Page 1

1401 North Plano Road, Richardson, Texas 75081

Phone: 972-234-3202 Fax: 972-497-0468

Receiving and Handling

PennBarry fans are carefully inspected

before leaving the factory. When the unit

is received, inspect the carton for any

signs of tampering. Inspect the unit for

any damage that may have occurred during transit and check for loose, missing or

damaged parts. Mishandled units can

void the warranty provisions. PennBarry

is not responsible for damages incurred

during shipment.

Avoid severe jarring and/or dropping.

Handle units with care to prevent damage

to components or special finishes.

Storage

Long-term storage requires special attention. Units should be stored on a level,

solid surface, preferably indoors. If outside storage is necessary, protect the

units against moisture and dirt by encasing the cartons in plastic or some similar

weatherproof material.

Unpacking

Place carton in an upright position and

remove staples or use a sharp (knife

edge) tool to CAREFULLY cut or scribe

the sealing tape on both sides at the top

of the carton. Open carton flaps. Remove

any cardboard and wooden filler pieces,

as well as loose components or accessories shipped with the unit.

Carefully remove the unit from the carton.

Inspect the unit for any damage that may

have occurred during transit and check

for loose, missing or damaged parts.

Installation

WARNING

To reduce the risk of

fire, electric shock, or

injury to persons - observe the following:

A. Use this unit only in the manner

intended by the manufacturer.

If you have questions, contact

the manufacturer.

B. Before servicing or cleaning unit,

switch power off at service panel

and lock the service panel to

prevent power from being switched

on accidentally. When the service

disconnecting means cannot be

locked, securely fasten a prominent

warning device, such as a tag,

to the service panel.

To reduce the risk of

fire, electric shock, or

injury to persons observe the following:

A. Installation work and electrical wiring

must be done by qualified person(s)

in accordance with all applicable

codes and standards, including fire

rated construction.

B. Sufficient air is needed for proper

combustion and exhausting of gases

through the flue (chimney) of fuel

burning equipment to prevent back

drafting. Follow the heating

equipment manufacturer’s guideline

and safety standards such as

those published by the National Fire

Protection Association (NFPA),

the American Society for Heating,

Refrigeration and Air Conditioning

Engineers (ASHRAE), and the local

code authorities.

C. When cutting or drilling into wall or

ceiling, do not damage electrical

wiring and other hidden utilities.

D. Duct fans must always

be vented to the outdoors.

E. If this unit is to be installed over a

tub or shower it must be marked as

appropriate for this application.

F. Never place a switch where it can

be reached from a tub or shower.

For general ventilating

use only. This product

is not to be used to exhaust hazardous or

explosive materials and vapors.

3.Follow all local electrical and

safety codes, as well as the

National Electrical Code (NEC)

and the Occupational Safety

and Health Act (OSHA).

4. Always disconnect the power

source before working on or near

a fan or motor.

Operation & Maintenance Manual

Zephyrette & Zephyr Jr. Ceiling Exhaust Ventilators

Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself and others by

observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage! Retain

instructions for future reference.

