Pentair JETINOX Series, MAX 80/60, MAX 80/48, AUTOMAX 80/48, MAX 120/60 Series Manual

...

MAX - MULTINOX-A

AUTOMAX - JET

NEWJET - JETINOX

AUTOJET

IT - ISTRUZIONI ORIGINALI IN LINGUA ITALIANA

IT 31PAG.P

1PAG.

43PAG.DK

85PAG.H

F7PAG.GB 37PAG.NL

49PAG.FIN

91PAG.CZ

13PAG.

D

55PAG.N

97PAG.TR

19PAG.

E

61PAG.S

103PAG.RUS

25PAG.

67PAG.GR

73PAG.PL

79PAG.RO

IT Dichiarazione di conformità

EN Declaration of conformity

FR Déclaration de Conformité

DE Konformitätserklärung

E Declaración de conformidad

NL Conformiteitsverklaring

IT - Direttive - Norme armonizzate

EN - Directives - Harmonised standards

FR - Directives - Normes harmonisées

DE - Richtlinien - Harmonisierte Normen

E - Directivas – Normas armonizadas

NL - Richtlijnen – Geharmoniseerde normen

2006/42/EC (MD)

2014/30/EU (EMC)

P Declaração de conformidade

DK Ef overensstemmelseserklæring

FIN Eu-vaatimustenmukaisuusvakuutus

N Samsvarserklæring

S Tillkännagivande om eu-överensstämmelse

GR ηλωση πpoσapογης εoκ

P - Directivas - Normas harmonizadas

DK - Direktiver – Harmoniserede standarder

FIN - Direktiivit – Harmonisoidut standardit

N - Direktiver - harmoniserte standarder

S - Harmoniserade direktiv/standarder

GR - Οδηγίες – Εναρονισένα πρότυπα

EN 60335-1:2012/AC:2014, EN ISO 12100:2010

EN 61000-6-3:2007/A1:2011, EN 61000-6-1:2007, EN 61000-6-4:2007/A1:2011,

EN 61000-6-2:2006, EN 55014-1:2006/A2:2011, EN 60730-1:2011

PL Deklaracja zgodności

RO Declaraţie ce de conformitate

H Európai uniós megfelelési nyilatkozat

CZ Prohlášení es o shodě

TR At uygunluk bildirisi

RUS Декларация o соответствии ec

PL - Dyrektywy – Normy zharmonizowane

RO - Directive - Standarde armonizate

H - Irányelvek – Harmonizált szabványok

CZ - Smĕrnice – harmonizované normy

TR - Direktifler – Uyumlaştırılmış standartlar

RUS - Директивы – гармонизированные нормы

2000/14/EC (ND) EN ISO 20361:2009

Pentair International Sarl - Avenue de Sévelin 18 - 1004 Lausanne - Suisse

IT - Noi dichiariamo sotto la nostra esclusiva responsabilità che il prodotto è conforme alle direttive citate.

EN - We hereby declare, under our sole responsibility, that the product is in accordance with the specified Directives.

FR - Nous déclarons sous notre propre responsabilité que le produit répond aux directives.

DE - Wir erklären in alleiniger Verantwortung, dass das Produkt den aufgeführten Richtlinien entspricht.

ES - Por la presente declaramos bajo nuestra responsabilidad exclusiva que el producto es conforme con las Directivas citadas.

NL - Wij verklaren geheel onder eigen verantwoordelijkheid dat het product voldoet aan de gestelde richtljnen.

P - Declaramos sob a nossa exclusiva responsabilidade que o produto é conforme com as directrizes citadas.

DK - Vi erklærer hermed, som eneste ansvarlige, at produktet er i overensstemmelse med de anførte Direktiver.

FIN - Vakuutamme yksinomaisella vastuullamme, että tuote on osoitettujen direktiivien mukainen.

N - Vi erklærer med dette, under vårt hele og fulle ansvar, at produktet samsvarer med de spesifiserte direktivene.

S - Vi försäkrar under eget ansvar att produkten är i överensstämmelse med nämnda direktiv.

GR - Με αποκλειστική ευθύνη δηλώνουε ότι το προϊόν συορφώνεται ε τις αναφερόενες οδηγίες.

PL - Z pełną odpowiedzialnością oświadczamy, że produkt odpowiada postanowieniom wymienionych dyrektyw.

RO - Noi declarăm pe propria noastră răspundere că produsul este conform cu directivele menionate.

H - Kizárólagos felelősségvállalással kijelentjük, hogy a termék megfelel a megnevezett irányelveknek.

