Pentair ULTRATEMP User Manual

ULTRATEMP®

ENGLISH

HEAT PUMP

FRANÇAIS

ESPAÑOL

INSTALLATION AND

USER’S GUIDE

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

i

IMPORTANT WARNING AND SAFETY INSTRUCTIONS

Important Notice:

This guide provides installation and operation instructions for

this heat pump. Consult Pentair with any questions regarding

this equipment.

Attention Installer: This guide contains important information about

the installation, operation and safe use of this product. This information

should be given to the owner and/or operator of this equipment after

installation or left on or near the heat pump.

Attention User: This manual contains important information that will

help you in operating and maintaining this heat pump. Please retain it

for future reference.

Before installing this product, read and follow

all warning notices and instructions which are

included. Failure to follow safety warnings and instructions can result

in severe injury, death, or property damage. Call (800) 831-7133 for

additional free copies of these instructions.

Codes and Standards

UltraTemp heat pumps are listed by ETL as complying with the

latest edition of the “UL Standard for Safety for Heating and Cooling

Equipment”, UL 1995 and CSA C22.2 No. 236.

All Pentair heat pumps must be installed in accordance with the local

building and installation codes as per the utility or authority having

jurisdiction. All local codes take precedence over national codes. In the

absence of local codes, refer to the latest edition of the National Electric

Code (NEC) in the United States and the Canadian Electric Code

(CEC) in Canada for installation.

RISK OF ELECTRICAL SHOCK OR

ELECTROCUTION. The electrical supply to

this product must be installed by a licensed, certified electrician or

qualified personnel in accordance with the National Electrical Code

and all applicable local codes and ordinances. Improper installation

will create an electrical hazard which could result in death or serious

injury to pool or spa users, installers, or others due to electrical

shock, and may also cause damage to property. Read and follow the

specific instructions inside this guide.

Do not permit children to use this product.

The following “Safety Rules for Hot Tubs”

recommended by the U.S. Consumer Product

Safety Commission should be observed when using the spa.

1. Spa or hot tub water temperatures should never exceed 104°F.

[40°C.]. A temperature of 100°F. [38°C.] is considered safe for

a healthy adult. Special caution is suggested for young children.

Prolonged immersion in hot water can induce hyperthermia.

2. Drinking of alcoholic beverages before or during spa or hot tub

use can cause drowsiness which could lead to unconsciousness

and subsequently result in drowning.

3. Pregnant women beware! Soaking in water above 100°F.

[38°C.] can cause fetal damage during the first three months of

pregnancy (which may result in the birth of a brain-damaged or

deformed child). Pregnant women should stick to the 100°F.

[38°C.] maximum rule.

4. Before entering the spa or hot tub, the user should check the

water temperature with an accurate thermometer. Spa or hot tub

thermostats may err in regulating water temperatures.

5. Persons with a medical history of heart disease, circulatory

problems, diabetes or blood pressure problems should obtain

their physician’s advice before using spas or hot tubs.

6. Persons taking medication which induce drowsiness, such as

tranquilizers, antihistamines or anticoagulants should not use

spas or hot tubs.

Hyperthermia occurs when the internal temperature of the body reaches

a level several degrees above normal body temperature of 98.6°F.

[37°C.]. The symptoms of hyperthermia include: drowsiness, lethargy,

dizziness, fainting, and an increase in the internal temperature of the

body.

The effects of hyperthermia include:

1. Unawareness of impending danger.

2. Failure to perceive heat.

3. Failure to recognize the need to leave the spa.

4. Physical inability to exit the spa.

5. Fetal damage in pregnant women.

6. Unconsciousness resulting in danger of drowning.

For units intended for use in other than single-

family dwellings, a clearly labeled emergency

switch shall be provided as part of the installation. The switch shall be

readily accessible to the occupants and shall be installed at least 5 feet

[1.52 m] away, adjacent to, and within sight of the unit.

Consumer Information and Safety

The UltraTemp series of heat pumps are designed and manufactured

to provide safe and reliable service when installed, operated and

maintained according to the information in this manual and the

installation codes referred to in later sections. Throughout the manual,

safety warnings and cautions are identified by the “ “ symbol. Be sure

to read and comply with all of the warnings and cautions.

The U.S. Consumer Product Safety Commission

warns that elevated water temperature can be

hazardous. See below for water temperature guidelines before setting

temperature.

ULTRATEMP

®

Heat Pump Installation and User’s Guide

General Specifications

Installation Location Certified for use:

OUTDOOR USE ONLY. Failure to provide the proper clearances

outlined on page 3 will lower the performance of the heat pump

and void the warranty.

Water Pipe/Heater Connection — Plastic 2” PVC (Unions included)

Flow Rate

Maximum 120 gpm [456 lpm] - If system flow rate exceeds 120 gpm, a

bypass valve is required.

Minimum 30 gpm [110 lpm]

Maximum Working Water Pressure 50 psi

For Electrical Supply and Voltage Requirements, refer to the table

on page 25.

CUSTOMER SERVICE / TECHNICAL SUPPORT

If you have questions about ordering Pentair replacement parts, and pool products, please use the following

contact information:

Customer Service

(8 A.M. to 4:30 P.M. — Eastern and Pacific Times)

Phone: (800) 831-7133

Fax: (800) 284-4151

Web site

Visit www.pentair.com for more information about

Pentair products.

Technical Support

Sanford, North Carolina (8 A.M. to 4:30 P.M. ET)

Phone: (919) 566-8000

Fax: (919) 566-8920

Moorpark, California (8 A.M. to 4:30 P.M. PT)

Phone: (805) 553-5000 (Ext. 5591)

Fax: (805) 553-5515

TABLE OF CONTENTS

ii

ENGLISH

Important Warning and Safety Instructions .......

Menu Tree Quick Start Guide ...............................

Before Installing the Heat Pump .........................

Heat Pump Overview

Installation Requirements

General Installation Information

General Features

Installation and Location .....................................

Materials Needed for Installation

Equipment Pad

Drainage and Condensation, Roof Run Off,

and Lawn Sprinklers

Heat Pump Dimensions

Location and Clearances

Anchor Clamp Installation

Water Connections and Plumbing

Automatic Flow Control Valve

Water Connections to the Heat Pump

Drainage Connection to the Heat Pump

Water Pressure Switch Adjustment

Multiple Unit Installation

Heat Pump, Heater, Solar Combination

Multiple Heat Pump Connections

Electrical Connections and Wiring

Wiring Diagram – (Single Phase – 50/60 Hz)

Wiring Diagram – (Three Phase – 60 Hz)

Connecting to an Automation System ...............

Remote Operation

Relay Remote Controls

Connecting to IntelliTouch or EasyTouch via

Heat Pump Spade Terminals

Connecting to IntelliTouch or EasyTouch via

RS-485 Connector

Pin Configuration for Heat Pump Control

Board to IntelliTouch

Connecting IntelliTouch or EasyTouch to

the Heat Pump

i

Operating the Heat Pump ...................................

iii

1

1

1

1

1

2

2

2

2

2

3

3

4

4

5

5

6

7

7

7

9

10

11

12

12

12

13

14

15

15

Swimming Pool Energy Saving Tips

Heat Pump Control Panel Overview

Operator Menu Tree Guide

Starting and Stopping the Heat Pump

Changing the Set Point - Pool and Spa

Heat, Cool, and Auto Modes

Heat Pump Timer

Relay Remote

RS-485 Remote (Serial Cable)

AutoSet Operation

Extend Operation

Timers and Delays

Control Panel Alarm Messages

Service Menu Tree Guide

Setting Temperature Scale

Set Water Temperature Offset

Defrost Cycle

Run Time Counters

Locking the Control Panel

Maintenance .........................................................

