U3 - U5 - U6

U3 K U3 K SPEZIAL U5 K U6 KE U6 KD

U3 KS U3 KS SPEZIAL U5 KS U6 KES U6 KDS

EN Instruction Manual

JUNG-PUMPEN.DE B 42054-30-1806

2

ENGLISH

You have purchased a product made by

JUNG PUMPEN and with it, therefore, also

excellent quality and service. Secure this

service by carrying out the installation

works in accordance with the instructions, so that our product can perform

its task to your complete satisfaction.

Please remember that damage caused

by incorrect installation or handling will

adversely affect the guarantee. Therefore please adhere to the instructions in

this manual!

This appliance can be used by children

aged 8 years or over and by persons with

limited physical, sensory or intellectual

capabilities, or with limited experience

and knowledge, provided that they are

supervised or have been instructed in

the safe use of the appliance and are

aware of the dangers involved. Children

must not be allowed to play with the appliance. Cleaning and user maintenance

must not be carried out by children unless they are supervised.

Damage prevention in case of failure

Like any other electrical device, this product

may fail due to a lack of mains voltage or a technical defect.

If damage (including consequential damage) can

occur as a result of product failure, the following

precautions can be taken at your discretion:

• Installation of a water level dependent (under

circumstances, mains-independent) alarm

system, so that the alarm can be heard before

damage occurs.

• Inspection of the collecting tank/chamber for

tightness up to the top edge before – or at the

latest, during – installation or operation of the

product.

• Installation of backow protection for drain-

age units that can be damaged by wastewater

leakage upon product failure.

• Installation of a further product that can com-

pensate in case of failure of the other product

(e.g. duplex unit).

• Installation of an emergency power genera-

tor.

As these precautions serve to prevent or minimise consequential damage upon product failure, they are to be strictly observed as the manufacturer’s guideline – in line with the standard

DIN EN specications as state of the art – when

using the product (Higher Regional Court Frankfurt/Main, Ref.: 2 U 205/11, 06/15/2012).

SAFETY INSTRUCTIONS

This instruction manual contains essential information that must be observed during installation, operation and servicing. It is therefore

important that the installer and the responsible

technician/operator read this instruction manual before the equipment is installed and put into

operation. The manual must always be available

at the location where the pump or the plant is

installed.

Failure to observe the safety instructions can

lead to the loss of all indemnity.

In this instruction manual, safety information is

distinctly labelled with particular symbols. Disregarding this information can be dangerous.

General danger to people

Warning of electrical voltage

NOTICE!

Danger to equipment and operation

Qualication and training of personnel

All personnel involved with the operation, servicing, inspection and installation of the equip-

ment must be suitably qualied for this work

and must have studied the instruction manual

in depth to ensure that they are suciently

conversant with its contents. The supervision,

competence and areas of responsibility of the

personnel must be precisely regulated by the

3

ENGLISH

operator. If the personnel do not have the necessary skills, they must be instructed and trained accordingly.

Safety-conscious working

The safety instructions in this instruction manual, the existing national regulations regarding

accident prevention, and any internal working,

operating and safety regulations must be adhered to.

Safety instructions for the operator/user

All legal regulations, local directives and safety

regulations must be adhered to.

The possibility of danger due to electrical energy must be prevented.

Leakages of dangerous (e.g. explosive, toxic,

hot) substances must be discharged such that

no danger to people or the environment occurs.

Legal regulations must be observed.

Safety instructions for installation, inspection

and maintenance works

As a basic principle, works may only be carried out to the equipment when it is shut down.

Pumps or plant that convey harmful substances

must be decontaminated.

All safety and protection components must be

re-tted and/or made operational immediately

after the works have been completed. Their effectiveness must be checked before restarting,

taking into account the current regulations and

stipulations.

Unauthorised modications, manufacture of

spare parts

The equipment may only be modied or altered

in agreement with the manufacturer. The use of

original spare parts and accessories approved

by the manufacturer is important for safety reasons. The use of other parts can result in liability

for consequential damage being rescinded.

Unauthorised operating methods

The operational safety of the supplied equipment is only guaranteed if the equipment is

used for its intended purpose. The limiting values given in the "Technical Data" section may not

be exceeded under any circumstances.

