Pensotti PCI 18/8-H Installation Manual

INSTALLATION

INSTRUCTIONS

18

B

C

A

3. INSTALLATION (authorized personnel)

3.1 Reference standard

Install in accordance with local building and electrical codes.

Failure to install a gas appliance correctly and in accordance with the above norms could lead to prosecution. It is

in the interest of the installer and safety that the codes are complied with.

The manufacturer’s instructions form an integral part of the installation and should be left with the appliance but do

not over ride in anyway statutory obligations.

Installation requirements

Please refer to local and national standards in force with the Country of destination of the product.

3.2 Unpacking

■ The materials (cardboard) used for packing the

appliance are fully recyclable.

■ It is recommended that the packing material is only

removed prior to installing the boiler. The manufacturer

will not be held responsible for damage caused by

incorrect storage of the product.

■ Packing materials (plastic bags, polystyrene, nails,

etc.) must not be left within reach of children, in that

these items represent a potential hazard.

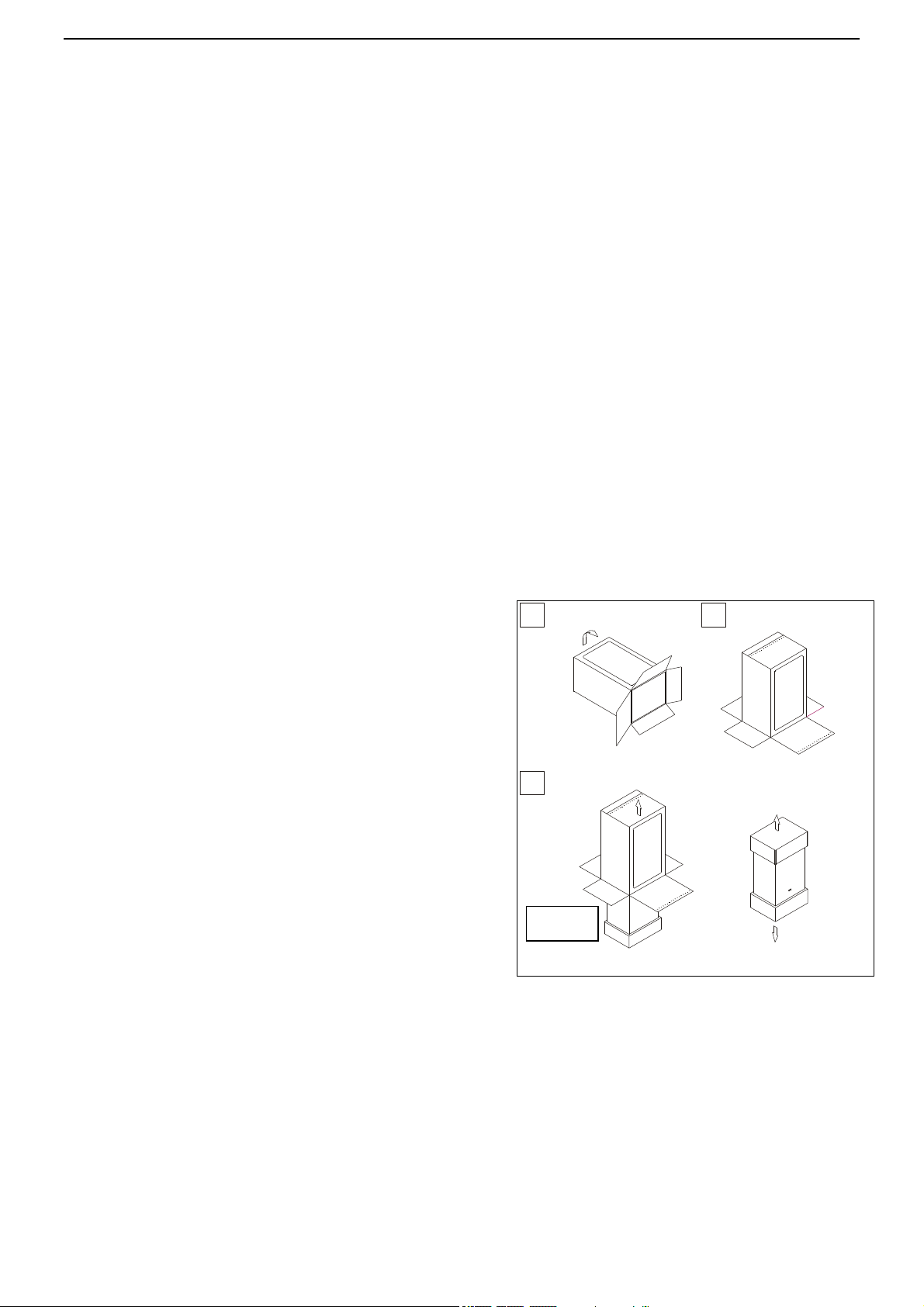

A. Place the packed appliance on the floor (see fig. 1)

making sure that the "up” arrow is facing down. Remove the

staples and open out the four flaps of the box.

B. Rotate the boiler 90° while manually supporting it from

underneath

C. Lift the box and remove the protections. Lift the boiler by

grasping the rear part and proceed with the installation.

STORAGE & HANDLING

Please note that prior to installation the Pensotti North

America boilers should be stored in the horizontal position

with no more than three boilers to a stack;

Ensure that the boilers are stored in dry conditions and be aware that the carton is a two-man lift;

Fig 1

INSTALLATION

INSTRUCTIONS

19

3.3 Installing the boiler.

The appliance must be installed

exclusively on a vertical solid wall capable of

supporting its weight.

■ The boiler should be fitted within the

building unless otherwise protected by a

suitable enclosure i.e. garage or outhouse.

(The boiler may be fitted inside a

cupboard)

■ /If the boiler is sited in an unheated

enclosure then it is recommended to leave

the ON/OFF switch always in ON position

to give frost protection.

■ If the boiler is installed in a room

containing a bath or shower reference

must be made to the relevant

requirements.

■ Appliance is approved for installation on

combustible walls.

