Page 1

OWNER’S MANUAL

Battery Backup System

NOTICE D’UTILISATION

Système de secours à batterie

MANUAL DEL USUARIO

Systema de respaldo de la batería

FG100-A1

Installation/Operation/Parts

For further operating, installation,

or maintenance assistance:

Call 1-888-957-8677

English ........................ Pages 2-15

Installation/Fonctionnement/Pièces

Pour plus de renseignements

concernant l’utilisation,

l’installation ou l’entretien,

Composer le

1 (888) 957-8677

Français .................. Pages 16-29

ALWAYS READ WARNINGS IN INSTRUCTION

A.C.POWER ON

MANUAL BEFORE USING.

PUMP RUN ALARM

AUDIBLE ALARM

MICRO PROCESSOR CONTROLLED

SILENCE

5 STAGE BATTERY CHARGE/MAINTAINER

12 VOLT 8 AMP

LOW BATTERY ALARM

CHARGING - YELLOW

CHARGED - GREEN

AUDIBLE ALARM

DISABLE

ALARM RESET

SOFT RESET

FG200-A1

Instalación/Operación/Piezas

Para mayor información sobre el

funcionamiento, instalación o

mantenimiento de la bomba:

Llame al 1-888-957-8677

Español .................. Paginas 30-44

293 WRIGHT STREET, DELAVAN, WI 53115 WWW.HYDROMATIC.COM

PH: 8889578677

© 2013 Pentair, Ltd. All Rights Reserved. HYD739 (Rev. 03/04/13)

Page 2

Safety 2

READ AND FOLLOW

SAFETY INSTRUCTIONS!

This is the safety alert symbol. When you see this

symbol on your pump or in this manual, look for

one of the following signal words and be alert to the

potential for personal injury!

DANGER warns about hazards that will

cause serious personal injury, death or major property

damage if ignored.

cause serious personal injury, death or major property

damage if ignored.

can cause minor personal injury or property damage if

ignored.

The word NOTICE indicates special instructions which

are important but not related to hazards.

1. To avoid risk of serious bodily injury due to electrical

shock or burns and property damage due to flooding,

read the safety instructions carefully before installing

pump.

WARNING warns about hazards that can

CAUTION warns about hazards that will or

5. Pump clear water only with this pump.

6. Pump is permanently lubricated at the factory. Do

not try to lubricate it!

7. Keep battery charger and battery box off of the floor

and in a dry, cool, well ventilated area.

NOTICE: If a Carbon Monoxide (CO) sensor is

installed, it must be at least 15 feet away from

battery charger in order to avoid nuisance CO

alarms. Please refer to your CO detector’s installation

guidelines for more information.

8. To avoid danger of fire or explosion, keep sparks and

flame (pilot light) away from battery.

9. Maximum vertical pumping distance is 16 feet

(4.9M) for Model FG100-A1 and 18 feet (5.5M) for

Model FG200-A1.

10. Make sure sump is clear of debris. Debris can

damage the pump which can result in flooding.

California Proposition 65 Warning

This product and related accessories contain

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

Battery acid is corrosive. Do not spill on

skin, clothing, or battery charger. Wear eye and head

protection when working with battery. Connect and

disconnect DC output terminals only after removing

the charger from the AC outlet. Never allow the DC

terminals to touch each other.

fatal electrical shock. Do not plug in or unplug battery

charger while standing on a wet floor or in water. Be

sure one hand is free when plugging in or unplugging

charger. If basement floor is wet, disconnect power to

basement before walking on floor.

To do so will damage seals and can cause leaking and

property damage.

2. Follow local and/or national plumbing and electrical

codes when installing the system. A ground fault

circuit interrupter (GFCI) is recommended for use on

any electrical appliance submerged in water.

3. Use this system only for backup sump pump duty

in a residential application. It is not designed as a

primary sump pump.

4. Do not lift pump by electrical cord.

pump by the electrical cord; lift pump only by the

discharge pipe, lifting ring or handle on the pump. Lifting

by the cord can damage the cord.

Hazardous Voltage. Can cause severe or

Risk of flooding. Do not run pump dry.

Risk of electrical shock. Do not lift the

GENERAL INFORMATION

The battery back-up sump system is not a sub stitute for

your primary sump pump. It is designed to temporarily

back up your primary sump pump during a power outage

or other problem which prevents normal operation of

the primary pump. Do not use this system to pump

flammable liquids or chemicals. Pump clear water only

with this pump.

Keep battery charger dry and protected from damage.

In an emergency (such as an extended power outage)

which depletes the system deep cycle battery, your

automobile battery may be temporarily substituted. Be

sure to replace the system deep cycle battery as soon

as possible. Use of an automobile battery instead of a

deep cycle battery in this system will significantly reduce

system total performance. Automobile batteries are not

designed for this type of application and will be quickly

ruined by the repeated charge/discharge cycling. Do

not use GEL-type batteries or maintenance-free (sealed)

batteries with this charger. GEL-type batteries require a

lower voltage than the charger is designed for; they may

overcharge. Maintenance-free (sealed) batteries require a

higher voltage and may never reach full charge.

NOTICE: This unit is not designed for applications

involving salt water or brine! Use with salt water or brine

will void warranty.

Page 3

Table of Contents 3

Page

General Safety .....................................................................................................2

Warranty..............................................................................................................3

Installation ......................................................................................................4-12

Operation .....................................................................................................13-14

Troubleshooting .................................................................................................14

Repair Parts .......................................................................................................15

Limited Warranty

HYDROMATIC warrants to the original consumer purchaser (“Purchaser” or “You”) of HYDROMATIC Sump Pumps,

Effluent Pumps, Sewage Pumps (other than 2-1/2”), and Package Systems, that they will be free from defects in material and

workmanship for the Warranty Period of 36 months from date of manufacture.

Our warranty will not apply to any product that, in our sole judgement, has been subject to negligence, misapplication,

improper installation, or improper maintenance. Without limiting the foregoing, operating a three phase motor with single phase

power through a phase converter will void the warranty. Note also that three phase motors must be protected by three-leg,

ambient compensated, extra-quick trip overload relays of the recommended size or the warranty is void.

Your only remedy, and HYDROMATIC’s only duty, is that HYDROMATIC repair or replace defective products (at

HYDROMATIC’s choice). You must pay all labor and shipping charges associated with this warranty and must request warranty

service through the installing dealer as soon as a problem is discovered. No request for service will be accepted if received after

the Warranty Period has expired. This warranty is not transferable.

EXCEPTIONS: Hydromatic Special Application Pumps, Battery Back-Up Sump Pumps, Filtered Effluent Pumps, Grinder

Pumps, and 2-1/2” Sewage Pumps are warranted for a period of 12 months from date of purchase or 18 months from date of

manufacture, whichever comes first.

HYDROMATIC SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR CONTINGENT

DAMAGESWHATSOEVER.

THE FOREGOING LIMITED WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS AND IMPLIED

WARRANTIES, INCLUDING BUT NOT LIMITED TO IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR

A PARTICULAR PURPOSE. THE FOREGOING LIMITED WARRANTIES SHALL NOT EXTEND BEYOND THE DURATION

PROVIDED HEREIN.

Some states do not allow the exclusion or limitation of incidental or consequential damages or limitations on the duration of an

implied warranty, so the above limitations or exclusions may not apply to You. This warranty gives You specific legal rights and

You may also have other rights which vary from state to state.

This Limited Warranty is effective June 1, 2011 and replaces all undated warranties and warranties dated before June 1, 2011.

HYDROMATIC

293 Wright Street, Delavan, WI 53115

Phone: 888-957-8677 • Fax: 800-426-9446 • Web Site: hydromatic.com

Page 4

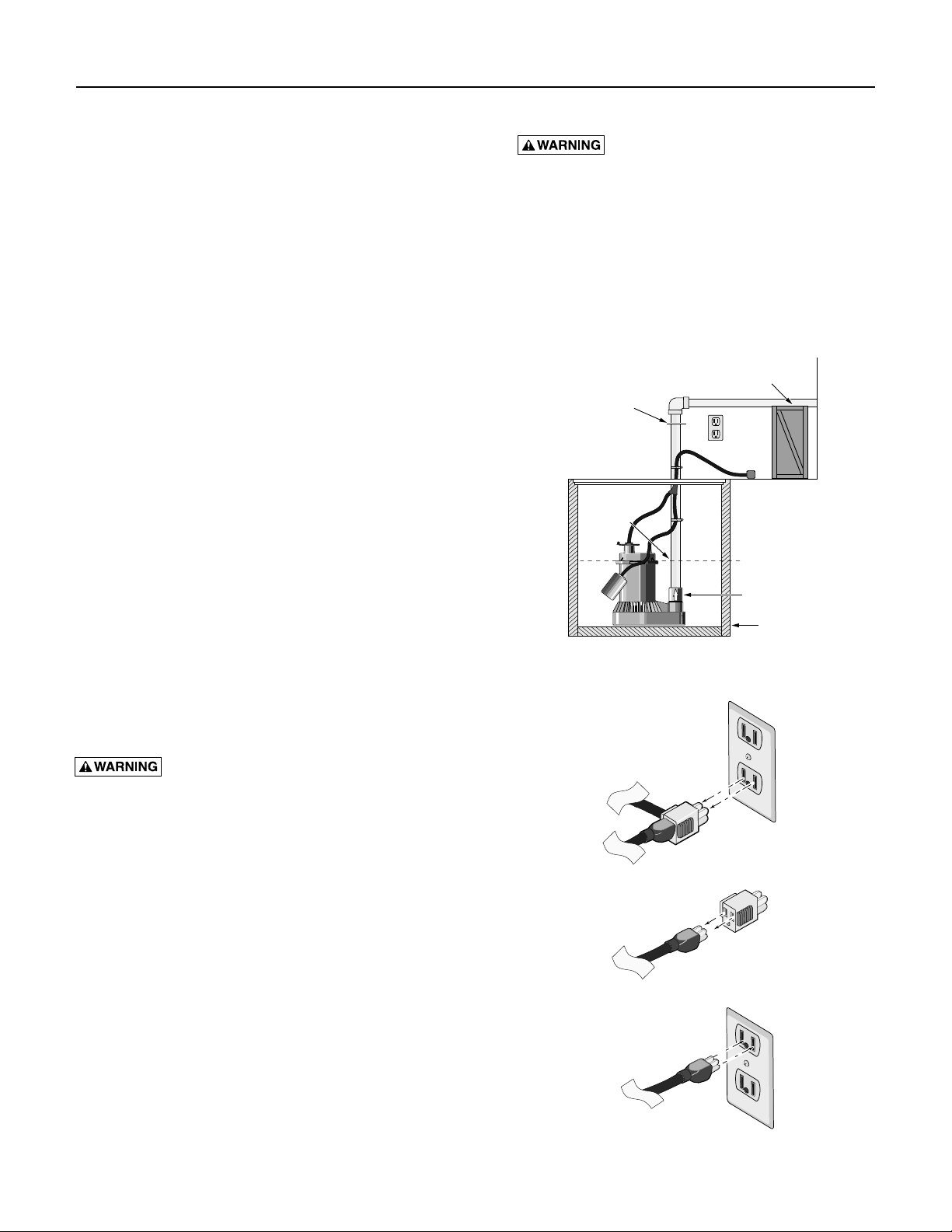

Installation 4

BATTERY BACKUP SYSTEM

INSTALLATION AND OPERATION

NOTICE:

• Install this system during a time when the primary

pump will not be needed. Gather all supplies before

starting. Read all warnings and installation steps

before you start.

• Bepreparedforwatertoleakfromthecouplingor

piping when disassembling or cutting the discharge

pipe. Protect system components, tools and supplies

from getting wet. Dry any work areas that get wet.

BASIC TOOLS AND

MATERIALS NEEDED

Channel locks or large pliers

Tape measure

Socket wrench or 5/16" Nut driver

Side cutters

Hacksaw (to cut PVC pipe)

Medium size pliers

Pencil

PTFE pipe thread sealant tape

PVC glue (solvent weld)

PVC pipe cleaner

Cloth towel

Size 24M Marine Deep Cycle Battery (sold separately)

or a

Size 27M Marine Deep Cycle Battery (sold separately)

Required Battery Capacity:

FG100-A1 – 100 ampere-hour maximum.

FG200-A1 – 130 ampere-hour maximum.

Personal injury and flood hazard. Do not

turn the pump on until all the fittings are glued and the

glue has dried. Loose fittings can explode off of pipes

and cause personal injury and flooding.

Remove Primary Pump From Sump Pit:

1. Locate the “on” water level of the primary sump

pump. Mark this location on the discharge pipe with

a pencil. See Figure 1.

2. Drain the sump pit. The water level must be pumped

down as low as possible before going on to the next

step. To drain the sump pit follow either step “2A” or

“2B” (below).

2A. Raise the float on the float switch until the

2B. If the sump pump has a piggy-back type power

pump turns on. Use a wooden broom handle or

a stick to do this.

cord, remove the float switch power cord plug

from the outlet and plug the pump power cord

plug directly into the outlet. See Figure 2.