Water Chemistry

Winterizing

Spring Start Up

Inspection and Service

Owner Inspection

Professional Maintenance and Service

Technical Information .........................................

Electrical Supply - Voltage Requirements

Temperature Resistance Chart

Ambient/Water Flow Table for Professional

Maintenance and Service

Heat Pump Pressure Drop

Troubleshooting ...................................................

Replacement Parts ..............................................

Illustrated Parts View

Parts List

16

16

16

17

18

18

18

18

18

18

19

19

20

20

21

22

22

22

22

22

23

23

23

23

23

24

24

25

25

25

26

26

27

32

32

33

For pool energy saving tips, refer to page 16, under “Operating the Heat Pump”. For technical data, voltage

requirements, or ambient/water flow information, refer to page 25 at the back of the manual.

ULTRATEMP

®

Heat Pump Installation and User’s Guide

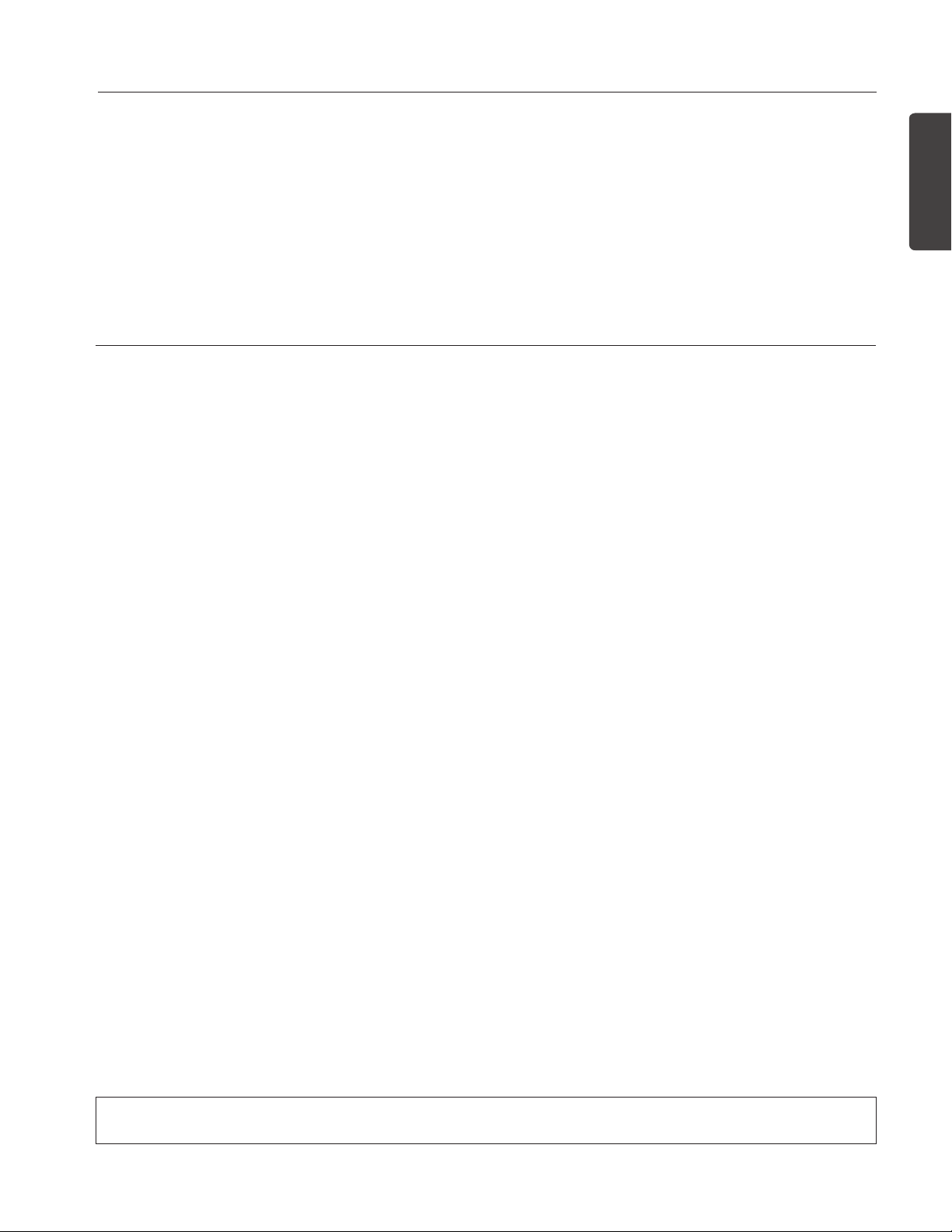

SERVICE

MENU TREE

LANGUAGE - IDIOMA - LANGUE

ENGLISH / ESPANOL / FRANCAIS

SOFTWARE VERSION

REV. ____

PUMP START TIME

TIME = 1 - 4 HRS

TEMPERATURE SCALE

FAHRENHEIT / CELSIUS

PRESS POOL/SPA

TO EXIT SETUP

WF HP LP PL SP

1 1 1 0 0

FAN COMP PMP REV

1 1 1 0

DEFROST

ENABLE / DISABLE

WATER TEMP OFFSET

OFFSET = -2 TO +2

PUMP START DELAY

TIME = 0 - 5 MINS

EXTEND

ENABLE / DISABLE

AUTOSET

ENABLE / DISABLE

†

††

RUN TIMES/COUNTS

OR TO VIEW

TEMP. RECORD

HOUR # ___ ___°F

INTELL ADDRESS

ADDRESS = 1-16

**

iii

ULTRATEMP® MENU TREE QUICK START GUIDE

1. Push the ON/OFF button to turn the unit on, the green “ON” light should be lit.

2. Select either Pool or Spa mode. The default is Pool mode.

3. Adjust the temperature to the desired setting by pushing either the UP arrow or DOWN arrow.

4. Allow 5 minutes for compressor restart delay.

See pages 17-22 for details on the Operator and Service menu screens on the control panel.

OPERATOR

MENU TREE

POOL

IDLE/HEAT/COOL

SET=__ ACT=__

SPA

IDLE/HEAT/COOL

SET=__ ACT=__

HEAT / COOL / AUTO

SET TO - H/C/A

HEAT PUMP RUNTIME

REMAINING = NONE

REMOTE MODE

OFF/RELAY/RS-485

AUTOSET

HEAT/COOL/AUTO

OVERRIDE IS ON/OFF

EXTEND

HEAT/COOL/AUTO

OVERRIDE IS ON/OFF

RESTART / PUMP START /

SENSING WATER TEMP

DELAYS

SUCTION TEMP

ACTUAL = ___

*

**

**

***

THE NUMBER ONE (1) IS

DISPLAYED WHEN THE

ASSOCIATED INPUT/

****

OUTPUT IS ON AND ZERO

(0) IS DISPLAYED WHEN

INPUT/OUTPUT IS OFF.

HEAT/COOL/AUTO MODE

Menu appears only if Heat and Cool mode is enabled

*

at the factory.

Menu appears only if AutoSet or Extend is enabled in the

**

Service menu.

Menu appears only if a delay is active.