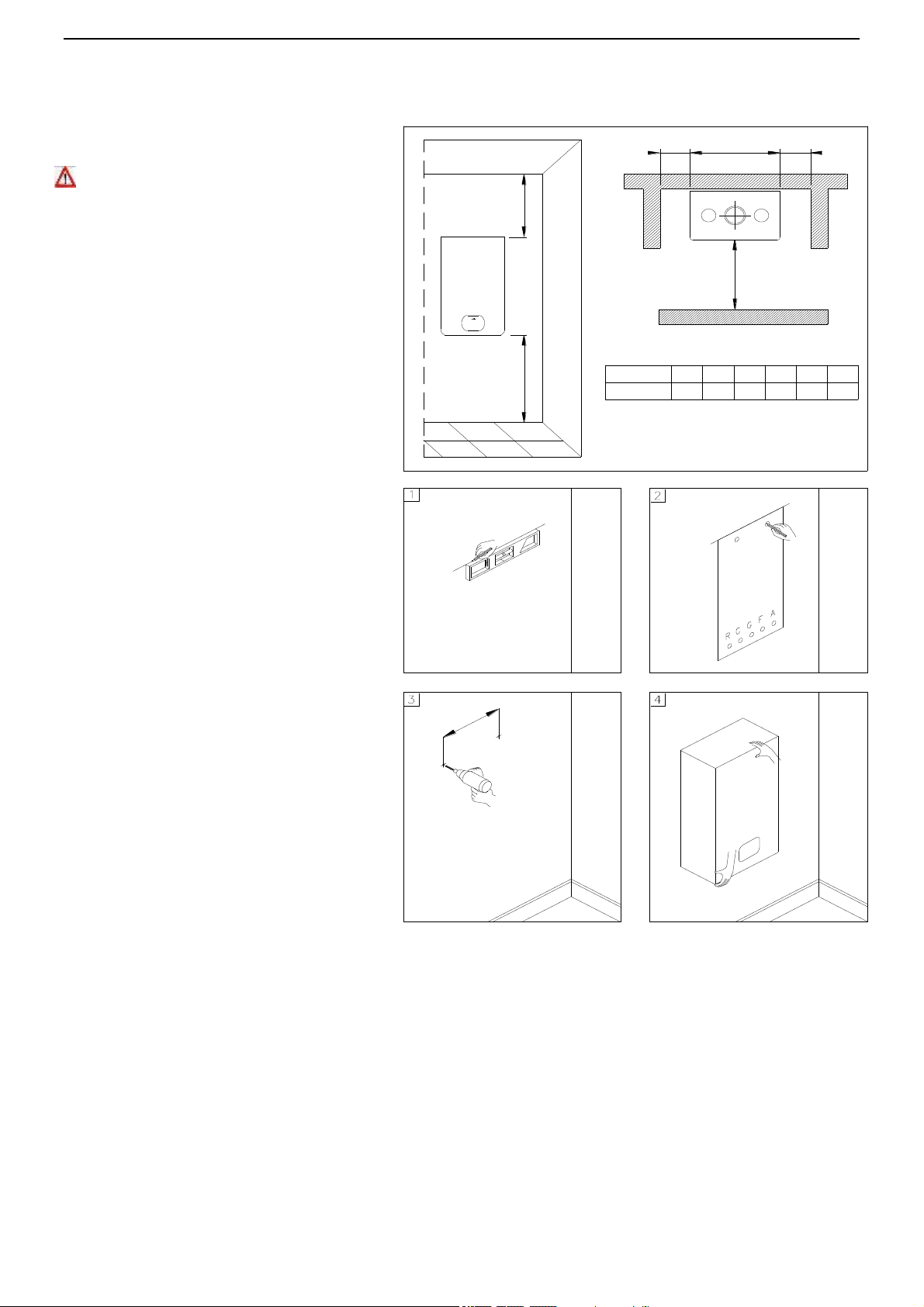

In order to allow access to the interior of the

boiler for maintenance purposes, it is

important that the minimum distances

indicated in figure 1 are respected. To make

the installation easier, the boiler is supplied

with a template to enable the pipe

connections to be positioned prior to fixing

the appliance to the wall.

To install the boiler, proceed as follows (see

fig. 2):

a. Use a level (of not less than 24” long) to

mark a horizontal line on the wall where

the boiler is to be fitted.

b. Position the top of the template along the

line drawn with the level, respecting the

distances indicated. Then mark the

centres of the positions of the two wall

screws or anchors. Finally, mark the

positions of the water and gas pipes.

c. Remove the template and install the

domestic hot and cold water pipes, the

gas supply pipe and the central heating

pipes using the fittings supplied with the

boiler.

Fix the boiler to the wall using the bracket

and connect the pipes.