Electrical shock hazard. Shock can

burn or kill. Do not use metal or any other electrical

conducting material to raise the float. Do not make

contact with the water in the sump pit. Failure to

follow this warning can result in personal injury or

death.

3. Drain the sump.

NOTICE: Do not let the pump run dry. This will

damage the pump.

4. Unplug the pump.

Support the

Pipe before

cutting.

'Turn on'

water level of

Primary Pump

Check

Valve

Sump Pit

Grounded

Electrical

Outlet

4166 0402

Remove the

hose coupling

or mark the

1st cut here.

Mark pipe with

pencil here

(2nd cut).

Figure 1 – Mark and cut pipe as shown

1.

Unplug the "Piggy-back"

float switch cord plug and

the pump power cord plug

from the grounded

electrical outlet.

2.

Separate the float switch cord plug

from the sump pump cord plug.

3.

Plug the pump power cord plug

directly into the outlet.

Figure 2 - To bypass the float switch

Page 5

Installation 5

Backup Pump Installation

5. To separate the primary pump from the discharge pipe:

5A. For applications with hose couplings: remove

the coupling clamps with a nut driver.

5B. For applications without rubber couplings: cut

the PVC discharge pipe with a hacksaw above

the basement floor, at a comfortable level. New

rubber couplings are included for reassembly.

See Figure 1 on Page 4.

NOTICE: The discharge pipe is filled with water.

Drain the water from the discharge pipe assembly.

Keep the work area dry.

Risk of pinching hands or fingers. To

avoid a hand injury from a collapse of plumbing,

support the pipe above the separation before cutting

or disassembly. See Figure 1.

6. Lift the primary pump and discharge pipe assembly

out of the sump.

Risk of electrical shock. Do not lift the

pump by the electrical cord; lift pump only by the

lifting ring, discharge pipe, or handle on the pump.

Lifting by the cord can damage the cord.

INSTALL BACKUP PUMP

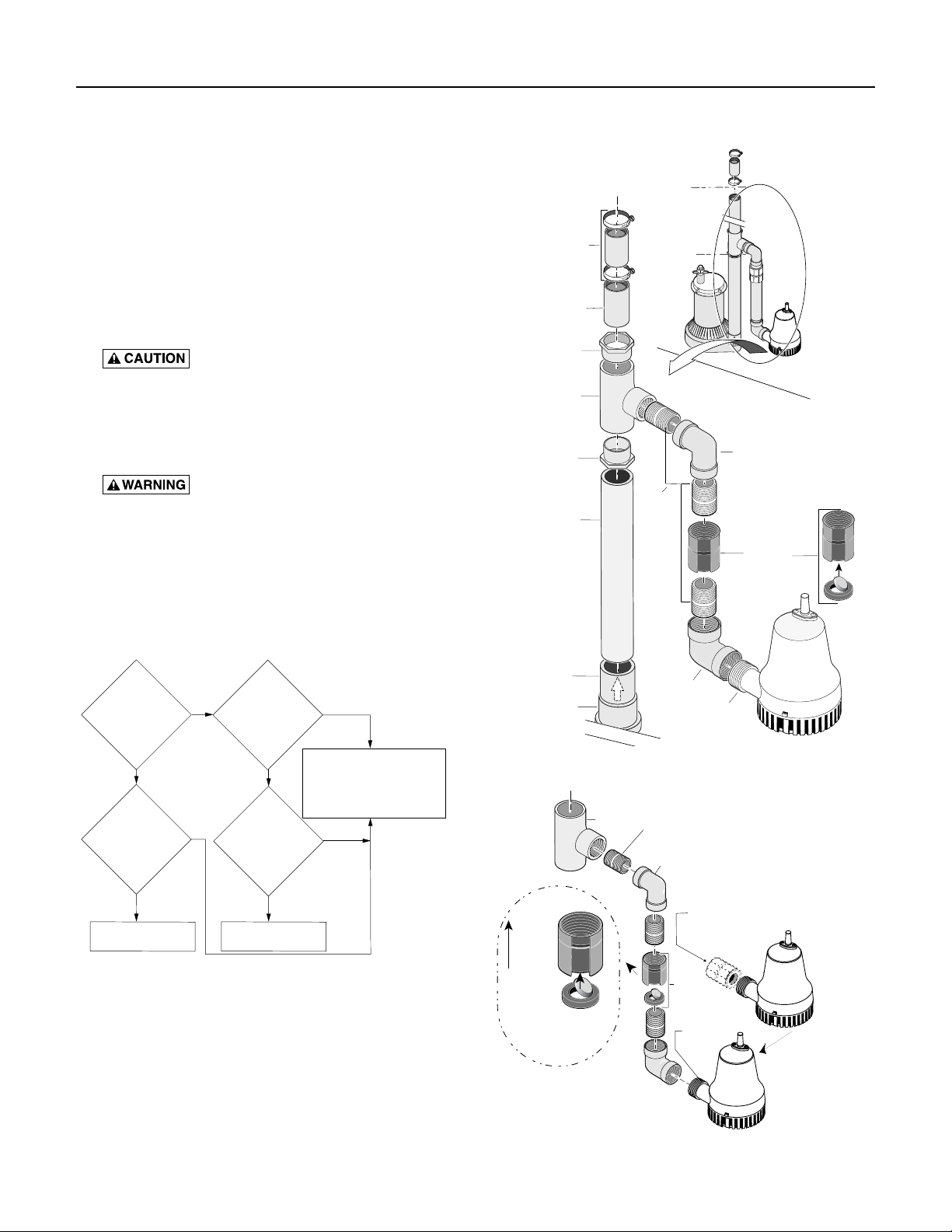

There are two ways to install the Battery Back-up Pump.

Method A and Method B. See Figure 3 to determine

which method to use. Both methods are acceptable.

Not to Scale

Switches and

Wiring omitted

for clarity

Hose Coupling

with Clamps

Cut-Off piece of

discharge pipe.

1-1/2"x1-1/4"

Reducer bushing

Tee

1-1/2"x 1-1/2"

slip x 1-1/4" FNPT

1-1/2"x1-1/4"

Reducer

bushing

Short Length

of Discharge Pipe

(may vary)

Primary Sump

Pump Check Valve

to prevent

recirculation

into the sump.

(Method A)

First Cut:

Second Cut:

at Marked

Water Line

Close

Pipe

Nipple

(1-1/4"

x 1-1/4")

(1 Nipple

is included

with the

back-up

pump

package)

1-1/4" Elbow

Check Valve

Assembly

Sump Pit

Diameter at

base at least

18"?

Yes

Sump Pit Depth

18-22"?

Yes

Method A

No No

Sump Pit

Diameter at

base at least

13.5"?

Sump Pit Depth

at least 22"?

No

Method B

BBU System may still

Yes

be installed but the

installation may need

to be changed.

Yes

No

Figure 3 - Choose an installation method

Method A

Method A suggests installing both of the pumps on the

floor of the sump pit. See Figure 4. The minimum required

sump basin diameter, at the bottom of the pit and the

recommended depth of the sump basin is 18".

Some additional materials you will need are 2 1-1/4" 90°

elbows and 2 1-1/4" close pipe nipples.

1-1/4"

Elbow

Primary Pump

Discharge Port

Back-up Pump

Discharge Port

Figure 4 - Method A installation diagram

Close

Pipe

Nipple

Elbow

Check

Valve

Assembly

Battery Back-up Pump comes

preassembled with the check

valve assembly installed on the

discharge.

Remove this check

valve assembly.

Back-up Pump

Discharge

Water

Flow

through

valve

(The valve

flap opens

away from the

pump outlet)

Tee

Figure 5 - Remove the pre-assembled check valve

Page 6

Installation 6

1. Make the second cut in the discharge pipe at the

pencil mark as shown in Figure 1 on page 4, and

in Figure 4, on Page 5. Clean the pipe ends with a

cloth towel and set the cut-off piece of discharge

pipe aside.

2. Remove the check valve assembly (Key No. 4 on

Page 15) from the battery back-up pump (Key No. 5)

discharge and set it aside. See Figure 5. The check

valve assembly will be used later, during assembly.

3. Thread a 90° elbow (purchased locally) onto the

discharge of the back-up pump.

4. Wrap the threads of all 3 of the close pipe nipples

(Key No. 3) with 2 turns of PTFE pipe thread sealant

tape and thread one of them into the elbow. Set the

other 2 aside.

5. Thread the check valve assembly, removed back in

step 2, onto the close pipe nipple.

NOTICE: Make sure the check valve is installed in the

correct direction. See the inset drawing in Figure 5.

6. Thread a close pipe nipple into the other end of the

check valve.

7 Thread the second 90° elbow onto the pipe nipple.

8. Thread the last pipe nipple into the elbow.

9. Thread the tee onto the pipe nipple and set this

assembly aside.

10. Install a short length of pipe into the top of the check

valve in the primary pump discharge. See Figure 6.

NOTICE: There must be a check valve installed in

the Primary Sump Pump discharge pipe between the

tee and the Primary Sump Pump. This will prevent

recirculation into the Primary Pump when the

Backup Sump Pump comes on.

11. Slip a reducer bushing (Key No. 2A) onto the end of

the pipe coming from the primary pump discharge.

Do not glue this connection yet.

NOTICE: If your discharge pipe diameter is 1-1/4",

you will need to glue the reducer bushings into the

tee first and then slip the cut off piece of discharge

pipe into the bushing.

12. Slip the tee and the back-up pump subassembly onto

the reducer bushing.

13. Glue the cut off piece of pipe into the top of the

reducer bushing in the top of the tee.

14. Mount the float switch assembly (Key No. 7) loosely

to the discharge pipe with the cable ties (Key Nos.

7A & 7B). See Figure 6. Approximately 2.5” (63.5

mm) of cord length should be left between the

float and the clamp. Do not tighten the cable ties.

Adjustments may be needed later.

15. Skip to the section “Cut the Discharge Pipe”, Page 7.

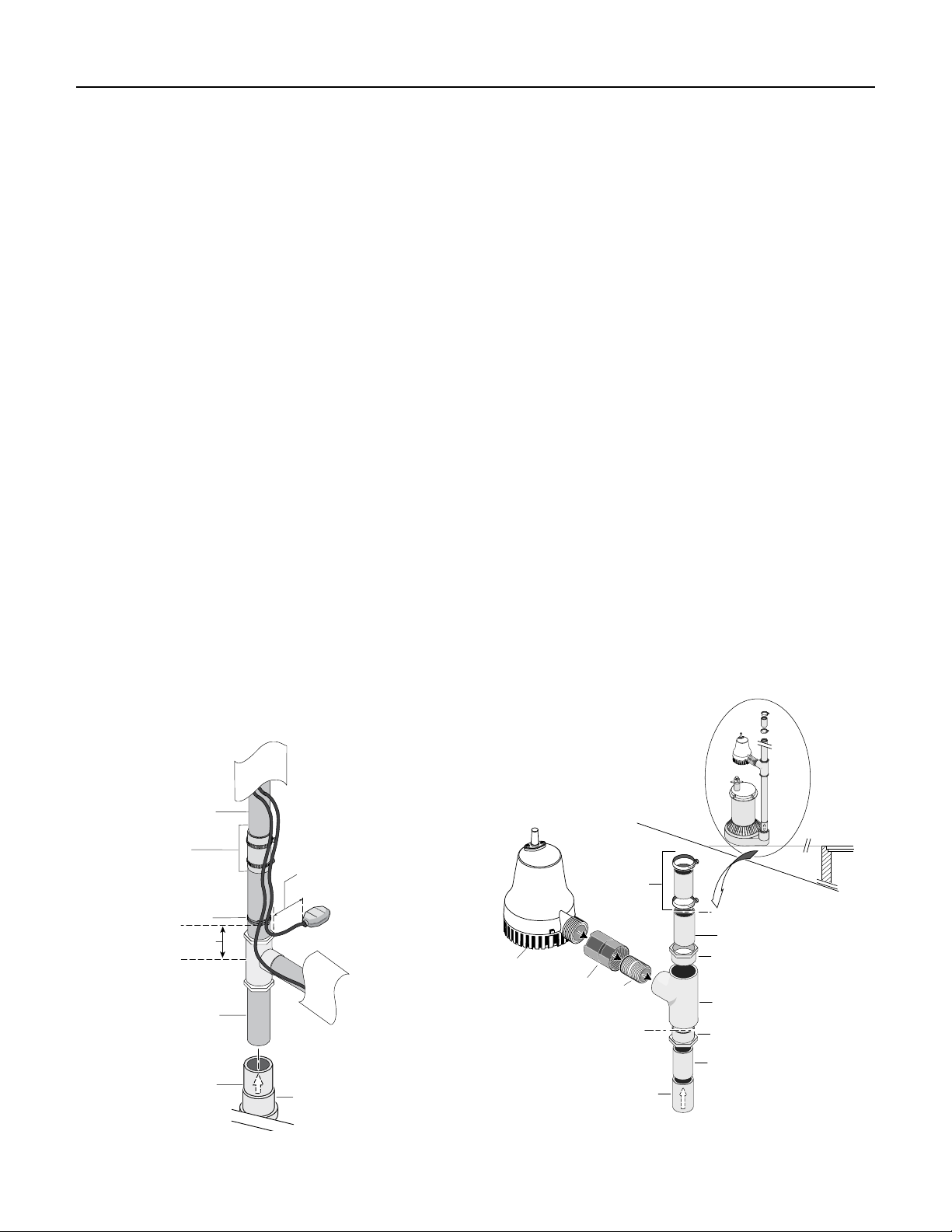

Method B

Method B suggests installing the back-up pump above

the primary sump pump. See Figure 7. The minimum

required sump basin diameter for this type of installation

is 13.5" at the bottom of the pit, and the minimum

recommended depth of the basin is 22".