***

Menu appears only if Defrost is enabled in the Service menu.

****

ULTRATEMP

ALARM STATUS

POOL/SPA

®

Heat Pump Installation and User’s Guide

INPUT STATUS

†

WF = WATER FLOW SWITCH

HP = HIGH REFRIGERANT PRESSURE SWITCH

LP - LOW REFRIGERANT PRESSURE SWITCH

PL - POOL REMOTE

SP - SPA REMOTE

††

OUTPUT STATUS

FAN - FAN

COMP - COMPRESSOR

PMP - FILTER PUMP

REV - REVERSING VALVE

BEFORE INSTALLING THE HEAT PUMP

1

Heat Pump Overview

Your Pentair heat pump will provide you with years of

heated pool enjoyment. Heat pumps operate by taking

heat from the surrounding air and transferring it into

the water. The warmer the air and the more humidity

in the air, the more latent heat is available for heating

your pool. With a properly sized heat pump for your

pool, the heat pump should raise your pool on average

1° F per hour depending on air temperature, humidity,

and water temperature. The ideal or rated condition for

the heat pump is 80° F air temperature, 80% relative

humidity, and 80° F water temperature. As conditions

decrease from 80/80/80, the heat pump performance

will decrease slightly.

Heat Pumps are best utilized to maintain a set water

temperature; they are not intended to provide instant

or fast heating. It is not reasonable to expect a heat

pump to perform like a gas heater which has a much

higher BTU output and faster response. Additionally,

gas heaters are not dependent on environmental

conditions. Swimming pool heat pumps are very similar

to home heating and air conditioning heat pumps and

therefore should be treated similarly.

Proper operation and use of the heat pump is to set

it at your desired temperature and leave it. Your heat

pump will turn on and off automatically to maintain your

desired temperature much like your home HVAC unit.

To take advantage of the sun’s energy, operate your

heat pump during the heat of the day.

Your heat pump will still operate when the temperature

drops at night, but the output will be decreased. It is

acceptable to shut the heat pump off and not use it

for extended periods of time. When you have a need

to heat your pool, please plan accordingly since it

may take the heat pump days to heat your pool back

to your desired temperature, depending on your pool

temperature and environmental conditions.

Heat Pump Installation Requirements

Correct installation is required to assure safe operation.

The requirements for Pentair heat pumps include the

following:

• Dimensions for critical connections.

• Field assembly (if required).

• Appropriate site location and clearances (pages

2-3).

• Proper electrical wiring (pages 9-11).

• Adequate water flow (page i).

This manual provides the information needed to

meet these requirements. Review all application and

installation procedures completely before continuing

the installation.

General Installation Information

1. Installation and service must be performed by a

qualified installer or service agency, and must conform

to all national, state, and local codes.

2. Heat pumps get electrical power from an external

source and provide a dual electronic thermostat

control system for pool/spa combinations or preheat

convenience.

3. This heat pump is specifically designed for heating

fresh water swimming pools and spas. Do not use it as

a general service heater. Consult your dealer for the

appropriate Pentair products for these applications.

General Features

• Dual digital thermostats offer precise temperature control

to maintain the desired separate water temperatures in

pool/spa combinations without overheating or wasting

energy.

• Long-life corrosion resistant composite plastic cabinet

stands up to severe climates and pool chemicals.

• 100% pure titanium heat exchanger assures corrosionfree performance for extra long life.

• Self-diagnostic control panel monitors and troubleshoots

heat pump operations to ensure safe, dependable

operation.

• Autoset (time clock over-ride) feature monitors water

temperature and turns the water circulation pump on and

off as needed to maintain desired pool temperatures.

• Extend (time clock over-ride) feature monitors water

temperature and turns the water circulation pump on and

off as needed to prolong a heating cycle that has been

interrupted.

• Automatic Defrost feature senses refrigerant temperature

and prevents the heat pump from freezing, allowing the

heat pump to operate at even lower temperatures.

• Compatible with all automated control packages. RS485 communication compatible with IntelliTouch® and

EasyTouch® Control Systems.

• Thermostatic expansion valve (TXV) controls refrigerant

flow for optimum efficiency and BTU output over a wider

operating range.

• Elevated base pan for positive drainage of condensation.

• 2-inch plumbing connections for easy installation.

• Separate isolated electrical compartment prevents

internal corrosion, extends heater life.

• Highest efficiency available, meets or exceeds existing

codes and standards.

• Adjustable timer allows the operator to set the heat

pump to run for a predetermined time. Incremental by 10

minutes to a maximum of 99 hours.

• An extensive list of operational conditions, alarms and

water temperatures are logged on the control board. This

information is available for the user to track performance

and troubleshoot issues.

ULTRATEMP

®

Heat Pump Installation and User’s Guide

ENGLISH

2

34.0"

(864 mm)

32.0"

(813 mm)

4.5"

(114 mm)

9.25"

(235 mm)

11.25"

(286 mm)

30.7"

(780 mm)

38.7"

(983 mm)

A

INSTALLATION AND LOCATION

When pool equipment is located below the pool surface, a leak from any component can cause large scale water loss or flooding.

Pentair Water Pool and Spa, Inc. cannot be responsible for such water loss or flooding which may cause damage to property or

to the product. Avoid placing the heat pump in locations where it can cause damage by water or condensate leakage. If this is not possible, provide a

suitable drain pan to catch and divert any leakage.

Only a qualified service person should install the

UltraTemp® Heat Pump. Before installing this product,

refer to the Important Warning and Safety Instructions

on page i.

Materials Needed for Installation

The following items are needed and are to be supplied

by the installer for all heat pump installations:

1. Plumbing connections (2-inch).

2. Level surface for proper drainage.

3. Suitable electrical supply line. See rating plate

on unit for electrical specifications. A junction

box is not needed at the heat pump; connections

are made inside of the heat pump electrical

compartment. Conduit may be attached directly to

the heat pump jacket.

4. Electric cutout switch that will interrupt all power

to the unit. This switch must be within line of

sight of the heat pump. Check local codes for

requirements.

5. Watertight conduit to run the electrical supply line.

Equipment Pad

For proper drainage of condensation and rain water,

place the heat pump on a flat slightly pitched surface,

such as a concrete or fabricated slab (pad).

If possible, place the pad at the same level or slightly

higher than the filter system equipment pad.

Note: Be sure that the pad is pitched not more than

1/4 in. per foot in any direction as needed for runoff.

Drainage and Condensation

Condensation occurs from the evaporator coil while

the unit is running, and drains at a steady rate (usually

three to five gallons per hour), depending upon ambient

air temperature and humidity. The more humid the

ambient conditions, the more condensation will be

produced.

The bottom of the unit acts as a tray to catch rainwater

and condensation. Keep the drain holes, located on the

bottom pan of the base of the unit, clear of debris.

Roof Run-off

Make sure the heat pump is not located where large

amounts of water may run-off from a roof into the

unit.

Sharp sloping roofs without gutters will allow massive

amounts of rain water, mixed with debris from the

roof to be forced through the unit. A gutter or down

spout may be needed to protect the heat pump.

Lawn Sprinklers

Avoid placing lawn sprinkler near the heater they can spray water into the heater and void the

warranty.

Be sure to direct any spraying water away from the

heater. Note the wind direction to be sure water from

sprinklers is not blown toward the heater. Sprinkler

heads can produce high water pressure and spray at

an angle, different from typical rain and humid weather.

