ULTRATEMP ETi

HYBRID HEATER

™

ENGLISH

ENGLISH

ESPAÑOL

FRANÇAIS

IMPORTANT SAFE T Y INSTRUCTIONS

RE AD AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

INSTALLATION AND

USER’S GUIDE

i

CUSTOMER SERVICE / TECHNICAL SUPPORT

If you have questions about ordering Pentair Aquatic Systems, (“Pentair”) replacement parts, and pool products,

please use the following contact information:

Customer Service (8 A.M. to 4:30 P.M. — Eastern

and Pacific Times)

Phone: (800) 831-7133

Fax: (800) 284-4151

Web site

Visit www.pentairpool.com or www.staritepool.com to

find information about Pentair products.

TABLE OF CONTENTS

Important Warning and Safety Instructions .......

General Information ..............................................

Heater Introduction

Installation Requirements

General Installation Information

General Features

Positioning the Heater ..........................................

Materials Needed for Installation

Roof Run-off

Lawn Sprinklers

Equipment Pad

Recommended Clearances

Flue Gas Condensation Management

Preventative Maintenance

Condensate Cartridge Service

Installation .............................................................

Anchor Clamp Installation

System Layout

Internal Automatic Flow Control Valve

Water Connections and Plumbing

Heat Pump Drainage Connection

Isolation and Check Valves

Manual Bypass Valve

Pressure Relief Valve (PRV)

Multi-Heater Installations

Solar Installations

Water Pressure Switch Adjustment

Gas Connections

Gas Line Installation

Checking Gas Pressure Through Gas

Control Valve

Sediment Traps

Gas Pressure Testing

Electrical Connections and Wiring

Wiring Diagram - Input

Wiring Diagram - Output

Connecting to an Automation System ................

Remote Operation

Relay Remote Controls

Connecting to EasyTouch via Heater Spade

Terminals

Connecting to EasyTouch via RS-485 Connector

Pin Configuration for Heater Control Board

to EasyTouch

Connecting EasyTouch to the Heater

Operating the Heater ............................................

Swimming Pool Energy Saving Tips

Control Panel Overview

Sequence of Operation

Pre-Startup

P/N 475922 Rev. A 5/18/18

Technical Support

Sanford, North Carolina (8 A.M. to 4:30 P.M. ET)

Phone: (919) 566-8000

Fax: (919) 566-8920

Moorpark, California (8 A.M. to 4:30 P.M. PT)

Phone: (805) 553-5000 (Ext. 5591)

Fax: (805) 553-5515

ii

1

1

1

1

1

2

2

2

2

3

3

5

5

5

6

6

6

7

7

7

8

8

8

9

10

10

11

11

12

12

12

13

14

15

16

16

16

17

18

19

19

20

20

20

21

21

Basic Operating Instructions

Turning Off Gas to the Heater

Safety Controls

Air Flow Switch (AFS)

Water Pressure Switch (WPS)

High Limit Switch (HLS) and Automatic Gas

Shut-off Switch (AGS)

Stack Flue Sensor (SFS)

Thermal Fuse (TF)

Float Switch (CFS)

Ignition Module Operation

Operator Menu Tree Guide and Navigation

Using the Operator Menus

Starting and Stopping the Heater

Changing the Set Point

Efficiency Mode Selection

Heater Timer

Remote Mode - Relay

Remote Mode - RS-485 (Serial Cable)

Remote Mode - IntelliFlo

Timers and Delays

Control Panel Alarm Messages

Service Menu Tree Guide and Navigation

Using the Service Menus

Eco-Time

Boost Temperature

Setting Temperature Scale

Set Water Temperature Offset

Defrost Cycle

Run Time Counters

Locking the Control Panel

Maintenance ........................................................

Water Chemistry

Total Alkalinity

Balancing pH

Disinfectant Residual

General Maintenance

Condensate Drainage

Winterizing

Spring Start Up

Professional Maintenance and Service

Technical Data .....................................................

Electrical Supply - Voltage Requirements

Temperature Resistance Chart

Pressure Chart

Pressure Drop Curves

Troubleshooting ..................................................

Replacement Parts ..............................................

Heater Parts Breakdown

Parts List - Refrigeration and Outer Shell

Parts List - Gas System

Parts List - Electrical

Parts List - Plumbing

22

22

22

23

23

23

23

24

24

24

24

25

26

26

26

26

26

26

27

27

27

28

29

29

30

30

30

30

30

31

31

32

32

32

32

32

33

33

34

34

34

35

35

35

36

36

37

43

43

44

45

46

47

ULTRATEMP ETI™ Hybrid Heater Installation and User’s Guide

IMPORTANT WARNING AND SAFETY INSTRUCTIONS

Important Notice:

This guide provides installation and operation instructions for this hybrid

heater. Consult Pentair with any questions regarding this equipment.

Attention Installer: This guide contains important information about the

installation, operation and safe use of this product. This information should

be given to the owner and/or operator of this equipment after installation

or left on or near the heater.

Attention User: This manual contains important information that will help

you in operating and maintaining this heater. Please retain it for future

reference.

READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This is the safety alert symbol. When you see this

symbol on your system or in this manual, look for

one of the following signal words and be alert to

the potential for personal injury.

Warns about hazards that can cause death,

serious personal injury, or major property damage

if ignored.

Warns about hazards that may cause death,

serious personal injury, or major property damage

if ignored.

Warns about hazards that may or can cause minor

personal injury or property damage if ignored.

NOTE Indicates special instructions not related to

hazards.

Carefully read and follow all safety instructions in this manual and on

equipment. Keep safety labels in good condition; replace if missing or

damaged.

Before installing this product, read and follow all

warning notices and instructions which are included.

Failure to follow safety warnings and instructions can result in severe

injury, death, or property damage. Call (800) 831-7133 for additional free

copies of these instructions.

Codes and Standards

UltraTemp ETi heaters are listed by UL as complying with the latest edition

of the “UL Standard for Safety for Heating and Cooling Equipment”, UL

1995, CSA C22.2 No. 236 and ANSI Z21.56

Installation must be in accordance with all local codes and/or the latest

edition of the National Fuel Gas Code, ANSI Z223.1 and the latest

edition of the National Electrical Code, NFPA 70 (US).

Installation in Canada must be in accordance with the latest CAN/

CGA-B149.1 or .2 and CSA C22.1 Canadian Electric Code, part 1.

This heater, when installed, must be electrically grounded and bonded

in accordance with local codes, or, in absence of local codes, with the

National Electrical Code, ANSI/NFPA70 (US) or in Canada in accordance

with the Canadian Electric Code, part 1 as applicable.

Do not permit children to use this product.

Improper installation, adjustment, alteration, service

or m ai ntenance c an cause property damage,

personal injury or death. Installation and service must be performed

by a qualified installer, service agency or the gas supplier.

RISK OF ELECTRICAL SHOCK OR

ELECTROCUTION.

The electrical supply to this product must be installed by a licensed,

certified electrician or qualified personnel in accordance with the National

Electrical Code and all applicable local codes and ordinances. Improper

installation will create an electrical hazard which could result in death or

serious injury to pool or spa users, installers, or others due to electrical

shock, and may also cause damage to property. Read and follow the

specific instructions inside this guide.

For units intended for use in other than single-family

dwellings, a clearly labeled emergency switch

shall be provided as part of the installation. The switch shall be readily

accessible to the occupants and shall be installed at least 5 feet [1.52

m] away, adjacent to, and within sight of the unit.

Consumer Information and Safety

UltraTemp ETi heaters are designed and manufactured to provide safe

and reliable service when installed, operated and maintained according

to the information in this manual and the installation codes referred to

in later sections. Throughout the manual, safety warnings and cautions

are identified by the “ “ symbol. Be sure to read and comply with all of

the warnings and cautions.

The U.S. Consumer Product Safety Commission warns

that elevated water temperature can be hazardous.

See below for water temperature guidelines before setting temperature.

The following “Safety Rules for Hot Tubs”

recommended by the U.S. Consumer Product

Safety Commission should be observed when using the spa:

1. Spa or hot tub water temperatures should never exceed 104° F. [40°

C.]. A temperature of 100° F. [38° C.] is considered safe for a healthy

adult. Special caution is suggested for young children. Prolonged

immersion in hot water can induce hyperthermia.

2. Drinking of alcoholic beverages before or during spa or hot tub

use can cause drowsiness which could lead to unconsciousness

and subsequently result in drowning.

3. Pregnant women beware! Soaking in water above 100° F.

[38° C.] can cause fetal damage during the first three months of

pregnancy (which may result in the birth of a brain-damaged or

deformed child). Pregnant women should stick to the 100° F. [38°

C.] maximum rule.

4. Before entering the spa or hot tub, the user should check the

water temperature with an accurate thermometer. Spa or hot tub

thermostats may err in regulating water temperatures.

5. Persons with a medical history of heart disease, circulatory

problems, diabetes or blood pressure problems should obtain

their physician’s advice before using spas or hot tubs.

6. Persons taking medication which induce drowsiness, such as

tranquilizers, antihistamines or anticoagulants should not use

spas or hot tubs.

Should overheating occur or the gas supply fail

to shut off, turn off the manual gas control valve

to the heater. Do not use this heater if any part has been under water.

Immediately call a qualified service technician to inspect the heater and

to replace any part of control system and gas control which has been

underwater.

Risk of fire, carbon monoxide poisoning, or

asphyxiation if exhaust venting system leaks.

Only qualified service technicians should attempt to service the heater, as

leakage of exhaust products or flammable gas may result from incorrect

servicing.

ii

ENGLISH

ULTRATEMP ETI™ Hybrid Heater Installation and User’s Guide

iii

IMPORTANT WARNING AND SAFETY INSTRUCTIONS

The U.S. Consumer Product Safety Commission

warns that carbon monoxide is an “invisible killer”.

Carbon monoxide is a colorless and odorless gas.

1. Carbon monoxide is produced by burning fuel, including natural gas

and propane.

2. Proper installation, operation and maintenance of fuel-burning

appliances in the home is the most important factor in reducing

carbon monoxide poisoning.

3. Be sure that fuel burning appliances such as heaters are installed by

professionals according to manufacturer’s instructions and codes.

4. Always follow the manufacturer’s directions for safe operation.

5. Have the heating system inspected and serviced annually by a trained

service technician.

6. Install battery-operated carbon monoxide alarms. The alarms should

be certified to the requirements of the most recent UL, IAS, CSA and

IAPMO standard for carbon monoxide alarms. Test carbon monoxide

alarms regularly and replace dead batteries.

Hyperthermia occurs when the internal temperature of the body reaches a

level several degrees above normal body temperature of 98.6° F. [37° C.].

The symptoms of hyperthermia include: drowsiness, lethargy, dizziness,

fainting, and an increase in the internal temperature of the body.

The symptoms of hyperthermia include:

1. Unawareness of impending danger.

2. Failure to perceive heat.

3. Failure to recognize the need to leave the spa.

4. Physical inability to exit the spa.

5. Fetal damage in pregnant women.

6. Unconsciousness resulting in danger of drowning.

CARBON MONOXIDE GAS IS DEADLY!

THIS PRODUCT MUST BE INSTALLED AND

SERVICED BY A PROFESSIONAL SERVICE TECHNICIAN, QUALIFIED

IN POOL HEATER INSTALLATION. Some jurisdictions require that

installers be licensed. Check with your local building authority about

contractor licensing requirements. Improper installation and/or operation

could create carbon monoxide gas and flue gases which could cause

serious injury or death. Improper installation and/or operation will void

the warranty.

