Page 1

U3 - U5 - U6

U3 K U3 K SPEZIAL U5 K U6 KE U6 KD

U3 KS U3 KS SPEZIAL U5 KS U6 KES U6 KDS

EN Instruction Manual

JUNG-PUMPEN.DE B 42054-30-1806

Page 2

2

ENGLISH

You have purchased a product made by

JUNG PUMPEN and with it, therefore, also

excellent quality and service. Secure this

service by carrying out the installation

works in accordance with the instructions, so that our product can perform

its task to your complete satisfaction.

Please remember that damage caused

by incorrect installation or handling will

adversely affect the guarantee. Therefore please adhere to the instructions in

this manual!

This appliance can be used by children

aged 8 years or over and by persons with

limited physical, sensory or intellectual

capabilities, or with limited experience

and knowledge, provided that they are

supervised or have been instructed in

the safe use of the appliance and are

aware of the dangers involved. Children

must not be allowed to play with the appliance. Cleaning and user maintenance

must not be carried out by children unless they are supervised.

Damage prevention in case of failure

Like any other electrical device, this product

may fail due to a lack of mains voltage or a technical defect.

If damage (including consequential damage) can

occur as a result of product failure, the following

precautions can be taken at your discretion:

• Installation of a water level dependent (under

circumstances, mains-independent) alarm

system, so that the alarm can be heard before

damage occurs.

• Inspection of the collecting tank/chamber for

tightness up to the top edge before – or at the

latest, during – installation or operation of the

product.

• Installation of backow protection for drain-

age units that can be damaged by wastewater

leakage upon product failure.

• Installation of a further product that can com-

pensate in case of failure of the other product

(e.g. duplex unit).

• Installation of an emergency power genera-

tor.

As these precautions serve to prevent or minimise consequential damage upon product failure, they are to be strictly observed as the manufacturer’s guideline – in line with the standard

DIN EN specications as state of the art – when

using the product (Higher Regional Court Frankfurt/Main, Ref.: 2 U 205/11, 06/15/2012).

SAFETY INSTRUCTIONS

This instruction manual contains essential information that must be observed during installation, operation and servicing. It is therefore

important that the installer and the responsible

technician/operator read this instruction manual before the equipment is installed and put into

operation. The manual must always be available

at the location where the pump or the plant is

installed.

Failure to observe the safety instructions can

lead to the loss of all indemnity.

In this instruction manual, safety information is

distinctly labelled with particular symbols. Disregarding this information can be dangerous.

General danger to people

Warning of electrical voltage

NOTICE!

Danger to equipment and operation

Qualication and training of personnel

All personnel involved with the operation, servicing, inspection and installation of the equip-

ment must be suitably qualied for this work

and must have studied the instruction manual

in depth to ensure that they are suciently

conversant with its contents. The supervision,

competence and areas of responsibility of the

personnel must be precisely regulated by the

Page 3

3

ENGLISH

operator. If the personnel do not have the necessary skills, they must be instructed and trained accordingly.

Safety-conscious working

The safety instructions in this instruction manual, the existing national regulations regarding

accident prevention, and any internal working,

operating and safety regulations must be adhered to.

Safety instructions for the operator/user

All legal regulations, local directives and safety

regulations must be adhered to.

The possibility of danger due to electrical energy must be prevented.

Leakages of dangerous (e.g. explosive, toxic,

hot) substances must be discharged such that

no danger to people or the environment occurs.

Legal regulations must be observed.

Safety instructions for installation, inspection

and maintenance works

As a basic principle, works may only be carried out to the equipment when it is shut down.

Pumps or plant that convey harmful substances

must be decontaminated.

All safety and protection components must be

re-tted and/or made operational immediately

after the works have been completed. Their effectiveness must be checked before restarting,

taking into account the current regulations and

stipulations.

Unauthorised modications, manufacture of

spare parts

The equipment may only be modied or altered

in agreement with the manufacturer. The use of

original spare parts and accessories approved

by the manufacturer is important for safety reasons. The use of other parts can result in liability

for consequential damage being rescinded.

Unauthorised operating methods

The operational safety of the supplied equipment is only guaranteed if the equipment is

used for its intended purpose. The limiting values given in the "Technical Data" section may not

be exceeded under any circumstances.

Instructions regarding accident prevention

Before commencing servicing or maintenance

works, cordon off the working area and check

that the lifting gear is in perfect condition.

Never work alone. Always wear a hard hat, safety

glasses and safety shoes and, if necessary, a

suitable safety belt.

Before carrying out welding works or using electrical devices, check to ensure there is no danger of explosion.

People working in wastewater systems must be

vaccinated against the pathogens that may be

found there. For the sake of your health, be sure

to pay meticulous attention to cleanliness wherever you are working.

Make sure that there are no toxic gases in the

working area.

Observe the health and safety at work regula-

tions and make sure that a rst-aid kit is to hand.

In some cases, the pump and the pumping medium may be hot and could cause burns.

For installations in areas subject to explosion

hazards, special regulations apply!

APPLICATION

WARNING!

The pump must only be connected to sockets

that have been installed properly in accordance with the regulations and are protected with

at least 10 A (slow) and RCD-safety switches

(30mA).

DANGER!

The pump must never be used when a person is

in the water.

Submersible pumps from the U3, U5 and U6 series are suitable for pumping domestic waste

water without stones. This includes also water

from household dishwashers and household

washing machines.