Also, sprinklers connected to a well water system can

cause mineral build up on the evaporator coils and

electronics. Salt water can also be an issue if located

near the coast.

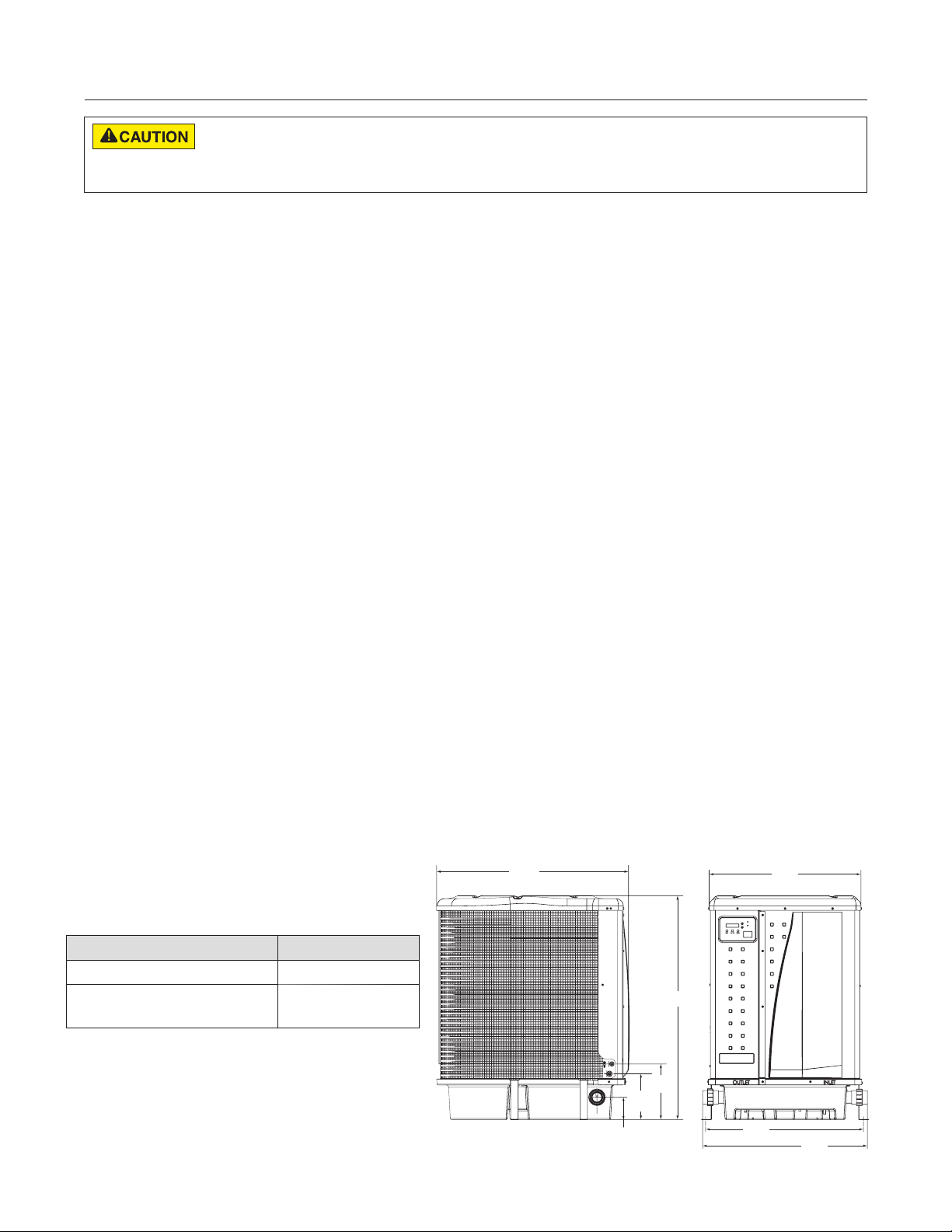

Heat Pump Dimensions

MODELS DIMENSION “A”

70, 90 33.5” (851 mm)

110, 120, 120C, 140C

120 H/C, 140, 140 H/C

ULTRATEMP

®

Heat Pump Installation and User’s Guide

45.5” (1156 mm)

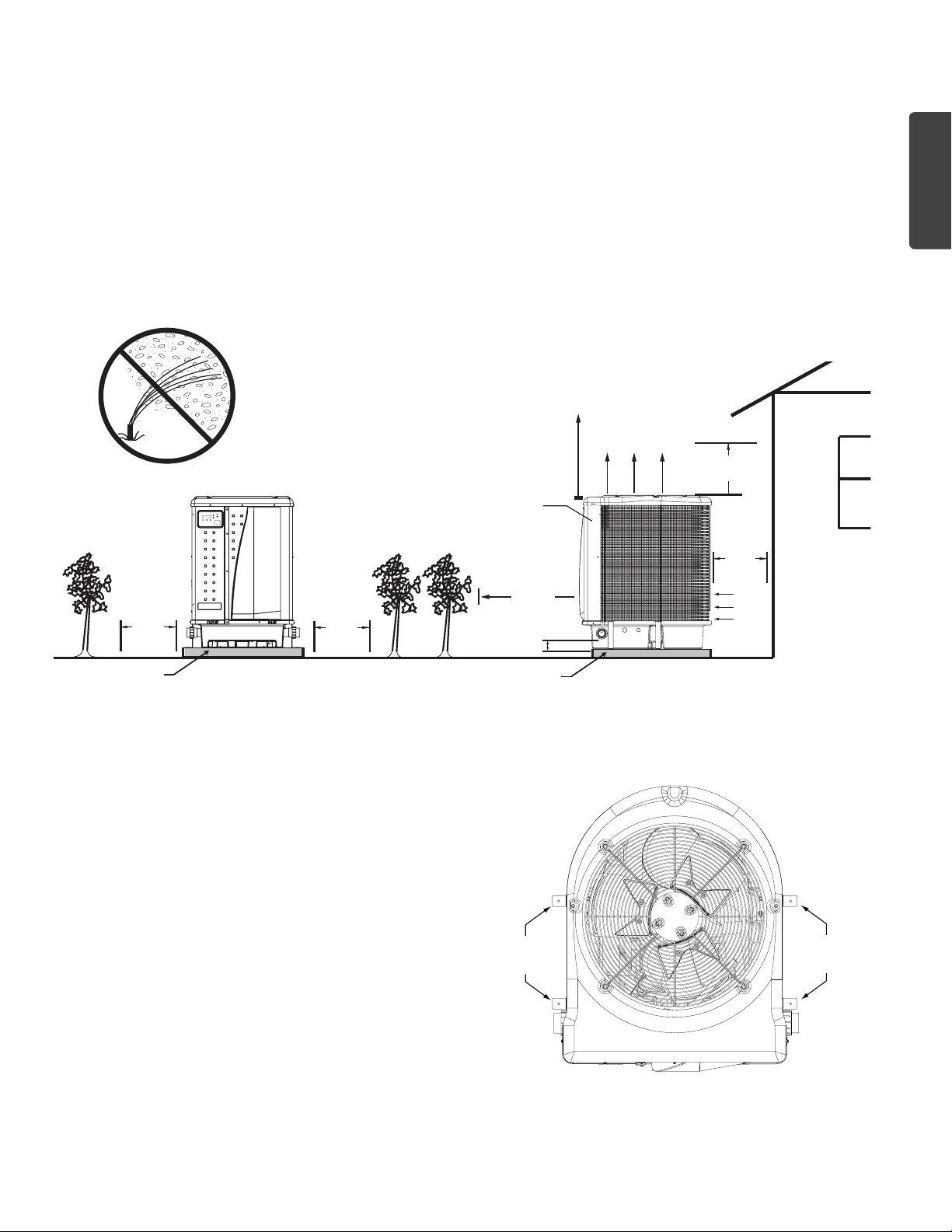

Location and Clearances

SLAB

SLAB

NO SPRINKLERS

Anchor

Clamps

Anchor

Clamps

All criteria given in the following sections reflect minimum

clearances. However, each installation must also be

evaluated, taking into account the prevailing local

conditions such as proximity and height of walls, and

proximity to public access areas.