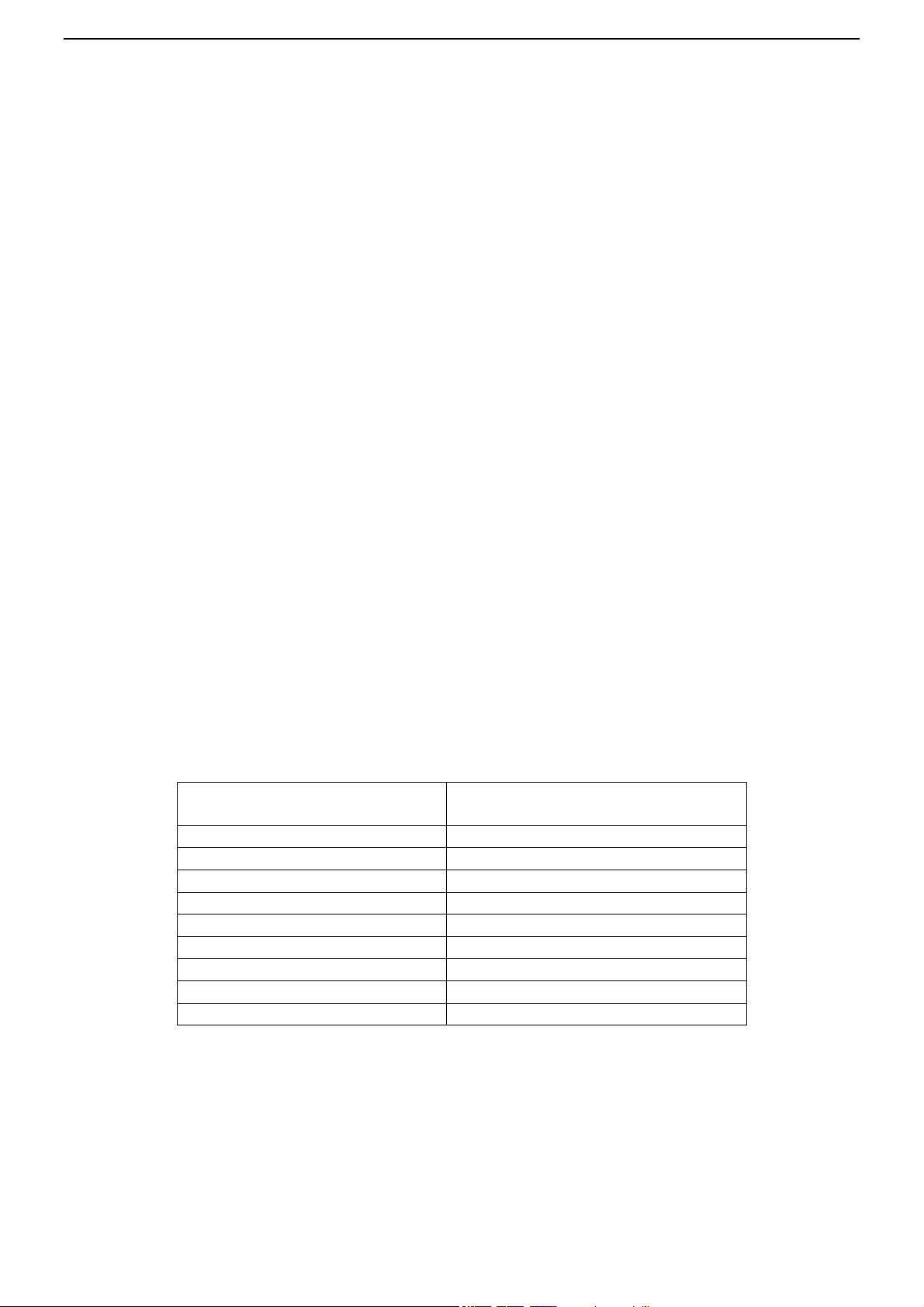

MINIMUM DISTANCES [INCHES]

H

A

X

L

Y

Model

PCI 18/8

X Y L H

40

17.7

2.52.5

B

A B

14 12

Fig. 1

Fig. 2

INSTALLATION

INSTRUCTIONS

19

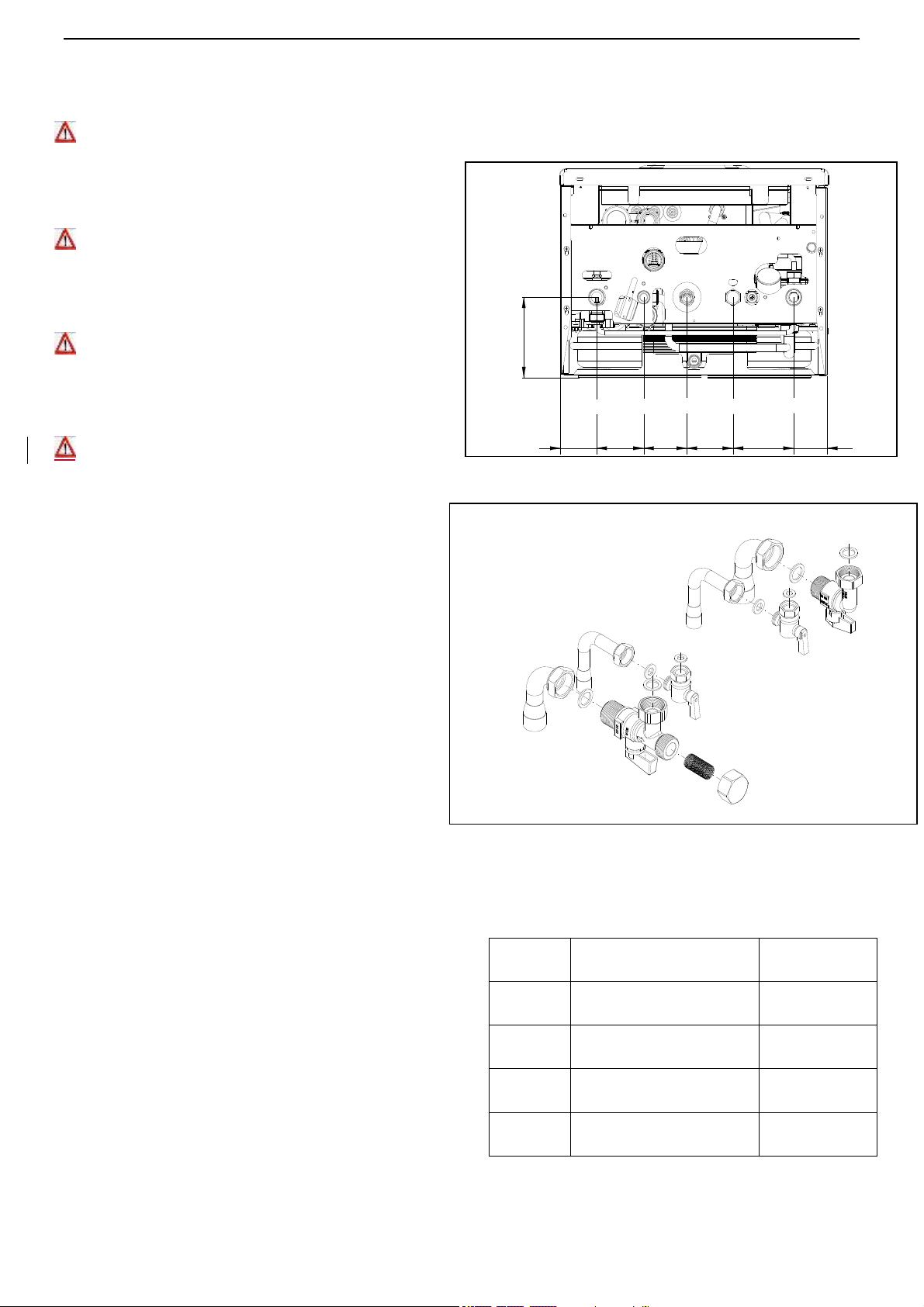

3.4 Water connections

In order to safeguard the heat exchanger and circulation pump, especially in case of boiler replacement, it

is recommended that the system is hot-flushed

to remove any impurities (especially oil and

grease) from the pipes and radiators.

In order to safeguard all waterside

components the supplied Fernox

Commissioning Kit Must be used in its

entirety.

Make sure that the domestic water and central

heating pipes are not used to earth the

electrical system. The pipes are totally

unsuitable for this purpose.

Isolation Valves must be installed on the

heating and D.H.W circuits. This will facilitate

all maintenance and service operations where

the boiler needs to be drained.

To prevent vibration and noise coming from the

system, do not use pipes of reduced diameter,

short radius elbows or severe reductions in the

cross sections of the water passages.

In order to guarantee the reliability of the water a

pressure reducing valve and backflow preventer

must be installed

To facilitate the installation, the boiler is supplied

with an hydraulic connection kit (see fig.2).