The U3 K spezial can also pump aqueous solutions with up to 10% salt content and condensate from gas condensing boilers.

Page 4

4

ENGLISH

The U6 can also pump ground water, drainage

silage liquor and liquid manure.

NOTICE! In outdoor applications, only pumps

with at least a 10-metre mains cable must be

used.

When using the pumps, the relevant national

laws, regulations and stipulations must be adhered to, for example:

• Domestic contaminated and waste water

(e.g. EN 12056 in Europe)

• Installation of low voltage systems

(e.g., VDE 0100 in Germany)

For non-standard utilization conditions, further

regulations must be observed (e.g. VDE 0100

in Germany, part 701: bathrooms and shower

rooms; part 702: swimming pools and fountains

and part 737: outdoor use).

Temperatures

The pumped medium must have a temperature

of max 35°C.

The submersible pump is frost-resistant down

to -20°C when stored in dry conditions. When

installed, however, it must not be allowed to

freeze in the water.

Transport

The pump must always be lifted by the handle

and never by the power supply cable! The pump

should only be lowered into deeper chambers or

pits using a rope or chain.

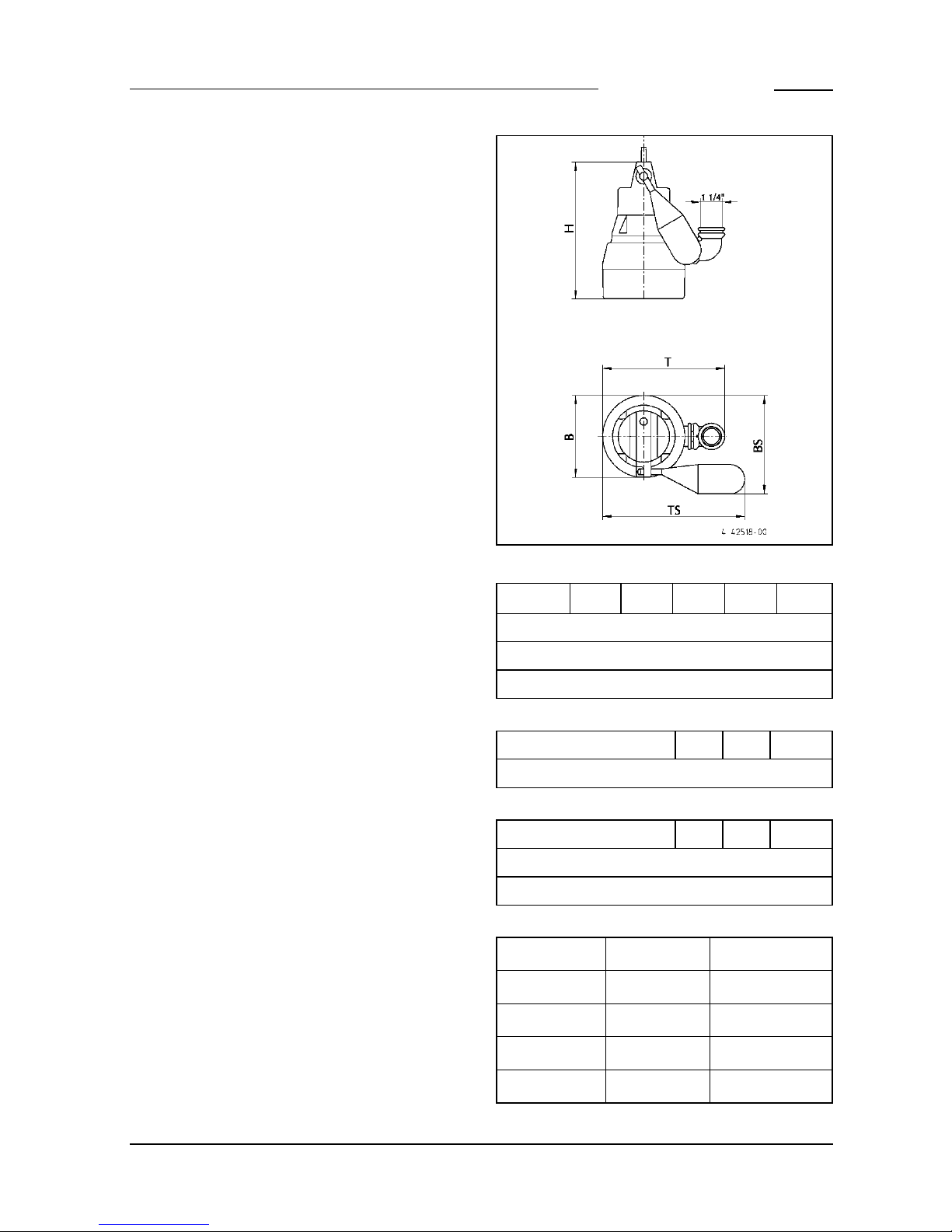

Dimensions [mm]

H B T BS TS

U3 K 255 160 225 195 280

U5 K 280 170 250 205 290

U6 K 335 175 255 210 295

Pumps with special oat assembly, (JP44795)

H BS TS

U3 KS 225 270 220

Pumps with special oat assembly, (JP44207)

H BS TS

U5 KS 280 245 285

U6 KS 335 250 290

Switching points On - Off for built-in switching

Normal Special

● ○ ● ○

U3 KS 215 110 105 45

U5 KS 240 135 - -

U6 KS 270 170 - -

Page 5

5

ENGLISH

ELECTRICAL

CONNECTION

NOTICE! Only qualied electricians may carry

out electrical works to the pump or the controls.