CZ - Prohlašujeme na svou vlastní výhradní odpovĕdnost, že tento výrobek vyhovuje požadavkům uvedených smĕrnic.

TR - Ürünün ilgili direktiflere uygunluğunu, bu konuda sorumluluğun yalnızca tarafımıza ait olduğunu beyan ederiz.

RUS - Заявляем под свою исключительную ответственность, что продукция соответствует указанным директивам

MULTINOX-A 200/40

MULTINOX-A 200/52

MULTINOX-A 200/65

MULTINOX-A 200/80

MAX 80/36

MAX 80/48

MAX 80/60

IT Altri documenti normativi EN Other normative documents FR Autres documents

normatifs DE Weitere normative Dokumente E Otros documentos normativos NL Overige

normatieve documenten P Outros documentos normativos DK Andre normative dokumenter

FIN Muut normatiiviset asiakirjat N Andre normative dokumenter S Övriga standardiserande

dokument GR

Άλλα κανονιστικά έγγραφα PL Pozostała dokumentacja normatywna

RO Alte documente normative H Egyéb normatív dokumentumok CZ Další normativní

dokumenty TR Standartlarla ilgili diğer belgeler RUS Прочие нормативные документы:

MAX 120/48

MAX 120/60

NEWJET 40/40

NEWJET 45/37

NEWJET 45/43

NEWJET 60/42

NEWJET 60/50

EN 60335-2-41:2003/A2:2010

JET600

JET800

JET1000

JET100/50

JET100/68

JET100/80

JET160/52

IT Persona abilitata per la documentazione tecnica EN Authorized person for technical

documentation FR Personne autorisée à la documentation technique DE Bevollmächtigter für

technische Dokumentation E Persona habilitada para la documentación técnica NL Bevoegd

persoon voor technische documentatie P Pessoa habilitada para a documentação técnica DK

Person autoriseret til udarbejdelse af den tekniske dokumentation FIN Teknisten asiakirjojen

laadintaan valtuutettu henkilö N Person kvalifisert for teknisk dokumentasjon S Person som är

behörig att ställa samman den tekniska dokumentationen GR Αρμόδιος καταρτισμένος

σχετικά με την τεχνική τεκμηρίωση PL Osoba upoważniona do sporządzenia dokumentacji

technicznej RO Persoana autorizată pentru documentaţia tehnică H A műszaki dokumentáció

elkészítésére jogosult személy CZ Osoba odbornĕ způsobilá ke zpracování technické dokumentace

TR Teknik dokümentasyon konusunda yetkili kişi RUS Лицо, имеющее право на составление

технической документации:

Pentair International S.a.r.l.