Instructions regarding accident prevention

Before commencing servicing or maintenance

works, cordon off the working area and check

that the lifting gear is in perfect condition.

Never work alone. Always wear a hard hat, safety

glasses and safety shoes and, if necessary, a

suitable safety belt.

Before carrying out welding works or using electrical devices, check to ensure there is no danger of explosion.

People working in wastewater systems must be

vaccinated against the pathogens that may be

found there. For the sake of your health, be sure

to pay meticulous attention to cleanliness wherever you are working.

Make sure that there are no toxic gases in the

working area.

Observe the health and safety at work regula-

tions and make sure that a rst-aid kit is to hand.

In some cases, the pump and the pumping medium may be hot and could cause burns.

For installations in areas subject to explosion

hazards, special regulations apply!

APPLICATION

WARNING!

The pump must only be connected to sockets

that have been installed properly in accordance with the regulations and are protected with

at least 10 A (slow) and RCD-safety switches

(30mA).

DANGER!

The pump must never be used when a person is

in the water.

Submersible pumps from the U3, U5 and U6 series are suitable for pumping domestic waste

water without stones. This includes also water

from household dishwashers and household

washing machines.

The U3 K spezial can also pump aqueous solutions with up to 10% salt content and condensate from gas condensing boilers.

4

ENGLISH

The U6 can also pump ground water, drainage

silage liquor and liquid manure.

NOTICE! In outdoor applications, only pumps

with at least a 10-metre mains cable must be

used.

When using the pumps, the relevant national

laws, regulations and stipulations must be adhered to, for example:

• Domestic contaminated and waste water

(e.g. EN 12056 in Europe)

• Installation of low voltage systems

(e.g., VDE 0100 in Germany)

For non-standard utilization conditions, further

regulations must be observed (e.g. VDE 0100

in Germany, part 701: bathrooms and shower

rooms; part 702: swimming pools and fountains

and part 737: outdoor use).

Temperatures

The pumped medium must have a temperature

of max 35°C.

The submersible pump is frost-resistant down

to -20°C when stored in dry conditions. When

installed, however, it must not be allowed to

freeze in the water.

Transport

The pump must always be lifted by the handle

and never by the power supply cable! The pump

should only be lowered into deeper chambers or

pits using a rope or chain.