WARNING!

Before carrying out any works: disconnect the

pump and the controls from the mains and take

steps to ensure that no one else can reconnect

them to the power supply.

The relevant standards (such as EN standards),

country-specic regulations (such as VDE in

Germany), and the regulations of the local power

supply companies must be observed.

NOTICE! Never put the mains plug or a free lead

end in water! If water gets into the plug, this can

cause malfunctions and damage.

Observe the operating voltage (see the type

plate)!

The pump is provided with a winding thermostat. In case of unacceptably high temperatures

it switches off the pump to protect it against

possible damage. Unacceptably high temperatures may result e.g. from dry running or mechanical or electrical overload.

CAUTION!

The pump is switched on again automatically after cooling down - risk of injury!

For this reason, always disconnect the device

from the mains before remedying the fault! In

order to do this, unplug from the mains supply

or remove the pre-fuses of the pump controls!

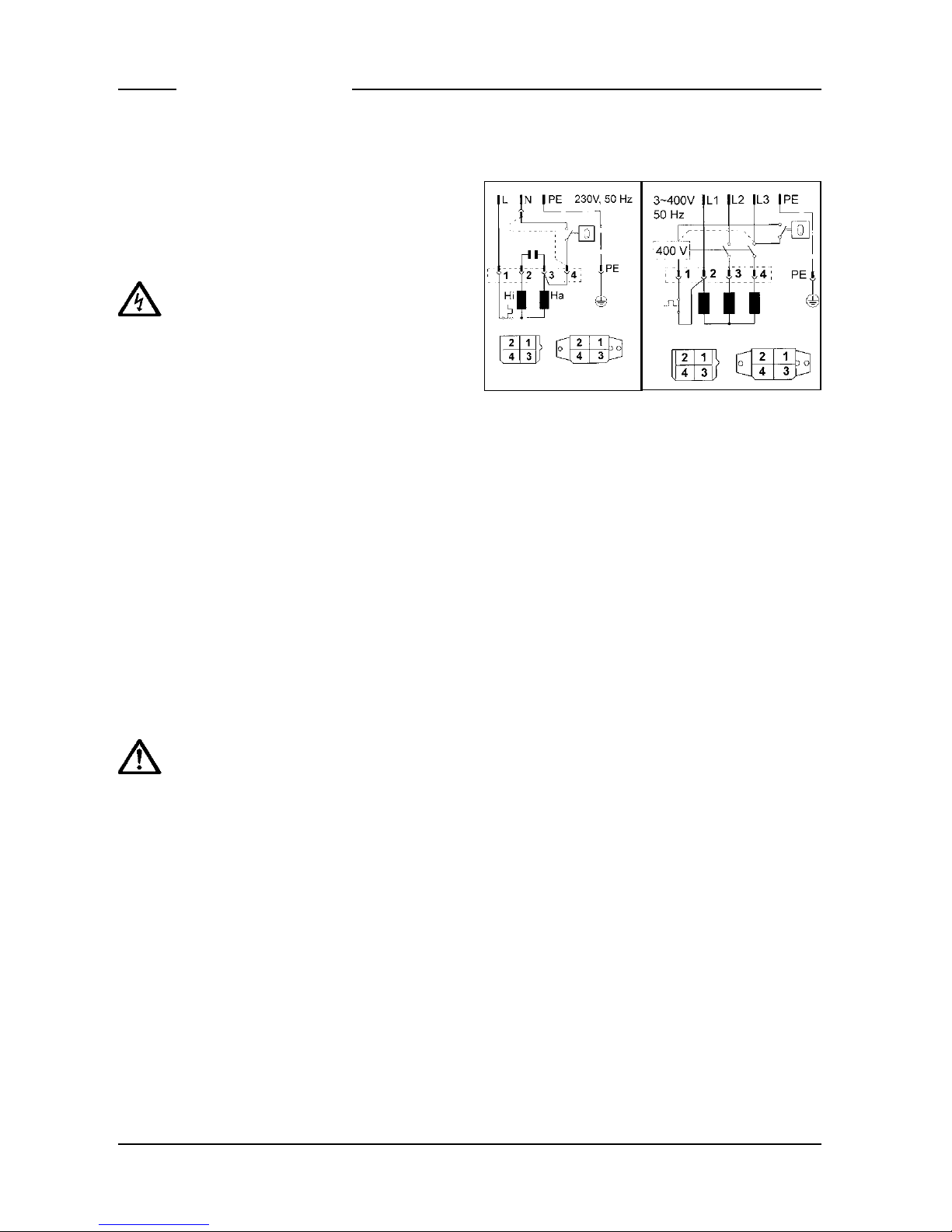

Rotational direction

Applies only for three-phase pumps. The rotational direction must be checked before installation! If the rotational direction is correct, the

start-up jolt should be counter-clockwise. If the

rotational direction is wrong, 2 phases of the

supply cable must be swapped over, because a

wrong direction of rotation results in an overload of the pump.

