Page 1

ORIGINAL INSTRUCTIONS

CONSERV® HE-3 HIGH EFFICIENCY REVERSE OSMOSIS SYSTEM

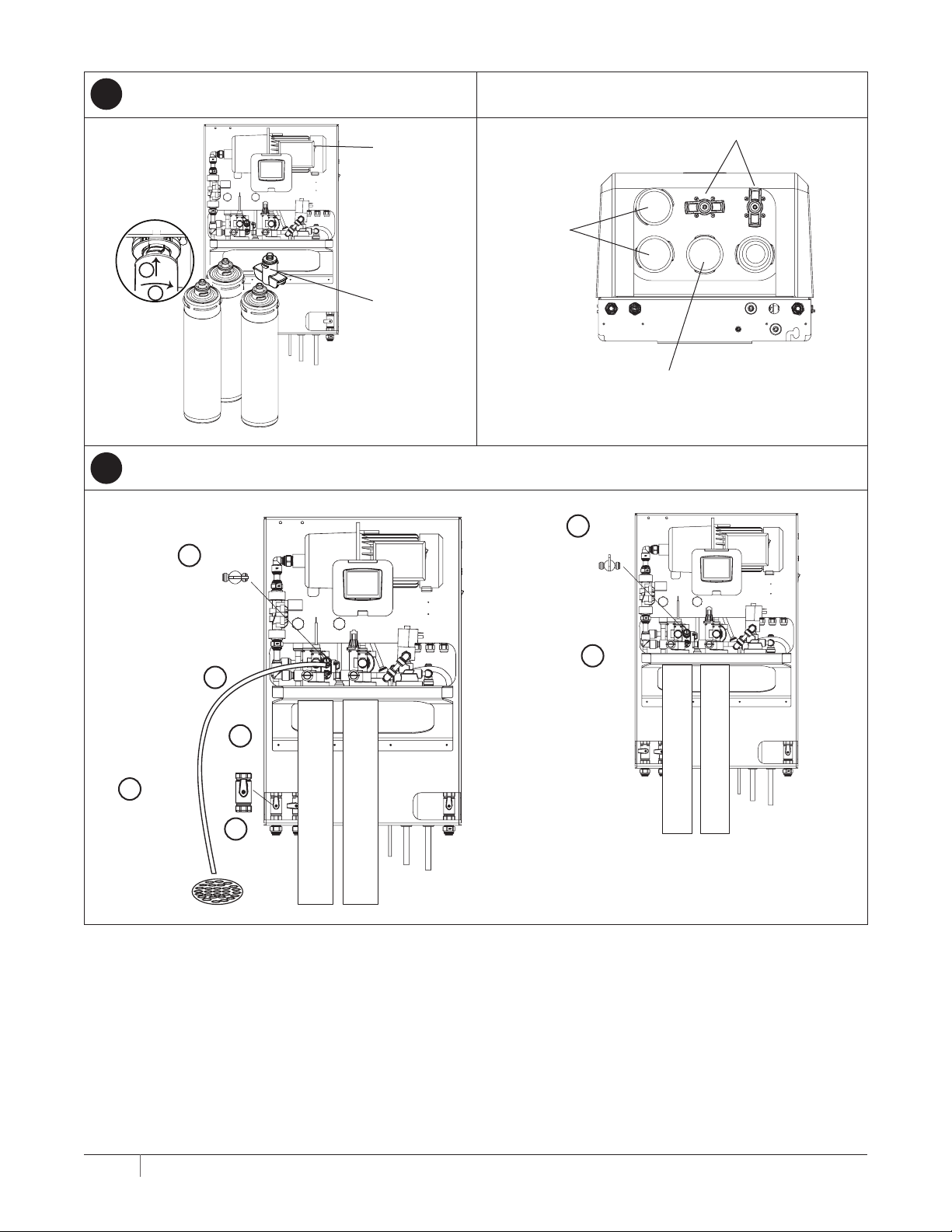

Conserv HE-3 Processor (Tank Included) Conserv HE-3 15 Gallon Tank

INTRODUCTION

The Everpure® Conserv HE-3 High Efficiency Reverse Osmosis System is a pre-engineered, pre-assembled system solution

designed to provide high purity water for numerous applications, such as premium espresso, coffee, ice, blended beverages

and steam. The system combines a number of water treatment technologies into one easy-to-install package. The system

provides superior protection against taste- and odor-causing contaminants while removing dirt*, particulates* and dissolved

solids that can foul or scale equipment.

* Protection against objectionable taste- and odor-causing contaminants and removal of dirt and particulates not performance

tested or certified by NSF®. Everpure SEN+ and SEN Fine Filter Cartridges not performance tested or certified by NSF.

UNPACKING AND INSPECTION

Inspect the carton for damage. Carefully unpack and inspect each item. Report any damage to freight carrier immediately and

retain all packaging materials.

The Everpure® Conserv® HE-3 RO System includes all the necessary fittings for installation. Lengths of 3/8-inch and 1/2-inch

tubing have been provided for connecting to the wastewater drain connection. Supply lines and distribution piping/tubing are not

included.

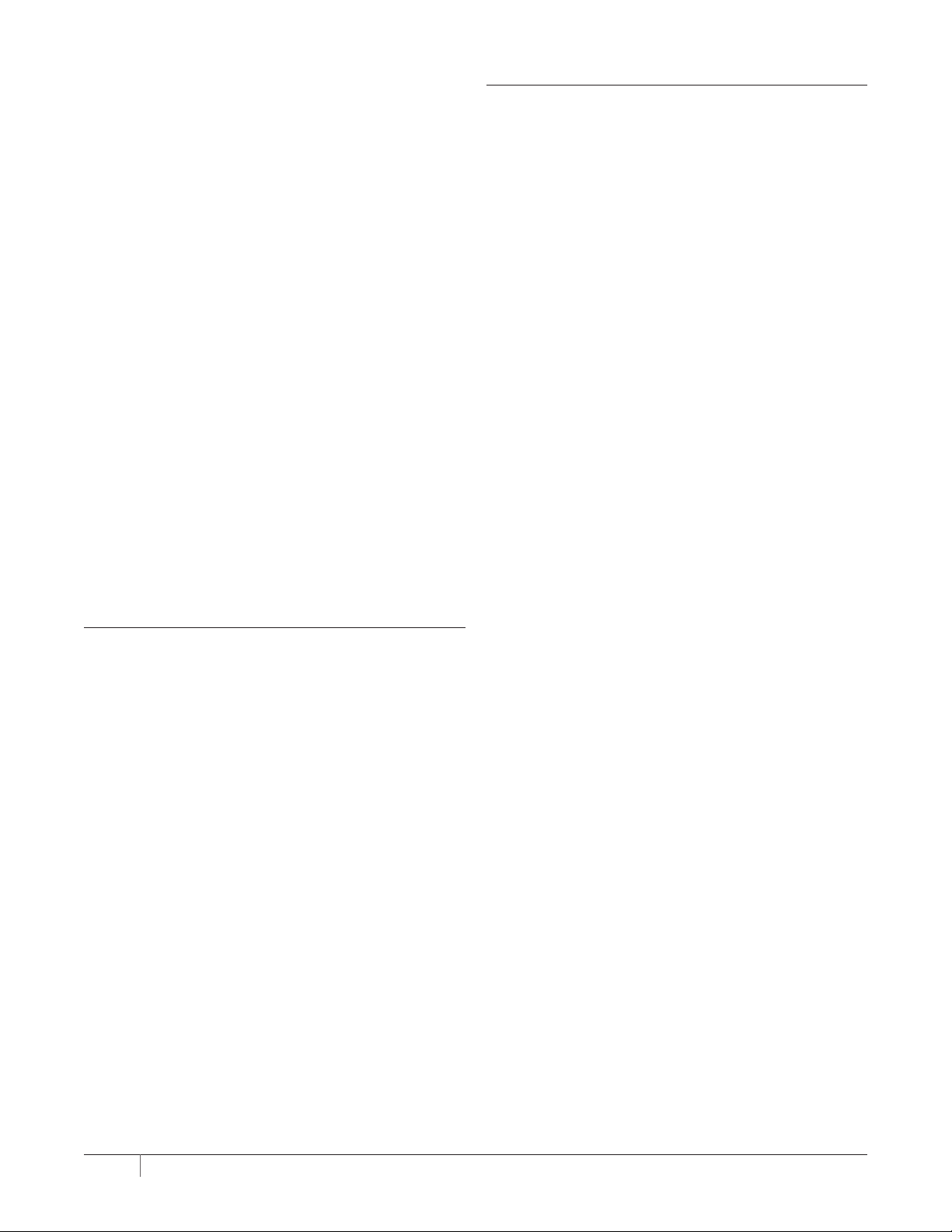

The Conserv HE-3 RO System is packaged as a complete unit in two (2) cartons. You should have the following:

Parts Quantity

1. Plate Mounted Processor Assembly:

RO Booster Pump

Cartridge Heads

Controller and Power Supply

2. Everpure MR-600F RO Membrane Cartridge 1

3. Everpure SEN+ Fine Filter Cartridges (Prefilter)

4. Everpure SEN Fine Filter Cartridge (Postfilter) 1

5. Parts Kit 1

6. Permeate Storage Tank with the Top Plate 1

7. Tank Booster Pump (Not shown) 1

8. 1/2 Gallon Accumulator (Not shown) 1

The MR-600F RO Heads and the SEN Postfilter Manifold will

each have one port plugged. If the installation requires the

use of a second MR-600F RO and the second SEN Postfilter,

the plugs must be removed to install these cartridges.

1

2

2

1

3

5

4

6

EVERPURE® CONSERV® HE-3 RO SYSTEM INSTALLATION AND OPERATION GUIDE

Page 2

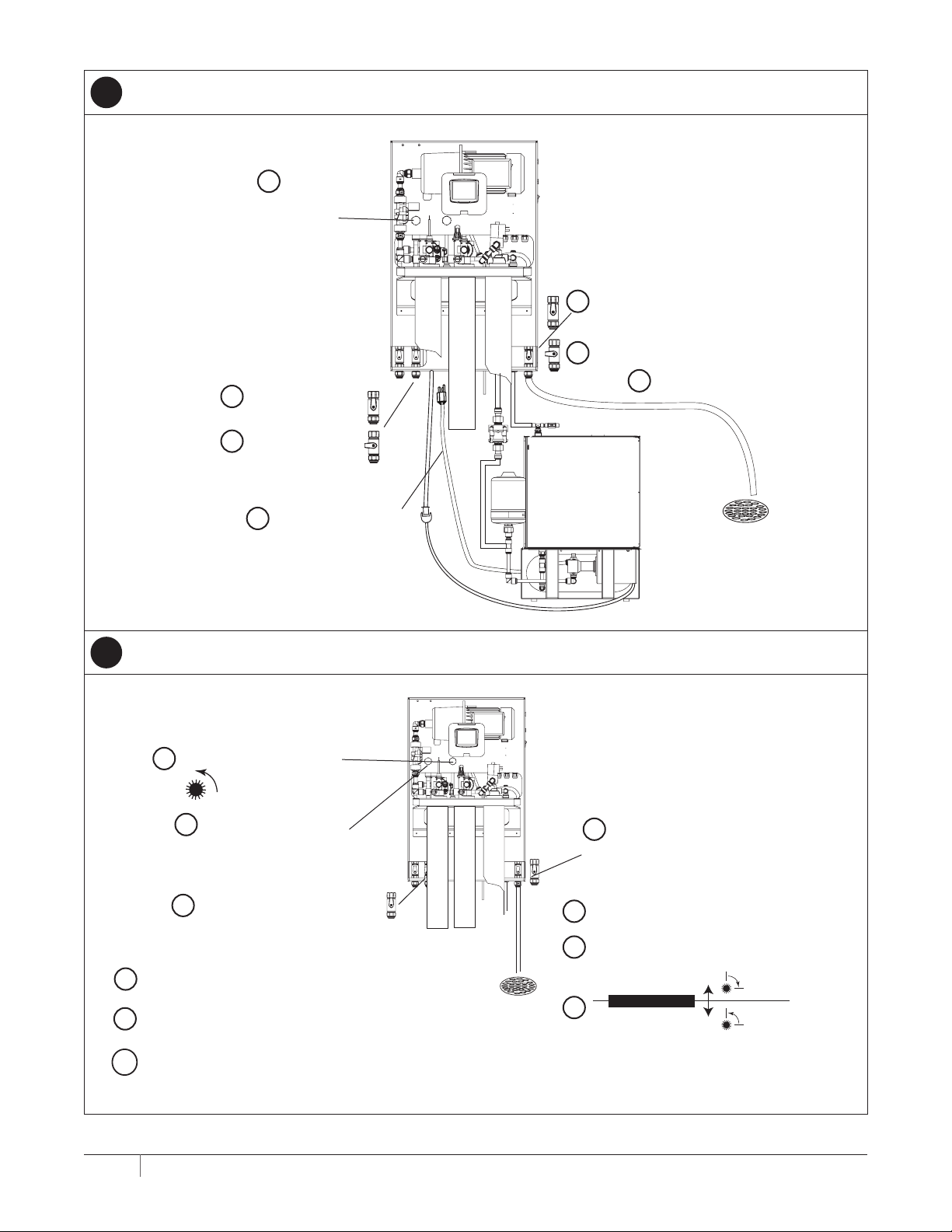

The system consists of seven (7) major components:

• Everpure® SEN+ Fine Filter Cartridges*

• Inlet Booster Pump

• Everpure MR-600F Reverse Osmosis (RO) Membrane

Cartridge

• Permeate Pump

• Everpure SEN Fine Filter Cartridge*

• Control System with Power Supply

• 15 Gallon Storage Tank

The SEN+ Fine Filter Cartridges contain multiple medias.

