Page 1

NGC-30 / UIT2

Programming guide

industrial heat tracing solutions

EN-RaychemNGC30UIT2Programming-AR-H5818602/16

1 / 84

Page 2

CONTENTS

Section 1 – Introduction ....................................................................................................................................4

1.1 Raychem NGC-30 ......................................................................................................................... 4

1.1.1 Product Overview ................................................................................................................ 4

1.1.2 Control NGC-30 .................................................................................................................. 4

1.1.3 Monitoring .......................................................................................................................... 5

1.1.4 Ground-Fault Protection .................................................................................................... 5

1.1.5 Installation ......................................................................................................................... 5

1.1.6 Communications ................................................................................................................ 6

1.1.7 Complete System ............................................................................................................... 6

1.1.8 The Raychem NGC-UIT2-Ex Programming Guide ............................................................. 6

1.1.9 User Interface Terminal (NGC-UIT2) Languages ............................................................... 6

1.2 Vital Information........................................................................................................................... 6

1.3 License Agreement ...................................................................................................................... 7

1.3.1 Raychem NGC-30 Software – License Agreement ............................................................ 7

1.4 User Responsibilities ................................................................................................................... 9

1.5 Safety Warnings ........................................................................................................................... 9

1.6 Warning, Error and Alarm Messages .......................................................................................... 9

1.7 Technical Support ...................................................................................................................... 10

1.8 Navigation .................................................................................................................................. 10

1.8.1 Navigating Between Windows .......................................................................................... 10

Section 2 – Basic Configuration Quick Start ................................................................................................... 12

2.1 An Example of A Simple 4 Circuit Setup .................................................................................... 12

2.2 Setting Up Additional Circuits .................................................................................................... 23

2.3 Circuits 1–4 Setup Complete Confirmation ............................................................................... 23

2.4 Starting the NGC-30 ................................................................................................................... 24

2.4.1 System Requirements ...................................................................................................... 24

2.4.2 Initial Setup....................................................................................................................... 24

Section 3 – Full Configuration ........................................................................................................................25

3.1 Setting the Network for Device(s) .............................................................................................. 25

3.1.1 Main Window .................................................................................................................... 27

3.2 Software Organization ................................................................................................................ 27

3.3 NGC-30 Windows – Detailed Descriptions ................................................................................ 28

3.3.1 Setup Window ................................................................................................................... 28

3.3.2 Main Status Window ........................................................................................................ 29

3.3.3 Setup | Circuit Window ..................................................................................................... 30

3.3.4 Control Modes Definitions ................................................................................................ 32

3.3.5 Setup | RTDs Window ....................................................................................................... 33

3.3.6 Setup | Temp Window ....................................................................................................... 35

3.3.7 Setup | Limit Cut-Out Window .......................................................................................... 36

3.3.8 Setup | Electrical Window ................................................................................................ 37

3.3.9 Setup | PASC Window ....................................................................................................... 39

3.3.10 Setup | PLI Window ........................................................................................................ 40

3.3.11 Setup | Maint. Window .................................................................................................... 41

3.3.12 Setup | Inputs ................................................................................................................. 42

3.3.13 Setup | Safety Limiter Window (Raychem NGC-20 Only) ............................................... 43

3.3.14 Setup | Load Shed Window (Raychem NGC-20 Only) ..................................................... 44

industrial heat tracing solutions

EN-RaychemNGC30UIT2Programming-AR-H5818602/16

2 / 84

Page 3

3.3.15 Status | Circuit Window .................................................................................................. 44

3.3.16 Status | RTDs Window .................................................................................................... 46

3.3.17 Status | PASC Window .................................................................................................... 46

3.3.18 Status | Voltage Window ................................................................................................. 47

3.3.19 Status | PLI Window ....................................................................................................... 47

3.3.19.1 PLI Test Utility .................................................................................................. 48

3.3.19.2 Unswitched Circuits ......................................................................................... 49

3.3.19.3 Switched Circuits .............................................................................................. 49

3.3.20 Status | Safety Limiter Window (Raychem NGC-20 Only) .............................................. 50

3.3.21 Status | Min / Max Window ............................................................................................. 51

3.3.22 Status | Maint. Window .................................................................................................. 52

3.3.23 Events Window ................................................................................................................ 52

3.3.24 Network | Devices Window ............................................................................................. 56

3.3.25 Network | PLI Window .................................................................................................... 57

3.3.26 Network | Relays Window ............................................................................................... 58

3.3.27 Network | RTDs Window ................................................................................................. 58

3.3.28 Network | Inputs Window ............................................................................................... 59

3.3.29 Network | Maint. Window ............................................................................................... 59

3.3.30 Network | Remove Window ............................................................................................ 60

3.3.31 System | Misc Window .................................................................................................... 60

3.3.32 System | Relays Window ................................................................................................. 61

3.3.33 System | Comm Window ................................................................................................. 62

3.3.34 System | Clock Window .................................................................................................. 66

3.3.35 System | Password Window ........................................................................................... 66

3.3.36 System | Maint. Window ................................................................................................. 67

Section 4 – Appendices ................................................................................................................................... 69

Appendix A. NGC-UIT2 Software Upgrade Process ................................................................... 69

Appendix B. NGC-UIT2 Backup Process .................................................................................... 70

Appendix C. Proportional Control .............................................................................................. 72

Appendix D. Proportional Ambient Sensing Control (PASC) ..................................................... 73

Appendix E. RTD Device / RTD Number Entry Windows ........................................................... 73

Monitor-Only Mode ......................................................................................................... 73

Control Mode With Local RTD Installed ......................................................................... 73

Control Mode Without Local RTD Installed .................................................................... 73

Appendix F. Terms and Definitions ............................................................................................ 74

Appendix G. Configuration Spreadsheet .................................................................................... 74

Index ............................................................................................................................................................... 79

Index of Fields and Windows ...................................................................................................... 79

Window Locations ...................................................................................................................... 82

industrial heat tracing solutions

EN-RaychemNGC30UIT2Programming-AR-H5818602/16

3 / 84

Page 4

SECTION 1 INTRODUCTION

NGC-30

P

l

1.1 RAYCHEM NGC30

1.1.1 PRODUCT OVERVIEW

This manual describes how both the Raychem NGC-20 and Raychem NGC-30 can be programmed

via the User Interface Terminal (NGC-UIT2-EX). The Raychem NGC-20 and Raychem NGC-30 are

part of the same family of controllers.

The Raychem NGC-20 is a compact networked single point heat-trace controller with an approved

integral safety temperature limiter (SIL 2). The controller is approved for use in Zone 1 and Zone 2

hazardous areas and can be mounted directly on the heat-traced pipe. Up to 247 individual Raychem

NGC-20 controllers can be connected in a single RS-485 multi drop “daisy chained” network and

communicate to a central user interface, the NGC-UIT2-EX. Up to two temperature sensors can be

connected directly to the controller. The limiter has its own temperature sensor.

The Raychem NGC-30 is a multipoint electronic control, monitoring and power distribution system

for heat-tracing used in process-temperature maintenance and freeze-protection applications.

The Raychem NGC-30 system can control up to 260 heat-tracing circuits with multiple networked

panels. Each panel can control up to 40 individual heat-tracing circuits and monitor up to 128

temperature inputs, with optional power distribution. The Raychem NGC-30 is available with two

output types: Electromechanical Relays (EMRs) or Solid-State Relays (SSRs). Both types allow

switching up to 60 amps at 600 Vac with single or three-phase power. Up to four Resistance

Temperature Detector (RTD) sensor inputs for each heat-tracing circuit allows for a variety of

combinations of temperature control, monitoring, and alarming. Systems can be configured for

nonhazardous and hazardous locations. The ability to monitor and configure the controller is

available both locally and remotely with the Raychem Supervisor software.

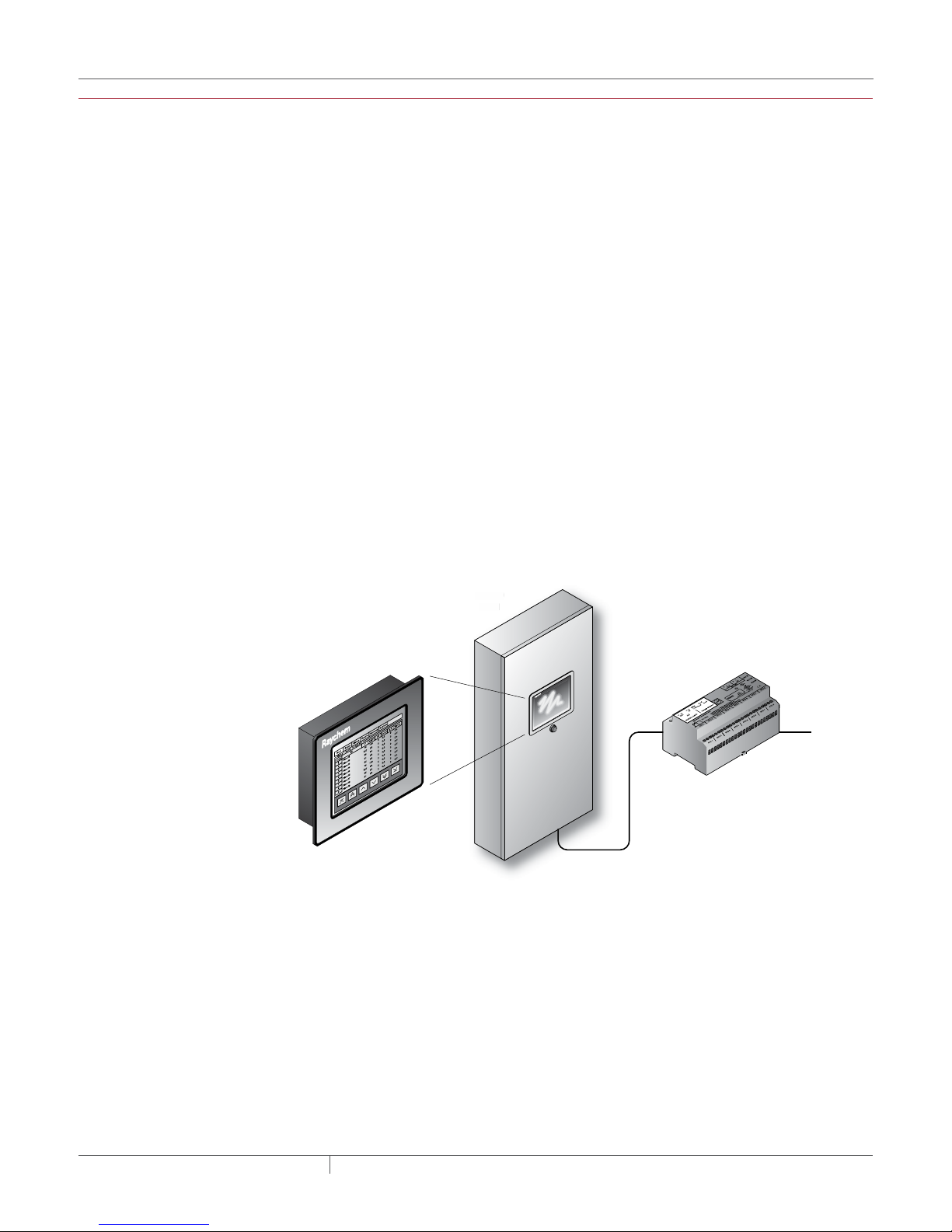

NGC-30

Panel

ane

NGC-UIT2

RS-485

Field located

RMM2

hem

ayc

R

To next

RMM2

Fig. 1.1 NGC-30 system, system example

1.1.2 CONTROL NGC-30

The Raychem NGC-30 measures temperatures with 3-wire, 100-ohm platinum RTDs connected

directly to the unit, or through optional Remote Monitoring Modules (RMM2 module). Each RMM2

module accepts up to eight RTDs. The RMM2 modules are typically located near the desired

measurement location (RTDs). Multiple RMM2 modules are networked over a single cable to

the NGC-30, significantly reducing the cost of RTD field wiring. The NGC-30 system supports

260 temperature inputs via the CRM/CRMS boards. Using RMM2 modules, an additional 128

temperature inputs can be supported for a maximum of 388 temperature inputs. With EMRs

and SSRs, the NGC-30 can be configured for On/Off, ambient sensing, and proportional ambient

sensing modes. Additionally, with SSRs, the panel can be configured for proportional, power

limiting, and soft start modes.

industrial heat tracing solutions

EN-RaychemNGC30UIT2Programming-AR-H5818602/16

4 / 84

Page 5

1.1.3 MONITORING

Both Raychem NGC-20 and Raychem NGC-30 can monitor multiple independent Electrical HeatTracing (EHT) parameters. The Raychem NGC-20 and Raychem NGC-30 monitor continuously

temperature, voltage, current and ground fault current leakage and report the values including alarms

to the UIT. An automated self-check feature is available where the systems periodically checks the

heating cables for faults and report the result to the UIT. This helps to avoid costly downtime. Dry

contact relays are provided for alarm annunciation back to a Distributed Control System (DCS).

1.1.4 GROUND-FAULT PROTECTION ACCORDING TO NORTH AMERICAN ELECTRICAL

CODE NEC STANDARD

National electrical codes require ground-fault equipment protection on all heat-tracing circuits.

Heat-tracing circuits equipped with Raychem NGC-30 controllers do not require additional

ground-fault detection equipment, simplifying installation and reducing costs. When applying the

IEC standards, additional RCD circuit breaker is required.

1.1.5 INSTALLATION

The Raychem NGC-30 system is configured with a User Interface Terminal (NGC-UIT2-EX) that has

LCD color touch-screen display technology. The NGC-UIT2-EX provides a user interface for easy

and efficient programming without keyboards or cryptic labels. The NGC-UIT2-EX model used

depends on the location of Raychem NGC-30 panel and the local environment.

Common NGC-UIT2 Interface and Programming

The term “NGC-UIT2” in this document refers to any of the available NGC-UIT2 models, regardless

of which model is actually installed. All NGC-UIT2s interface to the NGC-30-CRM, NGC-30-CRMS

(Card Rack Relay Control Modules), PLI (Power Line carrier Interface), and the RMM2 module

(Remote Monitoring Module). The three NGC-UIT2 versions described in Table 1.1 on page 5

all use the same wiring, system interface, and programming. The NGC-UIT2s differ only in the

environments in which they can be installed.

NGC-UIT2 Installed in Hazardous and Non-hazardous Indoor or Outdoor Panel Locations

If the panel is located in a hazardous/non-hazardous indoor or outdoor location, the NGC-UIT2-EX

model is required. This NGC-UIT2-EX model is specifically designed for these environments and

meets all applicable standards. The NGC-UIT2-EX model is installed locally on the Raychem NGC30 panel door.

NGC-UIT2 Installed Separately from the Panel Locations

If the user interface terminal needs to be mounted separately from the Raychem NGC-30 control

panel, such as when the panel is in a hazardous or difficult to access location, the NGC-UIT2ORD-R provides a wall-mount alternative for remote mounting in a nonhazardous (unclassified)

indoor or outdoor location.

Table 1.1 NGC-30 User Interface Terminals (UIT2s)

UIT2 type Area classification Usage

NGC-UIT2-EX Nonhazardous (Unclassified) Locations

Hazardous* Locations

Class 1 Div. 2, Groups A, B, C & D

Zone 2

NGC-UIT2-ORD-R Nonhazardous (Unclassified) Locations

• The NGC-UIT2-ORD-R must be

installed in a nonhazardous, indoor

or outdoor location.

• The NGC-UIT2-ORD-R connects

to NGC-30 panels using RS-485

communication wiring.

*Hazardous locations are defined by Article 500 of the National Electrical Code and Section 18 of the

Canadian Electrical Code.

Type 4

• (Indoors or Outdoors)

Type 4

• (Indoors or Outdoors)

industrial heat tracing solutions

EN-RaychemNGC30UIT2Programming-AR-H5818602/16

5 / 84

Page 6

1.1.6 COMMUNICATIONS

The NGC-UIT2 units can be networked to a host PC running Windows®-based Raychem

Supervisor client-server software for central programming, status review, and alarm

annunciation. NGC-UIT2s support the Modbus

or 10/100Base-T Ethernet communication interface.

®

protocol and are available with an RS-232, RS-485

1.1.7 COMPLETE SYSTEM

The Raychem NGC-30 is supplied as a complete system ready for field connections of power

wiring and temperature sensor input. Optional Power Distribution further enhances the reduction

of field wiring and labor to install.

1.1.8 THE Raychem NGC-UIT2-EX PROGRAMMING GUIDE

This Raychem NGC-UIT2-EX Programming Guide (H58186) assists in the set up and operation of

the Raychem NGC-20 and NGC-30 system.

