Page 1

Triton

®

Fiberglass Sand Filters

Models:

TR 40, TR 50, TR 60, TR 100, TR 140

TR 100HD, TR 100C, TR 140C

TR 100C-3, TR 140C-3 and

Triton HD - Commercial

Model: TR 60 with

Triton C - Commercial

Technology

Triton C-3 - Commercial

™

Triton II - Residential

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

Installation & User's Guide

SAVE THESE INSTRUCTIONS

Page 2

Customer Service

M EM B E R

N AT I O NA L

SPA & P OOL

I NSTI TU TE

If you have questions about ordering Pentair replacement parts, and pool products,

please use the following contact information:

Customer Service / Technical Support (8 A.M. to 5 P.M. — Eastern and Pacific Times)

Phone: (800) 831-7133

Fax: (800) 284-4151

Sanford, North Carolina (8 A.M. to 5 P.M. — Eastern Time)

Phone: (919) 566-8000

Fax: (919) 566-8920

Moorpark, California (8 A.M. to 5 P.M. — Pacific Time)

Phone: (805) 553-5000 (Ext. 5591)

Fax: (805) 553-5515

Web site

visit www.pentairpool.com or www.sta-ritepool.com to find information about Pentair products

© 2007 Pentair Water Pool and Spa, Inc. All rights reserved.

This document is subject to change without notice.

R

1620 Hawkins Ave., Sanford, NC 27330 • (919) 566-8000

10951 West Los Angeles Ave., Moorpark, CA 93021 • (805) 553-5000

Trademarks and Disclaimers: ClearPro is a trademark of Pentair Water Pool and Spa, Inc. The Pentair Pool Products logo and Triton are registered

trademarks of Pentair Water Pool and Spa, Inc. Other trademarks and trade names may be used in this document to refer to either the entities

claiming the marks and names or their products. Pentair Water Pool and Spa, Inc. disclaims any proprietary interest in trademarks and trade names

other than its own.

P/N 154901 Rev. C 5/21/07

Page 3

Table of Contents

Important Safety Precautions .............................................................................................. ii

Section 1: Introduction .....................................................................................................1

®

Triton

General Features..................................................................................................... 2

Section 2: Installation ....................................................................................................... 3

Installing the Triton

How your Triton

Installing the Triton

Initial Start-Up .......................................................................................................... 6

Section 3: Maintenance ..................................................................................................... 7

Triton

Triton

Triton

Fiberglass Sand Filters Overview ................................................................ 1

®

Fiberglass Sand Filter .............................................................. 3

®

Filter works .................................................................................. 3

®

Filter Threaded and Oval Closures .......................................... 5

®

Filter Care..................................................................................................... 7

®

Filter Cleaning ..............................................................................................7

®

Filter Backwash Procedure .......................................................................... 8

i

Chemical Cleaning Procedure ................................................................................. 9

Winterizing your Triton

®

Filter ...................................................................................9

Section 4: Troubleshooting .............................................................................................. 10

Section 5: Replacement Parts ..........................................................................................12

®

Triton

Installing Multiple Triton

Triton

Triton

Triton

Filter Pressure Drop Curve ..........................................................................12

®

Filters (Tandem Filter Piping Kits) ............................................ 12

®

II, TR60 ClearPro & Triton® HD Replacement Parts .....................................13

®

100C & 140C Replacement Parts ................................................................ 16

®

100C-3 & 140C-3 Replacement Parts .........................................................18

®

Après – Filtres à Sable en Fibre de Verre Triton

Después – Filtros de Arena de Fibra de Vidrio Triton

®

Triton® Fiberglass Sand Filter Installation and User’s Guide

Page 4

ii

IMPORTANT SAFETY PRECAUTIONS

Important Notice:

This guide provides installation and operation instructions for the Triton® Series Fiberglass

Sand Filters. Consult Pentair Water with any questions regarding this equipment.

Attention Installer: This guide contains important information about the installation, operation and safe usage of

this product. This information should be given to the owner and/or operator of this equipment after installation or left on

or near the filter.

Attention User: This manual contains important information that will help you in operating and maintaining this

filter. Please retain it for future reference.

WARNING —Before installing this product, read and follow all warning notices and instructions which are

included. Failure to follow safety warnings and instructions can result in severe injury, death,

or property damage. Call (800) 831-7133 for additional free copies of these instructions.

Consumer Information and Safety

The Triton® Series Sand Filters are designed and manufactured to provide many years of safe and reliable service when

installed, operated and maintained according to the information in this manual and the installation codes referred to in

later sections. Throughout the manual, safety warnings and cautions are identified by the “ “ symbol. Be sure to read

and comply with all of the warnings and cautions.

WARNING — THIS FILTER OPERATES UNDER HIGH PRESSURE

When any part of the circulating system, (e.g., closure, pump, filter, valve(s), etc.), is serviced, air

can enter the system and become pressurized. Pressurized air can cause the top closure to

separate which can result in severe injury, death, or property damage. To avoid this potential

hazard, follow these instructions:

1. If you are not familiar with your pool filtering system and/or heater:

a. Do NOT attempt to adjust or service without consulting your dealer, or a qualified pool

technician.

b. Read the entire Installation & User’s Guide before attempting to use, service or adjust the

pool filtering system or heater.

2. Before repositioning valve(s) and before beginning the assembly, disassembly, or any other

service of the circulating system: (A) Turn the pump OFF and shut OFF any automatic controls

to ensure the system is NOT inadvertently started during the servicing; (B) open the manual

air bleeder valve; (C) wait until all pressure is relieved.

3. Whenever installing the filter closure FOLLOW THE FILTER CLOSURE WARNINGS

EXACTLY.

4. Once service on the circulating system is complete FOLLOW INITIAL START-UP

INSTRUCTIONS EXACTLY.

5. Maintain circulation system properly. Replace worn or damaged parts immediately, (e.g.,

closure, pressure gauge, valve(s), o-rings, etc).

6. Be sure that the filter is properly mounted and positioned according to instructions provided.

Triton® Fiberglass Sand Filter Installation and User’s Guide

Page 5

IMPORTANT SAFETY PRECAUTIONS (continued)

WARNING — This filter must be installed by a licensed or certified electrician or a qualified pool serviceman in

accordance with the National Electrical Code and all applicable local codes and ordinances.

Improper installation could result in death or serious injury to pool users, installers, or others and

may also cause damage to property.

Always disconnect power to the pool circulating system at the circuit breaker before servicing the

filter. Ensure that the disconnected circuit is locked out or properly tagged so that it cannot be

switched on while you are working on the filter. Failure to do so could result in serious injury or

death to serviceman, pool users or others due to electric shock.

WARNING —Do not operate the filter until you have read and understand clearly all the operating instructions

and warning messages for all equipment that is a part of the pool circulating system. The

following instructions are intended as a guide for initially operating the filter in a general pool

installation. Failure to follow all operating instructions and warning messages can result in

property damage or severe personal injury or death.

iii

WARNING —To reduce the risk of injury, do not permit children to use this product unless they are closely

supervised at all times.

WARNING —Due to the potential risk that can be involved it is recommended that the pressure test be kept to

the minimum time required by the local code. Do not allow people to work around the system

when the circulation system is under pressure test. Post appropriate warning signs and establish

a barrier around the pressurized equipment. If the equipment is located in an equipment room,

lock the door and post a warning sign.

Never attempt to adjust any closures or lids or attempt to remove or tighten bolts when the system

is pressurized. These actions can cause the closure to blow off and could cause severe personal

injury or death if they were to strike a person.

WARNING —Never exceed the maximum operating pressure of the system components. Exceeding these

limits could result in a component failing under pressure. This instantaneous release of energy

can cause the closure to blow off and could cause severe personal injury or death if they were to

strike a person.

Triton® Fiberglass Sand Filter Installation and User’s Guide

Page 6

iv

This page is blank.

Triton® Fiberglass Sand Filter Installation and User’s Guide

Page 7

Triton® Fiberglass Sand Filters Overview

1

Section 1

Introduction

Triton

®

II Sand Filters

The #1 sand filter in the world

Triton II is the result of over 40 years of product evolution and refinement. It has set the industry standard for

effectiveness, efficiency, long runs between service, and providing years of dependable, low maintenance operation.

Triton II features a special internal design that keeps the sand bed level, ensuring even water flow, and resulting

in the most efficient filtration possible.

The best reputation in the industry for all the right reasons

Besides its superior filtration performance, Triton II delivers a level of dependability and ease of operation and

maintenance for a track record that’s unsurpassed. Every design detail has been refined to make Triton II the

industry standard.

Triton® C and Triton® C-3 Commercial Sand Filters

This filter series features multiple diverters for increased filtration rates in commercial applications up to

20 GPM/Sq. Ft.

Triton® HD Side Mount Sand Filters

All the same great performance and features of the original Triton’s with maximum operating pressure of 75 psi

for those special high pressure installations such as single pump in-floor cleaning systems.

Triton II - Residential

Triton HD - Commercial

Triton C-3 - Commercial

Triton C - Commercial

Triton® Fiberglass Sand Filter Installation and User’s Guide

Page 8

2

General Features

Triton® II

• Time-proven internal design ensures that all water receives maximum filtration for crystal clear results

• GlasLok™ process creates a one-piece, fiberglass reinforced tank with a UV-resistant coating for years of

dependable, corrosion-resistant service

• Flow system design controls filtration quality and ensures maximum run times between backwashing to save

you time

®

Triton

Triton

C and Triton® C-3

• Maximum Operating Pressure 50 psi

• Full 2 in. drain

• 8 in. opening for easy access to sand bed

• The Triton C-3 features standard 3 in. flange connections

• TR100C & TR140C models are available in black or almond

• TR100C-3 & TR140C-3 models are available in black only

®

HD

• Maximum Operating Pressure 75 psi

Additional Features:

• Combination sand and water drain speeds servicing and winterizing

• All internal parts are threaded for ease of maintenance

• Swing-away water diffuser allows instant access to sand and all internal parts

• NSF-Listed

Triton® Fiberglass Sand Filter Installation and User’s Guide

Page 9

Section 2

Installation

Note: Before installing this product, read and follow all warning notices and instructions starting

on page ii.