These medias filter out dirt and particles, reduce chlorine

and provide scale control, to extend RO membrane life.*

The Inlet Booster Pump increases the inlet pressure to

maintain consistent permeate production.

The MR-600F RO Membrane Cartridge contains a semipermeable reverse osmosis membrane. It’s here that most

of the dissolved impurities are separated from the water

and flushed down the drain. The water that is able to pass

through the membrane, which is very low in dissolved

impurities, is referred to as permeate or RO water.

The Storage Tank minimizes back pressure on the permeate

produced by the MR-600F RO Membrane Cartridge. This

reduction of back pressure provides consistent permeate

production and maximizes system efficiency for peak demand.

The SEN Fine Filter Cartridge acts as a postfilter, filtering the

RO water and any tap water added via the blending system.*

TOOLS, MATERIALS & SPECIAL EQUIPMENT

REQUIRED

In most cases, common hand tools and plumbing materials

suitable for use with RO water are all that is needed for

system installation. The system setup and calibration

requires special equipment:

• Two (2) - 32 ounce or 1,000 mL Graduated Containers

• Ball Valve for 1/2-inch O.D. Tubing

• Stopwatch

• Pressure Gauge

• Hardness Test Kit

• Chlorine Test Strips

• TDS Meter

• Utility Knife

• Eyedropper

• 5.25% Household Bleach or Equivalent Disinfectant

NOTE: Please read this entire manual prior to installing and

operating the system.

NOTE: Consult with your local building inspector for

approval and required permits to install this system.

Additional equipment, may be required. Installation

must meet all local and national codes.

OPERATING SPECIFICATIONS

Influent Water Characteristics:

Total Dissolved Solids: 0-1,000 ppm (0-1,000 mg/L)

pH: 6-9

Free Chlorine: 0-3 ppm (0-3 mg/L)

Chloramines: 0-3 ppm (0-3 mg/L)

Turbidity: 0-1 NTU

Silica SiO2 < 20 ppm

Iron and Manganese: 0-1 ppm (0-1 mg/L)

Bacterial Quality: Potable

Total Hardness: <1 grain

Dynamic Operating Pressure: 50–80 psi (3.5-5.5 bar,

0.35–0.55 MPa)

Pressure below 65 psi

(4.5 bar, 0.45 MPa) may

affect blend system†

performance

Maximum Static Pressure: 100 psi (6.9 bar, 0.69 MPa)

Operating Temperature: 60-100°F (15.5–37.8°C)‡

Daily Production Rate: 443.68 gpd (1,680.19 Lpd)

Efficiency Rating: 74.23%

Overall Reduction/Rejection 90.70%

†

Recovery Rating: 74.63%

Plumbing Connections:

Inlet/Outlet: 1/2-inch O.D. tube

(“push-in” quick-connect)

Reject: 1/4-inch O.D. tube

(“push-in” quick-connect)

Electrical - Rated Voltage and

Power Cord Type

System Part No. EV9977-50: 100-120VAC/60Hz - NEMA

5-15P

Wattage:

Standby: 25 W

Flush: 300 W

Run/Fill: 600 W

Branch Circuit Protection: 15 Amp minimum. To

minimize personnel shock

hazards, install on a GFI,

RCD, or equivalent protected

circuit.

Connectivity Connections:

Ethernet Port:

Softener Port:

Type CAT5

Type 4 pin RJ11

* Protection against objectionable taste- and odor-causing

contaminants and removal of dirt and particulates not

performance tested or certified by NSF®. SEN+ and SEN

Cartridges not performance tested or certified by NSF.

†

Blend system not performance tested or certified by NSF.

2 WATER YOU CAN TRUST

®

‡ If the incoming soft water temperature is less than 60°F

(15.5°C), a tempering valve should be used. Otherwise there

will be a reduction in RO production.

Page 3

NOTE: Incoming water supplies that do not meet the

18.4”

18.4”

18.4”

influent water characteristics requirements will

require the addition of pretreatment equipment prior

to the Conserv HE-3 RO System.

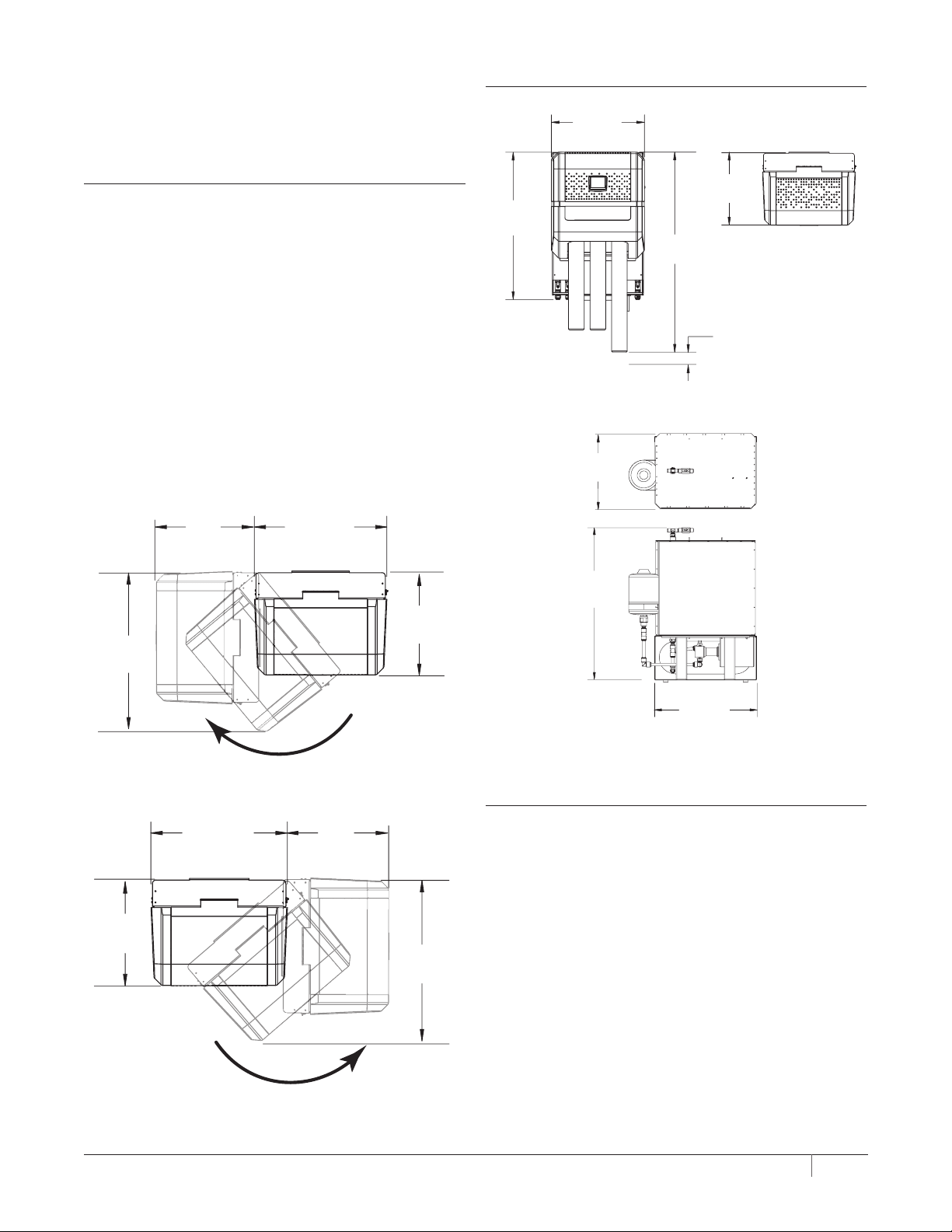

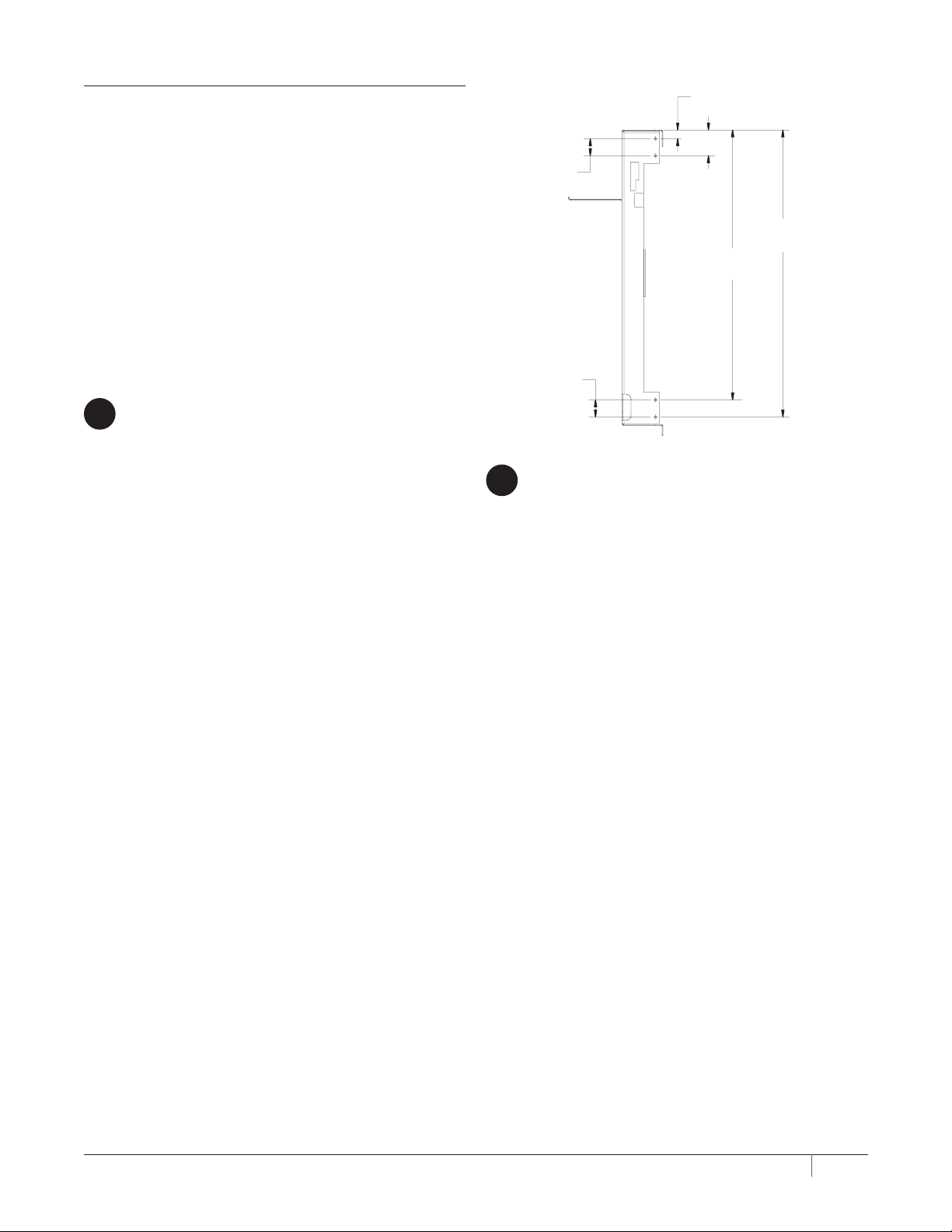

DIMENSIONS

(46.7 cm)

SELECTING A MOUNTING LOCATION

Locate the system in an area that is convenient to the inlet

water supply and drain facilities, with access for routing

the blended water tubing/piping to the equipment. Install

in a dry location, away from all forms of corrosive and/or

flammable materials. Consider ease of access for servicing

when selecting a location. If the Conserv HE-3 RO System

is replacing an existing Everpure® MRS-600HE-II High

Efficiency RO System the mounting system may be reused.

The Conserv HE-3 is designed to mount using the MRS-600

HE-II wall mount brackets. The Conserv HE-3 may also be

mounted using a new design wall mount hinge system (sold

separately).