The UltraTemp® Heat Pump must be placed to provide

clearances on all sides for maintenance and inspection.

1. At least 24 in. [610 mm] access must be available in

the front and 12 in. [305 mm] on all the other sides

of the heat pump for service and proper air flow.

(Manufacturer’s recommendation).

2. If the heat pump is to be installed under a cover

or under a vertical overhang, the unit must have

a minimum of five (5) feet [1.52 m] clearance

from the top of the heat pump. (Manufacturer’s

recommendation).

3. Install a minimum of five (5) feet [1.52 m] from the

inside wall of the pool or spa unless the heat pump

is separated from the pool or spa by a five (5)

foot [1.52 m] high solid fence or other permanent

barrier. Canadian installations require a minimum

of three (3) meters [9.84 ft] from pool water.

4. Install heat pump a minimum of 6 in. [153 mm] from

the wall of the house.

OPEN

3

ENGLISH

12"

min.

(305 mm)

12"

min.

(305 mm)

Heat Pump Location and Clearances

Anchor Clamp Installation

Installation of the anchor clamps is recommended in

all installations. Installation of the anchor clamps is

required in Florida (see Florida Building Code 301.13).

Anchor clamps hold the heat pump to the equipment

pad in order to withstand high winds caused during

extreme weather (i.e. hurricanes).

To install the anchor clamps:

1. Be sure the heat pump is in its permanent location

on the equipment pad.

2. Place the clamps at the base of the heat pump in the

four (4) locations, shown in the image to the right.

Note: Bolts and bolt anchors are not included

with the heat pump. The installer must provide

1/4” x 1-3/8” stainless steel anchor bolts and the

appropriate size concrete anchor to mount the clamp

to the equipment pad. Be sure to check local codes.

3. Fit the hook of each clamp over the lip on the base

panel of the heat pump. The hook should fit between

the lip of the base panel and the evaporator coil

guard.

EVAPORATOR

COILS

SERVICE

ACCESS

24" min.

(610 mm)

3"

(76 mm)

AIR FLOW OUT

OVER HANG

5

FT min.

(1.52 m)

"

6

min.

(153 mm)

AIR

FLOW

IN

Anchor Clamp Installation

ULTRATEMP

®

Heat Pump Installation and User’s Guide

4

HEAT PUMP

CHEMICAL FEEDER

OR CHLORINATOR

TO POOL OR SPA

POOL PUMP

FROM POOL OR SPA

FILTER

MANUAL BYPASS VALVE

(Optional)

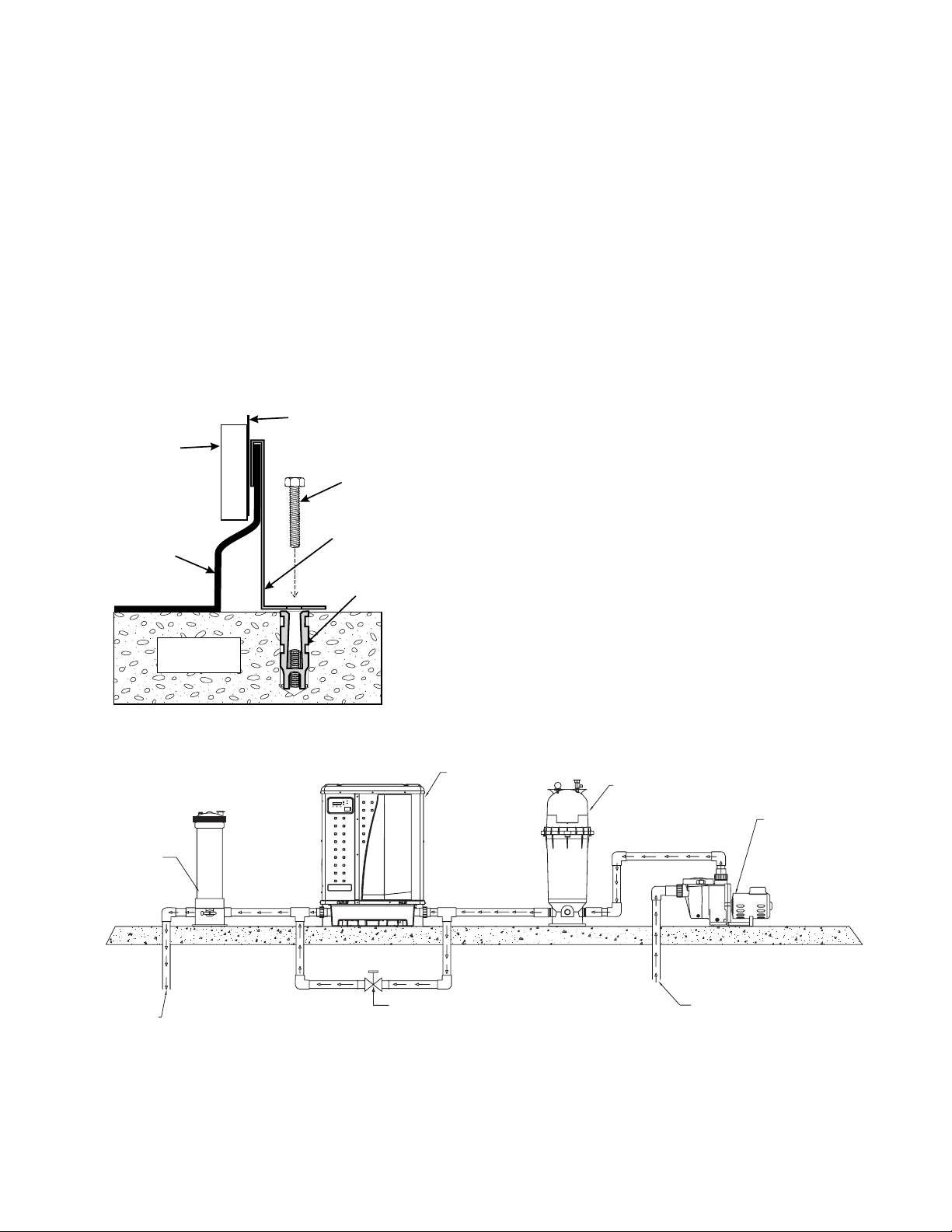

Anchor Clamp Installation, Continued

4. Mark the position of the hole in each clamp on the

equipment pad.

5. Use a masonry drill bit and drill a hole in the cement

with a diameter as determined by the concrete

anchor, at each of the marks on the equipment pad.

The hole should be approximately 1½ in. deep.

6. Insert a bolt anchor into each of the holes. Be sure

the anchors are set completely into the holes.

7. Position the anchor clamps so that the holes in the

clamps are over the bolt anchors.

Be sure that the clamp hooks are over the lip of the

heat pump base.

