Eclipse® High Rate Sand Filter Owner's Manual

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

Table of Contents

SECTION I. FILTER INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SECTION II. FILTER OPERATION AND CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SECTION III. EQUIPMENT MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

SECTION IV. TROUBLE SHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

SECTION V. TECHNICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

SECCIÓN I. INSTALACIÓN DEL FILTRO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

SECTION I. INSTALLATION DU FILTRE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

WARNING

Before installing this product, read and follow all warning notices and instructions accompanying this filter. Failure to

follow safety warnings and instructions can result in severe injury, death, or property damage.

Call (800) 831-7133 for additional free copies of this manual.

Important Notice

Attention Installer.

This manual contains important information about the installation, operation and safe use of this product.

This information should be given to the owner/operator of this equipment.

SECTION I. FILTER INSTALLATION.

1. The filter should be mounted on a level concrete slab. Position the filter so that the instructions, warnings and pressure

gauge are visible to the operator. Also, position the filter so that the piping

connections, control valve and drain port are convenient and accessible for

servicing and winterizing.

2. Install electrical controls (e.g., on/off switches, timers, control systems,

etc.) at least five (5) feet from the filter. This will allow you enough room to

stand clear of the filter during system start up.

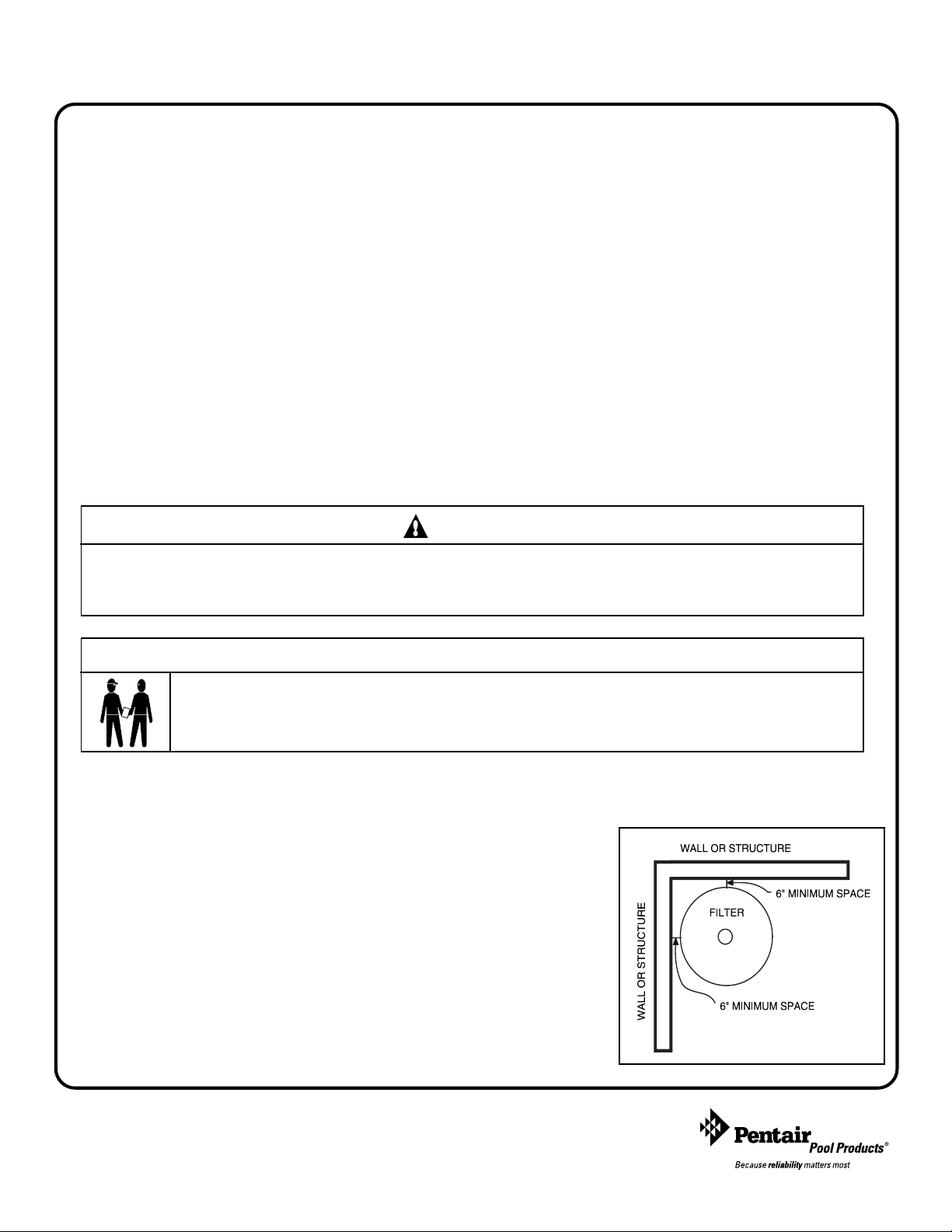

3. Provide sufficient clearance around the filter to permit visual verification

that the clamp is properly installed, see Figure 1.

4. Provide sufficient space above the filter to remove the filter lid or control

valve for cleaning and servicing. This distance will vary with the model of

filter you are using. See Table 1 for the required vertical clearance.

Pentair Pool Products

1620 Hawkins Ave., Sanford, NC 27330 • (919) 774-4151

10951 West Los Angeles Ave., Moorpark, CA 93021 • (805) 523-2400

Rev. H • Rev. H • Rév. H 5-15-01 1 P/N • Núm/Pte. • Réf. P/N 99226000

Figure 1.

5. When installing the High Flow™ manual air relief valve

position the filter to safely direct water drainage. Rotate the

High Flow™ manual air relief valve to safely direct purged air

or water. Water discharged from an improperly positioned

filter or valve can create an electrical hazard as well as damage

to property.

