speed is below the minimum speed.

• Failure of a fan.

• Cable break of a temperature sensor.

• Supply voltage of the electronic control system: undervoltage.

• Faulty Modbus communication.

• Failure of power supply unit 1 or 2.

• The actual cooling water temperature is above the limit value.

• Malfunction of the condensate pump (option).

• Door opened (option)

Note

In the event of a malfunction, refer to the "Troubleshooting" section.

Pos:23.3.1/Überschri ften/1.1/Ni cht bestim mungsgemäße Ver wendung @ 1 29\mod_133 7086719004_18. docx @ 1332 999 @ 2 @ 1

2.8 Incorrect use

Pos:23.3.2/Beschreib ung/Besti mmungswidrig e Verwendung /01-!! Grundsätzliches@ 129\m od_1337086111 550_18.d ocx @ 1332898 @@ 1

In general:

any incorrect use is classed as 'not for the intended purpose'. The manufacturer cannot be

held liable for any damage resulting from such use. The risk of such misuse lies entirely

with the user. Moreover, intended use of the unit also involves use in accordance with the

applicable international and national safety instructions as well as the safety instructions

in the manual.

Pos:23.4/Beschreib ung/Bestimmu ngswidrige Ver wendung /02 -DasGerä t ist unter and erem für folg ende Verw endungen NICH T vorgesehen: @ 129\mod_1337086308723_18.do cx @ 1332932 @ @1

Amongst others, the unit is NOT intended for the following applications:

Pos:23.5/Beschreib ung/Bestimmu ngswidrige Ver wendung /Betr ieb im Fr eien @ 154\ mod_13693179 83819_18.docx @ 1571962@ @1

• Outdoor use.

Pos:23.6/Beschreib ung/Bestimmu ngswidrige Ver wendung Betriebbeiei nem Überschreit en der zulä ssigen te chnischen Daten. Sieh e Kapitel "Te chnische Dat en". @ 18 8\mod_13951 27649326_18.d ocx @ 188429 3 @ @1

• Non-compliance with the permissible technical data. See the "Technical data"

section.

Pos:24/-- leer --/=== ===== @ 1\m od26_18.do cx @ 27188 @ @1

Page 17

VARISTAR Cooling unit SHX 30

Description / Overview 17

Pos:25/-- leer --/Sym bol -Weiterblät tern- @ 15\ mod_110303 6522860_18.do cx @ 125116 @ @1

Pos:26/-- leer --/=== ===== @ 1\m od26_18.do cx @ 27188 @ @1

Page 18

VARISTAR Cooling unit SHX 30

System Layout 18

Pos:27.1/Überschrifte n/1/Gerätea ufbau @ 1\m od6_18.docx @ 28614@ 1 @ 1

3 System Layout

Pos:27.2/Überschrifte n/1.1/Darstel lung @ 14\ mod5193_18. docx @ 28729 @2@ 1

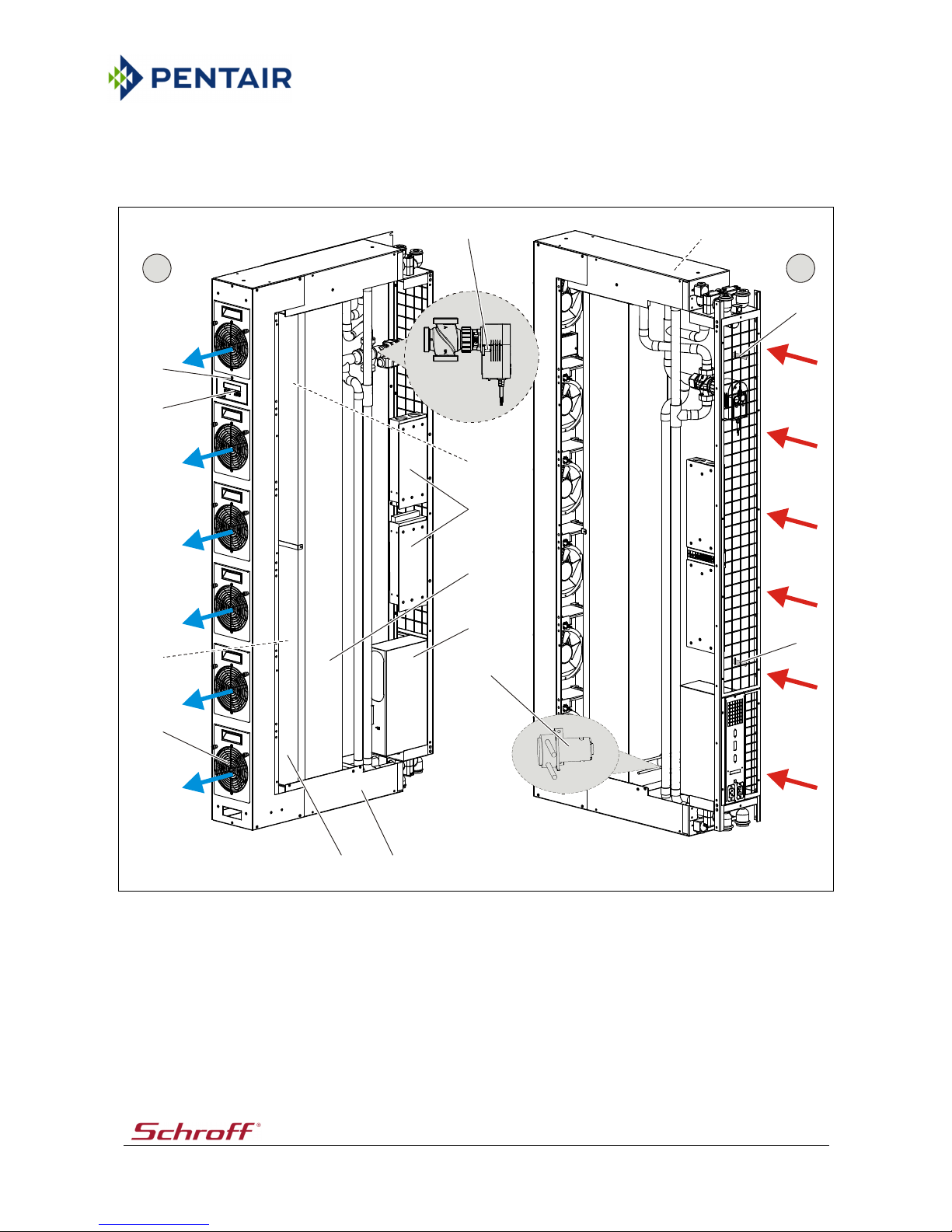

3.1 Overview

Pos:27.3/Gerateaufba u/Termotek/ Kühler SHX 30/DarstellungIM/SM @ 2 43\mod_142 296224166 4_18.docx @ 2236 200 @ @1

Fig. 2: Heat exchanger

12299-01

4

2

9

A

B

3

6

5

7

8

10

1

R2

R3

R5

R4

R1

Page 19

VARISTAR Cooling unit SHX 30

System Layout 19

1 Control valve with actuator

2 Power supply unit

3 Heat exchanger (air/water)

4 Switch box

5 Condensate pump with float switch (option)

6 Condensate tray

7 Demister

8 Fan

9 Control unit (display and operating unit)

10 LED (red)

- flashing: malfunction *)

Views

A Front view

B Back view

Temperature sensor

R1 Chilling medium inlet

R2 Air inlet (top)

R3 Air inlet (bottom)

R4 Air outlet (top)

R5 Air outlet (bottom)

Note

*) In the event of a malfunction, refer to the "Troubleshooting" section.

