Pentair QC10-CBR, QC10-EP, QC10-GAC, QC10-TSGAC, QC10-CGAC Installation And Operation Manual

...Page 1

PENTEK® QC10 SERIES QUICK-CHANGE WATER FILTER SYSTEM

INSTALLATION AND OPERATION MANUAL

©2012 Pentair Residential Filtration, LLC www.pentairaqua.com

Page 2

SPECIFICATIONS

WARNING:

CAUTION

CAUTION

CAUTION

PRECAUTIONS

Pressure Range: 30–125 psi (2.1–8.62 bar)

Temperature Range: 40–100°F (4.4–37.8°C)

Rated Service Flow:

QC10-CBR 0.5 gpm (1.9 Lpm)

QC10-EP 0.5 gpm (1.9 Lpm)

QC10-GAC 0.75 gpm (2.8 Lpm)

QC10-TSGAC 0.75 gpm (2.8 Lpm)

QC10-CGAC* 0.6 gpm (2.3 Lpm)

QC10-CB1* 0.6 gpm (2.3 Lpm)

Size: 2.187-inch x 11.625-inch

(55.5 mm x 295.3 mm)

*Not Performance Tested or Certified by NSF.

PARTS INCLUDED

• Filter head with built-in bracket and compression or

push-fit fittings

• Cartridge

• Hardware kit

TOOLS AND MATERIALS REQUIRED

• Phillips screwdriver

• Adjustable wrench (for 1/4-inch male threaded parts)

• Tape measure

• Pencil

• Safety glasses

• Separate drinking water faucet required if supplying

water directly to the kitchen sink

OPTIONAL MATERIALS

• Shut-off valve

• Saddle tap valve with shut-off

• Threaded copper "T"

• 1/4-inch (6.35 mm) plastic or copper tubing or flexible hose

• 3/8-inch (9.53 mm) plastic or copper tubing or flexible hose

Do not use with water that is microbiologically

unsafe or of unknown quality without adequate

disinfection before or after the system.

Protect against freezing to prevent cracking of the

filter and water leakage.

Because of the product’s limited service life and to

prevent costly repairs or possible water damage,

we strongly recommend that the head of the filter

be replaced every ten years. If the head of your

filter has been in use for longer than this period,

it should be replaced immediately. Date the top of

any new head to indicate the next recommended

replacement date.

Turn off water supply to head without cartridge if

it must be left unattended for an extended period

of time.

The QC10-CBR is Tested and Certified by NSF

International to NSF/ANSI Standard 42/53.

The QC10-EP is Tested and Certified by NSF

International to NSF/ANSI Standard 42 for the

aesthetic reduction of Chlorine Taste and Odor.

The QC10-GAC is Tested and Certified by NSF

International to NSF/ANSI Standard 42 for the

aesthetic reduction of Chlorine Taste and Odor.

The QC10-TSGAC is Tested and Certified by NSF

International to NSF/ANSI Standard 42 for the

aesthetic reduction of Chlorine Taste and Odor.

PRODUCT SPECIFICATIONS

Model Claims Filter Capacity

QC10-CBR

QC10-EP chlorine taste & odor

QC10-GAC chlorine taste & odor

QC10-TSGAC

QC10-CGAC*

QC10-CB1

Turbidity = 5 NTU Max.

*Not Performance Tested or Certified by NSF.

2 •PENTEK

®

QC10 SERIES Installation and Operation Manual

chlorine taste & odor,

sediment, lead, atrazine,

lindane, cysts** and turbidity

chlorine taste & odor with

phosphate crystals

chloramine taste & odor and

chlorine taste & odor*

chlorine taste & odor and

sediment*

500 gallons

(1,890 L)

1,500 gallons

(5,670 L)

2,500 gallons

(9,460 L)

1,700 gallons

(6,435 L)

500 gallons

(1,890 L)*

10,000 gallons

(37,850 L)*

Rated

Service

Flow

0.5 gpm

(1.9 L/min)

0.5 gpm

(1.9 L/min)

0.75 gpm

(2.8 L/min)

0.75 gpm

(2.8 L/min)

0.6 gpm

(2.3 L/min)*

0.6 gpm

(2.3 L/min)*

Micron

Rating

1/4-inch

Threaded

0.5 158667 158682 158691

5* 158668 158683 158692

– 158669 158684 158693

– – 158723 158724

– – 158719 158720

- – 158721 158722

1/4-inch

JG

Push fit

3/8-inch

JG

Push fit

QC10-TSGACR

**NSF/ANSI Standard 53 certified to reduce cysts such as

Cryptosporidium and Giardia by mechanical means.

Replacement

Cartridge

QC10-CBRR

155785-43

QC10-EPR

155962-43

QC10-GACR

155901-43

255706-43

QC10-CGACR

255704-43

QC10-CB1R

255705-43

Page 3

INSTALLATION

CAUTION

CAUTION

NOTE: For cold water use only.

