Page 1

B 44665-21-1403 www.jung-pumpen.de

EN Instruction Manual

JUNG PUMPEN OXYPERL

Page 2

2

ENGLISH

You have purchased a product made by JUNG

PUMPEN and with it, therefore, also excellent quality and service. Secure this service

by carrying out the installation works in accordance with the instructions, so that our

product can perform its task to your complete

satisfaction. Please remember that damage

caused by incorrect installation or handling

will adversely affect the guarantee.

Therefore please adhere to the instructions in

this manual!

As with all electrical devices, this product

can also fail to operate due to an interruption

in the electricity supply or due to a technical defect. If this could result in damage, a

mains-independent alarm system must be

installed. Depending on the application, you

may also wish to install an emergency power

generator, or a second system as a back-up.

SAFETY

INSTRUCTIONS

This instruction manual contains essential

information that must be observed during

installation, operation and servicing. It is

therefore important that the installer and

the responsible technician/operator read this

instruction manual before the equipment is

installed and put into operation. The manual

must always be available at the location

where the pump or the plant is installed.

Failure to observe the safety instructions can

lead to the loss of all indemnity.

In this instruction manual, safety information

is distinctly labelled with particular symbols.

Disregarding this information can be dangerous.

General danger to people

Warning of electrical voltage

ATTENTION!

Danger to equipment and operation

Qualification and training of

personnel

All personnel involved with the operation,

servicing, inspection and installation of the

equipment must be suitably qualified for this

work and must have studied the instruction

manual in depth to ensure that they are sufficiently conversant with its contents. The supervision, competence and areas of responsibility of the personnel must be precisely

regulated by the operator. If the personnel do

not have the necessary skills, they must be

instructed and trained accordingly.

Safety-conscious working

The safety instructions in this instruction

manual, the existing national regulations

regarding accident prevention, and any internal working, operating and safety regulations

must be adhered to.

Safety instructions for the

operator/user

All legal regulations, local directives and

safety regulations must be adhered to.

The possibility of danger due to electrical energy must be prevented.

Leakages of dangerous (e.g. explosive, toxic,

hot) substances must be discharged such

that no danger to people or the environment

occurs. Legal regulations must be observed.

Safety instructions for installation, inspection and maintenance works

As a basic principle, works may only be carried out to the equipment when it is shut

down. Pumps or plant that convey harmful

substances must be decontaminated.

All safety and protection components must

be re-fitted and/or made operational immediately after the works have been completed.

Their effectiveness must be checked before

restarting, taking into account the current

regulations and stipulations.

Unauthorised modifications,

manufacture of spare parts

The equipment may only be modified or altered in agreement with the manufacturer.

The use of original spare parts and acces-

sories approved by the manufacturer is important for safety reasons. The use of other

parts can result in liability for consequential

damage being rescinded.

Unauthorised operating

methods

The operational safety of the supplied equipment is only guaranteed if the equipment is

used for its intended purpose. The limiting

values given in the "Technical Data" section may not be exceeded under any circumstances.

Instructions regarding accident prevention

Before commencing servicing or maintenance

works, cordon off the working area and check

that the lifting gear is in perfect condition.

Never work alone. Always wear a hard hat,

safety glasses and safety shoes and, if necessary, a suitable safety belt.

Before carrying out welding works or using

electrical devices, check to ensure there is

no danger of explosion.

People working in wastewater systems must

be vaccinated against the pathogens that

may be found there. For the sake of your

health, be sure to pay meticulous attention to

cleanliness wherever you are working.

Make sure that there are no toxic gases in the

working area.

Observe the health and safety at work regulations and make sure that a first-aid kit is to

hand.

In some cases, the pump and the pumping

medium may be hot and could cause burns.

For installations in areas subject to explosion

hazards, special regulations apply!

This appliance can be used by children aged

8 years or over and by persons with limited

physical, sensory or intellectual capabilities,

or with limited experience and knowledge,

provided that they are supervised or have

been instructed in the safe use of the appliance and are aware of the dangers involved.

Children must not be allowed to play with the

appliance. Cleaning and user maintenance

must not be carried out by children unless

they are supervised.

