Pentair UNIVERSAL BOOSTER PUMP installation Manual

UNIVERSAL BOOSTER PUMP INSTALLATIONUNIVERSAL BOOSTER PUMP INSTALLATION

16” L

9” W

11.5” T

This booster pump is 3/4 horsepower with a 1.5

service factor producing a minimum of 50 psi at 12 GPM.

1. UNIT LOCATION

Pump should be installed on a firm and level surface.

Unless required by a local code, it need not be bolted

down. Installation should be as close as possib

le to a

filtered water return line and convenient location for

servicing. NOTE: Booster pump must always be con-

nected to return line on discharge side of filter. Nev

er

connect suction side booster pump ahead of filter. (See

Figure 1).

2. TYPICAL INSTALLATION - HEATER

CONSIDERATION

Suction side of booster pump must be connected to

the return line after the heater.

Except on solar installation, never connect suction side of booster pump ahead

of filter or heater. NOTE: Keep booster pump a mini-

mum of 3 feet from heater.

Figure 2A: Installation with Heater

POOL HEATER

SWEEP PUMP

3. INSTALLA

TION WITH SOLAR HEATER

With or without a gas heater for bac

FILTER

k-up, when installing any one of Pentair automatic pool cleaners in a

pool with solar heating, the in-line tee must be installed

on the return line between the filter and the solar

heater. This minimizes the possibilities of an air lock in

the sweep pump each time the solar panel is filled and

assures an ample supply of water. (See Figure 2B).

Figure 2B: Installation with Heater

FROM SOLAR PANEL

POOL HEATER

TO SOLAR PANEL

FILTER

FILTER

PUMP

4. INSTALLATION WITH SPA POOLS

Connect suction side of the booster pump before

spa bypass valve, if y

pool. (See Figure 3).

our pool is plumbed for a spa

Figure 3: Installation with Pool/Spa Combo

FROM POOL

TO POOL

TO SPA RETURN

SPA VALVE

TO POOL

RETURN

CAUTION: BEFORE MAKING ANY ELECTRICAL

CONNECTION T

SURE ALL ELECTRICAL PO

PUMP INLET CONNECTION TO POOL RETURN LINE

5.

O EXISTING POWER SOURCES, BE

WER IS OFF.

Use elbow and reducing bushing if needed on pre-

plumbed installation. Use tee on existing installation.

Connect pump suction to the return line after filter and

heater as follows: Preferably, underneath side

(NEVER ON TOP) of the horizontal return line.

6. INSTALLATION OF PUMP HOSES

a. To install hoses remove adapter from hose kit bag

(P/N 353020) and wrap thread seal tape around the 3/4

inch npt threads of the adapter. A minim

um of four

revolutions is required.

b. Screw adapter with thread seal tape into the pump

outlet. Torque to 60 inch x lbs

.

c. Cut hose to appropriate length. Six (6) feet of

hose has been pro

vided for both the inlet and outlet.

d. Place adapter cap over hose (See Figure 4) and

slide the hose onto the adapter until the hose is flush

against the wall where the threads begin. Heating of

the hose or use of a lubricant may be useful if the hose

is cold.

e. Screw adapter cap and tighten to the adapter to

secure the hose. Torque to 60 in. x lbs.

f. Repeat process for both inlet and outlet of pump.

When routing the hose make sure there are no tight

bends or kinks in the hose.

Figure 4: Installation of Pump Hoses

HOSE

ADAPTER CAP

ADAPTER

PUMP OUTLET

(3/4 IN. NPT)

HOSE

PUMP INLET

(3/4 IN. NPT)

GROUND

LOCATION

(REFERENCE)

BOLT ANCHOR

HOLES

7. SPECIFICATIONS

DIMENSIONS: 16” L X 9” W X 11.5” T

MOTOR: 3/4 HP, 60 HERTZ

POWER SUPPLY: 120/240 VAC

8. ELECTRICAL CONNECTIONS FOR BOOSTER

PUMP

Pentair Universal Booster Pump is pre-wired to

ate on 230 volts. The motor can also be wired to

oper

ate on 115 volts by making a simple modification

oper

at motor wire connection plate.

BEFORE TURNING ON POWER TO PUMP,

CHECK VOLT

AGE AT INTENDED SOURCE BEFORE

MAKING ELECTRICAL CONNECTION. PUMP

MOTOR CAN BE DAMAGED IF CONNECTED TO

WRONG VOLTAGE.

ELECTRICAL WORK SHOULD BE DONE BY A

LICENSED ELECTRICIAN.

CHECK ELECTRICAL CODES FOR REQUIRE-

MENTS IN YOUR LOCAL AREA.

9. SAFETY WARNING

Motor frame should be grounded for swimming pool

installations as specified in Article 680 of the National

Electrical Code. Failure to proper

ly ground motor can

result in serious electrical shock.

10.TIME CLOCK

A separate time clock is recommended. To ensure

proper sequence of filter pump and booster pump, the

time clocks must be reset if po

wer is interrupted.

