Pentair BERKELEY HL Series, BERKELEY SL Series, 5SL, 5HL, 7HL Owner's Manual

...

OWNER’S MANUAL

Convertible Deep Well Jet Pumps

60

40

80

20

100

“HL” and “SL” Series

Installation/Operation/Parts

For further operating, installation, or maintenance assistance:

Call 1-800-782-7483

293 WRIGHT STREET, DELAVAN, WI 53115 WWW.BERKELEYPUMPS.COM

PH: 888-782-7483

© 2013 Pentair, Ltd. All Rights Reserved. BE423 (Rev. 02/25/13)

Safety 2

READ AND FOLLOW

SAFETY INSTRUCTIONS!

This is the safety alert symbol. When you see this

symbol on your pump or in this manual, look for

one of the following signal words and be alert to the

potential for personal injury:

warns about hazards that will cause seri-

ous personal injury, death or major property damage if

ignored.

ous personal injury, death or major property damage if

ignored.

minor personal injury or property damage if ignored.

The label NOTICE indicates special instructions which

are important but not related to hazards.

Carefully read and follow all safety instructions in this

manual and on pump.

Keep safety labels in good condition.

Replace missing or damaged safety labels.

California Proposition 65 Warning

tain chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

warns about hazards that can cause seri-

warns about hazards that will or can cause

This product and related accessories con-

ELECTRICAL SAFETY

Capacitor voltage may be hazardous.

To discharge motor capacitor, hold insulated handle

screwdriver BY THE HANDLE and short capacitor terminals together. Do not touch metal screwdriver blade

or capacitor terminals. If in doubt, consult a qualified

electrician.

GENERAL SAFETY

Do not touch an operating motor. Modern

motors can operate at high temperatures. To avoid burns

when servicing pump, allow it to cool for 20 minutes

after shut-down before handling.

Do not allow pump or any system component to freeze.

To do so will void warranty.

Pump water only with this pump.

Periodically inspect pump and system components.

Wear safety glasses at all times when working on pumps.

Keep work area clean, uncluttered and properly lighted;

store properly all unused tools and equipment.

Keep visitors at a safe distance from the work areas.

Pump body may explode if used as a

booster pump unless relief valve capable of passing full

pump flow at 100 psi is installed.

WARNING

Hazardous voltage.

Can shock, burn, or

cause death.

Ground pump before

connecting to power

supply. Disconnect power

before working on pump,

motor or tank.

Wire motor for correct

voltage. See

“Electrical” section of

this manual and motor

nameplate.

Ground motor before

connecting to power

supply.

Meet National

Electrical Code,

Canadian Elec tri cal

Code, and local codes

for all wiring.

Follow wiring

instructions in this

manual when

connecting motor to

power lines.

WARNING

Hazardous pressure!

Install pressure relief

valve in discharge pipe.

Release all pressure on

system before working on

any component.

Table of Contents 3

Page

General Safety .....................................................................................................2

Warranty..............................................................................................................3