If the Conserv HE-3 RO System is wall mounted on hinges be

certain the unit has clearance to swing out for maintenance.

Evaluate the mounting surface for its ability to properly

support the weight of the processor when in operation

[approximately 90 lbs (40.8 kgs)].

14.4”

(36.5 cm)

(46.7 cm)

14.4”

(36.5 cm)

23.5”

(59.7 cm)

14.4”

(36.5 cm)

29.0”

(73.6 cm)

39.6”

(100.5 cm)

Provide 3" clearance for

changing cartridges

Figure 3 Conserv HE-3 RO System Dimensions

13.4”

(34.0 cm)

27.9”

(70.8 cm)

14.4”

(36.5 cm)

Figure 1 Left Swing Clearance

14.4”

(46.7 cm)

(36.5 cm)

Figure 2 Right Swing Clearance

23.5”

(59.7 cm)

18.62”

(47.3 cm)

Figure 4 Conserv HE-3 RO System Storage Tank Dimensions

PREINSTALLATION CHECKLIST

1. Can the unit be mounted within a reasonable distance of

the water supply, electrical service and drain facilities?

2. Is there an unswitched receptacle available for powering

the system?

3. Is there adequate clearance and support to install the

unit and permit access for maintenance? The Conserv

HE-3 RO System may be wall mounted on hinges.

Be certain the unit has clearance to swing out for

maintenance.

4. Does the inlet water supply meet the requirements

listed in the table (on page 2) under Influent Water

Characteristics?

5. Is there a minimum dynamic pressure of 50 psi (3.5 bar,

0.35 MPa) pressure at open flow?

®

CONSERV® HE-3 RO SYSTEM INSTALLATION AND OPERATION GUIDE

3 EVERPURE

Page 4

SAFETY INSTRUCTIONS

NOTE: The appliance is only to be installed in locations

where its use and maintenance is restricted to

trained personnel.

NOTE: Children should be supervised to ensure that they do

not play with the appliance.

NOTE: Cleaning and user maintenance shall not be made by

children without supervision.

NOTE: The appliance is not suitable for installation in an

area where a water jet could be used.

NOTE: If the supply cord is damaged, it must be replaced

by the manufacturer, its service agent or similarly

qualified persons in order to avoid a hazard.

NOTE: Substances listed as reduced are not necessarily in

your water. System must be maintained according to

manufacturer's instructions, including replacement

of filter cartridges.

NOTE: Your water must be within required influent water

characteristic limits for satisfactory operation. If not,

the RO membrane cartridge’s life may be shortened

and your warranty will be voided (see Operating

Specifications).

NOTE: Install on cold water line only.

NOTE: Do not install where system will be exposed to direct

sunlight.

NOTE: Make certain that installation complies with all state

and local laws and regulations. Use only plumbers

tape without adhesive backing to seal joints. Do not

use pipe compound (“pipe dope”), sticks, or similar

compounds with this unit; they contain petroleum

derivatives which can cause crazing and cracking of

the plastic in the filter housing.

WARNING: Installation shall comply with applicable local,

state, and national plumbing and electrical

regulations.

WARNING: This appliance must be grounded. This appliance

is equipped with a cord having an appliancegrounding conductor and a grounding plug. The

plug must be plugged into an appropriate outlet

that is installed and grounded in accordance with

all local codes and ordinances. If the supply cord

is damaged, it must be replaced by the manufacturer, its service agent or similarly qualified

persons in order to avoid a hazard.

WARNING: Improper connection of the appliance-grounding

conductor can result in a risk of electric shock.

Check with a qualified electrician or service

representative if you are in doubt whether the

appliance is properly grounded. Do not modify

the plug provided with the appliance; if it will not

fit in the outlet, have a proper outlet installed by

a qualified technician.

WARNING: The appliance is intended to be permanently

connected to the water mains and not connected

by a hose-set.

WARNING: Before installing the system, make certain

your water supply complies with the following

operating specifications. Failure to do so may

reduce the effectiveness of the system and will

void the warranty. Consult your local water

treatment utility or a certified water testing lab

to determine the quality of your water.

WARNING: Do not use with water that is microbiologically

unsafe or of unknown quality without adequate

disinfection before or after the system. The

Pentair Everpure® Conserv® HE-3 Reverse

Osmosis System will not protect against diseasecausing bacteria or remove naturally-occurring

harmless bacteria.

WARNING: The Everpure® Conserv® HE-3 Reverse Osmosis

System contains replaceable components that

are critical to the efficiency of the system.

Replacement of the reverse osmosis component

should be with one of identical specifications,

as defined by the manufacturer, to assure the

same efficiency and contaminant reduction

performance.

WARNING: The Everpure® Conserv® HE-3 Reverse Osmosis

System contains filter cartridges and an RO

membrane cartridge included with the system

that have limited service lives which are critical

for the effective reduction of total dissolved solids. Product water should be tested periodically

to verify that the system is working properly.

WARNING: The Everpure® Conserv® HE-3 Reverse Osmosis

System shall only be used for arsenic reduction on chlorinated water supplies containing

detectable residual free chlorine at the system

inlet. Water systems using an in-line chlorinator

should provide one (1) minute of chlorine contact

time before the unit.

CAUTION: The Everpure® Conserv® HE-3 Reverse Osmosis

System must be protected against freezing

which can cause the filter housing to crack,

resulting in water leakage. Do not use electrical

heating tape or propane torch on this unit.

4 WATER YOU CAN TRUST

®

Page 5

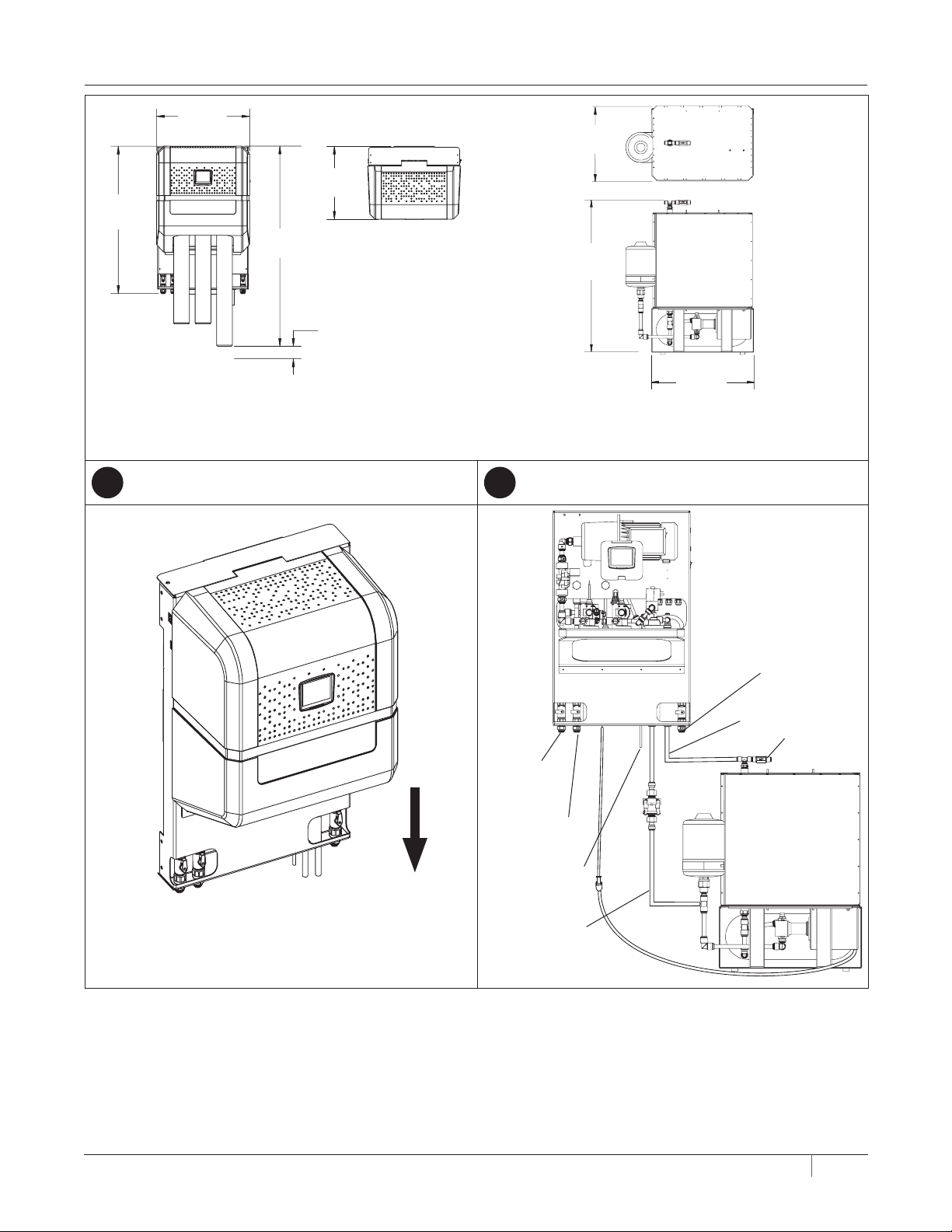

EVERPURE® CONSERV® HE3 RO SYSTEM QUICK START GUIDE

18.4”

29.0”

(73.6 cm)

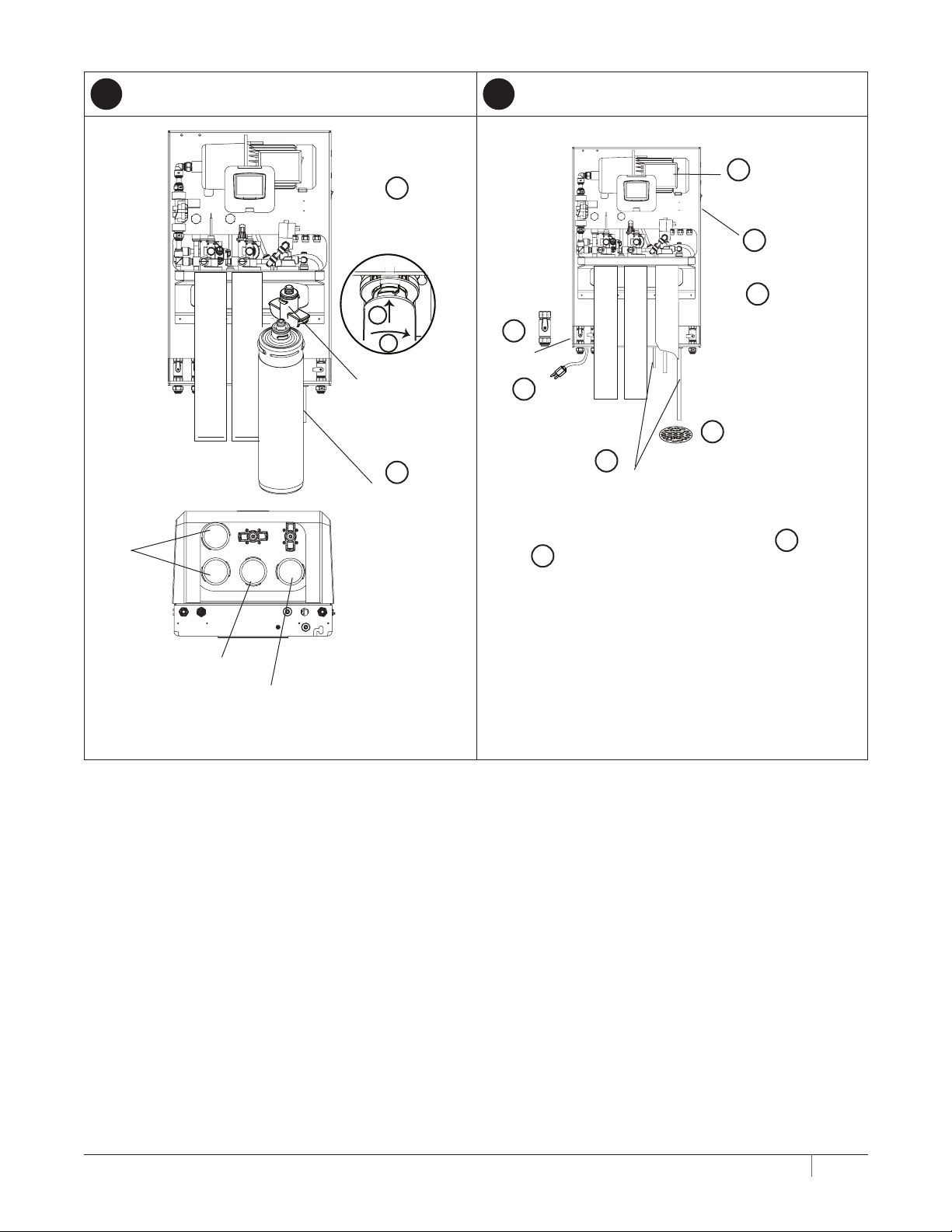

1

Wall Mounting

(46.7 cm)

39.6”

(100.5 cm)

14.4”

(36.5 cm)

Provide 3" clearance for

changing cartridges

13.4”

(34.0 cm)

27.9”

(70.8 cm)

2

Tubing Locations

18.62”

(47.3 cm)

NOTE: Shown without

cartridges installed.