Model Size Vert. Clear. Req.

58920100 3.5 sq. ft. 49 in.

58920200 4.6 sq. ft. 51 in.

58920300 6.5 sq. ft. 57 in.

Table 1.

WARNING

Risk of electrical shock or electrocution. Position the filter and High Flow™ manual air relief valve to safely direct water

drainage and purged air or water. Water discharged from an improperly positioned filter or valve can create an electrical hazard

that can cause severe injury as well as damage property.

6. Your filter requires one of the following Pentair Pool Products accessories which must be purchased separately.

a. Push-pull valve.

b. Multiport valve.

c. Bulkhead union set.

7. Make all plumbing connections in accordance with local plumbing and building codes. Filter plumbing connections are

provided with an O-ring seal. Use only a silicone base lubricant on the O-rings. Do not use pipe joint compound, glue or

solvent on the bulkhead connections to avoid damage to the O-rings.

CAUTION

For Multiport control valves with threaded ports use only Teflon tape, 100% pure Teflon paste (non-petroleum base), Permatex #2 sealant

on all threaded pipe connections, except fittings with O-rings. Use of other pipe joint compounds can damage components of this system

and cause leaks. For control valves with slip ports, use only ABS to PVC solvent welding adhesive.

8. The maximum working pressure of this filter is 50 psi, see Table 2. Never subject this filter to pressure in excess of this amount

- even when conducting hydrostatic pressure tests. Pressures above maximum working pressure can cause the lid to be blown

off, which can result in severe injury, death or property damage.

When performing hydrostatic pressure tests or when testing for external leaks of the completed filtration and plumbing

system, insure that the Maximum Pressure that the filtration system will be subjected to DOES NOT EXCEED THE

MAXIMUM WORKING PRESSURE OF ANY OF THE COMPONENTS CONTAINED WITHIN THE SYSTEM. In most

cases, the maximum pressure will be stated on each component of the system.

If doubt exists as to the pressure to which the system will be subjected, install an ASME approved automatic Pressure Relief

or Pressure Regulator in the circulation system for the lowest working pressure of any of the components in the system.

SECTION II. FILTER OPERATION AND CLEANING.

WARNING

THIS FILTER OPERATES UNDER HIGH PRESSURE. WHEN ANY PART OF THE CIRCULATING SYSTEM (E.G., CLAMP,

PUMP, FILTER, VALVES, ETC.) IS SERVICED, AIR CAN ENTER THE SYSTEM AND BECOME PRESSURIZED.

PRESSURIZED AIR CAN CAUSE THE LID OR CONTROL VALVE TO BLOW OFF WHICH CAN RESULT IN SEVERE INJURY,

DEATH, OR PROPERTY DAMAGE. TO AVOID THIS POTENTIAL HAZARD, FOLLOW THESE INSTRUCTIONS.

1. BEFORE REPOSITIONING VALVES AND BEFORE BEGINNING THE ASSEMBLY, DISASSEMBLY, OR ADJUSTMENT

OF THE CLAMP OR ANY OTHER SERVICE OF THE CIRCULATING SYSTEM: (A) TURN THE PUMP OFF AND SHUT

OFF ANY AUTOMATIC CONTROLS TO ENSURE THE SYSTEM IS NOT INADVERTENTLY STARTED DURING THE

SERVICING; (B) OPEN HIGH FLOW™ MANUAL AIR RELIEF VALVE; (C) WAIT UNTIL ALL PRESSURE IS RELIEVED,

PRESSURE GAUGE MUST READ ZERO (0).

2. WHENEVER INSTALLING THE FILTER CLAMP, FOLLOW THE FILTER LID AND CLAMP INSTALLATION

INSTRUCTIONS EXACTLY.

3. ONCE SERVICE ON THE CIRCULATING SYSTEM IS COMPLETE, FOLLOW SYSTEM RESTART INSTRUCTIONS

EXACTLY.

4. MAINTAIN CIRCULATION SYSTEM PROPERLY. REPLACE WORN OR DAMAGED PARTS IMMEDIATELY (E.G.,

CLAMP, PRESSURE GAUGE, RELIEF VALVE, O-RINGS, ETC.).

5. BE SURE THAT THE FILTER IS PROPERLY MOUNTED AND POSITIONED ACCORDING TO INSTRUCTIONS

PROVIDED.

P/N • Núm/Pte. • Réf. P/N 99226000 2 Rev. H • Rev. H • Rév. H 5-15-01

A. GENERAL INFORMATION - HOW YOUR FILTER WORKS.

1. Your high rate sand filter is designed to produce clear, sparkling water and operate for years with a minimum of maintenance

when installed, operated and maintained in accordance with these instructions:

Your filter uses special filter sand to remove dirt particles from the water. Dirt is collected in the filter by the sand bed as

water flows through the filter. Water enters the filter through the valve on top of the filter (or the top bulkhead fitting in the

case of side mounted control valves). It is then distributed evenly downward, across and through the sand bed. The dirt is

removed by the sand and the clean water flows through the piping (laterals) at the bottom of the filter up through the center

pipe back to the valve on top of the filter (or out of the lower bulkhead on side mounted filters), where the clean water is

returned to the pool through the piping.

After a period of time, dirt will accumulate in the filter causing a resistance to the flow of water through the filter. This

resistance results in a diminished flow rate and a rise in the pressure of the filter. Eventually the filter sand will have removed

so much dirt and the filter pressure risen to such a point that it will be necessary to clean (backwash) your filter.

By setting the control valve on the top or side of the filter to the backwash position, the flow direction of water is reversed

through the filter so that the water is directed to the bottom of the filter and up through the sand bed flushing the dirt and

debris out through the waste line. Once the backwash procedure is complete, the valve must be returned to its filter position to

resume normal filtration.