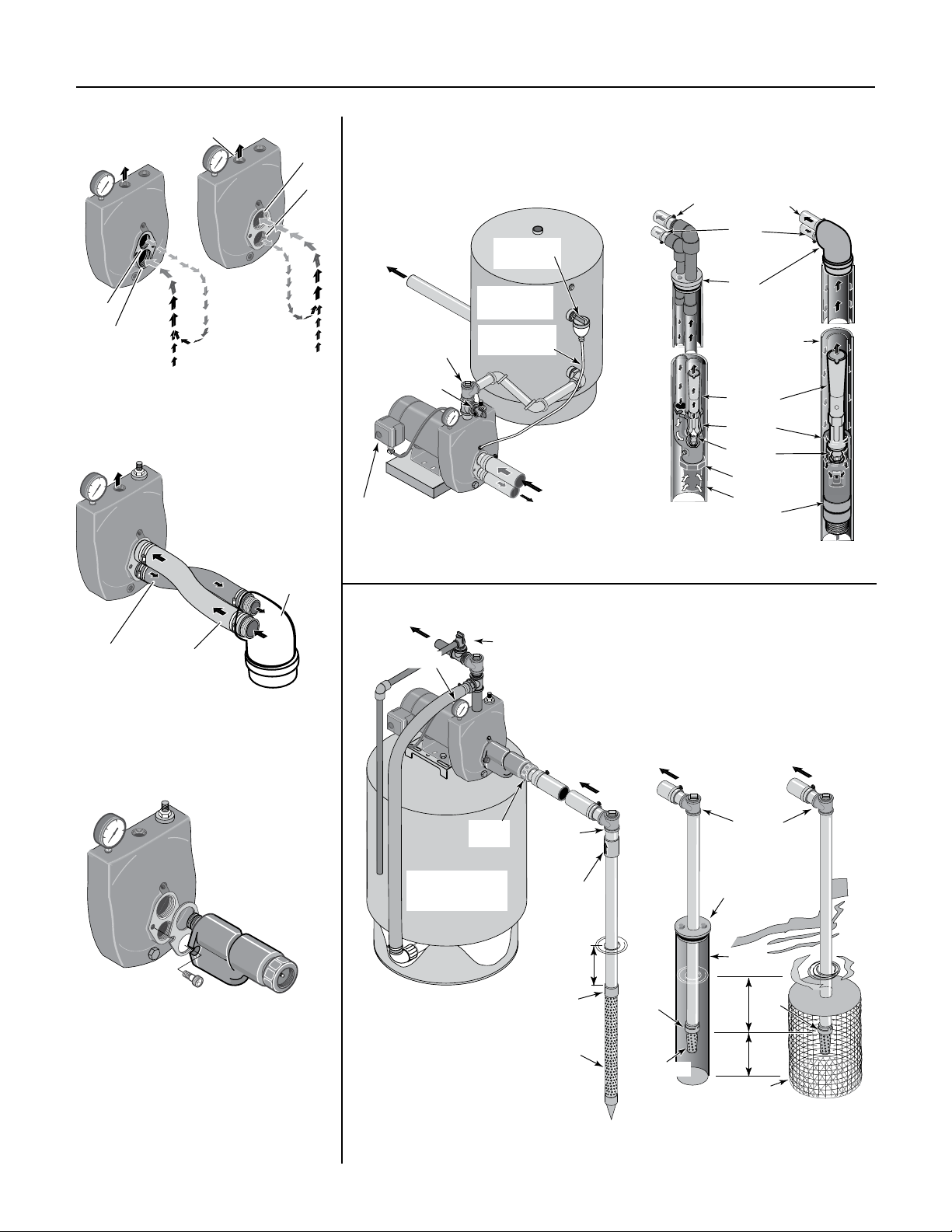

Typical Installations .............................................................................................4

Discharge Pipe and Pressure Tank Connections ..................................................5

Electrical ..........................................................................................................6, 7

Preparing To Start The Pump – Deep Well ..........................................................8

Preparing To Start The Pump – Shallow Well .....................................................9

Repair Parts .................................................................................................10,11

Troubleshooting ................................................................................................. 12

Performance ................................................................................................13, 14

Limited Warranty

BERKELEY warrants to the original consumer purchaser (“Purchaser” or “You”) of the products listed below, that they will be free

from defects in material and workmanship for the Warranty Period shown below.

Product Warranty Period

Water Systems:

Water Systems Products — jet pumps, small centrifugal pumps, submersible pumps and

related accessories

Pro-Source™

Pro-Source™ Steel Pressure Tanks 5 years from date of original installation

Pro-Source™ Epoxy-Lined Tanks 3 years from date of original installation

Sump/Sewage/Effluent Products

Agricultural/Commer

Centrifugals – close-coupled motor drive, frame mount, SAE mount, engine drive, VMS, SSCX,

SSHM, solids handling, submersible solids handling

Submersible T

Our limited warranty will not apply to any product that, in our sole judgement, has been subject to negligence, misapplication,

improper installation, or improper maintenance. Without limiting the foregoing, operating a three phase motor with single phase

power through a phase converter will void the warranty. Note also that three phase motors must be protected by three-leg,

ambient compensated, extra-quick trip overload relays of the recommended size or the warranty is void.

Your only remedy, and BERKELEY’s only duty, is that BERKELEY repair or replace defective products (at BERKELEY’s choice). You

must pay all labor and shipping charges associated with this warranty and must request warranty service through the installing

dealer as soon as a problem is discovered. No request for service will be accepted if received after the Warranty Period has

expired. This warranty is not transferable.

BERKELEY SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR CONTINGENT DAMAGES WHATSOEVER.

THE FOREGOING LIMITED WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS AND IMPLIED WARRANTIES,

INCLUDING BUT NOT LIMITED TO IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. THE FOREGOING LIMITED WARRANTIES SHALL NOT EXTEND BEYOND THE DURATION PROVIDED HEREIN.

Some states do not allow the exclusion or limitation of incidental or consequential damages or limitations on the duration of an

implied warranty, so the above limitations or exclusions may not apply to You. This warranty gives You specific legal rights and You

may also have other rights which vary from state to state.

This Limited Warranty is effective June 1, 2011 and replaces all undated warranties and warranties dated before June 1, 2011.

Composite Tanks 5 years from date of original installation

cial:

urbines, 6” diameter and larger

whichever occurs first:

12 months from date of original installation, or

18 months from date of manufacture

12 months from date of original installation, or

18 months from date of manufacture

12 months from date of original installation, or

24 months from date of manufacture

12 months from date of original installation, or

24 months from date of manufacture

In the U.S.: BERKELEY, 293 Wright St., Delavan, WI 53115

In Canada: 269 Trillium Dr., Kitchener, Ontario N2G 4W5

Piping omitted

1799 0497

n

1800 0497

1903 0497

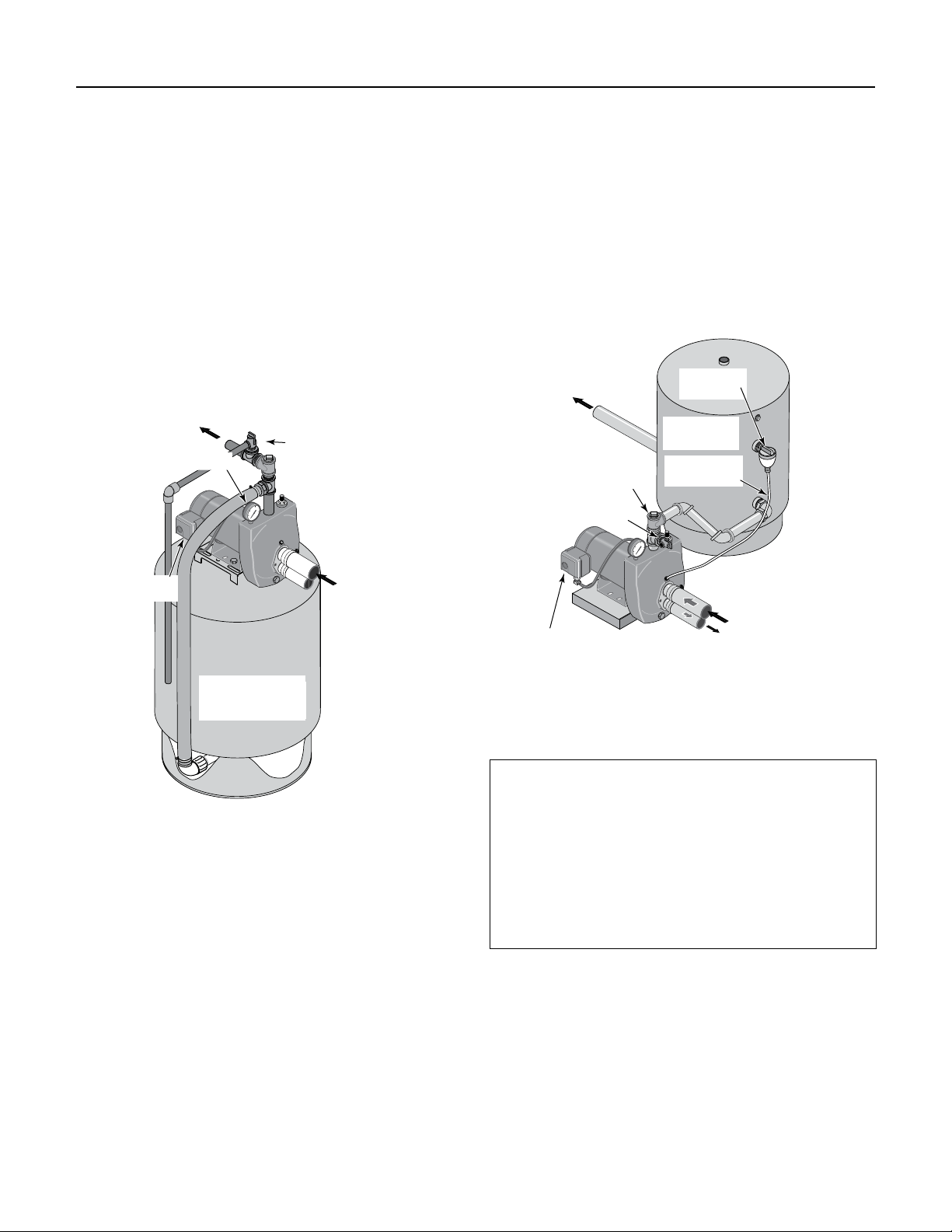

Typical Installations 4

)

To Household

Pressure Gauge

for clarity

40

20

Drive

over

Suction

60

80

100

Discharge

60

40

80

20

100

Drive Pipe

sends water

down the well

to

drive water

up through the

Suction Pipe

to Pump Suction

Suctio

over

Drive

Figure 1: Drive and Suction Functions

60

40

80

20

100

If well head and pump

don't match, twist

reinforced flexible pipe

to connect drive

and suction pipes.

Well

Head

To Household

Water System

Air Volume

Control

Standard

Tank

60

40

80

20

100

Drive Pipe

To Well

Air Volume

Control Tube

Suction Pipe

From Well

Relief Valve

Pressure

Switch

Priming Tee

and Plug

Figure 4: Typical Deep Well Installations

"Double Pipe"

(4" and Larger

Diameter Well)

Suction (Larger)

Pipe from Well

"Single Pipe"

(2" and 3"

Diameter Well

Drive

(Smaller)

Pipe to

Well

Well

Head

Well Casing

serves as

Drive Pipe

Venturi

Ejector

Nozzle

Foot Valve

Strainer

Leather

Cup Seals

24

J32P-

JET NO.

41

1834 0695

Drive

Pipe

Suction

Pipe

Figure 2: Reversed Connections

to Well

60

40

80

20

100

Figure 3: Mount Ejector –

Shallow Well

Water System

60

40

80

20

100

Check

Valve

Pre-charged

Precharged

Tank

Tank

Not

to

Scale

Relief Valve

Priming

Tee and

Plug

Drive point

below water

level

Drive

Point

Check

Valve

Drive

Coupling

Drive

Point

Cased

Well

Foot

Valve

Strainer

Suction Pipe

From Well

Priming

Tee and

Plug

Sanitary

Well Seal

Well

Casing

Foot

10'

Min.

Valve

5–10'

Screen

Open

Water

1836 0695

Figure 5: Typical Shallow Well Installations

Discharge Pipe and Pressure Tank Connections 5

To Well

To Household

PRE-CHARGE TANK CONNECTION (Figure 6)

If your system uses a pre-charged tank, it should be

connected to the pump as shown in Figure 6. The relief

valve must be capable of passing the entire pump capacity at 100 PSI pressure.