Page 3

3

ENGLISH

APPLICATION

The OXYPERL range of submersible motorised aerators is suitable for aerating and

circulating wastewater in small-scale clarification plants. Other uses, for instance, are

the insertion of oxygen into garden ponds or

fish ponds.

When using the aerators, the relevant national laws, regulations and stipulations

must be adhered to, for example:

• Household and similar electrical appliances - Safety (e.g. DIN EN 60335-2-41 in

Germany )

• Installation of low voltage systems (e.g.,

VDE 0100 (30 mA FI) in Germany)

Aeration of wastewater

The aeration propeller develops a vacuum

and takes air in through the suction hose,

which is connected to the atmosphere. The

narrow air ducts in the aeration propeller accelerate the air and release it into the wastewater in fine bubbles.

The aerator is optimised for a particular submersion depth. At greater depths the air insertion performance decreases. To maintain

the best possible air insertion performance it

is important to adhere to the specified depth

(please refer to the section entitled Installation).

Circulation of wastewater

The OXYPERL circulates the wastewater in

the small-scale clarification plant and, as a

result of this, the activated sludge flakes are

evenly distributed in the wastewater.

Due to a special wing design, the flake structure of the activated sludge is preserved well.

This is an important condition for achieving

good clarification results.

Temperatures

The maximum temperature of the wastewater medium is 86°F (30°C).

The submersible motorised aerator is frostresistant down to -4°F (-20°C) when stored

in dry conditions. When installed, however, it

must not be allowed to freeze in the water.

Transport

ATTENTION! The aerator must always be

lifted by the handle and never by the power

supply cable! The aerator should only be lowered into the medium using a rope or chain.

ATTENTION! During transport and when

setting the aerator down, there must not be

any mechanical load exerted on the aeration

propeller.