1. Make a second cut in the discharge pipe at the pencil

mark made in step 1, on Page 4, and set the cut-off

piece of discharge pipe aside. See Figures 1 and 7.

Backup Pump Installation

(Method B)

Discharge

Pipe

Hose

Coupling

and Clamps

Cable Ties

2" Minimum

Te e

Short length

of discharge

Pipe (length

may vary).

Check valve

Float Switch

Tether Length

2.5" (63.5 mm)

To the

back-up

pump

discharge

pipe.

Primary Sump

Pump Discharge

Pipe

Figure 6 - Back-up pump float switch tether length and

discharge pipe

Not to Scale

Switches and

Wiring omitted

for clarity

Hose Coupling

with Clamps

First Cut:

Cut-Off piece of

discharge pipe.

Backup

Sump

Pump

Check Valve

Assembly

(Included)

Primary Sump Pump

Check Valve to Prevent

Recirculation into Sump

Close

Pipe

Nipple

Second Cut:

at Marked

Water Line

1-1/2"x1-1/4"

Reducer

Bushing

Tee

1-1/2"x1-1/4"

Reducer

Bushing

Primary Pump

Discharge Pipe

Figure 7 – Method B installation diagram

Basement

Floor

Sump

Pit

Page 7

Installation 7

2. Wrap the threads of the close nipple (Key No. 3 on

Page 12) counterclockwise with 2 turns of PTFE pipe

thread sealant tape and set aside.

NOTICE: There must be a check valve installed in

the Primary Sump Pump discharge pipe between the

tee and the Primary Sump Pump. This will prevent

recirculation into the Primary Pump when the

Backup Sump Pump comes on.

3. The backup pump (Key No. 6) and check valve

assembly (Key Nos. 4 and 5) come preassembled.

Thread the close pipe nipple into the check valve.

4. To thread the tee (Key No. 2B - also included

reducer bushings) into the close nipple:

Hold the check valve assembly with the channel

locks, insert the screwdriver into the tee for leverage,

and tighten the tee with the screwdriver. Finish with

the tee in a straight up and down (vertical) position.

5. Clean the pipe ends with the cloth towel.

6. Glue the cut-off piece of discharge pipe into the top

of the tee.

NOTICE: If your pipe is 1-1/4", you will need to

glue the reducer bushings into the tee and glue the

pipe into the bushing. Place the assembly onto the

primary discharge pipe. Do not glue the tee onto the

primary pump discharge pipe.

7. Mount the back-up pump float switch assembly (Key

No. 7) loosely to the discharge pipe with the cable

ties (Key Nos. 7A & 7B). See Figure 6, on Page 6.

Approximately 2.5" (63.5 mm) of cord length should

be left between the float and the clamp. Do not

tighten the cable ties. Adjustments may be needed

later.

Cut the Discharge Pipe:

1. Put the double pump assembly into the sump pit.

NOTICE: The discharge pipe now overlaps the

discharge pipe that leads outside.

Method A Method B

Exterior

discharge

pipe

Make the Third Cut

(the overlap plus

the 1/4" air gap).

overlap

1/4" air gap

overlap

Exterior

discharge

pipe

Sump basin

inlet pipe (from

drain tiles to

sump basin).

2"

Recommended Minimum

2"

Previously marked

"on" water level

of Primary Sump Pump.

(See Figure 1, Page 4)

2. Mark the discharge pipe where it should be cut. Be

sure to leave a 1/4" air gap between the ends of the

pipes. This gap will absorb the noise from vibration

and allow for flexibility.

3. Make the third cut. See Figure 8.

TRIAL ASSEMBLY OF DOUBLE PUMP

ASSEMBLY IN THE SUMP PIT:

1. Connect the discharge pipe to the exterior discharge

pipe with the rubber coupling and clamp kit (Key

No. 1). Do not tighten the clamps until all the final

adjustments are complete.

2. Make the final adjustments. Make sure the pumps

and the switches do not interfere with each other.

Make sure there is plenty of room for the float

switches to either swing or to move up and down

from their “off” to their “on” positions.

Mark and Glue Assembly:

1. Mark the pipe and the fittings at all the connections

with a pencil. These marks will be used as a

reassembly guide while gluing to be sure everything is

still in the right place and nothing has moved.

2. Loosen the rubber coupling and clamp connection.

3. Carefully pull the double pump assembly back out of

the pit.

4. Take the tee assembly off of the primary discharge

pipe. Do Not unscrew any of the PTFE pipe thread

sealant taped pipe nipple connections.

5. Clean all the PVC pipe ends with the PVC cleaner.

and cleaner manufacturers instructions. Use the PVC

cement in a well ventilated area away from fire or

flames.

6. Glue the PVC fittings where indicated by the pencil

marks. Wait 10 minutes for the glue to cure.

Final Assembly:

1. Put the double pump assembly back into the pit.

2. Install and tighten the rubber coupling and clamp kit.

3. Make the final float switch adjustments and tighten

the cable ties.

Hazardous fumes. Follow the cement

Note: Always install the back-up sump pump as close

to the bottom of the sump pit as possible.

Figure 8 – Make the third cut to remove the excess

discharge pipe

Page 8

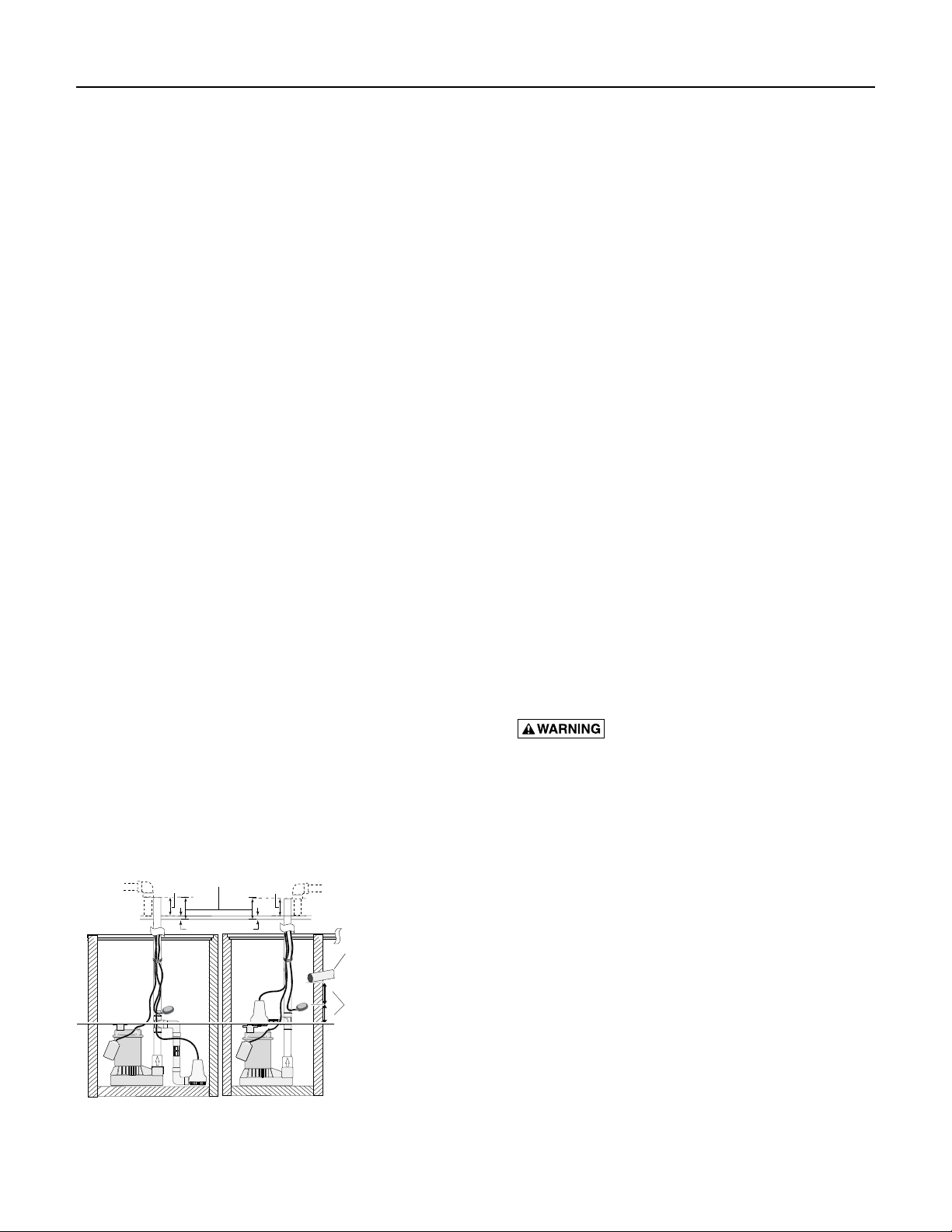

Installation 8

ELECTRICAL CONNECTIONS

Hazardous voltage. Can cause serious or

fatal electrical shock. Review safety instructions before

operating charger. Do not modify cord or plug.

4 STAGE LEAD-ACID

BATTERY CHARGER

BLACK TERMINAL NEGATIVE (-)

RED TERMINAL POSITIVE (+)

COMPLETE

CHARGE

FAULT

BATTERY CONNECTION

+

–

CHARGER CONNECTION

+

–

FLOAT SWITCH CONNECTION

REPLACE FUSE WITH SAME 25 AMP 36V TYPE AND RATING ONLY

PUMP FUSE &

CONNECTION

+

–

DISABLE ENABLE

AUDIBLE ALARM

DISABLE WHEN LIT

BATTERY CONNECTION

+

CHARGER CONNECTION

+

FLOAT SWITCH CONNECTION

REPLACE FUSE WITH SAME 20 AMP 36V TYPE AND RATING ONLY

PUMP FUSE &

CONNECTION

+

–

–

20

–

CHARGER/BATTERY INSTALLATION

NOTICE: An alarm, located in the junction box,

automatically sounds when the system runs if the alarm

is in the “Enable” position. The alarm is silenced when

the alarm switch is in the “Disable” position.

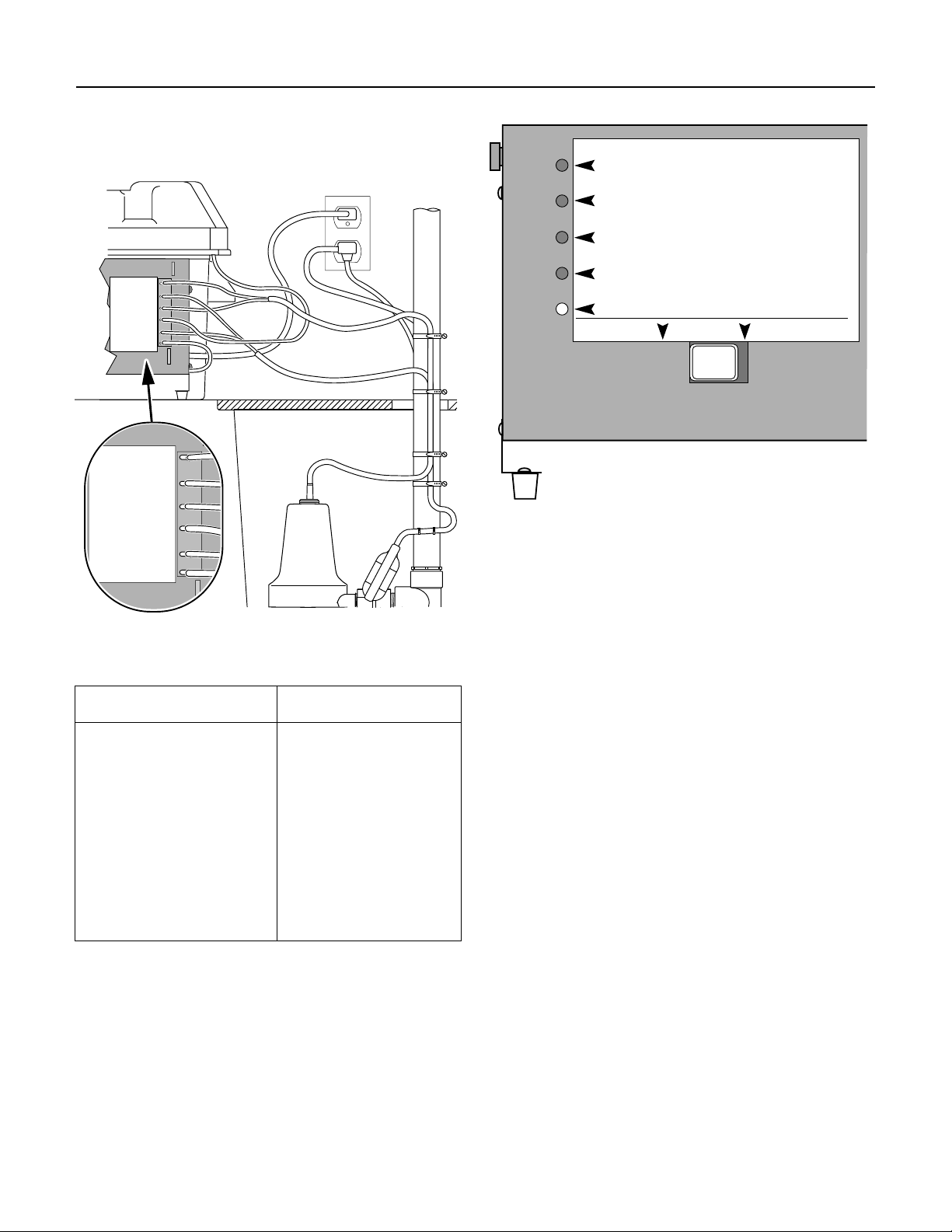

Model Number FG100-A1:

1. Apply two pieces of two-sided tape (provided, Key

No. 9) to the back of the junction box. Press the

junction box onto the battery box as illustrated in

Figure 9 and on Page 15 (Exploded View).

