Page 1

F2000-B2B, F2000-B2M FILTRATION SYSTEM

INSTRUCTION MANUAL

waterpurification.pentair.com

Page 2

WARNING:

SPECIFICATIONS

WARNING:

CAUTION

Temperature Range: ..................................40-100°F (4.4-37.8°C)

Pressure Range: ..................................40-100 psi (2.75-6.89 bar)

Service Flow Rate @ 60 psi (4.1 bar):

Model: F2000-B2B .......................................0.6 gpm (2.27 L/min)

Model: F2000-B2M .......................................0.6 gpm (2.27 L/min)

Rated Service Life:

Model: F2000-B2B ........................................675 gallons (2555 L)

Model: F2000-B2M ........................................675 gallons (2555 L)

Dimensions: .......................................................12.5" x 8" x 5.25"

(317mm x 203mm x 133mm)

Weight:

Model: F2000-B2B (system only) ..............................4.5 lbs (2 kg)

Model: F2000-B2M (system only) .............................4.5 lbs (2 kg)

PARTS INCLUDED

• Filter System with Cartridges

• Installation Hardware Kit

• Lead-free drinking water faucet

• 3/8" (white and blue) plastic tubing

PRECAUTIONS

Do not use with water that is microbiologically

unsafe or of unknown quality without adequate

disinfection before or after the system.

Systems certified for cyst reduction may be

used on disinfected waters that may contain

filterable cysts. Chemical and mechanical

reduction unit.

TOOLS AND MATERIALS REQUIRED

• Safety glasses

• Adjustable wrench

• Tube cutter or utility knife

• Hand or electric drill (cordless recommended)

• File

• 1/4" drill bit

If sink does not have hole for separate faucet:

• Center punch

• 3/4" drill bit or hole saw

• 3/32" drill bit

System must be protected against freezing, which

can cause cracking of the filter and water leakage.

NOTE:

• For cold water use only.

• Make certain that installation complies with all state and

local laws and regulations.

• The system must be maintained according to

manufacturer’s recommendations, including

replacement of filter cartridges. The contaminants or

other substances removed or reduced by the selected

cartridge are not necessarily in your water. Ask your

local water municipality for a copy of their water

analysis, or have your water tested by a reputable water

testing lab.

• After prolonged periods of non-use (such as during a

vacation) it is recommended that the system be flushed

thoroughly. Let water run for 5–6 minutes before using.

• The filter cartridges used with this system have a

limited service life. Changes in taste, odor, and/or flow

of the water being filtered indicate the cartridge should

be replaced.

CALIFORNIA PROPOSITION 65 WARNING

This product contains chemicals known to the

State of California to cause cancer or birth

defects or other reproductive harm.

2 • F2000-B2B, F2000-B2M Filtration Systems Instruction Manual

Page 3

INSTALLATION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

NOTE:

• For standard under-sink installation on 1/2" 14 NPS

threads or 3/8" x 3/8" compression

• Please read all instructions and precautions before

installing and using your Filtration System

• Numbered diagrams correspond with numbered steps

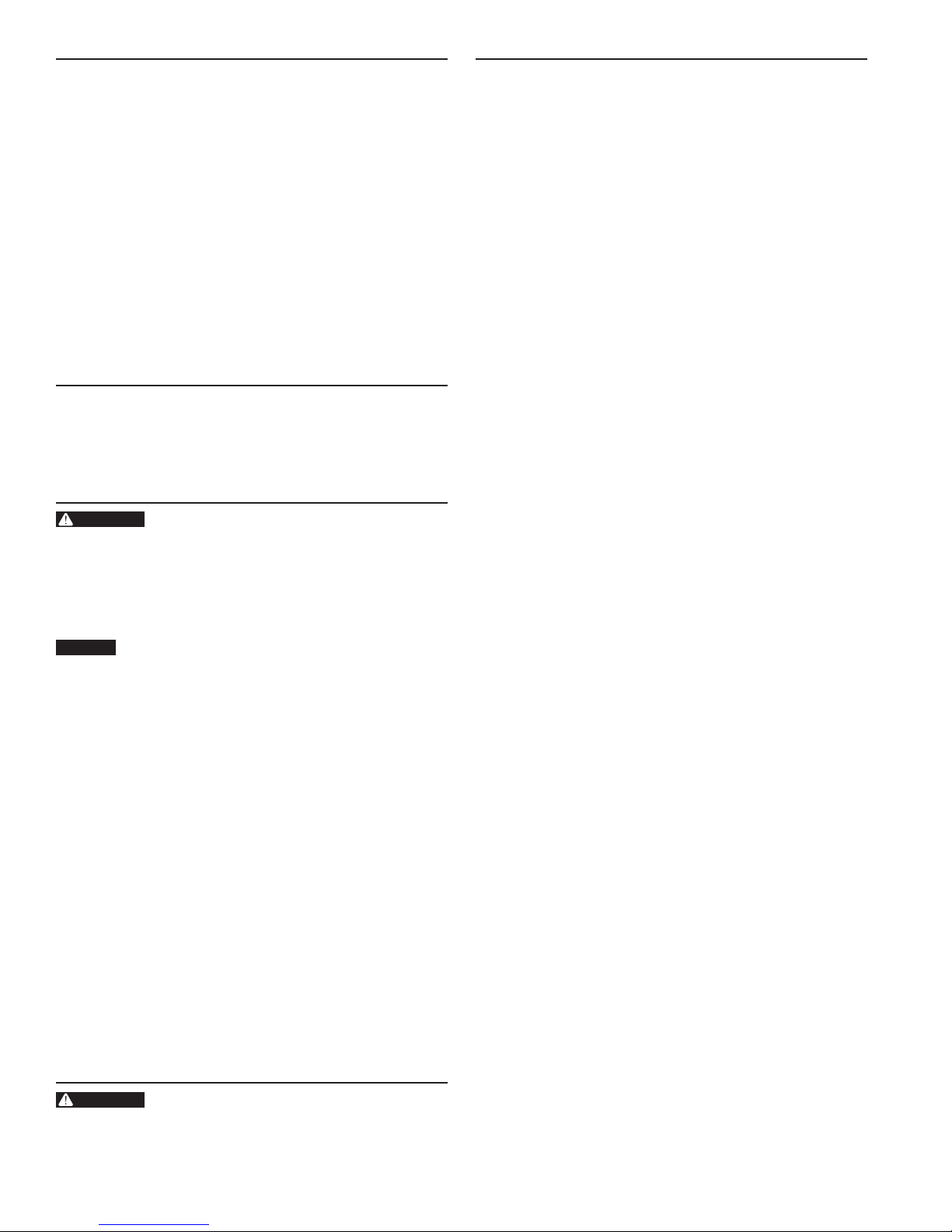

1. Installing the Water Supply Adapter

The supply adapter fits 1/2"-14 NPS supply threads or

3/8" x 3/8" compression. If local codes permit, it may be used

to connect the system to the cold water supply line. If local

codes do not permit the use of the supply adapter, alternate

connectors can be obtained from your local supplier.

A. Turn off cold water supply line. If cold water line does not

have a shut-off valve under the sink, you should install one.

B. Turn on the cold water faucet and allow all water to drain

from line.

C. Disconnect riser cold water supply valve.

D. Ensure the sealing gasket is fully seated into the feed

adapter valve female thread.

E. Install feed adapter valve onto supply valve. Hand tighten

only.

F. Connect the riser to the feed adapter valve.

NOTE: See Figures 1G-1H for configuring the feed adapter to

3/8" x 3/8" compression connections.

2. Selecting the Faucet Location

NOTE: The drinking water faucet should be positioned with

function, convenience, and appearance in mind. An

adequate flat area is required to allow faucet base to

rest securely. The faucet fits through a 3/4" hole. Most

sinks have pre-drilled 1-3⁄8" or 1-1⁄2" diameter holes

that may be used for faucet installation. If these predrilled holes cannot be used or are in an inconvenient

location, it will be necessary to drill a 3/4" hole in the

sink to accommodate the faucet.

This procedure may generate dust which can cause

severe irritation if inhaled or come in contact with

the eyes. The use of safety glasses and respirator

for this procedure is recommended.

DO NOT ATTEMPT TO DRILL THROUGH AN ALL-

PORCELAIN SINK. If you have an all-porcelain sink,

mount the faucet in pre-drilled sprayer hole or drill

through countertop next to sink.

When drilling through a countertop, make sure the

area below the drilled area is free of wiring and

piping. Make certain you have ample room to make

the proper connections to the bottom of the faucet.

Do not drill through a countertop that is more than

1" thick.

Do not attempt to drill through a tiled, marble,

granite or similar countertop. Consult a plumber

or the countertop manufacturer for advice or

assistance.