Alternating and three-phase current circuit diagrams

INSTALLATION

The pump must be installed as shown in the examples. For installations in accordance with EN

12056-4, the pressure pipe must be laid in a loop

above the local backow level and protected

with a backow prevention valve. The rubber

ap supplied (U3 and U5) is for mobile operation

only.

A correspondingly larger diameter pipe should

be used for longer pressure pipelines to avoid

pipe friction losses.

In contrast to pumps with built-in level control,

the ON an OFF switching heights of pumps without built-in level control are variable by the use

of a separate level controller. Our ready to connect level controls can be installed without spe-

cic electrotechnical skills.

Permanent venting may be necessary if the

pump runs dry from time to time (pressure outlet surfaced). This can occur for example if the

residual water in the collecting chamber evaporates or if the pump runs in “snore” mode during

the test run.

To vent the pump housing the attached elbow

must be drilled at the marked location to provide

a 6 mm drill-hole.

NOTICE! If the pump is malfunctioning, part of

the contents of the oil reservoir could escape

into the pumping medium.

Page 6

6

ENGLISH

Dimensions of chamber

Single installation with pump base: 40 x 40 cm

Single installation with guide rail system:

40 x 50 cm and Duplex installation: 50 x 50 cm

Example of installation with guide rail system

Installation

Fix the coupling base rmly to the oor of the

collection chamber using wall plugs and then

mount the guide rail. Next, install the pressure

pipe including the necessary ttings, such as

the non-return valve and shut-off valves.

Reseal the coupling catch at the pump and

tighten it until it is “hand tight”. Finally, t the

pump with the coupling catch onto the guide rail

and lower it into place using a chain xed to the

handle.

Example of installation Duplex unit

NOTICE! The oats of the level controller and

alarm system are installed so that they are freely

movable but not under the inlet. Please observe

the minimum distances. The controls may only

be installed in a dry and well ventilated room!

Flushing device

The pump can keep the intake section at the

bottom of the chamber clear of deposits to a

large extent if you carry out a small modication. This reduces the performance of the pump

only insignicantly.

This modication is carried out as follows. De-

tach the foot strainer and carefully drill a hole

into the 3 markings with the ø 5 symbols. Deburr the drillholes. When reattaching the foot

strainer, ensure that the new drill-holes are not

covered by the bars of the foot strainer. The U5

and U6 ranges provide markings on the housing

and the foot strainer to help you.

Low level pumping

Flooded areas can be pumped out leaving only

few mm of residual water without the need for

optional extras, U3K: 5 mm, U5K: 6 mm and U6K:

10 mm. To do so, the foot strainer must be levered off with a screwdriver. In the case of pumps

with an attached control, the oat switch must

be locked in the ON position. It is not possible

therefore in low level pumping to operate the

pump in switching mode.

To make the pump operate, the drainage hose

must be emptied before each pumping run and

there must be a minimum water level available of,

for U3K: 40 mm, for U5K: 60 mm and for U6K: 90

mm.

Page 7

7

ENGLISH

Mobile operation

For safety reasons, mobile operation is only al-

lowed with a foot strainer.

If a hose is used as a pressure line, care must

be taken to ensure that for every pumping operation the hose is completely empty before the

pump is submersed. Any residual liquid would

obstruct the ventilation of the pump housing

and therefore also hinder the pumping operation. For the same reason, the pump would not

operate if it was switched on before being submersed.

The pump can also be vented by providing a 6

mm drill-hole in the pump housing. This drillhole allows the pump to be vented even if the

rubber ap is used.

The enclosed rubber ap (not Flutboxand U6)

is tted in the pressure outlet (U3) or in the attached elbow (U5). Ensure that the ap opens in

the direction of ow.

Enlarging the free passage

The free passage of the U5 and U6 pump ranges

can be enlarged from 10 to 20 mm. This is done

by levering off the foot strainer and attaching

the enclosed extensions to the integrally mold-

ed pump feet. The foot strainer no longer ts

under the pump.

MAINTENANCE

We recommend that you service the equipment

in accordance with EN 12056-4.

WARNING!

Before carrying out any works: disconnect the

pump and the controls from the mains and take

steps to ensure that no one else can reconnect

them to the power supply.

WARNING!

Check the mains cable for signs of mechanical

and chemical damage. Damaged or kinked cables must be replaced.

NOTICE! If the water contains high levels of iron

or lime, insucient cleaning can result in irreparable damage to the seal and thus also to the

pump motor in the long term.

Consequently, the pump must be cleaned at

regular intervals according to the hardness of

the water.

Cleaning

The foot strainer prevents coarse impurities

from entering the pump. Regular cleaning of the

oat and the foot strainer ensures optimum performance and operation.

Page 8

8

ENGLISH

Cleaning of the impeller (U5 and U6)

To clean the impeller, and in the event of an

obstacle or blockage, the foot strainer must be

levered off. After this, take out the screws on the

underside of the pump and remove the cover.

The impeller can now be cleaned.

CAUTION!

Worn impellers can have sharp edges.

If the pump performance decreases, the impel-

ler must be checked for wear and replaced by

the manufacturer if necessary.