NOTE: Make certain that installation complies with all state

and local laws and regulations.

NOTE: The contaminants or other substances removed or

reduced by the selected cartridge are not necessarily

in your water. Filter must be maintained according

to manufacturer’s recommendation including

replacement of filter cartridges. Ask your local water

municipality for a copy of their water analysis, or

have your private well tested by a reputable water

testing lab.

NOTE: After prolonged periods of non-use (such as during

a vacation) it is recommended that the system be

flushed thoroughly. Let water run for 2-3 minutes

before using.

NOTE: The filter cartridge used with this system has a

limited service life. Changes in taste, odor, color,

and/or flow of the water being filtered indicate that

the cartridge should be replaced.

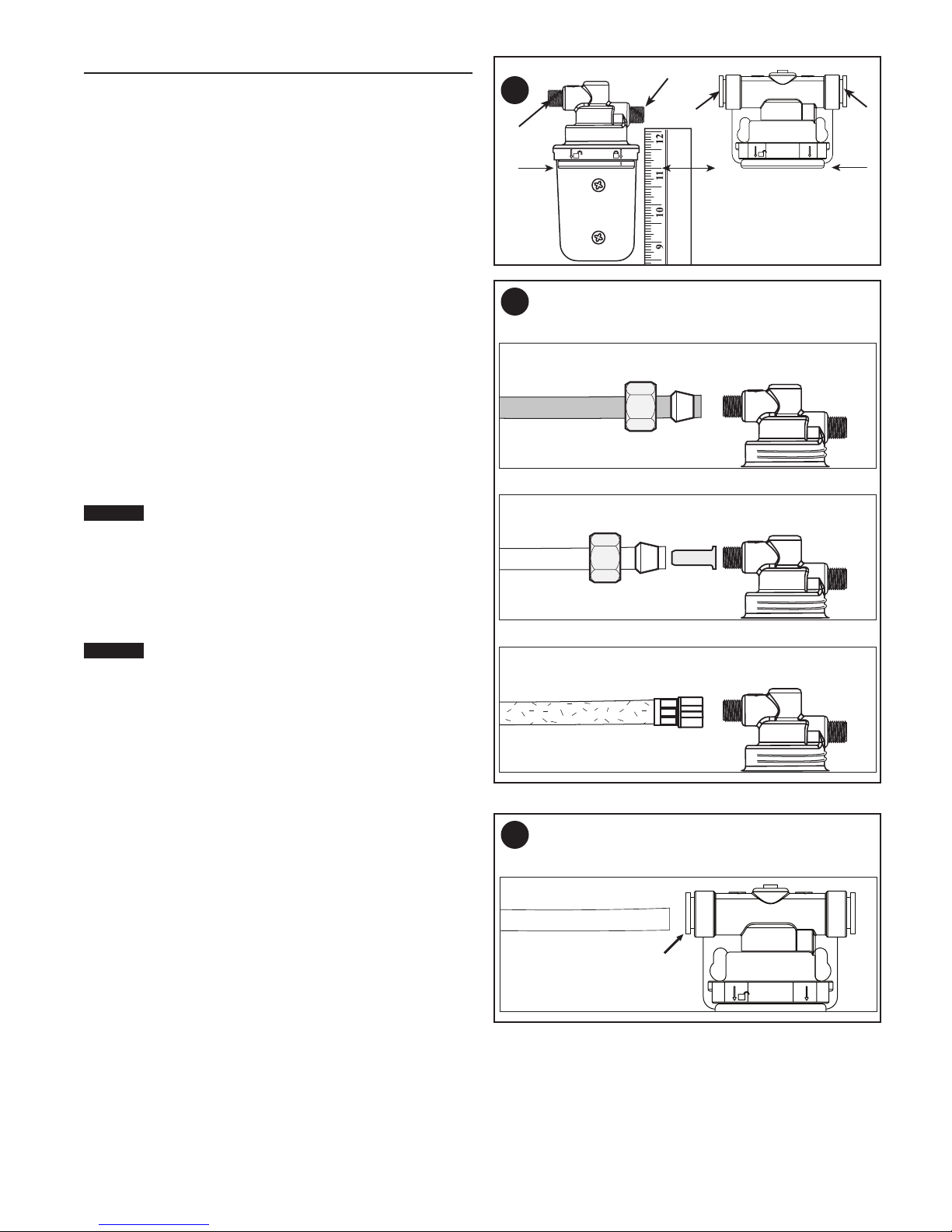

1. Mounting the Filter System

A. Select a location where filter system is to be mounted.

NOTE: Allow 1-1⁄2 inches (38 mm) clearance below housing

or 11-inches (279 mm) below filter head to enable

filter cartridge changes.

