SHURFLO® AQUA KING™ II FRESH WATER PUMPS

PREMIUM 4.0 GPM AND SUPREME 5.0 GPM

MODEL SERIES 4148 & 4158

The NEW SHURFLO AQUA KING™ II delivers smooth and high-powered fl ow.

SHURFLO’s New 4148 and 4158 series fresh water pump design was created with unique over-molded single-piece diaphragm

and internal by-pass, assuring long life and top performance in all plumbing systems. Designed as the next legendary pump to

exceed the expectations of our customers, the 4148 and 4158 series pumps are constructed for high fl ow demand, smooth fl ow

and no rapid cycling. Our quality reputation has been built on the reliability and dependability of every pump we build. The 4148

and 4158 series fresh water automatic demand pumps are quiet, thermally protected and can run dry without damage.

FEATURES

❚ 4 independent chambers

❚ Co-Molded diaphragm

❚ Adjustable switch and by-pass

❚ Self-priming up to 6 feet

❚ Dry run capability

❚ Sealed switch

❚ Sealed motor

❚ Corrosion resistant electro coated

motor

❚ Thermally protected

❚ Ignition protected, CE

INSTALLATION TIPS

❚ Properly sized plumbing

❚ Mount on a solid surface within 6 feet

of tank

❚ Properly sized wiring

❚ Use proper fuse size

❚ Install strainer on pump inlet

❚ Dry and accessible location

❚ Minimize plumbing elbows and valves

❚ Flexible high-pressure hose on inlet

and outlet

911-1026 REV. F 1

OPERATION TIPS

❚ Do not adjust switch or bypass settings without contacting customer

service

❚ Pump is designed for intermittent

operation only

❚ Turn off power to the pump when boat

is unattended

❚ Keep your strainer clean for ultimate

pump performance

❚ Do not use pump for Reverse Osmosis

fi ltration system

APPLICATION

❚ Marine 12V DC or 24V DC fresh water

systems—see pump label for rated

voltage

❚ Multi-Fixture, up to 4 fi xtures

❚ General fresh water transfer

❚ Pressurized water systems in cabins

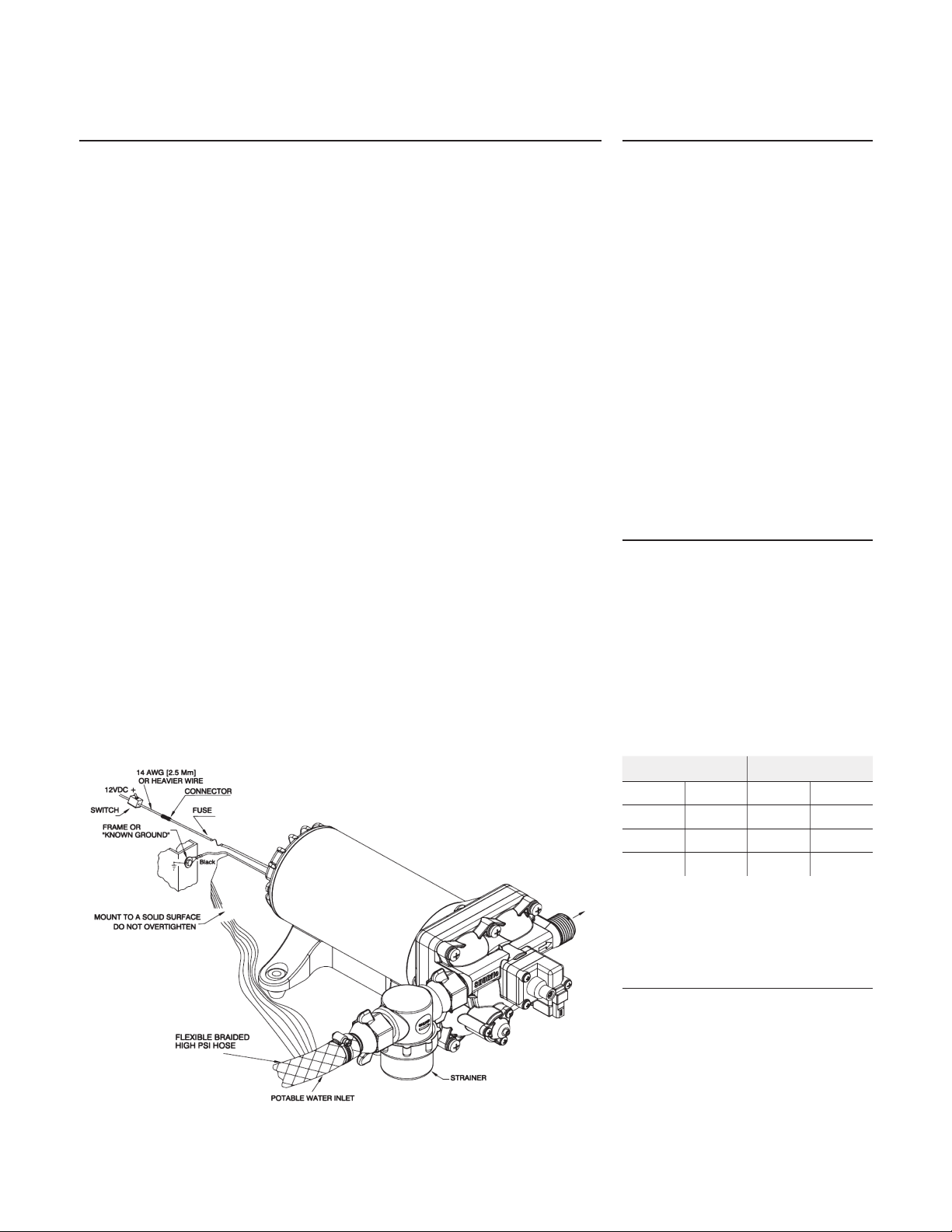

INSTALLATION

MOUNTING

The goal of installation is to provide a

quiet, easy to maintain installation with

good flow and low back pressure. This

can be accomplished with the following

guidelines:

❚ Mount on a solid surface in an accessible location for strainer cleaning and

pump maintenance.

❚ Use flexible high-pressure hose on

the pump inlet and outlet [such as

SHURFLO Kit 94-591- 01]. The pump

ports and strainer should not be connected to plastic or rigid pipe, or the

pump's normal motion will transmit

through rigid plumbing causing noise,

and possibly loosening or cracking

components.

❚ Pump must use an adequate 50-mesh

