Page 1

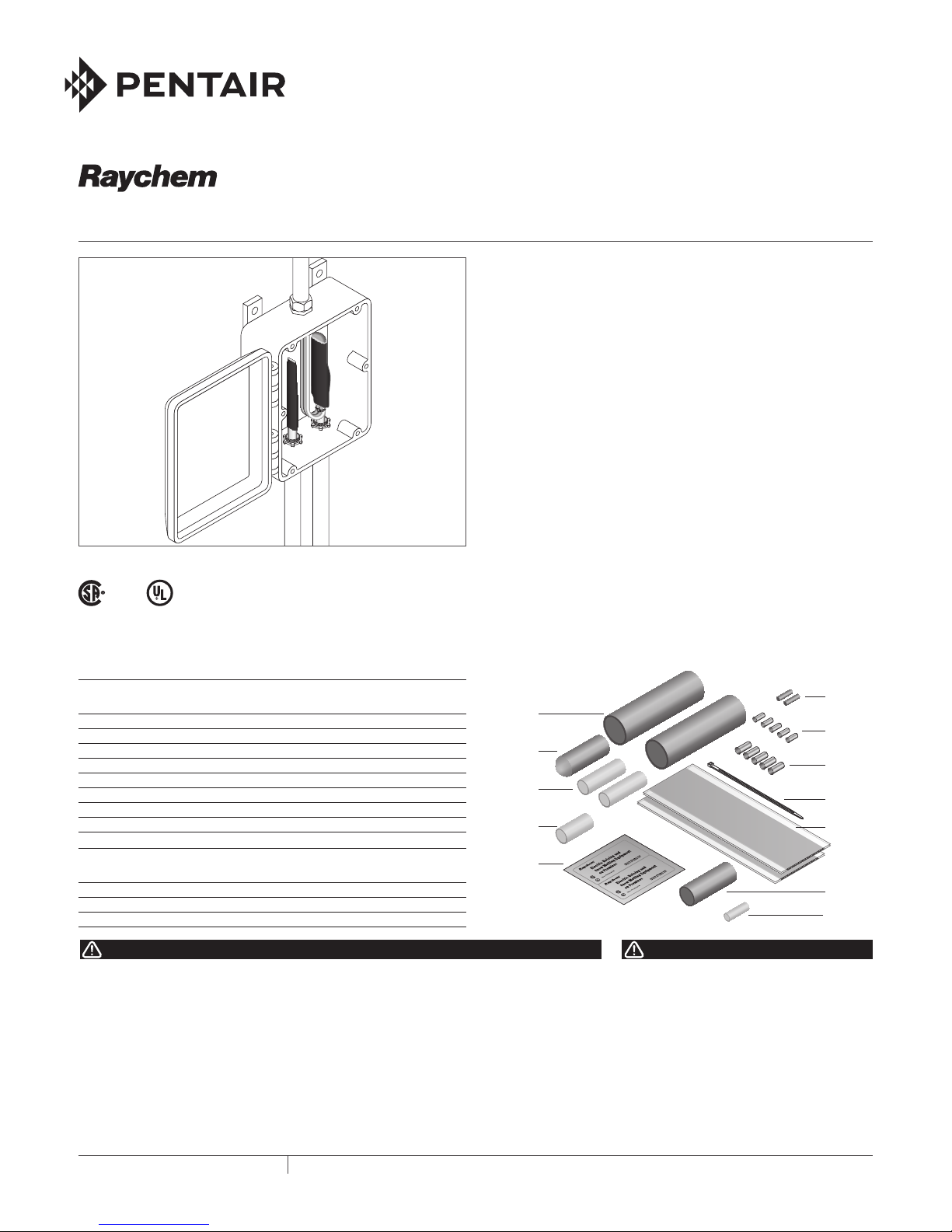

EMK-XP

WARNING:

CAUTION:

ElEctroMElt PowEr connEction and End SEal Kit inStallation inStructionS

DESCRIPTION

The ElectroMelt EMK-XP Power Connection and End Seal Kit is for

use with ElectroMelt EM2-XR heating cable for snow-melting and

anti-icing applications. Materials for one power connection and

one end seal are included. This kit is suitable for connecting the

heating cable to 14 through 4 AWG (Cu only) power wires. Power

wiring must meet NEC or CEC requirements and have a minimum

temperature rating of 167°F (75°C).