Installing the Triton® Fiberglass Sand Filter

Only a qualified service person should install the Triton Fiberglass Sand Filter. This filter is designed and

intended for use to filter water.

Triton® Introduction

The following general information describes how to install the Triton Fiberglass Sand Filter. This filter operates

under pressure and if assembled improperly or operated with air in the water circulation system, the top closure

can separate and result in an accident causing property damage or serious bodily injury. A warning label has been

affixed to the top of the filter and should not be removed. Keep safety labels in good condition and replace if

missing or illegible.

How your Triton® Filter works

Your high rate sand filter is designed to operate for years with a minimum of maintenance and when installed,

operated and maintained in accordance with these instructions, it will provide years of trouble free operation.

Dirt is collected in the filter as the water flows through the control valve at the side of the filter and is directed into

the top bulkhead. Dirty water flows into the diffuser at the top of the tank and is directed downward into the top

surface of the filter sand bed. The dirt is collected in the sand bed and the clean water flows through the laterals

and lower piping at the bottom of the filter up into the lower bulkhead. The flow then goes into the control valve

at the side of the filter. Clean water is returned through the piping system into the pool.

The pressure will rise and the flow to the pool will be lowered as the dirt is collected in the filter. Eventually, the filter

will become so plugged with dirt that it will be necessary to perform the backwash procedure. It is important to know

when to backwash the filter. Backwashing is discussed further under the subsequent sections of this guide.

Please note that a filter removes suspended matter and does not sanitize the pool. The pool water must be

sanitized and the water must be chemically balanced for sparkling clear water. Your filtration system should be

designed to meet your local health codes. As a minimum, you must be sure that your system will turn over the

total volume of water in your pool at least two to four times in a twenty-four hour period.

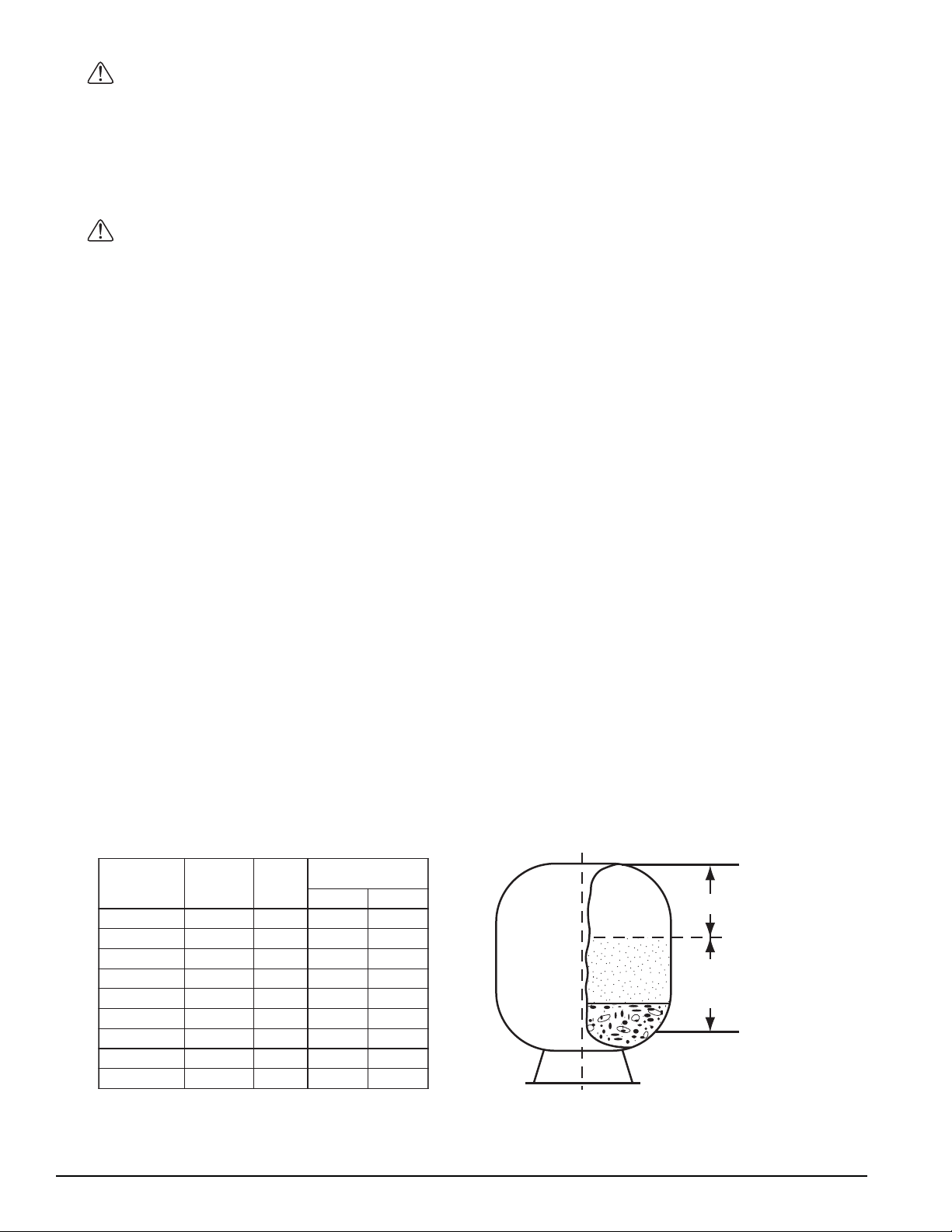

Refer to Table 1 for Filter Operation Data.

3

Table 1.

LEDOMRETLIF

LEDOM

04RT29.183086,

05RT64.294046,71025,32004,92082,53

06RT41.336086,22042,03008,73063,54

orPraelC06RT41.336086,22042,03008

001RT19.447046,62025,53004,44082,35

DH001RT19.489082,53040,74008,85065,07

3-C001RT/C001RT19.489082,53040,74008,8

041RT60.7601061,83088,05006,36023,67

3-C041RT/C041RT60.7141067,05086,76006,48025,101

RETLIF

AERA

(tF.qS).

ETARWOLF

)MPG(*

2

TF/MPG02@

31042,81008,22063,72

*TR100 AND TR140 ARE BASED ON 15 GPM/SQ. FT.

YADREPSNRUT4YADREPSNRUT3YADREPSNRUT4.2YADREPSNRUT2

(.tF.qS/MPG02nodesaB*)

Triton® Fiberglass Sand Filter Installation and User’s Guide

(YTICAPACREVONRUTsnollaG)

,73063,54

5065,07

Page 10

4

WARNING — Failure to operate your filter system or inadequate filtration can cause poor water clarity obstructing

visibility in your pool and can allow diving into or on top of obscured objects which can cause serious

personal injury or drowning.

Clear water is the result of proper filtration as well as proper water chemistry. Pool chemistry is a specialized

area and you should consult your local pool service specialist for specific details. In general, proper pool sanitation

requires a free chlorine level of 1 to 3 PPM and a pH range of 7.2 to 7.6.

WARNING — Filters should never be tested or subjected to air or gas under pressure. All gases are compressible

and under pressure create a danger. Severe bodily injury or property damage could occur if the filter

is subjected to air or gas pressure.

1. Check carton for any evidence of damage due to rough handling in shipment. If carton or any filter components

are damaged, notify the freight carrier immediately.

2. Carefully remove the accessory package and the filter tank from the carton.

3. Mount the filter on a permanent slab, preferably concrete poured in a form or on a platform constructed of

concrete block or brick. DO NOT use sand to level the filter or for the pump mounting, as it will wash away.

4. Provide space and lighting for routine maintenance access. Do not mount electrical controls over the filter. One

needs to be able to stand clear of the filter when starting the pump. Minimum space requirements may be found

on the large nameplate on the filter.

5. Position filter so that the port locations are in the desired final positions. Follow valve installation procedures.

6. If you have a Multiport Valve, assemble the valve to the tank, being sure the o-ring on the valve fittings are

in place and are clean. Use a lubricant, applied lightly, such as silicone grease, Dow #33, #40 or GE 300 or 623,

or similar product on o-rings and o-ring grooves prior to assembly.

7. If you have a two position slide valve, align the valve with the tank so that the handle is toward the top of the

tank, push valve into ports and turn the valve nuts snugly on the tank fittings. It is not necessary to cinch the

valve nuts to the tank fitting beyond hand tightness.

8. The shipping straps used to support the TR100C-3, TR140C and the TR140C-3 multi-diffuser should be

removed before loading sand and gravel in the filter.

9. Sand specifications – be certain the proper sand is used as described in Table 2. Before pouring the sand into

the filter, look inside and check the lower under-drain for broken or loose laterals (or fingers), which may have

been accidentally damaged by rough handling during shipment. Replace any broken parts if necessary.

NOTE: The free board distance is the most important variable and should be maintained. Sand density will vary

and therefore sand amount is given as a reference.

Tab le 2.

‡LEVARGAEPDNAS

†AIDEMRETLIF

)SDNUOP(

"X" FREE BOARD

ALL SAND

or

SAND & GRAVEL

LLA

LEDOM

04RT"4/1857105521

05RT"4/3952205571

06RT"2/10152305572

orPraelC06RT"2/10152305572

001RT"4/111006051054

DH001RT"4/111006051054

3-C00

1RT"4/111006051054

041RT"2/131529572056

3-C041RT"2/131529572056

† Media required to meet NSF requirements.

‡ Pea Gravel to be 1/4” to 1/8” diameter.

* Sand to be No. 25 standard silica (uniformity coefficient not greater than 1.75) .018-.020 in diameter particle size.