A. Line bottom of sink with newspaper to prevent metal

shavings, parts, or tools from falling down the drain.

B. Place masking tape over the area to be drilled to prevent

scratches if drill bit slips.

C. Mark hole with center punch. Use a 1/4" drill bit to drill

pilot hole.

D. Use a 3/4" drill bit and drill a hole completely through sink.

E. Smooth rough edges with a file.

1C

1G

2

1B

1A

1D

Sealing Gasket

1H

C

1

4”

D

11⁄4”

⁄

F2000-B2B, F2000-B2M Filtration Systems Instruction Manual • 3

Page 4

INSTALLATION CONTINUED

WARNING:

7” (178 mm)

16.25” (413mm)

10.75” (273 mm)

Inlet

Outlet

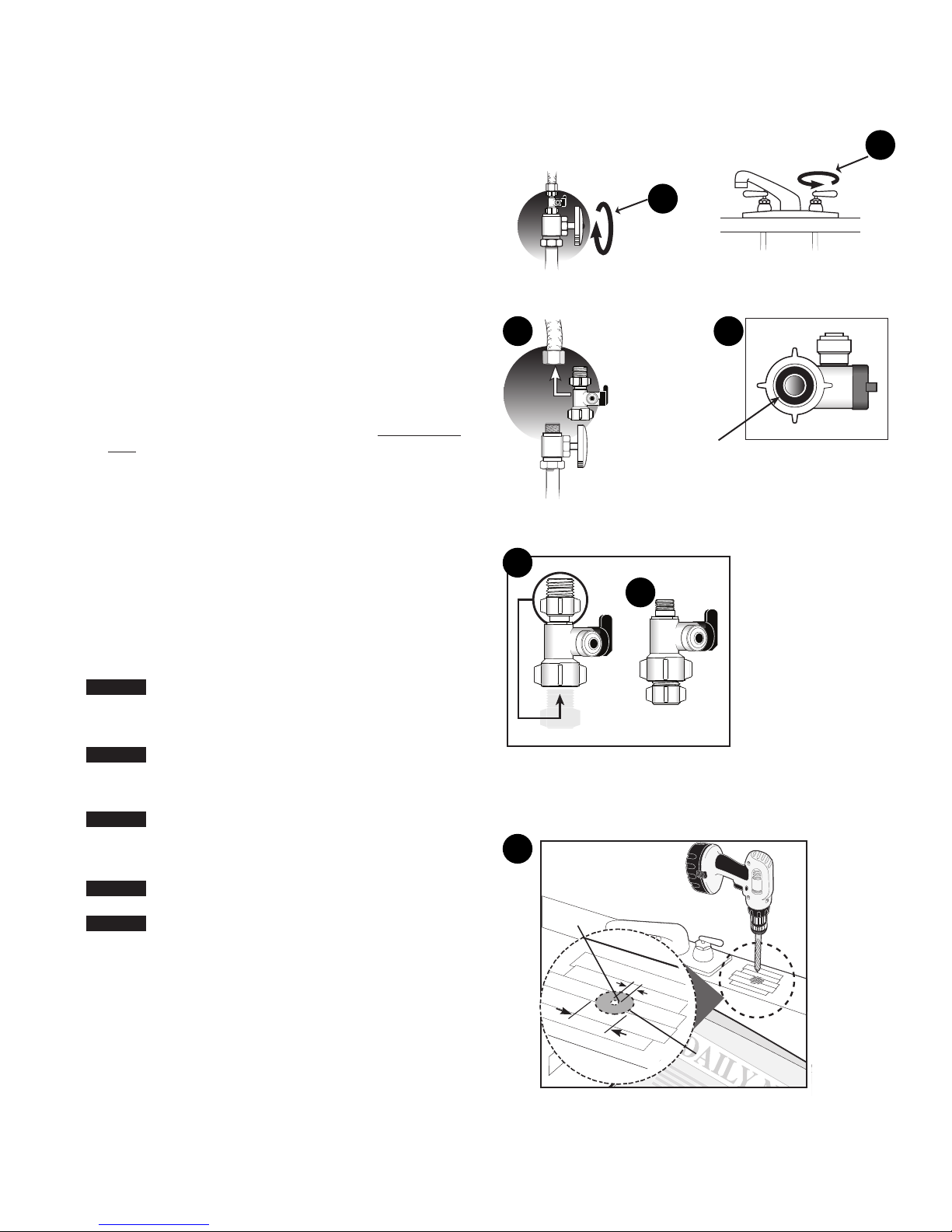

3. Mounting the Faucet

A. Apply 3-5 wraps of plumber tape to faucet stem.

B. Assemble faucet as shown in Figure 3.

C. Screw quick connector onto threaded end of faucet stem.

D. Place a mark 5/8" from one end of the blue tubing. Wet the

end of the 3/8" tube and push into bottom of connector. The

5/8" mark should be flush with the collar of the connector.