The automatic pool cleaner must be run for a

length of time necessary to clean the pool, but should

never be allowed to run while filter system is off. This

will result in damaging the booster pump. Running the

automatic pool cleaner without the filter system in operation will void warranty. The automatic pool cleaner

should start operating one half hour to forty-five minutes after the filter pump starts and stop one half hour

to forty-five minutes before the filter pump

stops.

11.MANUAL SWITCH

A manual switch is recommended. It should be

located between the time clock and the booster pump.

witch eliminates turning the pump off at the time

This s

clock.

12.PUMP SEAL

The booster pump is fitted with a mechanical shaft

seal which is water lubricated and water

cooled. If the

pump is run without water this seal will be damaged.

NEVER OPERATE UNLESS FILTER SYSTEM IS ON.

13.SERVICING THE BOOSTER PUMP

Note: This motor is a drip proof motor, but can be

damaged by rainfall, splash or flooding by causing

ater to enter the motor.

w

- To disassemble the booster pump -

1. Turn off booster pump motor and close v

alves.

2. Unscrew suction line in middle of volute.

3. Loosen nuts and remove bolts between booster

pump volute and seal bracket.

4. On back end of motor remove cap. Use a crescent

wrench or open end wrench to hold shaft from

spinning.

5. Hold wrench and turn impellar counter clockwise

to remove.

- To remove seal -

1. Stand motor on end, using one screwdriver slowly

y seal out of impellar. Remove seal bracket and

pr

dislodge seal from backside of seal bracket using

hammer and screwdriver.

- To re-assemble the unit -

1. After replacing the necessary parts, re-assemble

by reversing order of steps 1-5 abo

ve.

2. Ceramic seat must be perfectly clean of any

foreign objects or dirt. If seat is not clean, it will

cause leakage. The ceramic seat must go in with

the side containing grooves facing into the center

of the rubber gasket, otherwise it will leak.

3. Replace impellar and seals if warped or discolored.

This condition is caused by overheating due to

pump running dry. Smooth surface of ceramic seal

should be parallel to and facing away from back

side of impellar.

4. Silicone backside of metal flange on spring seal,

push down until flush in center of seal bracket.

Be careful not to get silicone on to spring seals

contact surface.

If you have any questions, contact

Pentair Pool Products at 1-800-831-7133

®

UNIVERSAL BOOSTER PUMP INSTALLATION

®

ELECTRIC MOTOR

LA295 SEAL BRACKET LA415 O-RING LA05L IMPELLER L39534 VOLUTE

UNIVERSAL

5

/16 - 18 X 21/2 NC BOLT

8 REQUIRED

LA41 MOTOR STAND

3

/8 - 16 X 13/4

NC BOLT

2 REQUIRED

3

/8 - 16 X 13/4 NC BOLT

2 REQUIRED

5

/16 NUT

8 REQUIRED

071734

SEAL INSTALLED

IN SEAL BRACKET

Qty. Description: Part # Qty. Description: Part #

8 Bolts LA115 1 O-Ring for Drain Plug PA375

8 Nuts LA125 1 Drain Plug LA385

1 Seal 071734 1 O-Ring LA415

1 Impeller LA05L 2 Bolts 3/8 - 16x3/4 NC LA135

1 Motor Stand LA41 4 Grommets MA36

1 Volute LA39534 2 Grommets MA36S

1 Seal Bracket LA295 2 Bolts 3/8 - 16x11/14 NC LA136

1 Hose Kit 353020

BOOSTER PUMP

INSTALLATION AND

PARTS LIST

IMPORTANT

A solid copper bonding conductor not

smaller than No. 8 AWG (8.4 mm2) should be

connected from the accessible wire connector

on the motor to all metal parts of the

wimming pool, spa, or hot tub structure and

s

to all electrical equipment, metal conduit and

metal piping within 5 ft. (1.5m) of the inside

walls of a swimming pool, spa or hot tub when

the motor is installed within 5 feet of the inside

walls of the swimming pool, spa or hot tub.

LIMITED WARRANTY

This limited warranty is extended to the original consumer purchaser. Pentair Pool Products, Inc. (Pentair Pool Products) warrants

the LA01N booster pump it manufactures, including all parts and components thereof, to be free of defects in material and

workmanship.

The warranty commences on the date of installation of the pump and shall remain in effect for a period of twelve months, but in no

event shall it be in effect for more than twenty-four months before the date of manufacture of the pump as established by the serial

number. If this pump is installed with a new Legend, Legend Platinum of Jet Vac Automatic Swimming Pool Cleaner and registered

by serial number on the warranty registration card of the Automatic Pool Cleaner, the above warranty will be extended by twelve

months. This limited warranty does not apply if the failure is caused or contributed by any of the following: improper handling,

improper storage, abuse, unsuitable application of the unit, lack of reasonable and necessary maintenance, winter freezing or

repairs made or attempted by other than Pentair Pool Products or one of its authorized service centers. Pentair Pool Products will

repair or replace, at its option, a unit or part proved to be defective within the warranty period and under the conditions of the

warranty. Pentair Pool Products is not responsible for the cost of removal of the unit, damages due to removal, any other expenses

incurred in shipping the unit or parts to or from the factory or its authorized service centers, or the installation of the repaired or

replaced unit. The consumer must bear these expenses.