These installation instructions should be used in conjunction with

the ElectroMelt System Design Guide (H53393) and ElectroMelt

System Installation and Operation Manual (H58086).

For technical support call Pentair Thermal Management at

(800)545-6258.

TOOLS REQUIRED

• Needle-nose pliers • Utility knife

• Heat gun or propane torch • Wire strippers

APPROVALS

DE-ICING AND

SNOW MELTING EQUIPMENT

-W

LISTED

877Z

KIT CONTENTS

Item Qty Description

Power Connection

A 1 Black heat-shrinkable tube – 1 1/2 x 6 in (38 x 152 mm)

B 1 Heat-shrinkable cap

C 2 Clear yellow heat-shrinkable tubes – 1/2 x 2 3/4 in (13 x 70 mm)

D 1 Clear yellow heat-shrinkable tube – 1/2 x 2 in (13 x 51 mm)

E 2 “Electric Deicing and Snow Melting” labels

F 2 Black heat-shrinkable tubes – 1/8 x 3/4 in (3 x 19 mm)

G 5 Small non-insulated crimp connectors

H 5 Large non-insulated crimp connectors

I 1 Cable tie

J 1 Mastic sheet – 3 x 12 in (76 x 305 mm)

End Seal

A 1 Black heat-shrinkable tube – 1 1/2 in x 6 in (38 mm x 152 mm)

J 1 Mastic sheet – 3 in x 12 in (76 mm x 305 mm)

K 1 Black heat-shrinkable tube – 1 in x 3 in (25 mm x 76 mm)

L 1 Clear yellow heat-shrinkable tube – 1/2 in x 1 1/2 in (13 mm x 38 mm)

• Ideal Crimp Tool Model 30-425 • Diagonal cutters

ADDITIONAL MATERIALS REQUIRED

• EMK-XJB (Not shown) or equivalent UL Listed or CSA Certified

weatherproof junction box suitable for the location. A minimum

of 400 cubic inches are needed for 1 power connection and 1 end

termination per junction box.

A

B

C

D

E

F

G

H

I

J

K

L

This component is an electrical device that must be installed correctly to ensure proper

operation and to prevent shock or fire. Read these important warnings and carefully follow

all the installation instructions.

• To minimize the danger of fire from sustained electrical arcing if the heating cable

is damaged or improperly installed, and to comply with the requirements of Pentair

Thermal Management, agency certifications, and national electrical codes, groundfault equipment protection must be used. Arcing may not be stopped by conventional

circuit breakers.

• Approvals and performance are based on the use of Pentair Thermal Managementspecified parts only. Do not substitute parts or use vinyl electrical tape.

• The black heating cable core is conductive and can short. It must be properly insulated

and kept dry.

• Damaged bus wires can overheat or short. Do not break bus wire strands when scoring

the jacket or core.

• Do not bury any of the components. Both the power connection and end seal must be

THERMAL BUILDING SOLUTIONS

Raychem-IM-H57284-EMKXP-EN-1612

installed in a dry junction box.

• Heat-damaged components can short. Use a heat gun or torch with a soft, yellow, lowheat flame. Keep the flame moving to avoid overheating, blistering, or charring the

heat-shrinkable tubes. Avoid heating other components. Replace any damaged part.

• Bus wires will short if they contact each other. Keep bus wires separated.

• Connection kits and heating cable ends must be kept dry before and during

installation.

• Damaged heating cable can cause electrical arcing or fire. Use only plastic cable ties

to secure the heating cable to the reinforcement. Do not use metal attachments such

as tie wire.

• Do not attempt to repair or energize damaged heating cable. Remove damaged

sections at once and replace them with a new length using the appropriate Raychem

splice kit. Replace damaged connection kits.