Printed in the USA Feb 2006

PART #59620-1

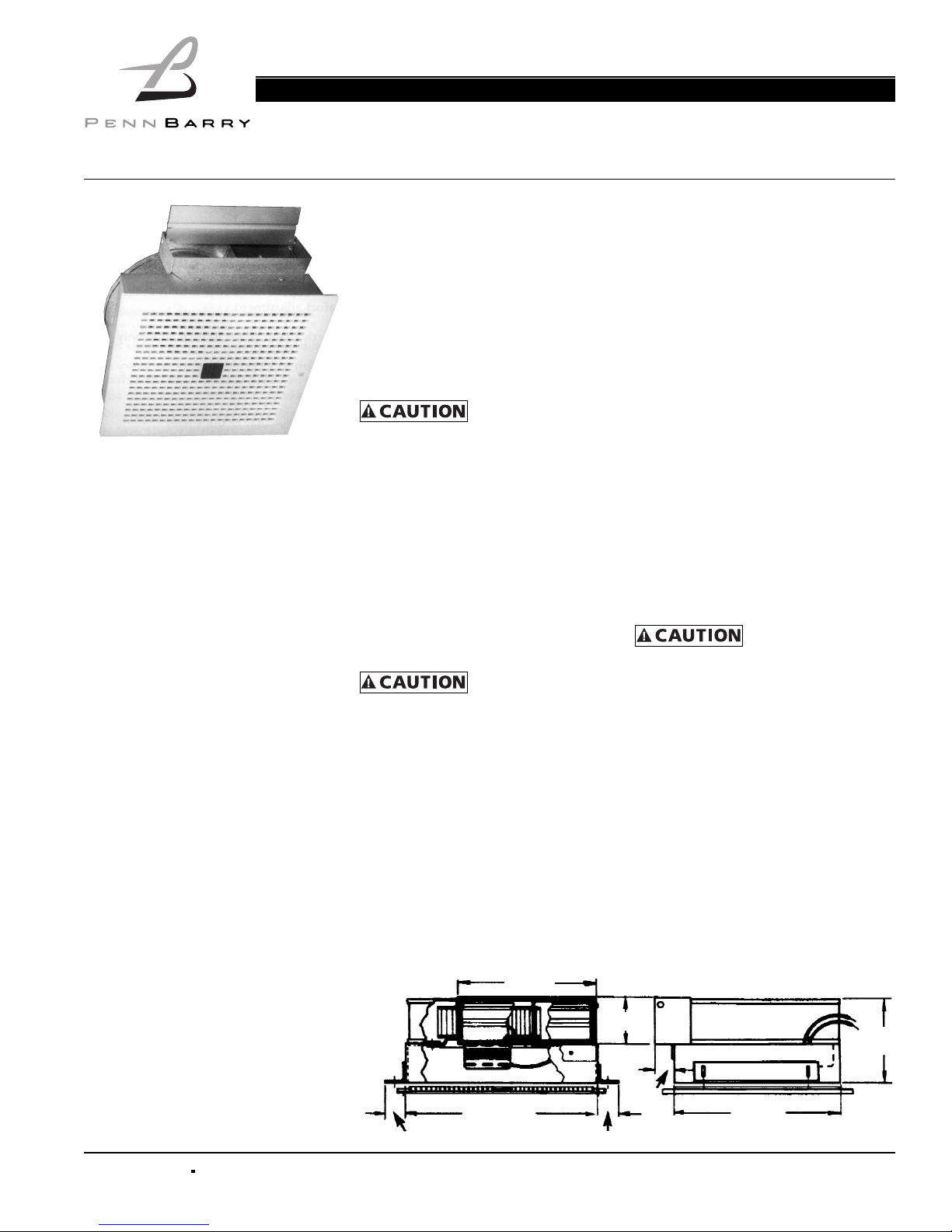

Description

PennBarry ceiling exhaust ventilators employ direct drive centrifugal blower wheels

powered by a 1200 RPM, 115V, 60 Hz sleeve bearing shaded pole motor. See specifications for CFM and sone ratings. Air deliveries are based on AMCA test codes. Units

have molded plastic grill and shatterproof backdraft damper. Motor and blower assembly can be removed from heavy gauge steel housing for cleaning. Adjustable mounting

brackets and hardware included. UL and CSA listed.

Figure 1: Dimensions

1-1/2"

13-3/4"

3-1/4"

1-1/2"

9-7/8"

6-5/8"

12"

1-1/4"

PLEASE READ AND SAVE THESE INSTRUCTIONS.

Page 2

Operation & Maintenance Manual

Zephyrette & Zephyr Jr. Ceiling Exhaust Ventilators

2 PENNBARRY

1401 North Plano Road, Richardson, Texas 75081

Phone: 972-234-3202 Fax: 972-497-0468

5. Make certain the power source conforms to the requirements shown in

the performance chart.

6. Protect the power cord from

coming in contact with sharp

edges or other objects.

7. Do not kink the power cord or allow

it to come in contact with oil, grease,

hot surfaces or chemicals.

CAUTION

1. For general ventilating use only.

Do not use to exhaust hazardous

or explosive materials and vapors.

