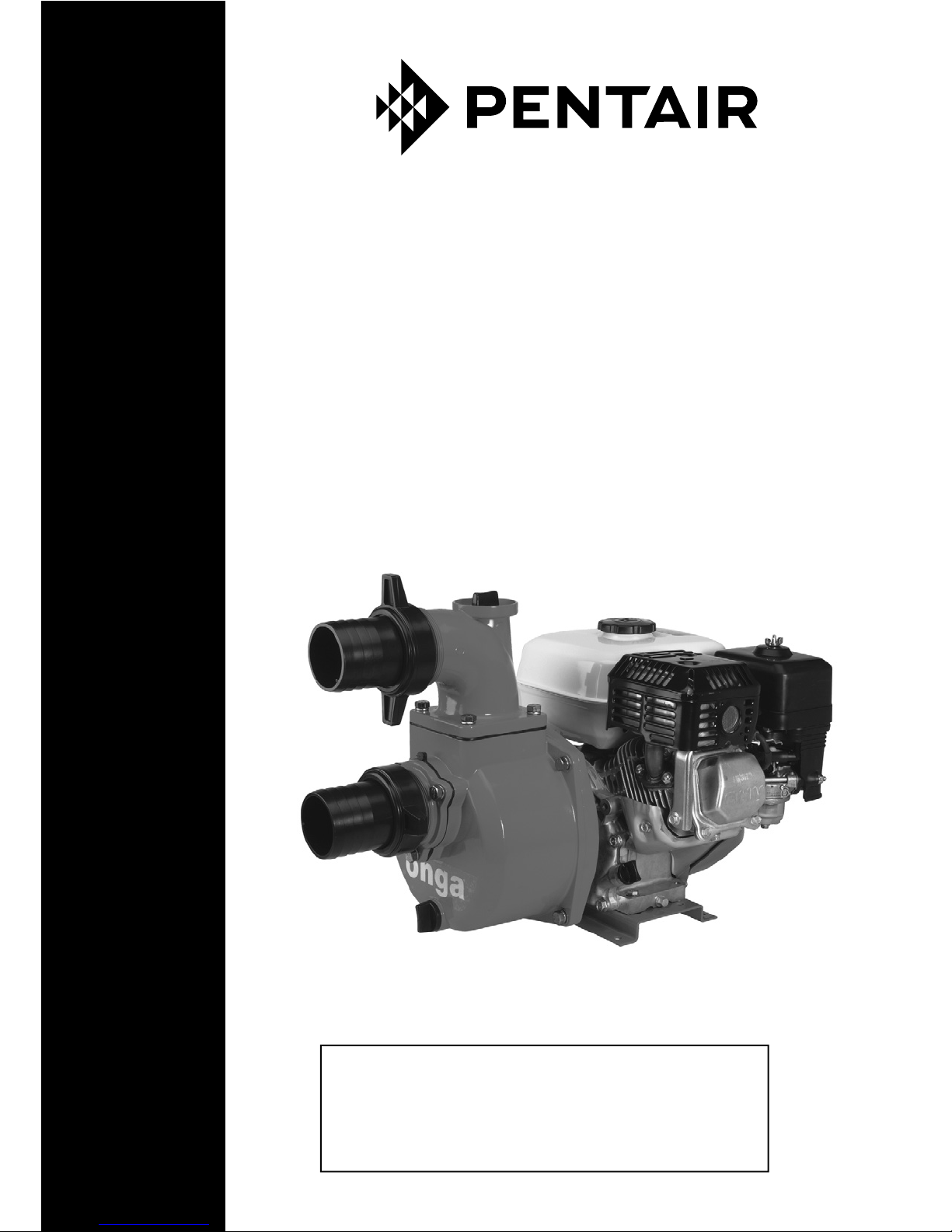

ENGINEMASTER

ENGINE DRIVEN WATER TRANSFER SYSTEM

GP960

OWNER`S MANUAL

1

Should the installer or owner be unfamiliar with the

correct

installation or operation of this type of

equipment,

contact the distributor or manufacturer

for correct

advice before proceeding with installation

or operation

of

the product

®

ONGA

2

Relax - you’ve bought an onga ...

Congratulations on your decision to purchase an onga

product. onga is one of the best known companies in its

field, with a proud local and international reputation.

In fact, wherever people need to move water from one point to

another - whether in industry, horticulture, agriculture or in and

around the home - onga is a byword for reliability, value for money

and technological innovation. So why does onga lead its field?

Here are a few simple reasons ...

1. Continual Product Improvement

onga employ the best engineers both in Australia and around the

world to develop new and better ways to pump and handle water.

2. Dedication to Quality

There is only one standard that we at onga set ourselves for both

product quality and the quality of our service. That standard is

excellence ... to have no-one better than us at what we do ... nothing

short of that is acceptable.

3. A Fair Price

onga pumps are neither the cheapest nor the most expensive in their

field. Our products do, on the other hand, always represent very

good value for money - they always have and they always will.

4. Our Team of Dealers

We believe onga’s hand picked authorised dealer network throughout Australia and worldwide - are second to none. We in

vest a huge sum training them and supporting them. They are your

link to us, and we value their expertise and trust.

3

OPERATING INSTRUCTIONS

Please read these instructions in full before installing and commissioning the pump unit.

Pump Protection

Warranty of these pumps is void unless they are housed correctly and

protected from weather, floods, chemicals, dust, vermin, insects etc.

Housing used should be weather-proof and well vented so that engine

heat and exhaust fumes can escape. To obtain best possible performance, pumps should be installed as close to water as possible.

Suction and Discharge Pipes

Suction pipe should be laid so that it rises evenly from water source to

pump. This makes priming easy and avoids airlocks.

Hoses should be the same size as the pump inlet and/or larger than the

discharge port.

All pipe joints must be sealed to ensure they are airtight.

Priming

To prime pump, remove priming plug and fill pump and suction pipe

with water. Pump is equipped with suction flap valve and should be

capable of drawing air out of normal size suction pipes or hoses. Replace plug and start the pump. If the pump pumps a little and stops,

turn the pump off, check suction pipe for possible leaks and repeat

priming procedure until the pump operates satisfactorily.

Self priming pumps, when filled with water, will gradually draw air out

of the suction line (depending on model) to a maximum vertical lift of

6 metres (20 ft). If priming a long or large diameter pipe, additional

water may have to be added to the pump at 3 minute intervals.

Loading...

Loading...