Avenue de Sevelin, 18

1004 Lausanne, Switzerland

Lausanne, 16-05-2016

JET160/60

JETINOX 45/37

JETINOX 45/43

JETINOX 60/42

JETINOX 60/50

JETINOX 70/50

JETINOX 90/43

JETINOX 90/50

AUTOJET 60/50

AUTOJET 70/50

AUTOMAX 80/48

AUTOMAX 120/60

Guillaume Goussé

European Operations Vice President

253CE043

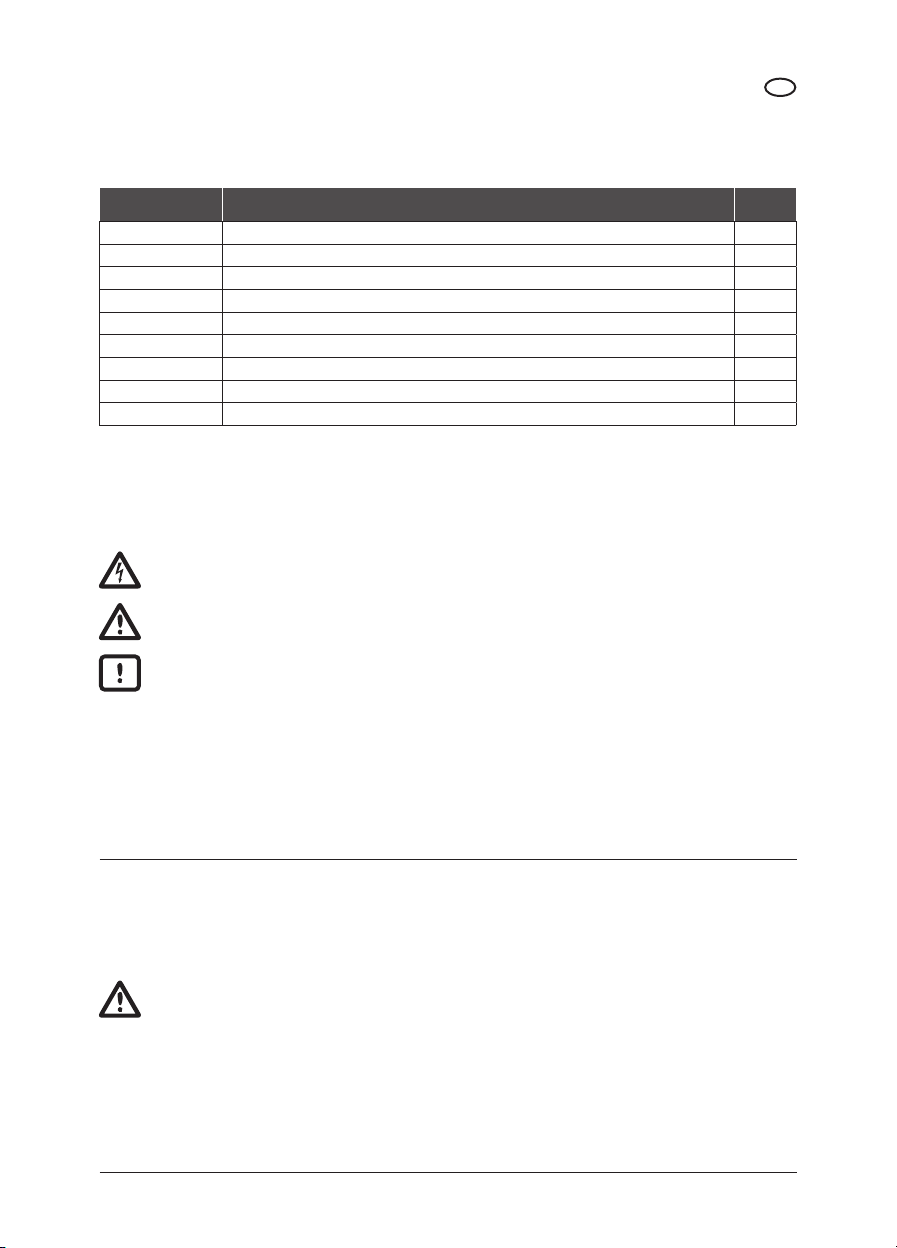

SUMMARY

CHAPTER DESCRIPTION PAGE

1 FEATURES 7

2 LIMITATIONS 8

3 INSTALLATION 9

4 ELECTRICAL CONNECTIONS 10

5 STARTING THE UNIT 10

6 OPERATION OF THE FLUSSCONTROL ELECTRONIC PRESSURE SWITCH 11

7 MAINTENANCE AND TROUBLESHOOTING 12

- FIGURES 109

- WARRANTY 112

WARNINGS FOR THE SAFETY OF INDIVIDUALS AND OBJECTS

Warnings for the safety of individuals and things.

Please pay careful attention to the following signs and indications.

DANGER - ELECTRIC SHOCK RISK

Warns that the failure to follow the directions given may cause electric shock.

DANGER

Warns that the failure to follow the directions given could cause serious risk to individuals or objects.

WARNING

This sign warns the operator that the failure to follow an instruction may damage the pump and/or the system.

GB

WARNING

Read this manual carefully before installing this pump.

This sign warns the operator that the failure to follow an instruction may damage the pump and/or the system.

CHAPTER 1

FEATURES

Carefully store this manual. If problems arise, contact the Customer Assistance Service.

Please verify that the pump has been used correctly and that the cause of the problem is not imputable to its operation.

Every electropump is carefully tested and packed during its assembly.

On receiving the pump, check that the pump has not been damaged during transportation. If the pump is damaged, immediately

inform the dealer within 8 days from the date of purchase.

DANGER

This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning use

of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

7

GB

CHAPTER 2

LIMITATIONS

JET, NEWJET, JETINOX, AUTOJET, MAX, MULTINOX-A, AUTOMAX pumps are suitable to pump clean water from wells, tanks, etc.; to

irrigate meadows and flowerbeds; to fill or drain collection tanks or basins; and to wash terraces or small paths.

The electric pumps in this series are centrifugal and self-priming with a “venturi“ system inserted into the body of the pump.

WARNING

The pump cannot be used for sea water and inflammable, corrosive, explosive or dangerous liquids.

WARNING

Verify that the electropump never runs without liquids.