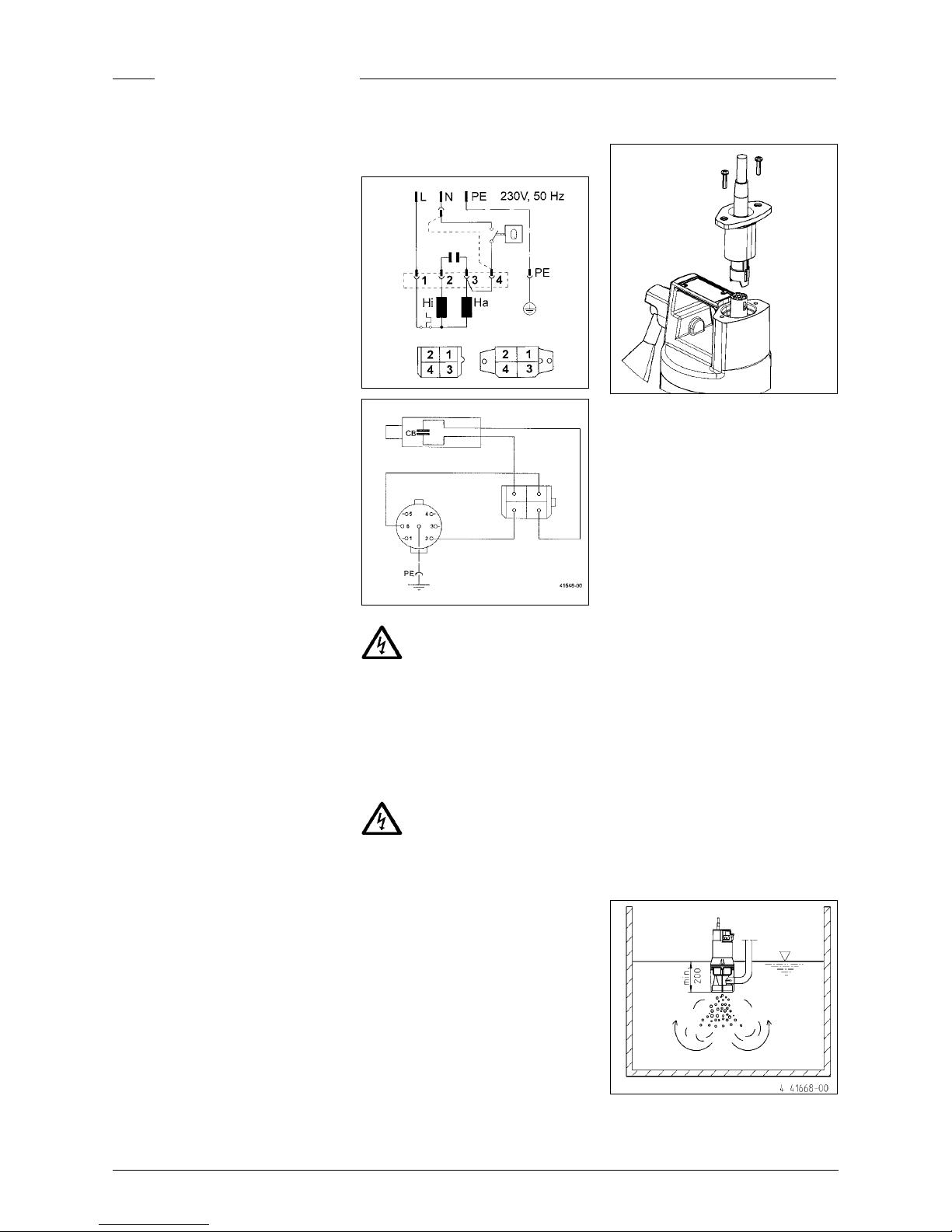

ELECTRICAL

CONNECTION

Only qualified electricians may

carry out electrical works to the

pump or the controls.

The relevant standards (such as EN standards), country-specific regulations (such as

VDE in Germany), and the regulations of the

local power supply companies must be observed.

ATTENTION! Never put the free lead end in

water! If water gets into the plug, this can

cause malfunctions and damage.

Observe the operating voltage (see

the type plate)!

The pump must only be connected up to

electrical installations with an earth wire in

accordance with the regulations. It must be

protected with a 10 A fuse. No additional motor protection is required, since the system

has an integrated winding thermostat. Inadmissible temperatures and operating times

will result in the thermostat switching the

system off (please refer to the section entitled Application). After the thermostat has

switched off the system, pull out the mains

plug before remedying the fault, since the

aerator can switch itself on again automatically after cooling down if the power is still

connected!

Replacing the connection cable

Only use original manufacturer’s parts.

We recommend replacing the seal and the

screws each time the connection cable is

replaced.

ATTENTION! When the connection cable is

loosened, the motor compartment is opened.

Please ensure clean and dry conditions when

handling the aerator.

ATTENTION! Do NOT use a power screwdriver. A size 2 PZ screwdriver must be used

to unscrew and tighten the connection cable.

Grease the sealing ring with Vaseline before

inserting the cartridge. Then tighten the

screws by hand (max 1 Nm).

INSTALLATION

The OXYPERL 3 develops a thrust of 20 N,

and the OXYPERL 5 a thrust of 38 N, due to

the propeller. The aerator must therefore be

securely attached to prevent it from twisting

or slipping.

During installation, particular care must be

taken to ensure that the four cooling surfaces

under the control head are fully submersed

in the wastewater and that the prescribed installation dimensions of at least 200 mm are

complied with! If there is insufficient cooling,

the motor temperature will rise and the electric motor will switch off automatically.