• Megohmmeters operate at high voltage. This voltage is hazardous and possibly lethal.

Read and follow all instructions included with the instrument you are using.

HealtH Hazard: Over heating heat-shrinkable tubes will produce

fumes that may cause irritation. Use adequate ventilation and avoid

charring or burning. Consult MSDS RAY4566 for further information.

CHEMTREC 24-hour emergency telephone:

(800) 424-9300

Non-emergency health and safety information:

(800) 545-6258

.

1 / 10

Page 2

Power Connection Installation and Assembly for ElectroMelt Snow-melting and Anti-icing System

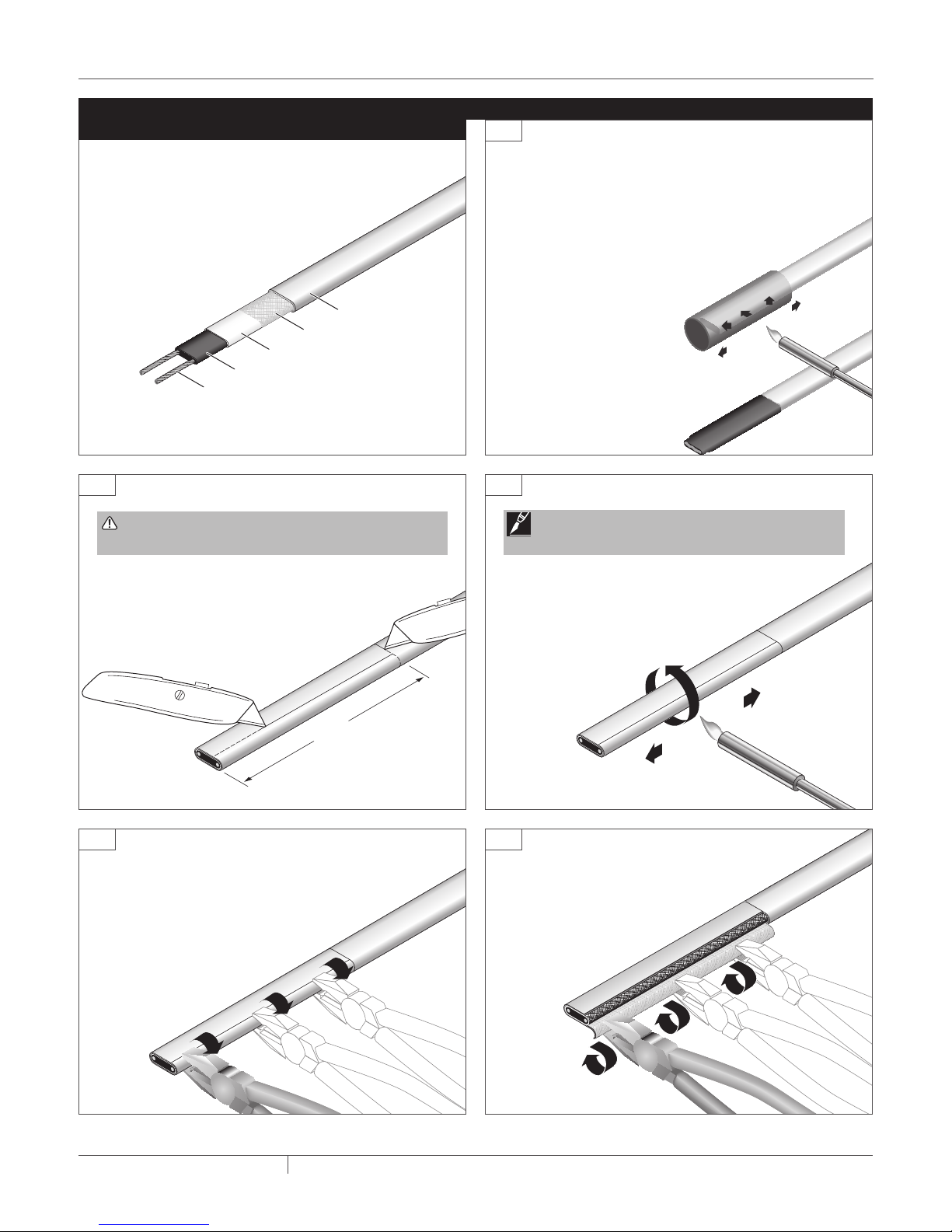

HEATING CABLE CONSTRUCTION

1

Instructions for using a heat gun or torch:

• Read important warnings on page 1 and follow

safety precautions provided with heat gun or torch.