2. To avoid motor bearing damage

and noisy and/or unbalanced

impellers, keep drywall spray, construction dust, etc. off power unit.

3. Please read specification label

on product for further information

and requirements.

ELECTRICAL CONNECTIONS

1. Connect motor per nameplate

to correct power supply.

2. Install all wiring, protection and

grounding in accordance with

the National Electrical Code (NEC)

and all local requirements.

3. Follow all local electrical and

safety codes, as well as the

National Electrical Code (NEC)

and the Occupational Safety

and Health Act (OSHA).

Make the necessary

connections by using

two wire nuts. A separate ground

wire must be connected to the

grounding screw. Replace the cover

of the junction box.

To reduce the risk of

injury of person, install

fan at least seven feet above the floor, if no

guard or grill is supplied.

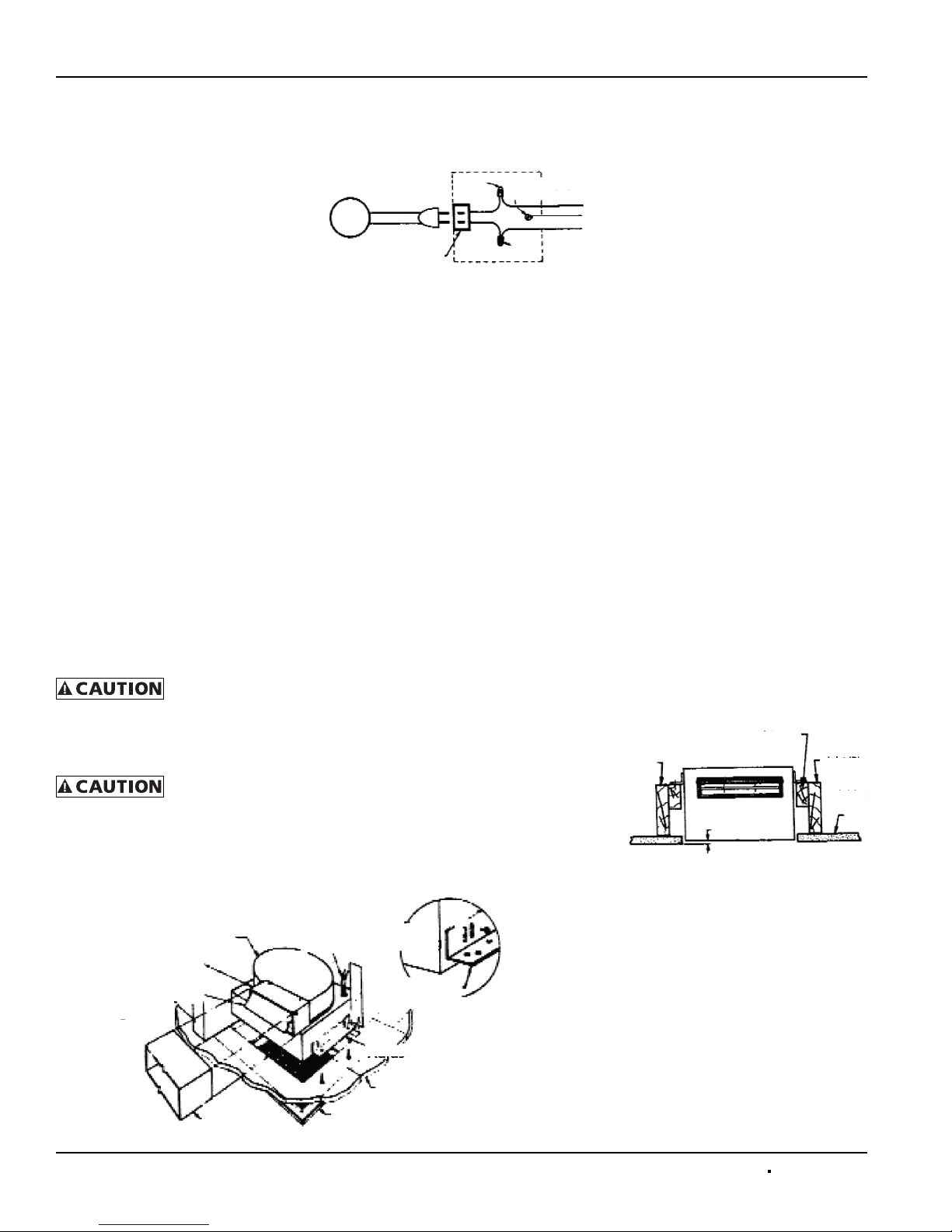

BEFORE A CEILING IS INSTALLED

WITH ACCESS FROM BELOW

Figure 2: Wiring Diagram

1. Disconnect motor cord and plug

from internal terminal and receptacle

before starting installation

(see figure 2).

2. Assemble adjustable flanges to fan

housing with four self-tapping metal

screws (provided). Adjustable

flanges should be located as

illustrated in Figure 3.

3. Secure the adjustable flanges to

each joist. Attach a properly sized

duct to the duct sleeve mounted on

the fan housing. Connect this duct

system to the appropriate size wall

cap or roof cap (see Figure 3).

4. Before wiring is attempted, Always

lock out the primary and secondary

power source. Utilizing the prepunched hole found at the terminal

box on the fan housing, insert a 3/8"

electrical connector. All wiring should

be in strict accordance with the

National Electrical Code and local,

state and federal standards.

5. If building out is necessary, an

appropriate piece(s) of wood should