Pos:27.4/-- leer --/= ======= @ 1\ mod26_18.do cx @ 27188 @ @1

Page 20

VARISTAR Cooling unit SHX 30

System Layout 20

Pos:27.5/Überschrifte n/1.1/Ans chlüsse @ 15\m od_110378697 9042_18.d ocx @ 126968 @2@ 1

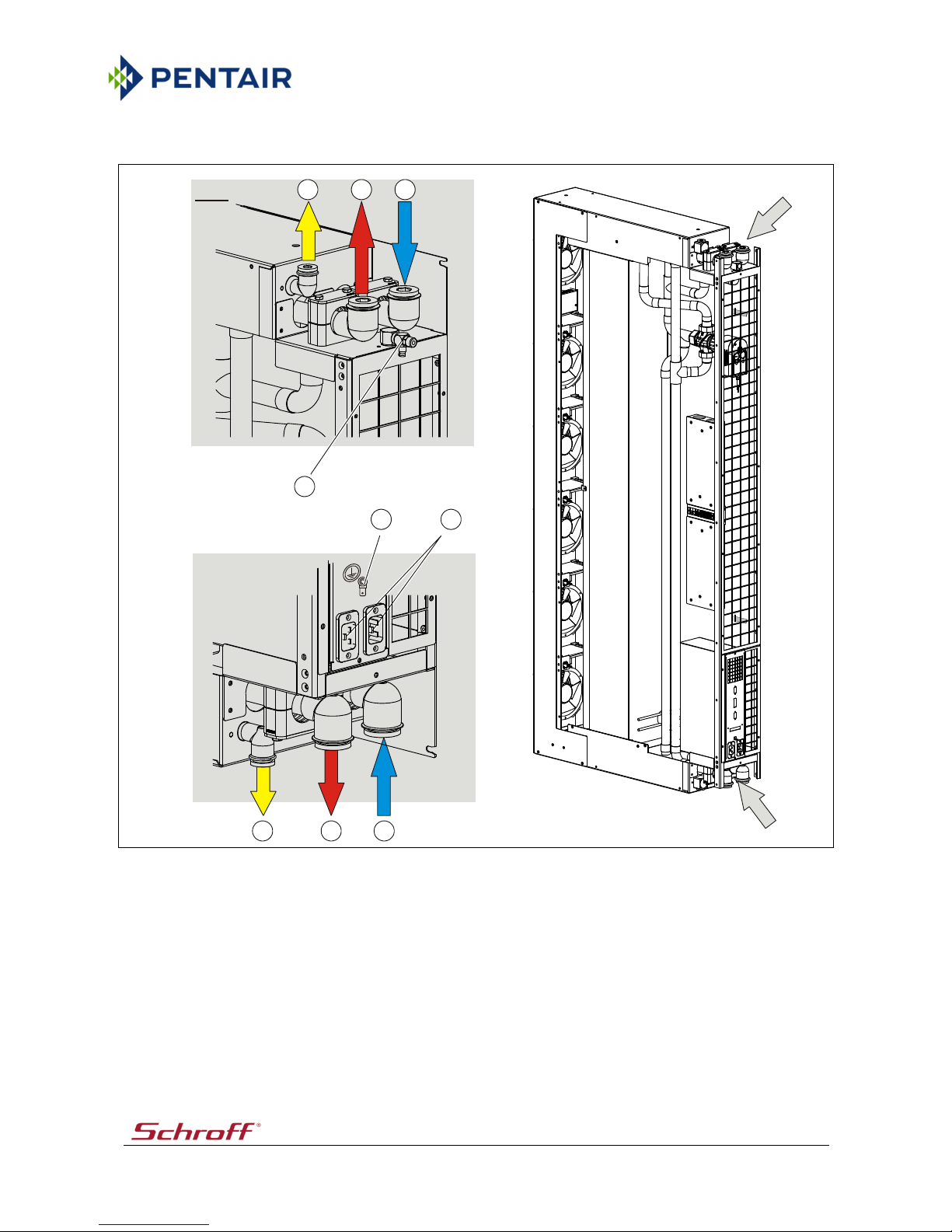

3.2 Connections

Pos:27.6/Gerateaufba u/Termotek/ Kühler SHX 30/Anschlüsse@ 243\m od_14229624388 46_18.do cx @ 2236274 @@ 1

Fig. 3: Connections

12299-01

Y

X

1 2 3

6

“X“

1 2 3

4

5

Page 21

VARISTAR Cooling unit SHX 30

System Layout 21

1 Condensate outlet

2 Chilling medium outlet

3 Chilling medium inlet

4 Venting point

5 Protective earth

6 Power supply connector (redundant power

supply)

X Connectors (top)

Y Connectors (bottom)

Note

• The chilling medium connectors are located at the top and bottom of the unit

(back). Connectors that are not required must be sealed with a blind plug.

• In the case of cooling modules with a water connection at the top, the condensate

outlet is also located at the top. These cooling modules are equipped with an

integrated condensate pump.

• Connect the condensate outlet with a sufficient gradient to the wastewater

system.

• Cooling modules with a redundant power supply are equipped with two power

supply units and mains power inputs. They can be supplied with power via two

independent mains power sources.

Pos:27.7/-- leer --/= ======= @ 1\ mod26_18.do cx @ 27188 @ @1

Page 22

VARISTAR Cooling unit SHX 30

System Layout 22

Pos:27.8/Überschrifte n/1.1/Schaltka sten @ 156\ mod_137223 0752978_1 8.docx @ 1589287 @2@ 1