Tightening torque M

A

for A2 screw materials

for M 5 M

A

= 5 Nm

for Amtec 3,5 M

A

= 1 Nm

for Amtec 5,0 MA = 2 Nm

QUICK TIPS FOR

REMEDYING FAULTS

Pump does not work

• Check mains current (do not use a pin gauge)

• Fuse faulty = may be too weak (please refer to

Electrical Connection)

• Mains supply cable damaged = repair to be

carried out by manufacturer only

Pump runs but does not pump

• Empty the pressure pipe or hose to allow the

non-return valve to open and the air to escape

from the pump housing, it may be necessary

to carry out a ventilation drilling

Impeller blocked

• Solids and brous matter have become lod-

ged in the pump housing = clean

Decreased pumping performance

• Foot strainer obstructed = clean

• Pressure pipe obstructed = clean

• Rotor worn out = repair to be carried out by

the manufacturer

• Wrong direction of rotation (for a three-pha-

se current) = ask a qualied electrician to

change 2 phases of the supply line

0197

JUNG PUMPEN GmbH - Industriestr. 4-6

33803 Steinhagen, Germany

13

401.13.1612

EN 12050-2:2001

Lifting plant for faecal-free wastewater DN 32

U3 K (JP00205/2)

U3 K spez. (JP09562/2)

U3 KS (JP00206/2)

U3 K spez. (JP44255)

U3 KS (JP09808/2)

U3 KS spez. (JP09563/2)

U3 KS spez. (JP45195)

U5 K (JP09386/0)

U5 KS (JP09387/0)

U5 KS (JP09417/0)

U6 K E (JP00226/2)

U6 K D (JP00228/3)

U6 K ES (JP00227/2)

U6 K ES (JP09260/2)

U6 K DS (JP00229/3)

U6 K DS (JP09261/3)

Collecting and automatically lifting faecal-free

waste water above the backow level in buildings

and sites

REACTION TO FIRE NPD

WATERTIGHTNESS Pass

EFFECTIVENESS (LIFTING EFFECT

- Pumping of solids Pass

- Pipe connections Pass

- Ventilation NPD

- Minimum ow velocity Pass

-

Minimum free passage of the plant

Pass

- Minimum useful volume NPD

MECHANICAL RESISTANCE

- Load bearing capacity and structural

stability of collection tank for use

NPD

- Structural stability of collection tank

for use inside buildings

NPD

NOISE LEVEL ≤ 70 dB(A)

DURABILITY

- of structural stability NPD

- of lifting effectiveness Pass

- of mechanical resistance NPD

DANGEROUS SUBSTANCES

NPD

Page 9

9

DE - Technische Daten EN - Technical Data FR - Caractéristiques Techniques

NL - Technische Gegevens IT - Dati Tecnici PL - Dane Techniczne

CZ - Technické Údaje HU - Műszaki Adatok RO - Date Tehnice

U3 K/KS U5 K/KS U6 KE/KES U6 KD/KDS U3 KS U6 KES

[kg] 3,7 / 3,4 4,7 / 4,5 5,9 / 5,3 6,6 / 5,8 3,4 5,3

DN 32 32 32 32 32 32

[mm] 10 10 / 20 10 / 20 10 / 20 10 10 / 20

P1 [W] 320 520 750 750 320 750

P2 [W] 200 380 490 550 200 490

U [V] 1/N/PE ~230 1/N/PE ~230 1/N/PE ~230 3/PE ~400 1/N/PEx230

1/N/PEx230

f [Hz] 50 50 50 50 60 60

I [A] 1,4 2,3 3,3 1,3 1,4 3,3

DE - Leistungen EN - Performance FR - Puissances

NL - Capaciteit IT - Prestazione PL - Wydajności i moce

CZ - Výkony HU - Teljesítmény RO - Capacităţi

H [m]

1 2 3 4 5 6 7 8 9

Q [m3/h]