be utilized. Nail wood spacer(s)

to joist(s) at the point where the fan

will be installed; the fan housing

should fit between the two joists

(or between the built-out spacers)

with approximately 1/2" clearance.

spacers should be sized according

to the fan housing dimensions

(see Figure 4).

6. Complete installation by cutting

an 11-7/8" x 13-3/4" ceiling opening

for the unit. Use care not to

exceed this dimension when

installing the fan.

7. The egg crate ceiling grill should be

installed by screwing the grill into the

fan housing using the two 2" plastic

bolts supplied with each unit.

8. Automatically operated thermal

protector to reduce risk of injury;

disconnect power supply

before servicing.

WITH CEILING IN PLACE

1. Disconnect motor cord and

plug from internal terminal

box and receptacle before

starting installation.

2. Assemble adjustable flanges

to fan housing with four self-tapping

metal screws (provided). Adjustable

flanges should be located as

illustrated in Figure 5. Install the

duct and electrical service in

accordance with the instructions

listed in the previous section.

SUSPENDED CEILING SYSTEMS

Installation of ceiling fans in suspended

ceiling systems require a minimum 10

gauge solid wire for hanging or suspending the ceiling fan. Four wires per unit

should be connected to the pre-punched

holes of the adjustable mounting flanges

(after the flanges have been mounted to

the fan housing as outlined above).

Figure 4: Using Spacers

Blower Scroll Housing

Adjustable

Flanges

Finished Ceiling

Removable Deluxe Face Grill

Duct-To

Outside

Duct Sleeve

Electrical

Leads

for

Conduit

Fan

Housing

Joist

Motor

115 volt

Thermoprotected

Plug

Receptacle

Junction Box

Wire

Nut

White

Ground

Screw

Ground Wire

Black

Wire

Nut

Joist ‘A’

Joist ‘B’

Finished

Ceiling

Wood Spacer

1/2"