Check the pre-charge of air in the tank with an ordinary

tire gauge. the pre-charge is measured when there is

no water pressure in the tank. Disconnect power to the

pump and drain the tank before checking the pre-charge.

Your pump has a 30/50 PSI switch, so the tank precharge pressure should be 28 PSI (that is, it should be 2

PSI lower than the cut-in pressure of the pressure switch.

No AVC is required for a pre-charged tank; the

1/8" NPT AVC port on the pump body should be

plugged.

Water System

Relief Valve

Pressure Gauge

60

40

80

20

100

From

Pressure

Switch

Well

STANDARD TANK CONNECTION (Figure 7)

If your system uses a standard tank, connect it to the

pump as shown in Figure 7. The relief valve used with

a standard tank must be capable of passing the entire

pump capacity at 75 PSI pressure.

Connect the Air Volume Control (AVC) tube to the

1/8" NPT AVC port on the pump body. Run the tubing

from the pump’s AVC port to the AVC mounted on the

tank. See the instructions provided with tank and AVC

for details.

To Household

Water System

Priming Tee

and Plug

Relief Valve

40

20

Standard

Tank

Air Volume

Control Tube

60

80

100

Air Volume

Control

Suction Pipe

From Well

Pre-charged

Pre-Charged

Tank

Tank

2110 0497

Figure 6: Pre-charged Tank Connections

Pressure

Switch

Drive Pipe

Figure 7: Standard Tank Connections

Sealing Pipe Joints

Use only PTFE pipe thread sealant tape for making

all threaded connections to the pump itself. Do not

use pipe joint compounds on plastic pumps: they

can react with the plastic in pump components.

Make sure that all pipe joints in the suction pipe are

air tight as well as water tight. If the suction pipe

can suck air, the pump will not be able to pull water

from the well.

Electrical 6

Disconnect power before working on pump, motor, pressure switch, or wiring.

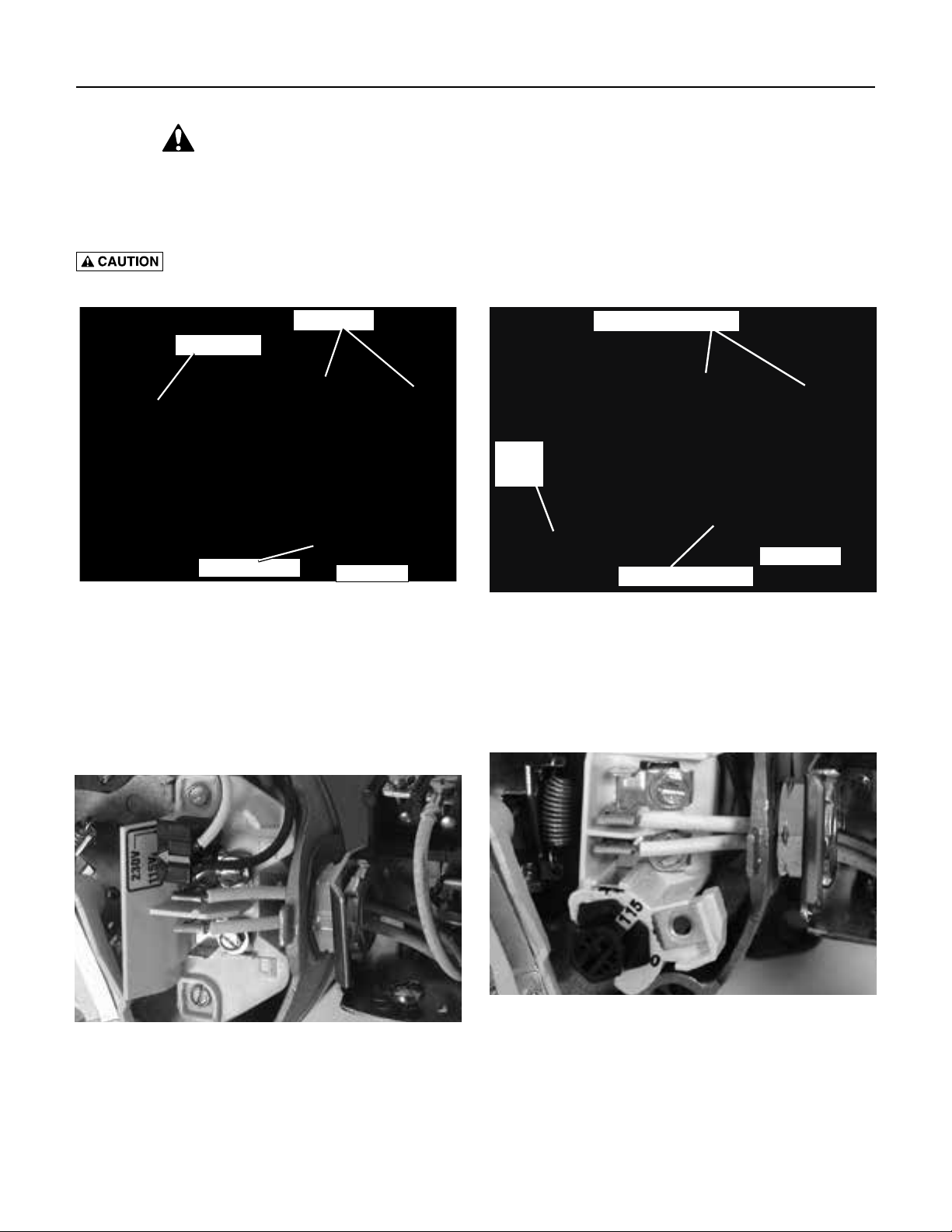

MOTOR SWITCH SETTINGS

NOTE: 1/2 HP motors are wired for 115 volts only, and have no motor wiring to change.