A pressure relief valve is installed in this dual purpose

boiler that is rated in accordance with and complying

with either The Standard for relief Valves and

Automatic Shutoff Devices for Hot Water Supply

Systems, AINSI Z21.22 or The ANSI/ASME Boiler and

Pressure Vessel Code, Section IV (Heating Boilers).

The relief valve must be installed such that the

discharge will be conducted to a suitable place for

disposal when relief occurs. The discharge line must

be installed to allow complete drainage of both the

valve and the line. If this unit is installed with a

separate storage vessel, the separate vessel must

have its own temperature and pressure relief valve.

This valve must also comply with The Standard for

Relief Valves and Automatic Shutoff Devices for Hot

Water Supply Systems. AINSI Z21.22 (in the U.S.

only). A temperature relief valve is not required but if

one is used, do not install the valve with the probe

directly in the flow of water. This may cause

unwarranted discharge of the valve.

LEGEND

HR

HEATING RETURN

Ø 3/4"

HF

HEATING SUPPLY

Ø 3/4"

G

GAS

Ø 1/2"

CWI

COLD WATER INLET

Ø 1/2"

HWO

HOT WATER OUTLET

Ø 1/2"

5.1

HF

CWI

G

HR

HWO

2.5 3.1

2.7

3.2

4

2.2

HR

HWO

CWI

HF

Fig. 2

Fig. 1

INSTALLATION

INSTRUCTIONS

20

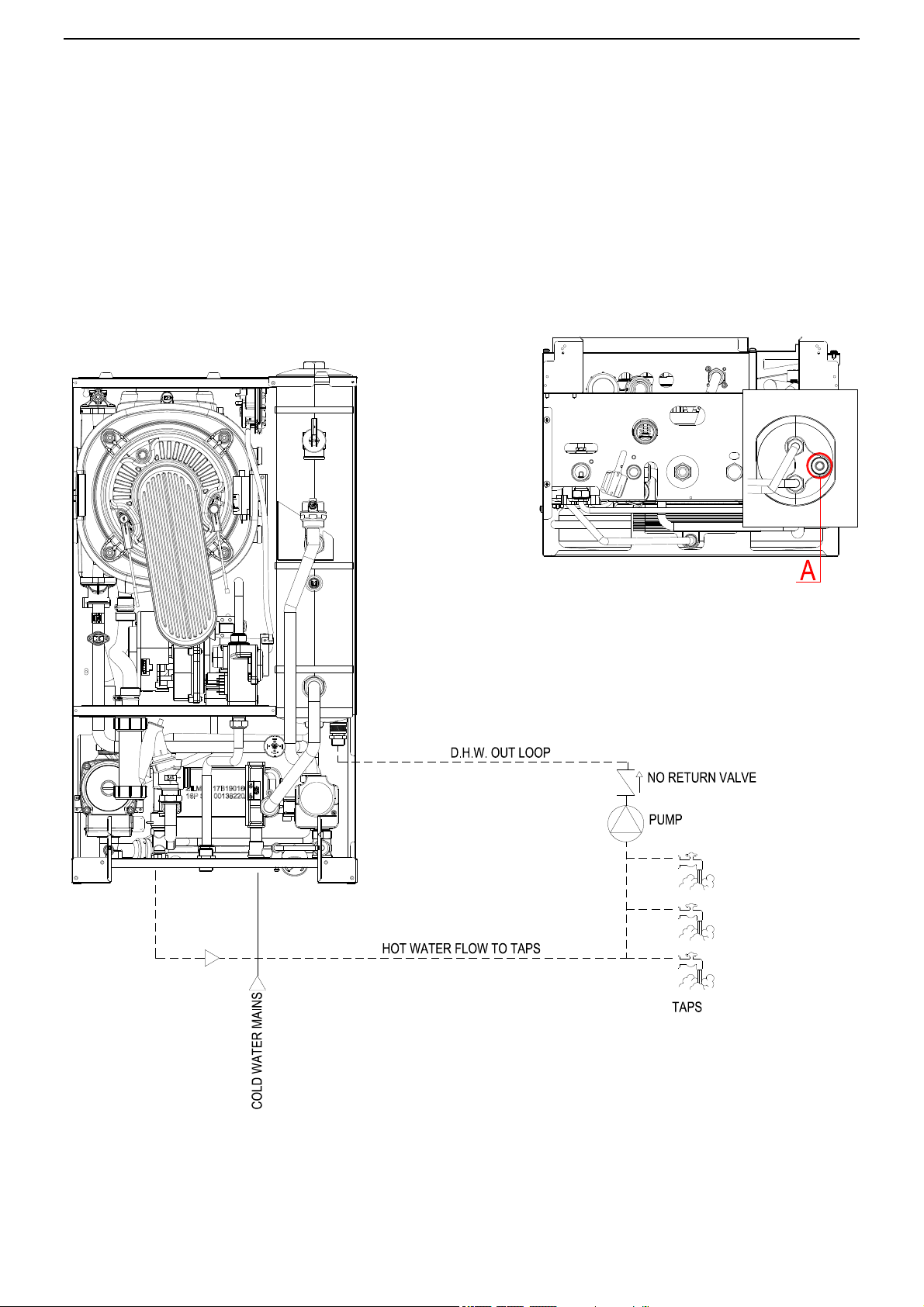

D.H.W. circulating loop

In order to joint the D.H.W out loop pipe, proceed as follows:

a) unscrew the ½” cap A and insert a ½” nipple;

b) joint the nipple to the D.H.W. circulating pipe;

INSTALLATION

INSTRUCTIONS

21

3.5 Domestic Hot Water Circuit

■ In order to prevent scaling and eventual damage to the D.H.W heat exchanger, the mains water supply must not

have a hardness rating of more than 7 grains/gal (120 ppm). It is nevertheless advisable to check the properties of

the water supply and install the appropriate treatment devices where necessary.

The cold water supply pressure at the inlet to the boiler must be between 7.25 psi (0.5 bar) and 87 psi (6 bar).

In areas with higher water inlet pressure a pressure reducing valve must be fitted before the boiler.

The frequency of the heat exchanger coil cleaning depends on the hardness of the mains water supply and the

presence of residual solids or impurities, which are often present in the case of a new installation. If the

characteristics of the mains water supply are such that require it to be treated, then the appropriate treatment

devices must be installed, while in the case of residues, an in-line filter should be sufficient.

Central heating circuit

In order to prevent scaling or deposits in the primary heat exchanger, the mains supply water to the heating circuit

must be treated according to the requirements of local standards.

This treatment is indispensable in the case where the circuit is frequently topped-up or when the system is often

either partially or fully drained.

In order to safeguard all waterside components, the supplied Fernox Commissioning Kit Must be used in

its entirety.