• When using a torch use a soft yellow, low-heat

flame. Apply just enough heat to do the job.

• Keep torch or heat gun moving

continuously to distribute the heat

evenly to avoid overheating,

Outer jacket (orange)

Braid

Inner jacket (white)

Core (black)

Bus wire

EM2-XR Heating Cable

blistering or charring the

heating cable and heatshrinkable tubes.

• Replace any heatdamaged parts.

2

WARNING: Do not cut into braid or inner jacket. This

could result in a short circuit.

• Allow 12 in (305 mm) of heating cable

in junction box for proper assembly.

• Score around outer jacket 4 in (102

mm) from end. Make one lengthwise

score as shown.

4 in

(102 mm)

4 5

• Use Ideal crimp tool No. 30-425 or blunt nose pliers to

pull outer jacket from braid.

3

Note: See Step 1 for proper heating techniques.

• Gently heat end of cable to loosen bond

between outer jacket and braid.

• Roll outer jacket back around

heating cable to remove.

THERMAL BUILDING SOLUTIONS

Raychem-IM-H57284-EMKXP-EN-1612

2 / 10

Page 3

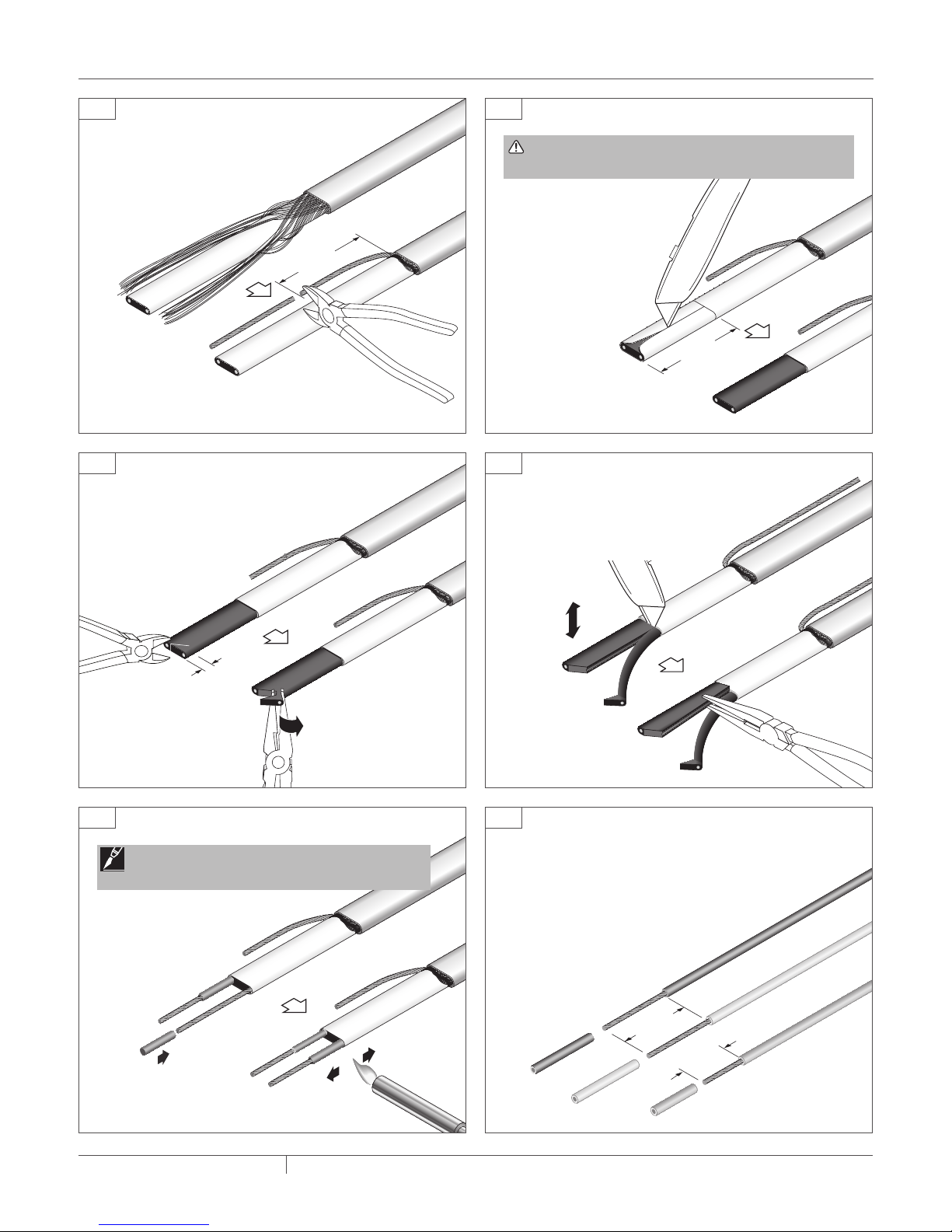

6

7

• Unravel braid and twist into a pigtail.

• Trim braid.

(51 mm)

8

• Notch core at the end.

• Twist back and peel bus

wire from core.

2 in

WARNING: Do not cut or damage bus wires.

Damaged wires can overheat or short.

• Lightly score inner

jacket around and

down as shown.

• Bend heating cable

to break jacket at

score.

2¼ in

(57 mm)

• Peel off jacket.

9

• Score between bus wires at inner jacket.

• Bend core to break free at inner jacket.

• Peel core and any remaining material

from bus wires.

¼ in

(6 mm)

10 11

Note: See Step 1 for proper heating techniques.

• Slide 3/4 in (19 mm)

long tubes (Item F)

over bus wires.

• Shrink tubes

completely.

• Remove 1 1/2 in (38 mm) insulation