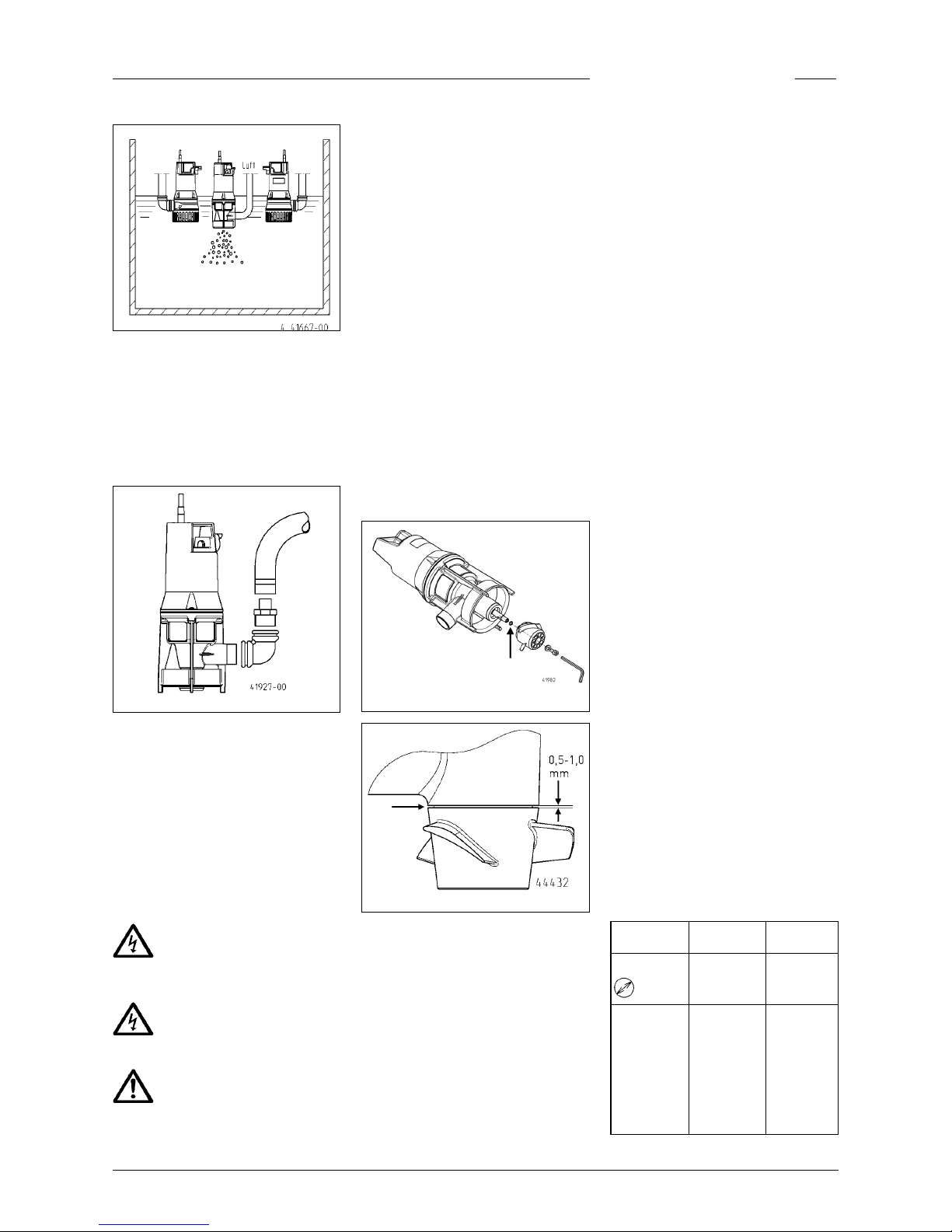

Installation of SBR system with two Oxylift

aerators

Page 4

4

ENGLISH

It must be ensured that all mains cables

from the submersible motorised aerator and

the pumps used are securely attached and

do not float in the wastewater. This will prevent the rotating propeller from coming into

contact with the cables and damaging them.

The propeller itself is protected by a guide

ring on the housing.

Attachment of aeration hose (example)

Securely attach a 90° bend to the male

thread socket and then screw a hose nozzle

into the bend. The suction hose can now be

secured to the nozzle with a hose clamp.

ATTENTION! If the pump is malfunctioning, a slight leakage of the contents of the

oil reservoir into the wastewater medium is

possible.

MAINTENANCE

Before carrying out any works:

disconnect the aerator and the

controls from the mains and take

steps to ensure that no one else can reconnect them to the power supply.

Check the mains cable for me-

chanical or chemical damage. A

damaged or kinked c

able must be

replaced.

When using a chain to lift the aera-

tor, please observe the relevant

national regulations regarding ac-

cident prevention.

Remove any solids and fibres from the aerator

housing and the aeration propeller. To maintain the function of the cooling surfaces, they

must be cleaned regularly to remove any residues (e.g. limescale).

Replacing the propeller

ATTENTION! In some models, there is a spe-

cial shim disc between the motor shaft and

the propeller. This must also be re-inserted

after the propeller has been replaced.