DRAOBEERF

"X"

*DNAS

)SDNUOP(

Triton® Fiberglass Sand Filter Installation and User’s Guide

Page 11

WARNING — Failure to position the Automatic Air Vent inside of the Closure will allow excessive trapped air to

accumulate in the filter. Trapped air and the closure not properly closed can cause the closure to

blow off and could cause severe bodily injury and/or property damage.

10. Pivot the diffuser out of the center of the tank on the TR40, 50, 60, TR60 ClearPro, 100 & 140 by rotating the

diffuser assembly counter clockwise. (NOTE: The multi-diffuser assembly should not be moved on models

TR100C, TR100C-3 and TR140C, TR140C-3. After installing the filter media as described below, check to make

sure the tops on the diffusers are parallel to the top of the sand bed.) Fill the tank about half full of water. Pour

pea gravel first (if used) and then the sand into the top of the filter at a slow rate so that the impact of the filter

media does not damage the laterals. See Table 2 for the proper amounts of sand and gravel. Fill filter to the proper

level to maintain freeboard, as shown in Table 2. Pivot the diffuser assembly back to its vertical position if it was

moved. Be certain the automatic air vent is protruding into the top of the closure as indicated below in Figure 1.

Ensure that the automatic air vent is in the center of the filter closure. Wash away all sand around the threaded

opening at the top of the tank.

WARNING —For Threaded Closures

Use care when installing closure. The closure should turn freely in the filter, if resistance to closure

insertion is felt, then slowly remove the closure by turning counter-clockwise. The starting thread of

the tank and closure must engage properly in order to secure the closure. Do not cross-thread

closure.

Failure to install the closure properly can cause the closure to blow off and could cause severe

bodily injury and/or property damage.

5

WARNING —For Oval Closures

Use care when installing closure. The closure should be inserted into the tank by placing the small

diameter of the oval closure into the larger diameter of the tank opening. Insert the side of the closure

that does not have the pressure gauge and air bleeder first. The closure will need to be inserted at

a 30° angle. Once the closure is inside the tank, it can be rotated 90° and lifted up to seal the tank.

The aluminum bridge with load spring can then be placed over the closure bolt and the hand knob

tightened to load the closure properly. The knob should be tightened by hand only. DO NOT USE A

WRENCH TO TIGHTEN THE KNOB. You could damage the tank or closure and cause a failure by

using a wrench. Failure to install the closure properly can cause the closure to blow off and could

cause severe bodily injury or property damage.

NEVER ATTEMPT TO TIGHTEN OR LOOSEN THE CLOSURE WITH THE PUMP RUNNING.

Failure to follow this instruction can result in the closure blowing off and causing severe bodily injury

or property damage.

11. Assemble the pressure gauge and bleeder valve to the closure lid. Clean

the lid o-ring and lubricate with silicone grease such as Dow #33, 40 or

GE 300, 623 lubricant. Place the closure lid on the filter and tighten,

making certain the air vent is up inside the dome of the closure.

12. With the plastic wrench, provided with the filter, tighten the closure as

tight as possible using two hands on the wrench handles. As a minimum,

MANUAL AIR

BLEEDER

VALVE

XX

XX

XX

XX

XX

PRESSURE

GAUGE

CLOSURE

the closure must be hand tight + 1/4 turn.

13. The oval closure that is used on the TR140C-3 and the TR100C-3 models

AUTOMATIC AIR

will need to be installed as described in the above warning note for oval

closures.

14. Assemble piping and pipe fittings to pump and valve. All piping must

TANK

conform to local and state plumbing and sanitary needs.

15. Use sealant compounds on all male connections of pipe and fittings. Use

only pipe compounds suited for plastic pipe. Support pipe to prevent

Figure 1.

strains on filter, pump or valve.

16. Long piping runs and elbows restrict flow. For best efficiency, use the fewest possible number of fittings, and

large diameter pipe (at least 2” for TR100 and TR140, at least 3” for TR100C-3 and TR140C-3).

VENT

Triton® Fiberglass Sand Filter Installation and User’s Guide

Page 12

6

CAUTION —Operating at excessive vacuum levels can cause the tank to crack and could cause property damage.

17. When installing backwash lines, it is recommended that a vacuum breaker be installed on installations where the

backwash line length exceeds 40 ft. or the backwash line discharges more than 10 ft. lower than the surface of the

pool. Alternately a vacuum break pit should be provided.

18. A check valve is recommended between the filter and heater to prevent hot water “back-up” which will damage the

filter and valve.

19. The maximum operating pressure of the unit is 50 pounds per square inch (psi) and 75 pounds per square inch (psi)

for the Triton HD model (only). Never operate this filter above these pressures or attach a pump to this filter that

has more than 50 psi shut off pressure or 75 psi shut off pressure for the Triton HD model (only).

20. Never install a chlorinator upstream of the filter. Always locate downstream and with a check valve between the

chlorinator and filter.

21. A positive shut off valve is not recommended at the outlet of the filtering system. If the system is ever run with such

a valve closed, the internal air relief system becomes inoperative and an explosive situation could exist. Additionally,

running the system with no flow will seriously damage the equipment.

22. Never store pool chemicals within 10 ft. of your pool filter. Pool chemicals should always be stored in a cool, dry

well ventilated area.

23. The oval closure used on the TR100C-3 and TR140C-3 is designed to provide a vacuum relief mechanism that

protects the tank from vacuum conditions. The closure will allow air to enter the tank if the tank is higher that 8 ft.

above the water level. In these cases, when the filter restarts after shut down, you may observe air being returned

to the pool in the return fittings. This is not unusual, it is simply the automatic air relief in the filter removing the air

in the filter.

Initial Start-up

1. On a new pool, clean the pool before filling the pool with water. Excessive dirt and large particles can cause damage

to the pump and filter.

2. Ensure the backwash line is open so that water is free to come from the pool and flow out the backwash line. Set

the valve position as follows:

a. If using a Multiport valve, set valve to backwash position.

b. If using a Two Position Slide Valve, push handle down to backwash position and engage lock by twisting handle.

3. Check pump strainer pot to be sure it is full of water.

WARNING — Air entering the filter and the tank closure not installed properly can cause the closure to blow off and

could cause severe bodily injury and/or property damage.

4. Check closure on filter for tightness.

5. Open the manual air bleeder on the filter closure. Stand clear of the filter and start the pump allowing it to prime.

6. Close the air bleeder on the closure when all the air is removed from the filter and a steady stream of water emerges.

NOTE: Pool filter sand is typically pre-washed and should not require extensive backwashing. However, the shipping

process may cause excessive abrasion which could require an extended backwash cycle at initial start-up; continue to

backwash until the backwash water is as clear as the pool water.

CAUTION — To prevent equipment damage and possible injury, always turn the pump off before changing the valve

position.

7. Stop the pump. Set the valve position as follows:

a. If using a Multiport valve, set the valve to the filter position.

b. If using the Two Position Slide Valve, raise the handle to filter position and engage valve lock by twisting handle.

8. Ensure all suction and pool return lines are open so that water is free to come from the pool and return to the pool.

9. Open the manual air bleeder on the filter closure. Stand clear of the filter and start the pump.

10. Close the air bleeder on the filter closure when all the air is removed from the filter and a steady stream of water emerges.

11. The filter has now started its filtering cycle. You should ensure that water is returning to the pool and take note of

the operating pressure when the filter is clean.

Triton® Fiberglass Sand Filter Installation and User’s Guide

Page 13

Section 3

Maintenance

This section describes how to maintain your Triton Fiberglass Sand Filter.

Filter Care

The filter is a very important part of the pool equipment and installation. Proper care and maintenance will add many

years of service and enjoyment to the pool. Follow these suggestions for long trouble-free operations:

1. To clean the exterior of the filter of dust and dirt, wash with a mild detergent and water then hose off. Do not

use solvents.

2. If internal maintenance is required, sand may be removed by removing the sand drain from the bottom of the

filter and flushing with a garden hose. Pentair Water Pool and Spa Sand Vacuum P/N 542090 may also be used.

3. If after a number of years, the filter tank appears foggy in color or rough in texture, the tank surface can be

painted. We recommend the use of a Quick Dry Spray Enamel. Do NOT paint the valve.

WARNING — Always visually inspect filter components during normal servicing to ensure structural safety. Replace

any item which is cracked, deformed or otherwise visually defective. Defective filter components can

allow the filter top or attachments to blow off and could cause severe bodily injury or property

damage.

7

4. The filter closure on your Triton Sand Filter was manufactured with high quality corrosion resistant materials.

This part should be carefully inspected whenever servicing your filter. If excessive leakage is noted coming

from the closure/tank interface, the closure and o-ring should be carefully inspected and replaced if any signs

of deterioration exist.

5. Your filter is a pressure vessel and should never be serviced while under pressure. Always relieve tank pressure

and open air bleeder on the filter closure before attempting to service your filter.

6. When restarting your filter, always open the manual air bleeder on the filter closure and stand clear of the filter.

Cleaning Frequency

1. The filter on a new pool should be backwashed, and cleaned after approximately 48 hours of operation to clean

out plaster dust and/or construction debris.

2. There are three different ways to identify when the filter needs backwashing.

a. The most accurate indicator on pool systems with a flow meter is to backwash when the flow decreases

30% from the original (clean filter) flow. For example, if the original flow was 60 GPM, the filter should

be backwashed when the flow is reduced by about 20 GPM (or 30%) to 40 GPM.

b. A more subjective and less accurate indicator is to observe the amount of water flowing from the flow

directionals located in the wall of the pool. The filter should be backwashed once it is detected that the flow

has been reduced by about 30%.

c. The most commonly used but less accurate indicator is to backwash when the filter gauge reading increases

10 PSI over the initial (clean filter) reading.

3. It is important not to backwash the filter solely on a timed basis such as every three days. It is also important

to note that backwashing too frequently actually causes poor filtration. Factors like weather conditions, heavy

rains, dust or pollen, and water temperature all affect the frequency of backwash. As you use your pool, you

will become aware of these influences.