The filter’s function is to remove suspended matter from the water and does not sanitize the water. For sparkling clear water

the water must be sanitized as well as chemically balanced. Pool chemistry is a specialized area and you should consult your

local pool service specialist for specific details. In general, proper pool sanitation requires a free chlorine level of 1 to 2 PPM

and a pH range of 7.2 to 7.6.

WARNING

Failure to operate your filter system or inadequate filtration can cause poor water clarity obstructing visibility in your pool. POOR WATER

CLARITY MAY OBSCURE OBJECTS IN THE WATER WHICH MAY EXPOSE SWIMMERS OR DIVERS TO THE RISK OF SEVERE INJURY OR

DEATH. NEVER SWIM IN A POOL WITH POOR WATER CLARITY.

2. This filter operates under pressure. When clamped properly and operated without air in the water system, this filter will

operate in a safe manner.

3. The pressure gauge is the primary indicator of how the filter is operating. Maintain your pressure gauge in good working order.

CAUTION

The following information should be read carefully since it outlines the proper manner of care and operation for your filter system. As a

result of following these instructions and taking the necessary preventative care, you can expect maximum efficiency and life from your

filtration system.

B. FILTER MEDIA.

1. Media - Your sand filter uses a #20 grade silica filter sand for its media (.45 - .55 mm). It should be free of all limestone or clay.

Most pool supply and building material stores carry silica sand. See Table 2 for the appropriate amounts of silica sand.

Table 2.

Maximum

Product # Filter Diameter Filter Area Sand Qty. Working PSI

58920100 26 in. 3.5 sq. ft. 225 lbs. 50 psi

58920200 30 in. 4.6 sq. ft. 350 lbs. 50 psi

58920300 36 in. 6.5 sq. ft. 575 lbs. 50 psi

2. Remove the lid from your filter and install the sand funnel on the top of the filter tank. It is important to swing the diffuser

basket(s) to a horizontal position before installing the funnel. Fill the tank about half full of water. Pour the silica sand into the

top of the filter tank slowly, so that the weight does not damage the lateral assembly in the bottom of the tank or the overdrain

plumbing near the top of the tank.

3. After filling the filter tank with the appropriate amount of silica sand, remove the sand funnel and wash away any loose sand

from the opening of the filter tank. Straighten the diffuser basket(s) up into the vertical operating position if you previously

moved them down.

4. To install lid, follow procedures in Section C, Lid and Valve Installation Instructions.

Rev. H • Rev. H • Rév. H 5-15-01 3 P/N • Núm/Pte. • Réf. P/N 99226000

CAUTION

For Multiport control valves with threaded ports use only Teflon tape, 100% pure Teflon paste (non-petroleum base), or Permatex #2

sealant on all threaded pipe connections, except fittings with O-rings. Use of other pipe joint compounds can damage components of this

system and cause leaks. For control valves with slip ports, use only ABS to PVC solvent welding adhesive.

5. The maximum working pressure of this filter is 35 or 50 psi, see Table 2. Never subject this filter to pressure in excess of this

amount - even when conducting hydrostatic pressure tests. Pressures above maximum working pressure can cause the lid to be

blown off, which can result in severe injury, death or property damage.

When performing hydrostatic pressure tests or when testing for external leaks of the completed filtration and plumbing

system, insure that the Maximum Pressure that the filtration system will be subjected to DOES NOT EXCEED THE

MAXIMUM WORKING PRESSURE OF ANY OF THE COMPONENTS CONTAINED WITHIN THE SYSTEM. In most

cases, the maximum pressure will be stated on each component of the system.

If doubt exists as to the pressure to which the system will be subjected, install an ASME approved automatic Pressure Relief

or Pressure Regulator in the circulation system for the lowest working pressure of any of the components in the system.

C. LID INSTALLATION INSTRUCTIONS.

These instructions MUST BE FOLLOWED EXACTLY to prevent the lid or valve from blowing off during system restart

or later operation:

1. Before working on any part of the circulating system, (e.g. clamp, pump, filter, valves, etc.) perform the following steps:

a. Turn the pump off and shut off any automatic controls to ensure that the system is not inadvertently started during

servicing.

b. Open the High Flow™ manual air relief valve.

c. Wait until all pressure is relieved. Never attempt to assemble, disassemble or adjust the lid while there is any

pressure in the filter.

2. Be sure that the chamfered sealing surface inside of the brass, or plastic flange at the top of the tank is clean and free of any

sand or debris. Apply a light coating of SILICONE BASE LUBRICANT to the lid O-ring and install into the opening in the

top of the filter tank.

NOTE

30 in. FILTERS ARE SHIPPED from the factory ready to accept a 2 in. control valve. If you wish to use the 1.5 in. control

valve, it is necessary to remove the 2 in. X 2 in. extension from the stand pipe and replace it with the 2 in. X 1.5 in. extension

fitting. This fitting is included in the accessory kit.

3. Install the lid in the following manner:

a. Thread the plastic lid into the top tank opening until the O-ring makes contact, then tighten an additional 1/4 to 1/2 turn.

4. Follow the system restart instructions in Section D.

WARNING

THIS FILTER OPERATES UNDER HIGH PRESSURE. WHEN ANY PART OF THE CIRCULATING SYSTEM (e.g., CLAMP, PUMP,

FILTER, VALVES, ETC.) IS SERVICED, AIR CAN ENTER THE SYSTEM AND BECOME PRESSURIZED. PRESSURIZED AIR CAN

CAUSE THE LID OR VALVE TO BE BLOWN OFF WHICH CAN RESULT IN SEVERE INJURY, DEATH, OR PROPERTY DAMAGE.

TO AVOID THIS POTENTIAL HAZARD, FOLLOW THESE INSTRUCTIONS.