Exhaust from this pool heater contains toxic levels of carbon monoxide, a

dangerous, poisonous gas you cannot see or smell. Symptoms of carbon

monoxide exposure or poisoning include dizziness, headache, nausea,

weakness, sleepiness, muscular twitching, vomiting and inability to think

clearly. IF YOU EXPERIENCE ANY OF THE ABOVE SYMPTOMS,

IMMEDIATELY TURN OFF THE POOL HEATER, LEAVE THE VICINITY

OF THE POOL OR SPA AND GET INTO FRESH AIR IMMEDIATELY.

THE POOL HEATER MUST BE THOROUGHLY TESTED BY A GAS

PROFESSIONAL BEFORE RESUMING OPERATION.

EXCESSIVE CARBON MONOXIDE EXPOSURE CAN CAUSE BRAIN

DAMAGE OR DEATH.

• NEVER use this pool heater indoors.

• NEVER use this pool heater in the home or in partly enclosed areas

(such as garages). Install far from open windows, doors, vents and

other openings.

• Pentair strongly recommends that exhaust systems be initially and

periodically tested for proper operation. This testing can be accomplished

by using a hand-held carbon monoxide meter and/or by consulting with

a gas professional.

ULTRATEMP ETI™ Hybrid Heater Installation and User’s Guide

• Pool heaters must be used in conjunction with carbon monoxide detectors

installed near the pool heater. The carbon monoxide detectors must be

periodically inspected for proper operation so as to insure continued

safety. Broken or malfunctioning carbon monoxide detectors must be

replaced immediately.

This heater is equipped with an unconventional gas

control valve that is factory set at a pressure of -.2 inches

wc. Improper installation, adjustment, alteration, service or maintenance can

cause property damage, personal injury or loss of life. Installation or service

must be performed by a qualified installer, service agency or the gas supplier.

If this control is replaced, it must be replaced with an identical control. Do not

attempt to adjust the gas flow by adjusting the regulator setting.

Risk of fire or explosion from incorrect fuel use.

Do not try to run a heater set up for natural gas on

propane gas or vice versa. Only qualified service technicians should attempt

to convert heater from one fuel to the other. Do not attempt to alter the rated

input or type of gas by changing the orifice. If it is necessary to convert to a

different type of gas, consult your Pentair dealer. Serious malfunction of the

burner can occur which may result in loss of life. Any additions, changes,

or conversions required in order for the appliance to satisfactorily meet the

application needs must be made by a Pentair dealer or other qualified agency

using factory specified and approved parts. The heater is available for use

with natural gas only. It is not designed to operate with any other fuels. Refer

to the nameplate for the type of gas the heater is equipped to use. Use only

fuel for which the heater in designed.

Risk of fire or explosion from flammable vapors.

Do not store gasoline, cleaning fluids, varnishes,

paints, or other volatile flammable liquids near heater.

Risk of explosion if unit is installed near propane

gas storage. Propane (LP) gas is heavier than air.

Consult local codes and fire protection authorities about specific installation

requirements and restrictions. Locate the heater away from propane gas

storage and filling equipment as specified by the Standard for the Storage

and Handling of Liquefied Petroleum Gases, CAN/CSA B149.2 (latest edition)

or ANSI/NFPA 58 (latest edition).

Combustion air contaminated by corrosive chemical

fumes can damage the heater and will void the warranty.

Label all wires prior to disconnection when servicing

controls. Wiri ng errors can cause i mproper and

dangerous operation. Wiring errors can also destroy the control board.

• Connect heater to 240 Volt, 60 Hz., Single Phase power only.

• Verify proper operation after servicing.

• Do not allow children to play on or around heater or associated

equipment.

• Never allow children to use the pool or spa without adult supervision.

• Read and follow other safety information contained in this manual prior

to operating this pool heater.

General Specifications

Installation Location Certified for Use: OUTDOOR USE ONLY. Failure

to provide the proper clearances outlined on page 3-4 will lower the

performance of the heat pump and void the warranty.

Water Pipe/Heater Connection: Plastic 2” PVC (Unions included)

Flow Rate:

Maximum 120 gpm [456 lpm] - If system flow rate exceeds 120 gpm, a

bypass valve is required.

Minimum 30 gpm [110 lpm].

Maximum Working Water Pressure 50 psi

For Electrical Supply and Voltage Requirements, refer to the table on

page 35.

GENERAL INFORMATION

1

Heater Introduction

Thank you for choosing the UltraTemp ETi™ Hybrid

Heater. Proper installation and service of your new heating

system, and correct chemical maintenance of the water

will ensure years of heater operation. The UltraTemp

ETi heater is equipped with Pentair’s advanced heater

technology which includes a heat pump and a pool heater,

with a multifunction temperature controller to continuously

monitor the hybrid heater for proper operation. These

heaters are designed with direct spark ignition (DSI) for

on demand heat, which eliminates the need for a standing

pilot.

The heater is certified as complying with the Standard

for Gas Fired Pool Heaters, ANSI Z21.56/CSA 4.7, and

with the Standard for Heating and Cooling Equipment, UL

1995/CSA C22.2 No. 236-15. This heater is intended for

use in heating fresh water swimming pools or spas.

Installation Requirements

Correct installation is required to assure safe operation.

The requirements for Pentair heaters include the following:

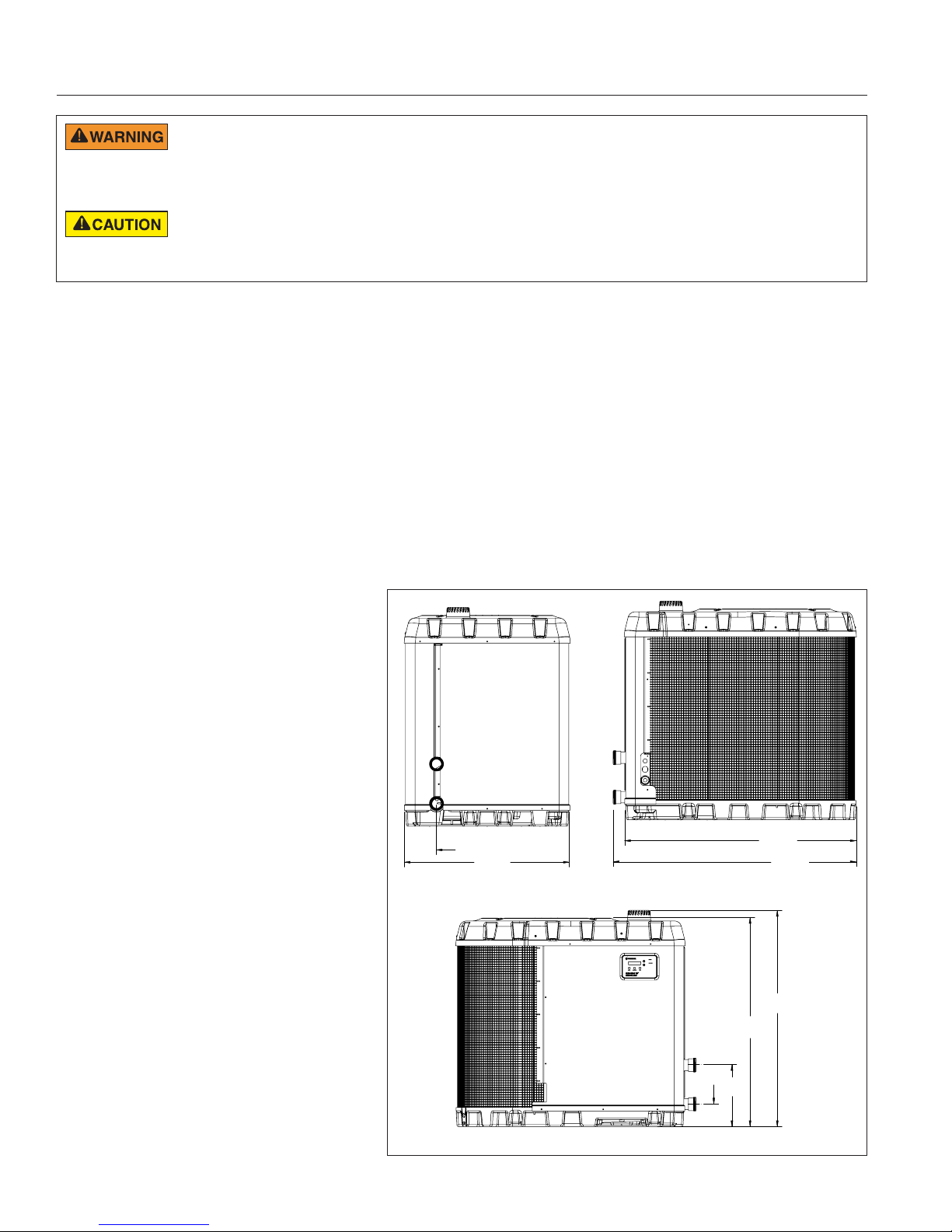

• Dimensions for critical connections (see Figure 1,

page 2).

• Field assembly (if required).

• Appropriate site location and clearances (pages 2-4).

• Proper electrical wiring (pages 14-16).

• Adequate water flow (see

page iii).

This manual provides the information needed to meet

these requirements. Review all application and installation

procedures completely before continuing the installation.

General Specifications,

General Installation Information

1. Installation and service must be performed by

a qualified installer or service agency, and must

conform to all national, state, and local codes.

2. Heaters get electrical power from an external

source and provide a dual electronic thermostat

control system for pool/spa combinations or preheat

convenience.

3. The heater is designed for the heating of chlorine,

bromine or salt system swimming pools and spas.

It should NOT be used as a space heating boiler, or

general purpose water heater.

4. The heater should be located in an area where

leakage of the heater or connections will not result in

damage to the area adjacent to the heater or to the

structure. When such locations cannot be avoided, it

is recommended that a suitable drain pan, adequately

drained, be installed under the heater. The pan must

not restrict air flow.

5. The heater is designed for outdoor operation

in non-freezing conditions only. If installed for

seasonal use in freezing climates, the heater

must be winterized to avoid freeze damage. See

Winterizing, page 34.

General Features

• Dual digital thermostats offer precise temperature

control to maintain the desired separate water

temperatures in pool/spa combinations without

overheating or wasting energy.

• Long-life corrosion resistant composite plastic

cabinet stands up to severe climates and pool

chemicals.

• 100% pure titanium heat pump and direct-fire

gas heat exchangers assure corrosion-free

performance for extra long life.

• Self-diagnostic control panel monitors and

troubleshoots heater operations to ensure safe,

dependable operation.

• Automatic Defrost feature senses refrigerant

temperature and prevents the heat pump

evaporator coil from freezing, allowing the heater to

operate at even lower temperatures.

• Compatible with all automated control packages.

RS-485 communication compatible with

EasyTouch® Control Systems.

• Thermostatic expansion valve (TXV) controls

refrigerant flow for optimum efficiency and BTU

output over a wider operating range.

• Elevated base pan for positive drainage of

condensation.

• 2-inch plumbing connections for easy installation.

• Separate isolated electrical compartment prevents

internal corrosion, extends heater life.

• Adjustable timer allows the operator to set the

heater to run for a predetermined time. Incremental

by 10 minutes to a maximum of 99 hours.

• An extensive list of operational conditions, alarms

and water temperatures are logged on the control

board. This information is available for the user to

track performance and troubleshoot issues.

• Four unique operating modes: Heat Pump only,

Gas Heater only, Dual and Hybrid.