4. If at any time the starting pressure after backwashing the filter indicates 4 to 6 PSI higher than normal starting

pressure, it is time to perform a chemical cleaning procedure.

Triton® Fiberglass Sand Filter Installation and User’s Guide

Page 14

8

Filter Backwash Procedure

WARNING —To prevent equipment damage and possible injury, always turn off pump before changing valve

positions.

1. Stop the pump.

2. Ensure that the suction and backwash lines are open so that water is free to come from the pool and flow out

the backwash line. Set control valve position as follows:

a. If using a Multiport Valve, set valve to backwash position.

b. If using a Two Position Slide Valve, push handle down to backwash position and engage lock by twisting

handle.

3. Stand clear of the filter and start pump.

4. Backwash filter for approximately 3 to 5 minutes or until backwash water is clean.

5. Stop the pump.

a. If using a Multiport Valve, set valve to rinse position and continue with remaining steps.

b. If using a Two Position Slide Valve, skip to step 8.

6. Stand clear of the filter and start pump.

7. Rinse filter for approximately 30 seconds.

8. Stop the pump and set valve as follows:

a. If using a Multiport Valve, set valve to filter position.

b. If using a Two Position Slide Valve, raise handle to filter position and engage valve lock by twisting handle.

9. Ensure that pool return line is open so that water may freely flow from the pool back to the pool.

10. Open manual air bleeder on Triton closure. Stand clear of filter and start pump.

11. Close manual air bleeder of the closure when all the air is removed and a steady stream of water emerges from

the bleeder.

12. The filter has now started its filtering cycle. You should ensure that water is returning to the pool and take note

of the filter pressure.

13. The filter pressure, in the above Step 12, should not exceed the pressure originally observed on the filter when

it was initially started. If after backwashing, the pressure is 4 to 6 PSI above the start condition, it will be

necessary to chemically clean the sand bed.

Triton® Fiberglass Sand Filter Installation and User’s Guide

Page 15

Chemical Cleaning Procedure

1. It is recommended that an approved cleaner be used. Please contact your local pool chemical supplier or retail

store for the proper cleaner.

These cleaners will remove oils, scale and rust from the sand bed in one cleaning operation.

2. Mix a solution following the manufacturers instructions on the label.

3. Backwash the filter as outlined on page 8.

4. If the filter is below pool level, shut off the pump and close appropriate valving to prevent draining the pool.

5. Shut off pump, open filter drain and let filter drain. Place valve in backwash position.

6. After filter has drained, close filter drain and remove the pump strainer pot lid.

7. Ensure that the backwash lines are open.

8. Turn the pump on and slowly pour the cleaning solution into the pump strainer with the pump running.

9. Continue adding solution until the sand bed is saturated with cleaning solution. Replace lid on pump.

10. Shut off the pump and leave filter in backwash position. Allow filter to stand overnight (12 hours).

11. Replace the pump lid and follow backwash procedures on page 8.

9

12. Do not allow the cleaning solution to get into the pool.

Winterizing your Filter

1. In areas that have freezing winter temperatures, protect the pool equipment by backwashing the filter.

2. After backwashing, shut the pump off, open the manual air bleeder on the closure and adjust the valve as follow:

a. On the Multiport Valves, move the handle of the valve to the Winterize Position (*).

b. On the Two Position Slide Valve, if possible, remove the valve piston assembly; clean, lubricate and store

in a dry location for the winter.

*NOTE: The Multiport valve should be left in the winterize position during shutdown season so the valve diverter

has no pressure on the rubber seal.

3. On the TR40, 50, 60, and TR60 ClearPro, remove the wing-type plug on the bottom of the filter. On the TR100,

TR100C, TR100C-3, and TR140, TR140C, TR140C-3, remove the 1½” drain plug cap. The filter will drain very

slowly, and therefore, it is recommended that the drain plug be left out.

4. Drain all appropriate system piping.

5. We recommend covering the equipment with a tarpaulin or plastic sheet to inhibit deterioration from weather.

Do NOT wrap pump motor with plastic.

Triton® Fiberglass Sand Filter Installation and User’s Guide

Page 16

10

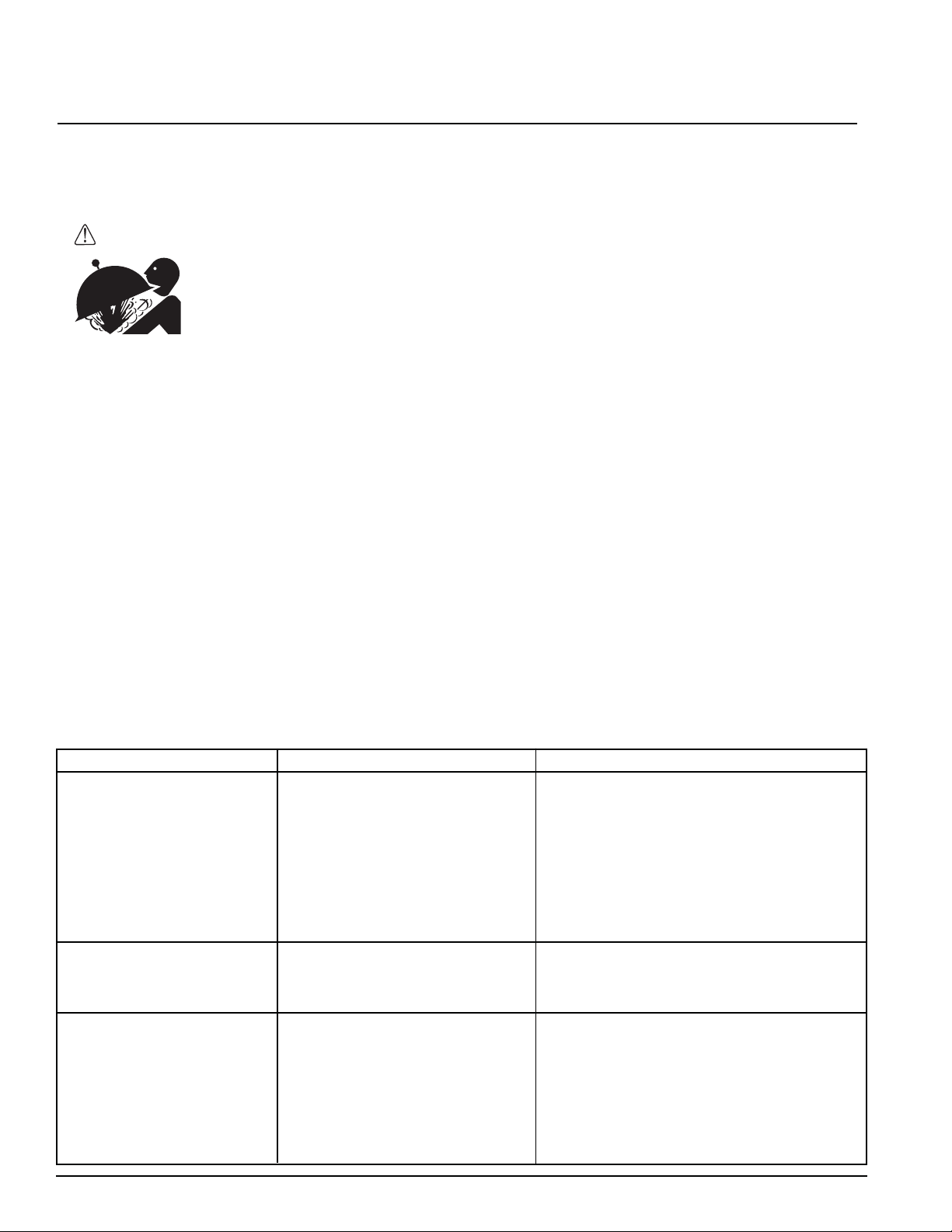

Troubleshooting

Use the following troubleshooting information to resolve possible problems with your Triton Filter.

WARNING — THIS FILTER OPERATES UNDER HIGH PRESSURE

When any part of the circulating system, (e.g., closure, pump, filter, valve(s), etc.), is serviced, air can

enter the system and become pressurized. Pressurized air can cause the top closure to separate which

can result in severe injury, death, or property damage. To avoid this potential hazard, follow these

instructions:

1. If you are not familiar with your pool filtering system and/or heater:

a. Do NOT attempt to adjust or service without consulting your dealer, or a qualified pool

technician.

b. Read the entire Installation & User’s Guide before attempting to use, service or adjust the

pool filtering system or heater.

2. Before repositioning valve(s) and before beginning the assembly, disassembly, or any other

service of the circulating system: (A) Turn the pump OFF and shut OFF any automatic controls

to ensure the system is NOT inadvertently started during the servicing; (B) open the manual air

bleeder valve; (C) wait until all pressure is relieved.

3. Whenever installing the filter closure FOLLOW THE FILTER CLOSURE WARNINGS EXACTLY.

4. Once service on the circulating system is complete FOLLOW INITIAL START-UP INSTRUCTIONS

EXACTLY.

5. Maintain circulation system properly. Replace worn or damaged parts immediately, (e.g., closure,

pressure gauge, valve(s), o-rings, etc).

6. Be sure that the filter is properly mounted and positioned according to instructions provided.

Section 4

Note: Turn off power to unit prior to attempting service or repair.

Problems and Corrective Actions

PROBLEM CAUSE REMEDY

Pool water not sufficiently clean 1. Pool chemistry not adequate to inhibit Maintain pool chemistry or consult pool service

algae growth. technician.

2. Too frequent a backwash cycle. Allow pressure to build to 10 psi above clean

filter condition before backwashing.

3. Improper amount or wrong sand size. Check sand bed Freeboard and sand size or

consult a pool service technician.