2. Connect the charger as shown in Table I and

Figure 9.

3. Plug the charger into a 115-120 Volt AC outlet

deliv er ing at least 15 amps. Do not use a switch

controlled outlet. Mark circuit in main power panel

“Backup sump pump power supply; do not turn off”.

4. With the charger properly connected and plugged in,

the panel on the front of the charger will show one

of the conditions illustrated in Figure 10.

Red LED - AC power is present

DISABLE ENABLE

AUDIBLE ALARM

DISABLE WHEN LIT

Figure 9 – Wiring Connections FG100-A1

TABLE I - FG100-A1 Wiring Connections

Connect the To the Junction Box’s

Positive (+) lead from the battery Positive battery connection

Negative (–) lead from the battery Negative battery connection

Positive lead from the charger Positive charger connection

Negative lead from the charger Negative charger connection

Backup sump pump Float switch

float switch (2 wires) connection (2 wires)

Positive lead from the pump Positive pump connection

Negative lead from the pump Negative pump connection

Red

Green

Yellow

Figure 10 – FG100-A1 LED Panel

Yellow LED - Prequalification test stage is complete and testing

or charging in process

Green/Occasional Yellow - Charger turns on intermittently to

maintain proper charge

Green LED - Charging complete

Green/Yellow LEDs Alternately Flashing - System is in Error Mode

(see Table II, Page 9)

NOTICE: For more detailed information, see “Charger Operation” on

Page 13.

Page 9

Installation 9

TABLE II - 800 mA Charger Error Table (Green and Yellow LEDs will flash alternately)

Error Description Possible Causes Fix

The Battery Failed The battery is highly sulfated Replace the battery with a 12-Volt deep-cycle

Pre-Qualification Test marine battery

The charger is connected to a Replace the battery with a 12-Volt deep-cycle

six-volt battery marine battery

Battery Over-Voltage The Charger is connected to a Replace the battery with a 12-Volt deep-cycle

24 Volt Battery marine battery

Charge Time Monitor Battery took too long to complete

its charge:

A. Load applied (e.g. the pump motor Be sure pump cannot start during charging;

started) during charging reset the charger

B. The battery ampere-hour rating Replace with correct size battery (see Page 4)

is too large (Max. 96 ampere-hours)

Excessive Battery Pump motor ran during charging Check primary sump pump. The BBU generally

Drain (that is, with the main A.C. power ON), runs only when the main A.C. power is out.

causing the system to shut down If there has not been any power outage and the BBU

has run, the primary pump itself may have failed

Reverse Battery Charger is connected backwards Reconnect Charger (+) to Battery (+)/(-) to (-)

Connection to the battery. (That is, Charger (+) to

Battery (-) and vice versa)

Battery Overheated Cells in an old battery may Replace battery with a 12-Volt deep-cycle

deteriorate with age marine battery

TABLE III - 800 mA Charger Light Indications

Charger Light On/Off/Flashing Indicates

All Lights Off System is not receiving AC power

Power (Red Light) On System is receiving AC power

Off System is NOT receiving AC power or battery leads are reversed

Charging (Yellow Light) Flashing 1x/Second Charger is running “Pre-Qualification” test (this lasts 45 seconds

to 6 hours)

On, steady Charger is either in “Constant Current” or “Constant Voltage” stage.

This may last up to 96 hours

Flashing alternately System is in an ERROR mode (see Table II, above)

with green light

Charged (Green Light) On, yellow light Off Battery is fully charged

Flashing alternately System is in an ERROR mode (see Table II, above)

with yellow light

Page 10

Installation 10

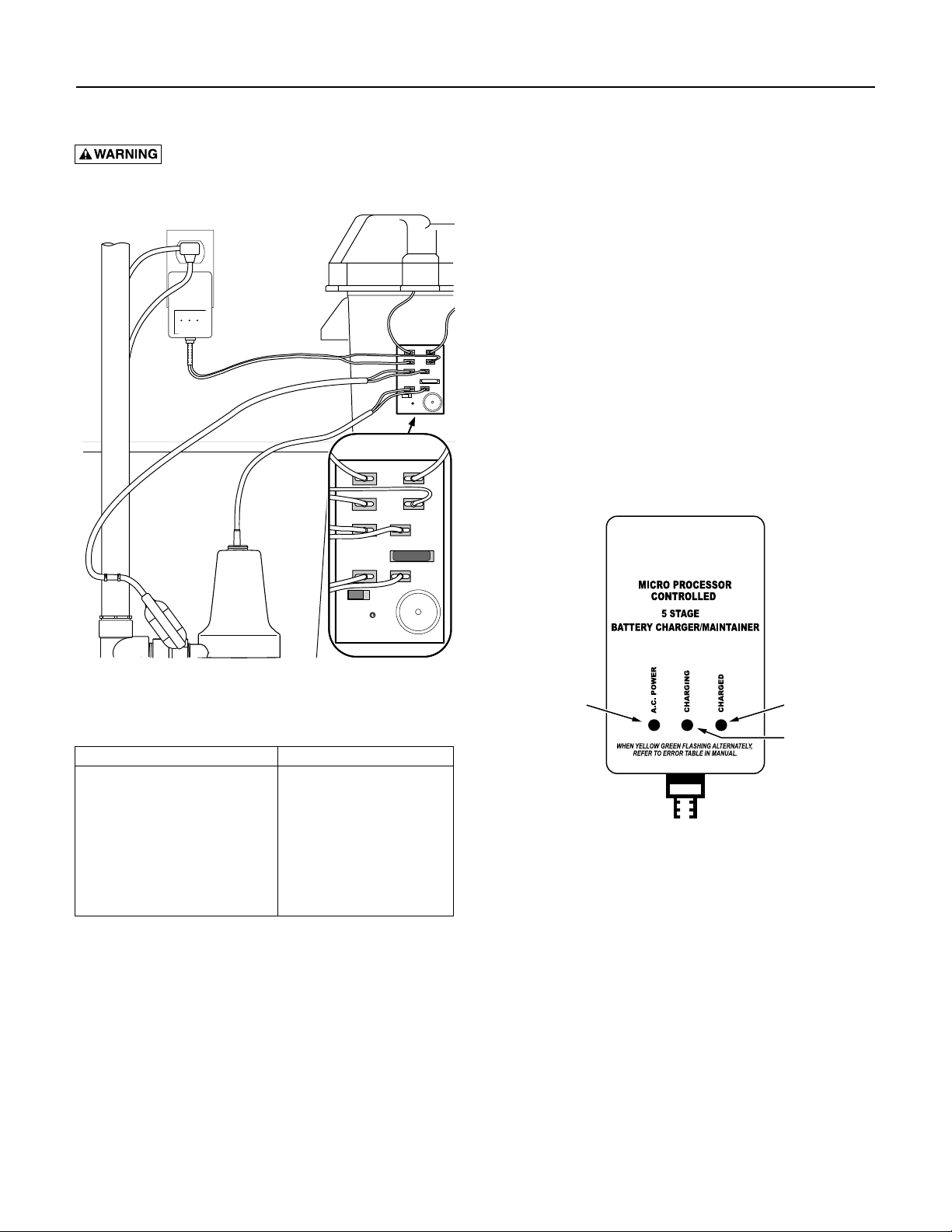

Model Number FG200-A1:

1. Connect charger as shown in Table IV and Figure 11.

A.C.POWER

STATUS

PUMP RUN

STATUS

ALARM SILENCE

ÉTAT DU COURANT ALTERNATIF.

ESTADO DE LA CORRIENTE ALTERNA.

ÉTAT DE FONCTIONNEMENT DE

LA POMPE.

ESTADO DE FUNCIONAMIENTO DE

LA BOMBA.

ARRÉT D'ALARME.

SILENCIO DE ALARMA.

PUMP/POMPE/BOMBA (+)

FLOAT/FLOTTEUR/FLOTADOR (+)

PUMP/POMPE/BOMBA (–)

BATTERY/BATTERIE/BATERÍA (–)

FLOAT/FLOTTEUR/FLOTADOR (–)

BATTERY/BATTERIE/BATERÍA (+)

PUMP/POMPE/BOMBA (+)

FLOAT/FLOTTEUR/FLOTADOR (+)

PUMP/POMPE/BOMBA (–)

BATTERY/BATTERIE/BATERÍA (–)

FLOAT/FLOTTEUR/FLOTADOR (–)

BATTERY/BATTERIE/BATERÍA (+)

Figure 11 – Wiring Connections FG200-A1

TABLE IV - FG200-A1 Wiring Connections

To the position indicated

Connect the below, on the charger

Positive (+) lead from the battery Positive battery terminal

(leads are provided)

Negative (–) lead from the battery Negative battery terminal

(leads are provided)

Positive (+) “Backup sump Pump” Positive pump lead terminal

lead (BROWN wire)

Negative (–) “Backup sump Pump” Negative pump lead terminal

lead (BLACK wire)

Positive (+) Float switch Lead Positive float switch terminal

(WHITE wire)

Negative (–) Float Switch Lead Negative float switch terminal

(BLACK wire)

BATTERY STATUS

CHARGER MODE

SILENCE

ARRÉT/SILENCIO

ÉTAT DE LA BATTERIE.

ESTADO DE LA BATERÍA.

MODE DU CHARGEUR.

MODO DE CARGADO.

ALARM

ALARME/ALARMA

RESET/RÉARMEMENT

REPOSICIÓN

3464 0799

Figure 12 – FG200-A1 LED Panel

Red “AC Power Status” LED - AC power is present

Yellow (bicolor) LED on continuously - Prequalification test is

complete and charging is in process

Yellow “Charging” LED flashing on and off quickly - Equalization

charge stage

Green (bicolor) LED is on - Battery is being maintained at full

charge

Bicolor LED flashing yellow/green alternatively - See Error

Charge Table (Table VI, Page 11)

Test the Assembly:

1. Plug the primary pump into a properly grounded

3-prong outlet.

2. Fill the sump with water to start the primary pump.

Check for leaks.

3. Unplug the primary pump and fill the sump with

water to start the backup system pump. Check for

leaks.

4. Plug the primary pump back into a properly grounded

3-prong outlet. The system is now ready for operation.

2. Plug the charger into a 115 Volt AC outlet deliv er-

ing at least 15 amps. Do not use a switch controlled

outlet. Mark the circuit in the main power panel

“Backup sump pump power supply; do not turn off”.

3. With the charger properly connected and plugged in,

the panel on the front of the charger will show one or

more of the following conditions (See Figure 12).