ENGLISH

ULTRATEMP ETI™ Hybrid Heater Installation and User’s Guide

2

POSITIONING THE HEATER

CARBON MONOXIDE GAS IS DEADLY – Exhaust from this pool heater contains carbon monoxide, a dangerous, poisonous gas you

cannot see or smell. Symptoms of carbon monoxide exposure or poisoning include dizziness, headache, nausea, weakness, sleepiness,

muscular twitching, vomiting and inability to think clearly. IF YOU EXPERIENCE ANY OF THE ABOVE SYMPTOMS, IMMEDIATELY TURN OFF THE POOL

HEATER, LEAVE THE VICINITY OF THE POOL OR SPA AND GET INTO FRESH AIR IMMEDIATELY. THE POOL HEATER MUST BE THOROUGHLY TESTED

BY A GAS PROFESSIONAL BEFORE RESUMING OPERATION. EXCESSIVE CARBON MONOXIDE EXPOSURE CAN CAUSE BRAIN DAMAGE OR DEATH.

When pool equipment is located below the pool surface, a leak from any component can cause large scale water loss or flooding.

Pentair Water Pool and Spa, Inc. can not be responsible for such water loss or flooding which may cause damage to property or to the

product. Avoid placing the heater in locations where it can cause damage by water or condensate leakage. If this is not possible, provide a suitable drain pan

to catch and divert any leakage.

Only a qualified service person should install the

UltraTemp ETi™ Hybrid Heater. Before installing this

product, refer to the Important Warning and Safety

Instructions on page ii.

In the United States, installation must be in accordance

with local codes and the most recent edition of the

National Fuel Gas Code, ANSI Z223.1/NFPA-54. In

Canada, install the heater in accordance with local codes

and the most recent edition of the Natural Gas and

Propane Installation Code, CAN/CSA B149.1.

Materials Needed for Installation

The following items are needed and are to be supplied by

the installer for all heater installations:

1. Plumbing connections (2-inch).

2. Level surface for proper drainage.

3. Suitable electrical supply line. See rating

plate on unit for electrical specifications.

A junction box is not needed at the

heater; connections are made inside

of the heater electrical compartment.

Conduit may be attached directly to the

heater jacket.

4. Electric cutout switch that will interrupt

all power to the unit. This switch must be

within line of sight of the heater. Check

local codes for requirements.

5. Watertight conduit to run the electrical

supply line.

6. Suitable gas supply line with sediment

trap (see Table 1 on page 11 for sizing

requirements).

6.7”

(170mm)

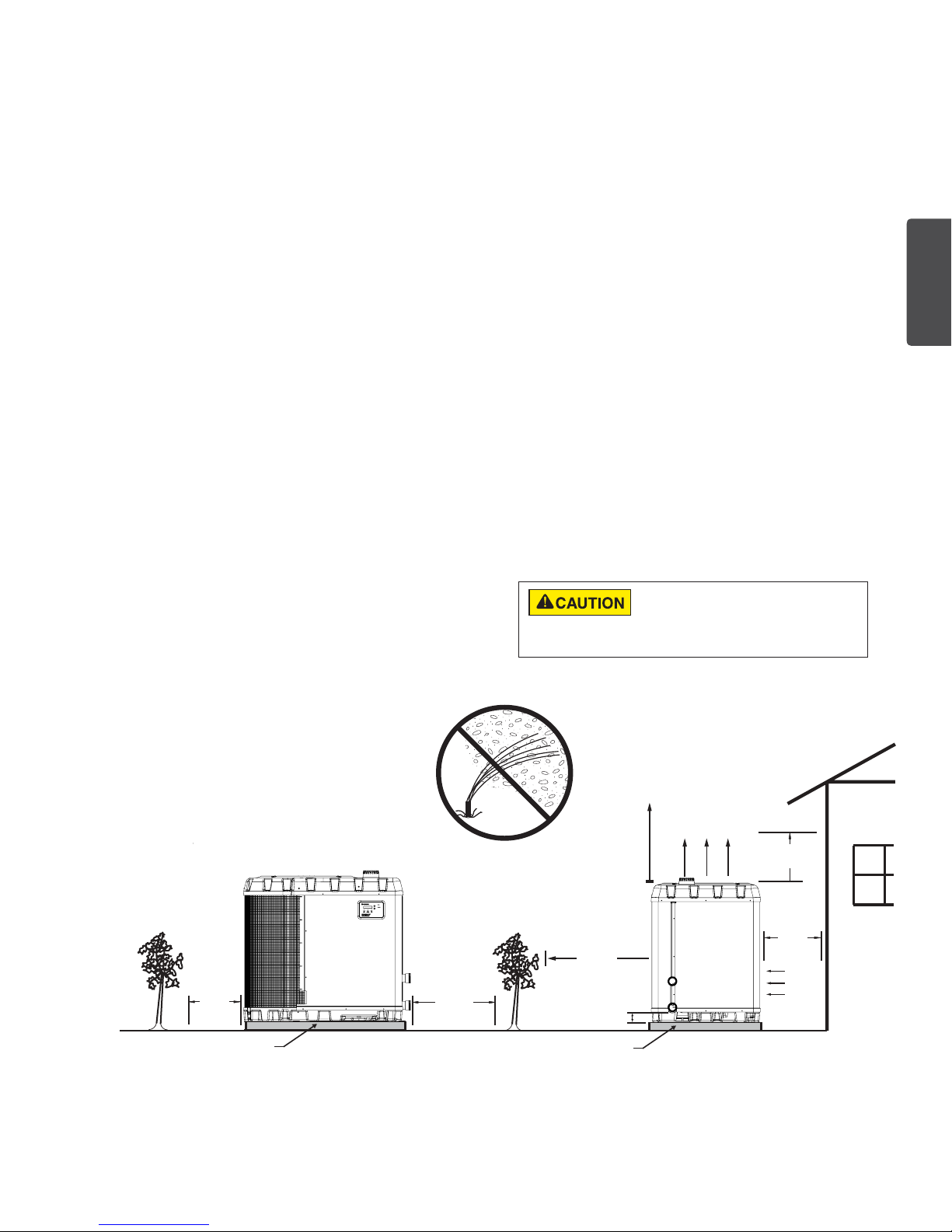

Lawn Sprinklers

Avoid placing lawn sprinkler near the heater they can spray water into the heater and void the

warranty. Be sure to direct any spraying water away

from the heater. Note the wind direction to be sure

water from sprinklers is not blown toward the heater.

Sprinkler heads can produce high water pressure and

spray at an angle, different from typical rain and humid

weather. Also, sprinklers connected to a well water

system can cause mineral build up on the evaporator

coils and electronics. Salt water can also be an issue if

located near the coast.

48.3”

34.4”

(874mm)

(1227mm)

50.7”

(1288mm)

Roof Run-off

Make sure the heater is not located where

large amounts of water may run-off from a

roof into the unit.

Sharp sloping roofs without gutters will

allow massive amounts of rain water, mixed

with debris from the roof to be forced

through the unit. A gutter or down spout

may be needed to protect the heater.

ULTRATEMP ETI™ Hybrid Heater Installation and User’s Guide

4.7”

(119mm)

(1115mm)

12.9”

(328mm)

43.9”

45.7”

(1146mm)

Figure 1

Equipment Pad

For proper drainage of condensation and rain water, place the heater on a flat slightly pitched surface, such as a

concrete or fabricated slab (pad).

If possible, place the pad at the same level or slightly higher than the filter system equipment pad.

The equipment pad should also be in an area where leaves or other combustible debris will not collect on or

around the heater.

Note:

Be sure that the pad is pitched not more than 1/4 in. per foot in any direction as needed for runoff.

Note: The equipment pad should be no less than 4 in. (100 mm) thick.

Recommended Clearances

All criteria given in the following sections reflect

minimum clearances. However, each installation must

also be evaluated, taking into account the prevailing

local conditions such as proximity and height of walls,

and proximity to public access areas.

The UltraTemp ETi™ Hybrid Heater must be placed

to provide clearances on all sides for maintenance

and inspection. Refer to Figure 2 for a visual

representation of the proper clearances.

1. At least 30 inches [610 mm] of clearance is

required on both the plumbing and control panel

side of the heater. This will provide necessary

room for servicing.

2. At least 12 inches [305 mm] of clearance must

be available on all the other sides of the heater to

allow for proper air flow.

3. If the heater is to be installed under a cover or

under a vertical overhang, the unit must have a

minimum of five (5) feet [1.5 m] clearance from

the top of the heater.

4. Install a minimum of five (5) feet [1.52 m] from the

inside wall of the pool or spa unless the heater is

separated from the pool or spa by a five (5) foot

[1.52 m] high solid fence or other permanent barrier.

Canadian installations require a minimum of three

(3) meters [9.84 ft] from pool water.

5. Install heater a minimum of 12 in. [305 mm] from the

wall of the house.

6. For minimum exhaust vent clearances, see Figure 3

on next page.

Note: In Canada, the heater must be installed with

the top of the vent at least 10 ft. (3 m) below, or to

either side of, any opening into a building.

If installing the heater next to or near an air

conditioning unit, heater or another gas pool

heater, allow a minimum of 36 in. (91.4 cm) between the unit and

the heater.

3

ENGLISH

12"

min.

(305 mm)

SLAB

NO SPRINKLERS

SERVICE

ACCESS

30"

min.

(762 mm)

Figure 2: Heater Clearances

ULTRATEMP ETI™ Hybrid Heater Installation and User’s Guide

SERVICE

ACCESS

30" min.

(762 mm)

3"

(76 mm)

SLAB

OPEN

AIR FLOW OUT

OVER HANG

5

FT min.

(1.5 m)

12

"

min.

(305 mm)

AIR

FLOW

IN

4

Recommended Clearances (cont.)

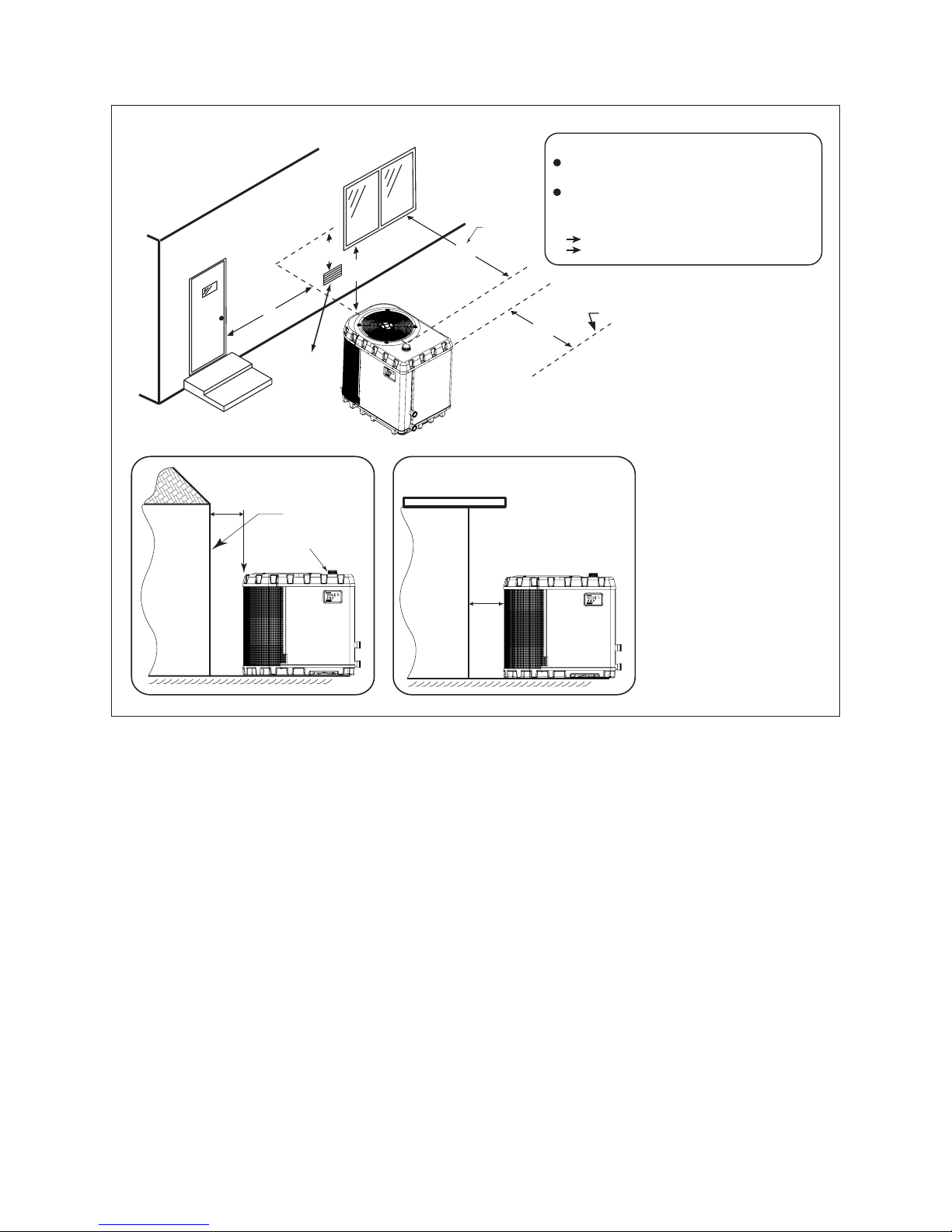

OUTDOOR INSTALLATION

VENTING GUIDELINES

3’

