MAINTENANCE INSTRUCTIONS

6. MAINTENANCE (authorized personnel)

6.1 General Warnings

All maintenance operations must be carried out by professionally qualified personnel, authorized by

PENSOTTI

The frequency of boiler maintenance is REQUIRED to be carried out once a year.

In order to guarantee the long life of the appliance and in accordance with the current gas safety

regulations, only use original replacement parts

Before carrying out any type of maintenance operation, disconnect the appliance from the electrical supply

and shut off the gas valve.

Warranty will not be offered if required maintenance is not followed.

Keep appliance area clear and free from combustible material, gasoline and other flammable vapors and

liquids.

In order to safeguard all waterside components the supplied Fernox Commissioning Kit must be used in

its entirety.

6.2 Maintenance

Periodic examination of the entire venting system is REQUIRED. Make sure all the venting

connections/joints are tight and in good condition.

Clean the burner cylinder using a non-metal brush and without damaging the ceramic fiber.

Clean the heat exchanger using a recommended detergent from PENSOTTI for the stainless steel. Do not

wet the ceramic fiber coating.

Visually inspect the burner flame. The flame must burn with a clean, stable flame. If the burner flame

appearance is not satisfactory or debris is visible on the burners, remove and clean with a vacuum

cleaner.

All electric motors are permanently lubricated and do not need oiling. Remove the combustion air blower

and clean wheel and housing with soft brush or vacuum.

Verify proper operation after any servicing using a properly calibrated electronic combustion analyzer.

Verify proper operation of safety circuits.

Wipe the outside surface with a wet cloth; then dry the surface. Use a neutral detergent to clean any stains.

Vent termination should be inspected for blockage during maintenance checks.

Check for blockage at the drain pipe and condensate trap.

Clean condensate trap and check for correct level of water.

Check for water leaks from the equipment and piping.

Warranty will not be offered if required maintenance is not followed.

56

MAINTENANCE INSTRUCTIONS

6.3 Boiler inspection

In order to ensure that the boiler operates efficiently and safely, it is recommended that the appliance is

inspected by a suitably competent technician at least once a year.

The following operations should be carried out annually:

■ Check the condition of the gas seals and replace where necessary.

■ Check the condition of the water seals and replace where necessary.

■ Visually inspect the condition of the combustion chamber and flame.

■ Check that the combustion is correctly regulated and if necessary proceed in line with section “Commissioning

the boiler”.

■ Remove and clean any oxidation from the burner.

If a relief valve discharges periodically, this may be due to thermal expansion in a closed water supply system.

Contact a qualified plumber to correct this situation. DO NOT PLUG THE RELIEF VALVE.

■ Check that the seal of the room-sealed chamber is undamaged and positioned correctly.

■ Check the primary heat exchanger and clean if necessary.

■ Check the maximum and minimum modulation pressures and the modulation itself.

■ Check the condition and operation of the ignition and gas safety systems. If necessary, remove and clean the

scaling from the ignition and flame detection electrodes, paying particular attention to replace them at the

correct distance from the burner.

■ Check the heating safety systems: temperature limit safety thermostat, pressure limit safety device.

■ Check the pre-fill pressure of the expansion tank (see expansion tank rating plate).

■ For safety reasons, periodically check the integrity and operation of the exhaust system.

■ Check that the connection to the mains electricity supply complies with that reported in the boiler’s instruction

manual.

■ Check the electrical connections inside the control panel.

■ Check the D.H.W flow rate and temperature.

■ Check that the condensate drain system is working correctly, including any parts of the system outside the boiler

such as condensate collection devices along the length of the exhaust vent and/or any acid neutralizing devices.

■ Check that the condensate flows freely and that there are no exhaust fumes present within the appliance.

Warranty will not be offered if required maintenance is not followed.