D. SYSTEM RESTART INSTRUCTIONS.

1. Open the High Flow™ manual air relief valve until it snaps into the full open position (this only requires a quarter turn

counterclockwise). Opening this valve rapidly releases air trapped in the filter.

2. Stand clear of the filter tank, then start the pump.

3. Close the High Flow™ manual air relief valve after a steady stream of water appears.

4. The system is not working properly if either of the following conditions exist:

a. A solid stream of water does not appear within 30 seconds, after the pump’s inlet basket fills with water.

b. The pressure gauge indicates pressure before water out-flow appears.

P/N • Núm/Pte. • Réf. P/N 99226000 4 Rev. H • Rev. H • Rév. H 5-15-01

If either condition exists, shut off the pump immediately, open valves in the water return line to relieve pressure, and clean

the High Flow™ manual air relief valve, see Section II, Filter Operation and Cleaning.

If the problem persists, call 1-800-831-7133 for assistance.

E. CONTROL VALVE FUNCTIONS.

1. Side Mounted Push-pull valves have two operating positions, see Table 3.

a. Filter, T-handle is fully extended to its uppermost position.

b. Backwash, T-handle is fully compressed to its lowermost position.

2. Rotary type multiport control valves offer more operating positions and allow more options on how to direct the flow of water

in your pool system.

a. 8-Way Multiport valves provide all of the following functions, see Table 3.

TABLE 3

FILTER From pump, through valve, downward through filter sand bed, back through laterals and piping to valve return

port, and back to the pool. This position is used for normal filtering and vacuuming to clean the pool water.

BACKWASH From pump, through valve, down through piping and laterals, up through filter sand bed to valve, and out

waste port. This position is used for cleaning filter by reversing flow.

RINSE From the pump, through valve, downward through filter sand bed, back through laterals and piping to valve

and out waste port. This position is used for start-up cleaning and resettling filter bed after backwashing.

WASTE From pump, through valve (bypasses filter) and goes to waste port. This position is for vacuuming directly to

waste, lowering pool level, or draining pool.

CLOSED NO FLOW IN THIS POSITION - DO NOT USE THIS SETTING WITH PUMP OPERATING.

RECIRCULATE From pump, through valve, bypasses filter and goes to return port and back to pool. This position is for

circulating water without going through filter.

SERVICE NO FLOW IN THIS POSITION - DO NOT USE THIS SETTING WITH PUMP OPERATING. It allows the

removal of the handle pin for servicing.

WINTERIZE For areas that have freezing temperatures during the winter.

F. FILTER START UP - INITIAL SAND BED RINSE.

1. Valve operations, with pump shut off:

a. Push-pull backwash valve.

(1) Push handle down with slight twisting motion as far as it will go.

(2) Lock upper pin in cap.

(3) Open High Flow™ manual air relief valve on the filter.

(4) Proceed through steps 2 to 3 which follow.

b. Multiport rotary valve.

(1) Position valve to “Backwash” setting.

(2) Open High Flow™ manual air relief valve on the filter.

(3) Proceed through steps 2 to 3, which follow.

2. Follow steps in Section D, System Restart. On initial start up the pump must be primed by filling the hair and lint strainer with

water You may have to do this several times.

3. Your filter is now backwashing accumulated dust or dirt from the new silica sand bed. Backwash for two (2) minutes, or until

water is flowing clear out the backwash line, or appears clear in sight glass, then shut off pump.

G. FILTER START UP - POOL FILTRATION.

1. Valve operations, with pump shut off:

a. Push-pull backwash valve.

(1) Twist to unlock plunger.

Rev. H • Rev. H • Rév. H 5-15-01 5 P/N • Núm/Pte. • Réf. P/N 99226000

(2) Raise the handle as far as it will go.

(3) Turn handle clockwise to lock under pin in underside of cap.

(4) Proceed through steps G.2 to G.3, which follow.

b. Multiport rotary valve.

(1) Position valve to “Filter” setting. This is your normal flow from the pump through the filter back to the pool.

(2) Proceed through steps G.2 to G.3, which follow.

2. Follow steps in Section D, System Restart. Your filter is now in full operation. Note the original starting pressure on the gauge.

3. Backwash your filter when pressure reads between 5 to 11 psi over the original starting pressure, see Step G.5. When your

filter builds up pressure from its starting point, then your filter is performing its function. However, this buildup of pressure

will vary because of different bathing loads, temperature, weather conditions, etc.

a. MY ORIGINAL STARTING PRESSURE IS _____ psi (pounds per square inch). I SHOULD BACKWASH AT

_____ psi

NOTE

Small grains of sand may leave the filter during backwashing or may even appear at the return line when filter is first started

up. This is characteristic of permanent media filters.

WARNING

Always turn pump off before changing valve positions. CHANGING VALVE POSITIONS WHILE THE PUMP IS RUNNING CAN DAMAGE

THE CONTROL VALVE, AND MAY RESULT IN PERSONAL INJURY OR PROPERTY DAMAGE.

4. Check the system for water leaks. If a leak is found, shut pump off and relieve system pressure, before correcting the leak.

5. As the filter removes dirt and impurities from the pool water, the accumulation will cause the filter pressure to rise and the flow

to diminish. It is time to backwash the filter if you are using 1hp or smaller pump and the pressure gauge reading is 5 to 7 psi

higher than the clean filter reading noted in Step G.3, above. For systems with larger than 1 hp pumps, this pressure rise will be

in the 9 to 11 psi range before it is time to backwash.

CAUTION

To prevent damage to the pump and filter and for proper operation of the system, clean pump strainer and skimmer baskets regularly.