(0.9m)

4’

(1.2m)

4’

(1.2m)

From window

or door

Vent Termination:

Must be at least 3 ft. (0.9 m) above any forced

air inlet located within a 10 ft. (3.5 m) radius.

Must be located 12 in. (30.5 cm) away from the building

wall and the following distances away from any building

wall openings, included but not limited to vented eaves,

doors, windows, gravity air inlet:

4 ft. (1.2 m) below,

4 ft. (1.2 m) horizontally

Building

12"

(30.5cm)

4’

(1.2m)

Force

Air Inlet

SIDE VIEW

From building wall

Exhaust Grill

(Vent)

Roof Overhang

Building

4’

(1.2m)

Check local b

for setback requirements.

ROOF OVERHANG

12"

(30.5cm)

Property Line

uilding codes

Figure 3:

Vent Clearances

ULTRATEMP ETI™ Hybrid Heater Installation and User’s Guide

5

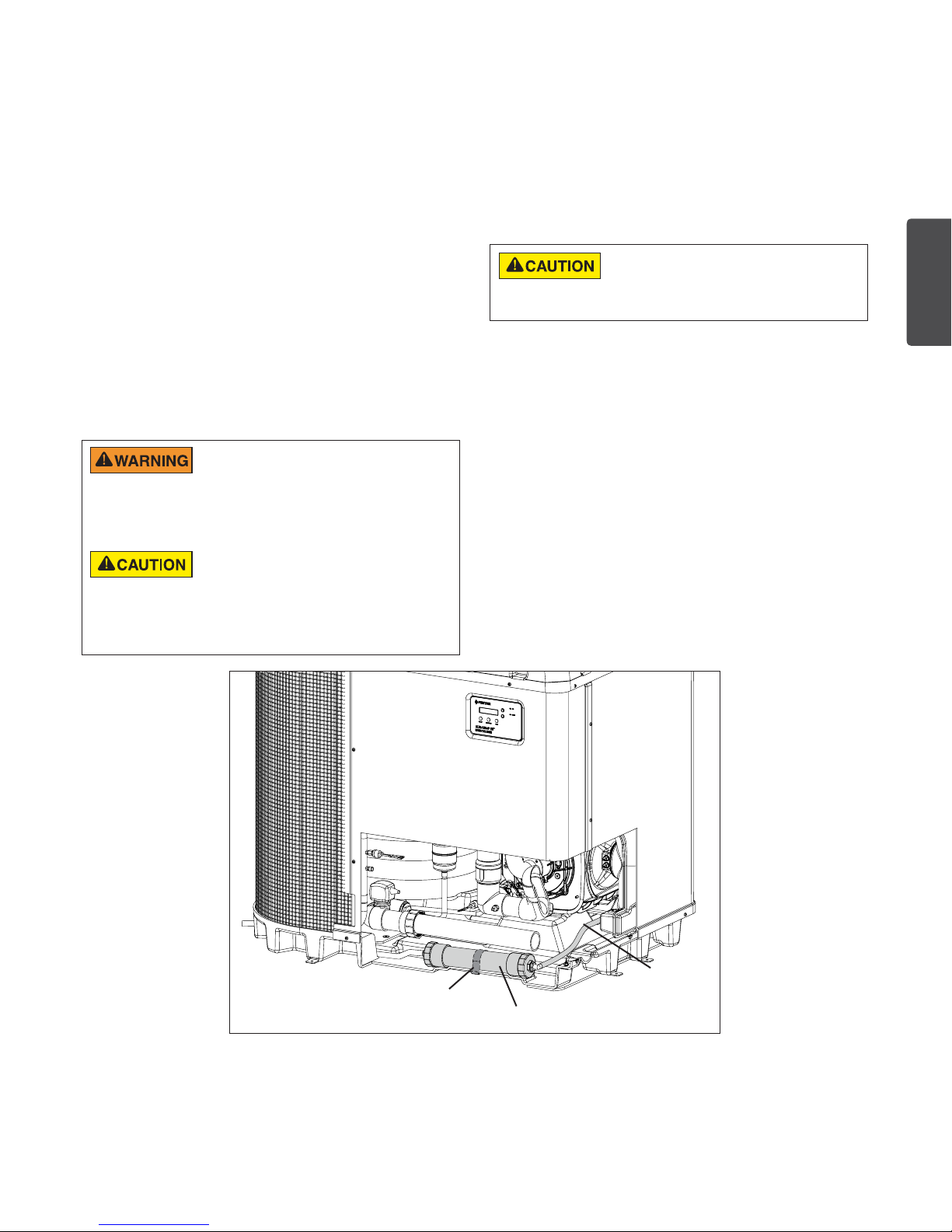

Flue Gas Condensation

Management

The UltraTemp ETi™ Hybrid Heater is a condensing

appliance. The flue gases will produce condensate

while in operation and must be drained correctly.

The condensate pH level is between 3.1 and 4.2.

Pentair recommends neutralizing the condensate

to avoid potential damage over time to the drainage

system, and to comply with local water authorities

where applicable. To neutralize the condensate, use

the Condensate Neutralizer Cartridge provided with

the heater. The condensate drain must be installed

so as to prevent accumulation of condensate. When

a condensate pump is not used, the tubing must

continuously slope downward toward the drain with no

spiraling.

Note: Consult local codes for treated condensate

disposal method.

DO NOT allow the exhaust flue gases to vent

through the neutra lizer. All condensate drains

MUST have a trap to prevent flue gas leakage. Flue gas leakage can

cause personal injury or death from carbon monoxide. Check with local

authorities for regulations regarding discharge of condensate to the drain

sewer system.

pH levels of 5.0 and below may harm some floor

drains and/or pipes, particularly those that are metal.

Ensure that the drain, drainpipe, and anything that will come in contact

with the condensate can withstand the acidity. Damage caused by failure

to install a neutralizer kit or to adequately treat condensate will not be the

manufacturer’s responsibility.

Preventative Maintenance

Annual condensate assembly inspection: Inspect

the internal tubing top for any dirt or particles that

could collect and clog the condensate neutralizer

cartridge.

Based on operating conditions, algae buildup in the

condensate cartridge may occur. Excessive algae

buildup can prevent proper condensate drainage

ENGLISH

DO NOT expose the condensate cartridge to

freezing temperatures without draining. This

could damage the cartridge. See page 34 for proper Winterizing

instructions.

Condensate Cartridge Service

If the control board reads “REPLACE CNC”, check

pH of condensate liquid. If the pH is below 5.0,

replace the condensate cartridge with a Condensate

Neutralizer Kit, (P/N 475954).

If the pH is not known, replace the condensate

cartridge when the control board recommends.

To clear this alarm, press the DOWN arrow and MODE

button simultaneously. The alarm may take a few

moments to clear after the buttons are pressed.

Figure 4: Condensate Neutralizer Cartridge Installed

Mounting

Bracket

in the Heater Base

Internal

Tubing

Condensate Neutralizer

ULTRATEMP ETI™ Hybrid Heater Installation and User’s Guide

6

ANCHOR

CLAMPS

ANCHOR

CLAMPS

ANCHOR

CLAMPS

FILTER

HEATER

TO

POOL

GATE

VALVE

FROM

POOL

FROM

FILTER

MANUAL

BY-PASS

1/4” x 2-1/4” Stainless

Steel Anchor Bolt

(not included)

INSTALLATION

The installation instructions contained in this manual are designed for use by qualified personnel only, trained especially

for installation of this type of heating equipment and related components. Some states require installation and repair by

licensed personnel. If this applies in your state, be sure your contractor possesses the appropriate license.