The propeller is attached to the motor shaft

with a cylinder head screw. This screw must

first of all be removed using an Allen key, and

then the propeller can be carefully taken off

the motor shaft and replaced.

The propeller must not rub against the housing once it has been tightened, otherwise a

shim must be inserted between the housing

and the propeller.

ATTENTION! The gap between the housing

and the propeller must not be greater than

1 mm, as otherwise the mechanical seal

on the OXYPERL will not be sufficiently prestressed and oil leaks may occur.

Tightening torque MA of the screws

M 6 with M

A

= 5 Nm, Amtec 3.5 with MA= 1 Nm

and Amtec 5.0 with MA= 2 Nm.

Air reflux valve (Accessory)

A particularly for problematic cases developed optional air reflux valve presents a

pressure compensation when switching off

the aggregate. This also ensures that no solids get into the propeller.

Quick tips for remedying

faults

OXYPERL is not working

∙ Check mains current (do not use a pin

gauge)

∙ Fuse faulty = may be too weak (please

refer to the section entitled Electrical

connection)

∙ Mains cable damaged = replace cable

∙ The cooling surfaces are not completely

submersed or are soiled and the electric

motor has overheated and cut out = wait

for a while and the OXYPERL will start

up again automatically (clean the cool-

ing surfaces and check the installation

dimensions).

Reduced air insertion

∙ Ensure that the air ducts in the aeration

propeller are not clogged. If necessary,

flush any solids out.

∙ Check that there are no obstructions in

the suction hose.

Reduced circulation performance

∙ Propeller is rubbing against the aerator

housing

1. The propeller is resting loosely on the

motor shaft = tighten the cylinder head

screw.

2. Solids are caught between the propeller

and the aerator housing = loosen the cylinder head screw and lift the propeller off

the motor shaft. Clean the parts and screw

all parts on again tightly.

3. The gap between the propeller and the

housing is too small and the original st

ate cannot be restored = insert a special

shim disc (mat. no. 41957) between the

shaft and the propeller

∙ The propeller is damaged or worn =

replace

Power input too high

∙ The gap between the propeller and the

housing is too small and the original

state cannot be restored = insert a

special shim disc between the shaft and

the propeller.