from power supply lines.

• Remove 1 in (25 mm) insulation from

equipment grounding conductor.

Power supply

1½ in

(38 mm)

1 in

(25 mm)

Equipment ground

THERMAL BUILDING SOLUTIONS

Raychem-IM-H57284-EMKXP-EN-1612

3 / 10

Page 4

12

WARNING: Shock and Fire Hazard

Improper crimp connections can cause overheating and a danger of shock and

fire. Carefully follow the crimping instructions in Step 13 to ensure a proper

electrical connection.

Do not substitute crimps or wire nuts. Component approvals and performance

are based on Pentair Thermal Management-specified parts only.

• Select the correct crimp connectors for the gauge of power supply wire used (see table).

Supply wire gauge Crimp connector size

8 – 14 AWG Ideal 411 (small, Item G)

4 – 6 AWG Ideal 412 (large, Item H)

• Connect power supply wires to bus wires. Use two crimps for each connection and

crimp twice on each connector (see Step 13).

• Use one crimp connector to attach equipment grounding conductor to heating cable

braid (see Step 14).

13

• Use the correct crimp tool (Ideal 30-425) when

making the connections.

• To make the proper crimp connection, position the

heating cable bus wire directly below the larger

supply wire.

• Position the supply wire and bus wire in the crimp

Conductor position in crimp

Supply

wire

Crimp

Heating

cable

bus wire

connectors and crimp tool exactly as shown.

• Crimp each connector twice (see detail).

Equipment

grounding

conductor

Braid

Power

supply

wires

Bus wires

14 15

• Use only one crimp

connector to attach

equipment grounding

conductor to heating cable

braid (see detail).

2 ¾ in (70 mm)

Detail

Trim

excess

wire

1st crimp

21

2nd crimp

Detail

excess

IncorrectCorrect

Note: See Step 1 for

proper heating techniques.