Condensate drain

Refer to the city, town or municipality have jurisdiction for codes regarding the proper discharge of

condensate.

The condensate drain flexible pipe supplied with the boiler must be connected to a proper condensate trap. The

condensate discharge into the drainage system is allowed providing a condensate trap (siphon) is installed.

Any condensate discharge pipe work external to the building (or in an unheated part of it) must be insulated to

protect against frost. Before switching the boiler On, check the correct condensate discharge.

Expansion Tank Capacity

Max. System Operating

Temperature (°F)

Maximum System Water

Content (Gals.)*

100

114

110

85

120

65

130

52

140

43

150

36

160

30

170

26

180

24

Pensotti requires the

installation of a pressure

reducing valve & backflow

preventer with all Solenne

Series boilers.

INSTALLATION

INSTRUCTIONS

22

3.6 Piping Diagram

Dirt / Scale Separation

Along with the application of our Fernox commissioning kit Pensotti highly recommends the installation

of a dirt separator in the return piping of all Solenne Series boiler models. Follow the manufacturer’s

instructions when installing these devices.

This piping diagram is an example for illustrative purposes only.

It is not designed to be used as a piping schematic.

*Max. 4 pipe diameters between tees

*External Low Water Cut-Off if required by local code

*Tempering Valve May be Required – Consult Local Codes

*Must leave at least 15” of straight pipe on either side of

closely spaced tees

INSTALLATION

INSTRUCTIONS

23

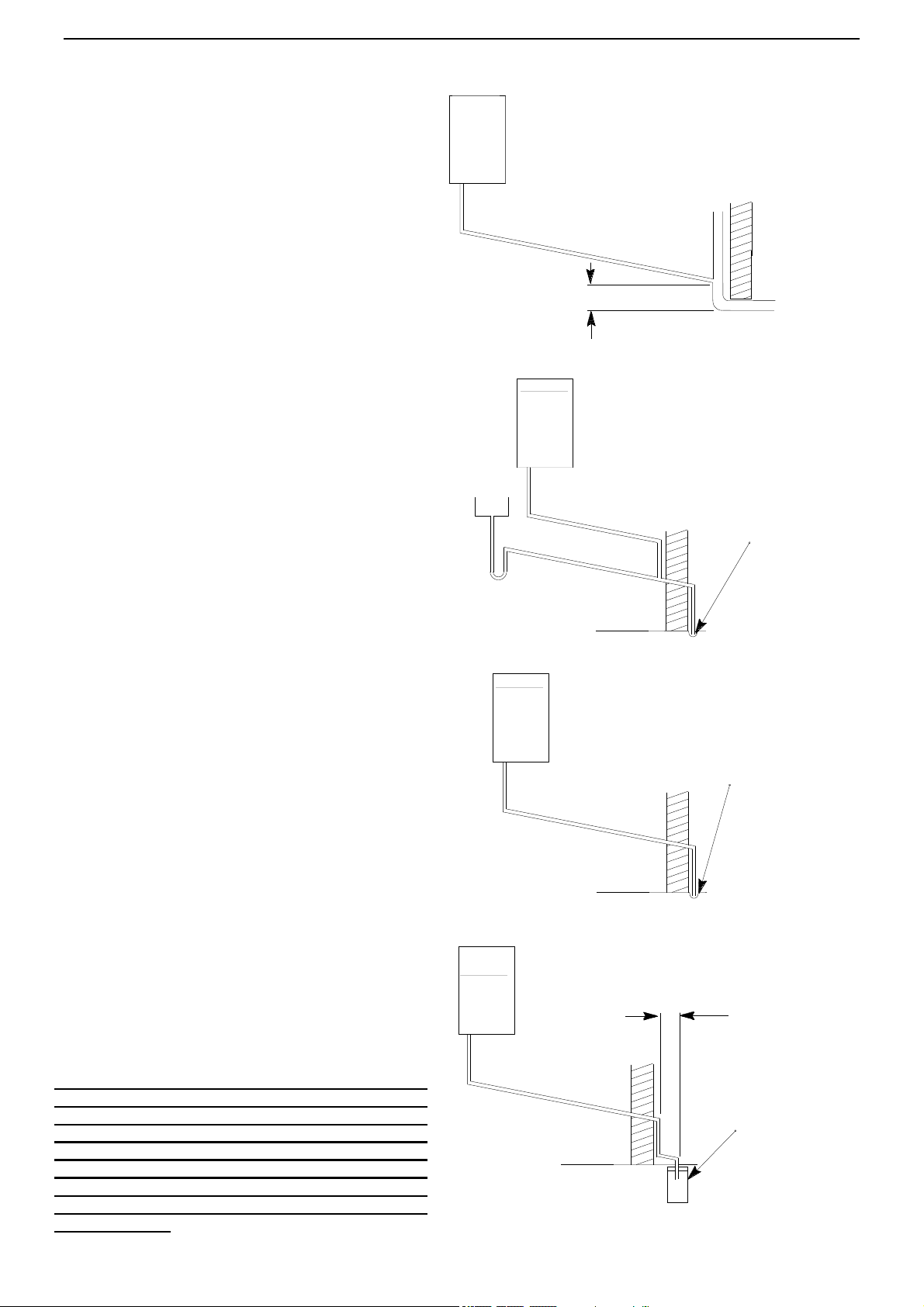

3.7 Condensate drain

FAILURE TO INSTALL THE CONDENSATE

DISCHARGE PIPEWORK CORRECTLY WILL

AFFECT THE RELIABLE OPERATION OF THE

DUAL PURPOSE BOILER. The condensate

discharge pipe MUST NOT RISE at any point along

its length. There MUST be a fall of AT LEAST 2.5° (1”

per 20”) along the entire run.

I. The condensate outlet terminates in 7/8” nut and

seal for the connection of 7/8” plastic overflow pipe

which should generally discharge internally into the

household drainage system. If this is not possible,

discharge into an outside drain is acceptable.

2. Ensure condensate piping, neutralizer, and

discharge of condensate complies with any and all

local and national codes.

3. The discharge pipe should be run in a proprietary

drain pipe material e.g. PVC, PVC-U, ABS, PVC-C or

PP.

4. Metal pipe work is NOT suitable for use in

condensate discharge systems.

5. The pipe should be a minimum of 7/8” diameter and

must be supported using suitably spaced clips to

prevent sagging.

6. Any pipe fitted externally must not exceed 10 feet.

7 Any condensate discharge pipe work external to the

building (or in an unheated part of it e.g. garage) must

be insulated to protect against frost. It is also

recommended that the pipe diameter is increased to 1

¼”.