Approximately

90 lbs

(40.8 kgs)

Operating

Weight

Blended Water

To Application

RO Water To

Storage Tank

Tank Relief

To Dr a in

Soft Water

Connection

Hard Water

Connection

RO Waste To

Drain

RO Water

From Tank

Accumulator

®

CONSERV® HE-3 RO SYSTEM INSTALLATION AND OPERATION GUIDE

5 EVERPURE

Page 6

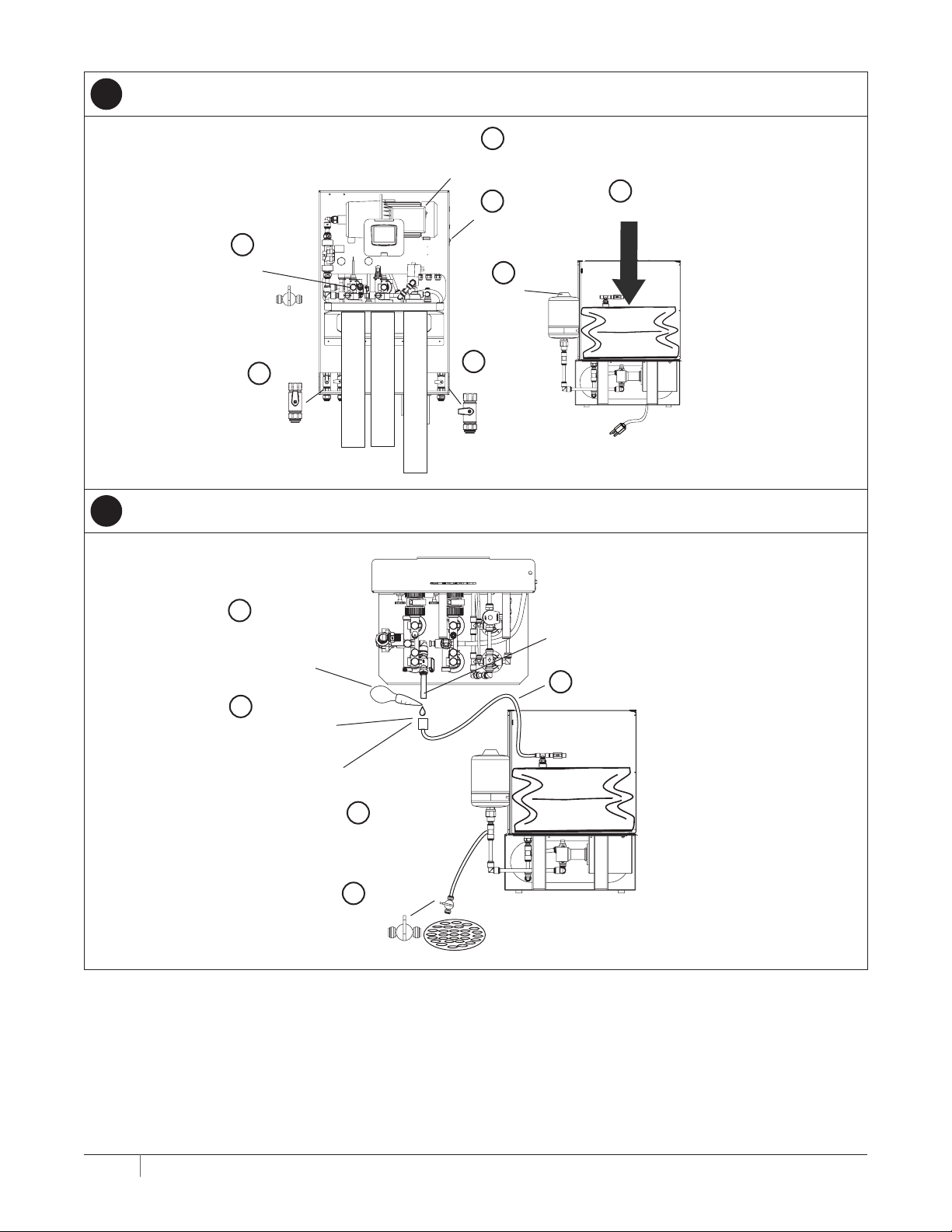

3

Install Everpure

1

2

®

SEN+ and SEN Cartridges

+

+

SEN

SEN

SEN

Pump

Motor

Switch Off

Plug Open Head

(Pre-installed)

Cartridge Positions

+

SEN

Plugs

SEN

Bottom View

4

Flush Everpure SEN

2

OPEN

Insert 1/2"

Tubing O.D.

4

Flush for Five

(5) Minutes

1

3

OPEN

5

Close Soft

Water Valve

+

Cartridge

6

CLOSE

7

Remove

Tubing

6 WATER YOU CAN TRUST

®

Page 7

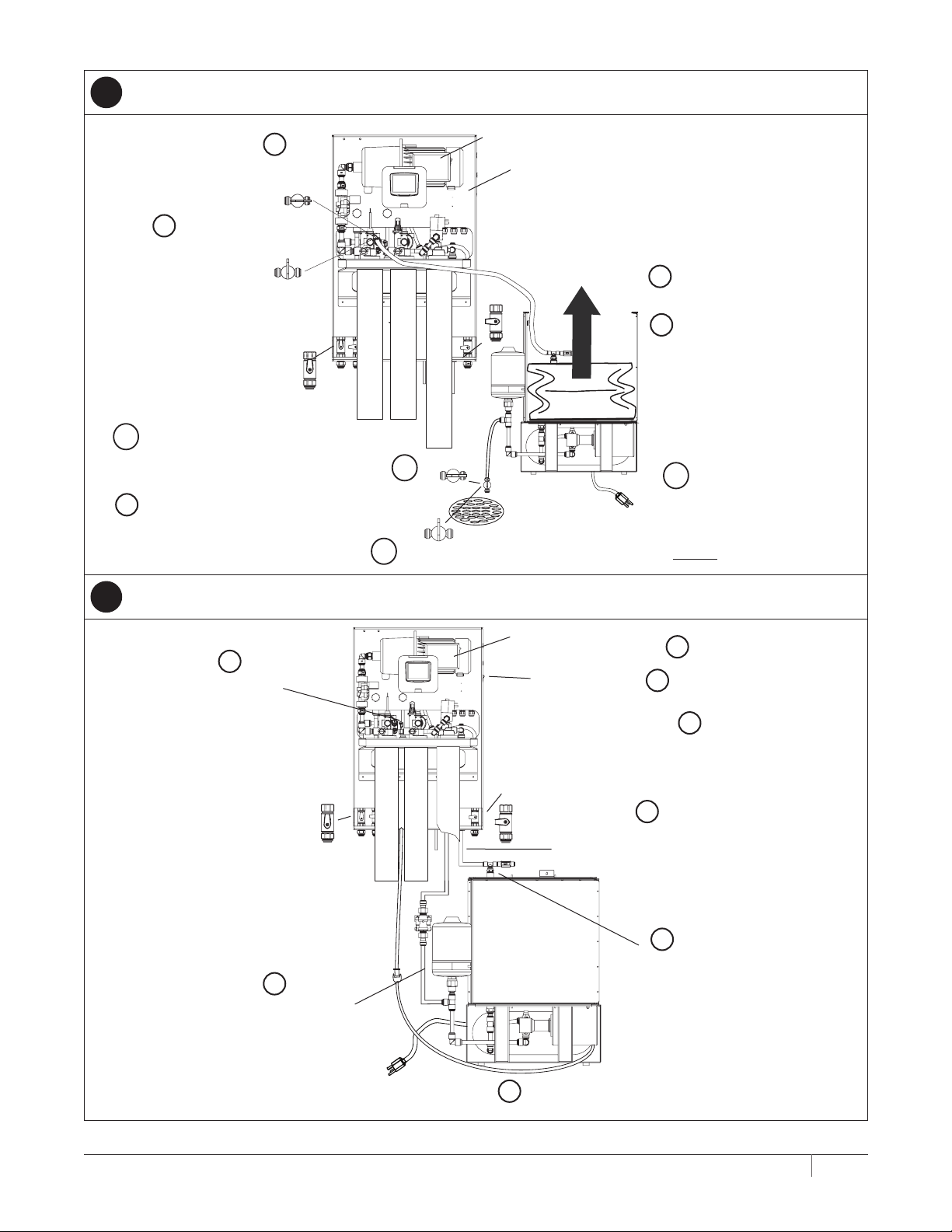

5

Install Everpure® MR-600F RO Cartridge

1

Install

Cartridge(s)

6

Flush Everpure

®

MR-600F RO Cartridge

1

Pump Switch Off

4

Turn Power Switch ON

SEN

+

SEN

SEN

MR-600F

+

1

2

Plug Open

Head

(Pre-installed)

2

Connect 3/8"

Tubing

5

Open

3

Plug Power

Cord Into

Outlet

9

Install Correct

Restrictor for

6

When Water Exits

Both Tubes, Turn

Pump Switch ON

Application

Until TDS < 50 PPM

8

Turn System Switch OFF

Direct 1/4" and 3/8"

2

Lines to Drain

7

Perform RO Rinse

for 90 Minutes or

from 3/8" Line

(Production)

SEN

MR-600F

Bottom View

®

CONSERV® HE-3 RO SYSTEM INSTALLATION AND OPERATION GUIDE

7 EVERPURE

Page 8

7

Prepare Storage Tank

Flush Valve

Closed

1

Pump Switch

Off

2

Power

5

Switch Off

Force Air Out

6

Cover

Removed

7

Check

Precharge

(40 psi)

8

Sanitize Storage Tank

Add 8 Oz. (237 mL) of 5.25%

Bleach

15 gal (56.8 L) @ 200 ppm

Connect to Flush Valve

2

3

4

Open

Adapter

4

Insert

1/2" O.D.

Tubing

3

Closed

Unplugged

1/2" O.D. Tubing

3/8" O.D. Tubing

1

8 WATER YOU CAN TRUST

CLOSE

5

®

Page 9

8

Sanitize Storage Tank - Continued

Flush Valve

OPEN

8

CLOSE Flush Valve

Once Tank Is Filled

13

Repeat Steps 6-12 Two (2)

Times

9

Remove Ball Valve

6

Open

10

OPEN Valve

Slowly

12

When Empty, (Bladder Stops Compressing) Unplug and CLOSE Ball Valve

Pump Switch Off

Power

Switch

Off

Closed

7

Tank Fills

9

Wait 15

Minutes

11

Plug Into

Wall Outlet

9

Connect Tank Tubing and Fill Tank

1

Remove Tubing

From Flush Valve

3

Connect Tank

Accumulator to

Permeate Inlet: Insert

1/2" Tubing

When Tank Begins to

Fill, Turn ON Pump

Power Switch ON

Closed

Connect 3/8" Tubing to Permeate

5

4

Allow Tank to Fill

6

2

Water Out

8

Once Full, Remove Fitting,

Install Cover and Re-insert

Fitting

Connect Tank Sensor

7

®

CONSERV® HE-3 RO SYSTEM INSTALLATION AND OPERATION GUIDE

9 EVERPURE

Page 10

10

Flush Everpure

®

Postfilter Cartridge

3

OPEN

Hard Water Blend Valve

OPEN Hard Water

2

Inlet Valve

CLOSE Hard

5

Water Inlet Valve

Plug Storage Tank

7

Power Cord into HE-3

System

SEN

OPEN Blended Water Outlet Valve and

4

6

Flush for Five (5) Minutes.

CLOSE Outlet Valve

1/2" O.D. Tubing to Drain

1

11

Adjust The Blending Valves

RO Permeate Blend Valve

1

Repeat Steps 5 - 7 Until TDS Is At Target Level

8

CLOSE Outlet Valve

9

Remove Drain Tube From Blended

10

Water Outlet and Connect to

Downstream Application

OPEN Fully

2

Hard Water Blend Valve

CLOSE Fully Then OPEN One

(1) Rotation

OPEN Hard Water Inlet Valve

3

NOTE: Tank Not Shown

4

OPEN Blended Water Outlet

Run Water To Drain For Two (2) Minutes

5

Test The TDS. Check Display for TDS Value

6

HI

7

Target TDS

LOW

Hard Water Blending Valve

Hard Water Blending Valve

10 WATER YOU CAN TRUST

®

Page 11

SYSTEM ASSEMBLY

WARNING: Mounting surface may require reinforcement to

support the Processor Assembly safely. Hollow

walls, drywall and other non-structural surfaces

are not suitable for mounting unless reinforced.