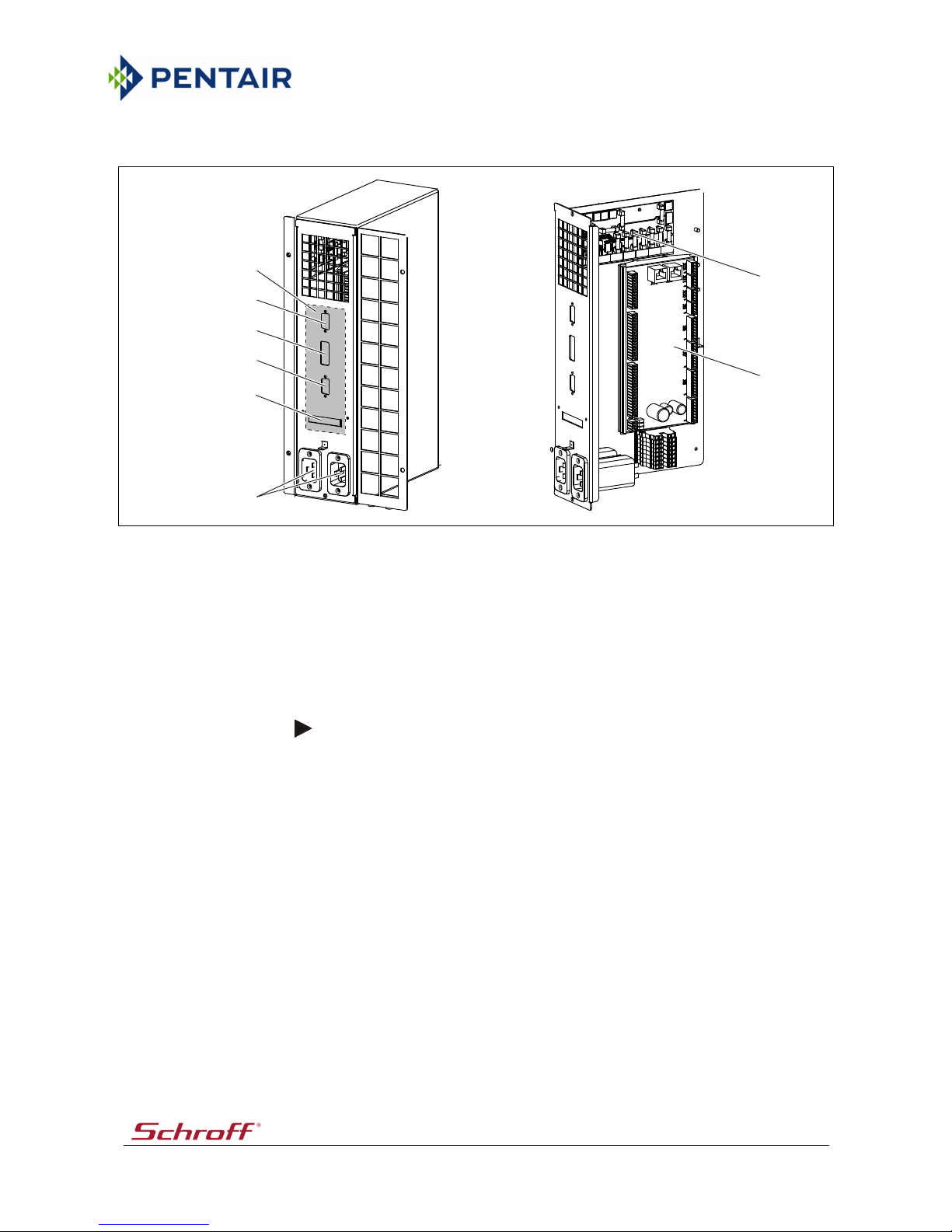

3.3 Electrical box

Pos:27.9/Gerateaufba u/Termotek/ Kühler SHX 30/Schaltkasten@ 242\ mod_14229563 80558_18.d ocx @ 22348 54 @ @1

Fig. 4: Electrical box

1 Fuse board (circuit board with miniature fuses)

2 Basic electronic system, type TIOM 112 (I/O unit)

3 Power supply connector (optionally with a

second power supply unit)

4 Interlock-interface (DI/DO, 10 pin)

5 Data interface (RS232, SUB-D, 6 pin)

6 Data interface (RS485, 2x RJ45)

7 Connector for connecting the external

temperature sensor

8 Interface board

Pos:27.10/Hinweise/All gemeinHi nweis - Stro mlaufplan beac hten @ 174\ mod_13855439 96932_18.doc x@ 1767106@ @1

Note

Follow the instructions given in the circuit diagram.

Pos:27.11/-- leer --/== ====== @ 1\ mod26_18.d ocx @ 27188 @@ 1

12300-01

3

5

6

7

1

2

8

4

Page 23

VARISTAR Cooling unit SHX 30

System Layout 23

Pos:27.12/Überschrifte n/1.1/Syst emschema @14\mod5130_18.docx @ 2 8752 @ 2 @ 1

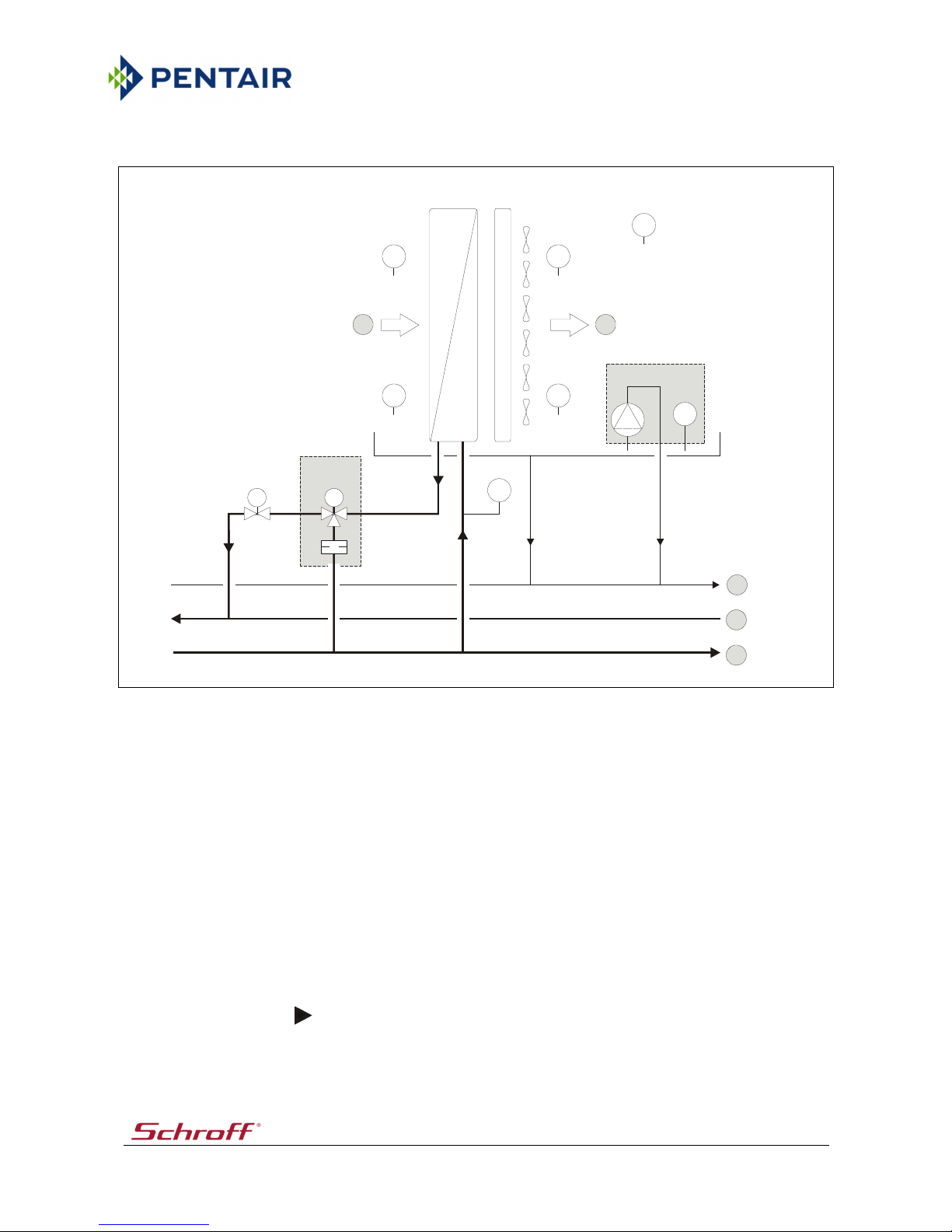

3.4 Schematic system diagram

Pos:27.13/Gerateauf bau/Termotek/ Kühler SHX 30/S ystemsche ma @ 152\m od_136618942 1554_18.d ocx @ 153772 8 @ @1

Fig. 5: Schematic system diagram

1 Heat exchanger (air/water)

2 Demister

3 Fan

4 Condensate pump with float switch (option)

5 Condensate tray

6 Control valve (two-way valve) with actuator

7 Control valve (three-way valve) with actuator

(option)

8 Orifice plate (option)

9 External temperature sensor (option.

Connection: customer-specific)

A Air flow (inlet, outlet)

Connectors

B Condensate outlet

C Chilling medium outlet

D Chilling medium inlet

Temperature sensors

R1 Chilling medium inlet

R2 Air inlet (top)

R3 Air inlet (bottom)

R4 Air outlet (top)

R5 Air outlet (bottom)

Pos:27.14/Hinweise/All gemeinHi nweis - Stro mlaufplan beac hten @ 174\ mod_13855439 96932_18.doc x@ 1767106@ @1

Note

Follow the instructions given in the circuit diagram.