H. FILTER CLEANING - CLEANING FREQUENCY.

1. Cleaning frequency will vary from pool to pool and with other factors such as weather conditions, heavy rains, dust pollen,

bather load, and water chemistry. Check the pressure gauge reading on a regular basis. If you have a 1 HP or smaller pump,

backwash when the pressure gauge reading increases 5 to 7 psi over the initial clean filter reading. With larger pumps,

backwash when the increase is 9 to 11 psi.

2. It is important NOT to backwash the filter solely on a timed basis such as every two days. Backwashing too frequently

actually causes poor filtration.

I. FILTER CLEANING - FILTER BACKWASH PROCEDURE.

1. Since the sand media bed is the key to efficient filtration in this type filter system, that media bed should be visually inspected

at least once each year.

WARNING

Always turn pump off before changing valve positions. CHANGING VALVE POSITIONS WHILE THE PUMP IS RUNNING CAN DAMAGE

THE CONTROL VALVE, AND MAY RESULT IN PERSONAL INJURY OR PROPERTY DAMAGE.

2. Turn the pump off, shut off any automatic controls to ensure that the system is not inadvertently started during servicing.

3. Open the High Flow™ manual air relief valve and waste drain valve, or plug, if your system has one. Ensure that suction and

backwash lines are open so that water is free to come from the pool and flow out the backwash line.

4. Remove hair and lint pot lid from pump and clean basket. Replace basket, refill hair and lint pot with water, install lid and

clamp securely.

P/N • Núm/Pte. • Réf. P/N 99226000 6 Rev. H • Rev. H • Rév. H 5-15-01

5. Valve Operations:

a. Push-pull backwash valve.

(1) Push handle on valve down with slight twisting motion as far as it will go.

(2) Lock upper pin in cap.

(3) Proceed through steps I.6 to I.11, which follow.

b. Multiport rotary valve.

(1) Position valve to ‘Backwash’ setting.

6. Stand clear of the filter and start pump. Filter is now running in its backwash mode. Close High Flow™ manual air relief valve

only after a continuous stream of water is flowing from the valve.

7. Backwash filter for approximately 3-5 minutes or until backwash water is clean.

8. Turn off pump. Set control valve back to filter position and open High Flow™ manual air relief valve again.

a. Push-pull backwash valve.

(1) Twist to unlock plunger; then raise handle as far as it will go.

(2) Turn handle clockwise to lock upper pin in underside of cap.

b. Multiport rotary valve.

(1) Position valve to ‘Filter and Vacuum to Pool’ setting.

9.

Stand clear of the filter and start pump. Close High Flow™ manual air relief valve only after a continuous stream of water is

flowing from the valve.

10. The filter has now started its filtering cycle. Check that there is water returning to the pool and take note of the filter pressure.

11. The filter pressure in step I.7 above should not exceed the pressure originally observed on the filter when it was initially

started. If, after backwashing, the pressure is 4 to 6 psi above the start condition, it may be necessary to change the sand in the

filter.

NOTE

Over a period of time certain foreign matter and materials can become imbedded in the top of the sand media bed and will successfully resist

being flushed out during the backwash cycle. During inspection as noted above, this foreign material and any contaminated sand should be

removed from the tank. Replace any old sand removed with new clean silica sand. Replace tank lid or valve and carefully follow instructions

in Section C, Lid and Valve Installation Instructions.

J. WINTERIZING THE FILTER.

1. In areas that have freezing winter temperatures the pool equipment must be winterized to protect it from damage.

2. Backwash the filter. Shut off the pump, any automatic controls and set the rotary multiport control valve to the winterize

position. For Push-pull valve equipped filters, leave the valve in the backwash (T-handle down) position.

3. Remove the small knurled drain port cap at the bottom of the filter.

NOTE

Remove ONLY the drain port cap to drain water from filter.

CAUTION

Removing the entire fitting will drain the sand. The filter will drain slowly. Leave the drain port cap off and store it during the time the

system is shut down.

CAUTION

The rotary multiport control valve should be left in the winterize position during the shutdown season so that the rubber seal of the valve

diverter has no pressure on it. Failure to do so can damage the valve’s spider gasket which can cause property damage from leaking

water.

4. Drain all appropriate system piping.

5. It is recommended that the pump and filter be covered with a tarpaulin or plastic sheet to inhibit deterioration from the weather.

DO NOT wrap pump motor with plastic.