The Raychem NGC-UIT software (version 4.x and higher), installed in the NGC-UIT2-EX (User

Interface Terminal), is designed to configure various Raychem devices.

This software version supports the:

1) Raychem NGC-20 controllers

2) Raychem NGC-30 Heating-Tracing Panels using:

a) NGC-30-CRM/-CRMS card rack modules with or without multiplexed RTD inputs via the

Raychem RMM2 module or RTD inputs via the Raychem PLI module.

b) MONI-RMC and RMM-DI modules for digital input and relay output signals.

It supports the RMC modules and RMM-DI for digital inputs and outputs as well.

The software provides several features to help configure and maintain the Raychem devices. This

document is not intended to provide detailed explanations of the specific features of each product,

but rather to show how to access various parameters within the devices using the Raychem NGC30 software. Please refer to specific detailed product use documentation:

• Raychem NGC-30 Installation Manual (H57878)

• Raychem NGC-UIT2 Modbus Protocol Interface Mapping for NGC-30 Systems (H57880).

1.2 VITAL INFORMATION

1.1.9 USER INTERFACE TERMINAL (NGC-UIT2) LANGUAGES

The languages supported by the NGC-UIT2 display are - and not limited to -: English, Spanish,

French, German, Russian, Chinese, Italian and Czech. The display language is selected by

accessing the System|Misc. screen. Refer to section 3.3.31 System | Misc Window on page 60 for

additional information.

This manual is a guide for the setup and operation of the Raychem NGC-30 and NGC-20 in

combination with the NGC-UIT2-EX user interface.

Important: All information, including illustrations, is believed to be reliable. Users, however,

should independently evaluate the suitability of each product for their particular application.

Pentair Industrial Heat Tracing Solutions makes no warranties as to the accuracy or completeness

of the information, and disclaims any liability regarding its use.

Pentair Industrial Heat Tracing Solutions only obligations are those in the Pentair Industrial Heat

Tracing Solutions Standard Terms and Conditions of Sale for this product, and in no case will

Pentair Industrial Heat Tracing Solutions or its distributors be liable for any incidental, indirect, or

consequential damages arising from the sale, resale, use, or misuse of the product. Specifications

are subject to change without notice. In addition, Pentair Industrial Heat Tracing Solutions

reserves the right to make changes—without notification to Buyer—to processing or materials

that do not affect compliance with any applicable specification.

industrial heat tracing solutions

EN-RaychemNGC30UIT2Programming-AR-H5818602/16

6 / 84

Page 7

1.3 LICENSE AGREEMENT

1.3.1 Raychem NGC-30 SOFTWARE – LICENSE AGREEMENT

This agreement is a legal agreement between you, “the end user”, and Pentair Industrial

Heat Tracing Solutions, LLC (“Pentair Industrial Heat Tracing Solutions”). BY INSTALLING OR

OTHERWISE ACCESSING THIS PROGRAM, YOU ARE AGREEING TO BECOME BOUND BY THE

TERMS OF THIS AGREEMENT. IF YOU DO NOT AGREE TO THE TERMS OF THIS AGREEMENT, DO

NOT INSTALL OR ACCESS THIS PROGRAM. IF INSTALLING OR OTHERWISE ACCESSING THIS

PROGRAM BY OPENING A SEALED DISK PACKAGE, PROMPTLY RETURN THE UNOPENED DISK

PACKAGE AND THE OTHER ITEMS (INCLUDING WRITTEN MATERIALS OR OTHER CONTAINERS)

TO THE PLACE WHERE YOU OBTAINED THEM.

1. GRANT OF LICENSE. The Raychem NGC-30 Software (the “Software”) is licensed, not

sold, to you for use only under the terms of this Agreement, and Pentair Industrial Heat

Tracing Solutions reserves any rights not expressly granted to you. Subject to the terms and

conditions of this Agreement, Pentair Industrial Heat Tracing Solutions grants to you a nonexclusive, nontransferable, limited license (without the right to sublicense others) to use

the one copy, including written materials if any, of the Software on a single computer at the

location (company and address) to which Pentair Industrial Heat Tracing Solutions issued

this copy of the Raychem NGC-30 Software. The Software is owned by Pentair Industrial Heat

Tracing Solutions LLC and is protected by United States copyright laws and international

treaty provisions. All copies made by you are subject to the terms and conditions of this

Agreement. The structure, organization and code of the Software are valuable trade secrets

and confidential information of Pentair Industrial Heat Tracing Solutions. You agree not to

modify, alter, merge, adapt, duplicate, distribute, translate, decompile, disassemble, reverse

engineer, create derivative works, copy for use on any other computer or at any other location,

or otherwise make this software available to any person or entity outside this location. The

Software is licensed only to you. In no event may you transfer, sell, sublicense, rent, assign

or transfer rights, lease, or otherwise dispose of the Software on a temporary or permanent

basis without the prior written consent of Pentair Industrial Heat Tracing Solutions. You agree

to use reasonable efforts to protect against the unauthorized copying and use of the Software

by others. You agree not to remove, disable or circumvent any proprietary notices or labels

contained on or within the Software.

2. OTHER RESTRICTIONS.

1. You may not sublicense, rent or lease the Raychem NGC-30 Software to anyone.

2. You agree to notify Pentair Industrial Heat Tracing Solutions promptly if “bugs” or seemingly

incorrect or anomalous behavior is discovered when using the Software.

3. You agree that the Raychem NGC-30 Software, including written materials (if any) and all

copies in whole or in part, will be destroyed or returned to Pentair Industrial Heat Tracing

Solutions at the written request of the Pentair Industrial Heat Tracing Solutions Product

Manager.

4. By installing or otherwise accessing the Raychem NGC-30 Software you acknowledge that

you have read and understood Pentair Industrial Heat Tracing Solutions’ Disclaimer of

Warranty and Limitation of Liability, set forth below.

5. You agree to use reasonable efforts to protect against the unauthorized copying and use the

Raychem NGC-30 Software by others.

3. DISCLAIMER OF WARRANTY. THE Raychem NGC-30 SOFTWARE AND ACCOMPANYING

WRITTEN MATERIALS ARE PROVIDED “AS IS” WITHOUT WARRANTY OF ANY KIND. THE

ENTIRE RISK AS TO THE RESULTS AND PERFORMANCE OF THE Raychem NGC-30 SOFTWARE

IS ASSUMED BY YOU. Pentair Industrial Heat Tracing Solutions DOES NOT WARRANT THAT

THE FUNCTIONS CONTAINED IN THE SOFTWARE WILL MEET YOUR REQUIREMENTS OR THAT

THE OPERATION OF THE SOFTWARE WILL BE UNINTERRUPTED OR ERROR-FREE, OR THAT

PROGRAM DEFECTS WILL BE CORRECTED.

4. LIMITED WARRANTY – MEDIA. THE MEDIUM ON WHICH THE PROGRAM IS ENCODED IS

WARRANTED TO BE FREE FROM DEFECTS IN MATERIAL AND WORKMANSHIP UNDER

NORMAL USE FOR A PERIOD OF SIXTY (60) DAYS FROM THE DATE OF DELIVERY TO YOU

AS EVIDENCED BY A COPY OF YOUR RECEIPT. ALTHOUGH Pentair Industrial Heat Tracing

Solutions BELIEVES THE MEDIA AND THE PROGRAM TO BE FREE OF VIRUSES, THE MEDIUM

AND THE PROGRAM ARE NOT WARRANTED TO BE VIRUS FREE. Pentair Industrial Heat

Tracing Solutions’ LIABILITY AND YOUR EXCLUSIVE REMEDY IF THE MEDIUM IS DEFECTIVE

industrial heat tracing solutions

EN-RaychemNGC30UIT2Programming-AR-H5818602/16

7 / 84

Page 8

OR INCLUDES ANY VIRUS SHALL BE PROMPT REPLACEMENT OF THE MEDIUM WITH A NEW

Raychem NGC-30 SOFTWARE PRE-ENCODED DISC.

5. EXCLUSION OF ALL OTHER WARRANTIES. EXCEPT AS EXPRESSLY PROVIDED ABOVE, Pentair

Industrial Heat Tracing Solutions DISCLAIMS ALL WARRANTIES, EITHER EXPRESS, IMPLIED

OR STATUTORY, INCLUDING BUT NOT LIMITED TO ANY WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE, EVEN IF Pentair Industrial Heat Tracing Solutions HAS

BEEN ADVISED OF SUCH PURPOSE. THIS AGREEMENT GIVES YOU SPECIFIC LEGAL RIGHTS.

SOME STATES OR COUNTRIES DO NOT ALLOW THE EXCLUSION OF WARRANTIES SO THE

ABOVE EXCLUSION MAY NOT APPLY TO YOU.

6. LIMITATION OF LIABILITY. THE ENTIRE RISK AS TO THE RESULTS AND PERFORMANCE OF

THE SOFTWARE IS ASSUMED BY YOU. IN NO EVENT SHALL Pentair Industrial Heat Tracing

Solutions, ITS AFFILIATES, DIRECTORS, OFFICERS, SHAREHOLDERS, EMPLOYEES OR

OTHER REPRE-SENTATIVES BE LIABLE FOR DAMAGES OF ANY KIND, INCLUDING WITHOUT

LIMITATION, ANY LOSS, DAMAGE, OR DELAY, OR FOR ANY LOST PROFITS, LOSS OF USE,

INTERRUPTION OF BUSINESS, OR FOR ANY COMPENSATORY, SPECIAL, INCIDENTAL,

CONSEQUENTIAL, INDIRECT DAMAGES (HOWEVER ARISING, INCLUDING NEGLIGENCE) OF

ANY KIND ARISING OUT OF OR IN CONNECTION WITH THE USE OF, OR THE INABILITY TO

USE, THE SOFTWARE OR THIS AGREEMENT (EVEN IF Pentair Industrial Heat Tracing Solutions

HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES). FURTHER, IN NO EVENT

SHALL Pentair Industrial Heat Tracing Solutions, ITS AFFILIATES, DIRECTORS, OFFICERS,

SHAREHOLDERS, EMPLOYEES OR OTHER REPRESENTATIVES BE LIABLE TO YOU IN AN

AMOUNT GREATER THAN THE AMOUNT ACTUALLY PAID BY YOU, IF ANY, FOR THE SOFTWARE.

YOU FURTHER AGREE THAT REGARDLESS OF ANY STATUTE OR LAW TO THE CONTRARY, ANY

CLAIM OR CAUSE OF ACTION ARISING OUT OF OR RELATED TO USE OF THE SOFTWARE OR

THE TERMS AND CONDITIONS MUST BE FILED WITHIN ONE (1) YEAR AFTER SUCH CLAIM OR

CAUSE OF ACTION AROSE OR BE FOREVER BARRED.

7. INDEMNITY. To the extent allowed under federal and state law, you agree to indemnify and

hold Pentair Industrial Heat Tracing Solutions, its parents, subsidiaries, affiliates, officers,

employees, sponsors and partners harmless from any claim, loss, cost, expense, demand, or

damage, including reasonable attorneys’ fees, arising directly or indirectly out of (a) your use of,

or inability to use, the Software, (b) your activities in connection therewith, or (c) your breach of

this Agreement or violation of the rights of any other party.

8. TERMINATION. The license granted herein will automatically terminate without notice from

Pentair Industrial Heat Tracing Solutions if you fail to comply with any term or condition of this

Agreement. You agree, upon such termination, to remove the Raychem NGC-30 Software from

any memory and/or storage media or device, and to return the Raychem NGC-30 Software,

including all media and written materials, or destroy the same and certify such destruction

to Pentair Industrial Heat Tracing Solutions, along with any backup or other copies in your

possession.

9. COMPLETE AGREEMENT – MODIFICATION IN WRITING. This Agreement constitutes the

sole and complete understanding between the parties with respect to the Raychem NGC-30

Software and its use, and may not be varied except by a writing signed by an officer of Pentair

Industrial Heat Tracing Solutions. You agree that you may not rely on any representations

concerning the Raychem NGC-30 Software to the extent they vary from this Agreement, and

such representations, if any, will neither add to nor vary the terms of this Agreement.

10. CHOICE OF LAWS. This Agreement is governed by the laws of the State of California and the

United States, including U.S. Copyright Laws.

11. EXPORT LAWS. The Raychem NGC-30 Software may require a license from the U.S.

Department of Commerce or other governmental agency before it may be exported. The term

“export” includes many acts (such as transferring the Raychem NGC-30 Software to a foreign

citizen within the United States), in addition to sending or taking the Raychem NGC-30 Software

outside the United States. You agree to ascertain the necessary licensing procedures and

obtain any required licenses before exporting the Raychem NGC-30 Software. You also agree to

indemnify Pentair Industrial Heat Tracing Solutions and assume all financial responsibility for

any losses it may suffer if you do not comply with this paragraph.

12. GOVERNMENT RESTRICTED RIGHTS. User acknowledges that the Raychem NGC-30

Software has been developed at private expense and is provided with “Restricted Rights.”

Use, duplication or disclosure by the Government is subject to restrictions as set forth in

subparagraph (b)(3) and paragraph (c) of the Rights in Technical Data clause at 48 C.F.R.

252.227-7013, or subparagraphs (c)(1) and (2) of the Commercial Computer Software –

industrial heat tracing solutions

EN-RaychemNGC30UIT2Programming-AR-H5818602/16

8 / 84

Page 9

Restricted Rights clause at 48 C.F.R. 52.227-19, as applicable. This provision applies to the

Raychem NGC-30 Software acquired directly or indirectly by or on behalf of any government.

The Raychem NGC-30 Software is a commercial product, licensed on the open market at

market prices, and was developed entirely at private expense and without the use of any

government funds. Any use, modification, reproduction, release, performance, display, or

disclosure of the Raychem NGC-30 Software by any government shall be governed solely by

the terms of this Agreement and shall be prohibited except to the extent expressly permitted by

the terms of this Agreement, and no license to the Raychem NGC-30 Software is granted to any

government requiring different terms.

13. ASSIGNMENT. You may neither assign any right nor delegate any obligation under this

Agreement and attempted assignment or delegation shall be void. Pentair Industrial Heat

Tracing Solutions may freely assign this agreement and its rights and obligations there under

to any third party.

14. INVALID PROVISIONS. If any of the provisions of this provisions Agreement are invalid under

any applicable statute or rule of law, they are to that extent deemed omitted.

15. WAIVER. No failure or delay of Pentair Industrial Heat Tracing Solutions in exercising or

enforcing any right or provision of this Agreement shall constitute a waiver of such right

or provision, or any other right or provision hereunder. Furthermore, any waiver by Pentair

Industrial Heat Tracing Solutions of any right or provision of this Agreement shall not be

construed as, or constitute, a continuing waiver of such right or provision, or waiver of any

other right or provision of this Agreement.

16. HEADINGS. The section titles in this Agreement are for convenience only.

17. SURVIVABILITY. You agree that the terms and conditions of this Agreement shall survive any

termination of this Agreement and your rights to use the Software.

Should you have any questions concerning this Agreement, or if you desire to contact Pentair

Industrial Heat Tracing Solutions for any reason, please write to:

Pentair Industrial Heat Tracing Solutions

307 Constitution Drive

Menlo Park, CA 94025-1164

U.S.A.

1.4 USER RESPONSIBILITIES

The performance, reliability and safety of your heat-tracing system depend on proper design,

selection, and installation. The Raychem NGC-UIT2-EX Software will help you configure and

monitor a system that meets your requirements, but it is only a tool. It assumes that your input

is accurate, that you are familiar with heat-tracing system design and configuration, and that you

will ensure that all components of the heat-tracing system are installed, maintained and used

as intended. The configuration of the Raychem NGC-UIT2-EX Software should be reviewed by a

knowledgeable engineer to ensure it is appropriate for your application. Additional information

relating to safety, design, and installation is contained in Design Guides, Installation Manuals,

Data Sheets, and other literature available from Pentair Industrial Heat Tracing Solutions. Be sure to

consult these documents as needed.

1.5 SAFETY WARNINGS

There are important safety warnings which are shipped with Pentair Industrial Heat Tracing

Solutions products and that are also printed in the Raychem NGC-20 Installation Manual

(ML-RaychemNGC20CLE-IM-INSTALL130) and Raychem NGC-30 Installation Manual (H57878). Be

sure to read and follow these safety warnings to reduce the risk of fire, shock, or personal injury.

If you have any questions, contact your local representative or contact Pentair Industrial Heat

Tracing Solutions directly.