Pos:27.15/-- leer --/== ====== @ 1\ mod26_18.d ocx @ 27188 @@ 1

12316

TCTC

TCTC

TCTCLC

123

R2

R3

R4

R5

R1

5

7

8

A

ABC946D

Page 24

VARISTAR Cooling unit SHX 30

System Layout 24

Pos:27.16/Gerateauf bau/Termotek/ Kühler SHX 30/1 .1 Funktio nsübersicht @242\mod_1422956485 872_18.d ocx @ 2234888 @2@ 1

3.5 Function overview

Fig. 6: Function overview (principle)

1 Control unit (display and operating unit)

2 Basic electronic system (I/O unit)

3 Interface board

4 Fuse board (circuit board with miniature fuses)

5 Temperature sensor (internal)

6 Temperature sensor (external)

7 Control valve

8 Condensate pump

9 Terminating resistor

10 Float switch

11 Fan

Pos:27.17/Hinweise/All gemeinHi nweis - Stro mlaufplan beac hten @ 174\ mod_13855439 96932_18.doc x@ 1767106@ @1

Note

Follow the instructions given in the circuit diagram.

Pos:27.18/-- leer --/== ====== @ 1\ mod26_18.d ocx @ 27188 @@ 1

12356-01

X2

X11X11

X10

X9 X8 X7 X6 X5

X13

X12

X14

X4X3X2X1

12345678OFF

ON

X1X2X3X4X5X6X7

X0

XG4

RS232

(SUB-D, 6 pol.)

RS485

RJ45

RS485

RJ45

R

X8

X9

X10

1

234

5

6

7810

11

9

LC

TC

Interlocks

TC

TC

TC

TC

TC

Page 25

VARISTAR Cooling unit SHX 30

System Layout 25

Pos:27.19/Überschrifte n/1.1/Sc hilder / Symbole a m Gerät @ 80\ mod_12 66232817346_18. docx @ 8799 17 @ 2 @ 1

3.6 Symbols / labels on the unit

Pos:27.20/Gerateauf bau/Termotek/ Kühler SHX 30/S childer a m Gerät @ 24 3\mod_1423 119597319_18.d ocx @ 22375 01 @ @1

Fig. 7: Labels on the unit

Label Description

1 Bar code

2 Chilling medium outlet

3 Venting point

4 Chilling medium inlet

5 Information concerning the interface (RS232, RS485) and

connection of the external temperature sensor

6 Connection point for I/O signal

• Interlock-interface (DI/DO, 10 pin)

7 Power supply connector (redundant power supply)

A Connector 1

B Connector 2 (redundant)

8 Type plate of the unit

Pos:28/-- leer --/=== ===== @ 1\m od26_18.do cx @ 27188 @ @1

12367-01

123

4824567

Bleeding

External

Temperature sensor

RS485RS232

INTERLOCKS

100-240V AC

50/60 Hz

B A

....

....

....

Page 26

VARISTAR Cooling unit SHX 30

Components 26

Pos:29.1/Überschrifte n/1/Kompo nenten @ 1\ mod7_18.doc x @ 32547 @ 1 @1

4 Components

Pos:29.2/Überschrifte n/1.1/Regelve ntil @ 20\ mod_11326533 21810_18. docx@ 245690@ 2 @ 1

4.1 Control valve

Pos:29.3/Komponenten /Regelventil/Sa uter/AV M105 - Allge mein @ 243\ mod_1422962 588574_18.do cx @ 2236308 @ @1

Control valve for the continuous control of cooling media in loops.

Fig. 8: Actuator, control valve (Example)

1 Actuator

2 Control valve

3 Display for opening degree of control valve (0-

100%)

4 Adjusting screw of actuator

5 Cover cap of DIP switch

6 Valve spindle

7 Locking mechanism (engaging)

8 Selector switch (Automatic / Manual)

9 Connection cable

The actuator is directly plugged onto the control valve and fixed with a nut. The

connection of the drive with the valve spindle is done automatically.

The valve is closed with the valve spindle pulled out.

Note

• The drive will move out during the first commissioning of the plant. The cap closes

automatically when reaching the lower valve seat. The stroke of the valve is

detected by the drive.

• The DIP switch is set ex works. Setting: see circuit diagram.

Pos:29.4/-- leer --/= ======= @ 1\ mod26_18.do cx @ 27188 @ @1

12430

0

%

1

0

0

%

"X"

X

auto

man

123789456

Page 27

VARISTAR Cooling unit SHX 30

Components 27

Pos:29.5/Überschrifte n/1.1/Gerätest euerung @ 15\mod_1106550857781_18.docx @ 134733@2 @1

4.2 Control unit

Pos:29.6/Komponenten /Modulgrup pen/Term otek/Text - Gerät esteuerung @ 1 56\mod_137 215431688 3_18.docx @1588585@ @1

Adjustments and adaptations concerning the cooling module can be performed via the

control unit (display and operating unit). Under normal operating conditions, the display

unit displays the actual value of the selected temperature sensor. The control unit is

located at the front of the cooling module.

Apart from four membrane keys and display with 2 x 20 digits, the display and operating

unit also includes the entire electronic control system. The electronic control system is

connected to a remote I/O unit (basic electronic system) at the back of the cooling module

via a CAN bus.

Pos:29.7/Komponenten /Gerätesteu erung/TRE 02 2/112/Bedient asten, Display (TRE-022)- Fa. Schr off @ 156\ mod_13721535 58752_18.doc x@ 1588399@ @1

Fig. 9: Control unit (front view)

1 Confirmation key (Enter key)

2 Cancel key (ESC key)/backward key

3 Selection and setting key (down key)

4 Selection and setting key (up key)

5 Display

Pos:29.8/Komponenten /Gerätesteu erung/TRE 02 2/112/Ans chlüsse (TRE -022) @ 39\mod_1 181905266 127_18.doc x@ 47 5517 @ @1

Fig. 10: Control unit (connections)

1 CAN interface - digital inputs / outputs (option)

2 Power supply

3 RS232/485 jack

Pos:29.9/-- leer --/= ======= @ 1\ mod26_18.do cx @ 27188 @ @1

12302

1

2

3

4

5

D4096G007

1 2 3

Page 28

VARISTAR Cooling unit SHX 30

Components 28

Pos:29.10/Komponente n/Modulgru ppen/Term otek/1.1 SH X 30 -I nterfa ceboard - Schnittst elle (RS232, RS485(RJ45)) @ 242\m od_1422956838 259_18.do cx @ 2234958 @2@ 1

4.3 Interface board

Fig. 11: Interface board

The interface board is a device interface and used for the connection of an external

temperature sensor (1).

RS485:

The RS485 data interface (2x RJ45, female connector) is used for the communication

between the cooling module and an external monitoring module via the Modbus protocol.

Pin Name

4 B

5 A

6 GND

12358-01

Interlocks

1 8 1 8

RS485

(RJ45)

RS232

(SUB-D, 6 pol.)

