Operation Manual

Start up and Maintenance

Manuel d’utilisation

Mise en marche et Maintenance

Manual de Puesta en Marcha

Puesta en marcha y Mantenimiento

Steuerung Bedienungshandbuch

Inbetriebnahme und Wartung

2

24

46

70

225555 // LLOOGGIIXX 774400 -- 776600

De

Es

Fr

En

Valve Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

LCD Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Location selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Water line connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Drain line connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Overflow line connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Regenerant line connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Start-up of your softener . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Step 1 - Program system size . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Step 2 - Placing conditioner into operation . . . . . . . . . . . . . . . . . 7

Step 3 - Basic programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

World LOGIX settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Step 4 - Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Step 5 - Hardness setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Resetting the control to unprogrammed . . . . . . . . . . . . . . . . . . . . . . . 13

Manual regenerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Flow diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Valve exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

SYNOPSIS

2

En

4

5

6

6

6

7

8

8

9

9

9

11

14

15

15

15

15

16

18

20

21

3

En

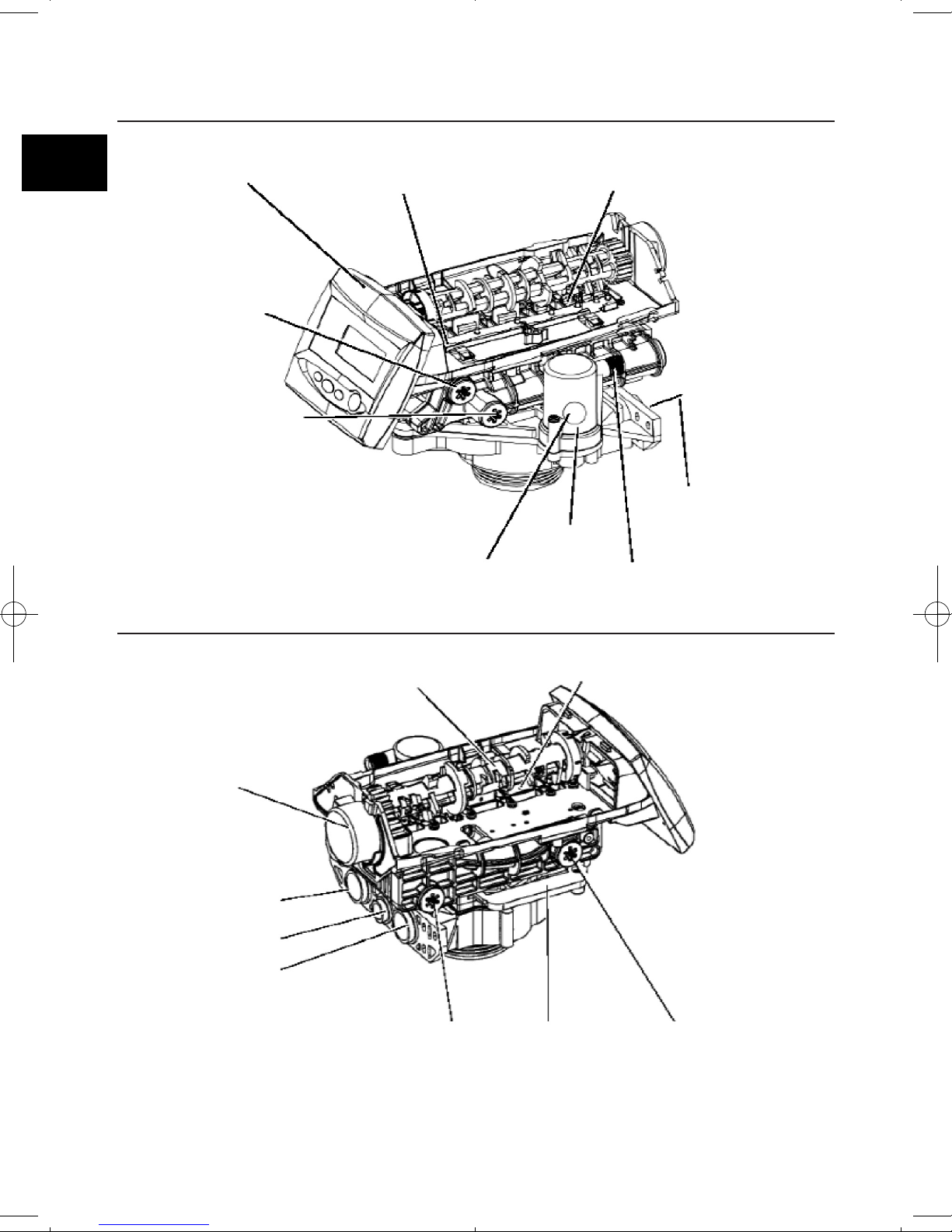

Complete Valve - Front view

Complete Valve - Back view

Control module

mount

Optical sensor

One piece valve

disc spring

Manifold

connection

Regenerant tank

tube connection

Aircheck

Check ball

Injector

and cap

Refill

Controller

Camshaft

Valve

discs

Injector

screen filter

Locking bar

Backwash

drain control

Inlet

Drain

Outlet

Motor

4

En

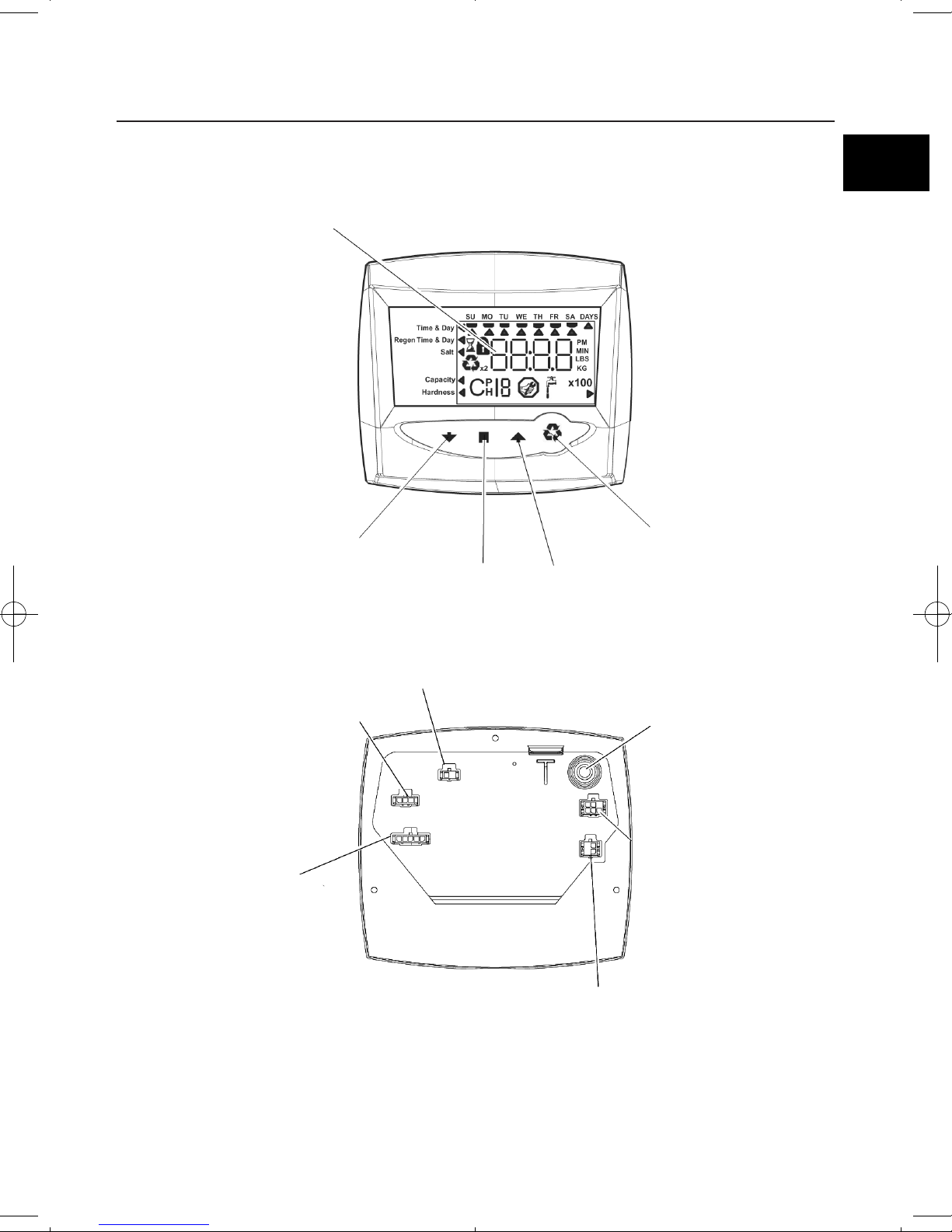

LCD Display

LCD Display

Manual regen

button

Down

button

Up

Button

Set

button

Secondary valve

motor control

(772 only)

Chlorine generator outlet

(EU and 742/762 versions only)

Lockout connection

(772 only)

AC adapter input

(low voltage)

Sensor input 716

by turbine 760/762

Dry contact signal input 740/742

5

En

INSTALLATION

Location selection

Location of a water treatment system is important. The following conditions are required :

●

Level platform or floor.

●

Room to access equipment for maintenance and adding regenerant (salt) to tank.

●

Ambiant temperatures over 34°F (1°C) and below 120°F (49°C).

●

Water pressure below 120 psi (8.27 bar) and above 20 psi (1.4 bar).

●

Constant electrical supply to operate the controller.

●

Total minimum pipe run to water heater of ten feet (three meters) to prevent

backup of hot water into system.

●

Local drain for discharge as close as possible.

●

Water line connections with shutoff or bypass valves.

●

Must meet any local and state codes for site of installation.

●

Valve is designed for minor plumbing misalignments. Do not support weight of

system on the plumbing.

●

Be sur all soldered pipes are fully cooled before attaching plastic valve to the

plumbing.

Water line connection

A by-pass valve system should be installed on all water conditioning systems.

Bypass valves isolate the conditioner from the water system and allow unconditioned

water to be used. Service or routine maintenance procedures may also require that