1.6 WARNING, ERROR AND ALARM MESSAGES

Under certain conditions, the Raychem NGC-30 program will alert the user with a warning or an

error message. These are typically either because the program cannot find an acceptable answer

based on user input, or because the user may need to take some additional action to ensure the

design requirements are completely met. These warnings and error messages are detailed on

page 52.

industrial heat tracing solutions

EN-RaychemNGC30UIT2Programming-AR-H5818602/16

9 / 84

Page 10

1.7 TECHNICAL SUPPORT

Menu

(changes with each main menu selected)

1.8 NAVIGATION

For technical support, contact your local representative, or contact Pentair Industrial Heat Tracing

Solutions directly:

Pentair Industrial Heat Tracing Solutions

7433 Harwin Drive

Houston, TX 77036

USA

Tel: 800-545-6258

Tel: 650-216-1526 (outside U.S.)

email: technicalsupport@pentairthermal.com

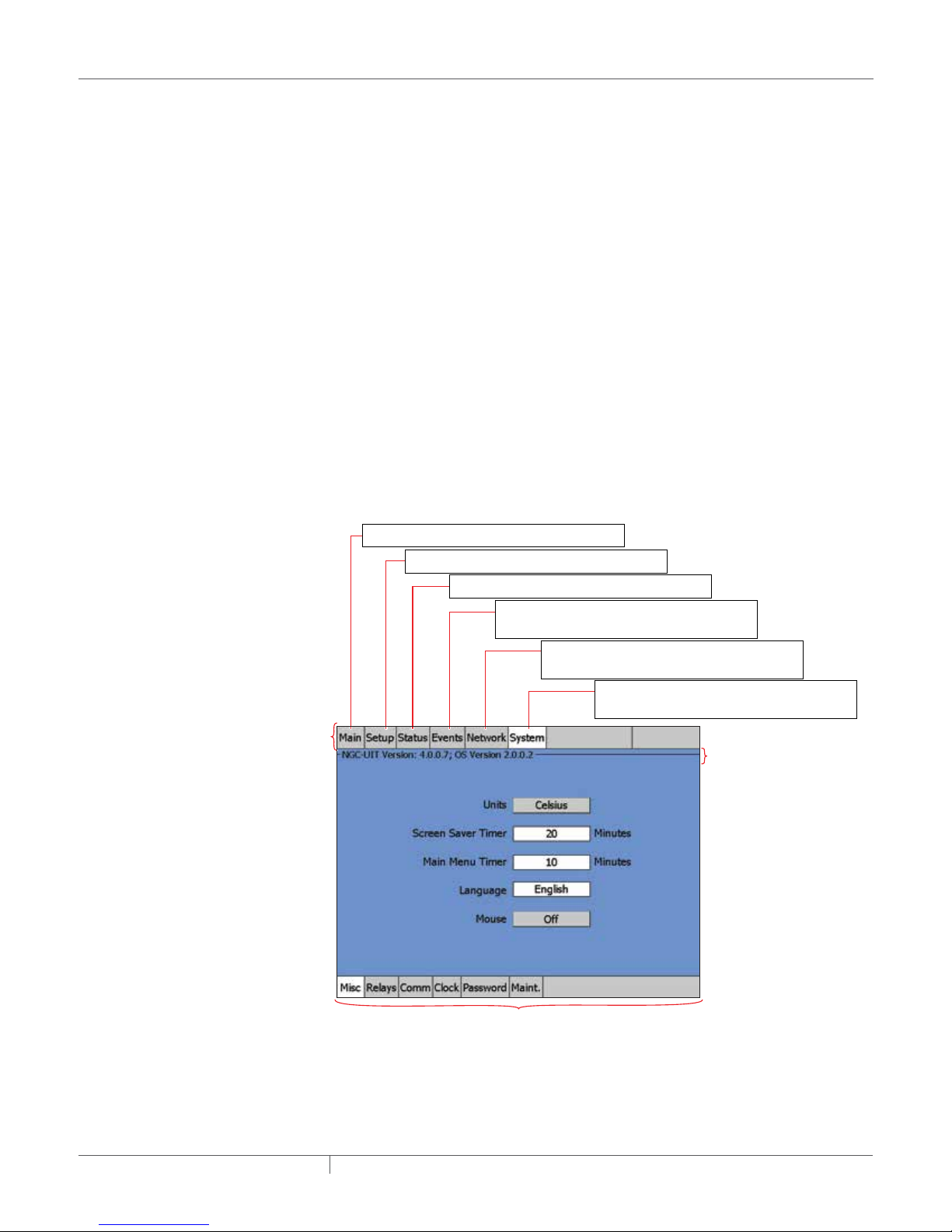

1.8.1 NAVIGATING BETWEEN WINDOWS

The top row of the window contains the main menu buttons, and the bottom row contains subsets

of those main menu buttons.

When asked to navigate between windows in this manual, simply press a combination of a Main

Menu | Submenu buttons.

For example in Step 1, the System | Misc window must be accessed. To perform this action, press

the System button on the top row. On the bottom row, press the Misc button.

On Setup and Status windows, a Status legend displays. This information shows what Device

address and Relay address have been assigned to a particular Circuit.

Main: Displays the status of all Circuits

Setup: Displays the setup parameters for a CircuitSetup: Displays the setup parameters for a Circuit

Status: Displays the status for a Circuit

Events: Displays the chronological history of

all events and alarms

Network: Displays the summariazation of the

device addresses and resources

System: Displays system wide (global) set-up

parameters for all Circuits

Main

Fig. 1.2 Navigation

industrial heat tracing solutions

Main Menu’s Sub-Menu

EN-RaychemNGC30UIT2Programming-AR-H5818602/16

Navigational

Header

10 / 84

Page 11

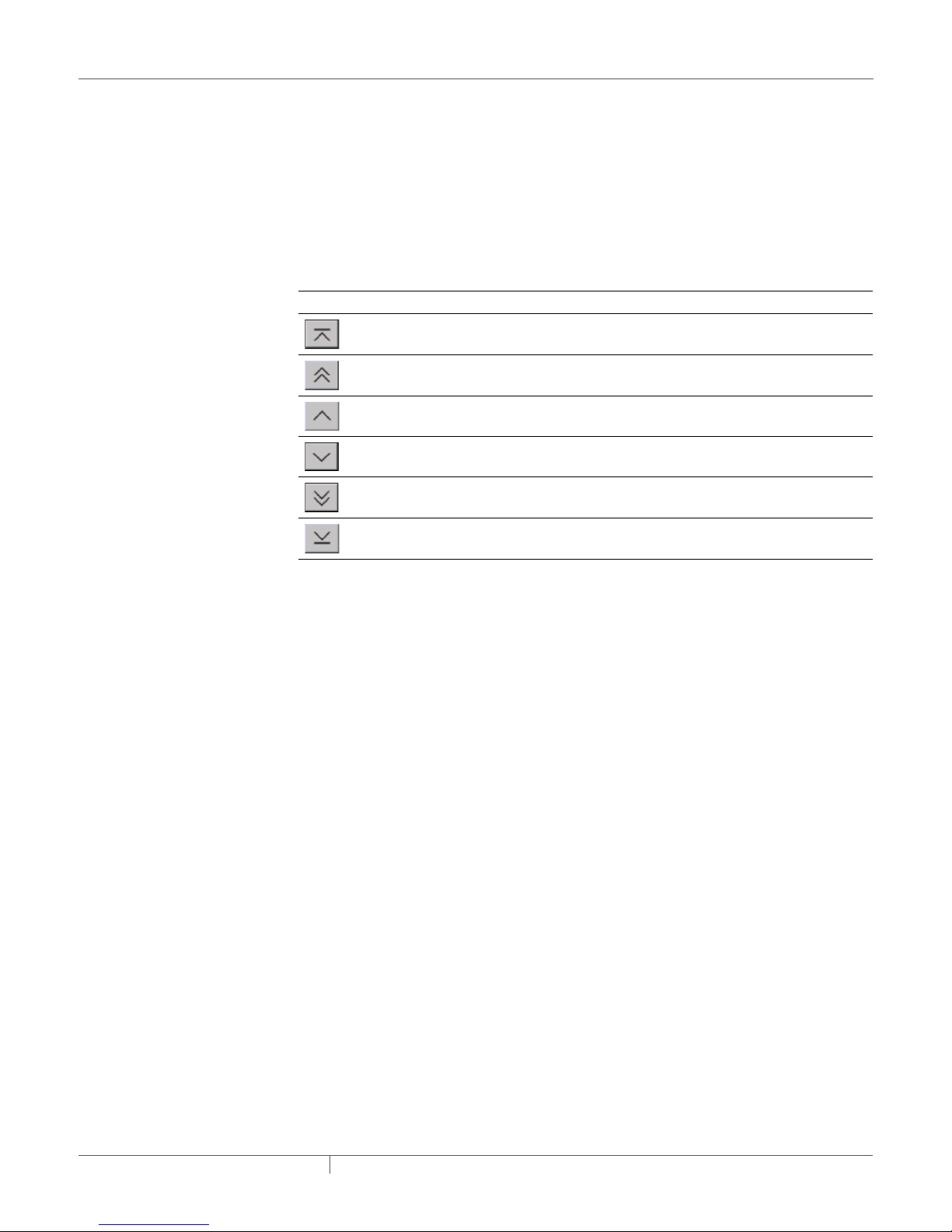

Main Window and Events/Alarms Navigation

Navigation Buttons

At the bottom of the Main Window and Events Window, the navigation buttons will appear once six

events have occurred. Use buttons to scroll up and down to view the status of the Circuits on the

Main Window, and on the Events/Alarms on the Events Window.

Shortcut: If a Circuit number is associated with an Event or Alarm, selecting it automatically sends

you to that circuit’s Status/Circuit window. This will help in troubleshooting.

When in the Main or Events|Alarms windows, press on any data field for a Circuit to see the Status

window for that Circuit.

Table 1.2 Navigation Buttons

Top of list When selected, displays the first five Circuits of the

Main and the Events windows.

Page up When selected, displays the previous five Circuits of the

Main and the Events windows.

Move up one Circuit When selected, displays the previous Circuit on the

Main and the Events windows.

Move down one Circuit When selected, displays the next Circuit on the Main

and the Events windows.

Page down When selected, displays the next five Circuits of the

Main and the Events windows.

Bottom of list When selected, displays the last five Circuits of the

Main and the Events windows.

industrial heat tracing solutions

EN-RaychemNGC30UIT2Programming-AR-H5818602/16

11 / 84

Page 12

SECTION 2 BASIC CONFIGURATION QUICK START

The following gives an overview of how to implement a simple 4 Circuit system. For greater detail

and PLI module configuration, please go to Section 3 – Full Configuration on page 25.

2.1 AN EXAMPLE OF A SIMPLE 4 CIRCUIT SETUP

IMPORTANT: A Configuration Spreadsheet has been developed to assist in the collection of

specific

circuit (Circuit) details. This spreadsheet is located in Appendix E.

The following is a typical heat-tracing system for a four (4) Circuit Setup:

• Four (4) pipes (Pipe #1, Pipe #2, Pipe #3, Pipe #4)

• Four (4) heaters (one per pipe: Heater #1, Heater #2, Heater #3, Heater #4)

• Four (4) output relays (Relay #1, Relay #2, Relay #3, Relay #4) which control the heater’s

contactors

• Four (4) RTD temperature sensors (RTD #1, RTD #2, RTD #3, RTD #4)

• Four (4) On/Off control modes

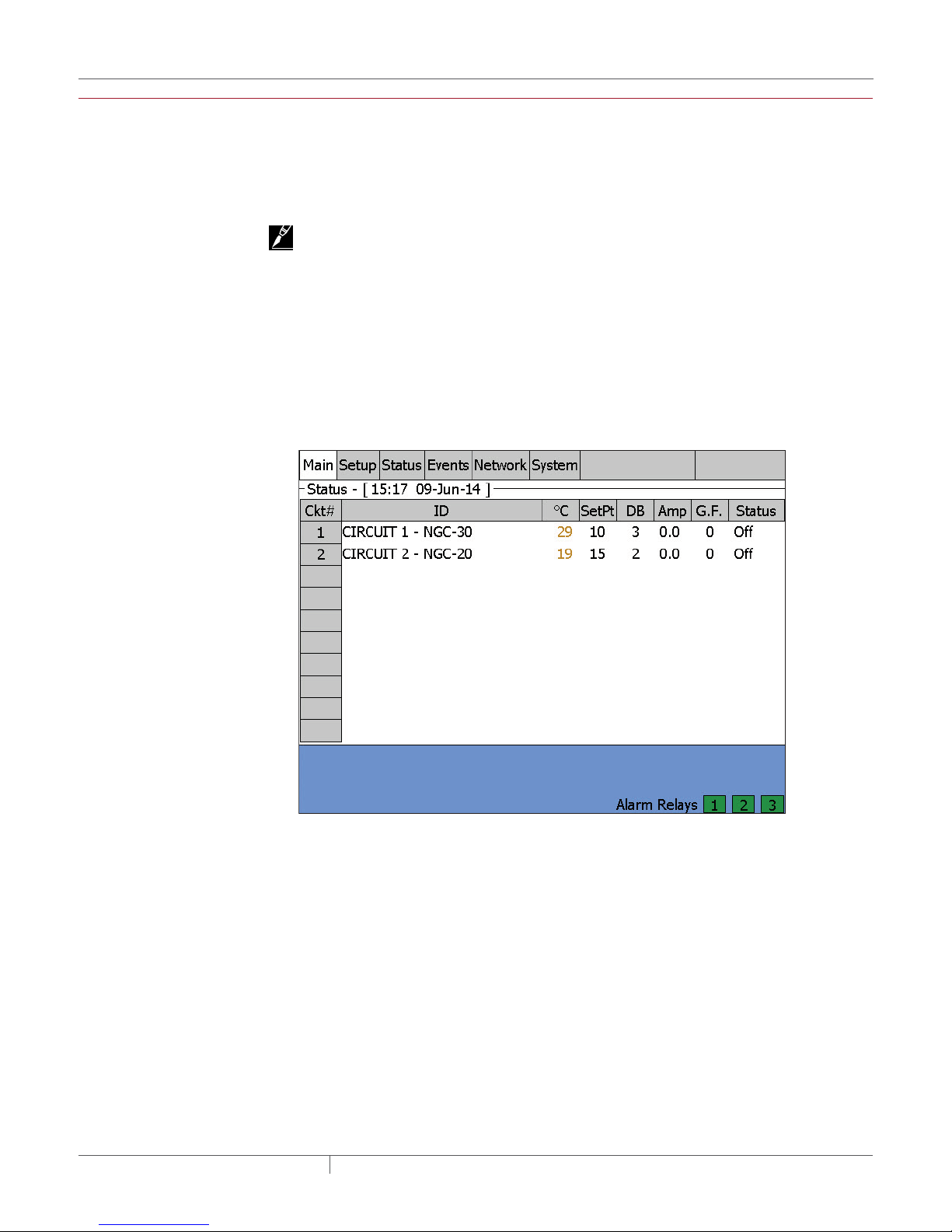

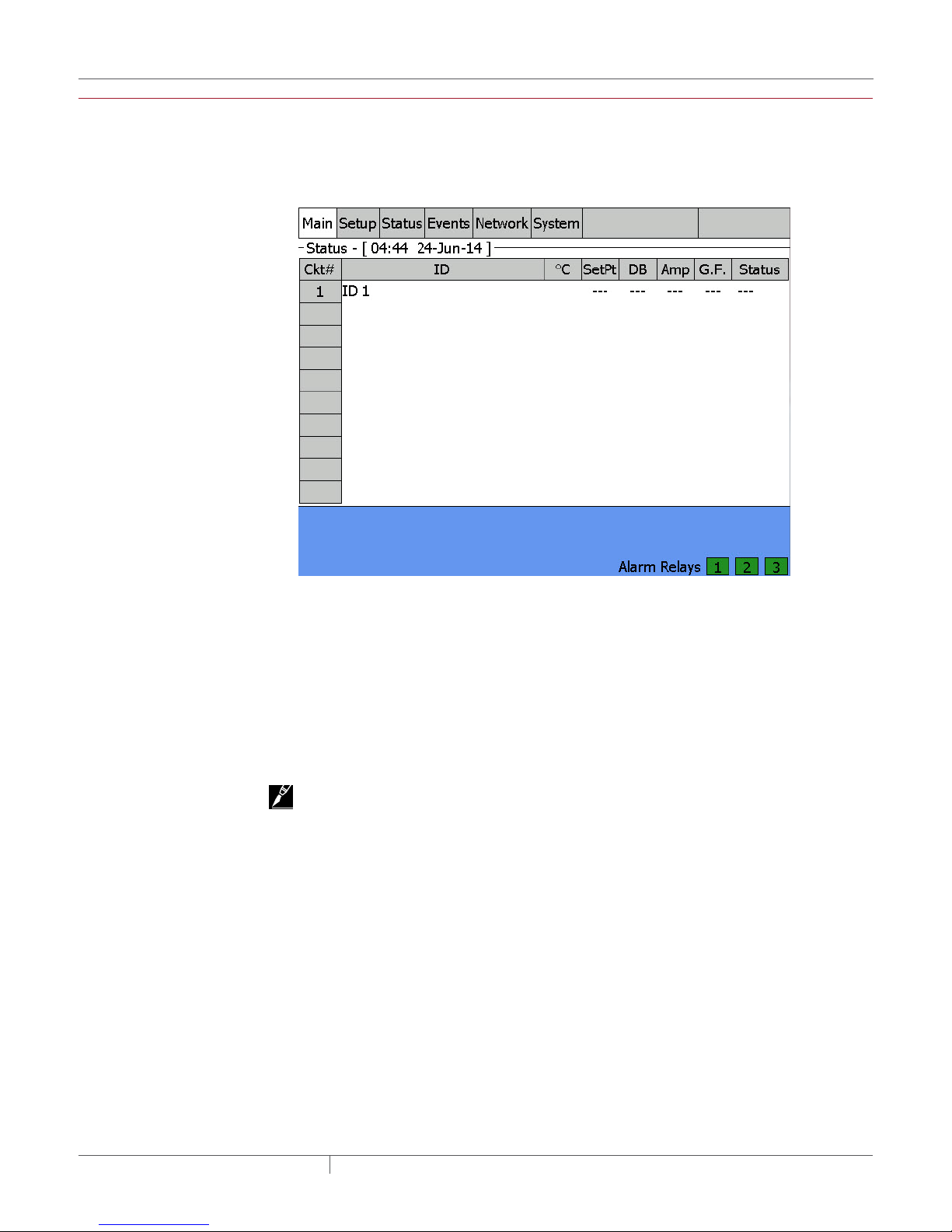

This is the first window that appears when the program loads.