NOTE: To remove the tube, push on the fittings' collar and pull

the tube out.

E. Holding the faucet, feed the tubing through the hole in the

sink. Position the faucet handle at a desired location.

F. Center the faucet and slip slotted disc between the bottom

of the counter or sink and lock washer. Tighten the stem

nut with a wrench until it is tight.

G. Firmly insert spout into faucet base.

4. Mounting the System

A. Select a location under the sink, or other suitable area

where the system will be installed.

NOTE: The system carton can be used to determine the

operational footprint required for installation of the

system and replacement cartridges. (Figure 4a)

B. Mount the system vertically. Ensure mounting is level.

Place a pencil mark in the upper slots of the bracket

mounting holes. (Figure 4b). Alternate mounting option: If

mounting the system near the floor, place the pencil marks

above each of the mounting holes on the bracket to ensure

enough space resides below the cartridge and the floor for

cartridge replacement (Figure 4c). Use the 3/32" drill bit to

create pilot holes for mounting.

The system should be mounted to a firm, solid

surface that is able to support the weight of the

system.

3

4a

Faucet Stem

Chrome

Plate

Rubber

Washer

Slotted

Disk

Lock Washer

Stem Nut

Quick

Connector

3/8” Tubing

Count er Top

4b

Filter

4c

Filter

4 • F2000-B2B, F2000-B2M Filtration Systems Instruction Manual

Page 5

CAUTION

INSTALLATION CONTINUED

5. Connecting the Faucet to the System

A. Determine the length of plastic blue tubing needed to

connect to the outlet (right) side of the filter from the

faucet. Be sure to allow enough tubing to prevent kinking

and cut the tubing squarely. Use a marker to mark one end

of the tubing 5/8" from the end (Figure 5). Wet the end of

the 3/8" tube and push into the outlet (right) connection of

the system up to the mark.

Do not bend or crimp tube inserting.

B. Gently pull back on the tube to ensure it is connected

properly.

6. Connecting the Supply Adapter

A. Determine the length of plastic white tubing needed

to connect the inlet (left) side of the filter with the feed

adapter installed on the cold water supply line. Be sure to

allow enough tubing to prevent kinking and cut the tubing

squarely. Place a mark 5/8" from one end of the tubing. Wet

the end of the tubing. Insert the end of the tubing into the

3/8" fitting of the inlet supply adapter. The 5/8" mark should

be flush with the collar of the fitting located on the inlet

supply adapter (Figure 6a).

B. Mark the remaining end of the tubing. Use a marker to

mark 5/8" from the end. Wet the end of the tube. Insert the

end into the feed connection on the inlet side (left) of the

system. The tube should go in up to the mark. (Figure 6b).

7. Placing the System into Operation

A. Slowly turn on the cold water supply. Ensure that the feed

adapter valve is also open.

B. Open faucet and flush filter for 10 minutes. Discard water.

C. Check for leaks at all fittings before leaving installation. If

leaks appear, see Troubleshooting.

NOTE: A drinking water cartridge may contain carbon fines

(very fine black powder). If carbon fines appear in

the water, discard water. More flushing is required if

carbon fines are present.

NOTE: Initially, filtered water may appear cloudy. If

cloudiness in a glass of water disappears from the

bottom; fine air bubbles are present. This air within

the water will disappear within a few weeks after

installation.

5

6b

7

6a

INSTALLATION IS NOW COMPLETE.

F2000-B2B, F2000-B2M Filtration Systems Instruction Manual • 5

Page 6

FILTER CARTRIDGE REPLACEMENT

NOTE: The life of the filter cartridges depends on water

volume used and the quality of the feed water. It is

recommended that the filter cartridges be replaced

every 6-12 months, or when there is a noticeable

change in taste, odor, or flow of filtered water.

Ensure the correct cartridge set is purchased for

the system.