Filter head should be mounted securely to a solid

stud or surface. The mounting bracket will support

the weight of the filter and help prevent strain on

the cold water line.

B. Filter head should be mounted in vertical position. Use

mounting bracket as a template to mark screw locations.

Mount filter head in marked location using the screws

provided in the hardware kit.

Cold water supply to the filter should have a

separate shut-off valve. If it does not, a separate

shut-off should be installed.

2. Connecting the Tubing and Fittings

A. Assemble fittings as shown in Figure 2A. Press appropriate

tubing into the inlet and outlet fittings until it stops. Handtighten connections. Then tighten 1 to 1-1⁄2 turn(s) with a

wrench.

B. Cut and deburr 1/4-inch or 3/8-inch tubing. Insert tubing

into push fittings. Push tubing in until you hit a hard stop as

shown in Figure 2B, page 3. To remove tubing from fitting,

depress tube collar around the tube while pulling the tube

out.

Outlet

1A

Inlet

Inlet

11"

1/4-inch THREADED COMPRESSION FITTINGS

2A

COPPER TUBING Hand tighten plus 1 to 1-1/2 turns with a wrench

Ferrule

Nut

PLASTIC TUBING Hand tighten plus 1 to 1-1/2 turns with a wrench

Ferrule

Nut

FLEX TUBING Wrench tighten, do not over tighten

1/4-inch Compression

Flexible Braided Hose

JG PUSH FIT FITTINGS

2B

Push tubing into fitting until you hit a hard stop.

11"

Outlet

3. Installing the Cartridge

See Filter Cartridge Replacement, Step R3, for installation

instructions.

1/4" or 3/8"

Copper or Plastic

Tubing

PENTEK

®

QC10 SERIES Installation and Operation Manual • 3

Tube

Collar

Page 4

FILTER CARTRIDGE REPLACEMENT

(R1) Relieve pressure by turning off water supply to the filter

and dispensing water from the faucet.

(R2) (a) Twist cartridge away from the locked position to the

unlock position , and (b) remove cartridge (R2).

(R3) (c) Line up arrow on replacement cartridge with the

unlocked position on head and firmly push cartridge

into head and (d) turn to locked position (R3).

(R4) Turn on water and check for leaks. If leaks are found, see

Troubleshooting section, page 4.

NOTE: A water cartridge may contain carbon fines (very

fine black powder). This will be released during your

initial flushing.

(R5) Flush water through filter for 5 minutes to remove carbon

fines. Check for leaks again before leaving installation.

R3R2

TROUBLESHOOTING

Leaks:

...Between head and cartridge

1. Turn off the water supply to the filter and dispense water

from faucet.

2. Remove cartridge and inspect o-rings to make sure they

are in place and clean.

3. Install cartridge and turn on water supply, if it still leaks,

contact Technical Support at 800.279.9404. Turn off

icemaker if filtered water goes to icemaker.

...From fittings

1. Relieve pressure by turning off water supply to the filter

opening until water and airflow stops.

2. For copper or plastic tubing, loosen the compression nut

and pull the tubing from the brass fitting.

3. Inspect to see if the ferrule and insert (plastic only) are

properly installed on the tubing.

4. If so, reconnect tubing finger-tight, then tighten nut about

1 to 1-1⁄2 turn(s) with a wrench.

5. Install cartridge and turn on water supply, if it still leaks,

contact Technical Support at 800.279.9404. Turn off

icemaker if filtered water goes to icemaker.

b

Zoomed

View

MAINTENANCE

a

c

d

Contact your local water treatment professional for

replacement cartridge pricing or call Customer Service at

800.279.9404 for a dealer near you.

REPLACEMENT PARTS

Part No. Model No. Description Replacement for

144842 QCH Head Assembly

257438 QCH-1/4PF

257439 QCH-3/8PF

144846

244430 QC-PF Push Fit Hardware Kit John Guest Push Fit

Head & Bracket

Assembly

Head & Bracket

Assembly

1/4-inch MT Hardware

Kit

1/4-inch Male

Threaded Ports

1/4-inch John Guest

Push Fit

3/8-inch John Guest

Push Fit

1/4-inch Male

Threaded Ports

4 •PENTEK

®

QC10 SERIES Installation and Operation Manual

Page 5

PERFORMANCE DATA

WARNING:

WARNING:

Important Notice: Read this performance data and compare

the capabilities of these systems with your actual water

treatment needs. It is recommended that, before installing a

water treatment system, you have your water supply tested to

determine your actual water treatment needs.

This system has been tested according to NSF/ANSI 42 and

53 for the reduction of the substances listed below. The

concentration of the indicated substances in water entering

the system was reduced to a concentration less than or

equal to the permissible limit for water leaving the system as

specified in NSF/ANSI 42 and 53.