Fig. 2.1 Main window

industrial heat tracing solutions

EN-RaychemNGC30UIT2Programming-AR-H5818602/16

12 / 84

Page 13

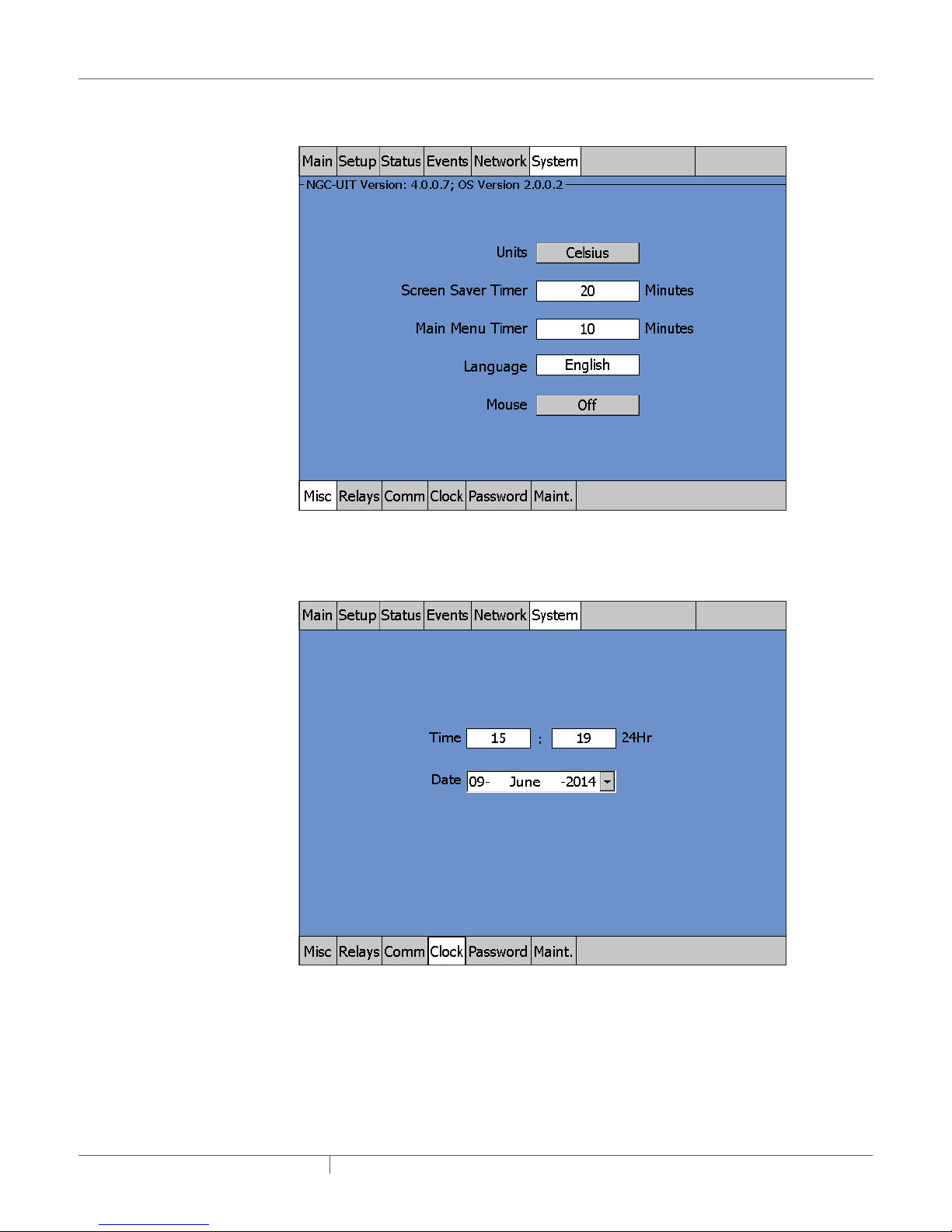

Step 1: Setting up Units and Language

Go to the System | Misc window and enter the appropriate Units and Language.

Fig. 2.2 System|Misc window

Step 2: Setting Time and Date

Go to the System | Clock window and set the time and date

Fig. 2.3 System | Clock window

industrial heat tracing solutions

EN-RaychemNGC30UIT2Programming-AR-H5818602/16

13 / 84

Page 14

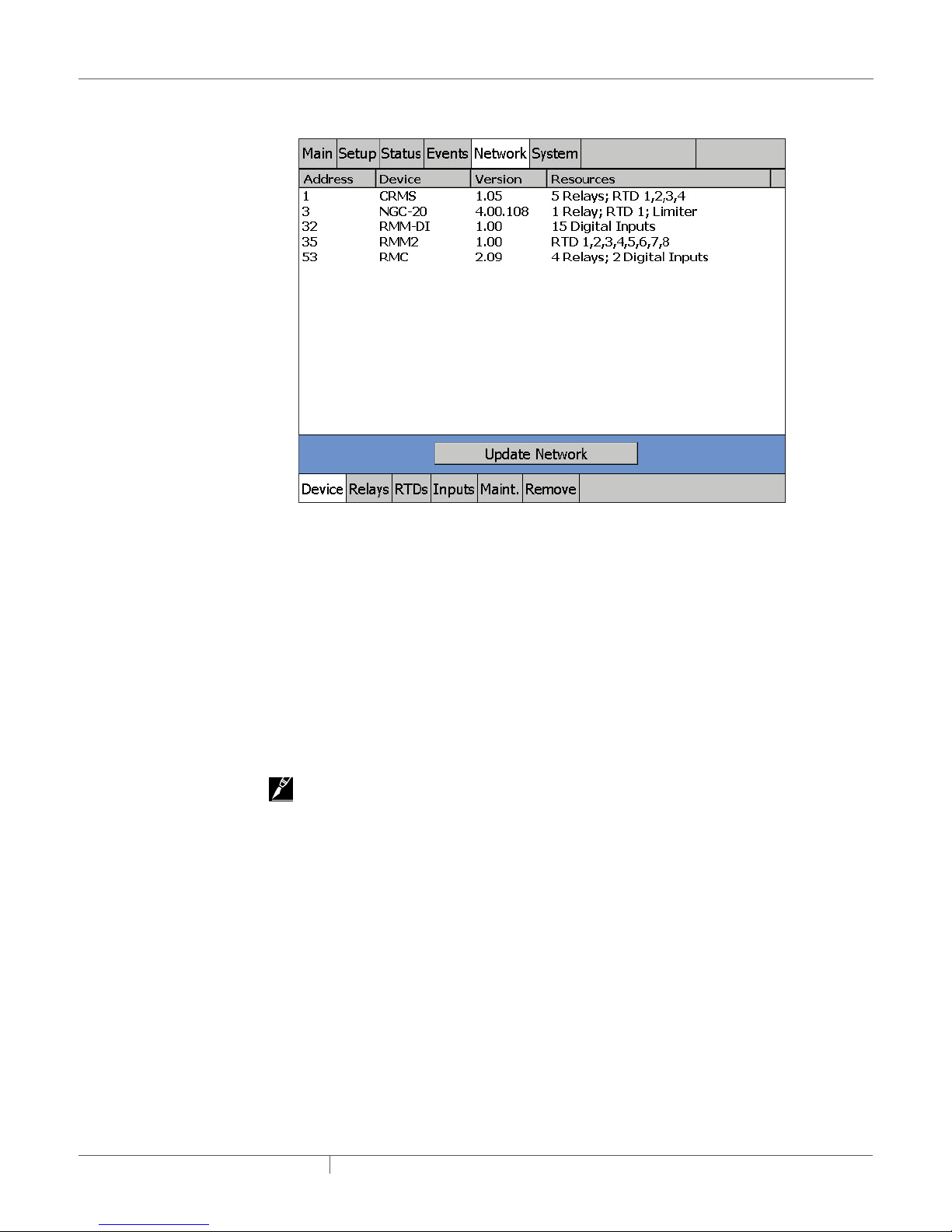

Step 3: Setting Up the Network for Device(s)

Go to the Network | Devices window.

Fig. 2.4 Network | Devices window

Press “Update Network”. The NGC-UIT2 will scan all NGC-30-CRMs/-CRMSs, PLI modules, NGC20 controllers, RMC modules, RMM-DI modules and/or RMM2 modules into the network database.

Once the database exists, no further scanning is done. A device address is the number assigned

via the rotary switches on the NGC-30-CRM-CRMS, PLI, RMC, RMM-DI modules or RMM2 module

circuit board. See the Raychem NGC-30 Installation Manual (H57878) for more information.

In this example the system found 4 devices. These are:

1) A CRMS board with 4 RTDs installed on position 1, 2, 3, and 4

2) A Raychem NGC-20 controller with 2 RTD connected directly to the controller. The Raychem

NGC-20 is equipped with a limiter (which has its own temperature sensor).

3) RMM with 7 RTDs connected to it.

4) RMM-DI with 15 digital inputs

5) RMC with 2 relays outputs and 2 digital inputs.

IMPORTANT: See page 56 for additional information.

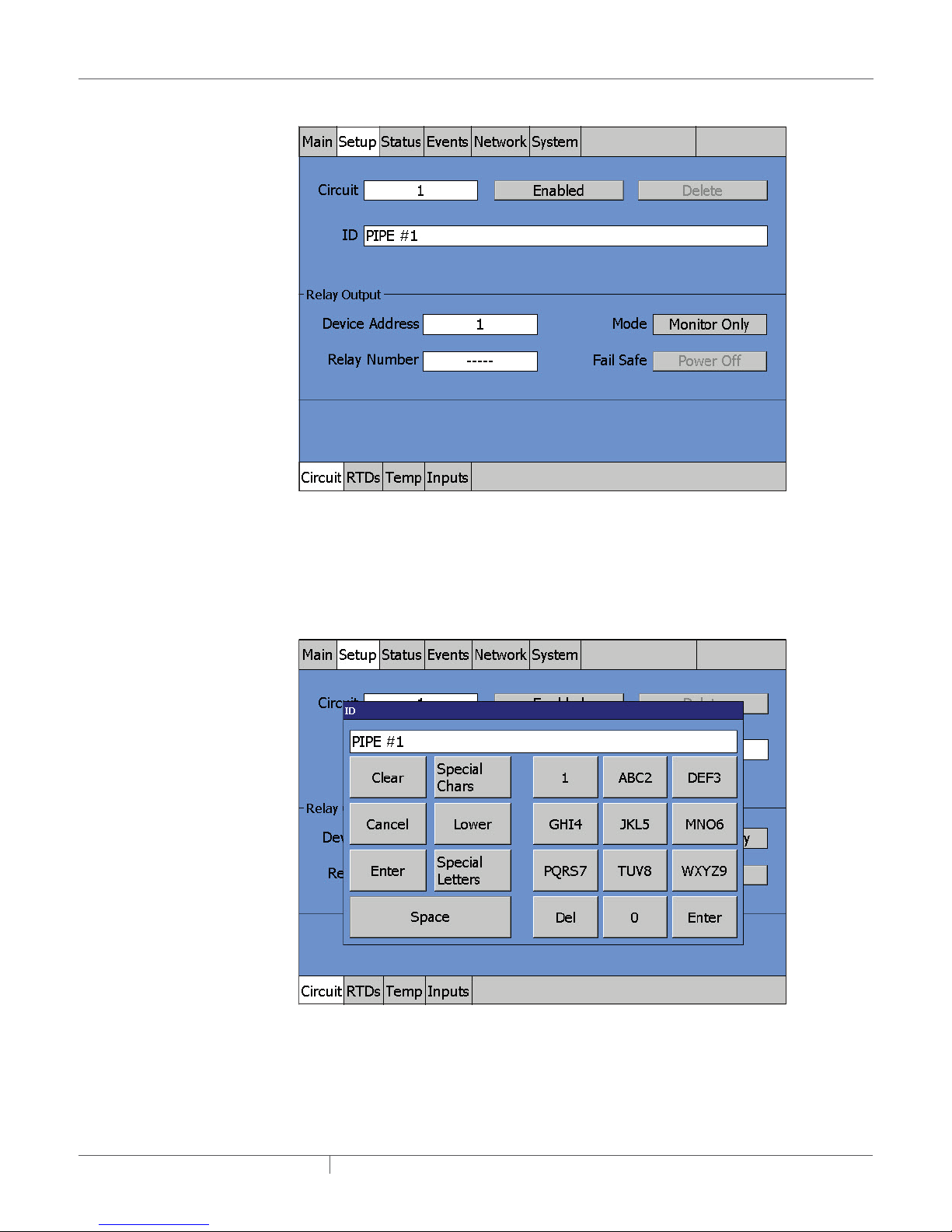

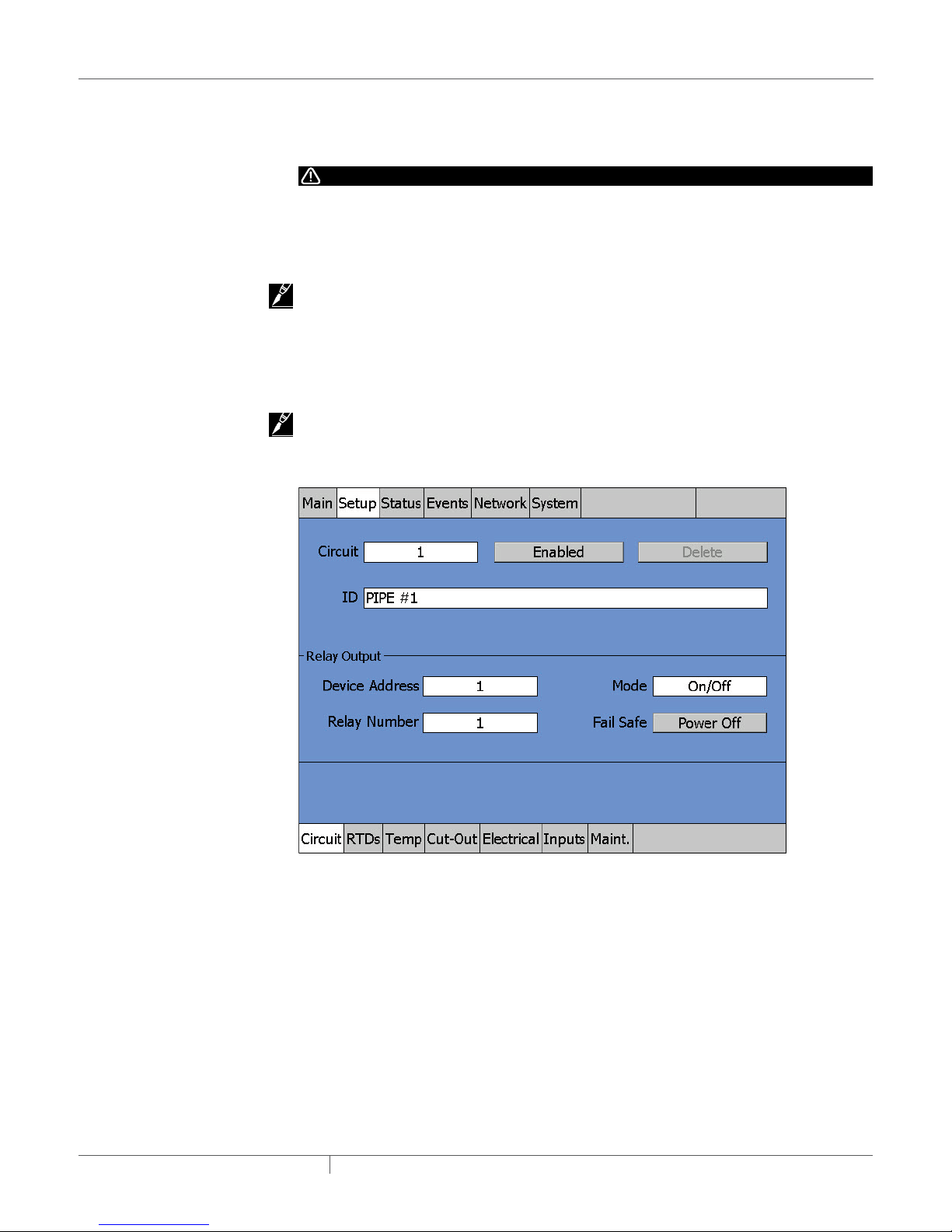

Step 4: Setting up a Circuit

In this manual we set up a circuit on the NGC-30-CRMS controller. For the Raychem NGC-20

controller the same steps can be followed. As the Raychem NGC-20 controller is not identical to

the Raychem NGC-30 controller, it is possible that the screens differ.

industrial heat tracing solutions

EN-RaychemNGC30UIT2Programming-AR-H5818602/16

14 / 84

Page 15

Step 4A: Go to Fig. 2.6 | ID pop-up window

Fig. 2.5 Setup|Circuit window

At initial start-up, the Setup|Circuit window automatically displays Circuit 1.