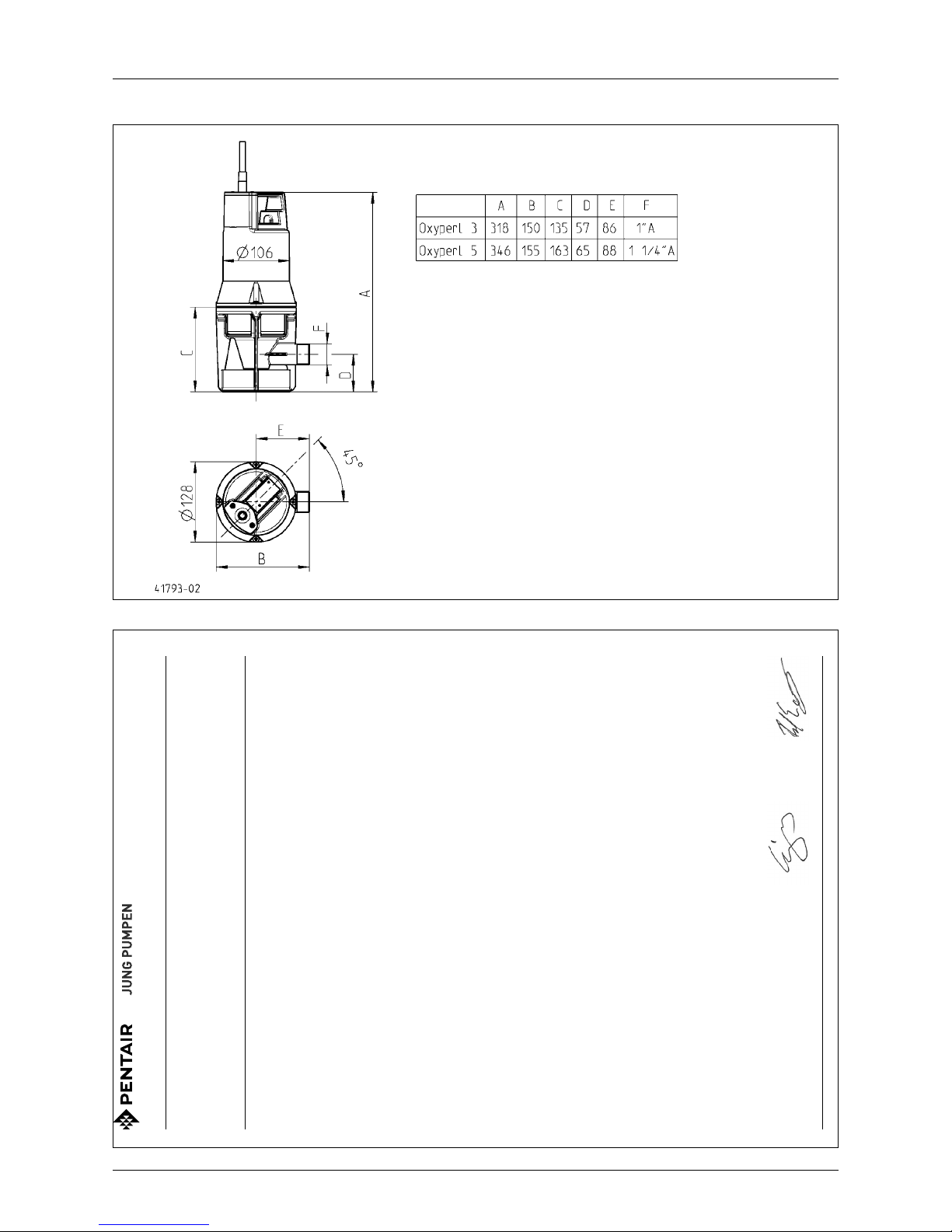

TECHNICAL DATA

OXYPERL

3 /2

OXYPERL

5 /1

[kg] 4 5

[mm] 32 40

P1 [W] 310 540

P2 [W] 210 390

U [V] 1/N/PE ~230 1/N/PE ~230

f [Hz] 50 50

I [A] 1,37 2,36

n [min

-1

] 2765 2700

Page 5

5

DE Konformitätserklärung

CZ · Prohlášeni o shodě

DK · Overensstemmelseserklæring

EN · Declaration of Conformity

FI · Vaatimustenmukaisuusvakuutus

FR · Déclaration de Conformité

HU · Megfelelöségi nyilatkozat

IT · Dichiarazione di conformità

NL · Conformiteitsverklaring

PL · Deklaracja zgodności

RO · Declaraţie de conformitate

SE · Försäkran om överensstämmelse

SK · Vyhlásenie o zhode

JUNG PUMPEN GmbH - Industriestr. 4-6 - 33803 Steinhagen - Germany -

www.jung-pumpen.de

DE · Wir erklären in alleiniger Verantwortung, dass das Produkt den aufgeführten Richtlinien entspricht.

CZ · Prohlašujeme na svou výlučnou odpovědnost, že výrobek odpovídá jmenovaným směrnicím.

DK · Vi erklærer under ansvar at produktet i overensstemmelse med de retningslinjer

EN · We hereby declare, under our sole responsibility, that the product is in accordance with the specified Directives.

FI · Me vakuutamme omalla vastuullamme, että tuote täyttää ohjeita.

FR · Nous déclarons sous notre propre responsabilité que le produit répond aux directives.

HU · Kizárólagos felelősségünk tudatában kijelentjük, hogy ez a termék megfelel az Európai Unió fentnevezett irányelveinek.

IT · Noi dichiariamo sotto la nostra esclusiva responsabilità che il prodotto è conforme alle direttive citate

NL · Wij verklaren geheel onder eigen verantwoordelijkheid dat het product voldoet aan de gestelde richtlijnen.

PL · Z pełną odpowiedzialnością oświadczamy, że produkt odpowiada postanowieniom wymienionych dyrektyw.

RO · Declarăm pe proprie răspundere că produsul corespunde normelor prevăzute de directivele mai sus menţionate.

SE · Vi försäkrar att produkten på vårt ansvar är utförd enligt gällande riktlinjer.

SK · Na výlučnú zodpovednosť vyhlasujeme, že výrobok spíňa požiadavky uvedených smerníc.