Figure 3: Typical Ceiling Installation

Adjustable Mounting Flanges

Backdraft

Damper

Page 3

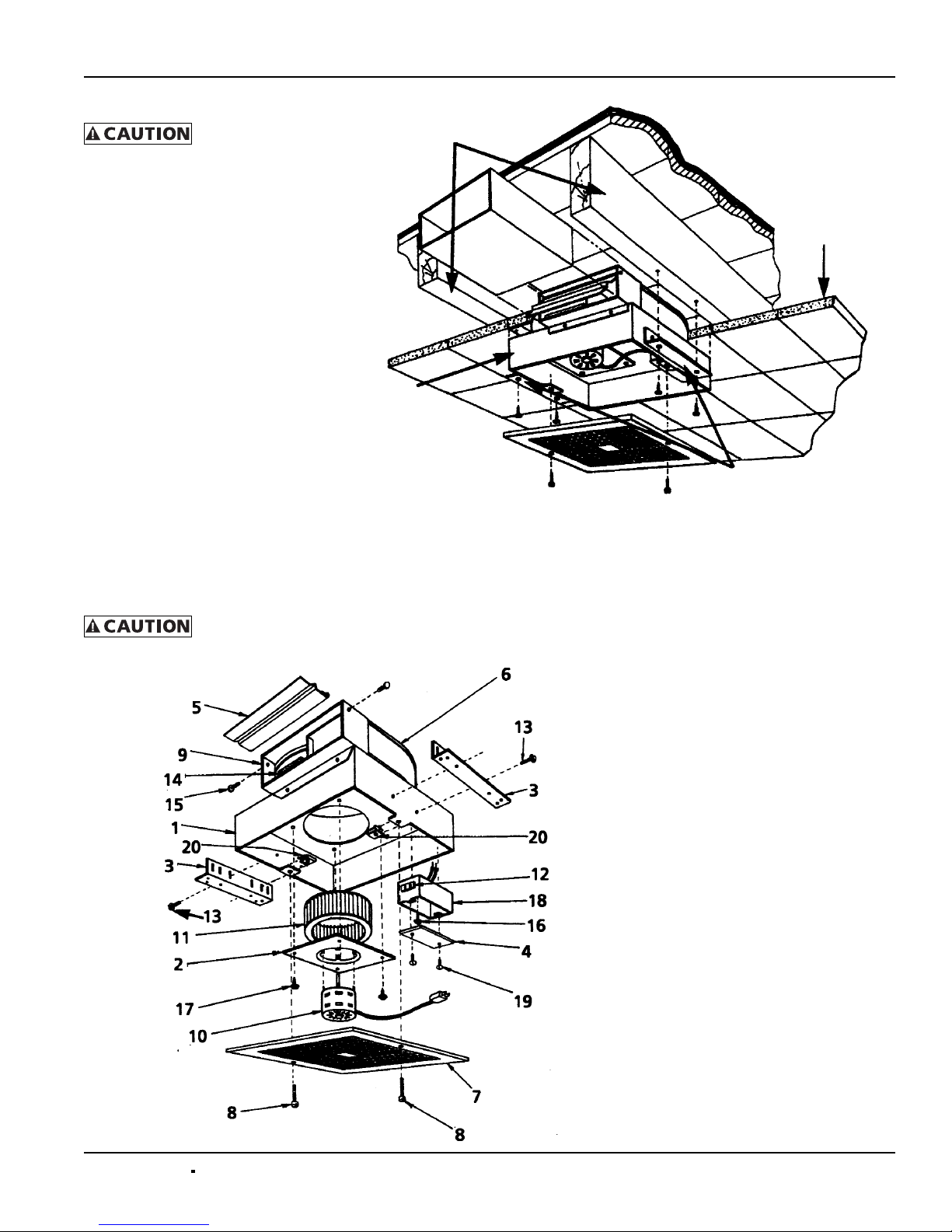

Maintenance

Disconnect power

source before working

on unit. Maintenance should be done

yearly or as conditions warrant.

CLEANING BLOWER WHEEL,

HOUSING & GRILL

1. The blower wheel, housing and

grill can be cleaned of dust and

grease if required.

a. Remove the grill. Using a vacuum

cleaner with appropriate attachments, vacuum dust from the grill.

Wash the grill with a warm, soapy

solution of water. Allow the grill to

dry thoroughly before re-installing.

b. To clean blower wheel(s) and hous-

ing, unplug blower motor from integral terminal box. Unscrew the selftapping screws which secure the

motor and blower support plate.

Carefully remove entire blower/

motor assembly. Vacuum blower

wheel. If necessary, the wheel can

be washed. Wipe blower wheel dry

with an absorbent cloth. Before

replacing blower/motor assembly,

wipe out interior of housing. Replace

blower/motor assembly and secure

with self-tapping screws. Plug in

blower motor to terminal box.

Do not allow water

to enter motor.

MOTOR LUBRICATION

Oil every six months with 2 drops of

SAE 20 oil.