Step 4B: Press on the ID field and a pop-up window appears

Fig. 2.6 ID pop-up window

• The pop-up window is a text-editing window that works similar to cell phone text messaging.

There are selection keys for Upper Case Letters, Lower Case Letters, and Special Characters.

The keypad portion allows you to enter text by pushing the appropriate keys.

• For this example, Pipe #1 was entered for the ID tag.

• Press Enter when done.

industrial heat tracing solutions

EN-RaychemNGC30UIT2Programming-AR-H5818602/16

15 / 84

Page 16

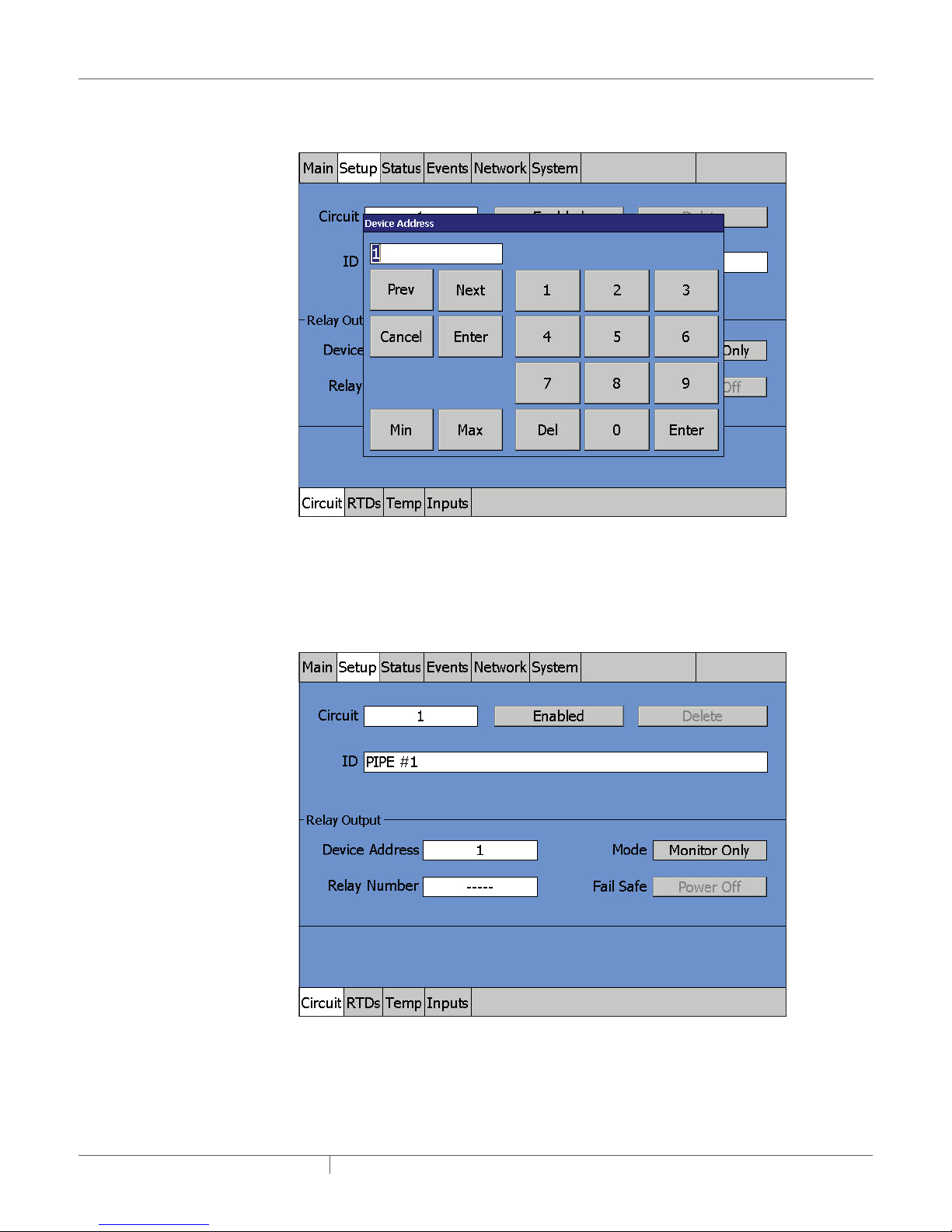

Step 4C: Press on the Device Address field

Fig. 2.7 Device Address window

• A numeric entry pop-up window appears. Type in the device address (in this case, 1) for this

Circuit and press Enter. (See page 56 for more on device addresses.)

Step 4D: Press on the Relay Number field

Fig. 2.8 Relay number window

industrial heat tracing solutions

EN-RaychemNGC30UIT2Programming-AR-H5818602/16

16 / 84

Page 17

Step 4D continued: This window shows the pop-up window prior to any Relay assignment

Fig. 2.9 Pop-up window prior to any Relay Assignment

• Press on the word “Available” to the right of #1 to assign Relay 1 as the output device for Circuit 1.

IMPORTANT: The window will always display which Relays are still available on this device for

Circuit assignment.

Step 4D continued: Press Enter after Relay assignment to return to the Setup window

Fig. 2.10 Device Address, Assign Relay Number window

industrial heat tracing solutions

EN-RaychemNGC30UIT2Programming-AR-H5818602/16

17 / 84

Page 18

• Press Enter.

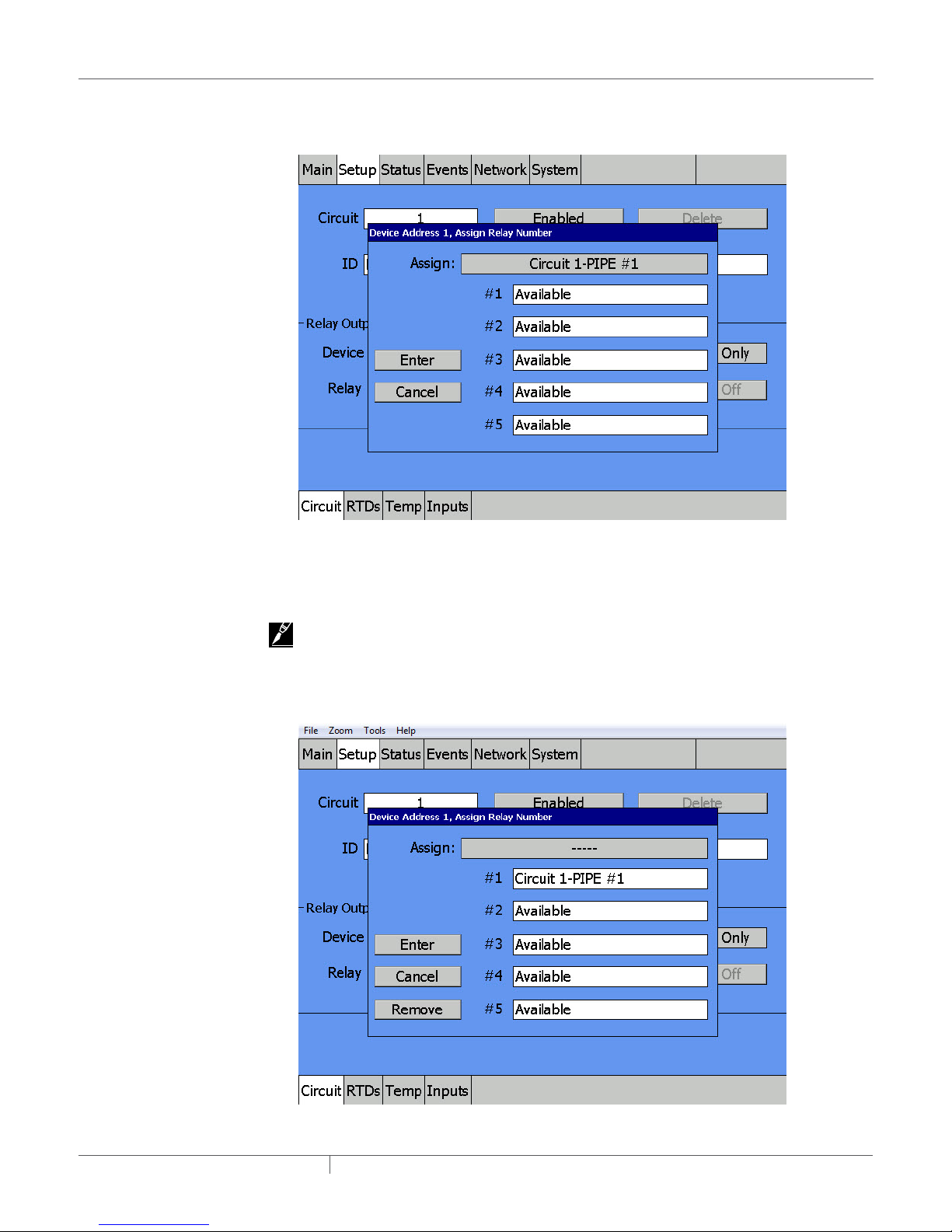

Step 4E: Press on the Mode field and a pop-up window appears, showing all available

control modes

Fig. 2.11 Mode window pop-up

Step 4E (continued): Pop-up window for control mode appears

Fig. 2.12 Mode - Select window

At the Mode - SELECT window:

• This pop-up window lets you select a Circuit’s basic operating mode. The NGC-30-CRMS, used

in this example, has the following Control modes available: On/Off, Always On, Always Off,

PASC, Voltage and Proportional.

• The On/Off mode is a simple setpoint/dead band operation.

• Press On/Off to select this control mode and return to the Setup Circuit window.

industrial heat tracing solutions

EN-RaychemNGC30UIT2Programming-AR-H5818602/16

18 / 84

Page 19

Step 5: Review the Fail Safe setting

Fig. 2.13 Setup|Circuit window and Fail Safe button

At the Setup|Circuit window:

• Pressing the Fail Safe toggle button alternates the Fail Safe mode between Power Off and

Power On. This selection tells the NGC-30-CRM/-CRMS if the heater should be turned on or off

if all of the RTD(s) for this Circuit fail.

• If the main concern is to prevent pipes from freezing, then Power On is a good choice. However,

if the heater is oversized and overheating is a concern, then Power Off could be a better choice.

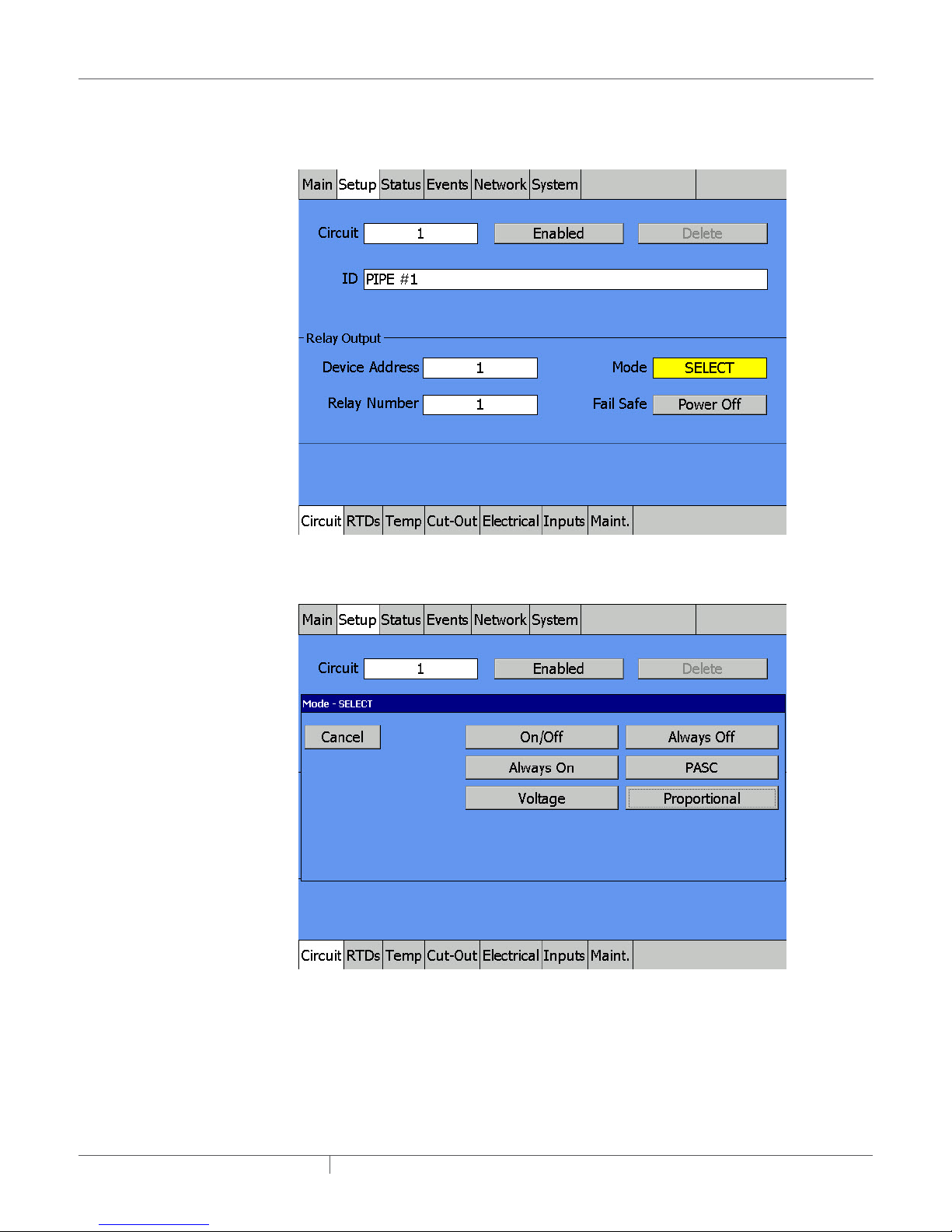

Step 6: Go to Setup | RTDs window

Fig. 2.14 Setup | RTDs window

industrial heat tracing solutions

EN-RaychemNGC30UIT2Programming-AR-H5818602/16

19 / 84

Page 20

At the Setup|RTD window:

• The Raychem NGC-30 program first checks to see if the default RTD is available. On any

NGC-30-CRM/-CRMS board, the first RTD input is automatically coupled with the first relay

output; the second RTD is linked with the second output relay, etc. (In the case an RMC - RMM2

combination is chosen, then the user must define himself which RTD Device address is coupled

with the RMC output.)