CE 314-11-1403

Steinhagen, 10-03-2014

______________________ ppa. ____________________

Stefan Sirges, General Manager Frank Erdt, Sales Director

DE · Weitere normative Dokumente CZ · Jinými normativními dokumenty DK · Andre normative doku-

menter EN · Other normativ e documents FI · Muiden normien FR · Autres documents normatifs HU

· Egyéb szabályozó dokumentumokban leírtaknak IT · Altri documenti normativi NL · Verdere normatieve

documenten PL · Innymi dokumentami normatywnymi RO · Alte acte normative SE · Vidare normerande

dokument SK · Iným záväzným dokumentom:

EN 60335-2-41:2010

• 2006/42 EG (Machinery) EN ISO 12100:2010, EN 60335-1:2012

• 2004/108 EG (EMC) EN 55014-1:2012, EN 55014-2:2008, EN 61000-3-2:2010, EN 61000-3-3:2009

DE · Richtlinien - Harmonisierte Normen

CZ · Směrnice - Harmonizované normy

DK · Direktiv - Harmoniseret standard

EN · Directives - Harmonised standards

FI · Direktiivi - Yhdenmukaistettu standardi

FR · Directives -

Normes harmonisées

HU · Irányelve - Harmonizá szabványok

IT · Direttive - Norme armonizzate

NL · Richtlijnen - Geharmoniseerde normen

PL · Dyrektywy - Normy zharmonizowane

RO · Directivă - Norme coroborate

SE · Direktiv - Harmoniserade normer

SK · Smernice - Harmonizované normy

oxyperl 3 (JP44430)

oxyperl 3 (JP44431)

oxyperl 3 (JP44432)

oxyperl 5 (JP45228)

oxylift 2 (JP09469)

oxylift 2 (JP09471)

oxylift 2 (JP09473)

oxylift 2 S (JP09470)

oxylift 2 S (JP09472)

DE · Bevollmächtigter für technische Dokumentation CZ · Oprávněná osoba pro technickou dokumentaci

DK · Autoriseret person for teknisk dokumentation EN · Authorized person for technical documentation

FI · Valtuutettu henkilö tekninen dokumentaatio FR · Personne autorisée à la documentation technique

HU · Hivatalos személy műszaki dokumentáció IT · Persona abilitata per la documentazione tecnica

NL · Bevoegd persoon voor technische documentatie PL · Pełnomocnik ds. dokumentacji technicznej

RO · Persoană autorizată pentru documentatiei tehnice SE · Auktoriserad person för teknisk dokumenta-

tion SK · Oprávnená osoba pre technickú dokumentáciu:

JUNG PUMPEN - Stefan Sirges - Industriestr. 4-6 - 33803 Steinhagen

Page 6

Ersatzteile - Spare parts - Pièces de rechange - Reserveonderdelen - Parti di ricambio - Reservedele - Reservdelar Varaosat - Części zamienne - Náhradní díly - Alkatrészek - Piese de schimb - Запасные части -

备件

B 44297-21-1609 www.jung-pumpen.de

JUNG PUMPEN OXYPERL 3 · OXYPERL 5

①

Haube Top cover JP46928

②

Kabelbaum Cable gland

Oxyperl 3 JP46921

Oxyperl 5 JP46930

③

Leitung Cable

1,5 m JP46925

4 m JP46926

10 m JP45084

20 m JP46927

④

Belüftergehäuse Aerator housing

Oxyperl 3 JP45082

Oxyperl 5 JP46196

⑤

Motoreinheit Motor unit

Oxyperl 3 JP45081

Oxyperl 5 JP46195

⑥

Propeller Propeller

Oxyperl 3 JP45083

Oxyperl 5 JP46197

⑦

Ausgleichscheiben Compensating disks JP45109

⑧

Schraubensatz Screw set JP42773

⑨

Motordichtung Motor seal JP48224

⑩

Dichtungssatz Seal set JP46354

6

Page 7

7

Page 8

Pump Technical Services Limited - Pump House - Unit 12 - Bilton Road

Industrial Estate - Erith - Kent - DA8 2AN

Tel: 01322 357 080 - Fax: 01322 341 341 - Email: sales@pts-jung.co.uk

Loading...

Loading...