8. If the boiler is fitted in an unheated location the

entire condensate discharge pipe should be treated

as an external run.

9. In alI cases discharge pipe must be installed to aid

disposal of the condensate. To reduce the risk of

condensate being trapped, as few bends and fittings

as possible should be used.

10. When discharging condensate into a soil stack or

waste pipe the effects of existing plumbing must be

considered. If soil pipes or waste pipes are subjected

to internal pressure fluctuations when WC's are

flushed or sinks emptied then back-pressure may

force water out of the boiler trap and cause appliance

lockout.

Information Only:

Examples are shown of the following methods of

termination:-

i) to an internal soil & vent pipe

ii) via an internal discharge branch (e.g. sink waste)

iii) to a drain or gully

iv) to a purpose made soak away

Ensure condensate piping, neutralizer, and

discharge of condensate complies with any and

all local and national codes.

IF, FOR ANY REASON, THE CONDENSATE

DRAINAGE SYSTEM FAILS AND CONDENSATE IS

PERMITTED TO FLOW BACK INTO THE

INTERNAL CONDENSATE BOTTLE INSIDE THE

BOILER, THE BOILER WILL STOP AND WILL

DISPLAY AN E01 ERROR. THE CONDENSATE

DRAINAGE SYSTEM PROBLEM MUST THEN BE

CORRECTED BEFORE THE BOILER IS PUT BACK

IN OPERATION.

18" min

Holes in the soak-away must

face away from the building

20" min

External termination to a purpose made soak-away

External termination to a drain or gully

Pipe must terminate above

water level but below

surrounding surface

1" per 20" of pipe run

2.5° Minimum fall

1" per 20" of pipe run

2.5° Minimum fall

Boiler

Pipe must terminate above

water level but below

surrounding surface

1" per 20" of pipe run

2.5° Minimum fall

External termination via internal discharge

branch e.g. sink waste - downstream

Sink

2.5° Minimum fall

1" per 20" of pipe run

Termination to an internal soil and vent pipe

Boiler

Boiler

Boiler

INSTALLATION

INSTRUCTIONS

24

3.8 Gas Connection

3.8.1 Gas Piping Guidelines

Follow all local codes and/or the most recent edition of the National Fuel Gas Code (ANSI Z223.1/NFPA 54) in

the USA or the Natural Gas and Propane Installation Code in Canada (CAN/CSA B149.1).

3.8.2 Gas Supply Lines Pressures

The minimum and maximum inlet gas pressures are Natural Gas Min. 7.00”WC – Max. 14.00”WC. and

Propane Gas Min. 11.00”WC – Max. 21.00”WC.

Gas pressures over and above the specified range will result in adverse performance and

dangerous operating conditions; any damage resulting from extreme gas supply pressures will not

be covered by the limited warranty.

Until pressure testing of the main gas supply line is completed, ensure the gas line to the

PENSOTTI Boiler is disconnected to avoid any damage to the boiler.

The appliance and its individual shut off valve must be disconnected from the gas supply piping

system during any pressure testing of that system at test pressures in excess of 0.5 psi (3.5 kPa)..

The appliance must be isolated from the gas supply piping system by closing its individual manual

shut-off valve during any pressure testing of the gas supply system at test pressures equal to or less

that 0.5 psi (3.5 kPa).

The gas appliance and its gas connections must be leak tested before placing the appliance in

operation. Leaks can be found by using a gas leak detection device or by applying soapy water

to all gas fittings. Should bubbles occur, tighten those connections and re-test.

Always purge the gas line for any debris before connecting to the boiler gas inlet.

Never use an open flame to test for gas leaks as property damage, personal injury or death could result.

The maximum inlet gas pressure must not exceed the valve specified by the manufacturer and that the

minimum valve listed as for the purposes of input adjustment.

The connection to the gas supply must be carried out by professionally qualified personnel in accordance with

the relevant standards.

■ Check the internal and external seals of the gas supply system.

■ A gas shut-off valve and sedim ent trap must be installed upstream of the appliance .

■ Before starting up the boiler, make sure that the type of gas corresponds to that for which the appliance has

been set-up.

■ The gas supply pressure must be between the values reported on

the rating plate.

■ Conversion of the appliance from natural gas to LPG or vice

versa must be carried out by qualified personnel.

■ The power supply cable must be replaced by a qualified

electrician. If the cable is damaged in any way, switch off the

appliance and have the cable replaced by a suitably qualified

electrician.

When using an electrical appliance, a few fundamental rules

must be observed: Do not touch the appliance with damp or

wet parts of the body or when barefoot. Do not pull on the

electric wires.

Do not allow the appliance to be used by children or anyone

unfamiliar with its operation.