57

MAINTENANCE INSTRUCTIONS

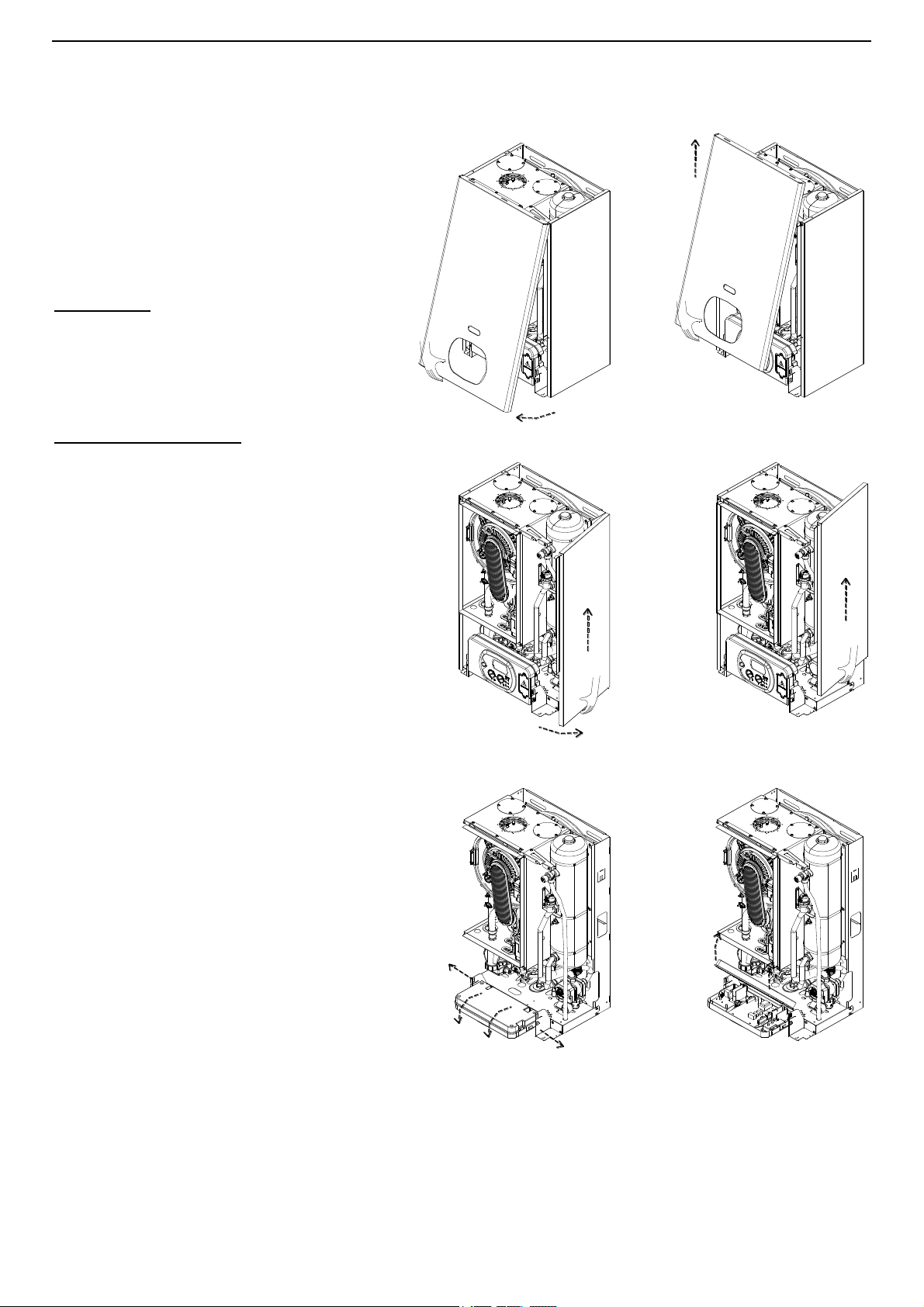

Fig. 1

Fig. 2

Fig. 5

Fig. 6

Fig. 3

Fig. 4

6.4 Accessing the boiler

All maintenance operations require one or

more of the boiler casing panels to be

removed.

The side panels can only be removed after

the front panel has been removed.

Front panel:

Remove the fixing screws at the lower

edge of the front panel.

Grasp the lower part of the panel and pull

it outwards (fig. 1) and then up.

Left and right side panel:

Remove the fixing screws at the front and

lower edge of the side panel to remove.

Grasp the bottom of the panel, move it

sideways and then upwards to remove

it.

To access the electrical connections of the

control panel, proceed as follows:

Remove the front panel (see fig. 1).

Grasp the left and right control panel support

brackets and pull them outwards, at the

same time rotating the panel downwards.

Unscrew the four fixing screws and remove

the cover.