• Here an RTD has been connected to the RTD 1 terminal block, so the RTD set-up window

indicates the default assignment is already completed.

• There are three blank slots available so you can assign additional RTDs to this output relay. You

may desire additional RTDs if you need a more exact temperature sampling for a temperaturesensitive fluid. If you assign additional RTDs, the lowest RTD value from the list will be used for

control temperature.

• Each of the four RTDs can be independently set as Control or Monitoring only sensor. If you are

using a PLI module with SES-CONT sensors, an additional Continuity mode will be available.

See Section 3 for more details.

• See page 33 for information on how to set up additional RTDs. For this simple Circuit Quick

Start example, the default set-up RTD is used.

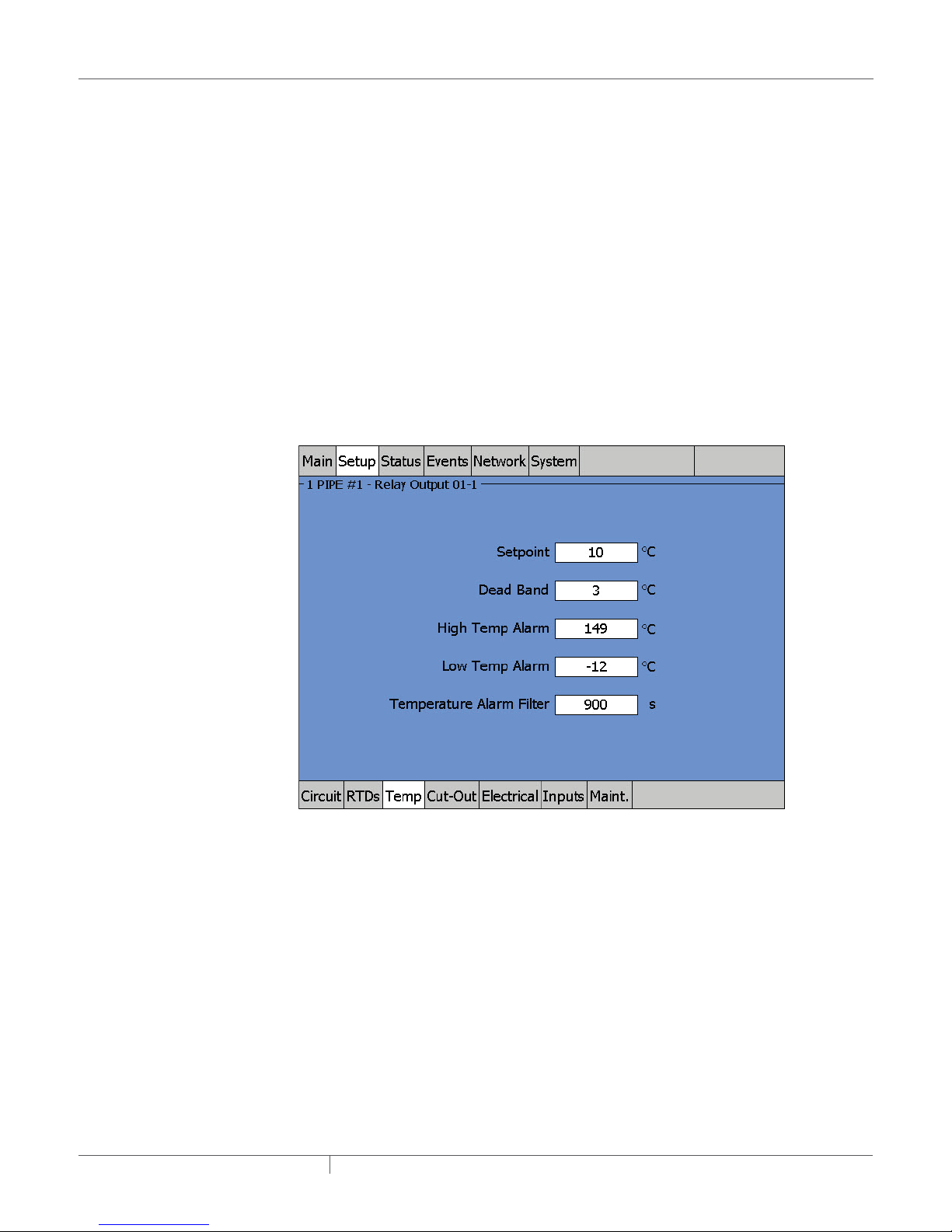

Step 7: Go to the Setup | Temp window

Fig. 2.15 Setup | Temp window

At the Setup|Temp window:

• Input the Setpoint, Dead Band, High Temp Alarm, and Low Temp Alarm by pressing on each of

the four numeric fields in turn.

• For this example, the Setpoint temperature is 10°C, a dead band of 3°C and high and low

temperature alarms at 149°C and -12°C respectively.

• Use the default value of 900 seconds (15 minutes) for the Temperature Alarm Filter (time delay

before the NGC-30 reports any temperature alarm) and the default value of Disable for the High

Temp Cut-Out. To implement the High Temp Cut-Out feature. See “High Limit Cut-Out Entry

Field” on page 36.

industrial heat tracing solutions

EN-RaychemNGC30UIT2Programming-AR-H5818602/16

20 / 84

Page 21

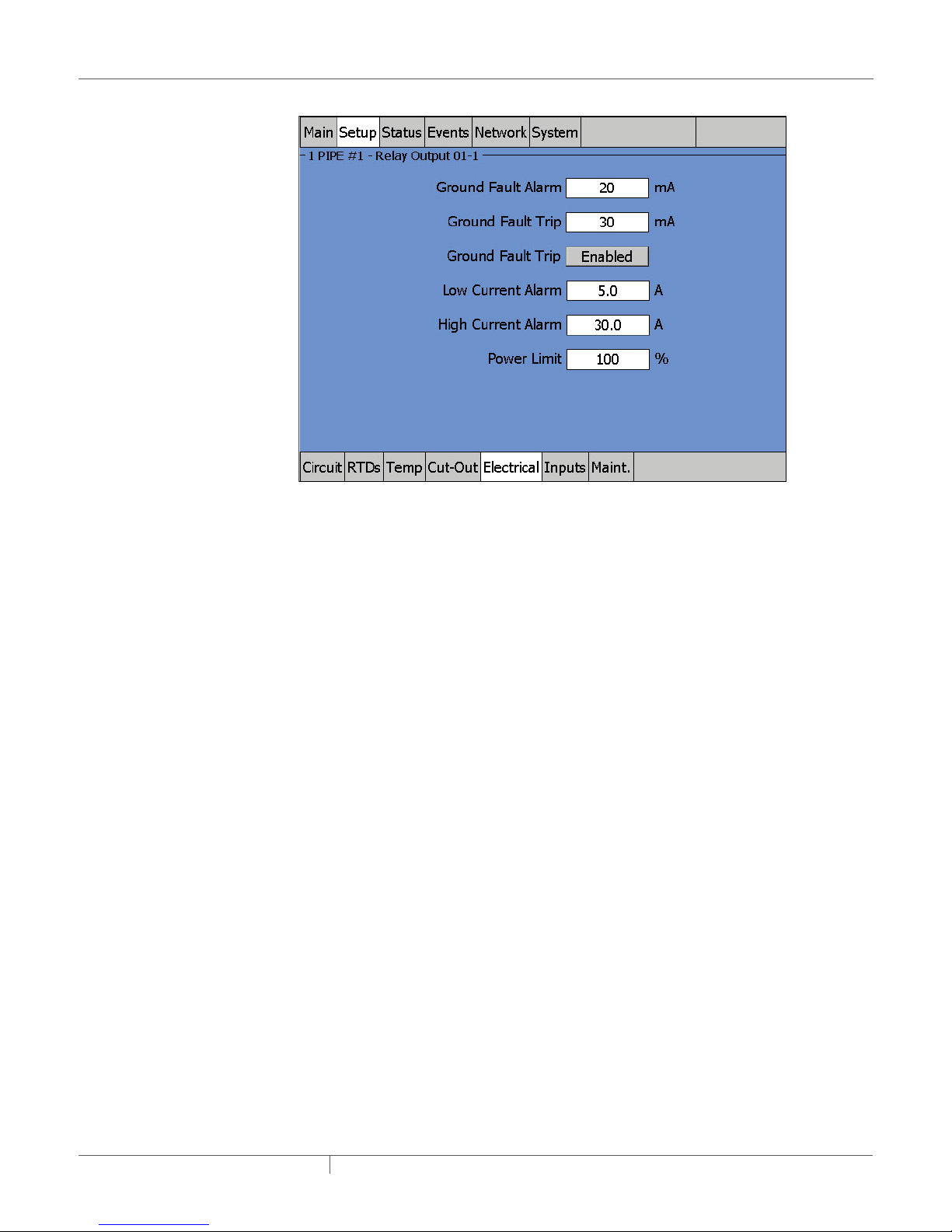

Step 8: Go to Setup | Electrical

Fig. 2.16 Setup | Electrical

At the Setup | Electrical:

• Input the Ground-Fault Current Alarm and Ground-Fault Current Trip by pressing each of the

two numeric fields in turn.

• For this example, the Ground-Fault Current Alarm and Ground-Fault Current Trip levels are set

to 20 mA and 30 mA respectively.

– At less than 20 mA, the Raychem NGC-30 program takes no action. At 20 mA or more

leakage, an alarm is indicated and logged to the Events List.

– At 30 mA the output relay assigned to this Circuit is tripped off.

High Voltage Alarm Entry Screen

If the voltage monitoring module measures line voltage above this threshold, the NGC-UIT2

generates an alarm.

Range: 50 – 305 V

Default: 270 V

Low Voltage Alarm Entry Screen

If the voltage monitoring module measures line voltage below this threshold, the NGC-UIT2

generates an alarm.

Range: 50 – 305 V

Default: 90 V

industrial heat tracing solutions

EN-RaychemNGC30UIT2Programming-AR-H5818602/16

21 / 84

Page 22

• Input the High Current Alarm and Low Current Alarm by pressing each of the two numeric

fields in turn. For this example, High Current Alarm is set to 30 A, and Low Current Alarm is set

to 5 A.

WARNING:

Fire Hazard. A ground-fault alarm means the heating cable has been damaged or improperly

installed and must not be ignored. Disabling the ground-fault trip function reduces safety and

could result in sustained electrical arcing or fire. To minimize the risk of fire if the alarm activates,

shut off the power and repair the system immediately

IMPORTANT: Setting 0 for both High and Low Current Alarms completely deactivates the Current

Alarm function.

• Power Limit – This is enabled only when SSR control devices are detected (NGC-30-CRMS

panel). A Power Limit setting less than 100% will limit the “on-time” of a constant wattage

heater to the percentage indicated in the entry field. This has the effect of lowering the amount

of power that the heater can produce.

IMPORTANT: Power Limiting is not recommended if self-regulating heaters are installed.

Step 10: Enable or Disable the Circuit

Fig. 2.17 Circuit 1 enabled

At the Setup|Circuit window with Circuit #1 selected:

• By default, once you program a Circuit, it immediately begins to control the heater based on the

input information.

• If you do not want this Circuit to activate until all Circuits are programmed, go to Setup | Circuit

window and press the Enabled toggle button once, which disables the Circuit. To re-Enable,

press the Enable/Disable button again.

industrial heat tracing solutions

EN-RaychemNGC30UIT2Programming-AR-H5818602/16

22 / 84

Page 23

Fig. 2.18 Circuit 1 disabled

At the Main status display with Circuit #1 disabled:

• On the Main menu window, any Disabled Circuit is grayed out as above.

2.2 SETTING UP ADDITIONAL CIRCUITS

Follow Steps 4 through 10 above to set-up each additional Circuit.

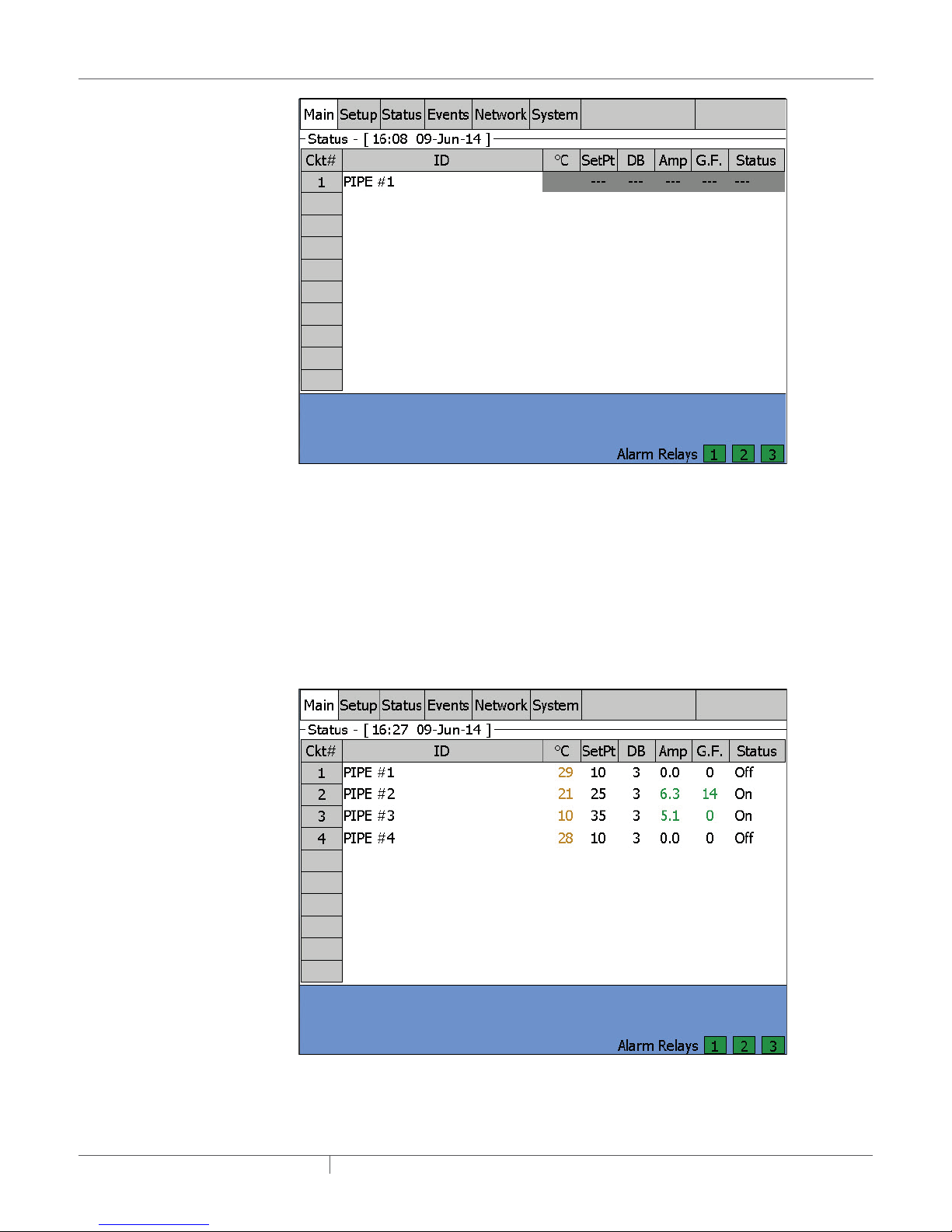

2.3 CIRCUITS 14 SETUP COMPLETE CONFIRMATION

After completing the Setup for Circuits 1, 2, 3, and 4, and Circuits are Enabled, go to the Main

window to confirm all Circuits are activated and working properly.

Fig. 2.19 Main status window for confirmation

industrial heat tracing solutions

EN-RaychemNGC30UIT2Programming-AR-H5818602/16

23 / 84

Page 24

2.4 STARTING THE NGC30

2.4.1 SYSTEM REQUIREMENTS

The minimum configuration to use the Raychem NGC-30 software is:

• Raychem NGC-UIT2 hardware

• At least one of the following:

– NGC-30-CRM/-CRMS

– RMM2 Remote Monitoring Module

– RMC Module

– NGC-20 Controller

Maximum optional equipment configuration:

• Up to 52 Heat Trace Controller Boards (total count in any combination)

– NGC-30-CRM

– NGC-30-CRMS

• Up to 16 RMM2 modules (8 channel RTD multiplexing hubs)

• Up to 4 PLI modules (127 RTDs if SES/SPC transmitters are used, or 255 RTDs if 700-TT

transmitters are used)

• Up to 247 NGC-20 controllers

• Up to 247 RMM-DI modules

Total combination of output devices including NGC-30-CRM/-CRMS, NGC-20 and RMC DO cannot

exceed 260 circuits.