INSTALLATION

INSTRUCTIONS

25

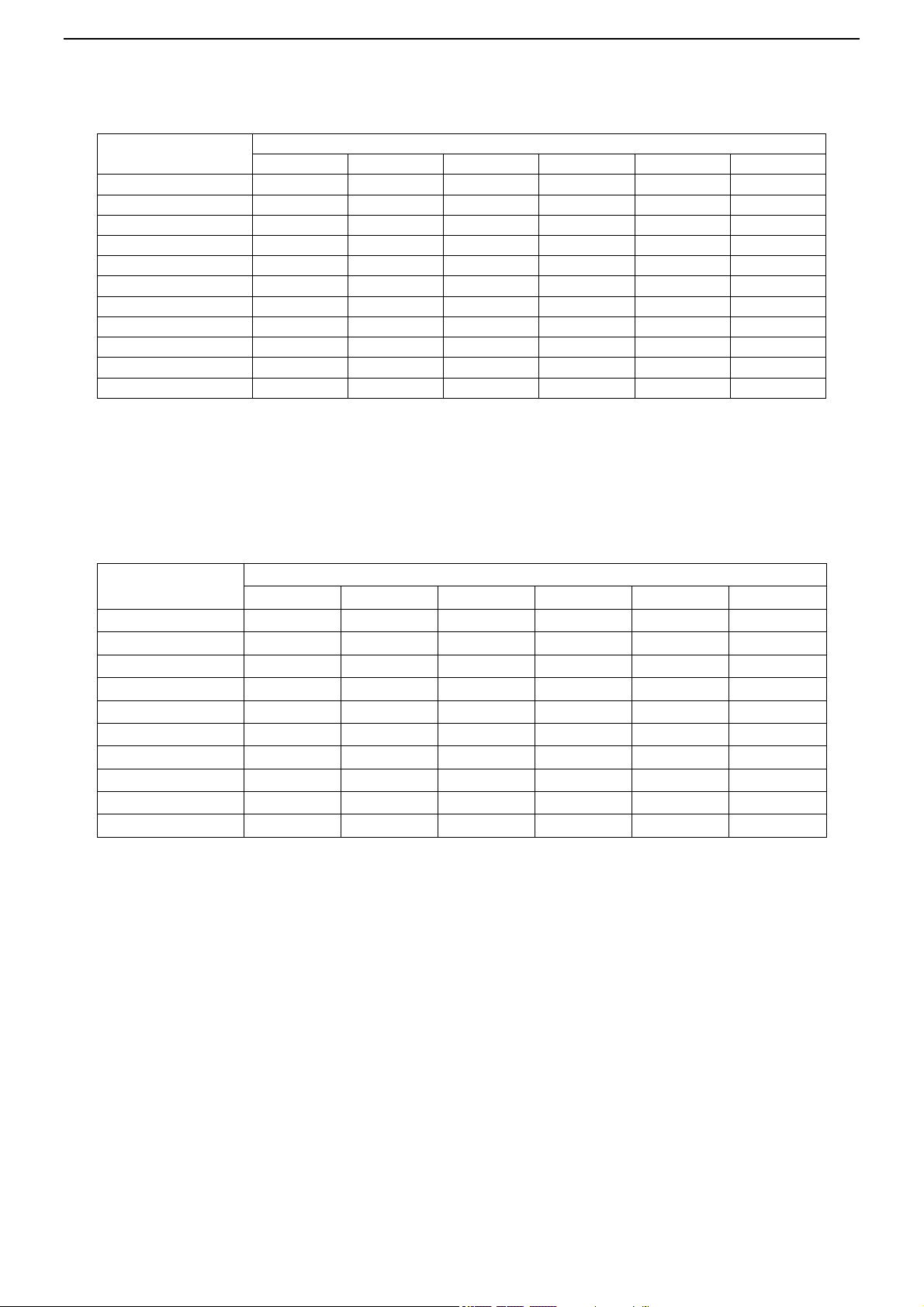

Natural Gas Pipe Sizing Chart

Length of

Pipe In Feet

Size of Schd. 40 Black Iron Pipe in Inches

1/2"

3/4"

1"

1-1/4"

1-1/2"

2"

10

108

230

387

793

1237

2259

20

75

160

280

569

877

1610

30

61

129

224

471

719

1335

40

52

110

196

401

635

1143

50

46

98

177

364

560

1041

60

42

89

159

336

513

957

70

38

82

149

317

476

896

80

36

76

140

239

443

840

90

33

71

133

275

420

793

100

32

68

126

266

411

775

125

28

60

117

243

369

700

Natural Gas flow is given in thousands of BTU/hr. - One cubic foot of natural gas = 1000 BTU

Nominal pressure at the burner for Natural Gas is 3.5" of water column. (Typical machine supply 5"-7")

Pipe length must include additional length for all fittings. Add approximately 5 feet of pipe per fitting

Natural Gas Example: A machine with a burner that requires 440,000 BTU would need a 1 -1/4" pipe for

a 20' long run.

Liquid Propane Gas Pipe Sizing Chart

Length of

Pipe in Feet

Size of Schd. 40 Black Iron Pipe in Inches

1/2"

3/4"

1"

1-1/4"

1-1/2"

2"

10

275

567

1071

2205

3307

6221

20

189

393

732

1496

2299

4331

30

152

315

590

1212

1858

3465

40

129

267

504

1039

1559

2992

50

114

237

448

913

1417

2646

60

103

217

409

834

1275

2394

80

89

185

346

724

1086

2047

100

78

162

307

630

976

1811

125

69

146

275

567

866

1606

150

63

132

252

511

787

1496

LP Gas flow is given in thousands of BTU/hr. - One cubic foot of LP gas - 2516 BTU

This chart refers to low pressure LP, after regulation Standard nominal pressure at the burner for

Liquid Propane Gas is 11" of water column.

Pipe length must include additional length for all fittings. Add approximately 5 feet of pipe per fitting

LP Example: A machine with a burner that requires 440,000 BTU would need a 1" pipe for a 20' long run.

Make sure the boiler is operating normally.

Shut down the unit by pressing the ON/OFF button on the control panel.

Remove the front panel and disconnect the flame rod sensor.

Restart the boiler. The burner should light but shut down after a few seconds.

If that is the case, the system is OK. It the burner does not shut down, push the ON/OFF switch to

shut down the boiler and perform a troubleshooting procedure.

INSTALLATION

INSTRUCTIONS

25

3.9 Electrical connections

3.9.1 General warnings

Follow the electrical code requirements of the local authority having jurisdiction. In the absence of

such requirements, follow the latest edition of the National Electrical Code (NFPA 70) in the U.S.

or the latest edition of CGA C22.1 Canadian Electrical Code – Part 1 in Canada.

3.9.2 Electric Wiring: Ground and Surges

All units come with factory installed 3-pronged (grounded) plug end. The boiler can be plugged into

any standard electrical duplex outlet close to the unit as it requires only 4 Amps.

If the local jurisdiction requires the unit to be wired directly, remove and discard the factory installed plug. An

ON/OFF switch controlling the main power between the breaker and the Boiler should be provided to facilitate

end-user maintenance and servicing. This should be done by a qualified electrician.

The boiler must be electrically grounded. Ensure the electrical receptacle, in which the boiler will be

plugged into, is properly grounded; if wiring directly, do not attach the ground wire to either the gas or the

water piping as plastic pipe or dielectric unions may isolate the boiler electrically.

The use of a surge protector, surge capacitor, line conditioner or equivalent is recommended to protect the

appliance from power surges.

If a generator is to be used as “backup” power care must be taken that a line conditioner is used to protect the

appliance from erratic voltage.

If the boiler is to be installed in a structure utilizing a emergency stand-by generator, the installation of a surge

capacitor, surge protector, line conditioner or equivalent is required.

If the boiler is to be installed in a structure where frequent power outages are experienced the installation of a

surge capacitor, surge protector, line conditioner or equivalent is required.

Do not energize electric power to the unit until all plumbing and gas piping is complete and the boiler has

been filled with water.

The electrical supply required by the boiler is 120VAC at 60Hz with a maximum 4A rating with proper

grounding. Protection must be in place to prevent the Boiler from being exposed to voltage in excess of

130VAC Max or 95VAC Min.

Damage caused by excessive voltage is not covered under warranty.

DO NOT connect 220-240VAC and any other voltage to this PENSOTTI Boiler. This will damage the boiler

and void the warranty.

Do not disconnect the power supply when the unit is in normal operation.