Page 11

Installation 11

TABLE V - 8 Amp Charger Error Table

Error Description Possible Causes Fix

The Battery Failed The battery is highly sulfated Replace the battery with a 12-Volt deep-cycle

Pre-Qualification Test marine battery

The charger is connected to a Replace the battery with a 12-Volt deep-cycle

six-volt battery marine battery

Battery Over-Voltage The Charger is connected to a Replace the battery with a 12-Volt deep-cycle

24 Volt Battery marine battery

Charge Time Monitor Battery took too long to complete

its charge:

A. Load applied (e.g. the pump motor Be sure pump cannot start during charging;

started) during charging reset the charger

B. The battery ampere-hour rating Replace with correct size battery (see Page 4)

is too large (Max. 130 ampere-hours)

Excessive Battery Pump motor ran during charging Check primary sump pump. The BBU generally

Drain (that is, with the main A.C. power ON), runs only when the main A.C. power is out.

causing the system to shut down If there has not been any power outage and the BBU

has run, the primary pump itself may have failed

Reverse Battery Charger is connected backwards Reconnect Charger (+) to Battery (+)/(-) to (-)

Connection to the battery. (That is, Charger (+) to

Battery (-) and vice versa)

Battery Overheated Cells in an old battery may Replace battery with a 12-Volt deep-cycle

deteriorate with age marine battery

Charging Error An internal error occurred in the charger Unplug the charger

during one of the charging stages

in again. If error occurs again, refer to Table VI, below

for 10 seconds and then plug it

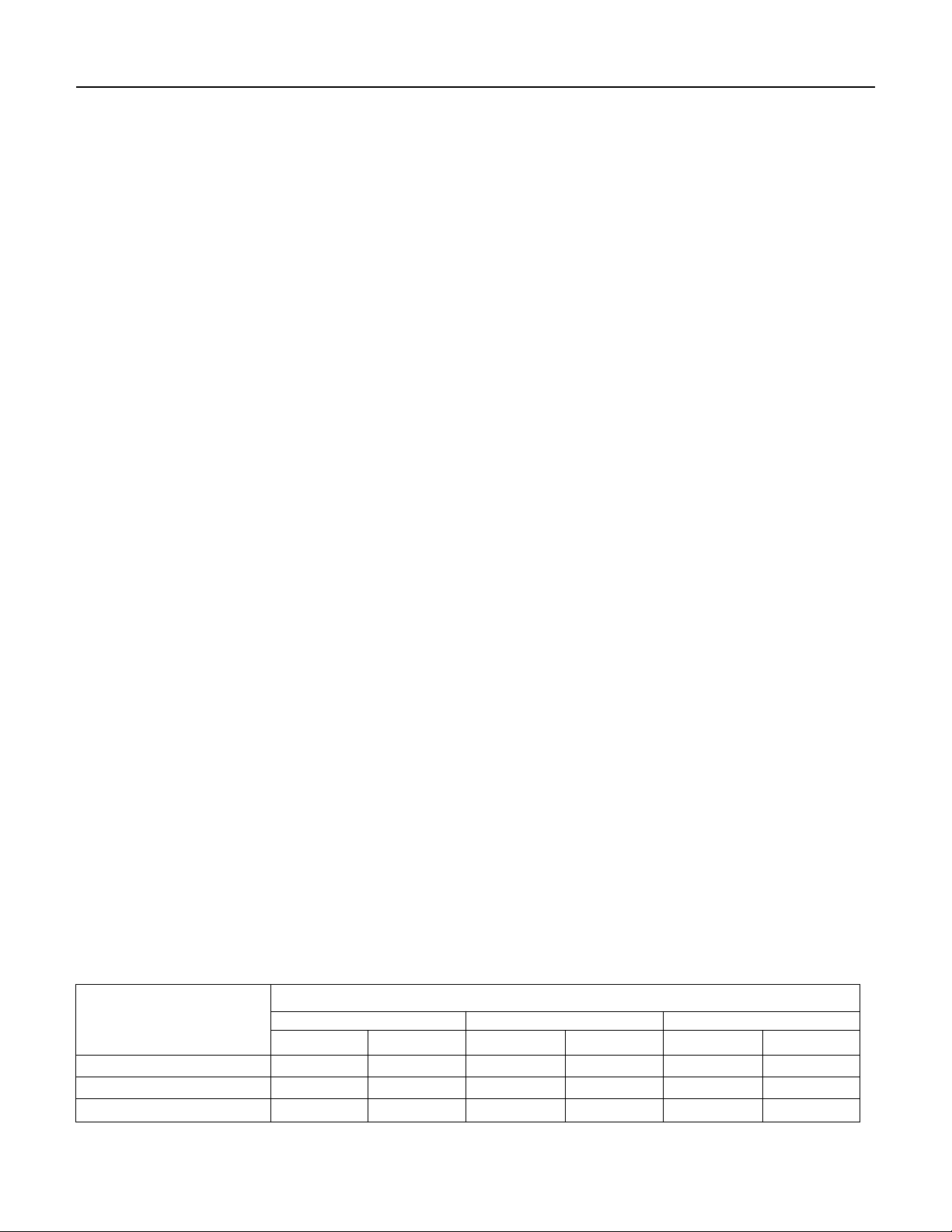

TABLE VI - 8 Amp Charger Error Light Indications

NOTE: This chart identifies light codes indicating various char-

ger error modes. It only applies when the ‘Charger Mode’ light

flashes YELLOW/GREEN alternately. The light codes listed here

DO NOT relate directly to the legends on the charger housing

A.C. Power Pump Run Alarm Charge

Status Status Silence Mode Error Mode

Flashing Off Off Flashing Yellow/Green Battery Overheated

Flashing Off Flashing Flashing Yellow/Green Charge Time Monitor

Flashing Flashing Off Flashing Yellow/Green Excessive Battery Drain

Flashing Flashing Flashing Flashing Yellow/Green Failed Pre-Qualification Test

Off Off Flashing Flashing Yellow/Green Battery Over-Voltage

Off Flashing Off Flashing Yellow/Green Reverse Battery Connection

Off Flashing Flashing Flashing Yellow/Green Output Over-Current

(A.C. Power Status, Pump Run Status, Alarm Silence, etc.). The

legends on the charger apply ONLY when the ‘Charger Mode’

light is NOT flashing yellow/green.

LED Status

“Silence Alarm/Reset” Rocker Switch:

Push the LEFT side of the rocker switch on the front of the

charger to silence the alarm. NOTE: This will NOT silence the

alarm when the battery is below 8.2 volts or the system is in

ERROR mode.

Push the RIGHT side of the rocker switch to reset the ‘Pump

System Status’ LED after the pump has run, or to reset the system from an error mode. When you reset the system, the charger will start its diagnostic procedure (pre-qualification test,

etc.) from the beginning. If the cause of the ERROR mode is not

corrected, the system will go into the ERROR mode again.

Page 12

Installation 12

TABLE VII - 8 Amp Charger Light Indications

Charger Light On/Off/Flashing Alarm Buzzer Indicates

All LEDs Flash ONCE Off Connected system to AC power or to battery; or, pressed

‘Reset’ when in ERROR mode

AC Power On Off System is receiving AC power

Status

Very Slow Flash Off System is not receiving AC power

Pump Run Fast Flash (2x/second) Beep in synch Pump is running. Press LEFT side of rocker

Status with LED flash switch to silence alarm

Slow Flash (1x/2 seconds) Off Pump has run, but is not running now

Off Off Pump has not run

Alarm Silence On Alarm is silenced

Off Alarm is active

Battery Status On Off System is not connected to a battery or is connected to a

battery charged to less than 1 volt DC

Slow Flash On Battery voltage less than 10.9 volts. Alarm

can be silenced

Fast Flash On Battery voltage is less than 8.2 volts Alarm

CANNOT be silenced

Off Off System is properly connected to a battery

Charger Mode Slow YELLOW Flash Off System is in the “pre-qualification” stage. This will last

from 1 minute to 5 hours, depending on the condition

of your battery

Solid YELLOW Off System is in the “Constant Current Charge” stage. This

will continue until the battery voltage reaches

approximately 14.3 volts

Fast YELLOW Flash Off System is in the “Constant Voltage Charge stage”. This

could last up to 14.5 hours

Solid GREEN Off Battery is fully charged

Flashing alternately On - Beeping System is in an ERROR mode. Alarm will beep in synch

YELLOW/GREEN with one or more of the ‘AC Power Status’, ‘Pump Run

Status’, or ‘Alarm Silence’ LEDs. See Tables V and VI,

Page 11, for more information

TABLE VIII - 8 Amp Charger Audio Alarm Indications

Audio Alarm Mode Indicates Action

On - Beeping Slow Beep in Synch with Battery is Investigate cause; battery is very low. You

‘Battery Status’ LED down to about have limited pump run time left. Press

10.9 Volts and release LEFT side of toggle switch to

silence alarm

On - Beeping Fast Beep in Synch with Battery is Investigate cause; battery is nearly dead.

‘Battery Status’ LED down to about You have almost no pump run time left.

8.2 Volts Alarm CANNOT be silenced

On - Beeping Fast Beep in Synch with one or more System is Refer to ERROR Mode Charts, Page 11 for

of the ‘AC Power Status’, ‘Pump Run Status’, in ERROR more information

or ‘Alarm Silence’ LEDs and with the mode

‘Charger Mode’ LED flashing alternately

YELLOW/GREEN

On - Beeping Fast Beep in Synch with Pump is None. Alarm will stop when pump stops

‘Pump Run Status’ LED running running. To silence alarm, press and release

LEFT side of toggle switch

Page 13

Operation 13

CHARGER OPERATION

The backup pump will activate automatically when the

backup sump water level rises far enough to trip the float

switch.

If the power to the charger circuit is interrupted, the

length of time that the backup pump will run depends on

the Ampere-hour capacity of the battery used, the battery

charge level, and the required vertical pumping distance.

Extended periods of operation (for example, during an

extended power outage) may exhaust the battery. The

battery charger will begin charging the battery as long as

the battery has a voltage differential of 3 Volts or more.

Recharge Time:

FG100-A1: Approximately 100+ hours to fully recharge

a 27M battery in a “dead battery condition”. The

approximate recharge time for a 24M battery is 75 hours.

FG200-A1: Approximately 19 hours to fully recharge

a 27M battery in a “dead battery condition”. The

approximate recharge time for a 24M battery is 15 hours.

Industrial standards define a “dead battery condition” as

9 Volts or less.

The 5 Stages of the Charging Process for

Model Number FG100-A1:

NOTICE: The LED’s will only illuminate once the AC

power has been applied. They will not light up if the

charger is not plugged in.

1. Yellow LED light flashing on and off indicates:

Prequalification test stage is in progress. Normal

duration of this stage ranges from 18 minutes to 27

hours. If a battery has been left in a state of discharge

for long periods this stage may require 27 hours to

determine if the battery will even accept a charge.

2. Yellow LED light continuously on indicates:

Constant current charge stage. Charger is charging

battery at the full rated output. This stage ends when

the battery terminal voltage reaches the factory preset

voltage level.

3. Yellow LED light continuously on also indicates:

Constant voltage charge stage. Battery cells are being

equalized.

4. Green LED light on indicates:

Float charge stage. Battery is charged and ready

for use. Charging has stopped. To maintain a full

charge on the battery, the yellow and green LED may

alternately turn back on. This means the charger is

briefly turning back on to keep the battery voltage

from falling below a preset voltage level.

5. Recycle charge stage:

The charger automatically initiates a charge cycle that

begins with the prequalification test stage. This occurs

once the battery has been in the float charge stage for

84 days.

The 5 Stages of the Charging Process for

Model Number FG200-A1:

NOTICE: The LED’s will only illuminate once the AC

power has been applied. They will not light up if the

charger is not plugged in.

1. Yellow “charging”(bicolor) LED flashing slowly

indicates:

A. Prequalification test stage is in progress. The normal

duration of this stage is 20 seconds to 3 minutes.

However, if a battery has been left in a state of

discharge for long periods or if the initial voltage is

less than 10.5 volts, this stage may require 5 hours

to determine if the battery will even accept a charge.

2. Yellow (bicolor)“charging” LED continuously on

indicates:

Constant current charge stage. Charger is charging

battery at full rated output.

3. Yellow (bicolor)“charging” LED flashing quickly

indicates:

Constant voltage charge stage. Battery cells are being

equalized. This could last up to 14.5 hours.

4. Green (bicolor) “charging” LED indicates:

Float charge stage. Battery terminal voltage is reduced

to a regulated voltage and battery is being maintained

at full charge.