Parts Replacement

If replacing parts, do so with properly

selected components which duplicate the

original parts correctly. Incorrectly sized

parts can damage the fan.

PARTS LIST (SEE FIGURE 6)

1. Main Housing

2. Venturi (motor support plate)

3. Housing Bracket

4. Cover Plate (junction box)

5. Damper

6. Blower Housing

7. Grill

8. 1/4" - 20 x 2" Nylon Bolt

9. Duct Sleeve

10. Motor and Plug / Disconnect

11. Wheel

12. Electric Receptacle Device

13. 1/4" x 3/4" Screw (housing bracket)

14. Polyurethane Damper Stop

15. Damper Pivot Pin

16. Electric Grounding Screw

17. #14-1/2" Screw SM

18. Junction Box

19. #8-1/4" Screw SM

20. U-Clip Speed Nut

Operation & Maintenance Manual

Zephyrette & Zephyr Jr. Ceiling Exhaust Ventilators

PENNBARRY 3

1401 North Plano Road, Richardson, Texas 75081

Phone: 972-234-3202 Fax: 972-497-0468

Figure 5: Maintenance Diagram

Figure 6: Parts Diagram

Page 4

Operation & Maintenance Manual

Zephyrette & Zephyr Jr. Ceiling Exhaust Ventilators

4 PENNBARRY

1401 North Plano Road, Richardson, Texas 75081

Phone: 972-234-3202 Fax: 972-497-0468

Troubleshooting Checklist

Note: Care should be taken to follow all local electrical, safety and building codes. Provisions of the National Electric Code (NEC), as wells as the Occupational Safety

and Health Act (OSHA) should be followed.

All motors are checked prior to shipment. If motor defects should develop, prompt service can be obtained from the nearest authorized service station of the motor manufacturer while under warranty. Exchange, repair or replacement will be provided on a no

charge basis if the motor is defective within the warranty period. The PennBarry representative in your area will provide a name and

address of an authorized service station if requested. WARNING: Motor guarantee is void unless overload protection is provided in

motor wiring circuit.

Symptom Possible Cause(s) Corrective Action

Excessive noise

1. Defective or loose motor bearings 1. Replace motor with same frame size, RPM, HP

2. Ventilator base not securely anchored 2. Reset properly

3. Loose or unbalanced wheel/propeller

3. Tighten screws, remove build-up,

balance wheel/propeller

4. Misaligned pulleys or shaft 4. correct alignment

5. Loose or damaged wheel/propeller 4. Replace wheel/propeller

6. Wheel running in wrong direction 6. Reverse direction

Fan inoperative

1. Blown fuse or open circuit breaker 1. Replace fuses or circuit breaker

2. Loose or disconnected wiring

2. Shut off power and check wiring

for proper connections

3. Defective motor 3. Repair or replace motor

4. Broken belts 4. Replace belts

Insufficient airflow

1. Open access doors or loose sections of ducts 1. Check for leakage

2. Clogged filters 2. Clean filters

3. Operation in wrong direction 3. Correct rotation of wheel/propeller

4. Insufficient make-up air direction 4. Add make-up fan or louver opening

Water leaking

into ductwork or

collection of grease

under fan

1. Fan installed with slope in the wrong direction

1. Slope should be fitted in the direction of the

drainage opening or grease collection box and

drain spout

2. Clogged drain spout 2. Clean drain spout

3. Cooling tube or motor dome top removed

3. Install new cooling tube

with gasket and dome top

4. Grease container full 4. Empty grease box

Motor overheating

1. Belt slippage 1. Adjust tension or replace bad belts

2. Overvoltage or under voltage 2. Contact power supply company

3. Operation in wrong direction 3. Reverse direction of motor

4. Fan speed too high

4. Slow down fan by opening variable pitch

pulley on motor shaft

5. Incorrect motor (service factor 1.0,

low ambient temperature)