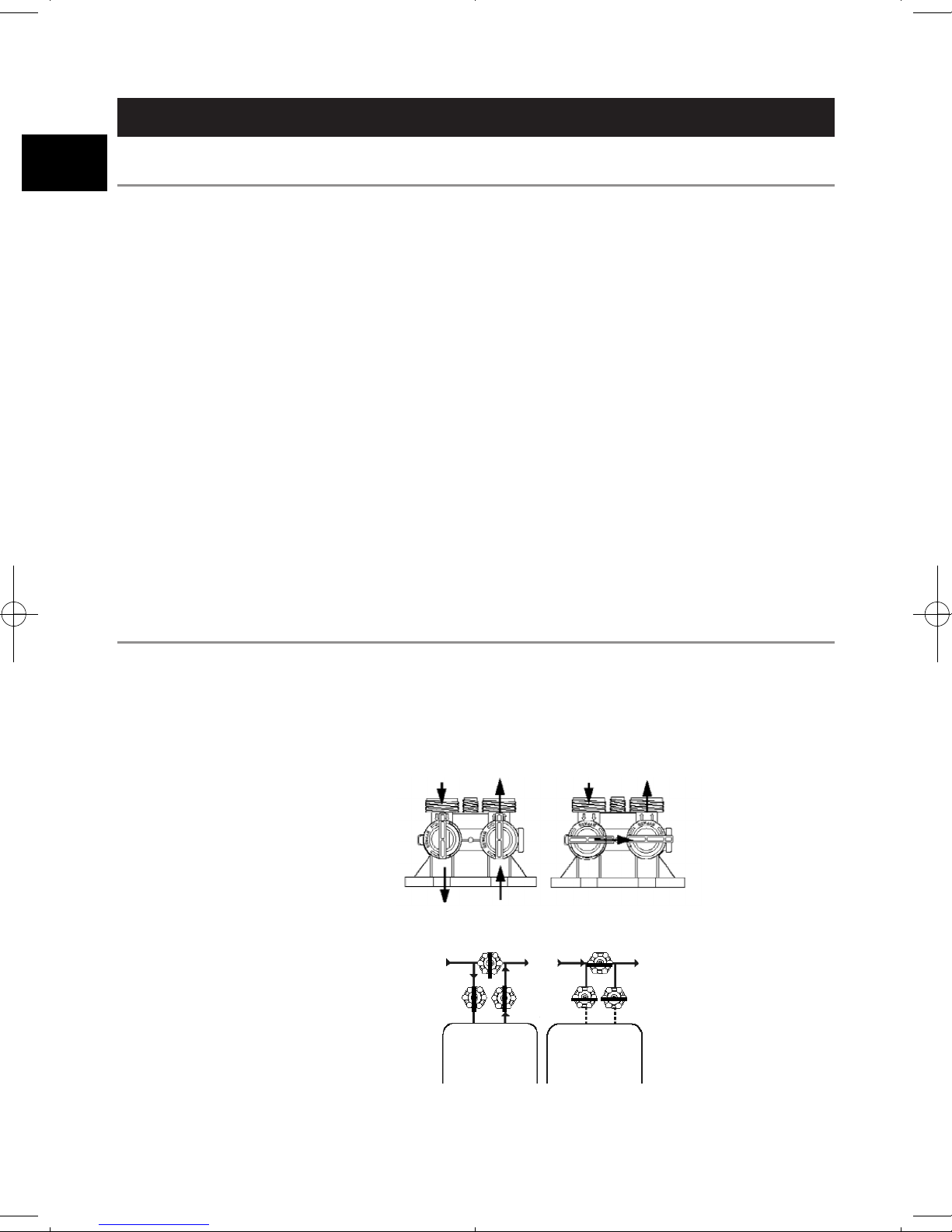

the system is bypassed. Figure 1 and 2 show the three common bypass methods.

Figure 1

256 By-pass for use

with 255 valve body.

Normal operation In by-pass

In Out OutIn

Figure 2

Typical globe valve

by-pass system

Normal

operation

Water

conditioner

Water

conditioner

In by-pass

6

En

Drain line connection

1. If the backwash flow rate exceeds 5 gpm (22.7 Lpm) or if the unit is located

20-40 feet (6.1-12.2 m) from drain, use 3/4-inch (1.9 cm) tubing. Use appropriate

fittings to connect the 3/4-inch tubing to the 3/4-inch NPT drain connection on

valve.

2. The drain line may be elevated up to 6 feet (1.8 m) providing the run does not

exceed 15 feet (4.6m) and water pressure at the conditioner is not less than

40 psi (2.76 bar). Elevation can increase by 2 feet (61 cm) for each addditional

10 psi (0.69 bar) of water pressure at the drain connector.