1

Page 29

VARISTAR Cooling unit SHX 30

Components 29

RS232, 6 pin:

The RS232 data interface (SUB-D, male connector) is used for the communication between

the cooling module and an external monitoring module via the Modbus protocol. For

service purposes, the interface is used for the firmware update of the control system.

Pin Name

2 TxD

3 RxD

4 GND

Interlock, DI/DO, 10 pin:

The Interlock-interface serves to connect the door contact switch and as an output for 4

freely programmable fault relays.

Pin Name

1 TK.1

2 TK.2

3 Out1.1

4 Out1.2

5 Out2.1

6 Out2.2

7 Out3.1

8 Out3.2

9 Out4.1

10 Out4.2

Pos:29.11/-- leer --/== ====== @ 1\ mod26_18.d ocx @ 27188 @@ 1

Page 30

VARISTAR Cooling unit SHX 30

Components 30

Pos:29.12/Komponente n/Modulgru ppen/Term otek/1.1 LHX 3 0 - Fuse-Board @156\mod_137225 1869402_18.do cx @ 1589762 @2@ 1

4.4 Fuse board

The fuse board is a circuit board that is equipped with miniature fuses and used for the

actuation and protection of the fans.

The fans are actuated via the control unit and I/O unit (basic electronic system).

The power supply of the fuse board is ensured by power supply units.

In the event of a failure of the fans, it may be necessary to check and replace the

miniature fuses.

Fig. 12: Fuse board

Miniature fuse Connector Fan

F1 X2 1

F2 X3 2

F3 X4 3

F4 X5 4

F5 X6 5

F6 X7 6

F7 X8 7 (option)

Pos:29.13/Hinweise/All gemeinHi nweis - Stro mlaufplan beac hten @ 174\ mod_13855439 96932_18.doc x@ 1767106@ @1

Note

Follow the instructions given in the circuit diagram.

Pos:29.14/-- leer --/== ====== @ 1\ mod26_18.d ocx @ 27188 @@ 1

12359

X1X2X3

X4X5

X6

X7

X8

X9

X10

X11

X13 X12 X17 X18 X16

X15

F9

F8

F10

F11

F7

F6

F5

F4

F3

F2

F1

Page 31

VARISTAR Cooling unit SHX 30

Components 31

Pos:29.15/Überschrifte n/1.1/Basi selektronik @ 1 5\mod_11077 60990524_ 18.docx @ 1 38873 @ 2 @ 1

4.5 Basic electronic system

Pos:29.16/Komponente n/Geräteste uerung/Basis elektronik_Kart en (Beieiner Versionier ung ergänz en: DIP-Schalt er (Einstellung sie he SLP)/TI OM/-112 fürIM@ 154\ mod_1368538 265582_18. docx @ 1566 308 @ @1

Fig. 13: Basic electronic system (example)

1 DIP switch (see the circuit diagram for setting information)

2 Pilot LED (CPU-K): LED flashes = processor active

3 Pilot LED (+24V-T): 24 V active on connector X13, X14

4 Pilot LED (RUN/ERR): CAN communication

- LED lights green = normal state

- LED lights red = communication problem

5 Jumper +24V - T

6 Jumper 0V - T

Connector Description

X1 Digital inputs

X2 Digital inputs

X3 Digital outputs

X4 Power supply

X5 Digital outputs

X6 Analogue outputs

X7 Analogue outputs

X8 Analogue inputs

X9 Analogue inputs

X10 Analogue inputs

X11 Analogue inputs

X12 Analogue inputs

X13, X14 CAN bus

Pos:30/-- leer --/=== ===== @ 1\m od26_18.do cx @ 27188 @ @1

12317

12345678OFF

ON

X12 X11 X10 X9 X8 X7 X6 X5

2

X13

X14

3

4

5

6

X1 X2 X3 X4

1

Page 32

VARISTAR Cooling unit SHX 30

Setting Up 32

Pos:31.1/Überschrifte n/1/Inbetrieb nahme @ 1 \mod8_18.d ocx @ 32593 @1@ 1

5 Setting Up

Pos:31.2/Überschrifte n/1.1Allge mein @ 15\ mod_110655320021 8_18.do cx@ 135193@ 2 @ 1

5.1 General information

Pos:31.3/Hinweise/War nung Perso nenWarnung -Kippgefahr (schmales Gerät)@1 90\mod_1396 607317081 _18.docx @ 1904739@ @ 1

WARNING

Danger of overturning!

Due to the slim set-up of the unit, there is a higher risk of injury when the unit tips over.

Ensure that the unit is sufficiently secured during the transport.

Pos:31.4/Hinweise/Vorsi cht / Ac htung - GerätA chtung - Schwit zwasser bei Tem.<15°C @ 190\mo d_13966074939 77_18.docx @1904807 @ @1

Notice

Danger of damage due to condensation!

At temperatures below 15°C/59°F, condensation may form inside the unit and cause

damage to the unit when it is switched on.

Prior to switching the unit on, ensure that the unit has acclimatised sufficiently.

Pos:31.5/Hinweise/Vorsi cht / Ac htung - GerätA chtung - Bes chädigung dur chS chmutzpartik el, Install . reinigen/spüle n @ 166\mod_1 381309051 871_18.doc x@ 16 60704 @ @1

Notice

Damage through dirt particles!

Dirt particles in customer-provided installations (e.g. pipes, hoses, ...) may lead to

malfunctions or damage to the components or unit/system.

• Ensure that the customer-provided installations (e.g. pipes, hoses, ...) are free

from dirt particles.

• If necessary, clean, rinse, or flush the customer-provided installations.

Pos:31.6/Hinweise/Vorsi cht / Ac htung - GerätA chtung - Ausfließ endes Medi um @ 190\ mod_139660 7422781_18.do cx @ 1904773 @@ 1

Notice

Risk of damage to components!

The medium that is to be connected (e.g. cooling water) can cause damage.

• Take suitable measures (e.g. leak sensors, automatic shut-off valves) in order to

prevent damage to the neighbouring components in the event of a leak or defect.

• These measures depend on the installation site and the building-relate conditions

on site. They are in the area of responsibility of the fitter or system planner.

Pos:31.7/-- leer --/= ======= @ 1\ mod26_18.do cx @ 27188 @ @1

Page 33

VARISTAR Cooling unit SHX 30

Setting Up 33

Pos:31.8/Inbetriebna hme - Montag eHinweis - O ptimale Wasserq ualität z.Befüllung: s.Kap."TD" - ( ohne Rohrtrenn er) @ 181\ mod_13896011 70371_18. docx @ 1840863 @ @1

Note

Optimum water quality for filling: information can be found in the “Technical Data”

section.

Pos:31.9/Inbetriebna hme - Montag e/MontageHinwei s - Au fstellen, Inbetrieb nahme, Ko mplettierung, War tung ... der Ger äte durc h Fachperso nal @ 190\mod_1 396609490 554_18.doc x@ 19 04841 @ @1

Note

• Only trained, specialised personnel is authorised to perform the set-up, start-up,

completion, maintenance, and service of the units.

• Observe the "Safety" section.

• Comply with the national rules and regulations concerning occupational health

and safety.

Pos:31.10/Inbetrieb nahme - Montag e/MontageHinwei s - Lag erung oder Trans port bei <0° C, Verweis a ufFr ostschutz... @190\mod_13966 09639905_18.d ocx @ 1904875 @@ 1

Note

The storage or transport at ambient temperatures below 0°C/32°F require special

measures in order to avoid frost damage.