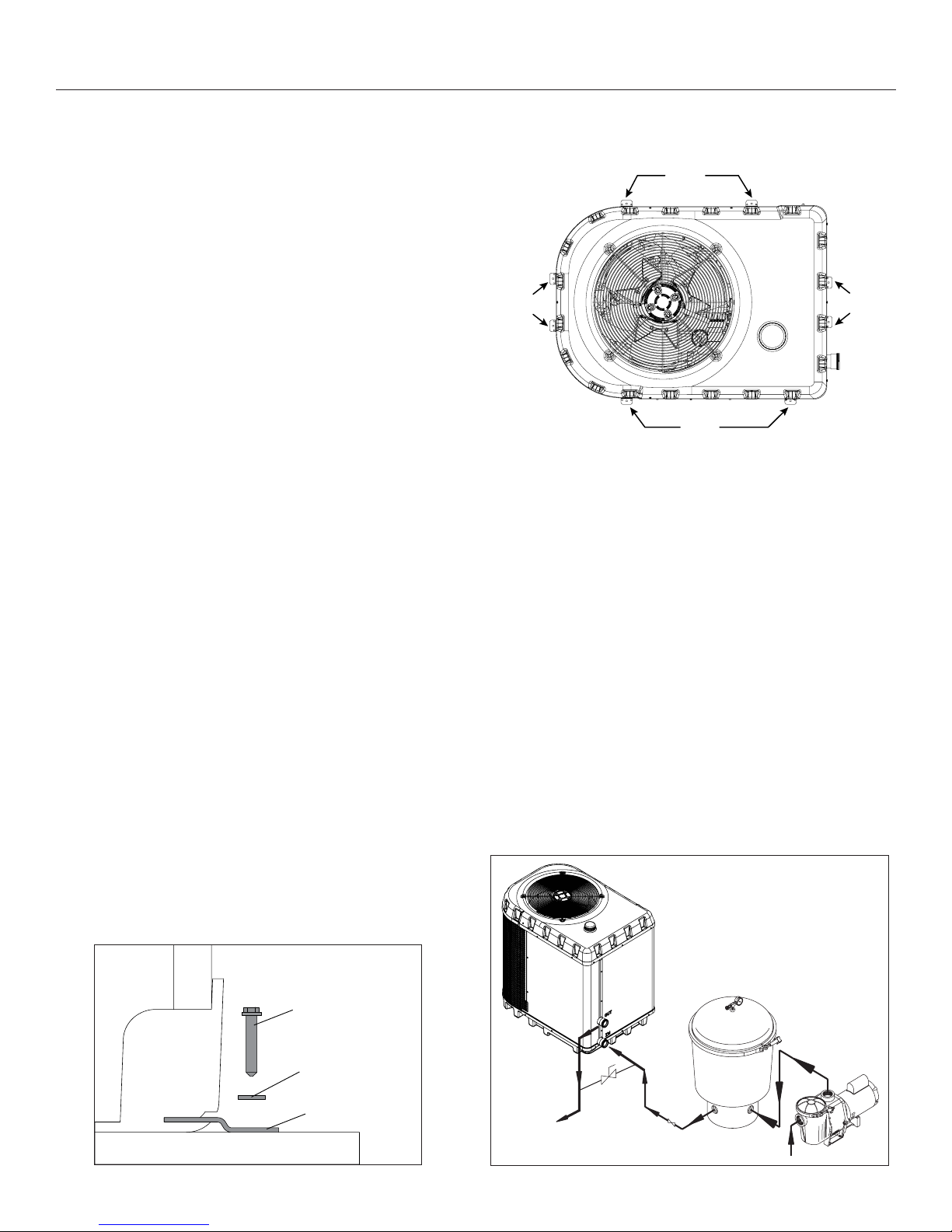

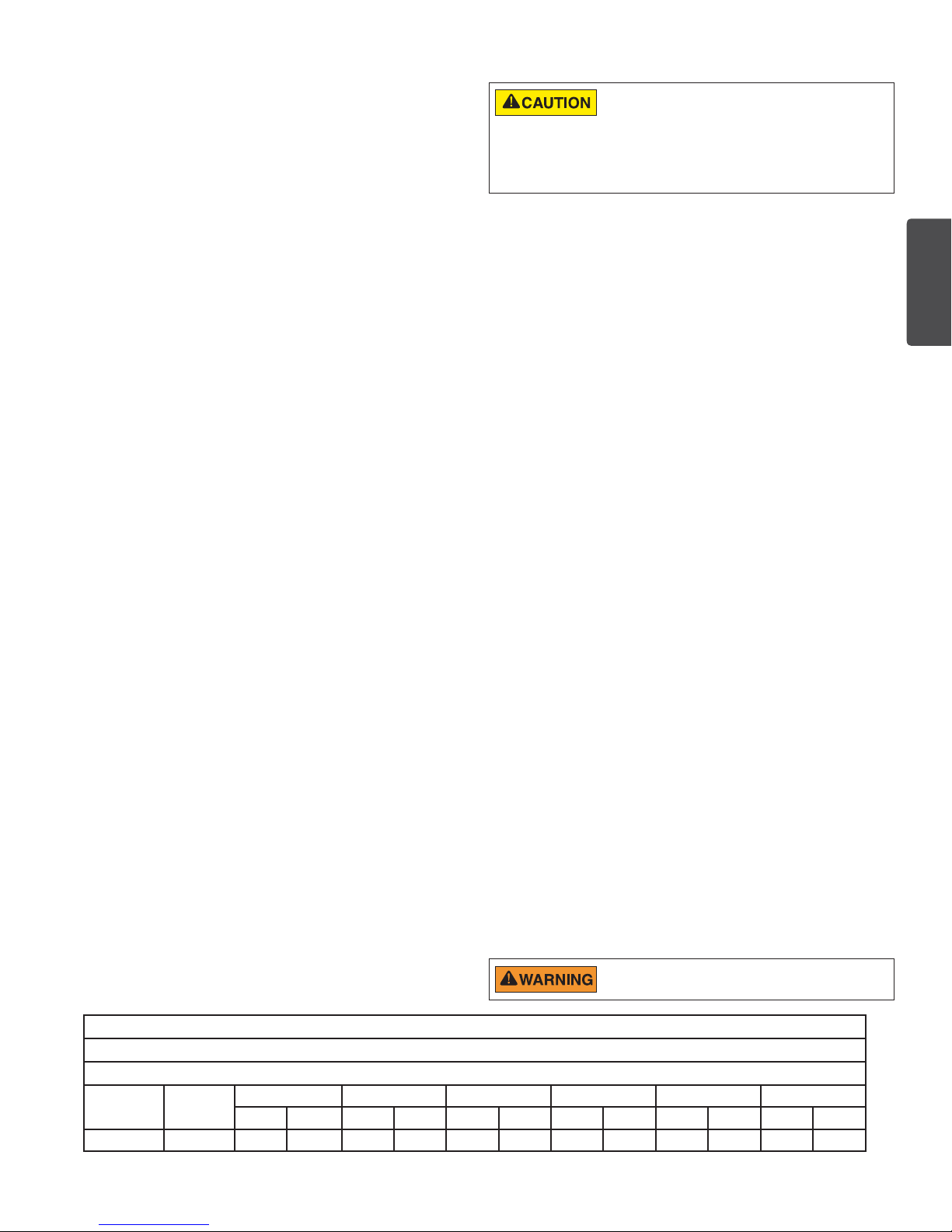

Anchor Clamp Installation

Installation of the anchor clamps is recommended in all

installations. Installation of the anchor clamps is required

in Florida (see Florida Building Code 301.13).

Anchor clamps hold the heater to the equipment pad in

order to withstand high winds caused during extreme

weather (i.e. hurricanes).

Note: Anchor clamps are included with the heater. They

can be found attached to the wood pallet that the heater

is shipped with.

To install the anchor clamps:

1. Be sure the heater is in its permanent location on the

equipment pad.

2. Place the clamps at the base of the heater in the eight

(8) locations, shown in Figure 5.

Note: Bolts and washers are not included with

the heater. The installer must provide 1/4” x 2-1/4”

stainless steel anchor bolts and the appropriate

size washers to mount the clamp to the concrete

equipment pad. Be sure to check local codes.

3. Fit the hook of each clamp into the slots in the base

panel of the heater.

4. Mark the position of the hole in each clamp on the

equipment pad.

5. Use a masonry drill bit and drill a hole in the cement

with a diameter as determined by the concrete anchor,

at each of the marks on the concrete equipment pad.

The hole should be approximately 2-3/4” (7 cm.) deep.

6. Position the anchor clamps so that the holes in the

clamps are over the drilled holes in the equipment pad

and the other end of the clamp is secured inside of the

heater base.

7. Insert an anchor bolt through each clamp into the anchor

and tighten to secure the clamp and heater to the

equipment pad. See Figure 6.

Note: Anchor bolts should be tightened to around

four (4) ft/lbs.