3/4 HP or 1 HP motor terminal boards (located under the motor end cover) should look like one of those below.

If the motor can operate at either 115 or 230 volts, it is set at the factory to 230 volts. Do not change motor wiring

if line voltage is 230 volts, or if you have a single voltage motor.

Never wire a 115 volt motor to a 230 volt line.

Plug Type Voltage Selector

Power Connections

Voltage Change Plug

Dial Type Voltage Selector

Power Supply Connections

Voltage

Change

Dial

Ground Wire Connection

Pressure Switch

Figure 8: Voltage set to 230 volts, Plug Type

Voltage is factory set to 230 volts. To change to 115 volts:

1. Make sure power is off.

2. Pull the voltage change plug off of the tabs.

3. Move the voltage change plug to the 115 volt position. The plug will now cover 2 metal tabs and the

arrow on the plug will line up with the 115V arrow on

the label (see Figure 9).

Pressure Switch

Ground Wire Connection

Figure 10: Voltage set to 230 volts, Dial Type

Voltage is factory set to 230 volts. To change to 115 volts:

1. Make sure power is off.

2. Turn the dial counter-clockwise until 115 shows in

the dial window as shown in Figure 11.

3. Attach the incoming power leads to the two outer

screws on the pressure switch as shown in Figure 10.

Figure 9: Voltage set to 115 volts, Plug Type

4. Attach the incoming power leads to the two outer

screws on the pressure switch as shown in Figure 8.

5. Attach the ground wire to one of the grounding

connections, shown in Figure 8.

6. If there are other wires, they should be capped.

7. Reinstall the Motor end cover.

Figure 11: Voltage set to 115 volts, Dial Type

4. Attach the ground wire to the grounding connections

as shown in Figure 10.

5. If there are other wires, they should be capped.

6. Reinstall the Motor end cover.

Electrical 7

Hazardous voltage. Can shock, burn, or

kill. Connect ground wire before connecting power supply wires. Use the wire size (including the ground wire)

specified in the wiring chart. If possible, connect the

pump to a separate branch circuit with no other appliances on it.

Explosion hazard. Do not ground to a gas

supply line.

WIRING CONNECTIONS

Fire hazard. Incorrect voltage can cause a

fire or seriously damage the motor and voids the warranty. The supply voltage must be within ±10% of the motor

nameplate voltage.

NOTICE: Dual-voltage motors are factory wired for 230

volts. If necessary, reconnect the motor for 115 volts, as

shown. Do not alter the wiring in single voltage motors.

Install, ground, wire, and maintain your pump in compliance with the National Electrical Code (NEC) or the

Canadian Electrical Code (CEC), as applicable, and with

all local codes and ordinances that apply. Consult your

local building inspector for code information.

Connection Procedure:

Step 1. Connect the ground wire first as shown in Figure

11. The ground wire must be a solid copper wire

at least as large as the power supply wires.

Step 2. There must be a solid metal connection between

the pressure switch and the motor for motor

grounding protection. If the pressure switch is

not connected to the motor, connect the green

ground screw in the switch to the green ground

screw under the motor end cover. Use a solid

copper wire at least as large as the power supply

wires.

Step 3. Connect the ground wire to a grounded lead in

a service panel, to a metal underground water

pipe, to a metal well casing at least ten feet (3M)

long, or to a ground electrode provided by the

power company or the hydro authority.

Step 4. Connect the power supply wires to the pressure

switch as shown in Figure 11.