• Observe the "Anti-freeze and corrosion protection" section.

• Transport the unit only without water.

Pos:31.11/Inbetrieb nahme - Montag eVerweis - WeitereInformatione n aufv ersch. Kapit el @ 30\m od_1161080564 982_18.d ocx @ 362557 @@ 1

For further information regarding connections, versions, pressure specifications, settings

etc. please refer to the following chapters:

• Layout / System layout

• Components

• Maintenance

• Technical Data

as well as the instruction labels on the unit (if provided).

Pos:31.12/-- leer --/== ====== @ 1\ mod26_18.d ocx @ 27188 @@ 1

Page 34

VARISTAR Cooling unit SHX 30

Setting Up 34

Pos:31.13/Überschrifte n/1.1/Trans port- und Verpa ckungsmateria l @ 18\ mod_11225445 39707_18.doc x@ 197743@ 2 @ 1

5.2 Transport and packaging material

Pos:31.14/Inbetrieb nahme - Montag e/Termotek/Te xt - Das Ger ät wird auf ei ner Sonderpalet te angelie fert. @ 156\m od_137206736 2377_18.d ocx @ 158754 3 @ @1

The unit will be delivered on a special pallet.

Pos:31.15/Inbetrieb nahme - Montag e/Transp ort von GerätenTran sport- un d Verpackungs material entfer nen. @ 15\ mod_11062346 11097_18. docx @ 1324 56 @ @1

Remove any transport material and packaging.

Pos:31.16/Inbetrieb nahme - Montag e/Transp ort von GerätenTran sport- un d Verpackungs material entsorg en @ 81\ mod_126779 2765671_18.do cx @ 891391 @ @1

Dispose of the transport and packaging material in an environmentally-compliant manner

and in accordance with the applicable local rules and regulations.

Pos:31.17/Hinweise/All gemeinHi nweis - Gerät nachAuspacken auf Trans portschäde n ... prüfen. @ 18 1\mod_1389 359794718_ 18.docx @ 1 840284 @ @1

Note

After unpacking, check the unit for signs of transport damage or other damage.

Pos:31.18/Hinweise/All gemeinHi nweis - Transp ortbeschädig ungen bei eventuell en Rückt ransport @ 190 \mod_13966 09731059_ 18.docx @ 19 04909 @ @1

Note

In order to avoid transport damage if the unit needs to be returned to the manufacturer,

return the unit solely in its original packaging.

Pos:31.19/Überschrifte n/1.1/Erstinb etriebna hme @ 156\mo d_13722350610 91_18.doc x @ 1589365 @2@ 1

5.3 Start-up

Pos:31.20/Hinweise/Elekt ro (Ge fahr, Warnung, Vor sicht)Ge fahr -E -Anschlü sse - Arbeiten a mg eöffnete n Gehäuse @190\mod_13960040470 08_18.docx @1897564 @ @1

DANGER

Electrical hazard!

It may be necessary to open the housing in order to perform work on the unit. Exposed

parts may be energised and cause an electric shock if they are touched.

Observe the following points when working on the electrical system:

• Observe the "Safety" section.

• Ensure that the tasks are performed solely by qualified experts.

1. Disconnect the unit from the power supply in order to deenergise it.

2. Secure the unit so that it cannot be switched on again accidentally.

3. Check whether the unit is properly disconnected from power and absolutely

voltage-free

4. Earth and short-circuit the unit.

5. Cover any adjacent live parts and secure the danger area.

Pos:31.21/Inbetrieb nahme - Montag e/Termotek/SH X30Erstin betriebnahm e @ 242\mod_ 142295900 8583_18.doc x@ 22 35520 @ @1

Prior to the start-up, the following tasks must be performed:

• Set the unit up.

• Connect the cooling water supply.

• Connect the power supply.

• Vent the unit.

Note

The set-up, start-up, maintenance, and service should be performed by the after-sales

service. If necessary, contact the after-sales service (see the "Contact addresses" section).

Pos:31.22/-- leer --/== ====== @ 1\ mod26_18.d ocx @ 27188 @@ 1

Page 35

VARISTAR Cooling unit SHX 30

Setting Up 35

Pos:31.23/Überschrifte n/1.1/Au fstellung @ 16\ mod_11080417 23954_18. docx @ 1409 65 @ 2 @ 1

5.4 Installation

Pos:31.24/Hinweise/All gemeinHi nweis - Kapitel "Sicherheit/ Standort wahl" - zur Auf stellung @ 166\ mod_1381309 999715_18. docx @ 1660 909 @ @1

Note

Comply with the instructions that are given in the "Safety/Selecting the installation site"

section.

Pos:31.25/Inbetrieb nahme - Montag e/Aufstellu ng/Text - Maxi male Längen Kap."TD". Anschlüsse z. G erät flexi bel, ausr. Druck festigk., Tem p.bestä @ 149\ mod_136266 3872876_1 8.docx @ 1518930 @@ 1

Comply with the maximum lengths (hoses, pipes, cables etc.) and pressure and

temperature values as stated in the "Technical Data" section.

The connections to the unit must be flexible and sufficiently pressure- and temperatureproof.

Pos:31.26/Überschrifte n/1.1/Ans chlüsse @ 15\ mod_11037869 79042_18. docx @ 12696 8 @ 2 @ 1

5.5 Connections

Pos:31.27/Inbetrieb nahme - Montag e/Anschlüsse /Mechanis ch/GlykolAchtu ng - Geschl. A bspvl im C-Krei s - unzul. Tem p. @ 190\ mod_13966105 61888_18. docx @ 1905103 @ @1

Notice

Risk of damage to components!

Closed shut-off devices in the chilling medium circuit lead to impermissible temperatures,

thereby causing the unit to be switched off, or they can damage the unit.

Ensure that the shut-off devices inside the unit and on site are open prior to starting the

unit.

Pos:31.28/Hinweise/All gemein/Hi nweis - Kühlme dium-Anschl uss (Anforder ungen) @ 1 53\mod_13669590 10415_18. docx @ 15577 63 @ @1

Notes concerning the chilling medium connection

• The customer-provided chilling infrastructure (external water circuit) must be

dimensioned by the system planner while taking into consideration the available

pump pressure, pump design, nominal pipe widths, and the expected pressure

losses in the consumer circuit (cooling modules).

• Keep the pipes (chilling medium) as short as possible in order to avoid pressure

losses in the system.

• The chilling medium pipes can be either fixed or flexible. The compatibility of the

materials in the cooling modules with the materials of the external system circuit

must be taken into consideration in order to avoid damage due to corrosion.

• When installing the customer-provided pipes, contamination of the pipes must be

absolutely avoided. Flush the pipes prior to connecting the cooling module.

• We recommend installing customer-provided shut-off and drain valves on every

cabinet or cooling module as well as using a central water filter and air separator.

Pos:31.29/Inbetrieb nahme - Montag e/Anschlüsse /Mechanis ch/All. Beschreib. : Verbindunge n zum Gerät vornehmen.@ 17\m od_111409461 5493_18.doc x @ 172408 @@ 1

Connect the unit.