8. Insert an anchor bolt through each clamp into the anchor

and tighten to secure the clamp and heat pump to

the equipment pad.

AIR COIL GUARD

AIR

COIL

HEAT PUMP

BASE

EQUIPMENT PAD

CONCRETE

Anchor Clamp Installation

1-3/8" HEX BOLT

(installer provided)

ANCHOR CLAMP

BOLT ANCHOR

(installer provided)

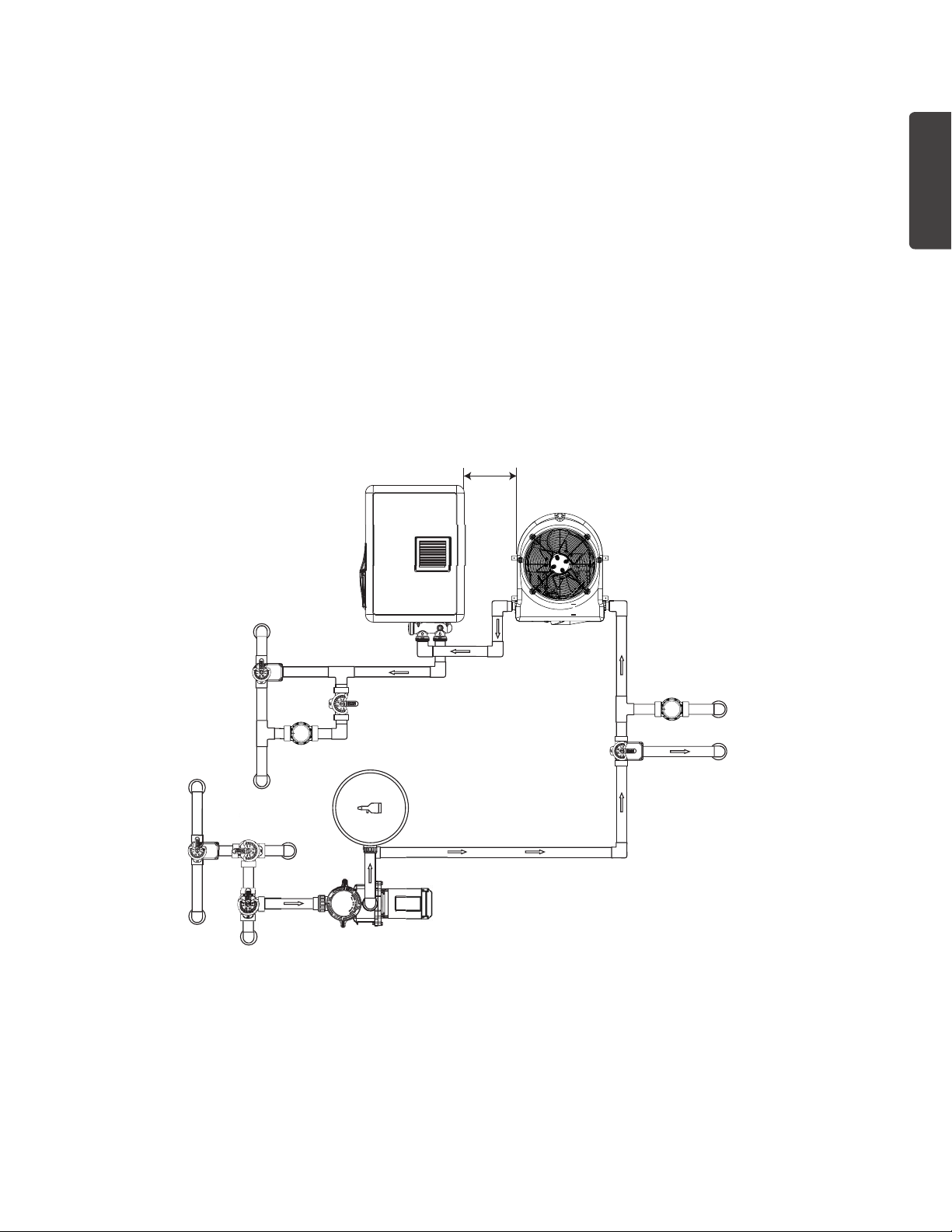

Water Connections and Plumbing

The image below shows the standard plumbing layout

with a single UltraTemp® Heat Pump unit. Follow the

image from right to left for the standard plumbing

sequence.

Arrangement of pool system components (other than the

standard plumbing image below), and the location of the

heat pump (above or below the pool water surface) can

affect the operation of the heat pump’s water pressure

switch.

The pressure switch can be adjusted to accommodate

this effect if the heat pump water connections are no

more than six (6) feet [1.82 m] below the pool water

surface.

See instructions for pressure switch adjustment on page

6. If the heat pump is installed outside of this range, an

external pressure switch may need to be installed in the

plumbing upstream of the heat pump.

Note: Be advised that when pool equipment is located

below the pool surface a leak can result in large-scale

water loss or flooding. Pentair is not responsible for such

water loss or flooding or damage.

Automatic Flow Control Valve

The inlet/outlet header of the heat pump comes equipped

with an internal automatic flow control valve. The

automatic flow control valve maintains the proper flow

through the heat pump at rates up to 120 gpm (456 lpm).

If the filter system flow rate is higher than 120 gpm (456

lpm), install a manual bypass valve, see image below.

Note: Be advised that if your circulation pump is over 2

HP or if the total flow exceeds 120 gpm (456 lpm), you

will have to add an external bypass valve. Excess water

flow will damage the heat exchanger.