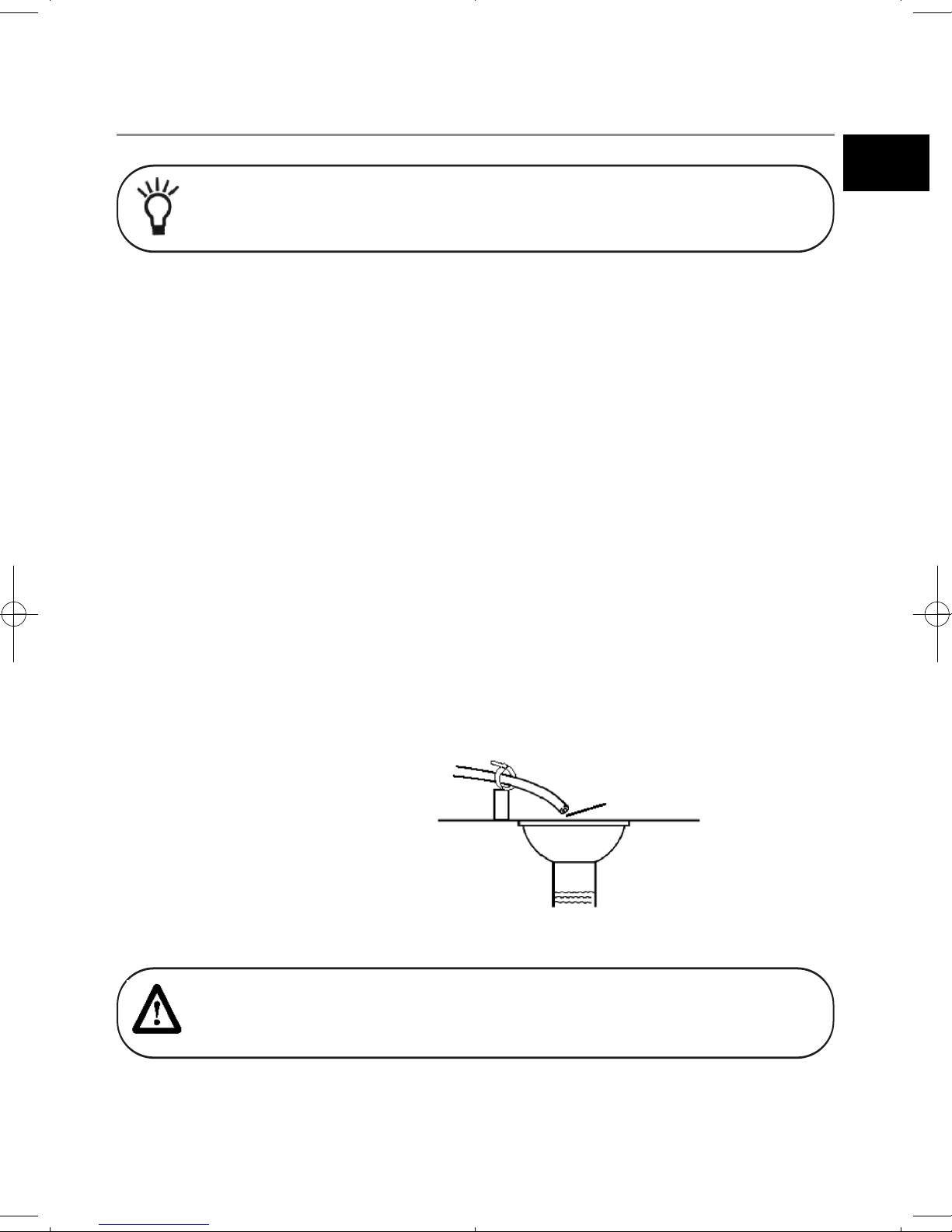

3. Where the drain line is elevated but empties into a drain below the level of the

control valve, form a 7-inch (18 cm) loop at the far end of the line so that the

bottom of the loop is level with the drain line connection.This will provide an

adequate siphon trap.

Where the drain empties into an overhead sewer line, a sink-type trap must

be used.

Secure the end of the drain line to prevent it from moving.

NOTE : Standard commercial practices are expressed here. Local codes may

require changes to the following suggestions. Check with local authorities

before installing a system.

Figure 3

Drain line connection

drain

air gap

WARNING : Never insert drain line directly into a drain, sewer line or trap

(figure 3). Always allow an air gap between the drain line and the wastewater

to prevent the possibility of sewage being back-siphoned into the conditioner.

7

En

Loading...

Loading...