Pos:31.30/-- leer --/......... .... Absatz ... ......... @ 77\ mod_1262789 107248_0. docx @ 85546 8 @ @1

Pos:31.31/Inbetrieb nahme - Montag e/Anschlüsse /Mechanis chHinweis -Anschlussgrößen gemäß Kapit el "TD" @ 17 0\mod_1382 684229585 _18.docx @ 1 706335 @ @1

Note

Connection sizes according to the "Technical Data" section

Pos:31.32/-- leer --/== ====== @ 1\ mod26_18.d ocx @ 27188 @@ 1

Page 36

VARISTAR Cooling unit SHX 30

Setting Up 36

Pos:31.33/Inbetrieb nahme - Montag e/Termotek/SH X30/Ansc hlüsse @ 243 \mod_14229 62702531_18.d ocx @ 223634 2 @ @1

Note

• Depending on the variant, the connectors and the condensate outlet are located

at the top or bottom of the cooling module. The pipes are fed in/out through the

bottom or top of the unit cabinet.

• Connectors that are not required must be sealed with blind plugs.

Fig. 14: Chilling medium connectors

X Connectors (top)

Y Connectors (bottom)

1 Condensate outlet

2 Chilling medium outlet

3 Chilling medium inlet

• Connect the chilling medium inlet.

• Connect the chilling medium outlet.

• Connect the condensate outlet with a sufficient gradient to the wastewater system.

Pos:31.34/-- leer --/== ====== @ 1\ mod26_18.d ocx @ 27188 @@ 1

12305-01

X

Y

“X“

1

2

3

“Y“

123

Page 37

VARISTAR Cooling unit SHX 30

Setting Up 37

Pos:31.35/Überschrifte n/1.1/Elekt rischer Ansc hluss @ 16\m od_1108040151 943_18.doc x @ 140896 @ 2@1

5.6 Electrical connection

Pos:31.36/Hinweise/Elekt ro (Ge fahr, Warnung, Vor sicht)Ge fahr - Lebensge fahr bei Anschl uss falscher A nschlusss pannung @ 181\ mod_13893615 45475_18. docx @ 1840 476 @ @1

DANGER

Danger to life due to electrical hazard!

There is a risk of death by electric shock if the connected voltages are not correct.

• Only qualified and specialised personnel is authorised to perform the connection.

• Compare the connection voltage to the voltage that is stated on the type plate.

• Comply with the specifications of the circuit diagram.

Pos:31.37/Hinweise/Elekt ro (Ge fahr, Warnung, Vor sicht)Ge fahr -E -Anschlü sse - Arbeiten a mg eöffnete n Gehäuse @190\mod_13960040470 08_18.docx @1897564 @ @1

DANGER

Electrical hazard!

It may be necessary to open the housing in order to perform work on the unit. Exposed

parts may be energised and cause an electric shock if they are touched.

Observe the following points when working on the electrical system:

• Observe the "Safety" section.

• Ensure that the tasks are performed solely by qualified experts.

1. Disconnect the unit from the power supply in order to deenergise it.

2. Secure the unit so that it cannot be switched on again accidentally.

3. Check whether the unit is properly disconnected from power and absolutely

voltage-free

4. Earth and short-circuit the unit.

5. Cover any adjacent live parts and secure the danger area.

Pos:31.38/Inbetrieb nahme - Montag e/Anschlüsse /ElektroAcht ung - Falsche An schlussspan nung @ 180\ mod_138864 9917441_1 8.docx @ 1831680 @@ 1

Notice

Wrong connected voltage!

Incorrect supply voltages can lead to component damage.

Compare the supply voltage value with the voltage specification stated on the nameplate.

Ensure the necessary fuse protection in accordance with the "Technical Data" section or

circuit diagram.

Pos:31.39/Inbetrieb nahme - Montag e/Termotek/Elek trische Ans chlüsse/Hinw eis - E-Ansc hluss @ 242 \mod_142295 9211225_18.do cx @ 2235622 @@ 1

Note

• Units with two mains power inputs are designed for the redundant power supply

via two independent mains power sources.

• The unit is supplied with operating voltage via an IEC320-C20 connector with cable

lock at the back of the unit.

• A corresponding connecting cable (IEC320-C19 - two-pin earthed connector) is

included in the scope of supply.

• The units must be protected by a series fuse in the building in accordance with the

"Technical data" section.

Pos:31.40/-- leer --/== ====== @ 1\ mod26_18.d ocx @ 27188 @@ 1

Page 38

VARISTAR Cooling unit SHX 30

Setting Up 38

Pos:31.41/Hinweise/All gemeinHi nweis - Stro mlaufplan beac hten @ 174\ mod_13855439 96932_18.doc x@ 1767106@ @1

Note

Follow the instructions given in the circuit diagram.

Pos:31.42/Inbetrieb nahme - Montag e/Termotek/SH X30/E-Ans chlüsse @ 242\ mod_1422957 897744_18 .docx @ 223 5136 @ @1

Fig. 15: Electrical connection

• If necessary, connect an interface cable for the device communication:

- Interlocks (DI/DO), 10 pin (2)

- RS232, 6 pin (3)

- 2x RJ45 (4)

• Connect the external temperature sensor (5) (depending on the customer

requirements).

• Connect the power supply (1).

• Observe the local rules and regulations.

• See the "Technical data" section.

Note

• In order to avoid communication problems, lay the interface cable (data line) and

the electrical power supply cables separate from each other.

• Once the operating voltage has been applied, the unit is in the standby mode.

Various components inside the unit are live.

• Disconnect the operating power supply prior to opening the unit.

• Once the operating voltage has been applied, the actuator of the control valve is

energised and performs an initialisation.

Pos:31.43/-- leer --/== ====== @ 1\ mod26_18.d ocx @ 27188 @@ 1

12305-01

X

“X“

54312

Page 39

VARISTAR Cooling unit SHX 30

Setting Up 39

Pos:31.44/Überschrifte n/1.1/Frost -, Korrosion sschutz @ 54\ mod_12072963 19973_18.do cx @ 608185 @ 2 @1

5.7 Antifreeze and anti-corrosion agents

Pos:31.45/Inbetrieb nahme - Montag e/Anschlüsse /Mechanis ch/T-Kreis/Glyk ol/Frost-, K orrosionssch utz/01a - Text: e xterne Rückk ühlanlage - Term otek (Kühl modul, ...) @ 153 \mod_13668 73150682_1 8.docx @ 15 56513 @ @1

If aluminium is used in the external water circuit, there is a risk of corrosion. In order to

avoid electrochemical corrosion, it must be checked whether the materials that are used

in the cooling module are compatible with the materials of the external cooling circuit.

The type and dose of a suitable anti-corrosion or anti-freeze agent depends on the

situation on site and also on the external re-cooling system. It must be determined by the

system planner.

The following materials are used in the cooling module.

• copper

• bras

• stainless steel

• gunmetal

Pos:31.46/Inbetrieb nahme - Montag e/Anschlüsse /Mechanis ch/T-Kreis/Glyk ol/Frost-, K orrosionssch utz/02 - Text: S chutz der Ba uteile KANN Syste mkreis be füllt sein @ 154\ mod_1368540 855491_18 .docx @ 156 6457 @ @1

In order to protect the components in the system circuit against corrosion and frost

damage, the system circuit must be filled with an anti-corrosion and anti-freeze agent.

Frost damage may be caused by contamination, air that is trapped inside the system, or by

a pump malfunction.