If there is a power failure in cold weather areas, the freeze prevention system in the boiler will not operate

and may result in freezing of the heat exchanger; in cold weather areas where power failures are

common, you must completely drain the unit to prevent damage if the power will be off for any extended

period of time.

Damage caused by freezing is not covered under warranty.

CAUTION : Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper

and dangerous operation. Verify proper operation after servicing.

The connection to the main power supply must be carried out by professionally qualified electrical personnel,

registered in accordance with current legislation and local authorities.

INSTALLATION

INSTRUCTIONS

26

Always check to make sure that the appliance has an efficient ground system. This requirement is only

satisfied if it has been properly connected to an efficient ground system installed in accordance with the

requirements of current safety standards and carried out by professionally qualified personnel.

This basic safety measure must be checked, verified and carried out by professionally qualified personnel.

Have the electrical system checked by a qualified electrician. The manufacturer will not be held liable for any

damage or injury caused as a result of an inefficient or faulty ground system.

■ Ensure the domestic power supply is checked by a qualified electrician to ensure that it can support the

maximum power absorption of the appliance, as indicated on the rating plate. In particular, make sure that the

cable sizes are adequate for the power absorbed by the appliance;

■ The power supply cable must be replaced by a qualified electrician. If the cable is damaged in any way, switch

off the appliance and have the cable replaced by a suitably qualified electrician;

When using an electrical appliance, a few fundamental rules must be observed:

Do not touch the appliance with damp or wet parts of the body or when barefoot.

Do not pull on the electric wires.

Do not allow the appliance to be used by children or anyone unfamiliar with its operation;

If the unit fails to re-start after any fault, unplug the unit for 30 seconds, then re-plug in the unit

and try to restart with the on/off switch. If the unit fails to restart, call a qualified Technician

for service.

INSTALLATION

INSTRUCTIONS

27

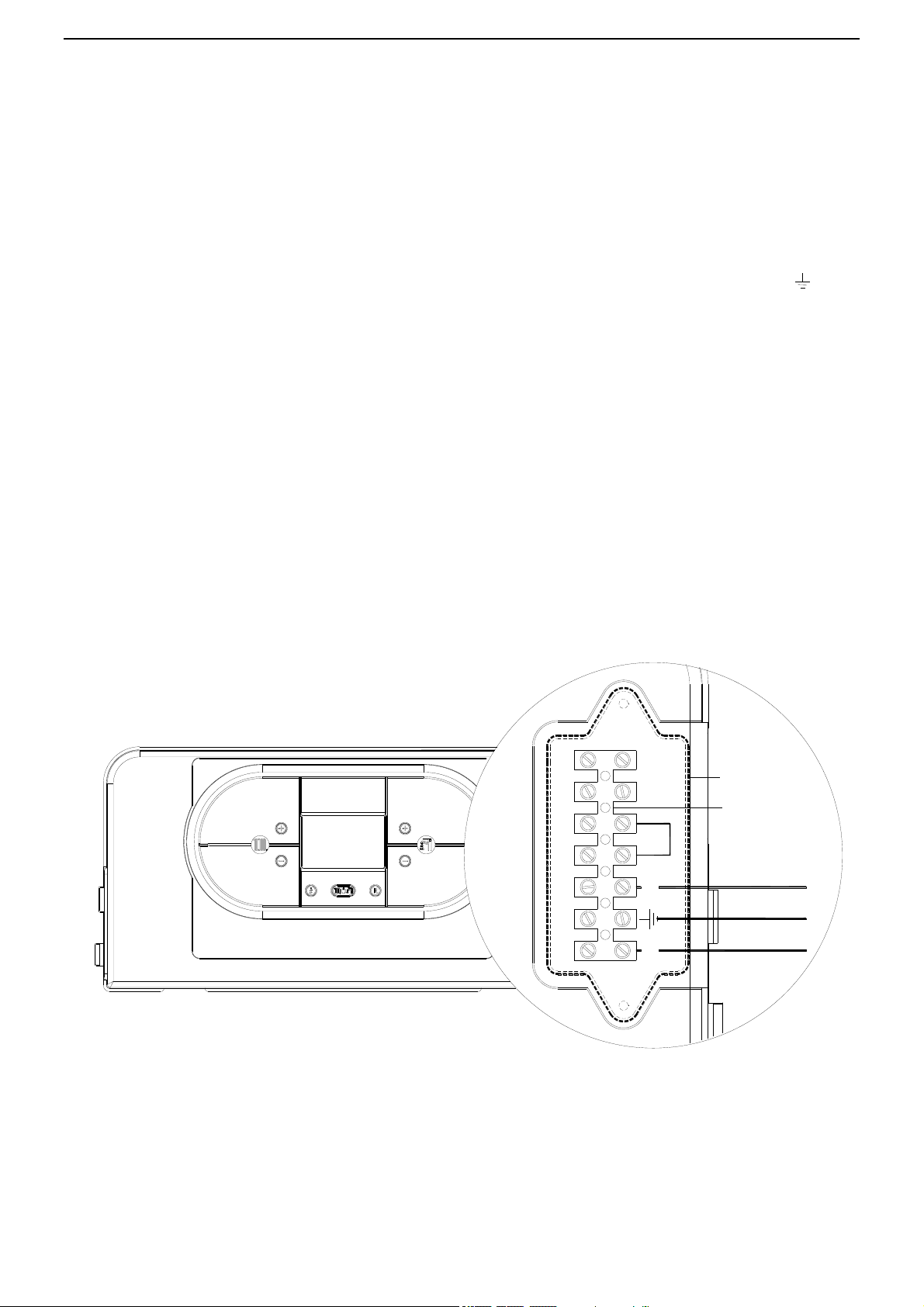

A

B

SeSeTaNL Ta

yellow/green

blue

brown

Electrical Connections

Connect the power supply to the terminal board inside the control panel as follows:

a. Switch off the power supply at service switch or breaker.

b. Remove the front case panel of the boiler.

c. Slacken the screws and remove plate A (see fig. 1).

d. With the plate removed, connect the wires to the terminal board B as follows:

Connect the earth wire (normally coloured green/yellow) to the terminal marked with the earth symbol “ “.

Connect the neutral wire (normally coloured blue) to the terminal marked with the letter “N”.

Connect the live wire (normally coloured brown) to the terminal marked with the letter “L”.

Terminals identified by the letters: Ta Room thermostat or End Switch

Se Outside temperature sensor

Ta terminals are 24V DC. Only a non-power robbing, battery operated thermostat or dry set of contacts can be installed

on Ta terminals.

When the wires have been connected, place plate “A" back to position. Switch the power supply back on.

Loading...

Loading...