4. Inadequate turnover rate. Run system for longer time or consult dealer or

pool service technician.

High filter pressure 1. Insufficient backwashing. Backwash until effluent runs clear.

2. Sand bed plugged with mineral deposits. Chemically clean filter.

3. Partially closed valve. Open valve or remove obstruction in return line.

Short cycles 1. Improper backwash. Backwash until effluent runs clear.

2. Pool chemistry not adequate to inhibit Maintain pool chemistry or consult pool

algae growth. service technician.

3. Plugged sand bed. Manually remove top 1” surface of sand bed,

replace with new sand and chemically clean entire

sand bed as described in the Chemical Cleaning Procedure.

4. Flow rate too high. Restrict flow to capacity of filter.

Triton® Fiberglass Sand Filter Installation and User’s Guide

Page 17

PROBLEM CAUSE REMEDY

Return flow to pool diminished, 1. Obstruction in pump hair and Clean basket in pump strainer.

low filter pressure lint strainer.

2. Obstruction in pump. Disassemble and clean pump.

3. Obstruction in suction line to pump. Clean skimmer basket. Remove obstruction in lines.

Open valves in suction line.

Sand returning to pool 1. Broken under drain lateral. Replace broken or damaged laterals.

Sand loss to waste 1. Backwash rate too high. Reduce backwash flow rate.

2. Improper sand size. Change to proper sand.

3. Air strainer is damaged or missing. Replace damage components.

Leak at closure 1. Improperly tightened closure. Shut off pump, relieve tank pressure,

open air bleeder, tighten closure properly.

2. Dirt or contamination on sealing surface. Shut off pump, relieve tank pressure, open

air bleeder, remove closure and clean all sealing

surfaces. Reassemble closure properly.

3. Damaged part. Same as above except replace damaged o-ring,

closure, tank or any combination of parts as required.

Leak at bulkhead 1. Improper tightened bulkhead assembly. Shut off pump, relieve tank pressure, open air bleeder,

remove closure and remove sand to access leaking

bulkhead on TR40, 50, 60, TR60 ClearPro, 100, 100C,

140 or 140C. Hold the 2” bulkhead and tighten the

2” internal locknut. On the TR100C-3/TR140C-3, using

the special wrench, P/N 154020, hold the 3” flange

spacer and with wrench, P/N 154019, tighten the

3” flange adapter. Hand tighten plus 1/2 turn.

2. Dirt or contamination on sealing surfaces. Shut off pump, relieve tank pressure, open

air bleeder, remove closure and remove sand to

access leaking bulkhead. Remove attached tank

internals and remove bulkhead assembly. Clean all

mating surfaces and seals. Replace the bulkhead

assembly, being careful to assemble properly.

Tighten assembly as indicated above.

3. Damaged part. Same as above except replace damaged part or

combination of parts.

11

Triton® Fiberglass Sand Filter Installation and User’s Guide

Page 18

12

Section 5

Replacement Parts

Pressure Drop Curve for the Triton Series Sand Filters

Pressure Drop in Feet

Flow Rate in G.P.M.

Installing Multiple Filters with Tandem Filter Piping Kits

CAUTION: WHEN MULITPLE FILTERS ARE

INSTALLED, WE HIGHLY RECOMMEND

THE USE OF A PENTAIR TANDEM FILTER

PIPING KIT. THESE KITS INCLUDE

PLUMBING SUPPORTS (BETWEEN

INLET AND OUTLET PIPING AND

BETWEEN OUTLET PIPING AND

FLOOR) TO ASSURE INTEGRITY

OF THE INSTALLATION.

SEE FIGURE A.

FIGURE A.

INLET

OUTLET

CAUTION: PENTAIR RECOMMENDS THE

USE OF A TANDEM FILTER

PLUMBING KIT(S) OR SOME

SORT OF PLUMBING SUPPORT

TO ASSURE PLUMBING INTEGRITY.

FAILURE TO INCLUDE THESE SUPPORTS

COULD VOID YOUR WARRANTY.

Triton® Fiberglass Sand Filter Installation and User’s Guide

Page 19

TRITON II & TRITON HD FIBERGLASS SAND FILTER

Replacement Parts

33

1

2

3

4

5

6

7

35

8

9

34

19

27

13

TR40

TR50

TR60

TR60 ClearPro

TR100

TR100HD

TR140

DETAIL A

After Dec. 1, 1991

6" BUTTRESS THREAD

10

11

12

13

14

15

16

17

26

18

20

22

21

28

23

25

24

29

32

29

30, 31

Filters manufactured after Dec 1, 1991 utilize a 6 in.

buttress thread in the filter tank top opening and on the

closure, see Detail A.

Filters manufactured before Dec 1, 1991 utilize a 6 in.

“V” type thread, see Detail B.

6 in. closures in Detail A. and B. are NOT

interchangeable.

18

DETAIL B

Before Dec. 1, 1991

6" "V" THREAD

26

17

★★

★ Used on

★★

TR100 and

TR140 filters.

LEDOM.MIDA.MIDB.MIDC.MIDD

04RT

05RT

06RT

06RT orPraelC

001RT

DH001RT

041RT

.ni½03.ni½91.ni¾01.ni½23

.ni¾43.ni½12.ni8/7-11.ni¾63

.ni½53.ni½42.ni8/5-31.ni½73

.ni½53.ni½42.ni8/5-31.ni½73

.ni¾93.ni½03.ni¼61.ni¾14

.ni¾93.ni½03.ni¼61.ni¾14

.ni¼54.ni½63.ni¾81.ni¼74

Triton® Fiberglass Sand Filter Installation and User’s Guide

Page 20

14

metI

.oN

1986451.yssaeet/redeelbriA

2007451redeelbriassarb-ret

3050551erusserptnuomkcab-eguaG

4166451retpadaredeelbria-gnir-O

5466451s/s61-.ni8/3-tuN

6075451AliateDees,dae

6955451BliateDees,.klBdaerht"V".ni6-erusolC

7394451etihw,erusolcgnir-O

8530051RT/LCEre

993005104RTfeilerriaebuT

904005106/05RTfeilerriaebuT

9140051001RTfeilerriaebuT

9240051041RTfeilerriaebuT

018

0199545106RT.yssaresuffiD

01264451001RT.yssaresuffiD

01609451041RT.yssaresuffiD

1130845

.oNtraP

padA

niartS

9545105/04RT.yssaresuffiD

104RTreppu.yssagnipiP

SRETLIFDNASDHNOTIRT&IINOTIRT

noitpircseD

TRITON II & TRITON HD

FIBERGLASS SAND FILTER

Replacement Parts

TR40

TR50

TR60

TR60 ClearPro

TR100

rhtsserttub.ni6-erusolC

TR100HD

TR140

NOTES

Filters manufactured after Dec 1, 1991 utilize

a 6 in. buttress thread in the filter tank top

opening and on the closure, see Detail A.

Filters manufactured before Dec 1, 1991 utilize

a 6 in. “V” type thread, see Detail B.

6 in. closures in Detail A. and B. are NOT

interchangeable.

To determine manufacture date, the first 4 digits

of the serial number indicate the month and year

product was manufactured.

1141865105RTreppu.yssagnipiP

1133545106RTreppu.yssagnipiP

11624451001RTreppu.yssagnipiP

110

21630051ebutfeilerriarotcennoC

3110845104RTrewol.yssagnipiP

3161865105RTrewol.yssagn

3150845106RTrewol.yssagnipiP

31482551laretaLnruT4/1-orPraelC06RTrewol.yssagnipiP

31708451001RTrewol.yssag

31984451041RTrewol.yssagnipiP

41636451AliateD,.dht.rtb.ni6-04RT.yssa.tf&knaT

41736451AliateD,.dht.rtb.ni

41836451AliateD,.dht.rtb.ni6-06RT.yssa.tf&knaT

41936451AliateD,.dht.rtb.ni6-001RT.yssa.

41046451AliateD,.dht.rtb.ni6-041RT.yssa.tf&knaT

41422651DH.klB.dht.rtb-DH001RT.yssa.tf&knaT

05451041RTreppu.yssagnipiP

ipiP

nipiP

6-05RT.yssa.tf&knaT

tf&knaT

TR60 ClearPro - 1/4 Turn Lateral for filters

manufactured after May 15, 2007 utilize Lower

Piping Assy. P/N 155284.