WARNING: Do not use screws smaller than #12 (5.5 mm) for

mounting the Processor Assembly.

The Everpure® Conserv® HE-3 Processor Cabinet is designed

to wall mount using either of two (2) methods.

1. If an Everpure® MRS-600HE-II System is being replaced,

the mounting brackets can be reused. The new Conserv

HE-3 will not swing open when using these brackets.

2. A mounting kit may be purchased that includes two (2)

hinges and a template with instructions. This mounting

kit allows the Conserv HE-3 to swing open for access to

the back of the cabinet.

1

Wall Mounting Using the Hinged Mounting Kit

The Everpure® Conserv® HE-3 Processor Cabinet can have

two (2) mounting hinges attached to one side of the cabinet.

The second half of the hinge is separate and will be mounted

to the wall. See Figure 5 for Dimensions. When this half of the

hinge is correctly mounted to the wall, it allows the cabinet to

be lifted and the hinge pieces to connect to each other.

NOTE: When the processor cabinet is hinge-mounted, it

can swing away from the wall to allow servicing.

Determine that the application site will allow the

cabinet to swing in the desired direction.

CAUTION: Be certain that the holes are vertically level.

Any deviation will cause the Conserv HE-3 RO

System Cabinet to swing during servicing.

1. Place the two (2) hinges in position over the mounting

holes with the pegs pointing up.

2. Secure the hinges with appropriate hardware.

52/64”

.82

2-29/64”

1-5/8”

1.63

1-5/8”

1.63

2.45

25-45/64”

25.70

27-21/64”

27.32

Figure 5

2

Tubing Locations

1. Refer to Figure 6 Conserv HE-3 RO System Assembly

for a description of major components and connection

points. These major components and connections will be

referred to in the following steps.

2. Prepare the plumbing to accept the RO system.

NOTE: The blended water tubing/piping and associated

fittings connecting the RO blended water outlet to

the equipment being serviced should be food-grade

material that meets NSF® Standard 51, 61, or similar,

with a minimum pressure rating of 100 psi (6.9 bar,

0.69 MPa). The blended water may react with metal

piping, creating a corrosive condition in addition

to imparting an objectionable taste. Plastic pipe or

reinforced beverage tubing are generally very good

material choices for RO water distribution piping.

The size of the blended water tubing/piping should

be 1/2-inch (12.7 mm) O.D. minimum. Distances of

25 feet (7.6 m) or greater from the RO system to the

equipment being serviced should be 1/2-inch (12.7

mm) O.D. minimum.

3. Locate an appropriate point in the hard water plumbing

to tie in a new section of tubing/piping that can be routed

to the RO system. CLOSE the nearest shut-off valve

that is upstream from the tie-in point and relieve the

pressure in the line. Tie in the new tubing/piping section

and connect it to the Hard Water Inlet fitting. See Figure

6 Conserv HE-3 RO System Assembly.

®

CONSERV® HE-3 RO SYSTEM INSTALLATION AND OPERATION GUIDE

11 EVERPURE

Page 12

4. Locate an appropriate point in the soft water plumbing

to tie in a new section of tubing/piping that can be routed

to the RO system. CLOSE the nearest shut-off valve

that is upstream from the tie-in point and relieve the

pressure in the line. Tie in the new tubing/piping section

and connect it to the Soft Water Inlet fitting. See Figure 6

Conserv HE-3 RO System Assembly.

5. Connect the appropriate size and type of tubing/piping

and associated fittings to the Everpure® Conserv® HE-3

RO System. Route the line(s) to the equipment being

serviced (i.e., steam, espresso, coffee, etc.). CLOSE the

Hard and Soft Water Inlet Valves, and the Blended Water

Outlet Valve on the RO system. Reapply pressure to

the hard water and soft water distribution plumbing by

slowly OPENING the shut-off valves that were closed in

the previous steps.

6. Connect a 1/4-inch (6.3 mm) O.D. tube to the port located

at the bottom of the processor labeled WASTE. Route

the other end of the tubing to a drain nearby, securing

it properly. Allow an air gap at the drain, following

any applicable local and national codes. See Figure 6

Conserv HE-3 RO System Assembly.

ELECTRICAL AND CONNECTIVITY CONNECTIONS

The Everpure® Conserv® HE-3 RO System is pre-wired at the

factory. Verify that the supply voltage matches the RO system

operating voltage. Also verify that the supply is a GFI, RCD, or

equivalent protected circuit rated at 15 amps minimum. Verify

that the pump motor switch (Figure 8) is in the off position.

Plug in the power cord.

The bottom of the Everpure Conserv HE-3 RO System has two

electrical connections. The permeate Storage Tank sensor

will plug into the white connector. The Storage Tank pump

power cord will plug into the remaining female connection.

WARNING: For proper operation, do not plug Storage Tank

pump into a wall receptacle.

IMPORTANT: Electrical brown-outs below 100 volts will

require the Everpure Conserve HE-3 RO

System must be turned OFF and back ON

(power cycled).

To monitor the Everpure Conserv HE-3 RO System remotely,

an Ethernet cable (type CAT5, not provided with the system)

must be connected between the RO system and the Internet

router.

To have connectivity between the Everpure Conserv HE-3

RO System and the CES-9100TS E-30C Softener, a phone

cord (type 4 pin RJ11, not provided with the system) must be

connected between the RO system and the softener.

Blended Water

Outlet Valve

To Storage Tank

Soft Water

Inlet Valve

Hard Water

Inlet Valve

RO Waste to Drain

From Storage

Tank

Pump

Tank Accumulator

Figure 6 Conserv HE-3 RO System Assembly

Ethernet Port

Softener Port

Figure 7

PREFILTER AND RO CARTRIDGE INSTALLATION AND

SYSTEM STARTUP

Switch and Valve Starting Positions:

• System Power - Off

• Pump (P1) Power - Off

• Soft Water Inlet Valve - Closed

• Hard Water Inlet Valve - Closed

• Blended Water Outlet Valve - Closed

12 WATER YOU CAN TRUST

®

Page 13

3

Install Everpure SEN+ and SEN Fine Filter Cartridges

1. Remove the outer shrink wrap and protective caps from

all of the cartridges.

2. Align the lugs on the Everpure SEN+ Fine Filter Cartridges

with the slots in the cartridge ports on the twin prefilter

header. Holding the head/bracket and cartridge firmly,

press the cartridge upward into the head fully, and then

turn the cartridge to the right until it stops (Figure 8).

Install the second SEN+ Fine Filter Cartridge and the SEN

Postfilter Cartridge in the same manner.

NOTE: If a second SEN Cartridge is installed, the pre-

installed plug must be removed.

Pump On/Off

Plug Open

1

Head

(Pre-installed)

2

+

+

SEN

SEN

SEN

SEN Postfilter

(installed after

tank flush)

1. Attach 1/2-inch O.D. tubing for a drain line to the

Flushing Valve. The tubing should run to a drain.

2. OPEN the Flushing Valve.

3. The store soft water supply valve should be open. OPEN

the Soft Water Inlet Valve on the Everpure® Conserv®

HE-3 RO System.

4. Flush the prefilters for a minimum of five (5) minutes at

0.5 gpm (1.8 Lpm).

5. CLOSE the Soft Water Inlet Valve.

6. CLOSE the Flushing Valve.

7. Remove the drain tube.

5

Install Everpure MR-600F RO Membrane Cartridge

1. Align the lugs on the Everpure MR-600F RO Membrane

Cartridge with the slots in the head. Holding the head

and cartridge firmly, press the cartridge upward into the

head fully, and then turn the cartridge to the right until it

stops.

NOTE: If a second MR-600F RO Membrane Cartridge is

installed, the pre-installed plug must be removed.

2. Attach a length of 3/8-inch O.D. tubing to the RO tube

that delivers permeate water to the Storage Tank (Figure

10). The open end should run to a drain.

CAUTION: To prevent damage to the pump (P1), the pump

head should be filled with water (primed) before

the unit is turned on.

Pump (P1)

On/ Off

Switch

Figure 8

4

Flush Everpure SEN+ Fine Filter Cartridge

Flushing Valve

Figure 9

®

CONSERV® HE-3 RO SYSTEM INSTALLATION AND OPERATION GUIDE

Soft Water Inlet Valve

RO Waste

to Drain

NOTE: Cartridges not shown.

System

On/Off

Switch

Permeate Port

Attach 3/8" O.D.

Tubing to Drain

Figure 10

13 EVERPURE

Page 14

3. Ensure that the Pump Switch (P1) is in the Off position.

Then turn the System On/Off Switch to ON. The solenoid

valve will open to allow water flow at store pressure into

the pump head.

6

Flush Everpure MR-600F RO Membrane Cartridge

1. Pump switch should be off.

2. Plug the HE-3 Cabinet power cord into an outlet.

3. Use the User Interface screen and press System

Settings. Enter the password to access the Air Purge/

Flush menu.

NOTE: Passwords are available through Pentair Everpure

Technical Support at 630.307.3000.

4. When the Air Purge/Flush menu is displayed, press

Perform RO Rinse.

NOTE: Water will exit both the RO waste and permeate

tubes Figure 10.

5. When water is exiting both tubes, turn ON the Pump (P1)

Switch.

6. The MR-600F RO Cartridges should be flushed for 90

minutes or until the TDS is below 50 ppm.

WARNING: DO NOT USE THIS RO WATER! It will likely

contain a preservative solution that should not

be consumed.

NOTE: The SEN Fine Filter Cartridges will not be flushed

until the Storage Tank has been flushed and

sanitized.

7. Turn OFF the system.

8. Remove the grey restrictor. Replace it with the correct

restrictor for the application. Refer to the Flow Restrictor

Table in the System Recovery Rate section.

7

Prepare Storage Tank

Switch and Valve Starting Positions:

• Power - Off

• Pump Power Switch - Off

• Soft Water Inlet Valve - Open

• Hard Water Inlet Valve - Closed

• Outlet Valve - Closed

• Power to Tank - Off (Unplugged)

• Prefilter Flush Valve - Closed

1. Place the Storage Tank in position. Allow for:

• Proximity to the Conserv HE-3 RO System.

• Minimal tubing lengths.

CAUTION: Before operation, the Storage Tank must be

sanitized and filled.

NOTE: The Storage Tank is shipped with the top cover

removed. To reduce the amount of air that must be

purged, push down on the bag, forcing air out of the

air pressure relief valve. When water is added, the

bag will expand and the trapped air will be

purged out.

2. Locate the small accumulator tank (see Figure 11).

8

Sanitize Storage Tank

1. Attach a length of 3/8-inch O.D. tubing to the Storage

Tank Inlet Tee fitting. The tubing should be long enough

to reach the Prefilter Flush Port.

2. Use an air gauge to check the tank's precharge. It should

be 40 psi (2.75 bar, 0.275 MPa).

3. Use an eye dropper or funnel to place 8 oz. (237 mL) of

5.25% bleach (200 ppm) into the tubing.

4. Connect the tubing to the Prefilter Flush Port

(Figure 11). Use the 3/8" to 1/2" adapter and a short

piece of 1/2" O.D. tubing.

Air Pressure

Relief Valve

Prefilter

Flush Port

1/2" O.D.

Tubing

3/8" O.D. to

1/2" O.D. Tubing

Adapter

Accumulator

Tank

Tank Outlet

1/2" O.D. Tubing

Ball Valve

5. Attach a length of 1/2-inch O.D. tubing to the Storage

Tank Outlet fitting. The other end will go to a drain.

6. Install a ball valve on the Storage Tank Outlet tubing and

set the valve to CLOSED.

7. Set the Prefilter Flushing Port Valve to partially open.

This will allow water and bleach to enter the

Storage Tank.

Tank Inlet

To Dr a in

Figure 11

14 WATER YOU CAN TRUST

®

Page 15

Soft Water Inlet Valve

9

Connect Tank Tubing

1. Remove the 3/8" to 1/2" Tubing Adapter and the 1/2" O.D.

tubing. Connect 3/8" tubing from the Storage Tank to

the connection (RO water out) on the Conserv HE-3 RO

System (Figure 13).

NOTE: Cartridges not shown.

NOTE: Cartridges not shown.

Figure 12

NOTE: Any air in the Storage Tank will need to be released.

The Air Pressure Relief Valve will open to remove

trapped air.

8. When the Storage Tank is full, CLOSE the Prefilter

Flushing Valve.

9. Allow the Storage Tank to sit for 15 minutes.

10. Drain the Storage Tank by OPENING the Drain Line

Ball Valve and applying power to the Storage Tank. The

Permeate Pump (P2) will turn on.

WARNING: When applying external power to the Storage

Tank Pump, do not run the pump after the

bladder is empty. When the bladder stops

collapsing, it is empty. Failure to follow this

instruction is likely to damage the pump.