Model F2000-B2B and F2000-B2M use F2B2-RC2 Replacement

Cartridge set

8. Cartridge Replacement

A. Relieve pressure by turning off the water supply to the

system and opening a faucet until water flow stops. Place a

bucket or towel under the system to catch any water drips

(Figure 8a).

B. Remove the cover and lift the locking bar upward until the

filter cartridge disengages from the filter head assembly

(Figure 8b).

C. Pull the cartridge away from the filter head assembly

(Figure 8c).

D. Ensure the locking bar is fully in the up position (Figure 8c).

E. Align the posts on the filter cartridge with the ports in the

filter head assembly. Slide the cartridge filter towards into

the filter head assembly engaging with the locking bar

causing it to drop forward and down. (Figure 8d).

F. Pull down the locking bar until it snaps into place

(Figure 8e)

G. Install cover.

NOTE: See Placing the System into Operation section for

remaining steps.

8a

8b

8c

TROUBLESHOOTING

Leaks between filter head assembly and filter

cartridge

1. Relieve pressure by turning off the water supply to the

system and opening faucet until water flow stops. Place a

bucket or towel under the system to catch any water drips.

2. Remove cartridge and inspect O-rings to make sure they

are seated and clean.

3. Install filter cartridge. Place system into operation and

check for leaks. If leaks persist, turn off the water supply

and contact Technical Support at 1-800-279-9404.

Leaks from tubing fittings

1. Relieve pressure by turning off the water supply to the

system and opening faucet until water flow stops. Place a

bucket or towel under the system to catch any water drips.

2. Depress collet on system or inlet supply adapter tubing

fittings and pull tubing from fitting. Inspect surface of

tubing for scratches or debris. Clean or cut back tubing to

access clean surface.

3. Wet the end of the inlet tubing and press into the inlet

fitting of the system. Ensure the tubing is fully pushed past

the fitting O-rings. Place system into operation and check

for leaks. If leaks persist, turn off the water supply and

contact Technical Support at 1-800-279-9404.

8d

8e

6 • F2000-B2B, F2000-B2M Filtration Systems Instruction Manual

Page 7

CARTRIDGE TIMER PROCEDURE

Metal

Blinks red 1x after 11 months

Blinks red 3x after 12 months

FILTER CARTRIDGE TIMER

(MONITORED SYSTEMS ONLY)

The filter cartridge timer can be installed to the systems

decorative cover by peeling away the adhesive backing on the

metal plate included with the cartridge timer. The timer can

also be attached to a metal magnetic surface using the magnet

that is factory installed on cartridge timer.

INSTALLATION AND ACTIVATION

Once the installation location has been selected, activate the

timer by pulling the plastic tab out from the side of the timer.

Press and release the key to verify the battery is operational.

The light will blink green three times. (Figure 9a)

NOTE: The timer operates on 12 month schedule. The timer

uses a coin cell type 2023 battery.

The Filter Cartridge Timer is Operational

Operation

1. The timer will begin to blink red once every three minutes

after 11 months, and will blink red three times every three

minutes after 12 months. (Figure 9b)

NOTE: Timer status of the cartridge life can also be

viewed immediately by pressing and releasing the

key.

Reset Timer

1. To reset the timer after filter cartridge replacement, press

the key and hold for 5 seconds. The timer is now reset to 12

months. (Figure 9c)

Battery Replacement

1. Replace the battery every 12 months. To replace the battery,

locate the slot on the side of the timer body and carefully

remove the front of the timer. The battery is now accessible.

(Figure 9d)

2. Slide the new battery under the battery retention bracket

with the positive + side of the battery facing up towards the

battery retention bracket. Align the tab on the timer back

to the slot on the timer front and press and snap both timer

halves together. Battery replacement will not reset the 12

month timer. If reset is required, press and hold key for 5

seconds.

9a

9b

9c

9d

Magnet

Press and hold for 5 seconds

Blinks

Greeen 3x

Key

F2000-B2B, F2000-B2M Filtration Systems Instruction Manual • 7

Page 8

REPLACEMENT PARTS

ITEM

NUMBER

1 655126-96 Cartridge Set, F2B2-RC2 1

2

3 4003596 Installation Kit 2 & 3 Stage 1

4 244960* Faucet 1

5 4003530 Cover, 2 Stage 1

6 4003641 Cartridge Timer 1

*Image may be different than actual faucet

PART

NUMBER

4004603 Filter Head, Model F2000-B2B 1

4004605 Filter Head, Model F2000-B2M 1

DESCRIPTION

5

5

QUANTITY

REQUIRED

4

4

6

6

2

2

3

3

1

1

For replacement parts, contact your nearest Pentair distributor or call

800.279.9404

8 • F2000-B2B, F2000-B2M Filtration Systems Instruction Manual

Page 9

PERFORMANCE DATA

Important Notice: Read performance data and compare the

capabilities of the system with your actual water treatment

requirements. It is recommended that the supply water be tested,

before installing a water treatment system, to determine your water

treatment needs.