6.5 Flushing out the primary side

Fill the boiler as per the filling instructions.

Using a drain off cock on the lowest point of

the system allow the water to drain from the

system and boiler.

In order to flush the system correctly, turn

off all radiators or fan coils. Open the filling

loop and drain cock simultaneously and allow

the water to flow through the boiler.

Open each individual radiator or fan coil,

allowing water to flow through. Then turn that

radiator or fan coil off and repeat for all

radiators or fan coil on the system.

Turn off the filling loop and close the drain cock open all radiators and open the filling to fill the system.

Continue to fill the system until the pressure gauge reads in the Green section of the gauge (14.5 psi = 1

bar)

In order to safeguard all waterside components the supplied Fernox Commissioning Kit must be used in its

entirety.

58

MAINTENANCE INSTRUCTIONS

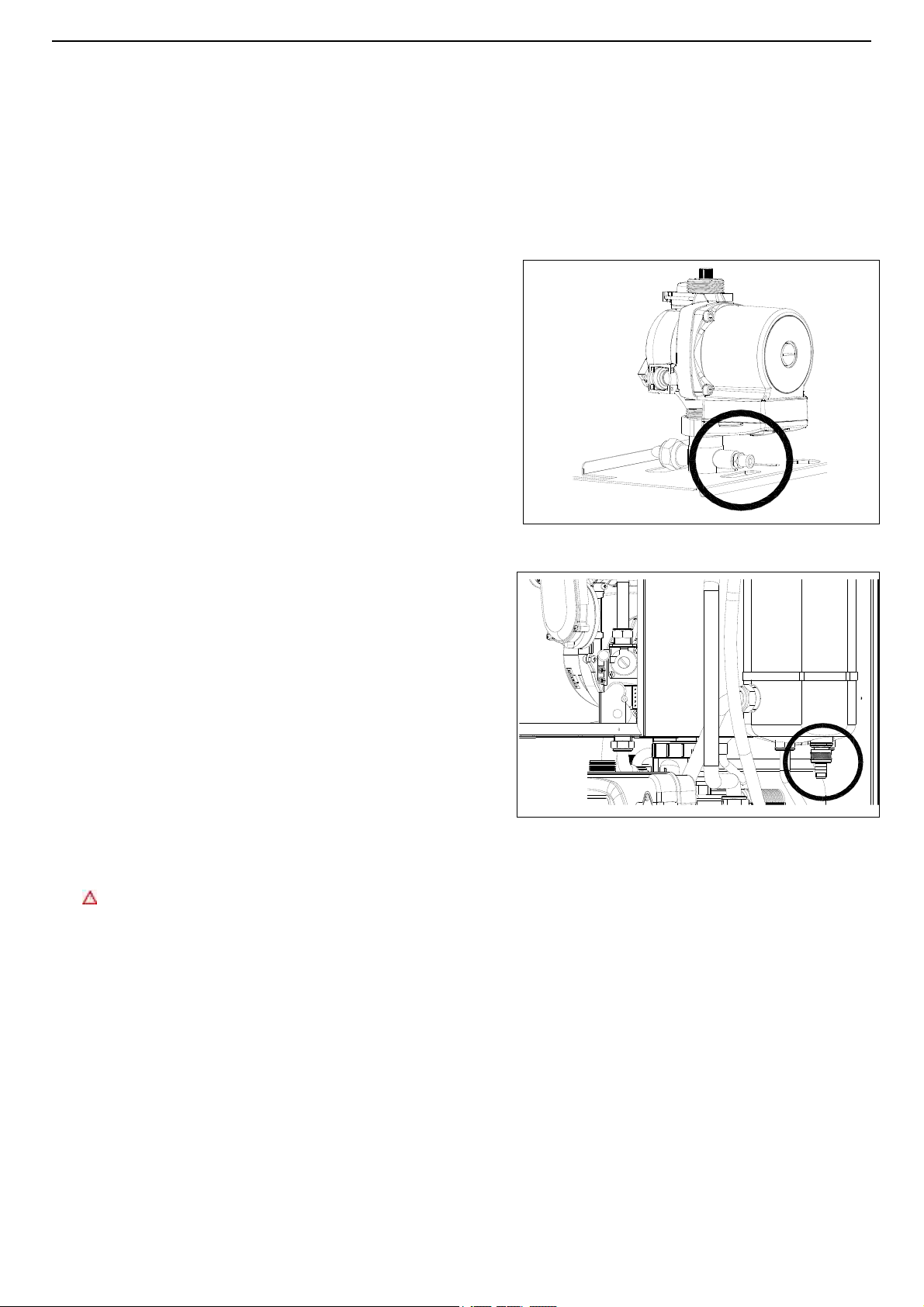

Fig. 1

Fig. 2

6.6 Draining the central heating system

If the need arises to drain the system, this can be done as follows:

Switch the system to “HEAT” mode and ignite the boiler.