ULTRATEMP

®

Heat Pump Installation and User’s Guide

Standard Plumbing Layout

5

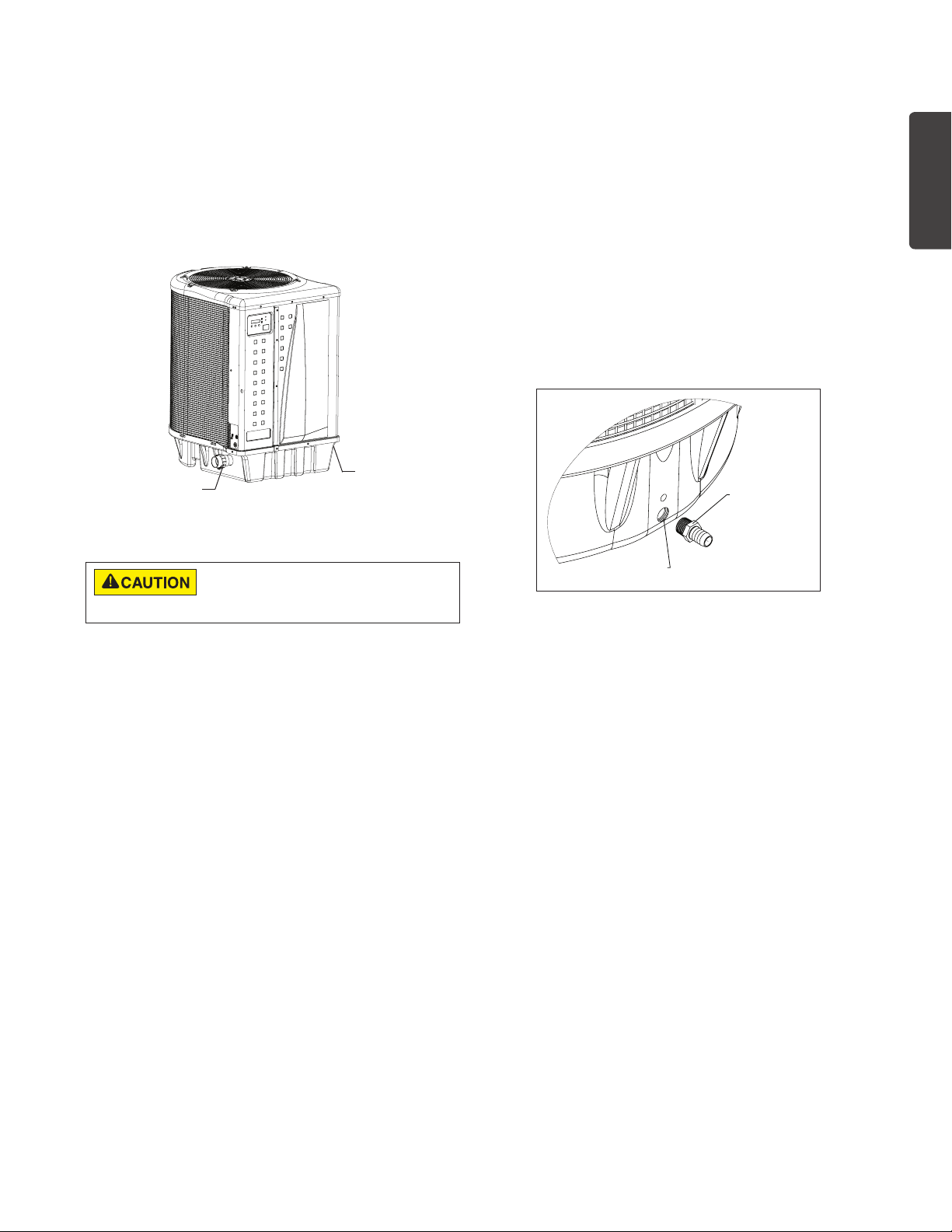

Water Connections to the Heat Pump

2 in. Quick Connect fittings have been installed on the

water inlet and outlet connections. Filtered cool water

is plumbed to the inlet, located on the right side of the

UltraTemp® Heat Pump. Heated water flows through the

outlet, located on the left side of the heat pump.

Plastic piping (PVC Schedule 40) should be connected

to the heat pump. The unions, provided with the unit,

accept 2 in. PVC pipe.

WATER

WATER

OUTLET UNION

Heat Pump Water Connections

INLET UNION

Drainage Connection to the Heat Pump

A 5/8” x 1/2” NPT threaded drain hose barb is included

with the heat pump union kit.

Before operating the heat pump for the first time, the drain

hose barb must be installed into the threaded drainage

outlet located in the base of the heat pump.

To install the Drain Hose Barb and Drain Hose:

1. Thread the drain hose barb into the threaded drainage

outlet in the base of the heat pump. See the image

below.

2. Connect a 5/8” garden hose to the hose barb.

3. Ensure the end of the garden hose is positioned so

that drainage will flow away from the heat pump and

equipment pad.

DRAIN HOSE BARB

5/8" X 1/2" NPT

ENGLISH

Always be sure that flow requirements and pool

water turnover rates can be maintained with the

installation of additional heat pumps and plumbing restrictions.

DRAINAGE

OUTLET

Drain Hose Barb Installation

ULTRATEMP

®

Heat Pump Installation and User’s Guide

6

Water Pressure Switch Adjustment

The water pressure switch should be adjusted to

turn the heater off when the pump is off. Setting the

switch to close at too low of a flow can damage the appliance. Adjust the

switch to turn the heater off, not on.

The pressure switch is preset at the factory for

activation at 1.5 psi [10 kPa]. This factory setting

works for most basic installations. Only adjust the

water pressure switch if the heat pump does not

operate when the proper flow is applied to unit

or if the heat pump does not shut off when the

filter pump is off. Occasionally, unusual plumbing

configurations or necessary restrictions in the

plumbing may cause pressure sensing problems.

In these rare situations, the plumbing system

configuration may require adjustment of the water

pressure switch.

Adjustment of the pressure switch may be necessary

if any part of the filter system piping is 3 feet [0.91 m]

or more above the top of the heat pump.

In general, if the heat pump is installed more than 6

feet [1.83 m] below the pool surface, an external water

flow switch must be added to the plumbing system.

On some installations, the piping from the heat pump

to the pool is very short. The back pressure could be

too low to trigger the pressure switch. If this happens,

install a directional fitting or elbow where the return

line enters the pool. This will increase back pressure for

the heat pump to operate properly. Be sure to check that

the system flow is above the minimum requirement of 30

gpm (110 lpm) after the directional fitting installation.

Be sure the pool filter is clean before making any

pressure switch adjustment: A dirty filter will restrict

the water flow and the pressure switch cannot be

adjusted properly.

To adjust the pressure switch:

The following adjustment is for installations where

the heat pump is below pool water level.

1. Be sure that all valves in the system are set to allow

water flow through the heat pump. Start the filter

pump.

2. Set the heat pump temperature above the actual

temperature to call for heat. Turn the heat Pump ON.

3. Once the heat pump is running, turn off the filter

pump. The heat pump should turn off immediately.

4. If the heat pump continues to operate when the filter

pump is off, then the water pressure switch needs to

be adjusted.

5. Remove the heat pump’s left front panel and remove

remaining right front panel. The water pressure switch

is located in the water plumbing in the lower right

corner of the heat pump.

6. Slowly rotate the adjustment wheel on the water

pressure switch in a clockwise direction until the “LOW

WATER FLOW” Alarm shows on the LCD, the red

SERVICE light turns ON, and the heat pump stops.

7. Check the setting of the water pressure switch by

starting and stopping the filter pump and checking

the control panel and operation of the heater between

each flow change.

8. If the water pressure switch cannot be adjusted to

accommodate the conditions listed above, an exter nal

flow switch must be added to the plumbing system

to ensure that the heat pump will not operate without

the proper flow through the heat exchanger.

The following adjustment is for installations where

the heat pump is above pool water level.

1. Be sure that all valves in the system are set to

allow water flow through the heat pump. Start the

filter pump.

2. Set the heat pump temperature above the actual

temperature to call for heat. Turn the heat pump

ON.

3. If the LCD shows a “LOW WATER FLOW” Alarm

and red SERVICE light is present then the water

pressure switch needs to be adjusted.

4. Remove the UltraTemp® Heat Pump’s left front

panel and remove remaining right front panel.

The water pressure switch is located in the water

plumbing in the lower right corner of the heat

pump.

5. Slowly rotate the adjustment wheel on the water

pressure switch in a counterclockwise direction

until the “LOW WATER FLOW” Alarm and red

SERVICE light vanish, time delay countdown will

start.

6. Once the heat pump is running, turn off the filter

pump. The heat pump should turn off immediately.

7. If the heat pump continues to operate when the

filter pump is off, turn the adjustment wheel on

the water pressure switch in a clockwise direction

until the “LOW WATER FLOW” Alarm shows on

the LCD, the red SERVICE light turns ON, and the

heat pump stops.

8. Check the setting of the water pressure switch by

starting and stopping the filter pump and checking

the control panel and operation of the heater

between each flow change.

9. If the water pressure switch cannot be adjusted

to accommodate the conditions listed above,

an external flow switch must be added to the

plumbing system to ensure that the heat pump will

not operate without the proper flow through the

heat exchanger.