2.4.2 INITIAL SETUP

The Raychem NGC-30 software is designed to run only on the NGC-UIT2 hardware platform.

Prior to shipment, the Raychem NGC-30 software is installed into a nonvolatile area of the NGCUIT2 memory. During the initial power-up, you will see a blue background “splash” window for

approximately 30 seconds as the system software is loaded and initializes.

industrial heat tracing solutions

EN-RaychemNGC30UIT2Programming-AR-H5818602/16

24 / 84

Page 25

SECTION 3 FULL CONFIGURATION

3.1 SETTING THE NETWORK FOR DEVICES

Go to the Network|Device window.

For the very first time, the Network screen will be blank. See below:

Fig. 3.1 Initial Network|Device window

Press "Update Network" and scan all NGC-30-CRM/-CRMS boards, RMM2 module and others

into the Network database. The Device Addresses for these modules will be scanned and a

database will be created. A device address is the number assigned via the rotary switches on the

NGC-30-CRM/-CRMS board, RMM2 module, PLI Module, RMC module and RMM-DI module. If an

expected device does not appear on the list after the scan is complete, it is most likely physically

disconnected from the RS-485 network wiring, or is not powered. Troubleshoot and verify all

network and power connections.

Once the database exists, no further scanning is done unless the system is forced to update the

network by activating the "Update Network" button.

IMPORTANT: If a new external hardware device is added after the initial scan, you must initiate a

manual scan by going to the Network|Devices window and pressing the "Update Network" button.

industrial heat tracing solutions

EN-RaychemNGC30UIT2Programming-AR-H5818602/16

25 / 84

Page 26

If a PLI (Power Line Carrier Interface) module is detected in the scanning process, a pop-up

window will open, asking whether the PLI Mode should be changed from the default mode of

PLI-SES/SPC to the PLI-TT. If a SES or SPC Transmitter is connected to the PLI module, the

option "NO" should be selected. The NGC-30 UIT2 indicates this PLI as PLI-SES/SPC. If a 700-TT

Transmitter is connected to the PLI module, the option "YES" should be selected. The NGC-30

UIT2 indicates this PLI as PLI-TT.

Fig. 3.2 Set PLI Mode

IMPORTANT: The NGC-30 Control System can support up to 4 PLI Modules. Each PLI module can

support up to 127 SES or SPC transmitters and up to 255 700-TT transmitters. The SES/SPC and

700-TT transmitters are not compatible and can not be connected to the same PLI module

The Network will then be updated with the connected devices, in this case with one NGC-30-CRMS

board, one RMM2 and one PLI-SES/SPC modules.

Fig. 3.3 Connected Network|Devices window

industrial heat tracing solutions

EN-RaychemNGC30UIT2Programming-AR-H5818602/16

26 / 84

Page 27

When a PLI module is detected in the Update Network process, the PLI tab will be added to the

Channel

GF = Ground fault

Network and Setup Sub-Menus.

IMPORTANT: For CRM/CRMS boards and RMM2 modules, the Resources Column indicates the

RTDs that are available for use in the Setup|RTD Screen. However, the Resources Column for PLISES/SPC or PLI-TT indicates the maximum number of RTDs that could be used. Please refer to

heater isometric drawings for each circuit for the assigned transmitters/RTD addresses to each

circuit.

3.1.1 MAIN WINDOW

After the first system scan

3.2 SOFTWARE ORGANIZATION

Fig. 3.4 Main status window

The Raychem NGC-30 is organized around the concept of control circuits, or simply “Circuits” as

they are called in the UIT2 windows. A typical Circuit consists of one output relay device, one RTD

sensor input, and one set of control parameters as shown below.

has been completed, the main window appears.

LC

Local

RTD

Local

RTD

Local

RTD

Local

RTD

Local

RTD

NGC-30-CRM/-CRMS Board

1

2

3

4

5

GF

LC

GF

LC

GF

LC

GF

LC

GF

LC = Line current

Output

Relay 1

Output

Relay

Output

Relay

Output

Relay

Output

Relay

Fig. 3.5 Simple control circuit

industrial heat tracing solutions

EN-RaychemNGC30UIT2Programming-AR-H5818602/16

27 / 84

Page 28

Channel

Local/A

RMM2 RMC RMM-DI

RTD

Local

RTD

Local

RTD

Local

RTD

Local

RTD

The Raychem NGC-30 software can manage up to 260 Circuits similar to that depicted above.

The control Circuit concept is not limited to the simple arrangement shown above. Multiple input

circuits and “monitor only” circuits are possible as depicted on the following page.

LC

1

2

3

4

5

GF

LC

GF

LC

GF

LC

GF

LC

GF

Output

Relay 1

Output

Relay

Output

Relay

Output

Relay

Output

Relay

NGC-30-CRM/-CRMS

Board

LC = Line current

GF = Ground fault

NGC-UIT

RS-485

B #1

C 2

D 3

4

5

6

7

8

Additional

RTDs

Fig. 3.6 Multiple input control circuit

3.3 NGC30 WINDOWS DETAILED DESCRIPTIONS

3.3.1 SETUP WINDOW

To input any device address, the modules must be connected and powered during startup of the

Raychem NGC-UIT2-EX program. The program scans for the device number(s) on the network

during the update network process. The Network|Devices window lists all the device address(es)

found. The addresses listed are the only device addresses that the program recognizes as valid.

If a device is added after the Raychem NGC-UIT2-EX program has scanned the network, go to the

Network window and select “Update Network.”

Each device must have a unique device address number. For example, if the design requires both

a NGC-30-CRM and a RMM2 module, and 32 is chosen for device address number for the NGC-30CRM, then the RMM2 module cannot also use address 32. This also applies to the other modules.

(See Available Device Address Table on page 56 for device address restrictions).

DI 1

DI 2

RO 1

RO 2

RO ...

Output

Relay 1

Output

Relay

Output

Relay

RTD 1

RTD 2

NGC-20

Lim RTD

DI 1

DI 2

...

DI 15

industrial heat tracing solutions

EN-RaychemNGC30UIT2Programming-AR-H5818602/16

28 / 84

Page 29

3.3.2 MAIN STATUS WINDOW

The main status window displays the status of all circuits that have been setup. For each circuit,

the main window displays:

Fig. 3.7 Main window with circuit status

Ckt# Circuit number

ID Identification tag for the Circuit

°C or °F The control temperature

SetPt Desired maintain temperature

DB Dead Band

Amps Heater current amperes

G.F. Heater ground-fault current

Status Relay (heater on, off or trip) and communication status

Color Coding of Main Window

The data in the °F/°C, Amps, and G.F. columns are displayed in color to identify their current state.

Green When heater is energized (status On), within Normal range of setup

parameters

Red In Alarm condition

Orange (°F/°C only) - Temperature not within setpoint + dead band range

Alarm Relay Status

Green No alarm

Red In Alarm condition

IMPORTANT: A Configuration Spreadsheet has been developed to assist in the collection of

specific circuit details. This spreadsheet is located in Appendix F.

industrial heat tracing solutions

EN-RaychemNGC30UIT2Programming-AR-H5818602/16

29 / 84

Page 30

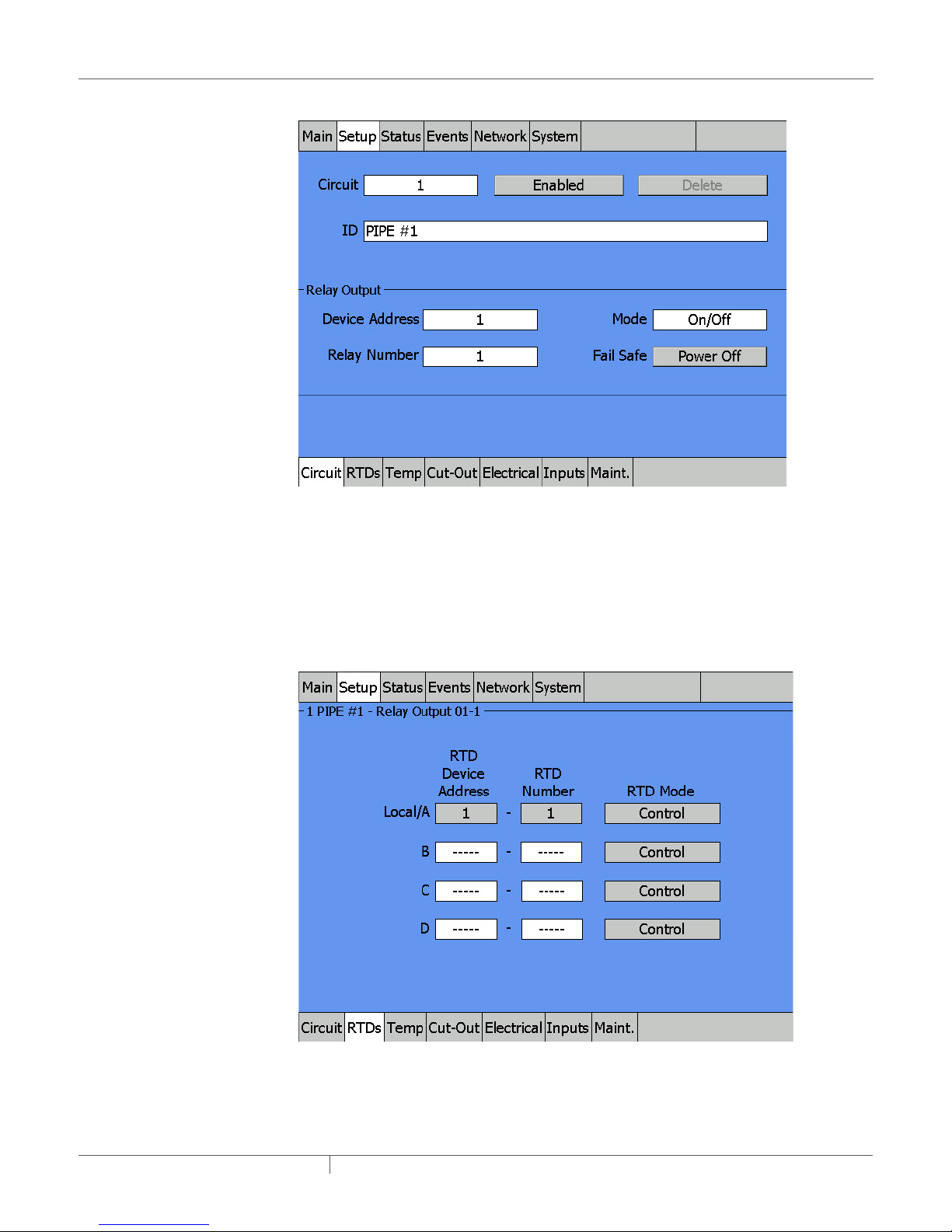

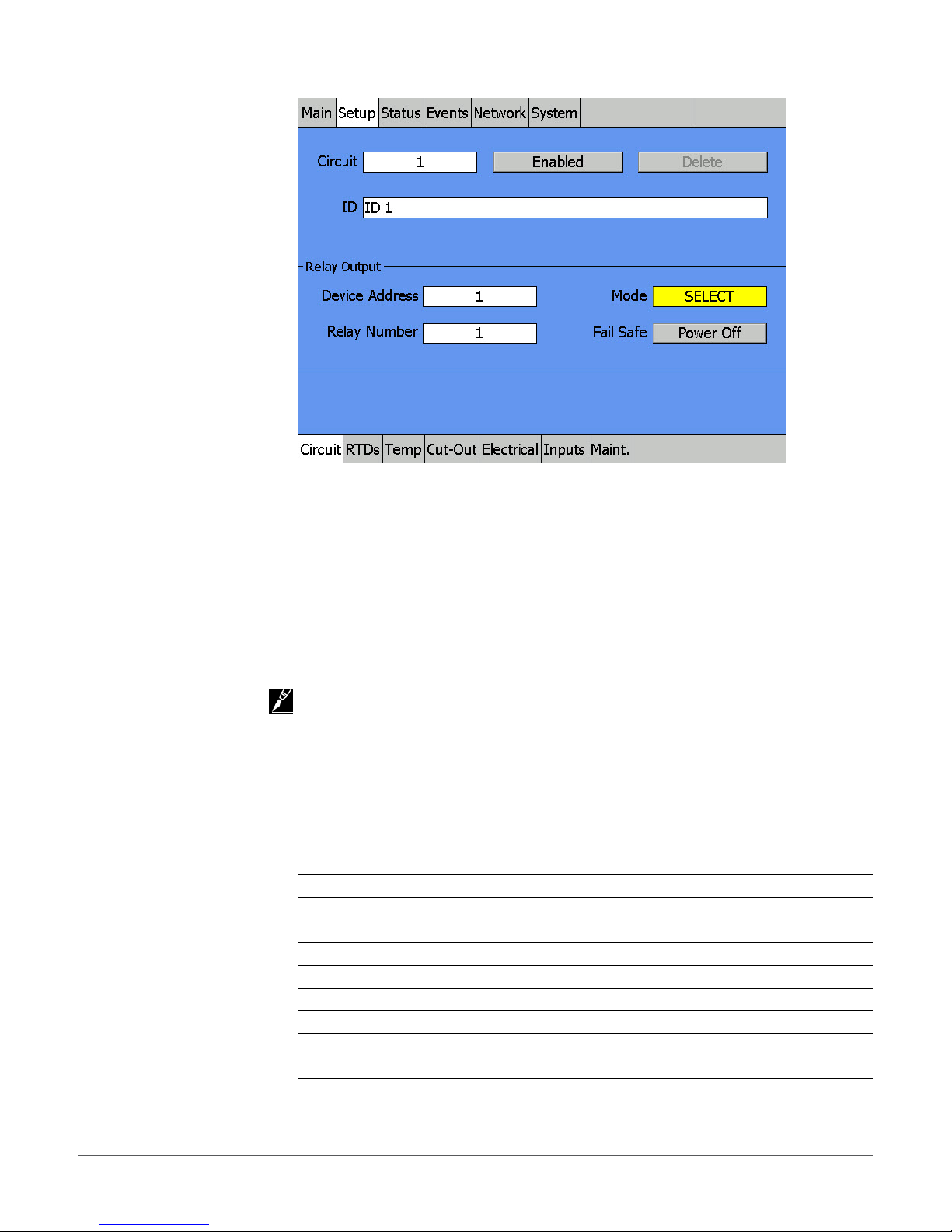

3.3.3 SETUP | CIRCUIT WINDOW

The Setup | Circuit window is the first window of the Setup sequence.

Fig. 3.8 Setup | Circuit window

Circuit Entry Field

The Circuit # is assigned when setting up a Circuit in the Raychem NGC-30 program. It is the

primary reference for all windows. Once a Circuit is added, you cannot change its Circuit number;

however you can delete the Circuit (except for Circuit 1). This Setup|Circuit window is also where

you can select an existing Circuit.

Enabled/Disabled Toggle Button

When Enabled, the NGC-UIT2 monitors and generates Circuit alarms.

If a relay output has been assigned to the Circuit, the relay output turns on or off based upon

set-up parameters and RTD inputs, and the selected control mode.

When Disabled, the NGC-UIT2 has disabled the Circuit, and does NOT generate alarms or

control the relay assigned to the Circuit. The relay remains in the off position. The Circuit is

grayed out in the main window to show it is Disabled.

Delete Button

Deletes the Circuit that is currently being displayed and removes it from the main window. Any

Circuit can be deleted EXCEPT for Circuit 1. The program asks for confirmation before deleting.

ID Entry Field

The Circuit ID is user-definable name tag. The default is “ID XXX” (where XXX is the Circuit

number).

Limit: 40 characters (character strings are truncated on the Main Window after 16

characters but displayed in full on Status and Setup win-dows)

industrial heat tracing solutions

EN-RaychemNGC30UIT2Programming-AR-H5818602/16

30 / 84

Page 31

Fig. 3.9 Setup | Circuit window mode

Relay Output Section This section defines the device/relay and the operating mode assigned to the

Circuit.

Device Address Entry Field The device address is the number assigned to a NGC-30-CRM/-CRMS

board via the rotary selector switches. Each NGC-30-CRM/-CRMS must be assigned a unique

number (no other device can share a device address whether it’s a Relay Output device or RTD

input device). All device addresses are scanned on initial startup. If devices are added after initial

startup, the user must perform a system re-scan. (For more information on scanning for devices,

see section 3.3.24 Network | Devices Window on page 56.)

Device Address Range: 0–99 (For available device addresses and specific limits, see Table

3.5 Available Device Addresses on page 54.)

IMPORTANT: If no device address is entered (0), the Circuit is limited to temperature-monitoring

and temperature- alarming only.