Rev. H • Rev. H • Rév. H 5-15-01 7 P/N • Núm/Pte. • Réf. P/N 99226000

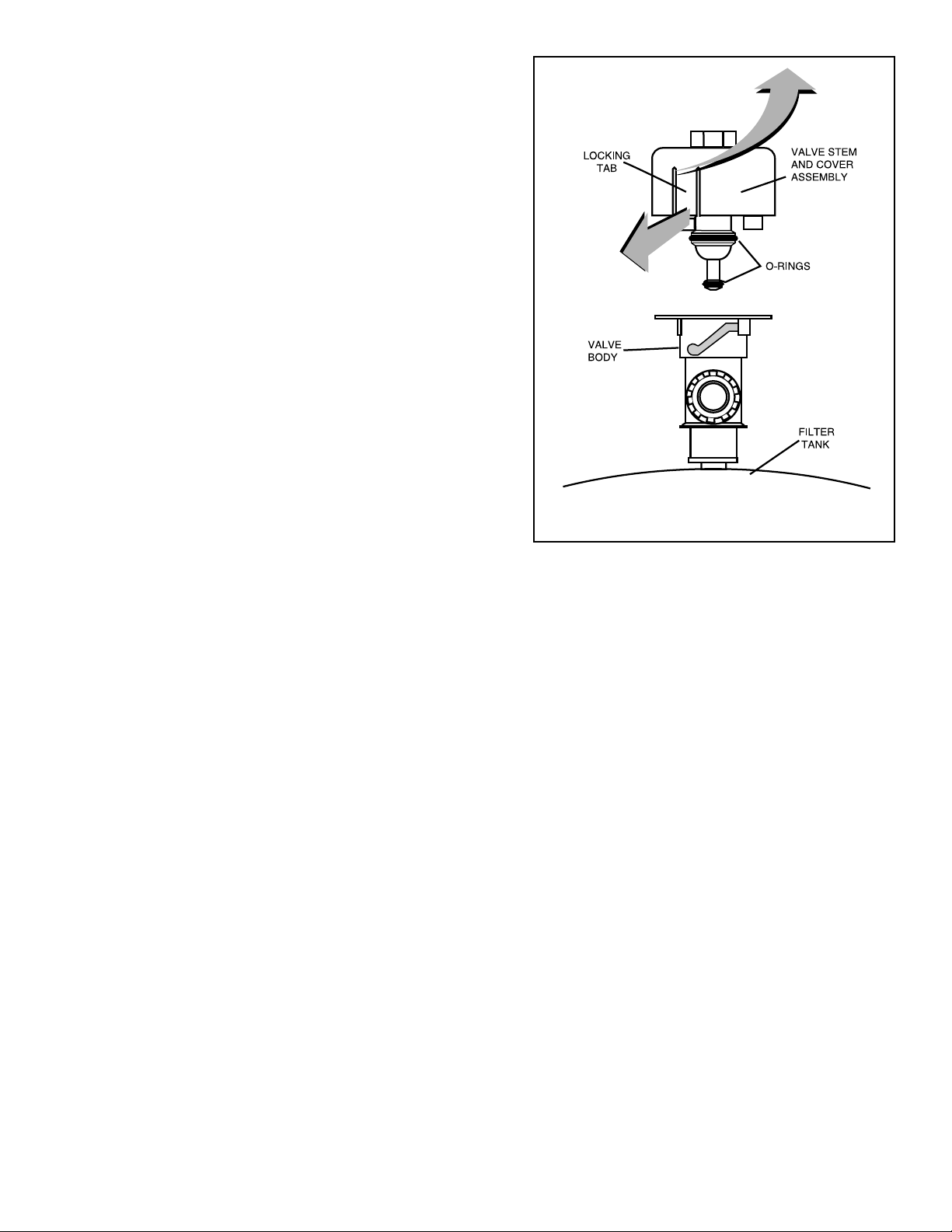

K. CLEANING THE HIGH FLOW™ MANUAL AIR RELIEF VALVE.

1. Turn the pump off and shut off any automatic controls to ensure

that the system is not inadvertently started during servicing.

2. OPEN THE HIGH FLOW™ MANUAL AIR RELIEF VALVE

UNTIL IT SNAPS INTO THE FULL OPEN POSITION, THEN

WAIT UNTIL ALL PRESSURE IS RELIEVED.

3. With the High Flow™ manual air relief valve attached to the filter

tank, pull out the locking tabs and remove the valve stem and

cover assembly with a counter-clockwise and lifting motion, see

Figure 2.

4. Clean debris from the valve stem and body. Verify that the filter

tank’s air passage is open by inserting a 5/16 in. drill bit through

the valve body. Verify that the O-rings are in good condition,

properly positioned, and lubricated with a silicone based lubricant.

5. Reinstall the valve stem and cover assembly with a downward and

clockwise motion until it snaps into position.

SECTION III. EQUIPMENT MAINTENANCE.

A. AIR ENTERING YOUR FILTER IS DANGEROUS AND CAN CAUSE

THE LID OR VALVE TO BLOW OFF.

1. Correct any conditions in your filtration system that allow air to

enter the system.

2. Some common ways to identify air entering the system are:

a. Low water level in pool or spa - skimmer is starving for water with pump running. Add water to pool or spa.

b. Air bubbles or low water level in pump hair and lint pot are caused by: Low water level, clogged skimmer basket, split

suction cleaner hose, leak in pump hair and lint pot lid, or leak in pump suction line.

c. Air bubbles coming out of water return lines into the pool or spa with pump running, see Steps 2.a. and 2.b. above.

d. Air is discharged from the High Flow™ manual air relief valve on top of the filter when the valve is opened with the pump

running, see Steps 2.a. and 2.b. above.

B. THE PRESSURE GAUGE IS YOUR PRIMARY INDICATOR OF HOW THE FILTER SYSTEM IS OPERATING.

1. It is an important part of your filter system.

2. Maintain your pressure gauge in good working order.

3. Check the operation of your pressure gauge in the following manner:

a. The pressure gauge should go to zero (0) when the system is turned off and pressure is relieved.

b. The pressure gauge should indicate pressure when the system is operating.

c. The pressure gauge should be readable and not damaged in any way.

d. Replace the pressure gauge if any of the above conditions exist.

Figure 2.

P/N • Núm/Pte. • Réf. P/N 99226000 8 Rev. H • Rev. H • Rév. H 5-15-01

SECTION IV. TROUBLE SHOOTING.

System Problem Cause Remedy

Pool water not 1. Pool chemistry not adequate to inhibit algae growth. Maintain pool chemistry or consult pool service technician.

sufficiently clean. 2. Backwashing too frequently. Allow pressure to build to 5-11 psi above clean filter condition before

backwashing, see SECTION II, G.5.

3. Improper amount or wrong sand size. Check sand bed depth and sand size or consult pool service technician.

4. Inadequate turnover rate. Run system for longer time or consult pool service technician.

High filter pressure. 1. Insufficient backwashing. Backwash until water runs clear.

2. Sand bed plugged with mineral deposits. Chemically clean filter and/or change sand, see SECTION I.

3. Partially closed valve or restriction in return. Open valve or remove obstruction in return line.

Requires frequent backwash 1. Improper backwash. Backwash until water runs clear.

(short filter cycle). 2. Pool chemistry not adequate to inhibit algae growth. Maintain pool chemistry or consult pool service technician.