U3

6,5 5,5 5,0 4,0 3,0 1,5

U5 11,5 10,5 9,0 7,5 6,5 4,5 2,5

U6 15,5 14,5 13,0 11,5

9,5 8,0 6,0 4,0 1,5

Page 10

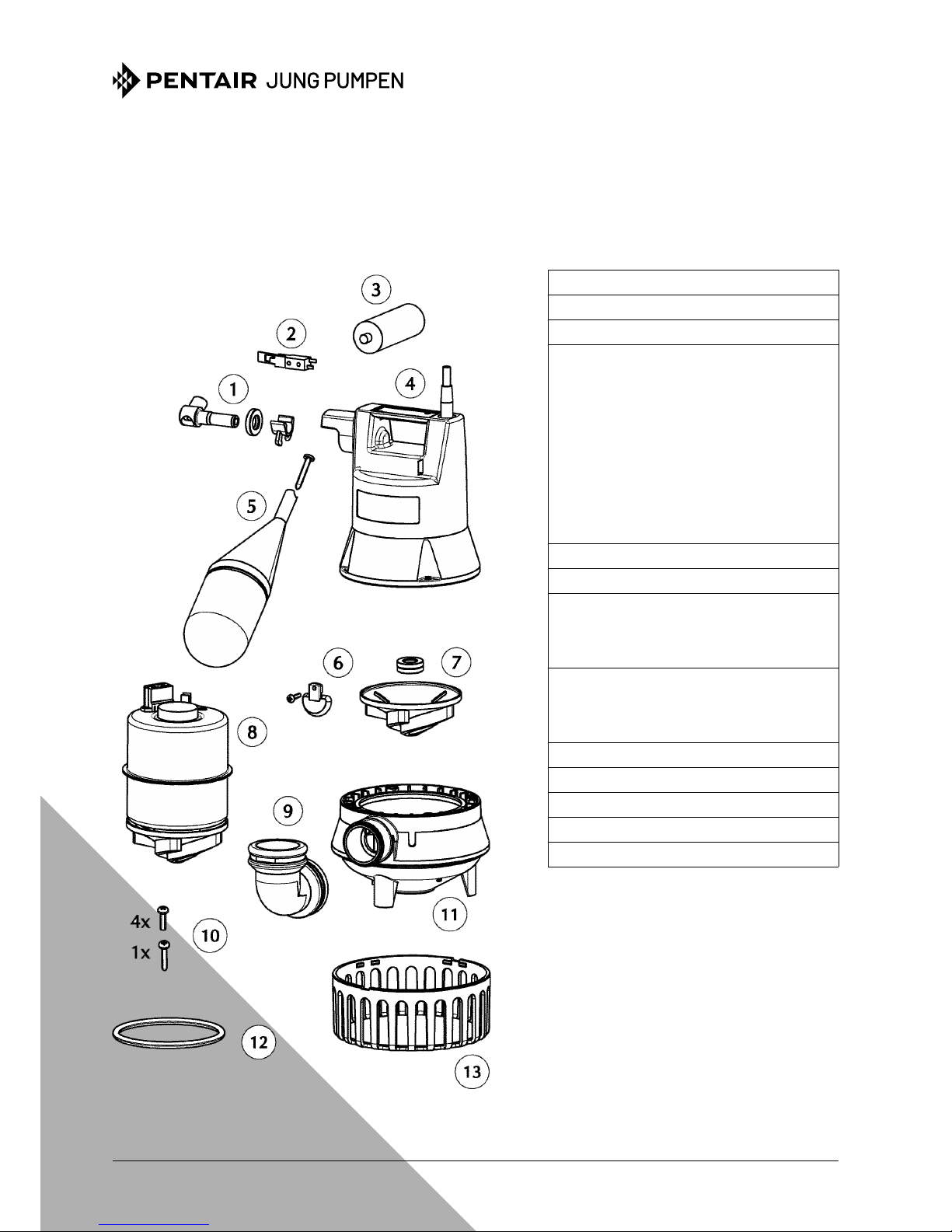

Ersatzteile - Spare parts - Pièces de rechange - Reserveondrdelen - Parti di ricambio - Reservedele - Reserv delar

Varaosat - Części zamienne - Náhradní díly - Alkatrészek - Piese de schimb - Запасные части -