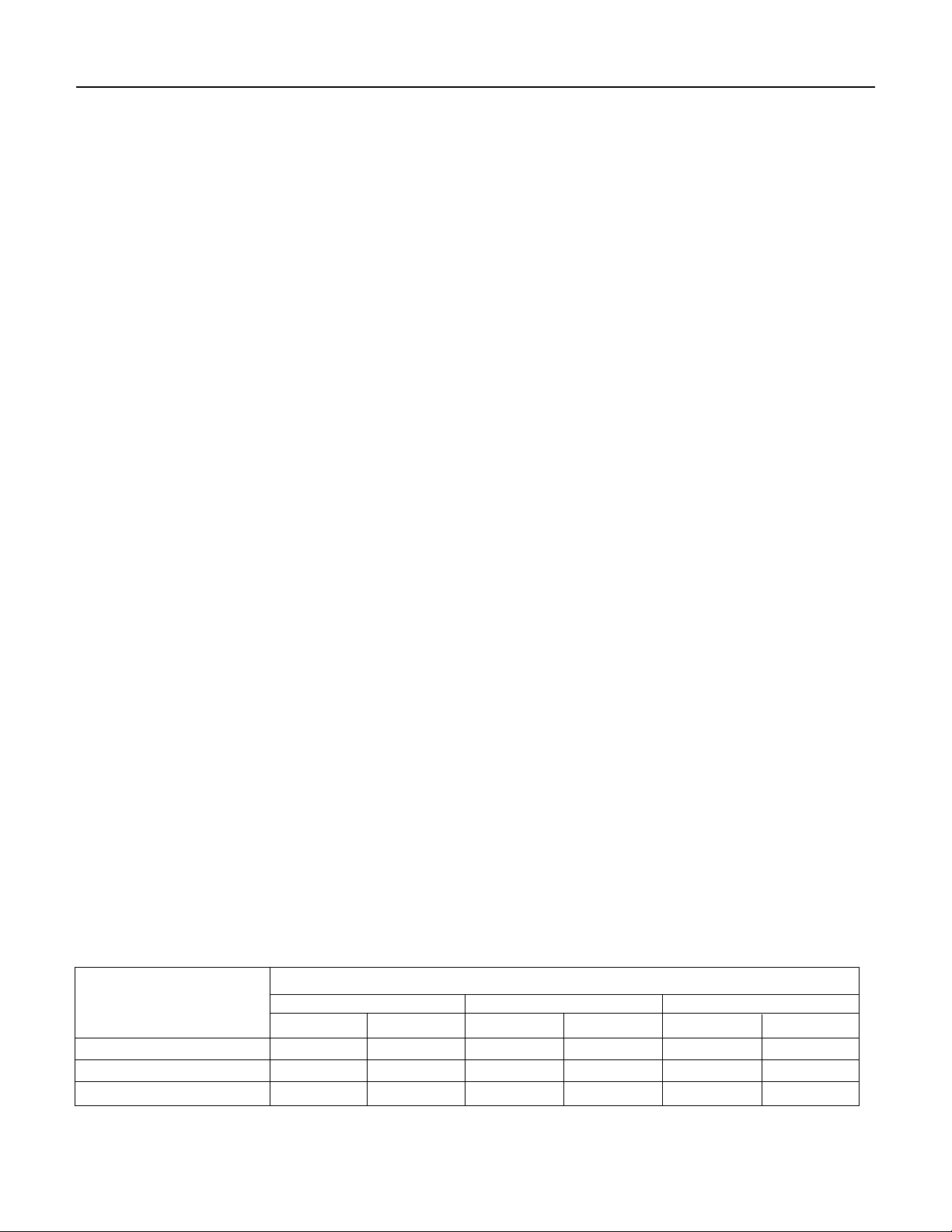

TABLE IX – Capacity Ratings with 27M Marine Battery

VERTICAL PUMPING DISTANCE

8 FEET 10 FEET 12 FEET

Model Numbers FG100-A1 FG200-A1 FG100-A1 FG200-A1 FG100-A1 FG200-A1

Gallons Per Hour 1,440 2,088 1,200 1,770 840 1,380

Hours Available 10 6.8 11 6.0 13 6.0

Total Gallons Pumped 8,500 8,500 7,000 7,000 5,000 5,000

* These flow rates were obtained with a constant 12.7 VDC battery source. The actual GPH will vary due to a reduction in output voltage from battery.

Page 14

Operation / Troubleshooting 14

5. Recycle charge stage:

The charger automatically initiates a charge cycle that

begins with the prequalification test stage. This occurs

once the battery has been in the float charge stage for

84 days.

Special Features:

• Thechargersareequippedwithreversebattery,short

circuit, and “run-away charge” protection.

• Abuilt-insafetytimerstartswhenthechargerenters

the Constant Current/Constant Voltage Charge stage

(Yellow LED is continuously on). The FG100-A1

system has a 90 hour safety timer and the FG200-A1

system has a 20.5 hour safety timer.

NOTICE: To reset the charger unplug it from the 120V

outlet for 10 seconds and then plug it back in.

BATTERY REQUIREMENTS

Hazardous electrical current. Can cause

severe burns and start a fire if battery terminals are short

circuited. Install the battery in a battery box (See Key

No. 8, Page 15). To prevent accidental shorting across

battery terminals, strap cover securely (See Figure 13) on

the battery box. Do not leave battery uncovered. Do not

allow children to play around the battery backup system

installation.

Use only the recommended battery or one of the same

type and size so it will fit in the battery box (maximum

size 12-5/8" long, 7" wide and 9-3/8" high [320.7mm

x 177.8mm x 238mm] including terminals) and supply

enough voltage for full performance.

BATTERY MAINTENANCE

Severe burn hazard. A filled battery contains

sulfuric acid. Avoid contact with skin, eyes or clothing.

NOTICE: To protect battery case from chipping and

gouging, do not let battery sit on concrete floor. Install

battery on a shelf or protective pad (plywood, 2x4s, etc.).

Always install battery in a dry location that is protected

from flooding.

Follow the battery manufacturer’s recommendations for

maintenance and safe use of battery.

TROUBLESHOOTING

Pump won’t run.

1. Check all wiring connections.

2. Check for low or defective battery.

3. Check that automatic switch is free to swing up and

down.

4. Check for a blown fuse in the junction box of the

FG100-A1 system or in the charger of the FG200-A1

system.

Figure 13 – Battery Hold-down Strap Threading

Your backup sump pump depends on the battery used

with it for power. The better the battery, the better the

performance of the pump. We recommend the use

of a size 27M Marine Deep Cycle Battery or a size

24M Marine Deep Cycle Battery. They will perform as

indicated in Table IX, on Page 13, and they stand up

well to long periods of little or no use.

NOTICE: A 24M battery will provide the same

performance as a 27M, but for a shorter length of time.

Use of a standard automobile battery, GEL type, or a

Maintenance Free (sealed) battery with this charger is

not recommended. An automobile battery may require

charging after only 1-2 hours of continuous use, and the

repeated charging cycles may cause early plate failure

in the battery. GEL-type batteries require a lower voltage

than the charger is designed for; they may overcharge.

Maintenance-free (sealed) batteries require a higher

voltage; they may never reach full charge.

Motor hums but pump won’t run:

1. Check for low or defective battery.

Pump runs but pumps very little or no water:

1. Make sure a check valve is installed and functioning

between primary pump discharge and Backup Sump

Pump tee.

2. Check for obstruction in discharge pipe.

3. Discharge pipe length and/or height exceeds capacity

of pump. See Table IX, Page 13, for pump capacity.

4. Check for low or defective battery.

5. Positive (+) and negative (–) wires are reversed.

Pump cycles too frequently:

1. Tether length too short on automatic float switch.

Make sure that tether is at least 2.5" (63.5mm); see

Figure 6, Page 6.

2. Main check valve located between discharge of

primary pump and the Backup Sump Pump tee is not

installed or is not working properly. Install or repair

as required.

Page 15

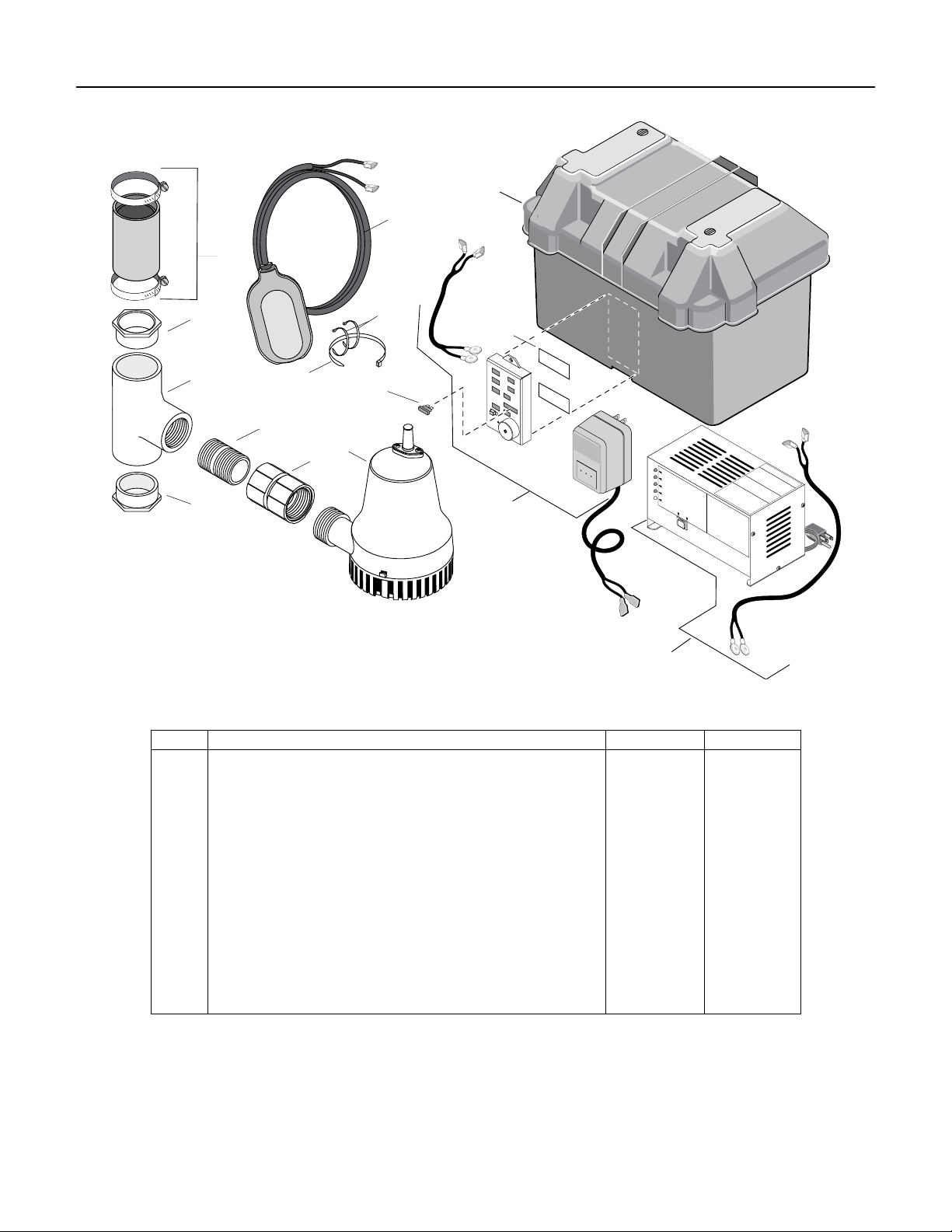

Repair Parts 15

8

7

1

2A

7A

9

U27-470

4 STA

BAT

G

E LEAD-A

TERY CHAR

CID

GER

BLACK TERMIN

RED TERMINAL POSITIVE (+)

A

L NEGATIVE (-)

COMPLETE

CHARGE

FAULT

A.C

PUMP RUN ALAR

AUDIBLE ALARM

SILENCE

LOW BA

CHARGING - YELLO

CHARGED - GREEN

AU

D

ALW

AYS READ

MANUAL BE

.PO

WARNINGS IN I

F

W

ORE

E

U

R O

SING.

NSTRU

N

CTION

MICRO PROCESSOR

M

5 STAGE BATTER

12 VOLT 8 AMP

CONTROLLED

Y CHARGE/MAINTAINER

TTERY ALAR

M

IBLE ALA

W

D

RM

ISAB

LE

ALAR

SO

M

FT R

R

ESET

ESET

2B

2A

BATTER

+

Y CONNECTION

CHARGER CONNECTION

7B

6

3

5

4

+

FLOAT SWITCH CONNECTION

REPLACE FUSE WITH SA

36V TYPE AND RA

PUMP FUSE &

CONNECTION

+

DISABLE ENABLE

AUD

DISABLE WHEN LIT

IBLE ALARM

–

–

TING ONLY

ME 25 AMP -

–

10

11

Key No. Part Description FG100-A1 FG200-A1

1 Rubber Hose Coupling and Clamps (†) U74-68 U74-68

2A 1-1/2 x 1-1/4 PVC Slip Reducer Bushing (†)(2) U78-876P U78-876P

2B PVC Tee 1-1/2 x 1-1/2 Slip x 1-1/4 FNPT (†) U78-846P U78-846P

3 PVC Pipe Nipple, 1-1/4 NPT x Close (†) U37-66P U37-66P

4 Coupling/Check Valve Assembly, 1-1/4 FNPT x 1-1/4 FNPT ZB902110 ZB902110

5 DC Backup Pump PS17-118 PS17-115

6 Replacement Fuse, - ATO 20 Amp, 12 Volt * *

7 Float Switch - 1/2HP, 8’, 16 Gauge PS17-161 PS17-161

7A Small Cable Ties (2) * *

7B Large Cable Tie * *

8 Battery Case (Complete) 24963B504B 24963B504B

9 Two Face Tape, 1/2" x 1" (†)(2) PS97-5 –

10 Charger Kit (FG100-A1) (includes wires, junction box) PS217-156 –

11 Charger Kit (FG200-A1) – PS217-119

• FittingsPackage PS198-10 PS198-11

5194 1105

† Included in Fittings Package.

†† Includes 1-1/2 x 1-1/4 Reducer Bushings (2).