Test Conditions

Flow Rate

F2000-B2B = 0.60 gpm (2.27 L/min)

F2000-B2M = 0.60 gpm (2.27 L/min)

Filter Capacity

F2000-B2B = 675 gallons (2555 L)

F2000-B2M = 675 gallons (2555 L)

Inlet Pressure = 60 psi (4.1 bar)

Temperature = 68°F +/- 5°F (20°C+/- 2.5°F)

Testing was performed under standard laboratory conditions, actual

performance may vary.

Operating Requirements for F2000-B2B and F2000-B2M Systems:

Pressure = 40-100 psi (2.75-6.89 bar)

Temperature = 40-100°F (4.4–37.8°C)

CARTRIDGE SEQUENCE

F2000-B2B F2000-B2M

F2000B2B, F2000B2M SYSTEMS

INSTALLED WITH F2B2RC2 FILTER

CARTRIDGE SET

This system has been tested according to NSF/ANSI 42 and 53 for

reduction of the substances listed below. The concentration of the

indicated substances in water entering the system was reduced to

a concentration less than or equal to the permissible limit for water

exiting the system, as specied in NSF/ANSI 42 and 53.

Conforms to NSF/ANSI 53 for VOC reduction. See performance data

sheet for individual contaminant and reduction performance.

Model F2000-B2B, F2000-B2M Systems

Max. Permissible

Product Water

Concentration

Reduction

Requirements

Minimum

Reduction

>85% 97.9%

Average

Reduction

6.5)

8.5)

(VOC

Influent Challenge

Concentration

2.0 mg/L±10% ≥50% 95.9%

at least 10,000

particulates/mL

0.15 mg/L ± 10% 0.010 mg/L 99.3% 99.9%

0.15 mg/L ± 10% 0.010 mg/L 99.3% 99.6%

0.300mg/L ± 10% 96.5% 98.8%

Substance

Standard 42

Chlorine

Taste & Odor

Particulates

(0.5-<1uM)

Class 1*

Standard 53

Cysts ** Minimum 50,000/L 99.95% 99.97% 99.99%

Atrazine 0.009 mg/L ± 10% 0.003 mg/L 90.5% 93.7%

Lead (pH

Lead (pH

Lindane 0.002 mg/L ± 10% 0.0002 mg/L 94.8% 97.4%

Chloroform

surrogate

chemical)

Flow Rate = 0.6 gpm (2.2 L/min); Capacity = 675 gallons (2555 L) or 12

months

Testing was performed under standard laboratory conditions, actual

performance may vary.

* Reduces particles as small as 0.5-1 micron in size by mechanical

means

** NSF/ANSI Standard 53 certified to reduce cysts such as

Cryptosporidium and Giardia by mechanical means.

The Model F2000-B2B and F2000-B2M are Tested and Certified by

NSF International aganist NSF/ANSI Standard 42 and 53 for the

reduction of substances specified on the Performance Data Sheet.

EPA Est. 082989-CHN-001

F2000-B2B, F2000-B2M Filtration Systems Instruction Manual • 9

Page 10

10 • F2000-B2B, F2000-B2M Filtration Systems Instruction Manual

Page 11

Page 12

For Pentair Product Warranties visit:

Pentair para las garantías de los productos visite:

Pour Pentair garanties produit visitez le site :

waterpurification.pentair.com

}

WATER QUALITY SYSTEMS

5730 NORTH GLEN PARK ROAD, MILWAUKEE, WI 53209

P: 262.238.4400 | WATERPURIFICATION.PENTAIR.COM | CUSTOMER CARE: 800.279.9404 | tech-supportpentair.com

§

For a detailed list of where Pentair trademarks are registered, please visit waterpurification.pentair.com/brands.

Pentair trademarks and logos are owned by Pentair plc or its affiliates. Third party registered and unregistered

trademarks and logos are the property of their respective owners.

4003610 REV B SE16 © 2016 Pentair Residential Filtration, LLC All Rights Reserved.

Loading...

Loading...