3. Plugged sand bed. Manually remove top 1 in. surface of sand bed and chemically clean as

required.

4. Flow rate too high. Restrict flow to capacity of filter.

Return flow to pool diminished 1. Obstruction in pump hair and lint strainer. Clean basket in strainer.

and low filter pressure. 2. Obstruction in pump. Disassemble and clean pump.

3. Obstruction in suction line to pump. Clean skimmer basket. Remove obstruction in lines. Open valves in

suction line.

Sand returning to pool. 1. Broken underdrain lateral. Replace broken or damaged laterals.

2. Backwash rate too high. Reduce backwash flow rate.

Rev. H • Rev. H • Rév. H 5-15-01 9 P/N • Núm/Pte. • Réf. P/N 99226000

SECTION V. TECHNICAL DATA

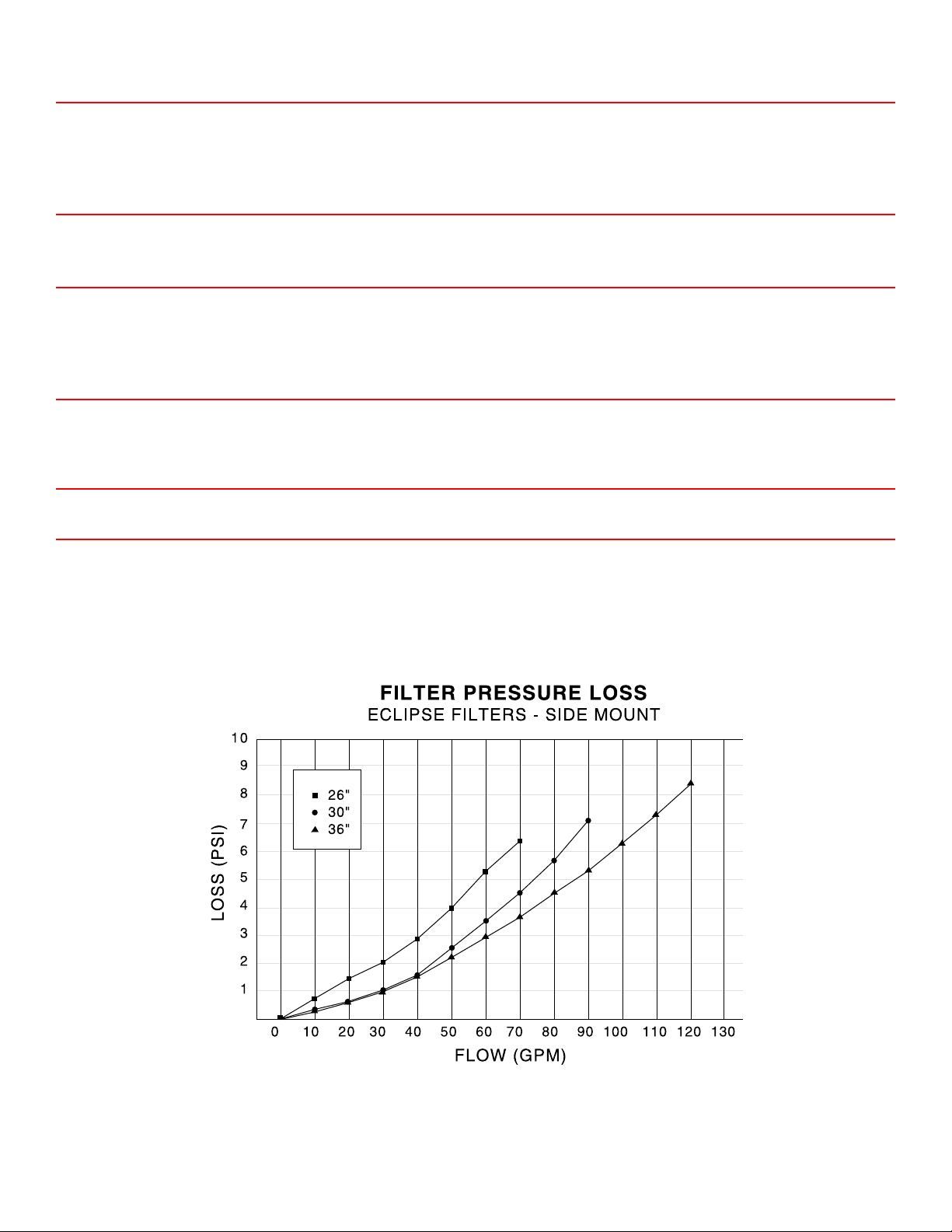

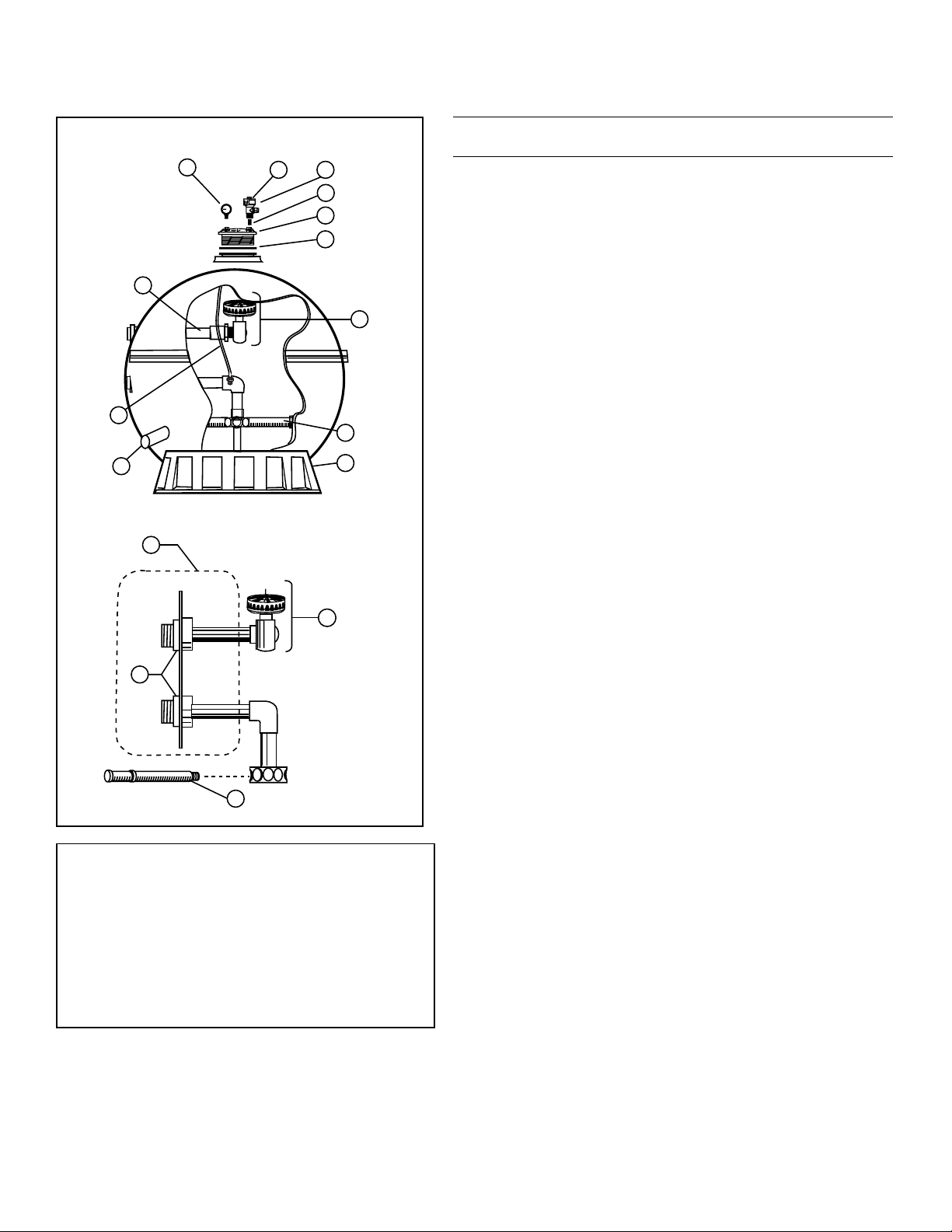

A. ECLIPSE SIDE MOUNT FILTER.

1

8

9

11

8

13

10

2

3

4

5

6

10

12

7

LEGEND

Used on filters manufactured before 9-94.

Used on filters manufactured after 9-94.

New improved laterals will fit hubs previously manufactured.

Used on filters manufactured before 11-98.

Used on filters manufactured after 11-98.

Used on filters manufactured before 11-1-99.

Used on filters manufactured after 11-1-99.

Item Part Description

No. No.

1 53003201 Gauge, pressure

2 98218900 Plug for High Flow manual air relief valve

3 98209800 High Flow manual air relief valve

4 57006800 O-ring

5 55022000 Lid

6 52000500 O-ring

7 55008300 Basket assy., overdrain 26 in. filter

7 150017 Diffuser assy., overdrain 26 in. filter

7

7 55008900 Basket assy., overdrain 30 in. filter

7 150018 Diffuser assy., overdrain 30 in. filter

7 55009100 Basket assy., overdrain 36 in. filter