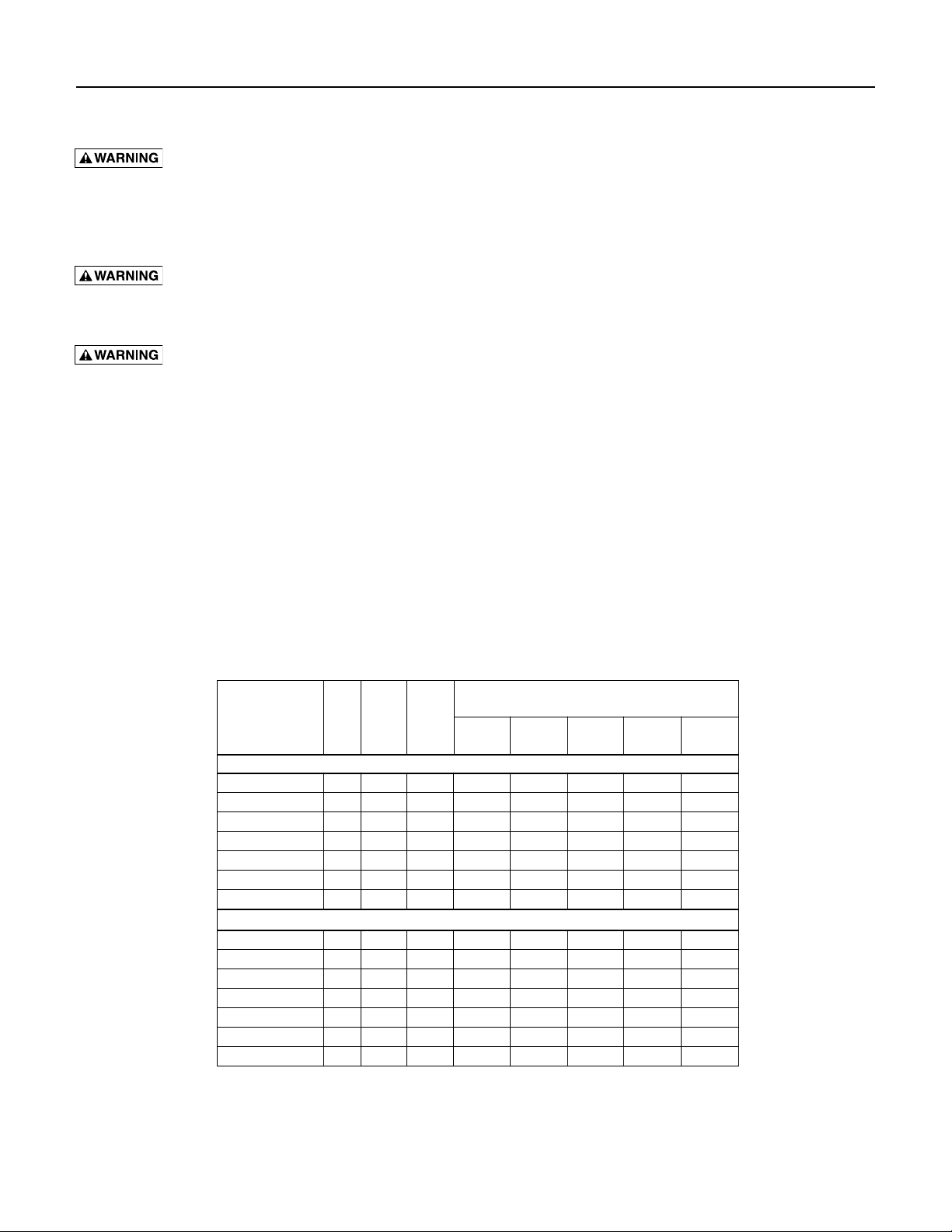

Table I: Wiring Chart – Recommended Wire and Fuse Sizes

Branch Distance in Feet (Meters);

Max Fuse Wire Size AWG (mm

Load Rating 0-100 101-200 201-300 301-400 401-500

Model HP Amps Amps (0-30) (31-61) (62-91) (92-122) (123-152)

115Volts:

5SL 1/2 9.9 15 14(2) 10(5.5) 8(8.4) 8(8.4) 6(14)

5HL 1/2 12.2 20 12(3) 10(5.5) 8(8.4) 6(14) 6(14)

7SL 3/4 12.2 20 12(3) 10(5.5) 8(8.4) 6(14) 6(14)

7HL 3/4 14.8 20 12(3) 8(8.4) 6(14) 6(14) 4(21)

10SL 1 14.8 20 12(3) 8(8.4) 6(14) 6(14) 4(21)

10HL 1 19.9 25 10(5.5) 8(8.4) 6(14) 4(21) 4(21)

15SL 1-1/2 19.9 25 10(5.5) 8(8.4) 6(14) 4(21) 4(21)

230 Volts:

5SL 1/2 5.0 15 14(2) 14(2) 14(2) 14(2) 12(3)

5HL 1/2 6.2 15 14(2) 14(2) 14(2) 12(3) 12(3)

7SL 3/4 6.2 15 14(2) 14(2) 14(2) 12(3) 12(3)

7HL 3/4 7.4 15 14(2) 14(2) 14(2) 12(3) 10(5.5)

10SL 1 7.4 15 14(2) 14(2) 14(2) 12(3) 10(5.5)

10HL 1 9.9 15 14(2) 14(2) 12(3) 10(5.5) 10(5.5)

15SL 1-1/2 9.9 15 14(2) 14(2) 12(3) 10(5.5) 10(5.5)

2

)