CLAMPS

ANCHOR

Figure 5: Anchor Clamp Locations

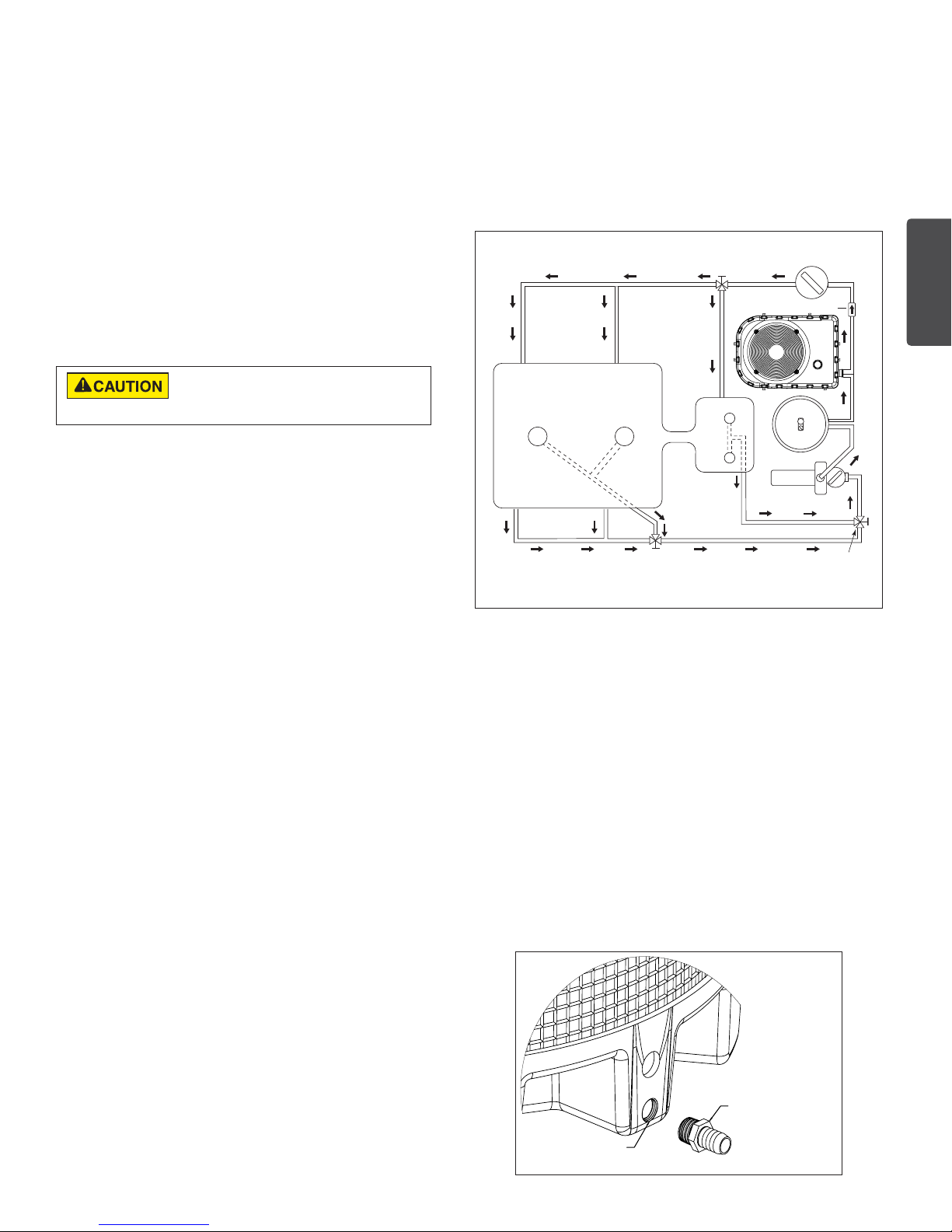

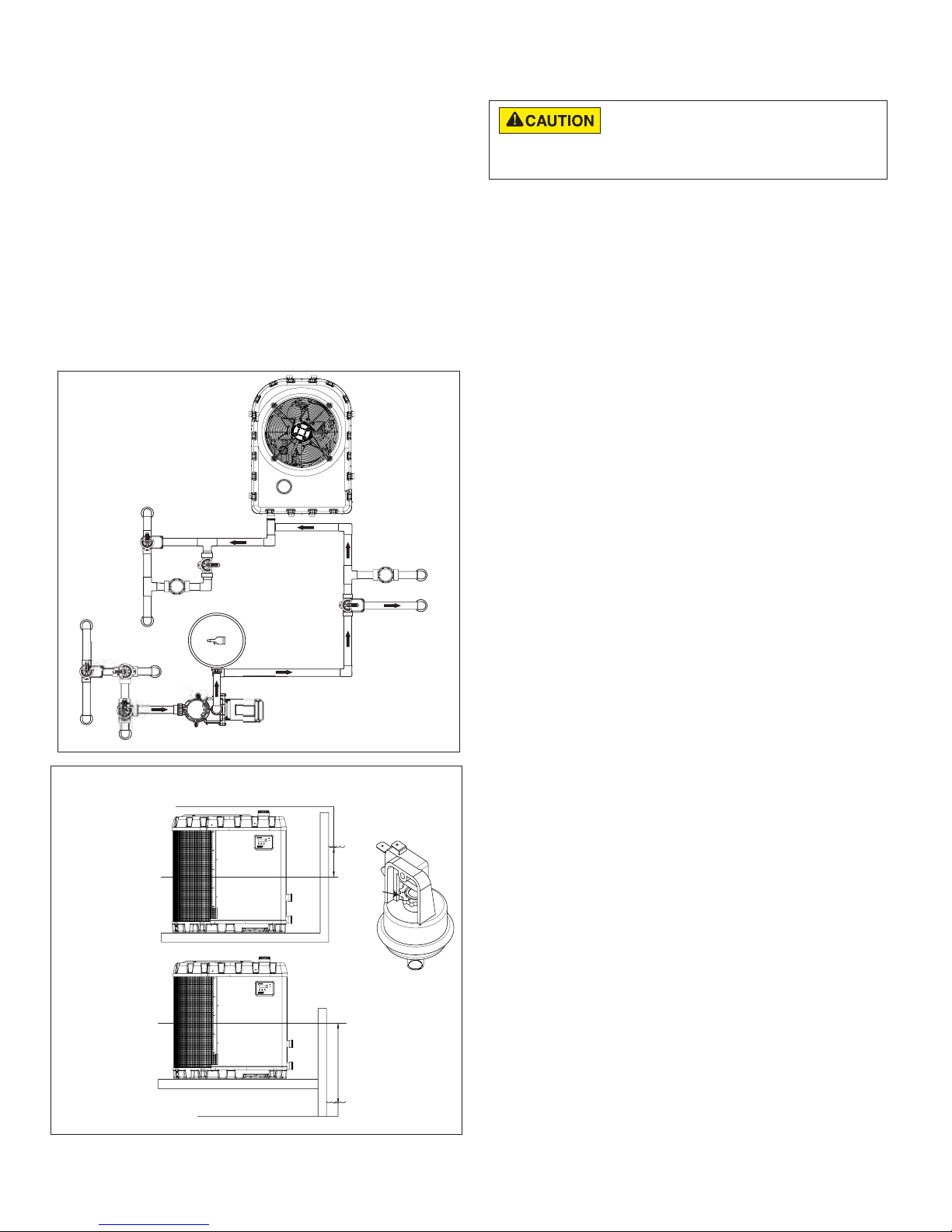

System Layout

The image below shows the standard plumbing layout with

a single UltraTemp ETi™ Hybrid Heater unit. Follow Figure

7 from right to left for the standard plumbing sequence.

Arrangement of pool system components (other than the

standard plumbing image below), and the location of the

heater (above or below the pool water surface) can affect

the operation of the heater’s water pressure switch.

The pressure switch can be adjusted to accommodate this

effect if the heater water connections are no more than six

(6) feet [1.82 m] below the pool water surface.

See instructions for pressure switch adjustment on pages

10-11. If the heater is installed outside of this range, an

external water flow switch may need to be installed in the

plumbing upstream of the heater.

Note:

Be advised that when pool equipment is located

below the pool surface a leak can result in large-scale

water loss or flooding. Pentair is not responsible for such

water loss or flooding or damage.

Figure 7

Heater

ULTRATEMP ETI™ Hybrid Heater Installation and User’s Guide

Base

Concrete Pad

1/4” Stainless

Steel Washer

(not included)

Anchor Clamp

Figure 6

PUMP

Internal Automatic Flow

Control Valves

The inlet/outlet header of the UltraTemp ETi™ Hybrid

Heater comes equipped with an internal water

management system with two automatic flow control

valves. The automatic flow control valves maintain the

proper flow through the heater at rates up to 120 gpm

(454 lpm). If the filter system flow rate is higher than

120 gpm (454 lpm), install a manual bypass valve.

Note:

Be advised that if your circulation pump is over 2

HP or if the total flow exceeds 120 gpm (454 lpm), you

will have to add an external bypass valve. Excess water

flow will damage the heat exchanger.

Water Connections and Plumbing

Always be sure that flow requirements and pool

water turnover rates can be maintained with the

installation of additional equipment and plumbing restrictions.

2 in. Quick Connect fittings have been installed on the

water inlet and outlet connections. Filtered cool water

is plumbed to the heater.

Plastic piping (PVC Schedule 40) should be

connected to the heater. The unions, provided with the

unit, accept 2 in. PVC pipe.

The heater requires proper water flow and pressure for

its operation. To properly operate the heater requires a

flow rate of at least 30 GPM, but optimal performance

is achieved at 50 GPM. The maximum working

pressure for the system is 50 PSI.

See Figure 8 for the recommended installation. The

filter pump discharges to the filter, the filter discharges

to the heater, and the heater discharges directly to the

pool or spa.

A manual bypass valve should be installed before the

heater when the pump flow exceeds 120 GPM (454

LPM).

Make sure that the outlet plumbing from the heater

contains no shut-off valves or other flow restrictions

that could prevent flow through the heater (except for

pool installations as noted below, or winterizing valves

where needed). To switch flow between the pool and

spa, use a diverter valve. Do not use any valve that

can shut off the flow.

Install the chemical feeder downstream of the heater.

Install a chemical resistant one-way check valve

between the heater and the chemical feeder to prevent

back-siphoning through the heater when the pump is

off.

Note: If the heater is plumbed in backwards, it will

cycle continuously. Make sure piping from filter is not

reversed when installing heater.

Connect the heater directly to 2 in. PVC pipe, using

the provided unions. Heat sinks are not required.

The low thermal mass of the heater will prevent

overheating of the piping connected to the pump even

if the heater shuts down unexpectedly.

7

Occasionally a two-speed pump will not develop enough

pressure on the low speed to operate the heater. In this case,

run the pump at high speed only to operate the heater. If

this does not solve the problem, do not try to run the heater.

Instead, correct the installation.

Do not operate the heater while an automatic pool cleaner is

also operating. If the circulation pump suction is plugged (for

example by leaves), there may not be adequate flow to the

heater. Do not rely on the pressure switch in this case.

Main

Drain

Pool

From Pool

3-Way

Valve

Spa

3-Way

Valve

Chlorinator

Check Valve

Filter

Pump

3-Way

Valve

Figure 8

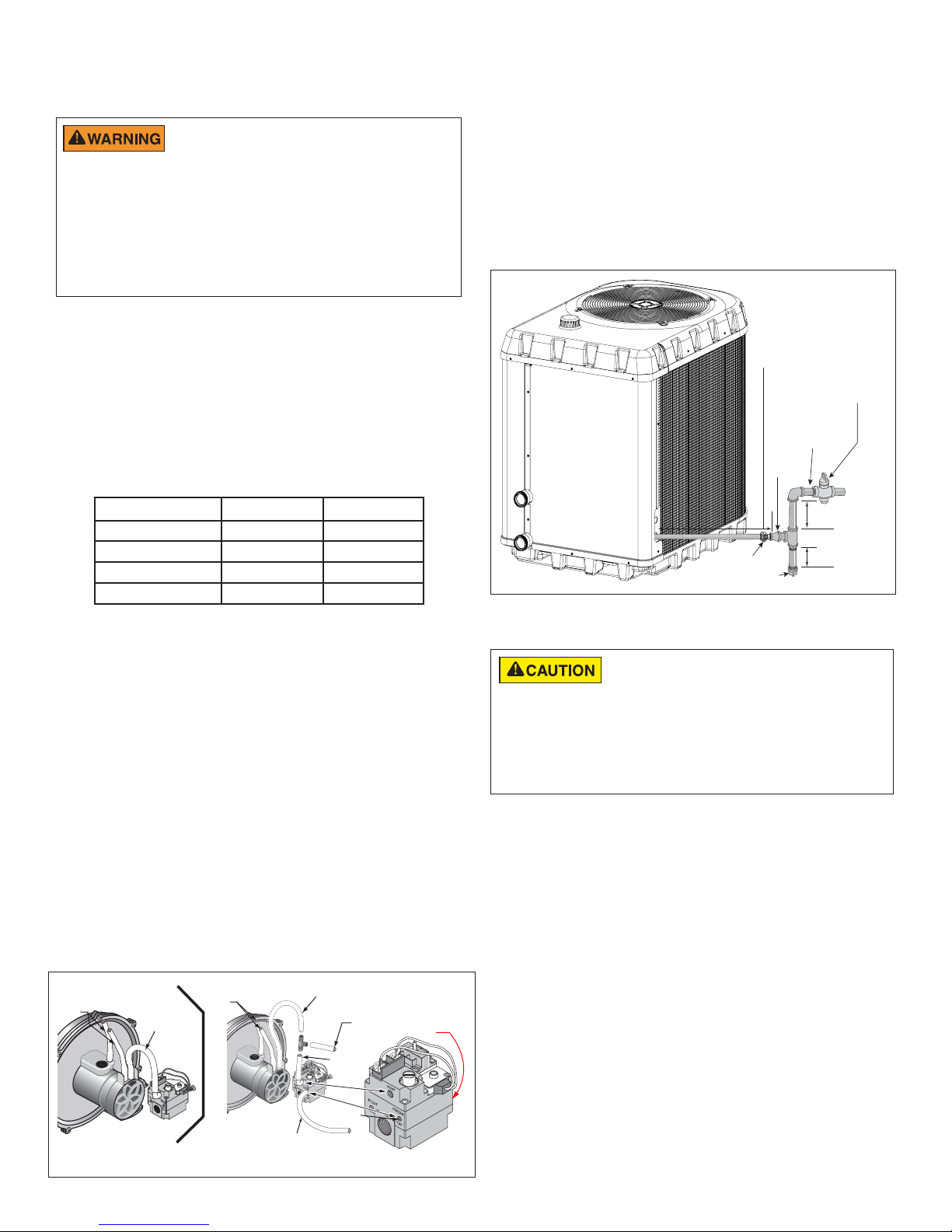

Heat Pump Drainage Connection

Condensation (water) will be produced while the heat pump

is in operation. The heater base is designed to allow the

condensation to exit through the bottom drain port when the

unit is running.

Before operating the heater for the first time, the drain hose barb

must be installed into the threaded drain port located in the base

of the heater.

To install the Drain Hose Barb and Drain Hose:

1. Thread the drain hose barb into the threaded drainage port in

the base of the heater. See Figure 9.

2. Connect a 5/8” garden hose to the hose barb.

3.

Ensure the end of the garden hose is positioned so that drainage

will flow away from the heater and equipment pad.

Figure 9

DRAIN HOSE BARB

5/8" X 1/2" NPT

HEAT PUMP

DRAINAGE PORT

ENGLISH

ULTRATEMP ETI™ Hybrid Heater Installation and User’s Guide

8

Isolation and Check Valves

When any equipment is located below the surface

of the pool or spa, valves should be placed in the

circulation piping system to isolate the equipment from

the pool or spa. Check valves are recommended to

prevent back-siphoning. Back-siphoning is most likely

to occur when the pump stops, creating a pressuresuction differential. Do NOT sanitize the pool by

putting chlorine tablets or sticks into the skimmer(s).

When the pump is off, this will cause a high

concentration of chlorine to enter the heater, which

could cause corrosion damage to the heat exchanger.

Exercise care when installing chemical feeders

so as to not allow back siphoning of chemical into

the heater, filters or pump. When chemical feeders are installed in the

circulation of the piping system, make sure the feeder outlet line is down

stream of the heater, and is equipped with a positive seal noncorrosive

Check Valve, (P/N R172288), between the feeder and heater.

Manual By-Pass Valve

Where the water flow rate exceeds the maximum

120 GPM, a manual bypass should be installed. After

installing the valve, adjust the valve to bring the flow

rate within the acceptable range. Then remove the

valve handle or lock it in place to avoid tampering.