11. Remove power to the Storage Tank and CLOSE the Drain

Line Ball Valve.

12. Repeat Steps 6 through 10, two (2) times.

13. Check that power is off to the Everpure® Conserv® HE-3

RO System.

14. Remove the tubing from the Prefilter Flush Port and

switch it to service (closed).

3/8" O.D. Tubing To Tank Inlet

1/2" O.D.

Tubing

From Tank

to Permeate

Inlet

Sensor

Adapter

Cable

Plug Into Storage Tank

Figure 13

2. Remove the ball valve from the Storage Tank Drain Line.

CAUTION: A water pressure reducing valve has been

included in the parts kit. This valve must be

assembled into the 1/2" O.D. tubing from the

Storage Tank to the permeate inlet. The

directional arrow on the body must point

towards the permeate inlet.

Failure to install the water pressure reducing

valve properly will likely cause damage to the

Conserv HE-3 RO System.

3. Connect the tubing with the water pressure reducing

valve from the Storage Tank Outlet (Storage Tank Drain

Line) to the permeate inlet connection on the Conserv

HE-3 RO System (Figure 13). The water pressure

reducing valve has a directional arrow molded into the

body. This arrow must point towards the Conserv HE-3

Cabinet.

4. Use the Sensor Adapter Cable to connect the electrical

port on the bottom of the Storage Tank to the white

connector from the Conserv HE-3 Cabinet.

5. Install the Storage Tank cover by removing the fitting at

the top. Position the cover and replace the fitting.

®

CONSERV® HE-3 RO SYSTEM INSTALLATION AND OPERATION GUIDE

15 EVERPURE

Page 16

NOTE: The Storage Tank will have a minor amount of

pressure. Some water will exit the hole when the

fitting is removed.

6. CLOSE the Soft Water Inlet Valve.

10

Flush Everpure Postfilter Cartridge

Switch and Valve Starting Positions:

• System Power - Off

• Storage Tank Power - Off

• Soft Water Inlet Valve - Closed

• Hard Water Inlet Valve - Closed

• Hard Water Blend Valve - Open

• Blended Water Outlet Valve - Closed

1. Connect 1/2-inch O.D. tubing to the Blended Water Outlet

Valve. Route this tubing to a drain.

2. OPEN the Hard Water Inlet Valve (Figure 14).

11

Adjust The Blending Valves

There are two (2) valves that are adjustable to provide a blend

of RO permeate and incoming water to suit the application.

RO Blend Valve

Hard Water

Blend Valve

Hard Water

Blend Valve

Hard Water

Inlet Valve

NOTE: Cartridges not shown.

Figure 14

3. OPEN the Blended Water Outlet Valve (Figure 14). Flush

the SEN Postfilter Cartridge(s) to drain for five (5)

minutes.

4. CLOSE the Hard Water Inlet Valve.

5. Remove the tubing from the Blended Water Outlet Valve.

6. Plug the Storage Tank Permeate Pump into the

connection at the bottom of the HE-3 System frame.

Blended Water

Outlet Valve

Soft Water

Inlet Valve

Hard Water

Inlet Valve

Figure 15

To adjust the blend:

1. Determine the desired TDS for the application.

2. Locate the two (2) Blend Valves above the filter

manifolds.

3. OPEN the RO Blend Valve fully, see Figure 15. This allows

maximum flow of the RO permeate water.

4. CLOSE the Hard Water Blend Valve, see Figure 15.

NOTE: This configuration provides only RO permeate water

with no hard water blend.

5. OPEN the Hard Water Blend Valve one (1) full rotation.

6. OPEN the Soft Water and the Hard Water Inlet Valves.

7. With the system turned ON, run water out of the Blended

Water Outlet Valve for two (2) minutes.

8. Test the TDS or check the post-filter status screen.

9. If the TDS is too high, then CLOSE the Hard Water Blend

Valve in small increments and retest. If the TDS is too

low, then OPEN the Hard Water Blend Valve in small

increments and retest. Allow water to flow for two (2)

minutes between tests.

10. When the blend is correct, mount and secure the HE-3

Processor Cover. Place the system into full operation.

Blended

Water Outlet

Valve

16 WATER YOU CAN TRUST

®

Page 17

USER INTERFACE (UI)

Item Name

Value

Setting

The operator of the Conserv HE-3 RO System can use the

touch screen display to access real-time performance data.

Operating parameters and calibration settings may be

reviewed and changed.

Navigation

Button

Press once to access the item shown.

Individual item usually followed by a

value.

The real time value of the individual

item. Also used for calibration values.

The up/down arrows are used to

change the setting value.

Cancel any changes on the current

screen.

Confirm and save any changes on the

current screen.

Jump back one screen.

Conserv® HE-3

System

Status

Calibrate

Sensors

Reset

Filter Life

Clear

Lockout

System

Settings

Contact

Info

Date and

Time

Figure 16

1. Press System Settings and enter the password to access

the Air Purge/Flush menu.

NOTE: Passwords are available through Pentair Everpure

Technical Support at 630.307.3000.

2. Press the Perform Tank Fill button to set the water level

in the tank.

Air Purge/Flush Menu

Jump to the top level home page.

Previous screen, cycles between

screens within each section shown.

Next screen, cycles between screens

within each section shown.

Sleep Mode

The user interface will enter sleep mode after five (5) minutes

of inactivity. The screen will become blank, but all the

functions continue to operate. To wake the screen from sleep

mode, press anywhere on the screen for two (2) seconds.

12

Place Into Operation

When the cartridges are flushed and the blend is set, the

Everpure® Conserv® HE-3 RO System is ready to begin

operation.

All of the tubing should be properly connected (Figure 6).

• OPEN the Hard Water Inlet Valve.

• OPEN the Soft Water Inlet Valve.

• CLOSE the Blended Water Outlet Valve.

• Turn ON the Pump Switch.

• Turn ON the System Switch.

Perform the following procedure to start up the HE-3 RO

System using basic settings.

The User Interface will display the top level Home Screen.

Perform

Air Purge

Perform

Tank Fill

Perform

RO Flush

Perform

RO Rinse

Figure 17

Tank Fill Cycle

Tank Fill in progress.

0

Tank Fill %

Figure 18

When the Tank Fill Cycle is complete, the Tank Fill %

window indicates the percent full.

If the Tank Fill % is over 80%, the Conserv HE-3 RO

System is ready for operation.

3. OPEN the Blended Water Outlet Valve.

If the Tank Fill % is under 80%, an Air Purge/Flush Cycle

must be performed.

4. Return to the Air Purge/Flush menu, press Perform Air

Purge and record the Set value. Select Start.

®

CONSERV® HE-3 RO SYSTEM INSTALLATION AND OPERATION GUIDE

17 EVERPURE

Page 18

NOTE: The Air Purge is used to push out any air that may

Air Purge/Flush Cycle

have entered the Storage Tank. Pressure will build

in the Storage Tank until air is forced out of the

Pressure Relief Valve.

Set value then press START.

Remote monitoring must be enabled to allow a Pentair

CES-9100TS E-30C Water Softener to communicate with

the Everpure Conserv HE-3 RO System.

To have connectivity beween the Everpure® Conserv®

HE-3 RO System and the CES-9100TS E-30C Softener,

a phone cord (Type 4 pin RJ11, not provided with the

system) must be connected between the RO system and

the softener.

Set

1400

START

Cnt

420

Figure 19

5. Begin the Air Purge by pressing Start. Observe the tank

relief valve. When the Air Purge Cycle is over, if no water

has exited the valve then increase the Set value by 25.

Press Start and run another Air Purge. Continue to

increase the Set value and perform an Air Purge until

water exits the Tank Relief Valve.

6. When the Air Purge is complete, press the Arrow button

at the bottom of the screen. The System Settings menu

should be showing.

System Settings Menu

Date and

Time

Units of

Measure

Store

Settings

Air Purge/

Flush

Connection Port

Figure 22

8. On the Store Settings menu, press the Softener In Use

button to enter a Yes or No setting, Figure 23.

NOTE: Only the Pentair CES-9100TS E-30C Water Softener

may be used with the Conserv HE-3 Controller.

Set Softener In Use

CES-9100TS E-30C

Water Softener In Use

no

Figure 20

7. Next, press the Store Settings button to display the Store

Settings menu. Next select Customer Number. The

display will show a screen to enter the customer and

location information for the installation.

Contact Pentair® Everpure® Technical Support to obtain

the customer ID and location numbers.

Set Customer Number

Customer #

01

1 2 3 4 5 6

7 8 9 0

Location #

01234

X

Figure 21

18 WATER YOU CAN TRUST

®

Figure 23

9. Return to the top level home screen.

SYSTEM RECOVERY RATE

The amount of incoming water that becomes RO water

should be 80%. This recovery percentage may be changed

by replacing the flow restrictor in the black waste tubes

located in the RO waste tubing connectors. There is one Flow

Restrictor for each RO head. They are accessed from the top

of the manifold tray.

CAUTION: The system should be run on 80% recovery when

tempered, softened, and under 1,000 ppm TDS

water is available. Any deviation from an 80%

recovery rate will affect the system's production

rate and/or life of the RO membrane. Please

consult Pentair Everpure for a recommendation

of any installation that does not meet this water

specification.

Page 19

Tub e s

NOTE: Some tubing

has been

Flow

Restrictors

removed from

this illustration

for clarity

Figure 24

Select the reject flow control assembly based on the flow

restrictor table below. Insert the reject flow control assembly

into the 1/4" (6.4 mm) O.D. tube, Figure 24. Insert the 1/4"

(6.4mm) O.D. tube with reject flow control assembly into the

elbow fitting on RO head.

Flow Restrictor Table

%

Recovery

Part Number Restrictor Description

90 EV3128-30 Red

80 EV3128-31 Brown

70 EV3128-32 Green

60 EV3128-27 Blue

50 EV3128-28 White Fully Trimmed

40 EV3128-29 Grey

NOTE: Everpure® Conserv® HE-3 RO System is supplied with

40% and 80% recovery restrictors.

For the appropriate selection of flow restrictors for your

application, please consult with Pentair Technical Service at

630.307.3000.

®

CONSERV® HE-3 RO SYSTEM INSTALLATION AND OPERATION GUIDE

19 EVERPURE

Page 20

EVERPURE® CONSERV® COMPLETE HE3 USER

System

Reset

System

Settings

Calibrate

Contact

INTERFACE

The User Interface allows the integration with several

features on the Conserv HE-3 RO System. A complete

explanation of the interface is provided in this manual.

The top level User Interface (UI) Home screen is accessed by

pressing the blank screen for two (2) seconds. This action will

bring the UI out of sleep mode. All other screens will display

a "Home" icon at the lower right corner. Pressing the Home

button will take the UI to the Home screen.

This screen normally will have five (5) buttons. Each button

will access user information.

Displays a set of six (6) buttons that, when

Status

pressed, will show the status of that item.

Settings accessed via this button are:

• Inlet

• Prefilter

• RO Membrane

• RO Water Tank

• Postfilter

• History

After replacing filters, the percentages for

Filter Life

filter life should be reset to 100%.

System

Status

Calibrate

Sensors

Conserv® HE-3

Reset

Filter Life

Clear

Lockout

System

Settings

Contact

Info

Date and

Time

Sensors

Info

This is a password-protected button. These

settings are critical to the operation of the

system. Contact Pentair Everpure Technical

Support, at 630.307.3000 for more information

about this setting.

Settings accessed by this button are:

• Date/Time

• Store Settings

• Air Purge/Flush

• Units of Measure

• Reset Filter Life

This is a password-protected button. These

settings are critical to the operation of the

system. Contact Pentair Everpure Technical

Support, at 630.307.3000 for more information

about this setting.

Settings accessed by this button are:

• Pressure Sensors

• Pressure 4 Threshold

• Tank Level

• TDS Sensors

• Flow Meters

Pentair Everpure contact information.

20 WATER YOU CAN TRUST

®

Page 21

Clear

This button will only display under the following

Date and

Time

Pre

RO

Membrane

RO Water

Post

System Status Menu

Lockout

conditions:

• The Main Pump (P1) is running.

• The system conditions are such that the

Storage Tank should be receiving RO

water.

• The Storage Tank is not filling.

• The Storage Tank Pump (P2) is not

running.

• 20 minutes have elapsed.

If the above conditions are true, then it is likely

there is a water leak in the system. In this

condition, the Conserv HE-3 RO System will

stop all incoming water flow. The Home Screen

buttons will turn to red and the Clear Lockout

button will be displayed. When the leak is

repaired, and no other faults are found, press

the Clear Lockout button to resume operation.

CAUTION: Any repair on the Everpure® Conserv® HE-3 RO

System may compromise water flow and/or

water quality. After repairing the water system,

a thorough review must be made of the areas

affected. Change filters, flush or sanitize as

needed to restore water quality.