strainer [such as SHURFLO 255 series

strainers].

❚ Use a minimum of 1/2" [13mm] Inner

Diameter plumbing. Smaller ID plumbing will cause cavitation, high back

pressure, low flow and noise.

❚ Pump is designed for intermittent duty

only: Do not use these pumps for running a Reverse-Osmosis [RO] Filtration

System. High pressure continuous duty

usage will shorten the life of the pump

and is not covered under warranty.

❚ Wire Size is 14 GA [2.5mm²] MINIMUM, 12GA [4mm²] is recommended—

See Wire Chart in Electrical Section for

minimum sizing.

❚ Minimum power requirement is a 15

Amp circuit.

❚ Reduce restrictions on inlet and outlet. This includes small inner diameter

shut-off valves, winterizing valves and

elbows.

INSTALLATION GUIDELINES

❚ Solid surface within 6 feet of tank

❚ Accessible location

❚ Minimize flow restrictions in the

system

❚ Strainer on pump inlet

❚ Properly sized wiring

❚ Flexible hose on inlet and outlet -

Proper electrical protection

❚ Minimize plumbing elbows and valves

❚ Properly sized plumbing

❚ Mount the pump within 6 feet (Max) of

the tank for best performance and pump

life. The pump will pull farther, but the

farther it pulls the more work it does,

increasing vibration and noise, and

reducing the output and pump life.

❚ Mount pump in a space of at least 1

cubic foot for adequate ventilation to

prevent overheating.

❚ Pump may be mounted in any position.

❚ Mount pump for easy access for

cleaning strainer, maintenance and

service.

❚ Mount pump on a solid surface to

prevent vibration and noise.

ELECTRICAL

❚ The pump should be on a dedicated

(individual) circuit protected by the

specified fuse on the motor label.

❚ A UL marine duty switch (ignition

protected) rated for 15 amps or higher is

recommended, and must interrupt current flow on the positive (+ red) lead.

❚ SHUT OFF POWER TO THE PUMP

WHEN LEAVING THE BOAT UNATTENDED.

Ft. [m] AWG [mm2]

0-20 [0-6] 14 [2.5]

20-50 [6-15] 12 4]

50-70 [15-21] 10 [6]

70-100 [21-30] 8 [8]

Minimum Wire Size for a 10% voltage drop on a 12VDC, 15 Amp

Circuit. Length is the distance from the power source to pump

and back to ground.

PLUMBING

Installation of a strainer is required to

prevent debris from entering the pump.

For noise and vibration reduction we

recommend at least 18 in. [.5 M] of

1/2" [13mm] I.D. flexible high-pressure

hose to both ports. The pump ports and

strainer should not be connected to

Typical Pump Installation

2

plastic or rigid pipe. This hose should

be anchored where it meets the hard

plumbing to reduce plumbing vibration.

Loading...

Loading...