备件

U3K /2 · U3KS /2 · U3K SPEZIAL /2 · U3KS SPEZIAL /2

JUNG-PUMPEN.DE B 40885-21-1809

①

Schaltwelle Shift shaft

JP42770

②

Mikroschalter Microswitch

JP46351

③

Kondensator Capacitor

JP46353

④

Anschlusseinheit Top cover

U3 K, 10m

JP46379

U3 KS, 4m

JP46380

U3 KS, 10m

JP46384

U3 K spez., 5m

JP46522

U3 K spez., 10m

JP46381

U3 KS spez., 4m

JP46382

U3 KS spez., 10m

JP46383

⑤

Schwimmer Float

JP42771

⑥

Gummiklappe Rubber ap

JP46356

⑦

Laufrad Impeller

U 3 K

JP46358

U 3 K spezial

JP46378

⑧

Motor Motor

U 3 K

JP46361

U 3 K spezial

JP46362

⑨

Winkel Elbow

JP46355

⑩

Schraubensatz Screw set

JP42773

⑪

Spiralgehäuse Volute casing

JP46359

⑫

Dichtungssatz Seal set

JP46354

⑬

Siebfuß Strainer base

JP46360

Page 11

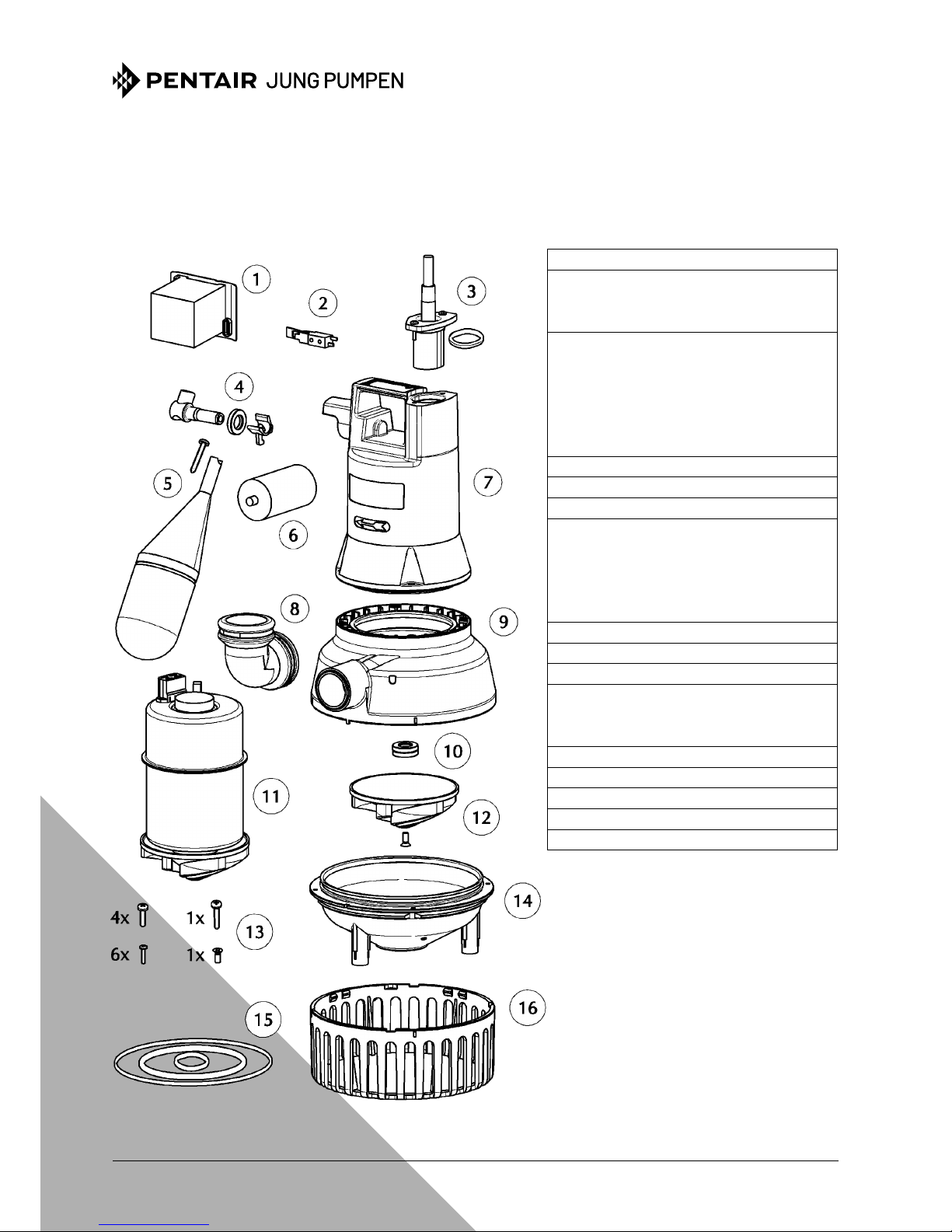

Ersatzteile - Spare parts - Pièces de rechange - Reserveonderdelen - Parti di ricambio - Reservedele - Reserv delar

Varaosat - Części zamienne - Náhradní díly - Alkatrészek - Piese de schimb - Запасные части -

备件

U5K · U5KS

JUNG-PUMPEN.DE B 40887-21-1809

①

Schaltwelle Shift shaft

JP42770

②

Mikroschalter Microswitch

JP46351

③

Kondensator Capacitor

JP46015

④

Anschlusseinheit Top cover

U5 K, 10m

JP46389

U5 KS, 4m

JP46390

U5 KS, 10m

JP46391

⑤

Schwimmer Float

JP42771

⑥

Motor Motor

JP46388

⑦

Dichtungen Seals

JP46385

⑧

Laufrad Impeller

JP46363

⑨

Winkel Elbow

JP46355

⑩

Gummiklappe Rubber ap

JP46366

⑪

Spiralgehäuse Volute casing

JP46364

⑫

Dichtungssatz Seal set

JP46354

⑬

Deckel Cover

JP46387

⑭

Schraubensatz Screw set

JP42773

⑮

Siebfuß Strainer base

JP46365

Page 12

Ersatzteile - Spare parts - Pièces de rechange - Reserveonderdelen - Parti di ricambio - Reservedele - Reserv delar

Varaosat - Części zamienne - Náhradní díly - Alkatrészek - Piese de schimb - Запасные части -

备件

U6 KE /2 · U6 KES /2 · U6 KD /3 · U6 KDS /3

JUNG-PUMPEN.DE B 42055-21-1809

①

Schaltschütz Motor contactor

JP46371

②

Mikroschalter Microswitch

ES

JP46351

DS

JP46352

③

Leitung Cable

E / ES, 4 m

JP42776

E / ES, 10 m

JP42777

D / DS, 4 m

JP42778

D / DS, 10 m

JP42779

10 m, A/NZ-plug

JP47221

④

Schaltwelle Shift shaft

JP42770

⑤

Schwimmer Float

JP42771

⑥

Kondensator Capacitor

JP46374

⑦

Haube Top cover

E

JP46919

D

JP46920

ES

JP46372

DS

JP46373

⑧

Winkel Elbow

JP46355

⑨

Spiralgehäuse Volute casing

JP46368

⑩

Dichtungen Seals

JP46370

⑪

Motor Motor

E / ES

JP46375

D / DS

JP46376

⑫

Laufrad Impeller

JP46369

⑬

Schraubensatz Screw set

JP42773

⑭

Deckel Cover

JP42772

⑮

Dichtungssatz Seal set

JP46354

⑯

Siebfuß Strainer base

JP46367

Page 13

13

EU-Konformitätserklärung

EU-Prohlášeni o shodě

EU-Overensstemmelseserklæring

EU-Declaration of Conformity

EU-Vaatimustenmukaisuusvakuutus

EU-Déclaration de Conformité

EU-Megfelelöségi nyilatkozat

EU-Dichiarazione di conformità

EU-Conformiteitsverklaring

EU-Deklaracja zgodności

EU-Declaraţie de conformitate

EU-Vyhlásenie o zhode

EU-Försäkran om överensstämmelse

e

JUNG PUMPEN GmbH - Industriestr. 4-6 - 33803 Steinhagen - Germany -

www.jung-pumpen.de

DE · Wir erklären in alleiniger Verantwortung, dass das Produkt den aufgeführten Richtlinien entspricht.