Switch off the power supply to the boiler.

Wait for the appliance to cool down.

Connect a hosepipe to the system drain point R and

locate the other end of the hose in a suitable drainage

system.

Open the system drain valve (fig. 1).

Open the manual air vent located on the primary heat

exchanger.

Open the air vents on the radiators, starting with the

highest and moving down the system to the lowest.

When the system has been drained, close the radiator

air vents and the drain valve.

If only the boiler needs to be drained, close the

flow/return isolating valves on the heating circuit

and open the drain valve R located at the bottom of

the boiler on the pump manifold (see fig. 1 );

Draining the domestic hot water system

If there is a danger of freezing, the domestic hot water

system should be drained. This can be done as follows:

Close the main water supply valve.

Joint the water draining pipe and open the cylinder

draining tap (see fig. 2)

Open all the hot and cold water taps.

On completion, close all the previously opened

taps.

Freeze Protection

Glycol must not be used in Domestic Hot Water applications.

System winterization (non-operative system)

Because it may be impossible to completely drain the boilers heating circuit, D.H.W circuit and distribution

system. Pensotti recommends the introduction of the proper type antifreeze to protect these systems from

freezing damage. Glycol must not be used in Domestic Hot Water applications.

System winterization (operating system)

Pensotti boilers are certified for indoor use ONLY. Proper precautions for freeze protection are

recommended for boilers and associated piping in areas where the danger of freezing exists. Do not use

automotive antifreeze. Pensotti recommends the use of inhibited glycol concentrations between 20-35%

glycol. Glycol products must be maintained properly so they do not become inactive or corrosive, consult

glycol specifications for more information.