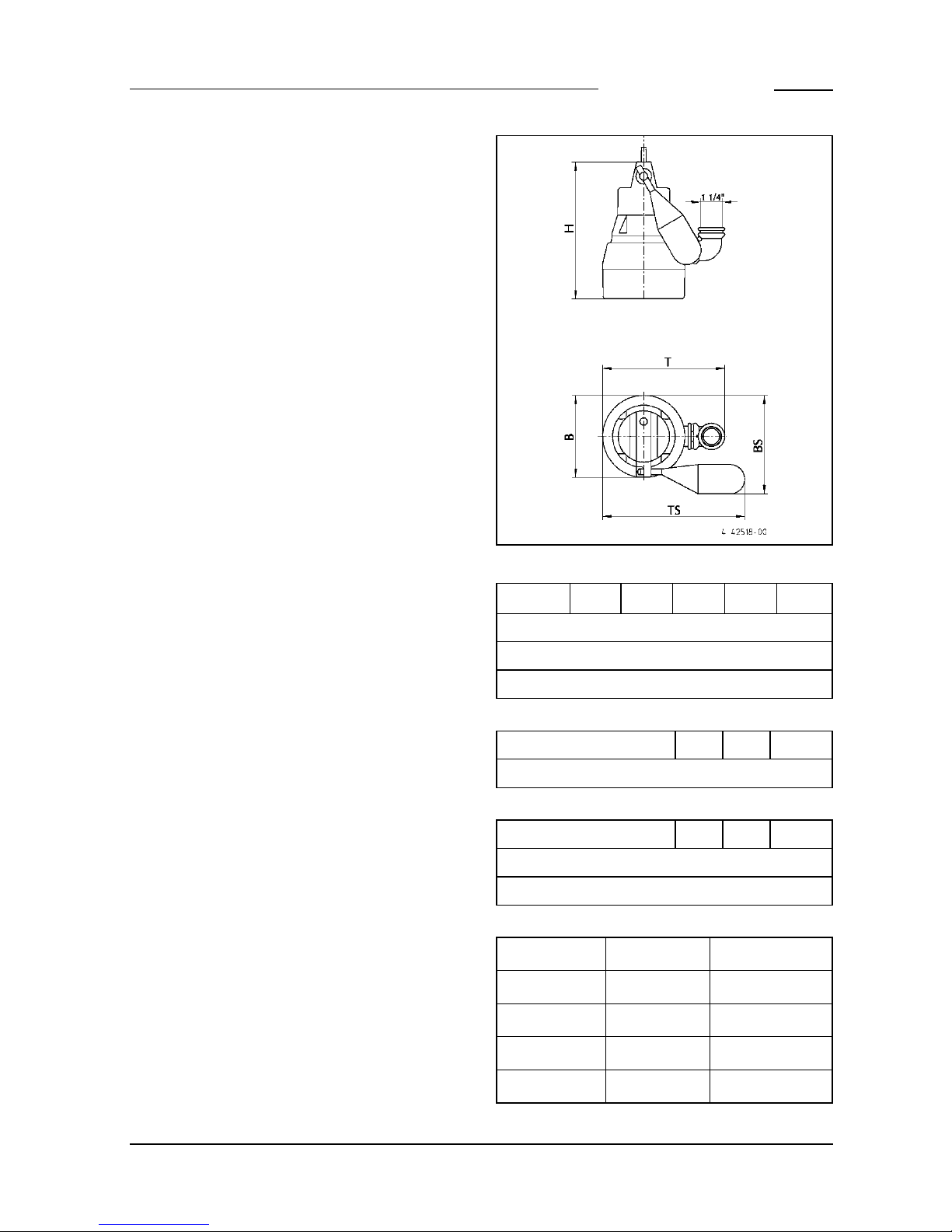

Dimensions [mm]

H B T BS TS

U3 K 255 160 225 195 280

U5 K 280 170 250 205 290

U6 K 335 175 255 210 295

Pumps with special oat assembly, (JP44795)

H BS TS

U3 KS 225 270 220

Pumps with special oat assembly, (JP44207)