Do not use with water that is microbiologically

unsafe or of unknown quality without adequate

disinfection before or after the system.

QC10CBR WITH QC10CBRR CARTRIDGE

Substance

Standard 42—Aesthetic Effects

Chlorine 2.0 mg/L ± 10% ≥ 50% 97.5%

Particulate,

Class I

Particles*

0.5 - 1 µm

Standard 53—Health Effects

Cyst** Minimum 50,000/L 99.95% 99.99%

Turbidity 11 mg/L ± 1 NTU 0.5 NTU 99.1%

Lead (pH

6.5)

Lead (pH

8.5)

Atrazine 0.009 mg/L ± 10% 0.003 mg/L 92.0%

Lindane 0.002 mg/L ± 10% 0.0002 mg/L 99.1%

Flow Rate = 0.5 gpm (1.9 L/min)

Capacity = 500 gallons (1,890 L) or 6 months

* Reduces particles as small as 0.5-1 micron in size by mechanical means.

**NSF/ANSI Standard 53 certified to reduce cysts such as Cryptosporidium and Giardia by

mechanical means.

Influent Challenge

Concentration

at least

10,000

particles/mL

0.15 mg/L ± 10% 0.010 mg/L 99.3%

0.15 mg/L ± 10% 0.010 mg/L 97.9%

Max. Permissible Product

Water Concentration

Reduction

Requirements

Minimum

Reduction

≥ 85% 99.7%

Average

Reduction

QC10TSGAC WITH QC10TSGACR

CARTRIDGE

Substance

Standard 42—Aesthetic Effects

Chlorine 2.0 mg/L ± 10% ≥ 50% 89.5% 96.5%

Flow Rate = 0.75 gpm (2.8 L/min)

Capacity = 1,700 gallons (6,435 L) or 9 months

Testing was performed under standard laboratory conditions; actual performance may vary.

Influent Challenge

Concentration

Test Conditions:

Flow Rate = 0.5 gpm (QC10-CBR & QC10-EP)

Inlet Pressure = 60 psi (4.1 bar)

pH = 7.5 ± 1

Temperature = 68˚F ± 5˚F (20˚C ± 2.5˚C)

Operating Requirements:

Pressure = 30-125 psi (2.1-8.62 bar)

Temperature = 40˚-100˚F (4.4˚-37.8˚C)

Turbidity = 5 NTU Max

California Residents - Proposition 65

This product contains chemicals known to the

Max. Permissible Product

Water Concentration

Reduction

Requirements

Minimum

Reduction

Average

Reduction

= 0.75 gpm (QC-GAC, QC10-TSGAC)

State of California to cause cancer or birth

defects or other reproductive harm.

QC10GAC WITH QC10GACR CARTRIDGE

Substance

Standard 42—Aesthetic Effects

Chlorine 2.0 mg/L ± 10% ≥ 50% 84.2%

Flow Rate = 0.75 gpm (2.8 L/min)

Capacity = 2,500 gallons (9,460 L) or 9 months

Influent Challenge

Concentration

Max. Permissible Product

Water Concentration

Reduction

Requirements

Minimum

Reduction

Average

Reduction

QC10EP WITH QC10EPR CARTRIDGE

Substance

Standard 42—Aesthetic Effects

Chlorine 2.0 mg/L ± 10% ≥ 50% 93.5%

Flow Rate = 0.5 gpm (1.9L/min)

Capacity = 1,500 gallons (5,670 L) or 9 months

Testing was performed under standard laboratory conditions; actual performance may vary.

Influent Challenge

Concentration

Max. Permissible Product

Water Concentration

Reduction

Requirements

Minimum

Reduction

Average

Reduction

EPA Est. #090375-MEX-001 PENTEK

®

QC10 SERIES Installation and Operation Manual • 5

Page 6

6 •PENTEK

®

QC10 SERIES Installation and Operation Manual

Page 7

PENTEK

®

QC10 SERIES Installation and Operation Manual • 7

Page 8

For Pentek® Product Warranties visit:

Pentek® para las gasantías de los productos visite:

Pour Pentek® garanties produit visitez le site:

www.pentairaqua.com/pro

}

FILTRATION & PROCESS

5730 NORTH GLEN PARK ROAD, MILWAUKEE, WI 53209

P: 262.238.4400 | WWW.PENTAIRAQUA.COM | CUSTOMER CARE: 800.279.9404 | tech-support@pentair.com

All Pentair trademarks and logos are owned by Pentair, Inc. or its affiliates. All other registered and unregistered trademarks and logos are the property of their

respective owners. Because we are continuously improving our products and services, Pentair reserves the right to change specifications without prior notice.

Pentair is an equal opportunity employer.

146224 REV F FE14 ©2014 Pentair Residential Filtration, LLC All Rights Reserved.

Loading...

Loading...