Lower Gas Engine

Manifold Plug

Figure 10

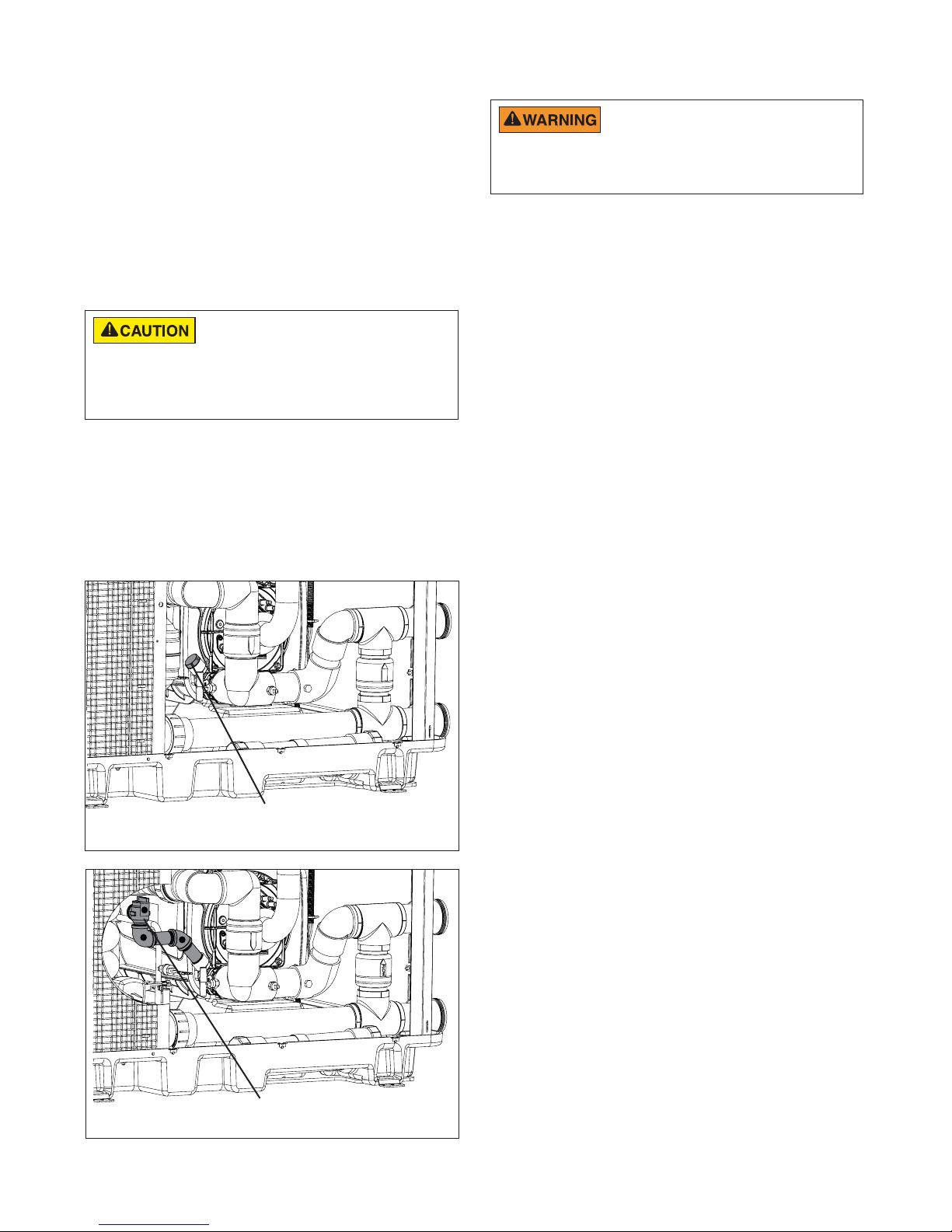

Pressure Relief Valve (PRV)

Ex p los i o n ha zar d ! A n y he ate r ins t all e d

with restri ctive devices in th e piping system

downstream from the heater, (including check valves, isolation valves,

flow nozzles, or therapeutic pool valving), must have a relief valve

installed as described in this section.

Canadian code, and some U.S. local codes, may

require installation of a Pressure Relief Valve (PRV).

Purchase and install a Hybrid Pressure Relief Valve

Kit (P/N 475943) complying with the ANSI/ASME

Boiler and Pressure Vessel Code, having a capacity

equal to the Btu/hr rating of the heater.

Note: The relief pressure of the valve MUST NOT

EXCEED 50 PSI. The relief valve must be installed

vertically.

To install the pressure relief valve:

Note: Be sure to use threaded seal tape (PTFE) or

equivalent, on all threaded metal pipe connections.

1. Remove the heater service panel.

2. Remove the lower gas engine manifold 3/4” brass

plug. See Figure 10.

3. Thread the Schedule 40 brass pipe and 45-degree

elbow [1], included in the PRV kit, into the lower

gas engine manifold. The elbow should be oriented

so that the elbow’s female thread is horizontal. See

Figure 11.

4. Thread the second Schedule 40 brass pipe and

90-degree elbow [2] into the 45-degree elbow [1].

Ensure that the open end of the 90-degree elbow is

oriented vertically. See Figure 11.

5. Install the Pentair pressure relief valve (P/N

072138), included in the PRV kit, or an equivalent

50 PSI 3/4” ASME-Type IV relief valve [3] into the

90-degree elbow [1]. See Figure 11.

Note: Ensure the relief valve is oriented so the

outlet is facing straight into the heater and will not

direct towards the service panel.

6. Inspect the valve annually to ensure proper

operation. Replace if improper operation is

determined.

!

"

Pressure Relief

Valve (Installed)

ULTRATEMP ETI™ Hybrid Heater Installation and User’s Guide

Figure 11

Extend 12" (305 mm)

past end heater

inlet for hydraulic

balancing

Extend 12" (305 mm)

past end heater

inlet for hydraulic

balancing

From Pool Pump

Flow Meter

Minimum

2" PVC Pipe

2" PVC Pipe

Flow Meter

To Pool

OPTIONAL

2" Check Valve Bypass

Check Valves are

optional on heater inlets

but will help system

balancing

36"

(914 mm)

12"

Extend 12"

(305 mm) past

end heater

inlet for hydraulic

balancing

Extend 12" (305 mm)

past end heater

inlet for hydraulic

balancing

From Pool Pump

Flow Meter

Minimum

3" PVC Pipe

2" PVC Pipe

Flow Meter

To Pool

3" Ball Valve Bypass

Check Valves are

optional on heater inlets

but will help for system

balancing

36"

(914 mm)

2" PVC Pipe2" PVC Pipe

2" PVC Pipe

3" PVC Pipe3" PVC Pipe

120 GPM (456 lpm)

Minimum

(305 mm)

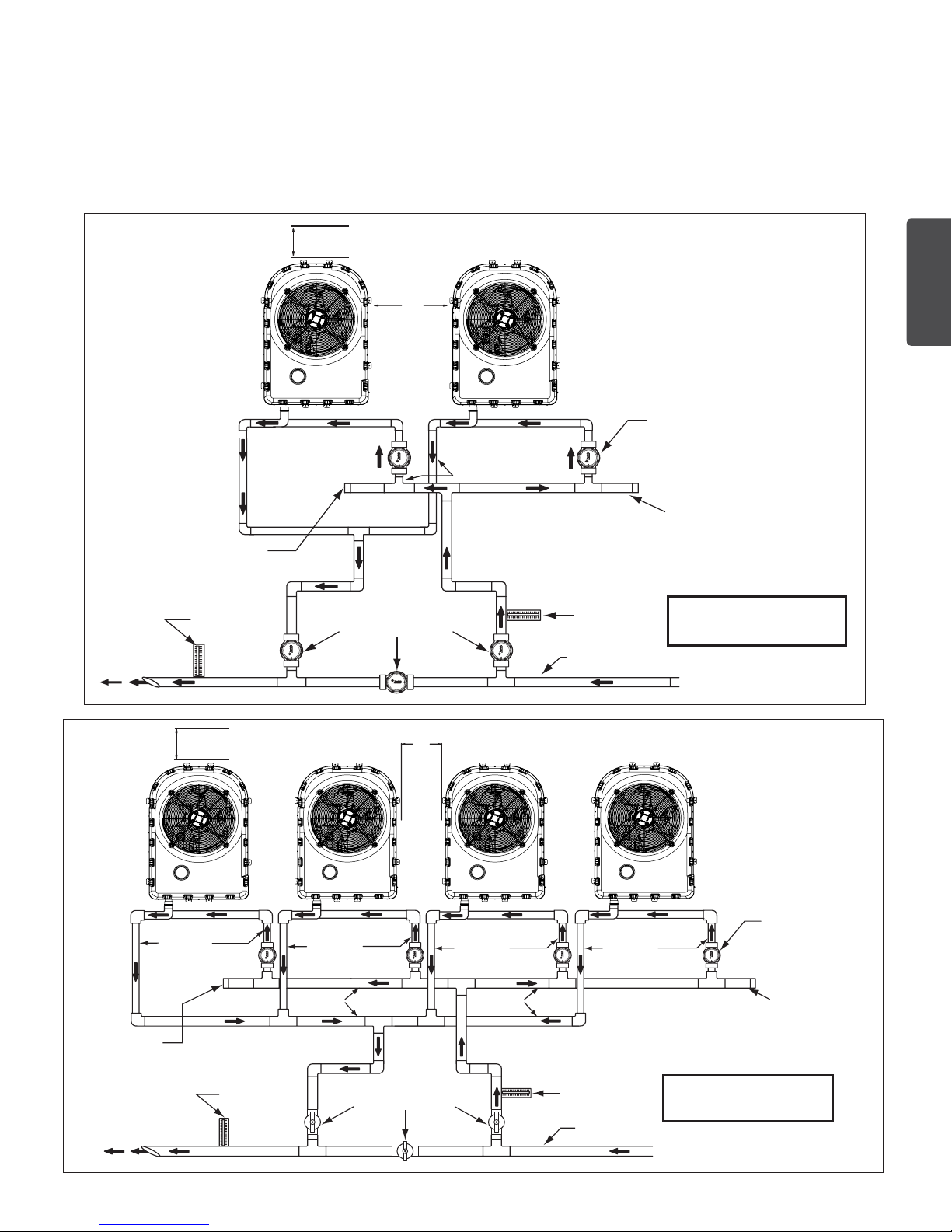

Multi-Heater Installations

All plumbing on multiple heater installations must be done in parallel (see Figure 12 and 13 below). An equal flow of

water to each heater is important for optimum operation.

Note: It may be necessary to adjust the water pressure switch if a unit is installed below the water level. Refer to page

10-11 for details on when and how to adjust the pressure switch.

Each heater in a multiple unit installation allows a maximum flow rate of 100 gpm (380 lpm) and requires a minimum

of 30 gpm (110 lpm).

9

(305 mm)

Figure 12

Dual Heater Layout

60 GPM (220 lpm)

Minimum

ENGLISH

12"

Figure 13

Multiple Heater

Layout

ULTRATEMP ETI™ Hybrid Heater Installation and User’s Guide

10

FILTE

S

SPA

OOL

A

RETURN

OOL

N

CHECK

VALVE

FROM SOLAR

TO SOLAR

PUMP

POOL

DRAIN

SPA

DRAIN

CHECK

VALVE

SPA

MAKE-UP

Solar Installations

The UltraTemp ETi™ Hybrid Heater can be used in

combination with other heating schemes such as solar. All

heat sources must be plumbed in series to work correctly

and efficiently.