13

15

16

DETAILED VIEW

Triton® Fiberglass Sand Filter Installation and User’s Guide

Detail for Triton® II - TR60 Filters

with ClearPro Technology

™

Page 21

15

metI

.oN

51092251.qer8,06/05/04RTL.ni61/116-laretaL

51580051.q

51880051.qer6,orPraelC06RT-.yssAlaretaL

51202251.qer8,001RTL.ni8/19-laretaL

513

51045451.qer8,041RTL.ni21-laretaL

6136745106/05/04RTlaretaLbuH

61222251orPraelC

61354451041/001RTlaretaLbuH

71022251.ni2niarddnaS

71896451niarddnasTPN.ni¾togipS

71586451niarddnas

81178451.ni½1.dhtpaC

81161753niardTPN.ni¼gulP

91215451erusolc.ni6hcnerW

91015451munimulaerusolchc

91806151munimulaerusolc.ni½8hcnerW

02214451.qer2,lanretni.ni2tunkcoL

12614451.qer2,lanretni.ni2recapS

22294

32804451.qer2,lanretxe.ni2recapS

42835451.qer2,daehklub.ni2teksaG

52504451.qer2,.ni

62494472.d.i.ni8/52X.ni61/3gnir-O

62511291retpadaria21-2#gnir-O

72814451s/s.ni8/3rehsaW

8262945105/04R

82025451)1ETONees(06RT,.aid.ni91tooF

82695451041/001RT,.aid.ni42tooF)1ETONees(

924944

03290172tik.rtpda.dht.ni2

13490172tik.rtpda.dht.ni½1

23690172tik.rtpdapils.ni2&.ni½

33146451ALIATED,.klB,.dhtsserttub.ni6,erusolctiK

33796451BLIATED,naT,.dht"V".ni6,erusolctiK

33658451.klB,.d

43786451)2ETONees(etelpmocegakcapgnittiF

5311645104RT.ni¾3reniartstnevriarecapS

321645106/05RT.ni½4reniartstnevriarecapS

5

53316451001RT.ni½5reniartstnevriarecapS

53416451041RT.ni5reniartstne

.oNtraP

45451.qer8,001RTL.ni½6-laretaL

06RT.yssAbuH

TPN.ni½togipS

nerW

451.qer2,daehklub.ni2gnir-O

2daehkluB

T,.aid.ni61tooF)1ETONees(

72.qer2,.rtpdaevlavgnir-O

1

vriarecapS

204451.qer3,06/05/04RTgnitnuom.tfepaT

704451.qer3,041/001RTgnitnuom.tfepaT

206151.ni2hcnerwdaehk

luB

41745152-02smetiedulcni,tikdaehkluB

noitpircseD

htsserttub.ni½8,erusolctiK

SRETLIFDNASDHNOTIRT&IINOTIRT

TRITON II & TRITON HD

FIBERGLASS SAND FILTER

er6,06RTnrut4/1-.yssAlaretaL

Replacement Parts

TR40

TR50

TR60

TR60 ClearPro

TR100

TR100HD

TR140

NOTES

Filters manufactured after Dec 1, 1991 utilize

a 6 in. buttress thread in the filter tank top

opening and on the closure, see Detail A.

Filters manufactured before Dec 1, 1991 utilize

a 6 in. “V” type thread, see Detail B.

6 in. closures in Detail A. and B. are NOT

interchangeable.

To determine manufacture date, the first 4 digits

of the serial number indicate the month and year

product was manufactured.

Used on Filters manufactured before 5-85.

Used on Filters manufactured after 5-85.

Used on Filters manufactured before 3-83.

Used on Filters manufactured after 3-83 thru 3-96.

For Installations w/out Valve (Pair).

Used on TR100 & 140 Filters.

NOTE 1: Replacement of tank foot requires the use of foot

mounting tape. See P/N’s

NOTE 2: Fitting package includes items 1, 2, 4, 5 and 27.

.

Triton® Fiberglass Sand Filter Installation and User’s Guide

Page 22

16

TRITON 100C & 140C FIBERGLASS SAND FILTER

Replacement Parts

9

31

30

10

32

TR100C

TR140C

11

27

25

26

TR 100C

TR 140C

12

9

10

29

28

17

24

31

32

3

2

1

30

6

4

5

7

13

14

37

8

11

18

19

16

UPPER PIPING SHOWN

IN ISOMETRIC

TANK VIEW TR 140C

Triton® Fiberglass Sand Filter Installation and User’s Guide

15

20

21

22

23

33

34

20

35, 36

LEDOM.MIDA.MIDB.MIDC.MIDD

C001RT.ni¾93.ni½03.ni½61.ni¾34

C041RT.ni¼54.ni½63.ni¾81.ni¼94

Page 23

17

metI

.oN

.oNtraP

noitpircseD

SRETLIFDNASC041RT&C001RT

TRITON 100C & 140C

FIBERGLASS SAND FILTER

1215372gnir-o/wredeelbriA

2315372wercsredeelbriagnir-O

3465

4050551eguagerusserP

5494472..d.i.ni8/5-2X.ni61/3gnir-O

6465372denihcamydobevlaV

7575

8905251.ni½8gnirerauqS

9995451C001RTresuffiD

9995451C041RTresuffiD

01553651C041RT,C001RT

3121445

41034351klB-.DHT.rtb.ni½8-C001RT.yssa.tf&knaT

41134351klB-.DHT.rtb.ni½8-C041RT.yssa.tf&knaT

51354451C041RT/C001RTlaretalbuH

372.yssaydobfeilerrialaunaM

451sserttub.ni½8erusolC

11443651C041RT,C001RTtelnireppu.yssagnipiP

21453651C041RTreppu.yssagnitcennocgnipiP

1lanretni.ni2tuN

reppu.yssagnipiP

Replacement Parts

metI

.oN

23530051feilerriareniartS

33494472.rtpdaevlavgnir-O

4369017

53290172)riap(evlavo/w.tsniroftik.rtpda.dht.ni2

63490172)ria

73658451.klB-.DHT.rtb.ni½8erusolctiK

Different quantities required for TR100C and TR140C Filters.

.oNtraP

2

)riap(

noitpircseD

NOTES

TR100C

TR140C

SRETLIFDNASC041RT&C001RT

evlavo/w.tsniroftik.rtpdapils.ni2&.ni½1

p(evlavo/w.tsniroftik.rtpda.dht.ni½1

61695451C041RT/C001RT.aid.ni42tooF

71202251.qer8,C001RT.ni8/19laretaL

71045451.q

81214451lanretni.ni2tunkcoL

91614451lanretni.ni2recapS

02294451daehklub.ni2gnir-O

1280445

1lanretxe.ni2recapS

22835451daehklub.ni2teksaG

32504451.ni2daehkluB

42494472.d.i.ni8/52X.ni61/3gnir-O

704451gnitn

52022251niarddnas.ni2

62178451.ni½1.dhtpaC

72725451erusolc.ni½8hcnerW

72806151munimula.ni½8hcnerW

827084

51C001RTrewol.yssagnipiP

82984451C041RTrewol.yssagnipiP

uom.tfepaT

er8,C041RT.ni21laretaL

92630051ebutfeilerriarotcennoC

03170372C001RT8-8141#wer

13140051C001RTfeilerriaebuT

13240051C041RTfeilerriaebuT

cS

Triton® Fiberglass Sand Filter Installation and User’s Guide

Page 24

18

TRITON 100C-3 & 140C-3 FIBERGLASS SAND FILTER

Replacement Parts

TR 100C-3 Upper Piping

29

10

36

29

28

27

26

25

19

24

23

22

30

26

28

13

32

31

1

2

30

2

1

33

3

34

35

9

11

6

4

5

7

8

9

12

13

21

TR100C-3

TR140C-3

Triton® Fiberglass Sand Filter Installation and User’s Guide

20

16

14

15

17

18

LEDOM.MIDA.MIDB.MIDC.MIDD

3-C001RT.ni¾93.ni½03.ni61/1-61.ni¾34

3-C041RT.ni¼54.ni½63.ni½81.ni¼94

Page 25

19

metI

.oN

.oNtraP

noitpircseD

SRETLIFDNAS3-C041&3-C001NOTIRT

TRITON 100C-3 & 140C-3

FIBERGLASS SAND FILTER

1215372gnir-ohtiwdeelbriA

2315372wercsredeelbriag

3465372denihcamydobevlaV

4050551eguagerusserP

5494451.ni6,retpadagnir-O

6465372.yssafeilerrialaunaM

7575

8214451lanretni.ni2tuN

9905251erusolcgnirerauqS

01725451erusolc.ni½8hcnerW

11658451.dhtssertt

21034351sserttub-3-C001RT.yssa.tf&knaT

21134351sserttub-3-C041RT.yssa.tf&knaT

317004513-C00

318004513-C041RT.yssagnipipreppU

41500451.qer2,343-2rekraPgnir-O

51200451.qer2,.ni3recapS

1400451.qer2,243-2rekraPgnir-O

6

451.ni½8erusolC

nir-O

uberusolc.ni½8tiK

Replacement Parts

TR100C-3

TR140C-3

metI

.oN

03530051RT/CLEreniartS

13850091isp.ni¼,eguaGerusser

23185451lavoRTbonK

33285451lavoRTgnirpS

43975451lavoRTegdirB

53675451lavo-erusolC

63148651erusolclavoRTtiK

1RT.yssagnipipreppU

.oNtraP

P

noitpircseD

NOTES

P/N 156841 includes items: 1, 9, 31 thru 35.

Used on filters manufactured before 3-97.

Used on filters manufactured after 3-97.

SRETLIFDNAS3-C041&3-C001NOTIRT

71300451.qer2,.ni3egnalF

81100451.qer2,.ni3egnalfretpadA

919004513-C001RT.yssagni

910104513-C041RT.yssagnipiprewoL

026954513-C041/3-C001RT.aid42tooF

12202251.qer8,3-C001RT.ni9laretaL

2045451.qer8,3-C041RT.ni21laretaL

1

22178451.ni½1.dhtpaC

32022251.ni2niarddnaS

42494472.qer2,.d.i.ni8/52X.ni61/3gn

52144451ebutfeilerriarotcennoC

62140051).ni32(3-C001RTfeilerriaebuT

62240051).ni72(3-C041RTfeilerriaebuT

7

2810451.qer2,3-C041RT.yssagnipipresuffiD

82474255.qer2,spillihpdaehtalf.ni½1-01#-wercS

929954513-C001RTrof.d'

piprewoL

ir-O

qer2-resuffiD

929954513-C041RTrof.d'qer4-resuffiD

Triton® Fiberglass Sand Filter Installation and User’s Guide

Page 26

20

NOTES

SAVE THESE INSTRUCTIONS

Triton® Fiberglass Sand Filter Installation and User’s Guide

Page 27

Triton® Filter

Page 28

P/N 154901 Rev. C 5/21/07

Page 29

Filtres à Sable en Fibre de Verre Triton

Modèles:

TR 40, TR 50, TR 60, TR 100, TR 140

TR 100HD, TR 100C, TR 140C

TR 100C-3, TR 140C-3 et

®

Modèle: TR 60 avec

Triton C - Commercial

Technology

Triton C-3 - Commercial

™

Triton HD - Commercial

Triton II - Résidentiel

Manuel d'Installation et d'Utilisation

CONSIGNES DE SÉCURITÉ IMPORTANTES

PRIÈRE DE LIRE ET D’OBSERVER TOUTES LES CONSIGNES

CONSERVER CETTE NOTICE

Page 30

Service Clients

M EM B E R

N AT I O NA L

SPA & P OOL

I NSTI TU TE

Si vous avez des questions liées aux pièces de rechange, et aux produits de piscine de

Pentair Water Pool and Spa, veuillez utiliser les coordonnées suivantes.