This limited warranty is in lieu of all other warranties, expressed or implied including the implied warranties or merchantability and fitness for a particular purpose, and all such other warranties are disclaimed e

warranty may be imposed by state consumer la

warranty gives you specific legal rights. You may have others which vary from state/jurisdiction to state/jurisdiction.

In no event shall Pentair Pool Products be liable for incidental or consequential damages of any nature or kind or for

damages to persons or property.

w is limited in duration to one (1) year from date of purchase. This limited

xcept to the extent any implied

IMPORTANT SAFETY INSTRUCTIONS.

READ AND FOLLOW ALL INSTRUCTIONS CAREFULLY.

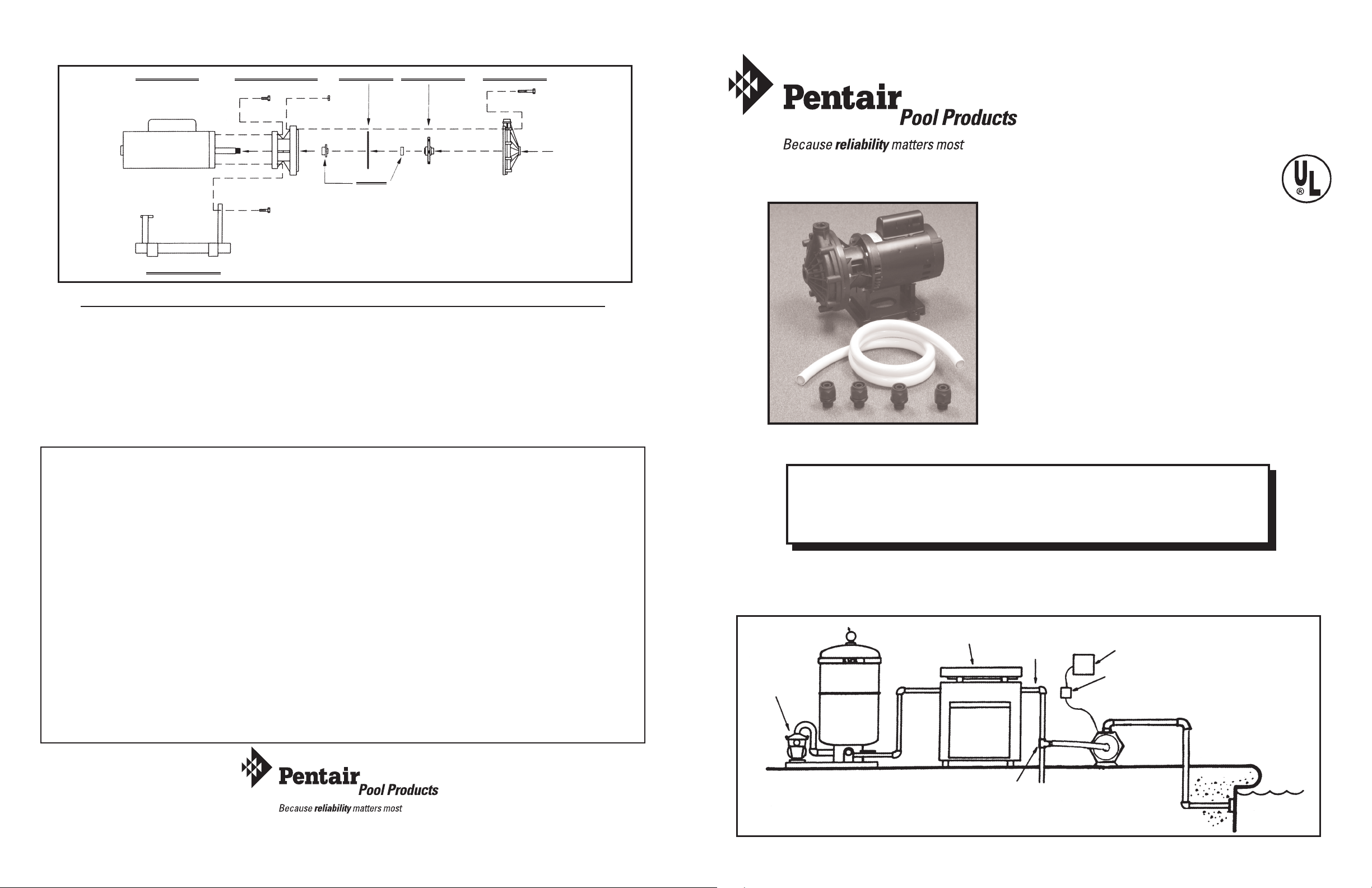

Figure 1: Typical Installation

FILTER

FILTER PUMP

SAVE THESE INSTRUCTIONS.

POOL HEATER

POOL

RETURN

LINE

TEE

REDUCER

TIME CLOCK

ON/OFF SWITCH

CONCRETE

YYA3 Rev. D

Pentair Pool Products

1620 Hawkins Ave., Sanford, NC 27330 (919)774-4151

10951 West Los Angeles Ave., Moor

park, CA 93021 (805)523-2400

Loading...

Loading...