ULTRATEMP

®

Heat Pump Installation and User’s Guide

Multiple Unit Installation

FROM SOLAR

R

S

SPA

OOL

A

OOL

N

7

1. Heat Pump, Heater and/or Solar Combination

In certain regions of the country it may be more

economical to run a UltraTemp® Heat Pump during the

warmer months and a gas heater during the cooler

months. In some situations it may be desirable to run

the heat pump in the “Chiller” mode, if so equipped,

during the hottest portion of the year and a heater

during the cooler months. The Pentair heat pump may

be used in conjunction with a gas or electric heater or

any combination of heat sources including solar. All heat

sources must be plumbed in series to work correctly and

efficiently.

A recommended plumbing layout for a heat pump /

heater / solar combination heating system for a pool /

spa combination is shown below. Your system may not

contain all of these components, but the basic plumbing

will apply by eliminating the component in the illustration

that is not a part of your system.

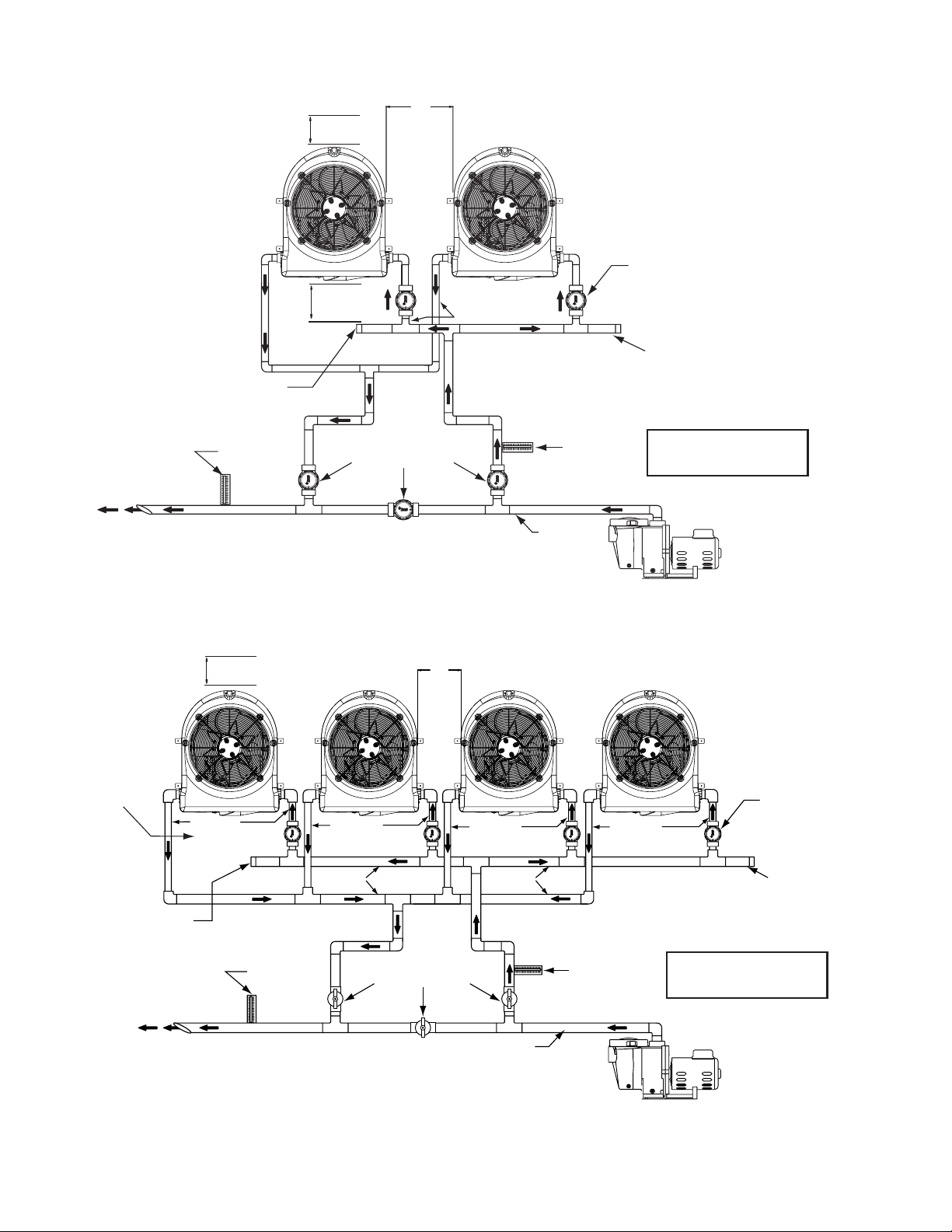

2. Multiple Heat Pump Connections

All plumbing on multiple heat pump installations must be

done in parallel (see next page). An equal flow of water

to each heat pump is important for optimum operation.

Note: It may be necessary to adjust the water pressure

switch if a unit is installed below the water level. Refer

back to page 6 for details on when and how to adjust the

pressure switch.

Each heat pump in a multiple unit installation

allows a maximum flow rate of 100 gpm (380 lpm)

and requires a minimum of 30 gpm (110 lpm).

12"

min.

(305 mm)

ENGLISH

HEAT PUMP

P

RETUR

CHECK

P

SPA

MAKE-UP

SP

SPA

DRAIN

CHECK

VALVE

FILTE

POOL

DRAIN

PUMP

P

VALVE

FROM SOLAR

TO SOLAR

Heater and/or Solar Combination

ULTRATEMP

®

Heat Pump Installation and User’s Guide

8

Extend 12" (305 mm)

past end heater

inlet for hydraulic

balancing

Extend 12" (305 mm)

past end heater

inlet for hydraulic

balancing

Pool Pump

Flow Meter

Minimum

2" PVC Pipe

2" PVC Pipe

Flow Meter

To Pool

OPTIONAL

2" Check Valve Bypass

Check Valves are

optional on heater inlets

but will help system

balancing

60 GPM (220 lpm)

Minimum

24"

(610 mm)

(153 mm)

12"

(305 mm)

6"

Multiple Unit Installation (cont.)

6"

(153 mm)

12"

(305 mm)

To Pool

Extend 12" (305 mm)

past end heater

inlet for hydraulic

balancing

Flow Meter

6"

(153 mm)

24"

(610 mm)

2" Check Valve Bypass

Two Heat Pump Plumbing Layout

OPTIONAL

12"

(305 mm)

2" PVC Pipe

Minimum

2" PVC Pipe

Flow Meter

Check Valves are

optional on heater inlets

but will help system

balancing

Extend 12" (305 mm)

past end heater

inlet for hydraulic

balancing

60 GPM (220 lpm)

Minimum

Pool Pump

24" (610 mm) min.

clearance for

service access.

Extend 12"

(305 mm) past

end heater

inlet for hydraulic

balancing

ULTRATEMP

®

Heat Pump Installation and User’s Guide

To Pool

2" PVC Pipe

Flow Meter

2" PVC Pipe

3" PVC Pipe3" PVC Pipe

3" Ball Valve Bypass

Minimum

3" PVC Pipe

Flow Meter

Four Heat Pump Plumbing Layout

Check Valves are

optional on heater inlets

2" PVC Pipe2" PVC Pipe

but will help for system

balancing

Extend 12" (305 mm)

past end heater

inlet for hydraulic

balancing

120 GPM (456 lpm)

Minimum

Pool Pump

Loading...

Loading...