59

MAINTENANCE INSTRUCTIONS

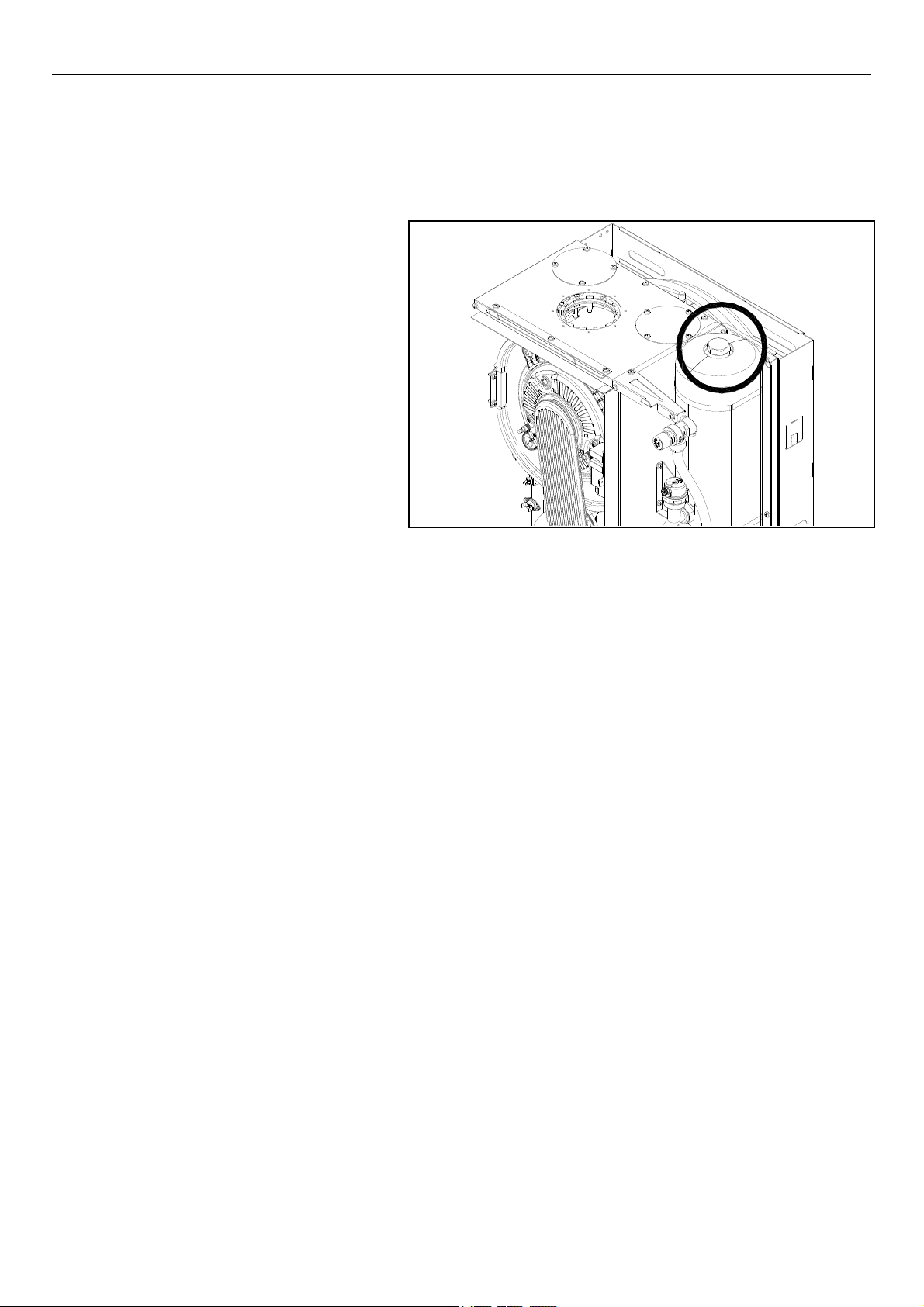

Fig. 3

STORAGE CYLINDER MAINTENANCE AND MAGNESIUM ANODE REPLACEMENT

Check the magnesium anode inside the

D.H.W. storage cylinder for erosion, a

minimum of every 12 months or more

frequently in case of hard water or

continuous operation. If it is worn-out,

replace it immediately. A non correct

maintenance will invalidate the cylinder

warranty.

To check the anode, unscrew the anode nut

located on the top of the cylinder (see fig.3)

by turning it counter-clockwise. If, at the

opening of the valve, water comes out of the

valve, the anode is worn and needs to be

replaced; if no water comes out of the valve,

the anode is not worn and therefore still

functioning. Once this operation has been

completed, close the small valve.