††† Included with Key No. 10.

§ Included with Key No. 13.

• Notillustrated.

* Purchase locally.

Page 16

Sécurité 16

LIRE TOUTES CES INSTRUCTIONS

ET LES SUIVRE!

Ce symbole indique qu'il faut être prudent. Lorsque

ce symbole apparaît sur la pompe ou dans cette

Notice, rechercher une des mises en garde qui suivent, car

elles indiquent un potentiel possible de blessures

corporelles.

avertit d'un danger qui causera des blessures

corporelles, la mort ou des dommages matériels importants

si on l'ignore.

avertit d'un danger qui risque de causer

des blessures corporelles, la mort ou des dommages

matériels importants si on l'ignore.

avertit d'un danger qui causera ou qui

risquera de causer des blessures corporelles, la mort ou des

dommages matériels importants si on l'ignore.

Le mot NOTA indique des instructions spéciales et

importantes n'ayant aucun rapport avec les dangers.

1. Avant de procéder à l'installation de la pompe, lire

attentivement les consignes de sécurité de façon à

éviter tout risque de blessures corporelles graves

causées par des secousses électriques ou des brûlures

et des dommages matériels causés par une inondation.

L'acide de la batterie est corrosif. Ne pas

en renverser sur la peau, les vêtements, ou le chargeur

de la batterie. Porter des lunettes antiéclaboussures et un

dispositif de protection de la tête lorsque l'on intervient sur

une batterie. Brancher et ne débrancher les bornes de sortie

en courant continu qu'après avoir débranché le chargeur

de la prise de courant. Ne jamais permettre aux bornes du

courant continu de venir en contact entre elles.

électriques, de brûlures, voire de mort. Ne pas brancher ni

débrancher le chargeur de la batterie si l'on se tient debout

sur un sol humide ou dans l'eau. S'assurer de toujours

avoir une main libre lorsque l'on branche ou débranche

le chargeur. Si le plancher du sous-sol est humide, couper

l'arrivée de courant du sous-sol avant de marcher sur le sol.

la pompe à sec, sinon ses joints seront endommagés, ce qui

risquera de causer des fuites et des dommages matériels.

2. Lors de l'installation du système, respecter les codes

de la municipalité et/ou du Canada concernant la

plomberie et l'électricité. L'utilisation d'un disjoncteur

de fuite à la terre est recommandé pour tout appareil

électrique immergé dans l'eau.

3. N'utiliser cette pompe que comme pompe de puisard

de secours et qu'à des fins résidentielles. Cette pompe

n'est pas conçue comme pompe de puisard principale.

4. Ne pas soulever la pompe par son cordon électrique.

lever la pompe par son cordon électrique; ne la lever

que par le tuyau de refoulement, son anneau de levage

ou sa poignée. Lever la pompe par son cordon électrique

endommagera le cordon.

5. Ne pomper que de l'eau limpide avec cette pompe.

Tension dangereuse. Risque de secousses

Risque d'inondation. Ne pas faire fonctionner

Risque de secousses électriques. Ne pas

6. Cette pompe est à graissage permanent. Ne pas la

graisser!

7. Le chargeur et le coffre de la batterie doivent toujours

être à une certaine hauteur du plancher et placés dans

un endroit sec, frais et bien aéré.

NOTA : Si un détecteur de monoxyde de carbone

(CO) est posé, il doit se trouver à au moins 15 pieds

(4,50 m) du chargeur de la batterie de façon à éviter

des alarmes intempestives de CO. Pour de plus amples

renseignements, se reporter aux directives d'installation

du détecteur de CO.

8. Pour éviter tout risque d'incendie ou d'explosion, ne

pas approcher d'étincelles ni de flammes nues de la

batterie.

9. La hauteur de refoulement verticale maximum de la

pompe est de 16 pieds (4,9 m) dans le cas du modèle

FG100-A1 et de 18 pieds (5,5 m) dans le cas du

modèle FG200-A1.

10. S'assurer qu'il n'y a pas de débris dans le puisard.

Avertissement lié à la Proposition 65 de la Californie

Ce produit et les accessoires connexes

contiennent des produits chimiques reconnus dans l’État

de la Californie comme pouvant provoquer des cancers,

des anomalies congénitales ou d’autres dangers relatifs à la

reproduction.

RENSEIGNEMENTS GÉNÉRAUX

Le système de puisard de secours à batterie n'est pas prévu

pour remplacer une pompe de puisard principale. Le

système est prévu comme pompe de secours temporaire de

la pompe de puisard principale au cas où il y aurait panne

de courant ou tout autre problème qui pourrait empêcher

le fonctionnement normal de la pompe principale. Ne pas

utiliser ce système pour pomper des liquides inflammables

ou des produits chimiques. Ne pomper que de l'eau

limpide avec cette pompe.

Toujours garder le chargeur de la batterie au sec et toujours

le protéger contre les dommages.

Si la batterie à décharge poussée du système venait à

complètement se décharger (suite à une panne de courant

prolongée, par exemple), une batterie d'automobile pourra

être temporairement utilisée. Ne pas oublier de remettre

en place dès que possible la batterie à décharge poussée

du système. L’utilisation, avec ce système, d’une batterie

d’automobile à la place d’une batterie à décharge poussée

diminuera considérablement le rendement total du système.

Les batteries d’automobiles ne sont pas prévues pour ce

type d’utilisation et elles seront rapidement abîmées par

les cycles de charge et de décharge répétitifs. Avec ce

chargeur, ne pas utiliser de batteries à électrolyte GÉLIFIÉE

ni de batteries sans entretien (batteries étanches). Les

batteries à électrolyte GÉLIFIÉE nécessitent une charge

inférieure à celles produites par le chargeur et elles risquent

d’être surchargées. Les batteries sans entretien (batteries

étanches) nécessitent, elles, une tension plus élevée et elles

risquent de ne jamais être complètement chargées.

NOTA : Cette pompe n’est pas conçue pour pomper de

l’eau salée ni de la saumure! La garantie sera annulée si

cette pompe est utilisée pour pomper de l’eau salée ou de

la saumure.

Page 17

Table des matières 17

Page

Sécurité..............................................................................................................16

Garantie.............................................................................................................17

Installation .................................................................................................18 à 26

Fonctionnement ........................................................................................27 et 28

Recherche des pannes .......................................................................................28

Pièces de rechange ............................................................................................29

Garantie limitée

HYDROMATIC garantit à l’acheteur/au consommateur d’origine (l’Acheteur) des pompes de puisard, pompes d’effluents, pompes

d’eaux d’égout (à l’exception de la pompe de 2-1/2 po), et les systèmes ensembles HYDROMATIC, que celles-ci seront exemptes de

tout vice de matériau et de fabrication pendant la période de garantie de 36 mois suivant la date de fabrication.

Nos garanties ne s’appliquent pas aux produits ayant fait l’objet de négligence, d’une mauvaise utilisation, d’une mauvaise installation

ou d’un manque d’entretien adéquat. Sans aucune limitation des présentes, la garantie des moteurs triphasés submersibles sera nulle

et non avenue si ces moteurs sont branchés et fonctionnent sur le courant monophasé par l’intermédiaire d’un déphaseur. Il faut

également noter que les moteurs triphasés doivent être protégés par un relais de surcharge tripolaire thermocompensé à déclenchement

extrêmement rapide du calibre recommandé, sinon la garantie sera nulle et non avenue.

Le seul recours de l’Acheteur et la seule responsabilité de HYDROMATIC consistent à réparer ou à remplacer (au choix de

HYDROMATIC) les produits qui se révéleraient défectueux. L’Acheteur s’engage à payer tous les frais de main d’œuvre et d’expédition

du produit couvert par sa garantie et de s’adresser au concessionnaire-installateur ayant procédé à l’installation dès qu’un problème est

découvert pour obtenir un service sous garantie. Aucune demande de service en vertu de sa garantie ne sera acceptée après expiration

de la durée de sa garantie. Ces garanties ne sont pas transférables.

EXCEPTIONS: Les pompes pour applications spéciales, les pompes de puisard de secours à batterie, les pompes d’effluents à filtre, les

pompes broyeuses, et les pompes d’eaux d’égout de 2-1/2 po Hydromatic sont garanties pendant une période de 12 mois suivant la date

d’achat, ou une période de 18 mois suivant la date de fabrication, selon la première occurrence.

HYDROMATIC DÉCLINE TOUTE RESPONSABILITÉ POUR TOUT DOMMAGE INDIRECT OU FORTUIT QUEL QU’IL SOIT.

LA GARANTIE LIMITÉE SUSMENTIONNÉE EST EXCLUSIVE ET REMPLACE TOUTES LES AUTRES GARANTIES EXPRESSES ET TACITES, Y

COMPRIS, MAIS SANS S’Y LIMITER, LES GARANTIES DE QUALITÉ MARCHANDE ET D’ADAPTATION À UN USAGE PARTICULIER. LA

GARANTIE LIMITÉE SUSMENTIONNÉE NE DOIT PAS ÊTRE PROLONGÉE AU-DELÀ DE LA DURÉE PRÉVUE AUX PRÉSENTES.

Certains états, territoires et certaines provinces ne permettent pas l’exclusion ou la limitation des dommages indirects ou fortuits, ni les

limitations relatives à la durée des garanties tacites. Par conséquent, il se peut que les limitations ou les exclusions stipulées dans les

présentes ne s’appliquent pas dans ce cas. Ces garanties accordent des droits juridiques précis, bien que l’on puisse bénéficier d’autres

droits, selon la province, le territoire ou l’état dans lequel on réside.

La présente garantie limitée est entrée en vigueur le 1er juin 2011 et remplace toute garantie non datée ou antérieure à cette date.

HYDROMATIC

293 Wright Street, Delavan, WI 53115

Tél. : 888-957-8677 • Téléc. : 800-426-9446 • Site Web : hydromatic.com

Page 18

Installation 18

Support the

3547 1099

INSTALLATION ET FONCTIONNEMENT

DU SYSTÈME DE SECOURS À BATTERIE

NOTA :

• Installercesystèmeàunmomentpendantlequel

l'utilisation de la pompe principale n'est pas requise.

Se procurer toutes les fournitures nécessaires avant de

procéder à l'installation. Lire tous les avertissements et

toutes les opérations d'installation avant de commencer

l'installation.

• Ilfaudraêtreprêtàfairefaceàunécoulementd'eau

provenant du manchon ou du tuyau lorsque l'on

démontera ou coupera le tuyau de refoulement. Protéger

tous les composants du système, les outils et les fournitures

contre l'eau. Essuyer immédiatement la zone de travail si

elle devient humide.

OUTILS ET MATÉRIAUX

DE BASE REQUIS

Pinces à prises multiples ou grandes pinces

Ruban à mesurer

Clé à douille ou tourne-écrou de 5/16 de po

Pinces coupantes de côté

Scie à métaux (pour couper les tuyaux en PVC)

Pinces de taille moyenne

Crayon

Ruban d’étanchéité en PTFE pour filetage

Colle pour tuyaux en PVC

Nettoyant de tuyau en PVC

Chiffon

Une batterie-marine à décharge poussée,

groupe 24M (Vendue séparément) ou

Une batterie-marine à décharge poussée,

groupe 27M (Vendue séparément)

Capacité requise de la batterie:

FG100-A1 – 100 ampères-heure maximum

FG200-A1 – 130 ampères-heure maximum

Risque de blessures et d'inondation. Ne pas

démarrer la pompe tant que tous les raccords ne sont pas collés

et tant que la colle n'est pas sèche. Des raccords mal collés

risquent d'être projetés des tuyaux et causer des blessures

corporelles et une inondation.

Sortir la pompe principale du puisard :

1. Repérer à quel niveau d'eau la pompe principale

démarre. Avec un crayon, tracer ce niveau sur le tuyau de

refoulement. Voir la Figure 1.

2. Vider le puisard. Le niveau de l’eau doit être pompé le

plus bas possible avant de passer à la prochaine opération.

Pour vider le puisard, suivre soit l’opération «2A», soit

l’opération «2B» qui suivent.

2A. Lever le flotteur de l’interrupteur jusqu’à ce que la

2B. Si la pompe du puisard est équipée d’un cordon

pompe démarre. Pour cela, utiliser un manche à

balai en bois ou un bâton.

électrique muni d’une fiche à prises multiples,

débrancher la fiche du cordon électrique de

l’interrupteur à flottard de la prise de courant, puis

brancher la fiche du cordon électrique de la pompe

directement dans la prise de courant. Se reporter à

Figure 2.

Risque de secousses électriques. Les

secousses électriques risquent de brûler, voire de provoquer

la mort. Ne pas utiliser de métal ni d’autre matériau

conducteur d’électricité pour relever le flotteur. Ne pas

faire contact avec l’eau du puisard. Ne pas respecter cet

avertissement risque de causer des blessures corporelles,

voire la mort.

3. Vider le puisard.

NOTA: Ne pas laisser la pompe fonctionner à sec, sinon

elle sera endommagée.