• MAXIMUM TEMPERATURE OF THE

PUMPED FLUID: 50 °C

• MAXIMUM/MINIMUM AMBIENT

TEMPERATURE: 40 °C / 5 °C*

• MAXIMUM NUMBER OF STARTS PER

HOUR: 40 uniformly distributed

* Below 5° C, drain the electropump to prevent failures or damages caused by frost

MODEL (LWA)** LPA

MAX 80/48

AUTOMAX 80/48

MAX 80/60 69 dB 61,3 dB

MAX 120/60

AUTOMAX 120/60

MULTINOX A 200/40

MULTINOX A 200/52

MULTINOX A 200/65

MULTINOX A 200/80

** Sound emission values obtained in conformity with the

EN 12639 standard.

• MAXIMUM SUCTION HEIGHT

(recommended): 9 m - Jet, Newjet,

Jetinox, Autojet

• MAXIMUM SUCTION HEIGHT

(recommended): 7 m - Max,

Multinox-A, Automax

66 dB 58,1 dB

73 dB 64,6 dB

79 dB 66,5 dB

MODEL (LWA)** LPA

JET 600

JET 800

JET 1000 86 dB 78,01 dB

NEWJET 40/40

NEWJET 45/43

NEWJET 60/50 85 dB 72,7 dB

JETINOX 45/43 78 dB 69,7 dB

JETINOX 60/50

AUTOJET 60/50

JETINOX 70/50

AUTOJET 70/50

JETINOX 90/43

JETINOX 90/50

** Measurement method according to EN ISO 3744.

• MAXIMUM ADMITTED WORKING

PRESSURE: 6 bar - Jet, Newjet,

Jetinox, Autojet

• MAXIMUM ADMITTED WORKING

PRESSURE: 7 bar - Max

• MAXIMUM ADMITTED WORKING

PRESSURE: 9 bar - Multinox-A

75 dB 68,1 dB

78 dB 69,7 dB

85 dB 72,7 dB

82 dB 70,1 dB

91 dB 83,2 dB

8

CHAPTER 3

INSTALLATION (SEE FIG. 1)

DANGER - ELECTRIC SHOCK RISK

When installing, please ensure electropump is disconnected from electrical supply. Pumps in this series are

not suitable for use in a swimming pool and the relevant cleaning and servicing operations.

WARNING

Protect the electropump and all pipes from bad weather or freezing conditions.

DANGER

To prevent possible injuries to people, avoid inserting hands into the mouth of the pump if this is connected

to the mains.

GB

• Use a suction pump (2) with a

diameter equivalent to that of the

suction mouth of the electropump (1)

• If the height (HA) is over 4 meters use

a tube with a larger diameter

• The suction line should be perfectly

airtight

• No elbows and/or slopes should be

present to prevent the formation

of air locks that could affect the

electropump efficiency

• A foot valve (3) with filter (4) should be

fitted at about half a metre below the

fluid that has to be pumped (HI) on

one end of the line

ATTENTION

Connection, suction and delivery pipes should be connected with the utmost care. Make sure that all connections fixed by means of

screws are sealed. Avoid applying excessive stress to tighten the screws of connections or of other components.

Use a Teflon tape to completely seal all joints.

To use the pump in continuous mode for swimming pools, garden ponds and in similar installations, it is necessary to fix the

electropump to a stable support. Mobile electropumps can be used for swimming pools, garden ponds or similar installations, only

if no people is contact with water or if the electric system has a safety cut-out switch.

The pump should be fitted in a stable position in order to avoid falls and protect it from inundation.

Contact a specialised electrician.

• Load losses can be reduced using

delivery piping with a diameter

equivalent or greater than the

electropump mouth (5)

• It is advisable to install a check

valve (6) directly on the delivery line

to prevent the electropump being

damaged by "water hammer"

• A cut-off valve (7) should also be

installed downstream from the check

valve, to facilitate servicing operations

• Piping should be fitted so that

vibrations, when existing, tension and

weight do not affect the pump

• Piping should be routed along

the shortest and straighter track,

avoiding an excessive number of

bends

• Verify that the motor is properly

ventilated

• For permanent installations, it is

advisable to fix the electropump to

the supporting base, connect the

system with a section of non flexible

pipe and insert a layer of rubber

(or another anti-vibration material)

between the supporting base and the

pump, in order to reduce vibrations

• The site of installation must be stable

and dry to guarantee the stability of

the pump

9

GB

CHAPTER 4

ELECTRICAL CONNECTIONS

WARNING

Verify that the voltage and frequency of the electropump shown on the nameplate correspond to those

available on the mains.