CS · Prohlašujeme na svou výlučnou odpovědnost, že výrobek odpovídá jmenovaným směrnicím.

DA · Vi erklærer under ansvar at produktet i overensstemmelse med de retningslinjer

EN · We hereby declare, under our sole responsibility, that the product is in accordance with the specified Directives.

FI · Me vakuutamme omalla vastuullamme, että tuote täyttää ohjeita.

FR · Nous déclarons sous notre propre responsabilité que le produit répond aux directives.

HU · Kizárólagos felelősségünk tudatában kijelentjük, hogy ez a termék megfelel az Európai Unió fentnevezett irányelveinek.

IT · Noi dichiariamo sotto la nostra esclusiva responsabilità che il prodotto è conforme alle direttive citate

NL · Wij verklaren geheel onder eigen verantwoordelijkheid dat het product voldoet aan de gestelde richtlijnen.

PL · Z pełną odpowiedzialnością oświadczamy, że produkt odpowiada postanowieniom wymienionych dyrektyw.

RO · Declarăm pe proprie răspundere că produsul corespunde normelor prevăzute de directivele mai sus menţionate.

SV · Vi försäkrar att produkten på vårt ansvar är utförd enligt gällande riktlinjer.

SK · Na výlučnú zodpovednosť vyhlasujeme, že výrobok spíňa požiadavky uvedených smerníc.

CE 301-13-1611

Steinhagen, 10-11-2016

______________________ i.V. ____________________

Stefan Sirges, General Manager Rüdiger Rokohl, Sales Manager

DE · Weitere normative Dokumente CS · Jinými normativními dokumenty DA · Andre normative dokumenter EN · Other normative documents FI · Muiden normien FR · Autres documents normatifs HU

· Egyéb szabályozó dokumentumokban leírtaknak IT · Altri documenti normativi NL · Verdere normatieve

documenten PL · Innymi dokumentami normatywnymi RO · Alte acte normative SV · Vidare normerande

dokument SK · Iným záväzným dokumentom:

EN 60335-2-41:2003/A2:2010

EN 62233:2008/AC:2008

• 2006/42/EG (MD) EN 809:1998/AC:2010, EN ISO 12100:2010, EN 60335-1:2012/AC:2014

• 2011/65/EU (RoHS)

• 2014/30/EU (EMC) EN 55014-1:2006/A2:2011, EN 55014-2:1997/A2:2008, EN 60034-1:2010

EN 61000-3-2:2014, EN 61000-3-3:2013

DE · Richtlinien - Harmonisierte Normen

CS · Směrnice - Harmonizované normy

DA · Direktiv - Harmoniseret standard

EN · Directives - Harmonised standards

FI · Direktiivi - Yhdenmukaistettu standardi

FR · Directives -

Normes harmonisées

HU · Irányelve - Harmonizá szabványok

IT · Direttive - Norme armonizzate

NL · Richtlijnen - Geharmoniseerde normen

PL · Dyrektywy - Normy zharmonizowane

RO · Directivă - Norme coroborate

SK · Smernice - Harmonizované normy

SV · Direktiv - Harmoniserade normer

U 3 K (JP00205/2)

U 3 KS (JP00206/2)

U 3 KS (JP09808/2)

U 3 K spez. (JP09562/2)

U 3 K spez. (JP44255)

U 3 KS spez. (JP09563/2)

U 3 KS spez. (JP45195)

U 5 K (JP09386/0)

U 5 KS (JP09387/0)

U 5 KS (JP09417/0)

U 6 K E (JP00226/2)

U 6 K D (JP00228/3)

U 6 K ES (JP00227/2)

U 6 K ES (JP09260/2)

U 6 K DS (JP00229/3)

U 6 K DS (JP09261/3)

J 67 ET (JP09153/1)

J 67 DT (JP09154/1)

UB 62 ES (JP09818/3)

UB 62 DS (JP09819/2)

UB 102 ES (JP09283/0)

UB 102 DS (JP00534/8)

UB 152 ES (JP09439/0)

UB 152 DS (JP09440/0)

UB 251 DS (JP09298/1)

DE · Bevollmächtigter für technische Dokumentation CS · Oprávněná osoba pro technickou dokumentaci

DA · Autoriseret person for teknisk dokumentation EN · Authorized person for technical documentation

FI · Valtuutettu henkilö tekninen dokumentaatio FR · Personne autorisée à la documentation technique

HU · Hivatalos személy műszaki dokumentáció IT · Persona abilitata per la documentazione tecnica

NL · Bevoegd persoon voor technische documentatie PL · Pełnomocnik ds. dokumentacji technicznej

RO · Persoană autorizată pentru documentatiei tehnice SV · Auktoriserad person för teknisk dokumenta-

tion SK · Oprávnená osoba pre technickú dokumentáciu:

JUNG PUMPEN - Stefan Sirges - Industriestr. 4-6 - 33803 Steinhagen

Page 14

Pump Technical Services Limited - Pump House - Unit 12 Bilton Road Industrial Estate - Erith - Kent - DA8 2AN

Tel: 01322 357 080 - Fax: 01322 341 341 - Email: sales@pts-jung.co.uk

Loading...

Loading...