Displays the date as mm/dd/yy and the time as

HH:MM am/pm.

System

Status

Calibrate

Sensors

Conserv® HE-3

Reset

Filter Life

Clear

Lockout

System

Settings

Contact

Info

Date and

Time

System Status Menu Interface

The System Status Menu Displays:

Inlet

Press to display inlet water conditions.

Press to display prefilter life.

Filter

Press to display RO process information.

Press to display tank status.

Tank

Press to display postfilter life.

Filter

History

Used for filter life, system statistics, and

performance information.

The Inlet Status screen is displayed when the Inlet button is

pressed. All of the values represent real-time information.

• Inlet flow rate in gallons per minute (gal/min) or Liters

per minute (L/min).

• Inlet pressure as psi (MPa).

• Inlet TDS as ppm.

• Inlet water temperature in °F (°C).

Inlet

History

Inlet Status

Inlet Pressure

Inlet TDS

Inlet Water Temp

Pre

Filter

Post

Filter

RO

Membrane

RO Water

Tank

0.00 gpmInlet Flow Rate

0 psi

0 ppm

32 °F

®

CONSERV® HE-3 RO SYSTEM INSTALLATION AND OPERATION GUIDE

21 EVERPURE

Page 22

RO Membrane Status

The Prefilter Status screen is displayed when the Prefilter

button is pressed.

• Pre-Filter Life is shown as a percentage remaining

based on the volume of water used.

• Pressure Drop represents the pressure difference as

measured before and after the prefilters.

The RO Membrane Status screen is displayed when the RO

Membrane button is pressed. All of the values represent

real-time information.

• RO Water TDS level measured as ppm.

• RO Pump Pressure (P1) of the RO inlet water

measured as psi (MPa).

• Waste TDS level of the water rejected by the RO

cartridge measured as ppm.

• Recovery is the real-time percentage, of the feed water

that becomes blended water.

• Rejection is the real-time percentage, of the minerals

in the water that are sent to waste or drain.

Prefilter Status

Pressure Drop 0 psi

RO Pump Pressure

Waste TDS

Recovery

Rejection 90 %

100 %Pre-Filter Life

0 ppmRO Water TDS

0 psi

0 ppm

80 %

The Water Tank Status screen is displayed when the RO

Water Tank button is pressed.

• Tank Status is an indicator of the water level (filling/

emptying/idle).

• Tank Level is the real-time percentage of the volume

of water in the Storage Tank.

The Post-Filter Status screen is displayed when the Postfilter

button is pressed. All of the values represent real-time

information.

• Outlet Pressure of the filtered water in psi (MPa).

• Pressure Drop represents the real-time pressure

difference as measured before and after the

postfilter(s).

• Blend Flow Rate is a measure of the water flow out of

the system to the application. It is measured in gallons

per minute (gal/min) or Liters per minute (L/min).

• Blend TDS is a real-time measurement in ppm of the

water going to the application.

• Post Filter Life is shown as a percentage remaining

based on the volume of water used.

Water Tank Status

IdleTank Status

Tank Level0 %

Post-Filter Status

0 psiOutlet Pressure

Pressure Drop

Blend Flow Rate

Blend TDS

Post Filter Life 100 %

0 psi

1.57 gpm

200 ppm

22 WATER YOU CAN TRUST

®

Page 23

Press the History button to display the first page of the

system's history. Use the Left/Right arrow buttons to move to

pages 2 and 3.

NOTE: Most of these values cannot be reset in the History

menus, with the exception of filter life percentages.

All of the values are real-time unless listed as Max

or Min.

The maximum and minimum inlet TDS values reflect the

highest and lowest TDS readings over the life of the system.

NOTE: Recovery and Rejection percentages will not total

100%. Recovery is the percentage of water that

becomes RO permeate and is sent to the Storage

Tank. Rejection is the percentage of minerals in

the water that do not pass through the RO filter

membrane.

History Page 1

Post-Filter Life

RO Membrane Life

Max Recovery

Min Recovery 90 %

History Page 2

RO Pump Hours

Tank Pump Cycles

Tank Pump Hours

# of Air Purge 0

# of Flushes 0

History Page 3

100 %Pre-Filter Life

100 %

100 %

80 %

1234567RO Pump Cycles

12345

1234567

12345

1234.5 galsInlet Flow Total

Max Inlet TDS

Min Inlet TDS

Blend Flow Total

Max Blend TDS 0 ppm

Min Blend TDS 0 ppm

1234.5 gals

809 ppm

1234.5 gals

®

CONSERV® HE-3 RO SYSTEM INSTALLATION AND OPERATION GUIDE

23 EVERPURE

Page 24

Reset Filter Life Menu Interface

Date and

Units of

Store

Air Purge/

Production

Date and

On the Top Level Menu, press the Reset Filter Life button to

display buttons that are used to reset the life percentages

of the individual filters. These buttons are used when the

cartridges are changed. Press to reset. The word "RESET"

will display when the filter life has been reset.

Carbon Prefilter life is displayed on the Prefilter Status

screen and the History Page 1 screen.

RO Membrane Life is displayed on the History Page 1 screen.

Carbon Post-Filter Life is displayed on the History Page 1

screen.

The # of RO is used to select the number of RO membrane

cartridges that are installed on the system.

Carbon

Pre-Filter

RESET

RO

Membrane

Reset Filter Life

Carbon

Post-Filter

# of RO

1 2

System Settings Menu Interface

On the top level menu, accessing the System Settings Menu

requires a password. Contact Pentair Everpure Technical

Support at 630.307.3000 to acquire the password.

Enter the password at the Home screen. The System Settings

Menu displays:

Used to enter/change the date and time.

Time

Press to make changes to the units and values

Measure

shown in the User Interface.

Press to make changes to settings for the

Settings

application.

Press to perform a manual tank air purge, a

Flush

flush, RO rinse, or a tank fill.

Press to view troubleshooting and sensor

Test

information.

Press the Set Date and Time Button to display

Time

a screen for setting the Day/Month/Year and

Time.

DST and

UTC

Press the Set DST and UTC button to display a

screen for setting Daylight Savings Time and

the time zone.

DST: Daylight Savings Time

UTC: Coordinated Universal Time

System Settings Menu

Date and

Time

Units of

Measure

System Settings Menu

Set Date

and Time

Store

Settings

Air Purge/

Flush

Set DST

and UTC

Adjust the settings and press the Check Mark to confirm and

change.

24 WATER YOU CAN TRUST

®

Date And Time

01

jan 16

fri

12 00 am

Page 25

Choose Yes or No for Daylight Savings Time. Set the

Air Purge

Customer

Softener

Coordinated Universal Time (UTC) to match the location of

the installation:

- 5 for East Coast

- 6 for Central Time

- 7 for Mountain Time

- 8 for West Coast

Press the Check Mark to confirm and change.

DST and UTC Time Zone

DST Activeyes

-6UTC Time Zone

Press the Units of Measure button to show the measurement

units displayed in the user interface. Press the unit shown to

change:

• PSI to MPa

• Gallons to Liters

• Fahrenheit to Celcius

Press the Store Settings Menu button to display:

Used to view and change the number of hours

Frequency

between air purgings.

Customer number and customer location are

Number

entered. This information is supplied by Pentair

Everpure.

The Pentair CES-9100TS E-30C Water Softener

In Use

has the ability to communicate with the Pentair

Everpure Conserv HE-3 RO System. If this

feature is used, select this screen and set to

YES.

Units of Measure

Pressure PSI

GALSFlow Rates/Totals

TemperatureºF

Store Settings Menu

Air Purge

Frequency

Customer

Number

Softener

in Use

On the Store Settings Menu, press the Air Purge Frequency

button to display the number of hours to the next automatic

air purge. The hours between air purgings may be changed.

Interval System Parameters

6 Hrs 1 RO membrane and cold water (below 70°F

[21°C])

5 Hrs 1 RO membrane and warm water (above 70°F

[21°C])

4 Hrs 2 RO membranes and cold water (below 70°F

[21°C])

3 Hrs 2 RO membranes and warm water (above 70°F

[21°C])

®

CONSERV® HE-3 RO SYSTEM INSTALLATION AND OPERATION GUIDE

Air Purge Frequency

# Of Hours To Next Air Purge

6

25 EVERPURE

Page 26

To enable remote monitoring on this unit, a customer ID and

location number must be entered.

On the Store Settings menu, press the Customer Number

button to enter the customer's ID number and location

number. These are supplied by Pentair Everpure.

NOTE: The fields must be green to enter numbers.

Contact Pentair® Everpure® Technical Support to obtain the

customer ID and location number.

Set Customer Number

Customer #

01

2 3 4 5 6

1

7 8 9 0

Location #

01234

X

When the HE-3 is connected with the Pentair CES-9100TS

E-30C, the HE-3 will sense low salt and no salt conditions

from the softener. On the Store Settings Menu, press the

Softener In Use button to enter a Yes or No setting.

To have connectivity beween the Everpure® Conserv® HE-3

RO System and the CES-9100TS E-30C Softener, a phone

cord (Type 4 pin RJ11, not provided with the system) must be

connected between the RO system and the softener.

NOTE: Only the Pentair CES-9100TS E-30C Water Softener

may be used with the Pentair Everpure Conserv

HE-3 Controller.

On the System Settings Menu, pressing the Air Purge/Flush

Menu button will provide four (4) selections: Perform Air

Purge, Perform Tank Fill, Perform RO Flush and Perform RO

Rinse.

Selecting Perform Air Purge will fill the Storage Tank and

force air out. This cycle is based on tank level settings

entered in the System Settings Menu.

Set Softener In Use

CES-9100TS E-30C

Water Softener In Use

Air Purge/Flush Menu

Perform

Air Purge

Perform

Tank Fill

no

Perform

RO Flush

Perform

RO Rinse

Selecting the Perform RO Flush will begin a flush cycle. The

flush will push RO water from the storage tank into the RO

cartridge(s). This forces the inlet water with high mineral

content out and surrounds the RO membrane(s) with RO

water on both sides.

The Flush Cycle is used to preserve the RO membrane during

periods of inactivity, such as overnight. The system will

resume normal operation when there is a demand for RO

water.

The system will automatically perform a Flush Cycle if there

has not been any flow for two (2) hours. If inactivity continues,

another Flush Cycle will be performed after 12 hours.

NOTE: The Everpure Conserv HE-3 RO System will perform

an automatic flush after 90 minutes of operation or

every 12 hours if it is idle.

26 WATER YOU CAN TRUST

®

Air Purge/Flush Cycle

Flush Cycle in progress.

Page 27

Press the Perform Tank Fill Button to display the Tank Fill

Air Purge/Flush Cycle

Progress screen. This will show the tank percentage full and

the current action.

Tank Fill Cycle

Tank Fill in progress.

0

Tank Fill %

Select Perform RO Rinse will pass water over a new RO

cartridge to initialize it.

At the start of an Air Purge, the Storage Tank must be above

80% full (as shown on the Tank Fill Cycle screen) for the Air

Purge to finish properly. If the Storage Tank is below 80% full,

navigate to the System Settings Menu and select Air Purge/

Flush. When the four (4) choices appear, press the Perform

Tank Fill button. A forced manual Storage Tank fill will occur.

When the Storage Tank fill is completed, return to the Air

Purge/Flush Cycle menu and record the Set value. Move back

to the Air Purge/Flush Menu and select Perform Air Purge.

NOTE: The Air Purge is used to push out any air that may

have entered the storage tank. Pressure will build in

the tank until air is forced out of the pressure relief

valve.

Observe the Storage Tank Pressure Relief Valve. When the

Air Purge cycle is over, if no water has exited the valve then

increase the Set value by 25. Press Start and run another

Air Purge. Continue to increase the Set value followed by an

Air Purge until water exits the Storage Tank Pressure Relief

Valve.

During an Automatic Air Purge, the status will be filling. The

Storage Tank level will be increasing.

IMPORTANT: The Storage Tank Air Purge cycle is based on

a setting that was established from the Air

Purge settings screen. If a manual Air Purge

was performed or excess water is leaking

from the Storage Tank Pressure Relief Valve,

the Storage Tank water level setting should be

reset.

Air Purge/Flush Cycle

RO Rinse in progress.

System Settings Menu

Date and

Time

Units of

Measure

Air Purge/Flush Menu

Perform

Air Purge

Perform

Tank Fill

Set value then press START.

Store

Settings

Air Purge/

Flush

Perform

RO Flush

Perform

RO Rinse

®

CONSERV® HE-3 RO SYSTEM INSTALLATION AND OPERATION GUIDE

Set

1400

START

Cnt

420

27 EVERPURE

Page 28

Calibrate Sensors Menu Interface

Pressure

Pump 2

Tank

Level

TDS

Sensors

Flow

oduction

w0

On the top level menu, accessing the Calibrate Sensors Menu

requires a password. Contact Pentair Everpure to acquire the

password.