• Slide 2 3/4 in (70 mm) long clear

yellow tubes (Item C) over bus

wire connectors.

clear yellow

shrink tube

• Shrink one tube completely and

immediately pinch end while

tube is hot; hold for

5 seconds to ensure

seal.

• Repeat for second tube.

• Allow tubes to cool.

Trim

wire

1st crimp

2nd crimp

2121

2nd crimp

1st crimp

Hold for 5 seconds

THERMAL BUILDING SOLUTIONS

Raychem-IM-H57284-EMKXP-EN-1612

4 / 10

Page 5

16

• Slide 2 in (51 mm) long clear yellow

tube (Item D) over braid wire/ground

connector.

• Shrink tubes completely and

immediately pinch end while tube is

still hot; hold for 5 seconds to ensure

seal.

• Allow tubes to cool.

1½ in

(38 mm)

2 in (51 mm)

clear yellow

shrink tube

Hold for 5 seconds

17

18

• Cut two 3 in x 1 3/4 in (76 mm x 44 mm)

pieces from one mastic sheet (Item J).

3 in

(76 mm)

1 ¾ in

(44 mm)

19 20

• Cut a 3 in x 5 in (76 mm x 127 mm)

piece from one mastic sheet (Item J).

• Wrap each power

wire with a 3 in x 1 3/4

in (76 mm x 44 mm)

piece of mastic.

1¾ in

(44 mm)

• Fold the

covered

power wires

flat against

the heating

cable.

3 in

(76 mm)

THERMAL BUILDING SOLUTIONS

Raychem-IM-H57284-EMKXP-EN-1612

5 in

(127 mm)

5 in

(127 mm)

• Use the 3 in x 5 in (76 mm x 127 mm) mastic sheet

to cover the first mastic sheet, bus wires, and wire

connectors. Do not cover outer jacket with mastic.

5 / 10

Page 6

21

Note: See Step 1 for proper heating techniques.

• Position the heat-shrinkable cap (Item B)

over the second mastic sheet. Push it all the

way down.

• Heat the cap until it shrinks completely.

IMPORTANT: If cap starts to slide off end while shrinking,

pull it back in place and hold until it cools.

22

• Cut second mastic sheet (Item J) into two pieces. 3 in x 6

in (76 mm x 152 mm)

23

• Secure all wires 2 in (51 mm) from end

of outer jacket using cable tie (Item I).

• Position braid connection next to cap.

• Wrap braid connection and 1/2 in (13

mm) of outer jacket with 3 in x 6 in (76

mm x 152 mm) mastic sheet (Item J).

Braid

connection

3 in

(76 mm)

3 in

(76 mm)

(152 mm)

Cable tie

(13 mm)

½ in

6 in

Trim

2 in

(51 mm)

Pinch and

squeeze mastic

THERMAL BUILDING SOLUTIONS

Raychem-IM-H57284-EMKXP-EN-1612

6 / 10

Page 7

24

Note: See Step 1 for proper heating techniques.

• Position the 6 in (152 mm) long heat-

6 in (152 mm) tube

shrinkable tube (Item A) over the mastic sheet,

1/2 in (13 mm) from end of mastic sheet.

• Begin heating tube at end near cable tie.

• Heat until tube is recovered completely and

adhesive or mastic flows from ends.

• Continue to heat center section to melt mastic

inside but do not blister or burn tube.

• Allow the connection to cool before placing in

junction box.

End Seal Installation Instructions

1

WARNING: Do not cut into braid or inner jacket. This

could result in a short circuit.

• Allow 12 in (305 mm) of heating cable in junction box for

proper assembly.

• Score around outer jacket 2 in (51 mm) from end.

• Make one lengthwise score as shown.

½ in

(13 mm)

Heat this end first

2

Note: See Step 1 for proper heating techniques.

• Gently heat cable to loosen bond

between outer jacket and braid.

2 in

(51 mm)

3 4

• Use Ideal crimp tool No. 30-425 or blunt

nose pliers to pull outer jacket from braid.