5. Replace motor with correct open,

NEMA service factors (1.15 or higher)

with 40 degrees ambient

6. Blocked cooling tube or leaky gasket 6. Remove blockage and seal cooling tube in place

7. Insufficient airflow to kitchen hood fan operating

on low speed with kitchen in full operation

7. Check airflow under hood and adjust

kitchen equipment output

8. Undersized motor

8. Check motor ratings with catalog speed

and air capacity chart

Page 5

Operation & Maintenance Manual

Zephyrette & Zephyr Jr. Ceiling Exhaust Ventilators

PENNBARRY 5

1401 North Plano Road, Richardson, Texas 75081

Phone: 972-234-3202 Fax: 972-497-0468

Notes:

Page 6

Operation & Maintenance Manual

Zephyrette & Zephyr Jr. Ceiling Exhaust Ventilators

6 PENNBARRY

1401 North Plano Road, Richardson, Texas 75081

Phone: 972-234-3202 Fax: 972-497-0468

Notes:

Page 7

Operation & Maintenance Manual

Zephyrette & Zephyr Jr. Ceiling Exhaust Ventilators

PENNBARRY 7

1401 North Plano Road, Richardson, Texas 75081

Phone: 972-234-3202 Fax: 972-497-0468

Notes:

Page 8

Limited Warranty

What Products Are Covered

PennBarry Fans and Ventilators (each, a "PennBarry Product")

One Year Limited Warranty For PennBarry Products

PennBarry warrants to the original commercial purchaser that the PennBarry Products will be free from defects in material and

workmanship for a period of one (1) year from the date of shipment.

Exclusive Remedy

PennBarry will, at its option, repair or replace (without removal or installation) the affected components of any defective PennBarry

Product; repair or replace (without removal or installation) the entire defective PennBarry Product; or refund

the invoice price of the PennBarry Product. In all cases, a reasonable time period must be allowed for warranty

repairs to be completed.

What You Must Do

In order to make a claim under these warranties:

1. You must be the original commercial purchaser of the PennBarry Product.

2. You must promptly notify us, within the warranty period, of any defect and provide us with any substantiation

that we may reasonably request.

3. The PennBarry Product must have been installed and maintained in accordance with good industry practice

and any specific PennBarry recommendations.

Exclusions

These warranties do not cover defects caused by:

1. Improper design or operation of the system into which the PennBarry Product is incorporated.

2. Improper installation.

3. Accident, abuse or misuse.

4. Unreasonable use (including any use for non-commercial purposes, failure to provide reasonable and necessary

maintenance as specified by PennBarry, misapplication and operation in excess of stated performance characteristics).

5. Components not manufactured by PennBarry.

Limitations

1. In all cases, PennBarry reserves the right to fully satisfy its obligations under the Limited Warranties by

refunding the invoice price of the defective PennBarry Product (or, if the PennBarry Product has been discontinued,

of the most nearly comparable current product).

2. PennBarry reserves the right to furnish a substitute or replacement component or product in the event a PennBarry

Product or any component of the product is discontinued or otherwise unavailable.

3. PennBarry's only obligation with respect to components not manufactured by PennBarry shall be to pass through

the warranty made by the manufacturer of the defective component.

General

The foregoing warranties are exclusive and in lieu of all other warranties except that of title, whether written, oral or

implied, in fact or in law (including any warranty of merchantability or fitness for a particular purpose).

PennBarry hereby disclaims any liability for special, punitive, indirect, incidental or consequential damages, including

without limitation lost profits or revenues, loss of use of equipment, cost of capital, cost of substitute products, facilities

or services, downtime, shutdown or slowdown costs.

The remedies of the original commercial purchaser set forth herein are exclusive and the liability of PennBarry

with respect to the PennBarry Products, whether in contract, tort, warranty, strict liability or other legal theory shall not exceed

the invoice price charged by PennBarry to its customer for the affected PennBarry Product at the time the claim is made.

Inquiries regarding these warranties should be sent to: PennBarry, 1401 North Plano Road, Richardson, TX 75081.

1401 North Plano Road, Richardson, Texas 75081

Phone: 972-234-3202 Fax: 972-497-0468

1401 North Plano Road, Richardson, Texas 75081

Phone: 972-234-3202 Fax: 972-497-0468

8 PENNBARRY

Zephyrette & Zephyr Jr. Ceiling Exhaust Ventilators

Operation & Maintenance Manual

Loading...

Loading...