Relay Number Entry Field The relay number defines which of the 5 control channels on the NGC30-CRM/-CRMS board controls the heater’s switching device. When the display shows dashes

(---) rather than an address, no switching device has been assigned to the Circuit. For NGC-20

controllers, the relay number will always be 1.

Mode Entry List The modes are the various control schemes that control a Circuit. There are four

different control modes associated with a NGC-30-CRM panel plus one voltage monitoring mode,

and five with a NGC-30-CRMS panel plus one voltage monitoring mode.

Table 3.1 Control Modes

Modes NGC-30-CRM NGC-30-CRMS* RMC NGC-20

On/Off X X X X

Proportional X

PASC X X X X

Always On X X X X

Always Off X X X X

Voltage X X X

Monitor Only X X

*Soft Start always active with CRMS (See Soft-Start Feature information below)

industrial heat tracing solutions

EN-RaychemNGC30UIT2Programming-AR-H5818602/16

31 / 84

Page 32

3.3.4 CONTROL MODES DEFINITIONS

On/Off

The NGC-UIT2 monitors the control temperature and compares it to the setpoint. If the control

temperature is above the setpoint by more than the Dead Band value (see page 35) the relay

output is turned off. If the control temperature falls below the setpoint temperature, the output is

turned on. The control temperature is defined as the lowest RTD temperature input value for that

Circuit.

Proportional

This algorithm monitors the control temperature of the Circuit and compares it to the setpoint

temperature. If the control temperature is at or below the setpoint temperature, then power is

applied to the heater with a duty cycle of 100%. If the control temperature is equal to or greater

than the control setpoint temperature +4°F, then the relay output will have a duty cycle of 0%. The

control temperature is constantly monitored, and the output duty cycle is adjusted proportionally

once per second. See Appendix A for additional information on Proportional Control.

Soft-Start Feature

This feature is a time-ramped soft start that reduces surge current produced by heaters at

startup. When a solid state output relay is first turned on, the duty cycle is ramped from 0 to 100%

in 2.5% (25 millisecond) increments over a 40 second period. The update rate for each step is fixed

at 1 second.

This automatic feature is included only when using SSRs as an output device. It is incorporated

into all control modes (On-Off, Proportional, PASC, Always On). If an output has been off for more

than 10 minutes, the soft-start algorithm will reset and be activated the next time the SSR turns

on. The soft-start algorithm will also reactivate whenever the NGC-30-CRMS boards loses power

or is reset.

PASC (Proportional Ambient Sensing Control)

PASC takes advantage of the fact that the heat loss from a pipe is proportional to the temperature

difference between the pipe and the ambient air. This is true regardless of heater type, insulation

type, or pipe size. Once the heat tracing and insulation on a pipe has been designed to balance

heat input with heat loss and maintain a particular temperature, the main variable in controlling

the pipe temperature becomes the ambient air temperature.

The NGC-30-CRM/-CRMS has a control algorithm that uses the measured ambient temperature,

desired maintain temperature, minimum ambient temperature assumption used during design,

and size of the smallest pipe diameter to calculate how long the heater should be on or off to

maintain a near-constant pipe temperature.

Always On

The relay output is switched on (user override), turns on the power to the heater and leaves it on.

IMPORTANT: Monitor the pipe temperatures to avoid overheating. Alarms are still active.

Always OFF

The relay output is switched off (user override), turns off the power to the heater, and leaves it off.

IMPORTANT: Monitor the pipe temperatures for low temperature alarms. Alarms are still active.

Voltage

Voltage mode allows the NGC-UIT2 to monitor line voltage from the NGC-30-CRM/-CRMS boards.

The NGC-30-CRM/-CRMS must have an NGC-30-CVM connected to the line current sensor input

when selecting voltage mode. As a result, this channel of the NGC-30-CRM/-CRMS cannot be

used to control an output device. But an RTD can be connected to this channel’s input to set up an

additional temperature monitoring Circuit. For an NGC-20 controller, the voltage mode is not an

option since this is a standard feature.

Monitor Only

This is the default mode that allows temperature monitoring for the Circuit. This means no output

device has been selected.

industrial heat tracing solutions

EN-RaychemNGC30UIT2Programming-AR-H5818602/16

32 / 84

Page 33

Fail Safe toggle button

The Fail Safe control button turns the power on or off to the heater if the Circuit loses all valid RTDs.

When the last remaining sensor for control fails (or communication with the sensor is lost), the

NGC-UIT2:

• Signals an alarm for the failure of the sensor

• Changes control of the circuit to the fail safe control selected

• Changes the control status display to indicate that control of the circuit is in the fail safe state

• Records the events

When the sensor for control is returned to service, the controller signals the alarm has been

cleared, returns the Circuit to its normal control mode, and records both of these events.

IMPORTANT: Default is OFF

3.3.5 SETUP | RTDS WINDOW

In order to assign an RTD to a Circuit, it must be shown in the Network|Devices table.

By default, each NGC-20 controller and each channel of the NGC-30-CRM/-CRMS has an

associated RTD input.

The NGC-30 program first checks to see if the default RTD is available. On any NGC-30-CRM/-

CRMS (5GF-C) board, the first RTD input is automatically coupled with the first relay output; the

second RTD is linked with the second output relay, etc. When a control layout is chosen with an

RMC and RMM2 then, by default, no RTD will be associated with the RMC output channel. The

users decide themselves which temperature input is linked to which output channel.

Fig. 3.11 indicates an RTD connected to the RTD 1 terminal block, so the RTD set-up screen

indicates the default assignment is already completed. This selection is grayed out because you

cannot alter this default selection. In the event of a communications failure or UIT2 failure, the

circuit reverts to this default RTD for control purposes.

Fig. 3.10 Setup | RTDs window - Default RTD, hard-wired to CRM/-CRMS board

In general, up to three additional RTDs can be associated with this Circuit. When the system is

fully functional, the lowest RTD value from the list of four will be used for control temperature. If

no RTD is connected to the input terminals for this Circuit, then all four lines can be used to assign

RTDs from elsewhere in the system. However, in the event of a communications or UIT2 failure, no

industrial heat tracing solutions

EN-RaychemNGC30UIT2Programming-AR-H5818602/16

33 / 84

Page 34

RTD input is available and the relay output for this Circuit goes to the failsafe mode established in

the Setup|Circuit window.

Fig. 3.11 Setup | RTDs window- Four RTDs are assigned to the circuit

Each RTD can be set to operate in two modes: Control or Monitoring. If an SES is used as a

Continuity sensor, a third option for Continuity is also selectable. If an RTD is set to Control, the

output of the Circuit will be based on this RTD in conjunction with any other Control RTDs in Auto

On/Off mode. These RTDs will also trigger temperature alarms and cutouts. However, if an RTD is

set to Monitoring, its temperatures will not be used to control the circuit's relay output. RTDs set

to Monitor will trigger temperature alarms but not high temp cutout. A RTD mode set to Continuity

will only report that power has reached the SES module.

The table below indicates the RTD Mode (RTD application) options for each RTD device.

Table 3.2 RTD Mode Options

Connection Type RS-485 Device RTD Device RTD Modes

Control Monitor Continuity

Hard-wired, local CRM/CRMS the

Direct X -- --

same circuit

Hard-wired, not

local

CRM/CRMS

another circuit

Direct X X --

Hard-wired, local NGC-20 Direct X -- --

Serial RMM2 Direct X X --

Serial PLI-SES/SPC via SES-RTD X X --

Serial PLI-SES/SPC No RTD -- -- X

Serial PLI-SES/SPC via SES-SPC X X --

Serial PLI-TT via 700-TT X X --

IMPORTANT: The SES-CONT device does not have any RTDs, thus can not control or monitor the

temperature. Therefore, the only RTD Mode that can be selected is Continuity. In Continuity Mode,

the integrity of the heat-tracing system is monitored.

industrial heat tracing solutions

EN-RaychemNGC30UIT2Programming-AR-H5818602/16

34 / 84

Page 35

3.3.6 SETUP | TEMP WINDOW

This window contains all temperature parameters for control and monitoring of Circuits.

Fig. 3.12 Setup | Temp window

Setpoint Entry Field Use with On/Off, Proportional, and PASC control modes. The Setpoint is the

desired maintain temperature for the circuit.

Based on the measured control temperature, the Raychem NGC-20 and NGC-30 switches the

relay output to maintain the system at the desired set point.

Range NGC-20: –80°C (–112 °F) to 700°C (1292 °F)

Default: 10°C (50°F)

Range NGC-30: –73°C (–99°F) to 482°C (900°F)

Default: 10°C (50°F)

Dead Band Entry Field Use with On/Off Control.

If the control temperature is above the Setpoint temperature plus Dead Band, the relay output is

turned off. If the control temperature is below the Setpoint temperature, the output is turned on.

Range NGC-30: 1°C (1°F) to 50°C (50°F)

Default: 3°C (5°F)

High Temp Alarm Entry Field Use with all modes.

If any RTDs assigned to a Circuit measures a temperature above this threshold, the NGC-UIT2

generates an alarm.

Range NGC-20: –80°C (–112°F) to 700°C (1292°F)

Default: 10°C (50°F)

Range NGC-30: –73°C (–99°F) to 482°C (900°F)

Default: 149°C (300°F)

Low Temp Alarm Entry Field Use with all modes.

If any RTDs assigned to a Circuit measures a temperature below this threshold, the NGC-UIT2

generates an alarm.

Range NGC-20: –80°C (–112°F) to 700 °C (1292°F)

Default: 10°C (50°F)

Range NGC-30: –73°C (–99°F) to 482°C (900°F)

Default: –12°C (–10°F)

industrial heat tracing solutions

EN-RaychemNGC30UIT2Programming-AR-H5818602/16

35 / 84

Page 36

Temperature Alarm Filter Entry List

This minimizes nuisance alarms by forcing the NGC-UIT2 to verify that the alarm condition

continually exists over the selected period of time before alarming.

Range: 10 to 59,940 seconds

Default: 900 seconds (15 minutes)

IMPORTANT: The 15 second option is for testing and demostration purposes. Choosing this option

for normal use may cause nuisance alarming since this option may not allow the NGC-UIT2 time

to verify that the alarm conditions exist.

3.3.7 SETUP | Limit Cut-Out window

Fig. 3.13 Setup | Limit Cut-Out window

High Limit Cut-Out Entry Field

High Limit Cut-Out feature is triggered depending on Control and RTD Modes. The Table below

indicates which RTD Modes will initiate a High Limit Cut-Out for each Control Mode. If these RTDs

are assigned to a Circuit and measure a temperature above the High Limit Cut-Out threshold, the

NGC-UIT2 generates an alarm and the relay output is turned off. If he High Limit temperature is

below this threshold minus the Deadband, the output is turned on.

Table 3.3 Control Modes and RTD Modes That Trigger High Limit Cut-Out

Control Modes RTD Modes

Control Monitor Continuity

On/Off X -- --

Proportional X -- --

PASC -- X --

Always On X -- --

Always Off -- -- --

industrial heat tracing solutions

EN-RaychemNGC30UIT2Programming-AR-H5818602/16

36 / 84

Page 37

These are the general settings for the Raychem NGC-30:

Range: –73°C (–99°F) to 482°C (900°F)

Default: 482°C (900°F)

For Raychem NGC-20:

Range: –80°C (–112°F) to 700°C (1292°F)

Default: 700°C (1292°F)

Low Limit Cut-Out Entry Field - NGC-20 Only

Low Limit Cut-Out feature is triggered depending on Control and RTD Modes of the NGC-20. Table

3.3 indicates which RTD Modes will initiate a Low Limit Cut-Out for each Control Mode. If these

RTDs are assigned to a Circuit and measure a temperature above the Low Limit Cut-Out threshold,

the NGC-UIT2 generates an alarm and the relay output is turned off. If the Low Limit temperature

is above this threshold plus the variable Deadband, the output is turned on.

Limit Cut-Out Enable/Disable Toggle Buttons

Enables or disables the high limit cut-out capability. When enabled, the NGC-UIT2 alarms and the

output relay turns OFF if any RTDs exceed the cut-out value. If the high limit cut-out is disabled,

the relay output will continue to function normally without the high temperature cut-out feature.

3.3.8 SETUP | ELECTRICAL WINDOW

This window configures ground fault alarm and trip values for the Circuit. (This feature is only

supported when used with CRM/CRMS or Raychem NGC-20 controller boards. This feature is not

supported with RMC controller output modules. Ground fault alarm is a latching alarm and must

be reset.) These alarms are latching alarms and must be reset.

Fig. 3.14 Setup | Electrical window

Ground-Fault Alarm Entry Field

Set the Ground-Fault Alarm threshold to the desired level. The ground-fault alarm may not be

disabled.

Range Raychem NGC-20: 10 mA to 250 mA

Range Raychem NGC-30: 10 mA to 200 mA

Default: 20 mA

industrial heat tracing solutions

EN-RaychemNGC30UIT2Programming-AR-H5818602/16

37 / 84

Page 38

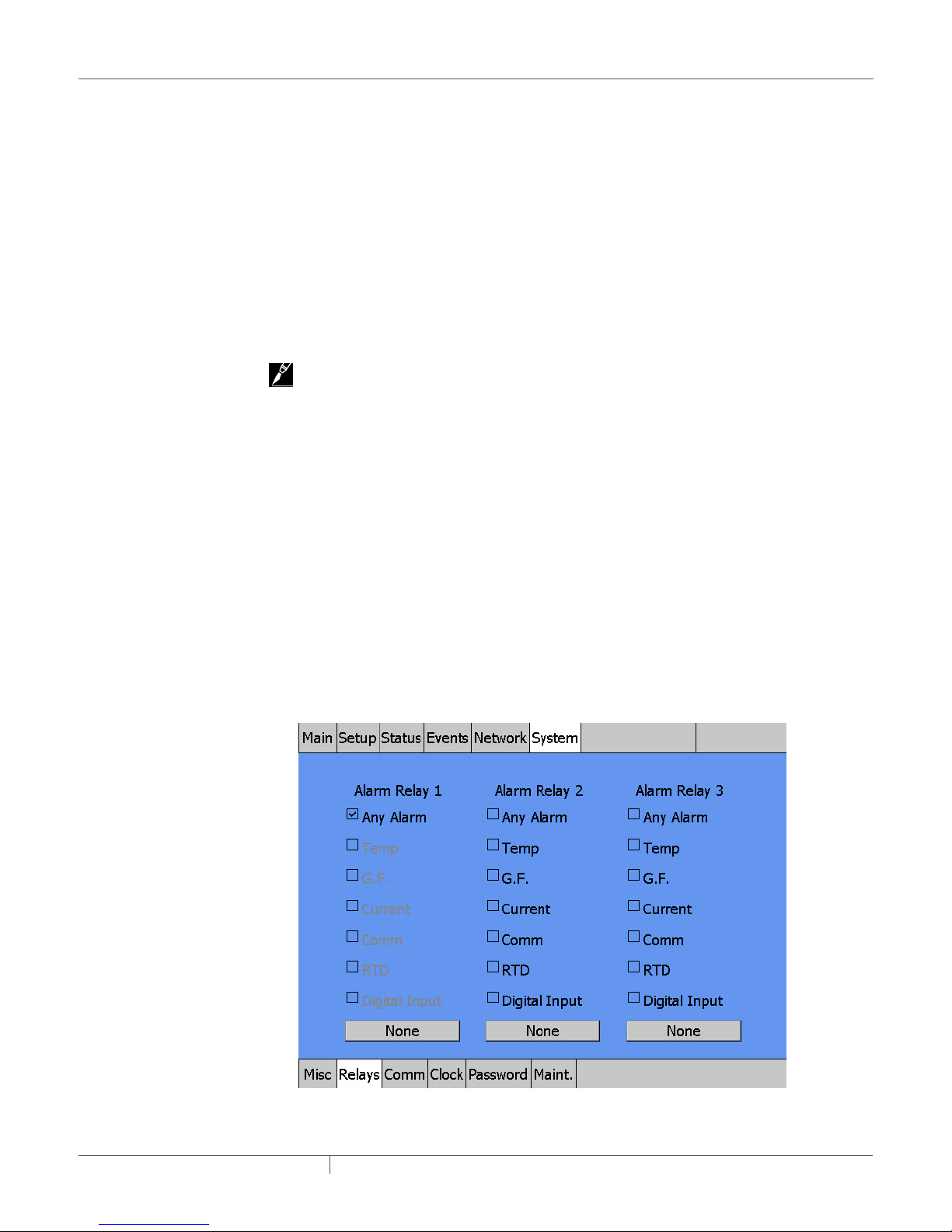

Ground-Fault Trip Entry Field