Service Clients / Support Technique (8h00 à 17h00 heure normale du Pacifique)

Téléphone: (800) 831-7133 (appuyez sur la touche trois

de la messagerie)

Télécopie: (800) 284-4151

Sanford, Caroline du Nord (8h00 à 17h00 heure normale de l'Est)

Téléphone: (919) 566-8000

Télécopie: (919) 566-8920

Moorpark, Californie (8h00 à 17h00 heure normale du Pacifique)

Téléphone: (805) 553-5000 (Ext. 5591)

Télécopie: (805) 553-5515

Site web

visitez www.pentairpool.com ou www.sta-ritepool.com pour trouver des renseignements

concernant Pentair Water Pool and Spa, Inc.

© 2007 Pentair Water Pool and Spa, Inc. Tous droits réservés.

Les renseignements se trouvant dans ce document sont assujettis à des changements sans préavis.

1620 Hawkins Ave., Sanford, NC 27330 • (919) 556-8000

10951 West Los Angeles Ave., Moorpark, CA 93021 • (805) 553-5000

Marque de commerce et Avis de non responsabilité: Triton, ClearPro et le logo Pentair Pool Products sont des marques de commerce enregistrées

de Pentair Water Pool and Spa, Inc. D'autres marques de commerce et noms de marque peuvent être utilisés dans ce document pour se référer

soit aux personnes morales utilisant les marques et noms ou à leurs produits. Pentair Water Pool and Spa, Inc. se décharge de toute marque de

commerce ou de nom de marque ne lui appartenant pas.

Réf. P/N 154901 Rév. C 5/21/07

R

Page 31

Table des Matières :

Importantes Précautions Relatives à la Sécurité ................................................................ii

Section 1: Introduction ..................................................................................................... 1

Vue d’Ensemble des Filtre à Sable en Fibre de Verre Triton ....................................1

Caractéristique Générales....................................................................................... 2

Section 2: Installation ....................................................................................................... 3

Installer le Filtre à Sable en Fibre de Verre Triton ..................................................... 3

Comment Fonctionne votre Filtre Triton ................................................................... 3

Installer les Bouchons Filetés et Couvercle Ovale du Filtre Triton........................... 5

Première Mise en Service ....................................................................................... 6

Section 3: Entretien ...........................................................................................................7

Entretien du Filtre Triton ........................................................................................... 7

(fr) i

Nettoyage du Filtre Triton .........................................................................................7

Procédure de Rétro Lavage du Filtre Triton ............................................................. 8

Procédure de Nettoyage Chimique ......................................................................... 9

Hivernage de votre Filtre Triton ................................................................................9

Section 4: Dépannage .......................................................................................................10

Section 5: Pìèces de Rechange ........................................................................................ 12

Courbe de Chute de Pression du Filtre Triton ..........................................................12

Installer de Multiples Filtres Triton

(Ensembles de Tuyauteries en Tandem de Filtre) ..................................... 12

Pièces de Rechange pour Triton II, TR60 ClearPro et Triton HD ............................. 13

Pièces de Rechange pour Triton 100C et 140C....................................................... 16

Pièces de Rechange pour Triton 100C-3 et 140C-3 ................................................ 18

Manuel d’Installation et d’Utilisation Filtres à Sable en Fibre de Verre Triton

®

Page 32

ii (fr)

IMPORTANTES CONSIGNES DE SÉCURITÉ

Mise en Garde Importante:

Ce manuel fournit les instructions de mise en service et d’utilisation des Filtres à Sable en Fibre de Verre de

la Série Triton

AA l’Attention de l’Installateur: Ce manuel contient d’importantes informations concernant l’installation,

l’exploitation et l’utilisation de ce produit de manière sûre. Cette information doit être fournie au propriétaire et/ou à

l’exploitant de cet équipement après l’installation, ou doit-être laissé sur ou bien à proximité de cet équipement.

A l’Attention de l’Utilisateur: Ce manuel contient d’importantes informations qui vous aideront à utiliser et

entretenir ce filtre. Conservez-le pour pouvoir le consulter ultérieurement.

ADVERTISSEMENT — Avant l’installation de ce produit, lire et respecter la totalité des avertissements et

®

. Consulter Pentair Eau pour toute question relative à cet équipement.

instructions inclus. Ne pas respecter les notices de sécurité peut entrainer des blessures

graves, la mort ou l’endommagement du bien. Appeler le (800) 831-7133 pour obtenir

des copies supplémentaires gratuites de ces instructions.

Information et Sécurité du Consommateur

Les Filtres à Sable en Fibre de Verre de la Série Triton® sont conçus et fabriqué pour donner de nombreuses années

de fonctionnement sûr et fiable dès l’instant où sont installés, exploités et entretenus en accord avec les informations

fournies dans le présent manuel et les normes d’installation référencés dans les sections suivantes. Les mises en garde

concernant la sécurité et les précautions sont identifiés par le symbole “ “ tout au long du manuel. Assurez-vous de

lire et de respecter la totalité des avertissements et précautions.

ADVERTISSEMENT — CE FILTRE EST SOUMIS À HAUTE PRESSION

Lorsque l’on intervient sur l’un ou l’autre des composants du circuit de circulation (ex : bouchon,

couvercle, pompe, filtre, robinet(s) etc..), l’air peut pénétrer n’importe où dans le circuit et devenir

pressurisé. L’air sous pression peut occasionner une séparation du couvercle supérieur pouvant

entrainer des blessures sérieuses, la mort ou l’endommagement du bien. Pour éviter ce danger

potentiel, respectez ces instructions:

1. Si vous ne connaissez pas bien votre système de filtration de piscine et/ou de réchauffage:

a. N’essayez Pas de procéder à des réglages ou effectuer l’entretien sans consulter votre

revendeur, ou un technicien de piscine qualifié.

b. Lisez la totalité du Manuel d’Installation et d’Utilisation avant de tenter d’utiliser, entretenir ou

régler le système de filtration ou de réchauffage.

2. Avant de remettre la (les) vanne(s) en position et avant de commencer le montage, démontage,

ou toute autre intervention sur le circuit : (A) Mettre la pompe sur ARRÊT et mettre HORS SERVICE

tout automatisme pour garantir que le système ne soit PAS démarré par inadvertance pendant

l’opération d’entretien ; (B) ouvrir le robinet manuel de purge d’air ; (C) attendre jusqu’à ce que

toute pression soit évacuée.

3. Lors du montage du couvercle de filtre RESPECTER EXACTEMENT LES INSTRUCTIONS

RELATIVES AU COUVERCLE DE FILTRE.

4. Une fois l’intervention sur le circuit terminée, RESPECTER EXACTEMENT LES INSTRUCTIONS

DE MISE EN SERVICE.

5. Maintenir le circuit de circulation correctement. Remplacer les pièces usées ou endommagées

immédiatement (par exemple : couvercle, manomètre, vanne(s), joints toriques, etc..)

6. S’assurer que le filtre est correctement monté et positionné suivant les instructions fournies.

Manuel d’Installation et d’Utilisation Filtres à Sable en Fibre de Verre Triton

®

Page 33

IMPORTANTES CONSIGNES DE SÉCURITÉ (Suite)

ADVERTISSEMENT — Ce filtre doit être installé par un électricien agréé ou certifié ou une personne d’entretien

de piscine qualifiée en accord avec le Code Electrique National (National Electrical

Code) et toute normes ou ordonnances locales applicables. Une installation incorrecte

peut entrainer la mort ou des blessures graves aux utilisateurs de piscine, installateurs

ou autres personnes, et peut également occasionner des dommages aux biens.

Toujours couper l’alimentation électrique du circuit de circulation de la piscine au niveau

du disjoncteur électrique avant de procéder à l’entretien du filtre. S’assurer que le circuit

déconnecté est verrouillé ou correctement identifié de façon à ce qu’il ne puisse être

enclenché pendant que vous travaillez sur le filtre. Ne pas respecter cela peut entrainer

la mort ou des blessures sérieuses aux installateurs, utilisateurs de piscine, ou autres

personnes par électrocution.

ADVERTISSEMENT — Ne pas mettre en fonctionnement le filtre avant que vous ayez clairement lu et compris

les instructions de fonctionnement et les messages d’avertissement concernant la totalité

des équipements constituant le circuit de circulation de la piscine. Les instructions

suivantes sont conçues pour guider la mise en service initiale du filtre lors d’une

installation générale de piscine. Un manquement au bon suivi des instructions de

fonctionnement et aux messages d’avertissement peut occasionner un endommagement

des biens, de sérieuses blessures aux personnes, ou la mort.

(fr) iii

ADVERTISSEMENT — Pour réduire le risque de blessure, ne pas permettre aux enfants d’utiliser ce produit, à

moins qu’ils ne soient surveillés de près à tout moment.

ADVERTISSEMENT — Du fait du risque potentiel pouvant exister, il est recommandé que la pression d’épreuve

soit maintenue le temps minimum requis par le code local. N’autoriser quiconque à

travailler autours du système quand le circuit de circulation est sous épreuve de pression.

Mettre en place des signaux appropriés d’avertissement et établir une barrière autour

des équipements sous pression. Si les équipements sont situés dans un local, verrouiller

la porte et mettre un signal d’avertissement.

Ne jamais essayer de procéder au réglage de bouchons ou couvercles, ou tenter de

retirer ou de serrer des boulons lorsque le circuit est sous pression. Ces actions peuvent

occasionner l’éclatement du couvercle et pourraient occasionner de sérieuses blessures

individuelles ou bien la mort s’ils venaient à heurter une personne.