A recommended plumbing layout for a heater-solar

combination heating system for a pool / spa combination

is shown below (Figure 14). Your system may not contain

all of these components, but the basic plumbing will apply

by eliminating the component in the illustration that is not a

part of your system.

Note: Water temperatures produced by supplemental

heating sources, such as solar, are not regulated or

controlled by the heater and may exceed the maximum

temperature allowed.

P

RETUR

P

SP

Figure 14

Heater-Solar Layout

Turn star wheel clockwise to raise

pressure set point

Turn star wheel counterclockwise to

lower pressure set point

A reference scale is on

the back of pressure switch

Water Pressure

Figure 15

Switch

Star Wheel

Water Pressure Switch Adjustment

The water pressure switch should be adjusted to turn

the heater off when the pump is off. Setting the switch

to close at too low of a flow can damage the appliance. Adjust the switch to

turn the heater off, not on.

The pressure switch is preset at the factory for activation

at 6 psi [41.4 kPa]. This factory setting works for most

basic installations. Only adjust the water pressure switch

if the heater does not operate when the proper flow is

applied to unit or if the heater does not shut off when

the filter pump is off. Occasionally, unusual plumbing

configurations or necessary restrictions in the plumbing

may cause pressure sensing problems. In these rare

situations, the plumbing system configuration may require

adjustment of the water pressure switch.

Adjustment of the pressure switch may be necessary if any

part of the filter system piping is 3 feet [0.91 m] or more

above the top of the heater.

In general, if the heater is installed more than 6 feet [1.83 m]

below the pool surface, an external water flow switch must

be added to the plumbing system.

On some installations, the piping from the heater to the pool

is very short. The back pressure could be too low to trigger

the pressure switch. If this happens, install a directional

fitting or elbow where the return line enters the pool. This

will increase back pressure for the heater to operate properly.

Be sure to check that the system flow is above the minimum

requirement of 30 gpm (110 lpm) after the directional fitting

installation.

Be sure the pool filter is clean before making any pressure

switch adjustment: A dirty filter will restrict the water flow and

the pressure switch cannot be adjusted properly.

To adjust the pressure switch:

The following adjustment is for installations where the

heater is

1. Be sure that all valves in the system are set to allow

2. Set the heater temperature above the actual temperature

3. Once the heater is running, turn off the filter pump. The

4. If the heater continues to operate when the filter pump is

5. Remove the heater’s left front panel and remove

6. Slowly rotate the adjustment wheel on the water pressure

below pool water level.

water flow through the heater. Start the filter pump.

to call for heat. Turn the heater ON.

heater should turn off immediately.

off, then the water pressure switch needs to be adjusted.

remaining right front panel. The water pressure switch

is located in the water plumbing in the lower corner of

the heater.

switch in a counterclockwise direction until the “LOW

WATER FLOW” Alarm shows on the LCD, the red

SERVICE light turns ON, and the heater stops. See

Figure 15.

ULTRATEMP ETI™ Hybrid Heater Installation and User’s Guide

Water Pressure Switch Adjustment (cont.)

7. Check the setting of the water pressure switch by

starting and stopping the filter pump and checking

the control panel and operation of the heater between

each flow change.

8. If the water pressure switch cannot be adjusted to

accommodate the conditions listed above, an external

flow switch must be added to the plumbing system

to ensure that the heater will not operate without the

proper flow through the heat exchanger.

The following adjustment is for installations where the

heater is above pool water level.

1. Be sure that all valves in the system are set to allow

water flow through the heater. Start the filter pump.

2. Set the heater temperature above the actual

temperature to call for heat. Turn the heater ON.

3. If the LCD shows a “LOW WATER FLOW” Alarm and

red SERVICE light is present then the water pressure

switch needs to be adjusted.

4. Remove the UltraTemp ETi™ Hybrid Heater’s left front

panel and remove remaining right front panel. The

water pressure switch is located in the water plumbing

in the lower corner of the heater.

5. Slowly rotate the adjustment wheel on the water

pressure switch in a counterclockwise direction until

the “LOW WATER FLOW” Alarm and red SERVICE

light vanish, time delay countdown will start.

6. Once the heater is running, turn off the filter pump. The

heater should turn off immediately.

7. If the heater continues to operate when the filter pump

is off, turn the adjustment wheel on the water pressure

switch in a clockwise direction until the “LOW WATER

FLOW” Alarm shows on the LCD, the red SERVICE

light turns ON, and the heater stops.

8. Check the setting of the water pressure switch by

starting and stopping the filter pump and checking

the control panel and operation of the heater between

each flow change.

9. If the water pressure switch cannot be adjusted to

accommodate the conditions listed above, an external

flow switch must be added to the plumbing system

to ensure that the heater will not operate without the

proper flow through the heat exchanger.

11

Gas Connections

The use of Flexible Gas Connectors (FLEX) is NOT

recommended unless they are properly sized according

to the supplier recommendations for the heater rating. In all cases, the

connectors must be bonded to the electrical service grounding point or, when

provided, the lighting protection grounding point according to the latest edition

of the National Fuel Gas Code.

Gas Line Installation

When sizing gas lines, calculate three (3) additional feet of

straight pipe for every elbow used. When installing the gas

line, avoid getting dirt, grease or other foreign material in

the pipe as this may cause damage to the gas valve, which

may result in heater failure.

The gas meter should be checked to make sure that it will

supply enough gas to the heater and any other appliances

that may be used on the same meter. The gas line from

the meter will usually be of a larger size than the gas

valve supplied with the heater. Therefore a reduction of the

connecting gas pipe will be necessary. Make this reduction

as close to the heater as possible.

The heater requires a gas supply of no less than 4 in.

(10.2 cm) wc, and no more than 10.5 in. (27 cm) wc for

natural gas (no more than 14 in. [36cm] for propane gas).

Gas supply pressures outside of this range may result in

improper burner operation. A minimum flowing or dynamic

inlet pressure (while the heater is running) of 4 in (10.2 cm)

wc is required to maintain input rating with no more than a

2 in. pressure drop between static and dynamic. The gas

supply must be installed in accordance with the National

Fuel Gas Code, ANSI Z223.1, or standard CSA B149.1,

Natural Gas and Propane Installation Codes, as applicable

and all applicable local codes. Install a manual shut-off

valve and a sediment trap and union located outside the

heater panels, see Figure 17 on the next page. Do not

use a restrictive gas cock. The following minimum gas pipe

sizes are recommended for natural gas supply piping, see

Table 1 below. Check for compliance with local codes.

The heater and any other gas appliances must be

disconnected from the gas supply piping system during

any pressure testing on that system, (greater than ½

PSI). The heater and its gas connection must be leak

tested before placing the heater in operation. Do not use

flame to test the gas line. Use soapy water or another

nonflammable method.

Note: A manual main shut-off valve for the heater must

be installed externally.

Do NOT install the gas line union inside the heater cabinet.

This will void the warranty.

ENGLISH

Model # BTUs

220 110,000 50’ 80’ 125’ 250’ 450’ 600’ - - - - - -

3/4” 1” 1-1/4” 1-1/2” 2” 2-1/2”

NG PRO NG PRO NG PRO NG PRO NG PRO NG PRO

Table 1: Gas Pipe Sizing

MAXIMUM EQUIVALENT PIPE LENGTH (FT.)

Natural Gas at 1000 B.T.U. per Cubic Ft.

Propane Gas at 2500 B.T.U. per Cubic Ft.

ULTRATEMP ETI™ Hybrid Heater Installation and User’s Guide

12

Manual

Shut-off

Valve

Sediment Trap

Union

At least 9-in (23 cm)

At least 3-in (8 cm)

1-in (3 cm) Diameter

or larger

(See

Recommended Pipe

Sizes Chart)

18–24-in of 3/4-in

Gas line from

Valve

Bell

Reducer

Checking Gas Pressure Through Gas

Control Valve

Risk of explosion if a unit burning propane gas is

installed in a pit or other low spot. Propane is heavier

than air. Do not install the heater using propane in pits or other locations

where gas might collect. Consult your local building code officials to determine

installation requirements and specific installation restrictions of the heater

relative to propane storage tanks and filling equipment. Installation must meet

the requirements for the Standard for the Storage and Handling of Liquefied

Petroleum Gases, CAN/CSA B149.2 (latest edition) or ANSI/NFPA 58 (latest

edition). Consult local codes and fire protection authorities about specific

installation restrictions.

The UltraTemp ETi™ Hybrid Heater is 100% factory

tested, however Pentair recommends installations

be tested to ensure proper combustion and optimal

performance. During the initial startup, run the heater

continuously for at least 10 minutes and then insert a

probe connected to a combustion analyzer capable of

reading CO and either CO2 or O2 into the exhaust vent.

Wait for the reading to stabilize and confirm values are

consistent with ranges in Table 2. If combustion values are

outside of these ranges, contact technical support.

Measured Gas High Low

CO 150 -

CO

2

O

2

Air-Free CO 199 -

9.2 7.8

7.2 4.8

Table 2

This appliance is equipped with an unconventional gas

control valve that is factory set with a manifold pressure of

–.2” (–0.5cm) wc. Installation or service must be performed

by a qualified installer, service agency, or the gas supplier.

If this control valve is replaced, it must be replaced with an

identical control.

The combination gas valve incorporates dual shut-off

valves and a negative-pressure regulator. For proper

operation, the regulated pressure at the outlet manifold of

the valve must be –0.2” (–0.5cm) wc below the reference

pressure at the blower mixer inlet, and the gas valve

‘VENT’ tap must be connected to the end cap air orifice as

shown in Figure 16.

Do not attempt to adjust the gas input by adjusting the

regulator setting. The correct gas regulator setting is

required to maintain proper combustion and must NOT be

altered.

To Gas

To Air Flow

Switch

To Gas

Valve Vent

To Air Flow

Switch

Valve Vent

To Low Side of

Differential Pressure Gauge

Vent

Pressure Tap

To High Side

of Differential

Pressure Gauge

Pressure Tap

Inlet

Figure 16

Sediment Traps

Install a sediment trap and union located outside

the heater panels in accordance with National code

requirements. Do not use a restrictive gas cock. The

sediment trap shall be either a tee fitting with a capped

nipple in the bottom outlet which can be removed for

cleaning, as shown in Figure 17, or an other device

recognized as an effective sediment trap. All gas piping

should be tested after installation in accordance with local

codes.

Figure 17

Gas Pressure Testing

The heater and its manual shut-off valve must be

disconnected from the gas supply during any pressure

testing of that system at test pressures in excess of 1/2 psi (3.45 Kpa).

Dissipate test pressure in the gas supply line before reconnecting the

heater and its manual shut off valve to gas supply line. Failure to follow

this procedure may damage the gas valve. Over pressurized gas valves

are not covered by warranty. The heater and its gas connections shall be

leak tested before placing the appliance in operation.

Before operating the heater, the heater and its gas

connections must be leak tested. Do NOT use an open

flame to test for leaks. Test all gas connections for leaks

with soapy water or another non-flammable method.

The heater and its individual shut-off valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in

excess of 1/2 psig (3.5 kPa). The heater must be isolated

from the gas supply system by closing its individual

manual shut-off valve during any pressure testing of the

gas supply at test pressures equal to or less than 1/2 psig

(3.5 kPa).

Note: Do not use threaded seal tape on gas line pipe

thread. A pipe compound rated for use with natural and

propane gases is recommended. Apply sparingly only on

male pipe ends, leaving the two end threads bare.

ULTRATEMP ETI™ Hybrid Heater Installation and User’s Guide

Loading...

Loading...