4. Débrancher la pompe.

Déposer le raccord

Remove the

hose coupling

en caoutchouc ou

or mark the

repérer la première

1st cut here.

coupe ici.

Avec un crayon, faire

un repère ici sur le

tuyau (2

Mark pipe with

pencil here

e

(2nd cut).

coupe).

Supporter le tuyau

Pipe before

avant de procéder

cutting.

à la coupe.

Niveau d’eau de

'Turn on'

démarrage de la

water level of

pompe primaire.

Primary Pump

Clapet de

Check

non retour

Valve

Puisard

Sump Pit

Figure 1 – Repérer et couper le tuyau comme il est illustré

1. Débrancher la fiche à prises multiples

du cordon électrique de l’interrupteur

1.

Unplug the "Piggy-back"

à flotteur, ainsi que la fiche du cordon

électrique de la prise de courant mise

à la terre.

2. Séparer la fiche à prises multiples du cordon électrique de

l’interrupteur à flotteur de la

fiche du cordon électrique de

la pompe de puisard.

3. Brancher la fiche du cordon élec-

trique de la pompe directement

dans la prise de courant.

float switch cord plug and

the pump power cord plug

from the grounded

electrical outlet.

2.

Separate the float switch cord plug

from the sump pump cord plug.

3.

Plug the pump power cord plug

directly into the outlet.

Prise de

Grounded

courant

Electrical

Outlet

électrique

mise à la terre

4166 0402

Figure 2 – Pour éviter l’interrupteur à flotteur

Page 19

Installation 19

Backup Pump Installation

5. Pour séparer la pompe principale du tuyau de refoulement:

5A. Dans le cas des installations équipées d’un raccord en

caoutchouc: à l’aide d’un tourne-écrou, déposer les

colliers du raccord en caoutchouc.

5B. Dans le cas des installations sans raccord en

caoutchouc: avec une scie à métaux, couper le

tuyau de refoulement juste au-dessus plancher du

sous-sol, à un niveau pratique. Des raccords en

caoutchouc neufs sont fournis pour le remontage. Se

reporter à la Figure 1 de la page 15.

NOTA: Le tuyau de refoulement est plein d’eau. Le vider.

Garder la zone de travail sèche.

On risque de se pincer les doigts ou les

mains. Pour ne pas se blesser une main au cas où la

tuyauterie tomberait, supporter le tuyau juste au-dessus

de la séparation avant de procéder à la coupe ou au

démontage. Se reporter à la Figure 1.

6. Sortir l’ensemble pompe principale et tuyau de

refoulement du puisard.

Risque de secousses électriques. Ne

pas lever la pompe par son cordon électrique; ne la lever

que par l’anneau de levage, le tuyau de refoulement ou la

poignée de la pompe. Le cordon électrique de la pompe sera

endommagé si on lève la pompe par son cordon électrique.

INSTALLATION DE LA

POMPE DE SECOURS

Il y a deux moyens d’installer la pompe de secours à batterie.

La Méthode A et la Méthode B. Se reporter à la figure 3 pour

déterminer quelle méthode on doit utiliser. Les deux méthodes

sont acceptables.

Installation de la pompe de secours

Pas à l’échelle

Not to Scale

Les interrupteurs et le

Switches and

câblage ne sont pas

Wiring omitted

montrés pour que l’illus-

for clarity

tration soit plus claire.

Hose Coupling

Raccord en

caoutchouc

with Clamps

et colliers

Morceau de tuyau

Cut-Off piece of

de refoulement

discharge pipe.

coupé.

Bague de réduction

1-1/2"x1-1/4"

de 1 1/2 x 1 1/4 po

Reducer bushing

Té de 1 1/2 x

Tee

1 1/2 po coulissant x

1-1/2"x 1-1/2"

1 1/4 po FNPT

slip x 1-1/4" FNPT

Bague de réduction

1-1/2"x1-1/4"

de 1 1/2 x 1 1/4 po

Reducer

bushing

Petite longueur de

Short Length

tuyau de refoulement

of Discharge Pipe

(peut varier)

(may vary)

Clapet de non retour

Primary Sump

de la pompe principale

Pump Check Valve

pour empêcher que

to prevent

l’eau retourne dans le

recirculation

puisard.

into the sump.

(Méthode A)

(Method A)

Première coupe

First Cut:

Deuxième

coupe : au

Second Cut:

repère de la

at Marked

ligne d’eau

Water Line

Close

Mamelon

Pipe

de tuyau

court

Nipple

(1 1/4 x

(1-1/4"

1 1/4

x 1-1/4")

po) (1

(1 Nipple

mamelon

is included

est fourni

with the

avec la

back-up

pompe de

pump

secours)

package)

Coude de 1 1/4 po

1-1/4" Elbow

Check Valve

Clapet de

non retour

Assembly

Diamètre

du puisard à

la base ?

46 cm

(18 po)?

Non Non

Diamètre

du puisard à

la base ?

34 cm

(13,5 po)?

Le système de pompe à

Oui

batterie de secours est

Oui

peut-être déjà installé.

Toutefois, l’installation

devra peut-être être modifiée.

Profondeur

du puisard ?

46 cm

(18 po)?

Oui

Non

Profondeur

du puisard ?

56 cm

(22 po)?

Oui

Non

Méthode BMéthode A

Figure 3 – Choix et méthodes d’installation

Méthode A

La Méthode A consiste à installer les deux pompes sur le fond

du puisard. Se reporter à la Figure 4. Le diamètre minimum

requis du fond du puisard, ainsi que de sa profondeur, est de

46 cm (18 po).

Les matériaux supplémentaires dont on aura besoin seront un

coude à 90° de 2 1-1/4 po et des mamelons de tuyau courts de

2 1-1/4 po.

Coude de

1-1/4"

1 1/4 po

Elbow

Back-up Pump

Orifice de refoulement

Primary Pump

de la pompe principale

Discharge Port

Orifice de refoulement

de la pompe de secours

Discharge Port

Figure 4 – Schéma d’installation - Méthode A

Mamelon

Close

de tuyau

Pipe

court

Nipple

Coude

Elbow

Check

Clapet

de non

Valve

retour

Assembly

Orifice de

refoulement

de la pompe

de secours

La pompe de secours à batterie est

Battery Back-up Pump comes

livrée pré-assemblée, le clapet de

preassembled with the check

non retour étant déjà installé sur le

valve assembly installed on the

tuyau de refoulement

discharge.

Déposer ce clapet

Remove this check

de non retour

valve assembly.

Back-up Pump

Discharge

Sens de

Water

circulation

Flow

de l’eau

through

dans le

valve

clapet de

non retour

(The valve

(Le battant du

flap opens

clapet de non

away from the

retour s’ouvre

à l’opposé de

pump outlet)

la sortie de la

pompe)

Tee

Té

Figure 5 – Déposer le clapet de non retour installé sur la

pompe de secours

Page 20

Installation 20

1. Faire la deuxième coupe sur le tuyau de refoulement là

où le repère au crayon a été fait et illustré à la Figure 1 de

la page 15 et à la Figure 4 de la page 16. Avec un chiffon

propre, essuyer les extrémités du tuyau, puis mettre de

côté le morceau de tuyau de refoulement coupé.

2. Déposer le clapet de non retour (Réf. 4 de la page 29) de

la pompe de secours à batterie (Réf. 5); le mettre de côté.

Se reporter à la Figure 5. Ce clapet de non retour sera

utilisé plus tard, lors du remontage.

3. Visser un coude à 90° (que l’on aura acheté localement)

sur le refoulement de la pompe de secours.

4. Envelopper les filets des 3 mamelons de tuyau courts (Réf.

3) de 2 tours de ruban d’étanchéité en PTFE pour filetage,

puis visser un de ces mamelons dans le coude. Mettre

les 2 autres mamelons de tuyau courts de côté pour le

moment.

5. Visser le clapet de non retour que l’on a déposé lors de

l’opération 2 sur le mamelon de tuyau court.

NOTA: S’assurer que le clapet de non retour est installé

dans le bon sens. Se reporter à l’encadré du schéma de la

Figure 5.

6. Visser un autre mamelon de tuyau court sur l’autre

extrémité du clapet de non retour.

7. Visser le deuxième coude à 90° sur le mamelon de tuyau

court.

8. Visser le dernier mamelon de tuyau court sur le coude.

9. Visser le té sur le mamelon de tuyau court et mettre cet

ensemble de côté.

10. Poser une petite longueur de tuyau dans la partie

supérieure du clapet de non retour du refoulement de la

pompe principale. Se reporter à la Figure 6.

NOTA: Un clapet de non retour doit être installé sur le tuyau

de refoulement de la pompe de puisard principale, entre le

té et la pompe de puisard principale. Ceci empêchera l’eau

de recirculer dans la pompe principale lorsque la pompe de

puisard de secours se mettra en marche.

11. Glisser une bague de réduction (Réf. 2A) sur l’extrémité du

tuyau branché sur le refoulement de la pompe principale.

Ne pas coller ce raccordement pour le moment.

NOTA: Si le diamètre du tuyau de refoulement est de 1

1/4 po, les bagues de réduction devront tout d’abord être

collées sur le té, puis il faudra glisser le morceau de tuyau

de refoulement coupé dans la bague de réduction.

12. Glisser le té et le sous-ensemble pompe de secours sur la

bague de réduction.

13. Coller le morceau de tuyau coupé dans la partie

supérieure de la bague de réduction qui se trouve sur le té.

14. Avec des colliers (Réf. 7A et 7B), et sans les serrer, attacher

l’interrupteur à flotteur (Réf. 7) sur le tuyau de refoulement.

Se reporter à la Figure 6. Il doit y avoir environ 6,35 cm

(2,5 po) de longueur de cordon, entre l’interrupteur à

flotteur et le dernier collier. Ne pas serrer les colliers. Les

réglages seront effectués plus tard.

15. Passer à la rubrique « Coupure du tuyau de refoulement »

à la page 21.

Méthode B

La Méthode B consiste à installer la pompe de secours au-dessus

de la pompe de puisard principale. Se reporter à la Figure 7.

Le diamètre minimum requis du fond du puisard pour ce type

d’installation doit être de 34 cm (13,5 po) et la profondeur

minimum requise du puisard doit être de 56 cm (22 po).

1. Faire la deuxième coupe sur le tuyau de refoulement là

où le repère au crayon a été fait lors de l’opération 1 de

la page 18, puis mettre de coté le morceau de tuyau de

refoulement coupé. Se reporter aux Figures 1 et 7.

Installation de la pompe

de secours

Backup Pump Installation

(Méthode B)

(Method B)

Tuyau de

Discharge

refoulement

Pipe

Raccord en caoutchouc

Hose

et colliers

Coupling

and Clamps

Colliers

Cable Ties

Minimum de

2" Minimum

15 cm (2 po)

Té

Te e

Short length

Petite longueur de

of discharge

tuyau de refoulement

Pipe (length

(la longueur peut

may vary).

varier)

Clapet de

Check valve

non retour

Float Switch

Longueur du cordon de

Tether Length

l’interrupteur à flotteur

6,35 cm (2,5 po)

2.5" (63.5 mm)

Primary Sump

Tuyau de refoulement

de la pompe de puisard

Pump Discharge

principale

Pipe

:

Vers le tuyau

To the

de refoulement

back-up

de la pompe de

pump

secours.

discharge

pipe.

Figure 6 – Tuyau de refoulement et longueur du cordon

de l’interrupteur à flotteur de la pompe de secours

Pas à l’échelle

Not to Scale

Switches and

Les interrupteurs et le câblage

Wiring omitted

ne sont pas montrés pour que

for clarity

l’illustration soit plus claire

Raccord en

Hose Coupling

caoutchouc

with Clamps

et colliers

Première coupe :

First Cut:

Morceau de tuyau de

Cut-Off piece of

refoulement coupé.

discharge pipe.

Bague de réduction

Pompe de

Backup

puisard de

Sump

secours

Pump

Clapet de

Check Valve

non retour

Assembly

(fourni)

(Included)

Clapet de non retour

de la pompe principale

Primary Sump Pump

Check Valve to Prevent

pour empêcher que l’eau

Recirculation into Sump

retourne dans le puisard

Close

Mamelon de

Pipe

tuyau court

Nipple

Deuxième coupe

Second Cut:

at Marked

au repère de la

Water Line

ligne d’eau

1-1/2"x1-1/4"

Reducer

de 1 1/2 x 1 1/4 po

Bushing

Tee

Té

1-1/2"x1-1/4"

Bague de réduction

Reducer

de 1 1/2 x 1 1/4 po

Bushing

Tuyau de refoulement

Primary Pump

Discharge Pipe

de la pompe principale

Figure 7– Schéma d’installation - Méthode B

Plancher du

Basement

sous-sol

Floor

Puisard

Sump

Pit

Page 21

Installation 21

2. Envelopper, en tournant à gauche, les filets du mamelon

de tuyau court (Réf. 3, page 23) de 2 tours de ruban

d’étanchéité en ruban d’étanchéité en PTFE pour filetage,

puis mettre ce mamelon de côté.