Pos:31.47/-- leer --/......... .... Absatz ... ......... @ 77\ mod_1262789 107248_0. docx @ 85546 8 @ @1

Pos:31.48/Inbetrieb nahme - Montag e/Anschlüsse /Mechanis ch/T-Kreis/Glyk ol/Frost-, K orrosionssch utz04 - Achtung-Hi nweis - Glykolk onzentra tion @ 174\ mod_13853838 84654_18.doc x@ 1 761828 @ @1

Notice

Damage to components

If the concentration of anti-corrosion or anti-freeze agents is too high or too low in the

circuit, components may be damaged (e.g. the seals). If the concentration is too low, the

corrosion may actually be stimulated.

When using anti-corrosion or antifreeze agents, please comply with the information

provided by the manufacturers concerning the area of application, the compatibility with

other materials, and the minimum/maximum mixing ratio, etc.

Pos:31.49/Inbetrieb nahme - Montag e/Anschlüsse /Mechanis ch/T-Kreis/Glyk ol/Frost-, K orrosionssch utz05.1 - Info BefüllungT-Kreis: Allge mein - alle @ 188 \mod_139513 8505119_1 8.docx @ 18 84657 @ @1

When using monoethylene glycol as the anti-corrosion and anti-freezing agent, please

observe the following points:

• Do not mix anti-corrosion and anti-freezing agents of different manufacturers.

Document the name and type of the anti-corrosion and anti-freezing agent that is

used.

• For filling the system control circuit with anti-corrosion and anti-freezing agents,

we recommend mixing the liquids in advance with the aid of a filling pump.

Pos:31.50/-- leer --/......... .... Absatz ... ......... @ 77\ mod_1262789 107248_0. docx @ 85546 8 @ @1

Pos:31.51/Inbetrieb nahme - Montag e/Anschlüsse /Mechanis ch/T-Kreis/Glyk ol/Frost-, K orrosionssch utzHinweis - Was serqualität gemä ß Kap. TD einhalten@ 181\mod_1 389603412 442_18.doc x@ 18 40968 @ @1

Note

In order to ensure the trouble-free operation of the unit, the water quality requirements

as stated in the "Technical data" section must be fulfilled.

Pos:31.52/-- leer --/== ====== @ 1\ mod26_18.d ocx @ 27188 @@ 1

Page 40

VARISTAR Cooling unit SHX 30

Setting Up 40

Pos:31.53/Überschrifte n/1.1/Einstell ungen @ 0\ mod123_18.d ocx @ 47267 @ 2@1

5.8 Adjustments

Pos:31.54/Inbetrieb nahme - Montag e/Termotek/ LHX30/Ein stellungen - Serv ice+Bediener @242\mod_14229593 04709_18.doc x @ 22356 57 @ @1

Note

• Please refer to the "Operation/Control Unit" section for information concerning

the operation of the control unit (display and operating unit).

• If an error is indicated, press the ESC key. Following the pressing of the ESC key,

the first parameter will be displayed.

• Select the various parameters by pressing the up or down key.

• Eliminate the malfunction (see the "Troubleshooting" section).

1. Switch the cooling module on via the control unit (see the start screen)

(parameter "Chiller" = "ON").

2. Check the following parameters at the control unit and adjust them if necessary:

Parameter Description Screen

Temperature Adjustment of the set temperature (air outlet). Start screen (overview)

Sensor selection Selection of the temperature sensor for the

temperature control.

Fan power Adjustment of the set speed of the fans.

Valve position Indication of the current opening degree of the

cooling valve in %.

Pos:31.55/-- leer --/== ====== @ 1\ mod26_18.d ocx @ 27188 @@ 1

Page 41

VARISTAR Cooling unit SHX 30

Setting Up 41

Pos:31.56/Überschrifte n/1.1/Entlü ften @ 129\ mod_1336546 374254_18.do cx @ 1328619 @2@ 1

5.9 Venting

Pos:31.57/Inbetrieb nahme - Montag e/Termotek/SH X30/Entl üften des Kühlsy stems, Testbet rieb @ 242\ mod_142295 9348221_18 .docx @ 223 5690 @ @1

In order to vent the cooling system, the control valve must be closed.

Note

If the control valve is open, chilling medium may flow from the return flow and into the

heat exchanger. Venting is not possible in this case.

The control valve is opened or closed by the electronic control system by way of an

electric actuator and based on the chilling medium demand.

When the cooling module is switched off by the control system, the actuator closes the

control valve. This process takes approximately 2 minutes.

If the operating voltage is disconnected before the actuator has closed the control valve,

the control valve must be closed manually.

Notice

Risk of damage to components!

There is a risk of damage if the actuator is manipulated while it is connected to the

operating voltage.

Do not adjust the actuator manually unless it is disconnected from the operating power

supply.

Prerequisite for venting:

• The water installation is complete. The inflow to the cooling module is still closed.

• The electrical installation is complete.

• Specialised personnel with access to the water installation is present.

Note

If the system comprises several cooling units, vent the systems one after the other in

order to ensure sufficient pressure for pushing the air out.

Page 42

VARISTAR Cooling unit SHX 30

Setting Up 42

Steps:

1. Switch the cooling module off at the control unit.

2. Wait for approximately 2 minutes. During this time, the control valve will close

automatically.

3. Open the back of the cabinet.

4. Ensure that the control valve has been closed via the actuator.

5. Disconnect operating power supply.

Note

If the operating voltage is disconnected before the actuator has closed the control valve,

the control valve must be closed manually.

Fig. 16: Manually adjusting the actuator

6. If necessary, manually adjust control valve. Carry out the following steps:

• Shift selector switch (2) of actuator (1) down to position "Manual (man)" (see "A").

• Set adjusting screw (4) of actuator by way of using an Allen key (5) to an opening

degree of the control valve of 0%.

Watch for display (3) (see "B").

• Upon completion of works, shift selector switch (2) up to position "Automatic

(auto)".

Note

The power supply to the cooling module must be disconnected when the control valve

needs to be adjusted manually.

12432

A

"X"

man

X

auto

B

12345

Page 43

VARISTAR Cooling unit SHX 30

Setting Up 43

7. Have the water inlet into the cabinets opened by specialised personnel. If present,

open the shut-off valves upstream of the cabinets in the double bottom.

8. Insert the venting hose into a vessel with a capacity of 1.5 litres minimum.

9. Open the vent valve with the supplied square socket key and let the air escape.

Close the vent valve when water starts to flow out.

10. Repeat these steps (starting with 7) for all of the cabinets.

Test run:

1. Connect the power supply.

2. Switch the cooling modules on via the operating unit.

Note

The fans will briefly run with maximum speed. Then, they will be set back to their

nominal speed. Since, at this point of time, there is no heat load in the cabinets, the set

temperature (e.g. 20°C) will be reached rather quickly.

3. Open the vent valve once again briefly after the test run in order to check whether

any air has collected in the heat exchanger.

The system is now completely filled with water and vented.

Pos:31.58/-- leer --/== ====== @ 1\ mod26_18.d ocx @ 27188 @@ 1

Page 44

VARISTAR Cooling unit SHX 30

Setting Up 44

Pos:31.59/Inbetrieb nahme - Montag e/Termotek/SH X30/1.1 A usbau, Einbau - durchKundendienst @242\mod_142295957 1741_18.d ocx @ 2235725 @2@ 1

5.10 Removal/installation

WARNING

Risk of injury for personnel!

There is an increased danger of injury during the installation or removal of the unit due to

its size and weight.

Install or remove the unit always with several persons and with the aid of suitable lifting

gear!

Note

Prior to the removal, the cooling module must be disconnected from the water supply

and the water connections must be closed in order to avoid damage caused by leaking

cooling water.

1. Disconnect the electrical connections.