ADVERTISSEMENT — Ne jamais dépasser la pression d’utilisation maximum des composants du circuit.

Excéder ces limites pourrait causer la détérioration d’un composant par la pression.

Cette libération instantanée d’énergie peut causer l’éclatement du couvercle et pourrait

occasionner de graves blessures individuelles ou bien la mort s’ils venaient à heurter

une personne.

Manuel d’Installation et d’Utilisation Filtres à Sable en Fibre de Verre Triton

®

Page 34

iv (fr)

Page blanche.

Manuel d’Installation et d’Utilisation Filtres à Sable en Fibre de Verre Triton

®

Page 35

Filtres à sable en fibre de verre Triton® - Généralités

(fr) 1

Section 1

Introduction

Filtres à sable Triton

®

II

Le numéro 1 du filtre à sable dans le monde

Triton II est le résultat de plus de 40 ans d’évolution et d’améliorations. Ce filtre est devenu la référence de

l’industrie en matière de performance, d’efficacité, de durée de service entre chaque maintenance, et des années

de fiabilité requérant un entretien minimal.

Le Triton II possède une conception interne qui maintient le lit de sable plat et le débit d’eau constant, assurant

ainsi une filtration optimale.

La meilleure réputation de l’industrie, et à juste titre

En plus de résultats de filtration supérieurs, le Triton II s’est taillé une réputation encore inégalée pour sa fiabilité

et sa facilité de fonctionnement et d‘entretien. De nombreux détails dans sa conception ont été améliorés pour

faire du Triton II le filtre de référence de l’industrie.

Filtres à sable commerciaux Triton® C et Triton® C-3

Ces filtres sont équipés de plusieurs dériveurs pour une meilleure vitesse de filtration dans des applications

commerciales, jusqu’à 20 GPM/pied carré.

Filtres à sable à montage latéral Triton® HD

Ces filtres possèdent les mêmes performances et caractéristiques exceptionnelles du premier Triton, avec une

pression de service de 75 psi pour les installations sous pression, comme les systèmes de nettoyage de niveau

à pompe unique.

Triton II - Résidentiel

Triton C - Commercial

Triton HD - Commercial

Triton C-3 - Commercial

Manuel d’Installation et d’Utilisation Filtres à Sable en Fibre de Verre Triton

®

Page 36

2 (fr)

Caractéristiques générales

Triton® II

• Sa conception interne, qui a déjà fait ses preuves avec le temps, permet de filtrer l’eau au maximum pour

donner des résultats clair comme de l’eau de roche

• Le processus GlasLok™ crée une cuve monocoque, renforcée de fibre de verre, avec un revêtement

anti-UV qui garantit des années de service fiable et sans corrosion

• Le système de débit contrôle la qualité de la filtration et assure des durées de service maximales entre le

lavage à contre courant, ce qui fait gagner du temps

Triton® C et Triton® C-3

• Pression de service maximum 50 psi

• Purgeur complet de 2 pouces

• Ouverture de 8 pouces pour accéder facilement au lit de sable

• Le Triton C-3 possède des joints à bride standard de 3 pouces

• Les modèles TR 100C et TR 140C sont disponibles en noir ou amande

• Les modèles TR 100C-3 et TR 140C-3 sont disponibles uniquement en noir

®

Triton

HD

• Pression de service maximum 75 psi

Autres caractéristiques

• Un système combiné de drainage du sable et de l’eau facilite l’entretien et l’hivernage

• Toutes les pièces internes sont filetées pour en faciliter l’entretien

• Une tête de distribution pivotante permet un accès direct au sable et à toutes les pièces internes

• Homologué NSF

Manuel d’Installation et d’Utilisation Filtres à Sable en Fibre de Verre Triton

®

Page 37

(fr) 3

Section 2

Installation

Remarque: Avant d’installer ce produit, lire et respecter tous les avis de mise en garde et les instructions d ébutant en page (fr) ii.

Installation du Filtre à Sable en Fibre de Verre Triton

Le Filtre à Sable en fibre de Verre Triton ne doit être installé que part un technicien d’entretien qualifié.

Ce filtre est conçu et prévu pour filtrer l’eau.

Triton® Introduction

L’information générale qui suit décrit comment installer le Filtre à Sable en fibre de Verre Triton. Ce filtre fonctionne sous

pression et, s’il est mal monté ou utilisé alors que de l’air est présent dans le circuit d’eau, son couvercle risque de se

désolidariser, ce qui peut avoir pour résultat un accident occasionnant des dégâts matériels importants ou blessures graves.

Une étiquette d’avertissement a été collée sur le dessus du filtre et doit y rester. Maintenez les étiquettes de sécurité en bon

état et remplacez-les si elles manquent ou sont illisibles.

Fonctionnement du Filtre

Ce filtre à sable à grand débit est conçu pour fonctionner pendant de nombreuses années avec un minimum d’entretien et,

lorsqu’il est installé, utilisé et entretenu conformément aux présentes instructions, fonctionnera pendant de nombreuses

années sans problème.

®

Les impuretés sont recueillies dans le filtre lorsque l’eau traverse la vanne de régulation qui se trouve sur le côté de celui-ci

et sont dirigées dans la traversée de paroi étanche supérieure. L’eau sale coule dans le diffuseur qui se trouve en haut du

réservoir, puis est dirigée vers le bas, jusque sur la surface supérieure du lit de sable. Les impuretés sont recueillies dans le

lit de sable et l’eau propre traverse les éléments latéraux et le tuyau inférieur qui se trouve au bas du filtre, puis remonte pour

pénétrer dans la traversée de paroi étanche inférieure. L’eau s’écoule ensuite dans la vanne de régulation située sur le côté

du filtre. L’eau propre retourne ensuite à la piscine par la tuyauterie.

La pression s’èlévera et le débit vers la piscine s’abaissera au fur et à mesure que les impuretés s’accumulent dans le filtre.

Celui-ci finira par être tellement obstrué par ces impuretés qu’il sera nécessaire de procéder à un lavage à contre-courant du

filtre. Il est important de savoir quand effectuer cette opération. Celle-ci est décrite plus en détails dans les sections suivantes

du présent livret.

Veuillez noter qu’un filtre élimine les particules en suspension et n’épure pas la piscine. L’eau de celle-ci doit être épurée et

sa composition chimique doit être équilibrée pour qu’elle soit très claire. Votre système de filtrage doit être conçu pour

respecter la réglementation sanitaire locale applicable. Vous devez au minimum veiller à ce que votre système renouvelle la

totalité de l’eau de votre piscine au moins deux à quatre fois par période de vingt-quatre heures.

Reportez-vous au Tableau 1 pour des données sur les spécifications des filtres.

Tableau 1.

2

ip/nm/lag02rusésaB(

*)

RUOJRAP

492(192111)08253(945331

2

TNEMELLEVUONEREDETICAPAC

STNEMELLEVUONER4,2

90762

OREMUN

ELEDOMED

ERTLIFED

04RT)2

05T)64,2(32,0)94(581)04671(47766)02532(33098)00

06RT)41,3(92,0)36(832)08622(35858)04203(074411)00873(880341)06354(607171

orPraelC06RT)4

001RT)19,4(74,0)47(082)04662(348001)02553(75

3-C001RT/C001RT)19,4(74,0)89(173)08253(945331)04074(560871)00885(285222)06507(8

041RT)60,7(56,0)601(104)06183(154441)08805(106291)00636(257042)02367(209882

3-C041RT/C041RT)60,7(56,0)141

*LES CHIFFRES APPLICABLES AUX TR100 ET TR140 SONT BASES SUR 15 GAL/MN/PI

ECAFRUS

ED

EGARTLIF

2

ip,2)

M(

9,1(81,0)83(441)08631(48715)04281(64096)00822(70368)06372(865301

1,3(92,0)36(832)08622(35858)04203(074411)00873(880341)06354(607171

TIBED

)NM/LAG,NM/L(*

2

ip/NM/LAG02à

(435)06705(741291)08676(691652)00648(542023)025101(592483

STNEMELLEVUONER4

RUOJRAP

4431)00444(270861)08235(686102

STNEMELLEVUONER3

RUOJRAP

)snollaG/sertiL(

STNEMELLEVUONER2

RUOJRAP

Manuel d’Installation et d’Utilisation Filtres à Sable en Fibre de Verre Triton

®

Page 38

4 (fr)

AVERTISSEMENT — Une non-utilisation de votre système de filtrage ou un filtrage insuffisant peut provoquer un manque de clarté de

l’eau gênant la visibilité dans votre piscine. Quelqu’un peut ainsi plonger dans ou sur des objets qu’il ne peut voir,

risquant de se blesser gravement, voire de se noyer.

L’eau claire est produite par un filtrage approprié et une composition chimique correcte de l’eau. Le traitement chimique d’une

piscine est l’affaire de spécialistes et il convient que vous consultiez votre spécialiste local de l’entretien des piscines à

propos de points particuliers. En règle générale, pour que l’eau d’une piscine soit correctement épurée, elle doit présenter un

niveau de chloration de 1 à 3 ppm et un pH compris entre 7,2 et 7,6.

AVERTISSEMENT — Les filtres ne doivent jamais subir des essais à l'air ou au gaz comprimé ni être exposés a ceux-ci. Tous les gaz sont

compressibles et, Iorsqu’ils sont comprimés, sont dangereux. Des blessures graves ou des dégâts matériels

importants peuvent resulter de l‘exposition d’un filtre à de l’air ou à du gaz sous pression.

l. Examinez le carton pour rechercher toute trace de dégâts dûs à une manutention brutale en cours de transport. Si le carton

ou tout élément du filtre est endommagé, avisez-en le transporteur immédiatement.

2. Retirez avec précaution du carton les accessoires et le réservoir du filtre.