THERMAL BUILDING SOLUTIONS

Raychem-IM-H57284-EMKXP-EN-1612

• Roll outer jacket back around

heating cable to remove.

7 / 10

Page 8

5

• Trim braid flush with outer jacket.

Smooth down any

sharp ends

6

Note: Heat-shrinkable tubing must be installed to prevent

electrical short. See Step 1 for proper heating techniques.

Short tube

Hold for 5 seconds

½ in

(13 mm)

• Refer to Material Safety Data Sheet RAY4566.

• Position short tube (Item L) over end of heating cable as

shown.

• Heat tube until it shrinks and adhesive flows out ends.

• While still hot, gently pinch end and hold for 5 seconds to

ensure a complete moisture seal.

• Allow tube to cool completely.

7

• Cut a 3 in x 1 1/2 in (76 mm x 38 mm)

piece from mastic sheet (Item J).

6 in

(152 mm)

3 in

(76 mm)

(38 mm)

9

Note: See Step 1 for proper heating techniques.

• Position 3 in (76 mm) long heat-shrinkable

tube (Item K) over the mastic and position

1/4 in (6 mm) from outer jacket.

• Heat the tube until adhesive or mastic flows

out ends.

• Remove heat source and immediately pinch

end with needle-nose pliers for 20 seconds

to ensure a complete moisture seal.

• Allow tube to cool completely.

1½ in

Outer tube extends

past inner mastic

8

• Wrap 3 in x 1 1/2 in (76 mm x 38 mm) mastic around

heating cable 1/4 in (6 mm) from outer jacket.

¼ in

(6 mm)

1 ½ in

(38 mm)

Adhesive or

Mastic

¼ in

(6 mm)

Adhesive

Hold for

20 seconds

THERMAL BUILDING SOLUTIONS

Raychem-IM-H57284-EMKXP-EN-1612

8 / 10

Page 9

10

• Wrap remaining 3 x 4 1/2 in (76 mm x 114 mm) mastic

sheet (Item J) around outer jacket with 1 in (25 mm)

overlapping the recovered heat-shrinkable tubing.

11

Note: See Step 1 for proper heating techniques.

• Slide the 6 in (152 mm) long heat-shrinkable tube

(Item A) over end. Position tubing so 1/2 in (13 mm)

extends beyond pinched end of inner tube.

• Begin heating tube at end next to mastic sheet.

• Heat the tube until it is completely recovered and

adhesive or mastic flows out ends.

• Continue to heat center section to melt mastic

inside but do not blister or burn tube.

• Remove heat source and immediately pinch end

with needle-nose pliers for 20 seconds to ensure a

complete moisture seal.

3 in

(76 mm)

1 in

(25 mm)

Heat this

end first

½ in

(13 mm)

Adhesive

Adhesive

Hold for

20 seconds

12

• Allow end seal to cool completely. Position end seal so it

does not come in contact with power connection.

• Route heating cable so that power connection and end

seal are in same junction box. Use an EMK-XJB junction

box or agency certified equivalent. A minimum of 400

cubic inches are needed for 1 power connection and 1 end

termination per junction box.

• Apply "Electrical Deicing and Snow Melting" label (Item E)

on junction box cover. Place second label near installation

where applicable.

• Leave these installation instructions with the end user for

future reference.

THERMAL BUILDING SOLUTIONS

Raychem-IM-H57284-EMKXP-EN-1612

9 / 10

Page 10

NORTH AMERICA

Tel: +1.800.545.6258

Fax: +1.800.527.5703

Tel: +1.650.216.1526

Fax: +1.650.474.7711

thermal.info@pentair.com

Pentair and ElecroMelt are owned by Pentair or its global affiliates. All other trademarks are the property of their respective owners. Pentair reserves the

right to change specifications without prior notice.

© 2008-2016 Pentair. PN 385755-000

Raychem-IM-H57284-EMKXP-EN-1612

WWW.PENTAIRTHERMAL.COM

10 / 10THERMAL buiLding SOLuTiOnS

Loading...

Loading...