Replace all

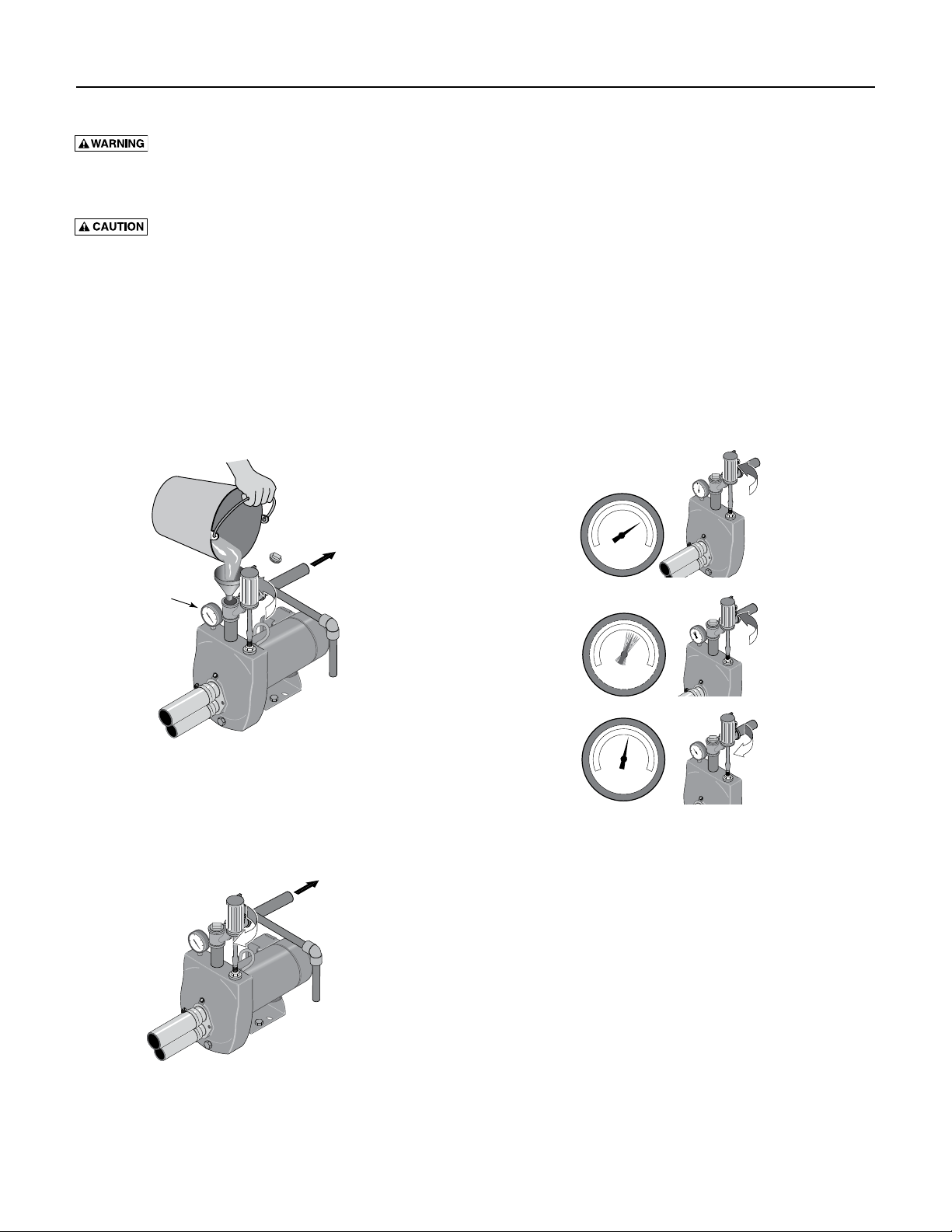

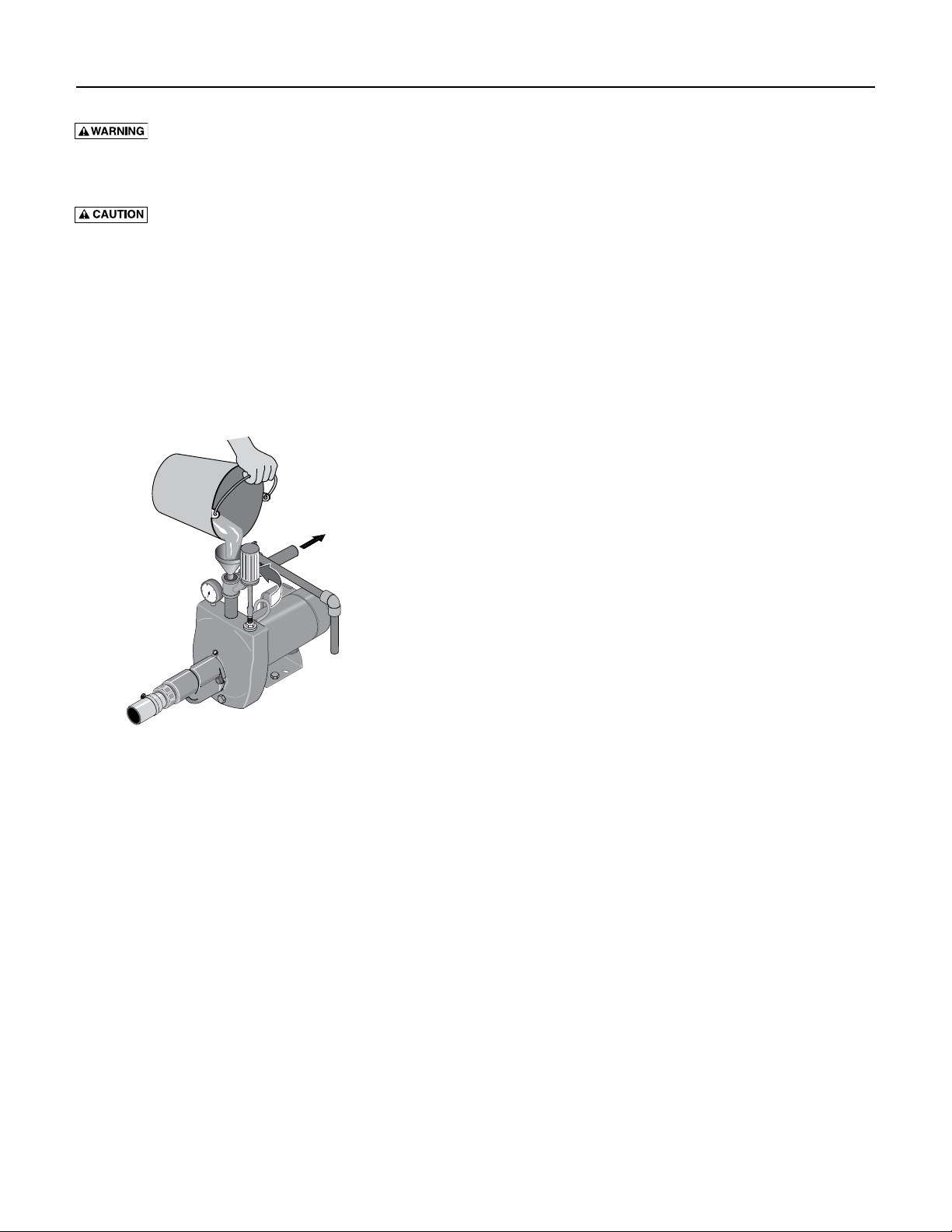

Preparing to Start the Pump – Deep Well 8

Never run pump against closed discharge.

To do so can boil water inside pump, causing hazardous

pressure in unit, risk of explosion and possibly scalding

persons handling pump.

Never run pump dry. Running pump without

water may cause pump to overheat, damaging seal and

possibly causing burns to persons handling pump. Fill

pump with water before starting.

Step 1. Open the control valve as far as possible (see

Figure 12). Then remove the priming plug

from the pump and fill the pump, fill all piping

between the pump and the well, and make sure

that all piping in the well is full. If you have also

installed a priming tee in the suction piping,

remove the plug from the tee and fill the suction

piping.

Open control valve

as far as possible

and fill pump and

piping through

priming tee.

To Household

Pressure

Gauge

60

40

80

20

100

Water System

Step 3. Power on! Start the pump and watch the pressure

gauge. The pressure should build rapidly to 50

PSI as the pump primes.

Step 4. After 2 or 3 minutes, the gauge should show pres-

sure. If not, stop the pump, remove the fill plugs,

reopen the control valve, and refill the pump and

piping. You may have to repeat this two or three

times in order to get all the trapped air out of the

piping. Don’t forget to close the control valve each

time before you start the pump.

Step 5. When pressure has built up and stabilized at

about 50 PSI, slowly open the control valve (see

Figure 14) and let the pressure drop until the

pressure gauge needle starts to flutter. When the

needle flutters, close the valve just enough to

stop the flutter (see Figure 14). Your pump is now

operating at its most efficient point.

60

80

40

20

100

A-Open Control Valve

60

80

40

20

100

Figure 12: Fill Pump

Step 2. Replace all fill plugs and close the control valve

completely (Figure 13).

fill plugs and

close control

valve completely.

To Household

Water System

60

40

80

20

100

Figure 13: Prime Pump

B-Watch for Pressure Gauge to Flutter

60

80

40

20

100

C-Close Control Valve until Pressure

Stabilizes

Figure 14: Set Control Valve

Step 6. After the pump has built up pressure in the

system and shut off, check the pressure switch

operation by opening a faucet or two and running enough water out to bleed off pressure until

the pump starts. The pump should start when