DANGER - ELECTRIC SHOCK RISK

The installer must make sure that the electric system is grounded in accordance with the law in force.

DANGER - ELECTRIC SHOCK RISK

Make sure that the electric system has a high-sensitivity circuit breaker ∆=30 mA (DIN VDE 0100T739).

OVERLOAD PROTECTION

The single phase motors are protected from overloads by a thermal device installed in the winding.

The protection for the three phase motor must be installed by the user.

Supply cables and extensions should have a section below that of H07 RN-F.

The plug and connections should be protected by water splashes.

For connecting single phase motors see Fig. 2

For connecting three phase motors see Fig. 3

For connecting double voltage single phase motors see Fig. 4

CHAPTER 5

STARTING THE UNIT (SEE FIG. 1)

WARNING

Use the electropump for the applications listed on the nameplate.

WARNING

Do not operate the pump dry, since lack of water could cause it to overheat. In this case, the water inside the system

gets very hot, so there is a risk of scalding. Take off the plug and let the system cool down.

WARNING

Do not run the electropump with a completely closed delivery.

INSTRUCTIONS FOR A SAFE PUMP START

• Avoid exposing the pump to humidity

• Protect the pump from rain, making

sure that there are no leaking fittings

over the pump

• Avoid using the pump in wet or damp

environments

DANGER - ELECTRIC SHOCK RISK

The power cable must be replaced by qualified personnel only.

10

• Make sure that the pump and the

electric connections are protected

from possible inundation

• Before using the pump, always

inspect it visually (especially power

cable and plug)

• Do not use the pump if it is damaged

• If the pump is damaged, have

it inspected by the specialised

assistance service only

• Do not transport the pump using the

cable or use the cable to remove the

plug from the socket

• Protect the plug and the power cable

from heat, oil or sharp edges

STARTUP (FIG. 1)

GB

• Before starting the pump, fill the

suction pipe (2) and the pump body (8)

using the filling cap (9)

• Close the cap after verifying that

there are no leaks

• Open the closing devices on the

delivery pipe (i.e. the water cock)

so that air can be released from the

suction cycle

• Insert the pump plug into a 230 V

alternate current socket and press

the switch

• Pompe JET, NEWJET, JETINOX,

AUTOJET, MAX, MULTINOX-A,

AUTOMAX are self-priming

• Therefore, it is possible to start them

without filling the suction pipe with

water

• However, it is still necessary to fill the

pump body

• The priming operation requires a few

minutes

CHAPTER 6

OPERATION OF THE FLUSSCONTROL ELECTRONIC PRESSURE SWITCH (FIG. 1, N. 12)

AUTOMAX 80/48, AUTOMAX 160/120, AUTOJET 60/50, AUTOJET 70/50

• A panel is mounted on the front of

the device which displays all the

operating phases of the system by

means of pilot lights: green pilot light

Power on, yellow pilot light Pump on,

red pilot light Failure

• At the moment of connection to the

electrical mains, the green light turns

on together with the yellow light

indicating the start-up of the pump

(fig. 5/A) which remains in operation

for a few seconds in order to allow the

system to build up pressure

• If this time is not sufficient, the red

Failure light will turn on (fig. 5/C);

in this case keep the red Restart

(rearm) button pressed and wait with

a service open for the red pilot light

to turn off

• After the service is closed, the device

stops the pump and goes into standby

mode, the green pilot light lit, ready

to carry out in complete autonomy all

the subsequent command and control

operations (fig. 5/B)

• On opening a service, the device

starts the pump which remains in

operation for as long as the service

itself is open (fig. 5/A)

• After the service has been closed, the

device restores maximum pressure to

the system, then stops the pump and

returns to the standby mode (fig. 5/B)

• It may also be necessary to fill the

pump body with water several times,

according to the length and diameter

of the suction pipe

• If the electropump is not used for a

long period of time, it is necessary to

repeat all the operations described

above before starting the pump

• In the event of water shortage during

aspiration, the device recognises the

failure which it signals with the red

Failure light, and stops the pump (fig.

5/C) protecting it from dry running

• Once the causes of a blockage have

been removed, it is sufficient to press

the red Restart (rearm) button to

restore normal operation

• In the case of a temporary power

outage the device will automatically

restart as soon as the electricity

returns

DANGER - ELECTRIC SHOCK RISK

The electronic FLUSSCONTROLL pressure switch (including the safety cables) can be opened or replaced

only by qualified personnel.

11

Loading...

Loading...