60

MAINTENANCE INSTRUCTIONS

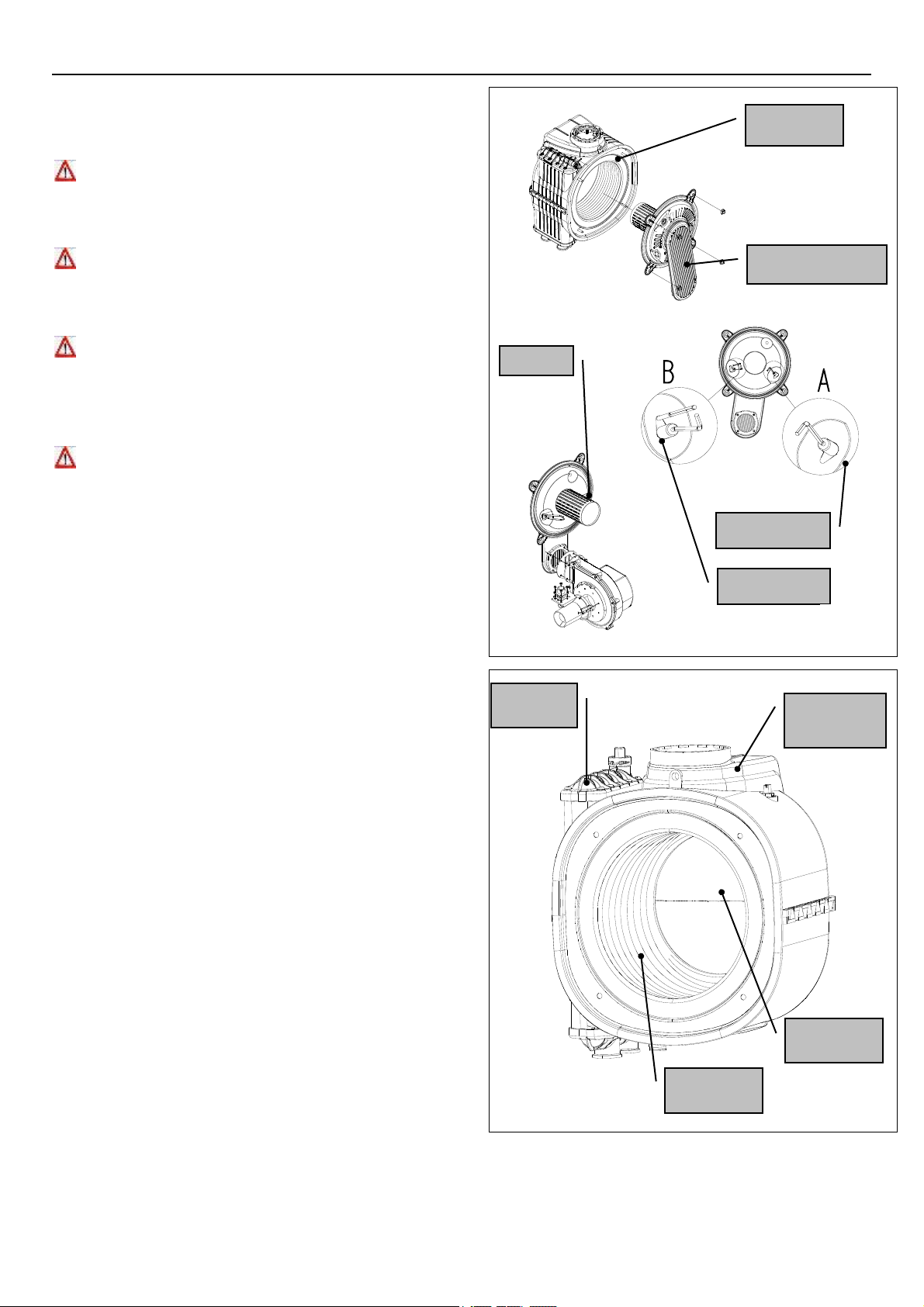

premix burner unit

burner

ionisation

ignition

primary heat

exchanger

B

A

primary

heat

flue

connection

stainless steel

pipe coil

ceramic fibre

washer

Fig. 1

Fig. 2

6.7 Maintenance operations

All maintenance operations must be carried out

by professionally qualified personnel,

authorised by Granby/Pensotti LLC.

The frequency of boiler maintenance must

comply with current law and, nevertheless,

should be carried out once a year.

In order to guarantee the long life of the

appliance and in accordance with the current

gas safety regulations, only use original spare

parts

Before carrying out any type of maintenance

operation, disconnect the appliance from the

main electricity supply and close the gas valve.

For all maintenance operations requiring removal of the

boiler casing, refer to the procedures described in

paragraph 6.4 “Accessing the boiler”.

Cleaning the main exchanger module and combustion unit

(fig. 1)

Disconnect the electrical connections of the electric fan.

Disconnect the joint and remove the pipe linking the gas

valve to the injector unit (venturi).

Disconnect the joint and remove the gas feed pipe from

the gas valve.

Un-plug the ignition electrode and flame detection wires

from the ignition control unit.

Unscrew the ring-nut at the bottom of the room-sealed

chamber and remove the gas valve.

Unscrew the nuts securing the burner unit (consisting of a

fan, manifold and burner) to the primary heat exchanger.

Remove the burner unit, paying particular attention not to

remove the ceramic fibre protection from the bottom of

the heat exchanger.

Check that the burner is not affected by deposits, scaling

or excessive oxidation. Check that all the holes in the

burner are free.

Clean the electrodes carefully without altering their

positions with respect to the burner.

Clean the burner cylinder using a non-metal brush and

without damaging the ceramic fibre.

Check the integrity of the gasket on the cover of the

burner.

Clean the heat exchanger using a household detergent for stainless steel, distributing the product on the spirals of

the exchanger using a brush. Do not wet the ceramic fibre coating. Wait a few minutes then remove the deposits

using a non-metal brush. Then remove the residues under running water.

61

Loading...

Loading...