pressure drops to 30 PSI and stop when pressure

reaches 50 PSI. Run the pump through one or

two complete cycles to verify correct operation.

This will also help clean the system of dirt and

scale dislodged during installation.

NOTICE: Packer jets (2" and 3" single pipe wells) do not

form a perfect seal. Normal irregularities in the cup seal

leather and the inner walls of the casing will allow the

pressure in a dormant system to leak off over time. This

will cause the pump to cycle periodically to maintain the

system pressure level.

Preparing to Start the Pump – Shallow Well 9

2411 0497

Never run pump against closed discharge.

To do so can boil water inside pump, causing hazardous

pressure in unit, risk of explosion and possibly scalding

persons handling pump.

Never run pump dry. Running pump without

water may cause pump to overheat, damaging seal and

possibly causing burns to persons handling pump. Fill

pump with water before starting.

Step 1. Open the control valve as far as possible (see

Figure 15). Then remove the priming plug

from the pump and fill the pump, fill all piping

between the pump and the well, and make sure

that all piping in the well is full. If you have also

installed a priming tee in the suction piping,

remove the plug from the tee and fill the suction

piping.

Open control valve

as far as possible

and fill pump and

piping through

priming port

or priming tee.

To Household

60

80

40

20

100

Water System

Step 2. Replace all fill plugs. Leave the control valve

open (in a shallow well installation, the control

valve always stays open).

Step 3. Power on! Start the pump. The pump should

pump water in two or three minutes.

Step 4. If you don’t have water after 2 or 3 minutes, stop

the pump and remove the fill plugs. Refill the

pump and piping. You may have to repeat this

two or three times in order to get all the trapped

air out of the piping. The control valve remains

open throughout this procedure.

Step 5. After the pump has built up pressure in the

system and shut off, check the pressure switch

operation by opening a faucet or two and running enough water out to bleed off pressure until

the pump starts. The pump should start when

pressure drops to 30 PSI and stop when pressure

reaches 50 PSI. Run the pump through one or

two complete cycles to verify correct operation.

This will also help clean the system of dirt and

scale dislodged during installation.

Figure 15: Open Control Valve

Loading...

Loading...