7 150019 Diffuser assy., overdrain 36 in. filter

8 55120000 Internal drain pipe assy., 26 in. filter

8 150020 Internal drain pipe assy., 26 in. filter

8 55120100 Internal drain pipe assy., 30 in. filter

8 150021 Internal drain pipe assy., 30 in. filter

8 55120200 Internal drain pipe assy., 36 in. filter

8 150022 Internal drain pipe assy., 36 in. filter

9 51999100 Kit, service air tube, 3/8 in. o.d.

9 55020300 Kit, service air tube, 26 in. filter

9 150023 Kit, service air tube, 26 in. filter

9 150037 Kit, service air tube, 26 in. filter

9 55020800 Kit, service air tube, 30 & 36 in. filter

9 150024 Kit, service air tube, 30 & 36 in. filter

9 150038 Kit, service air tube, 30 & 36 in. filter

9 150044 Kit, service air tube, 36 in. filter

10 55025800 Lateral, underdrain, 26 in. filter, (3-7/8 in.), 8 per filter

10 55025900 Lateral, underdrain, 30 in. filter, (7-7/8 in.), 8 per filter

10 55026300 Lateral, underdrain, 36 in. filter, (10 in.), 8 per filter

11 55007800 Drain assy., complete

11 86300300 Fitting, drain sand/water

11 86300400 Cap, drain

11 86300500 Gasket, drain cap

12 55226100 Base, 26 in. filter

12 55235000 Base, 30 & 36 in. filter

13 53007111 Fitting, bulkhead, outer

51021500 Gasket, bulkhead

52000100 O-ring, bulkhead, (1) req.

52000200 O-ring, bulkhead, (2) req.

55023200 Funnel, sand filling, 26, 30 & 36 in. filter

SAVE THESE INSTRUCTIONS.

P/N • Núm/Pte. • Réf. P/N 99226000 10 Rev. H • Rev. H • Rév. H 5-15-01

–

Pentair Pool Products

1620 Hawkins Ave., Sanford, NC 27330 • (919) 774-4151

10951 West Los Angeles Ave., Moorpark, CA 93021 • (805) 523-2400

Rev. H € Rev. H € Rév. H 5-15-01 11 P/N € Núm/Pte. € Réf. P/N 99226000

Loading...

Loading...