H BS TS

U5 KS 280 245 285

U6 KS 335 250 290

Switching points On - Off for built-in switching

Normal Special

● ○ ● ○

U3 KS 215 110 105 45

U5 KS 240 135 - -

U6 KS 270 170 - -

5

ENGLISH

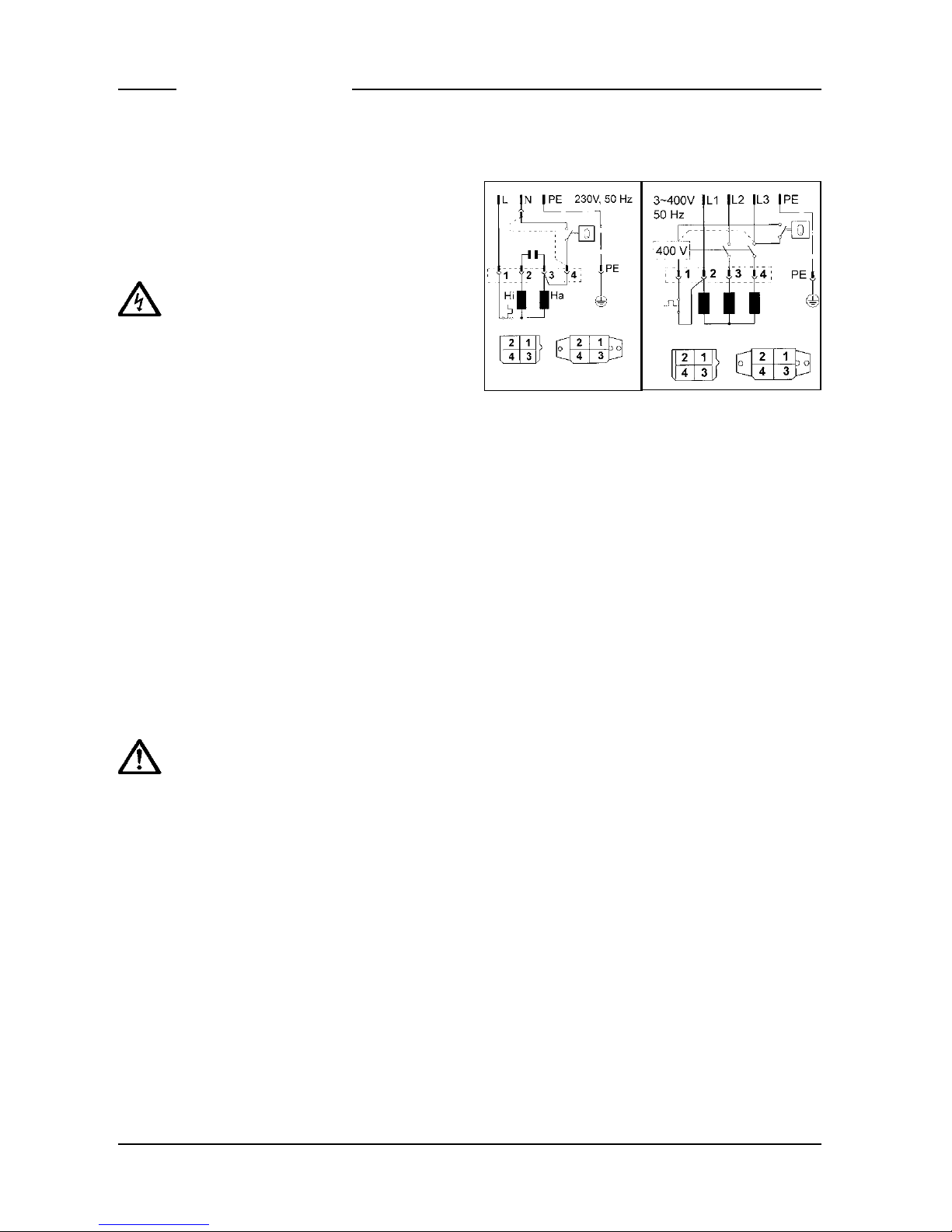

ELECTRICAL

CONNECTION

NOTICE! Only qualied electricians may carry

out electrical works to the pump or the controls.

WARNING!

Before carrying out any works: disconnect the

pump and the controls from the mains and take

steps to ensure that no one else can reconnect

them to the power supply.

The relevant standards (such as EN standards),

country-specic regulations (such as VDE in

Germany), and the regulations of the local power

supply companies must be observed.

NOTICE! Never put the mains plug or a free lead

end in water! If water gets into the plug, this can

cause malfunctions and damage.

Observe the operating voltage (see the type

plate)!

The pump is provided with a winding thermostat. In case of unacceptably high temperatures

it switches off the pump to protect it against

possible damage. Unacceptably high temperatures may result e.g. from dry running or mechanical or electrical overload.

CAUTION!

The pump is switched on again automatically after cooling down - risk of injury!

For this reason, always disconnect the device

from the mains before remedying the fault! In

order to do this, unplug from the mains supply

or remove the pre-fuses of the pump controls!

Rotational direction

Applies only for three-phase pumps. The rotational direction must be checked before installation! If the rotational direction is correct, the

start-up jolt should be counter-clockwise. If the

rotational direction is wrong, 2 phases of the

supply cable must be swapped over, because a

wrong direction of rotation results in an overload of the pump.

Alternating and three-phase current circuit diagrams

INSTALLATION

The pump must be installed as shown in the examples. For installations in accordance with EN

12056-4, the pressure pipe must be laid in a loop

above the local backow level and protected

with a backow prevention valve. The rubber

ap supplied (U3 and U5) is for mobile operation

only.

A correspondingly larger diameter pipe should

be used for longer pressure pipelines to avoid

pipe friction losses.

In contrast to pumps with built-in level control,

the ON an OFF switching heights of pumps without built-in level control are variable by the use

of a separate level controller. Our ready to connect level controls can be installed without spe-

cic electrotechnical skills.

Permanent venting may be necessary if the

pump runs dry from time to time (pressure outlet surfaced). This can occur for example if the

residual water in the collecting chamber evaporates or if the pump runs in “snore” mode during

the test run.

To vent the pump housing the attached elbow

must be drilled at the marked location to provide

a 6 mm drill-hole.

NOTICE! If the pump is malfunctioning, part of

the contents of the oil reservoir could escape

into the pumping medium.

Loading...

Loading...