CAUTION: Incorrect sensor settings will result in improper

operation of the Everpure® Conserv® HE-3 RO

System. Sensor calibration has been set at the

factory and should only be changed if a new

sensor has been installed. Use the calibration

data listed on the new sensor.

At the Home Screen, enter the password. The Calibrate

Sensors Menu displays:

Used to enter pressure sensor calibration

Sensors

settings.

Used to enter permeate pump (P2) threshold

Threshold

calibration settings.

Used to enter Storage Tank level sensor

calibration settings. Also used to enter offset

percentages for tank fill and tank empty.

Used to enter calibration settings for the four

(4) TDS sensors.

Used to enter sensor calibration settings for

Meters

flow meters F1 and F2.

Calibrate Sensors Menu

Pressure

Sensors

TDS

Sensors

Pump 2

Threshold

Flow

Meters

Tank

Level

Production

Test

Pr

Test

Select Production Test from the System

Settings Menu to access troubleshooting and

sensor information. The tank sensor has a

preset value and will not be shown.

CAUTION: The Storage Tank will be in fill mode as long as

the Production Test screen is displayed. When

this screen has been exited, the Storage Tank

will stop filling.

Press the Pressure Sensors button to display the Pressure

Calibration screen. Use the "c" value that is provided with the

new sensor.

To change the settings:

1. Press the window for the "c" value of the sensor.

2. Use the Up and Down arrows to enter the value listed on

sensor packaging.

3. When finished, press the Check Mark to save the

changes.

Press the Pump 2 Threshold button to display the Threshold

Calibration screen. This screen sets the pressure value for

the permeate pump (P2).

To properly set this value:

After blend is set, unplug tank pump. Allow system to

normalize, then record Run value. Enter Run value +5 into Set

box, confirm input, then re-plug in the pump.

Pressure Calibration

Sensor#

mc

Sensor 1-

Sensor 2

Sensor 3

Sensor 4

Sensor 5

Pump 2 Threshold Calibration

Set

Lo

After blend is set, unplug tank pump.

Allow system to normalize, then

record Run value. Enter Run value +5

into Set box, confirm input, then

re-plug in pump.

30

-

-

-

-

Run

28 WATER YOU CAN TRUST

®

Page 29

Press the Tank Level button to display the Tank Level

Calibration screen. Use the "m" and "b" values that are

shown on the Storage Tank sensor packaging.

CAUTION: If the High setting is above the value displayed

in the Run window, (refer to Pump 2 Threshold

Calibration screen) the (P1) pump will not turn off.

If the Low setting is below the value displayed in

the Run window, the (P1) pump will not turn on.

To calibrate the tank level sensor:

1. Press the window for the "m" value.

2. Use the Up and Down arrows to enter the value listed on

the sensor.

3. Press the window for the "b" value.

4. Use the Up and Down arrows to enter the value listed on

the sensor.

5. When finished, press the Check Mark to save the

changes.

NOTE: The Counts window is used by Pentair Everpure

Customer Service as a diagnostic tool.

Press the TDS Sensors button to display the TDS Calibration

screen. Use the calibration setting (C) that is shown on the

sensor packaging.

To change the TDS calibration setting:

1. Press the window for the "C" value of the sensor.

2. Use the Up and Down arrows to enter the value listed.

3. When finished, press the Check Mark to save the

changes.

Tank Level Calibration

Tank Level

mb

67 28

Counts

18

TDS Calibration

C

TDS 1 3.30

3.30TDS 2

TDS 3 3.30

3.30TDS 4

®

CONSERV® HE-3 RO SYSTEM INSTALLATION AND OPERATION GUIDE

29 EVERPURE

Page 30

Press the Flow Meters button to display the Flow Meter

Calibration screen. Use the "m" and "b" settings that are

shown on the flow meter packaging.

NOTE: System comes calibrated from the factory. Flow

meter calibration is only required when replacing a

flow meter.

To change the settings:

1. Press the window for the "m" value of the flow meter.

2. Use the Up and Down arrows to enter the value listed.

3. Press the window for the "b" value of the flow meter.

4. Use the Up and Down arrows to enter the value listed.

5. When finished, press the Check Mark to save the

changes.

Contact Info

Press the Contact Info button to display Pentair's address and

phone number.

Flow Meter Calibration

FMeter#

mb

0.00 0.00

Hanover Park, IL 60133

F1

F2

Conserv® HE-3

Pentair

1040 Muirfield Dr

(630) 307-3000

0.000.00

30 WATER YOU CAN TRUST

®

Page 31

MAINTENANCE SECTION

Performance Log

Test Date Run Hours

Outlet Flow

RO Water

Only

ounce/min

or

mL/min

Reject Flow

ounce/min

or

mL/min

Inlet

Pressure/

Temp.

psi/°F

or

MPa/°C

Inlet TDS

mg/L

Hard Water

TDS mg/L

RO Outlet

TDS mg/L

Percent TDS

Reduction

NOTES:

®

CONSERV® HE-3 RO SYSTEM INSTALLATION AND OPERATION GUIDE

31 EVERPURE

Page 32

TROUBLESHOOTING GUIDE

Problem Possible Cause Remedy

1. Insufficient blended

water volume during

normal operating

periods.

2. Insufficient blended

water volume during

peak periods.

Cartridge(s) plugged. Replace cartridge(s).

MR-600F RO Membrane Cartridge plugged. Replace MR-600F RO Membrane Cartridge.

Insufficient system inlet pressure. Check/repair booster pump and inlet line.

Refer to Problem 1. Refer to Problem 1.

System output too low for application. Verify system output. If output is within specification, increase output if applicable.

3. Low quality RO water. Refer to Problem 1. Refer to Problem 1.

MR-600F RO Membrane Cartridge failure. Replace MR-600F RO Membrane Cartridge.

4. Low water pressure

Restrictive tubing/piping run to equipment. Increase tubing/piping diameter. Refer to "System Installation" section for recommendations.

at water-using

equipment.

5. Objectionable blended

Prefiltration cartridge(s) exhausted. Replace prefiltration cartridge(s).

water odor.

6. Waste water flow too

low or decreases over

time.

Drain line restricted. Check/correct any restrictions in drain line tubing. Make sure to allow for an air gap at the drain.

Disconnect reject line at quick-connect fitting and inspect for obstruction or damage. Remove

obstruction. Replace if required.

Insufficient system inlet pressure. Check/repair booster pump and inlet line.

7. Pressure limit warning

error.

Electrical connector at the pressure transducer not

fully engaged.

Check electrical connector engagement with pressure transducer.

RO permeate pressure exceeds 114 psi (0.79 MPa). Check for restriction/blockage in permeate line causing abnormally high pressure. Relieve

pressure in permeate line and correct restriction/blockage condition.

RO cartridge bypassing. Measure RO permeate flow and TDS, then compare to previously recorded values or system

specifications. High permeate flow and/or poor TDS reduction indicates excessive passage of

water around or within the RO cartridge. Remove the RO cartridge and check the integrity of all

three (3) o-ring seals and correct as needed. If seals appear OK, replace the RO cartridge. After

making the repairs, press any key on controller to clear the fault, then recheck RO permeate

flows and TDS, then compare to previously recorded value or system specifications. If the fault

reappears after returning to normal operation, replace controller and/or pressure transducer or

contact Pentair® Everpure® Technical Support for further assistance.

32 WATER YOU CAN TRUST

®

Page 33

REPLACEMENT PARTS CONSERV HE3 RO SYSTEM

Contact your local Pentair Everpure Dealer for replacement

and spare parts.

11

7

1

3

Number Part Number Description

1 EV3148-51 Manifold Tray Assy

2 EV3145-01 Flotec® Pump

3 EV3111-61 Valve, Needle, PVC, 3/8"

4 EV3146-64 Controller

5 EV3119-75 Union Tee, 1/2" Tube

6 EV3149-69 Screen

7 EV3148-02 Valve, 1/2" x 1/2" Pl QC

8 EV3148-10 Check Valve, 1/2" x 1/2" Pl QC

9 EV3103-90 Reducing Elbow, 1/2" x 3/8"

10 EV3103-91 Check Valve

11 EV3128-08 Flush Valve, Solenoid, 24 VDC

* EV9692-66 Everpure SEN+ Fine Filter Cartridge, 1 PK

* EV9692-65 Everpure SEN Fine Filter Cartridge, 1 PK

* EV9627-22 Everpure MR-600F RO Membrane Cartridge

*Not Shown

6

4

2

10

8

9

5

®

CONSERV® HE-3 RO SYSTEM INSTALLATION AND OPERATION GUIDE

33 EVERPURE

Page 34

REPLACEMENT PARTS PERMEATE STORAGE TANK

13

12

5

17

15

4

1

24

18

25

16

18

7

21

22

Number Part Number Description

1 EV3145-33 PU Bladder, 15 gal.

2 EV3150-66 Vane/Delivery Pump

3 EV3145-74 Tank Shell Assy

4 EV3145-73 SM Tank Bottom/Top

5 EV3145-75 Accumulator, 0.5 gal

6 EV3112-51 Endcap, 3/4" NPT 1/2" JG Fitting

7 EV3119-75 Union Tee, 1/2" Tube

8 EV3148-01 Elbow, 1/2" QC x 3/8" NPT QC

9 EV3148-10 Check Valve 1/2 x 1/2 Pl QC

10 EV3146-12 Fitting, 1/2" NPT x 1/2 QC

11 EV3146-11 Elbow, 1/2" Stem x 1/2 QC

12 EV3148-03 Connector, 1/2" NPT x 3/8" QC

13 EV3144-24 Tee, Stem 3/8"

14 EV3144-99 Transducer, 0-15 psi

15 EV3145-61 Pressure Valve

16 EV3146-14 Elbow, 1/2" QC x 1/2" QC

17 EV3128-43 White PE Tube, 3/8" OD, 1.75" L

18 EV3148-11 White PE Tube, 1/2" OD, 2.0" L

26

27

23

16

6

7

15

10

14

19

3

27

11

2

18

8

11

Number Part Number Description

19 EV3145-19 Tank Base

20 EV3149-02 Male Connector

21 EV3148-11 White PE Tube, 1/2" OD, 3.0" L

22 EV3148-00 Elbow, 3/8" x 1/2" PI QC

23 EV3128-43 White PE Tube, 3/8" OD, 2.5" L

24 EV3149-77 Strap, HE-3 Accumulator

25 EV3148-11 White PE Tube, 1/2" OD, 4.750" L

26 EV3148-11 White PE Tube, 1/2" OD,

27 EV3148-11 White PE Tube, 1/2" OD

11

9

34 WATER YOU CAN TRUST

®

Page 35

MAINTENANCE

The Everpure® Conserv® HE-III System requires very little

maintenance. Regular cartridge replacement, system

recovery verification, and sanitization are the only normal

maintenance requirements. Typical service schedules are as

listed below.

Every 12 Months (Recommended)

Replace all of the cartridges and sanitize the permeate

storage tank.

Switch and valve starting positions:

• Power - OFF

• Soft Water Inlet Valve - CLOSED

• Hard Water Inlet Valve - CLOSED

• Blended Water Outlet Valve - CLOSED

1. Remove the cover on the Conserv HE-3 RO System.

NOTE: When the cartridges are removed, water will leak

from the heads. Be prepared to catch or clean up any

spills.

2. OPEN the outlet valve. Use the application equipment to

release water pressure. CLOSE the outlet valve.

3. Have the new replacement cartridges ready to install.

Remove all the old cartridges by grasping the outside of

the cartridge. Push up and turn it to the left until it stops.

The cartridge will then pull straight down and out.

4. Refer to "Prefilter and RO Cartridge Installation and

System Start-up" on page 12. Perform Steps 1

through 14.

5. Refer to the section "7 Prepare Storage Tank" on

page 14. Perform Steps 2 through 17.

6. Refer to the section "10 Flush Everpure Postfilter

Cartridge" on page 16, Perform Steps 1 through 10.

The system is ready to run. Use application blended water

for five (5) minutes and test the TDS. If the measured

TDS reading is not within the required specification of the

application, then the blend should be adjusted.

7. To adjust the TDS of the blended application water, refer

to the "

Adjust The Blending Valves" on page 16.

11

COMPLIANCE STATEMENTS

Check for compliance with state and local laws and regulations.

Do not use with water that is microbiologically unsafe, or of

unknown quality without adequate disinfection before or after

the system.

Substances reduced are not necessarily in your water. System

must be maintained according to manufacturer’s instruction,

including replacement of filter cartridges.

This system contains a replaceable mineral reduction (RO)

module critical for the effective reduction of total

dissolved solids.

Blended water should be tested periodically to verify that the

system is working properly.

This reverse osmosis system contains a replaceable

component critical to the efficiency of the system.

Replacement of the reverse osmosis component should

be with one of identical specifications, as defined by the