Page 1

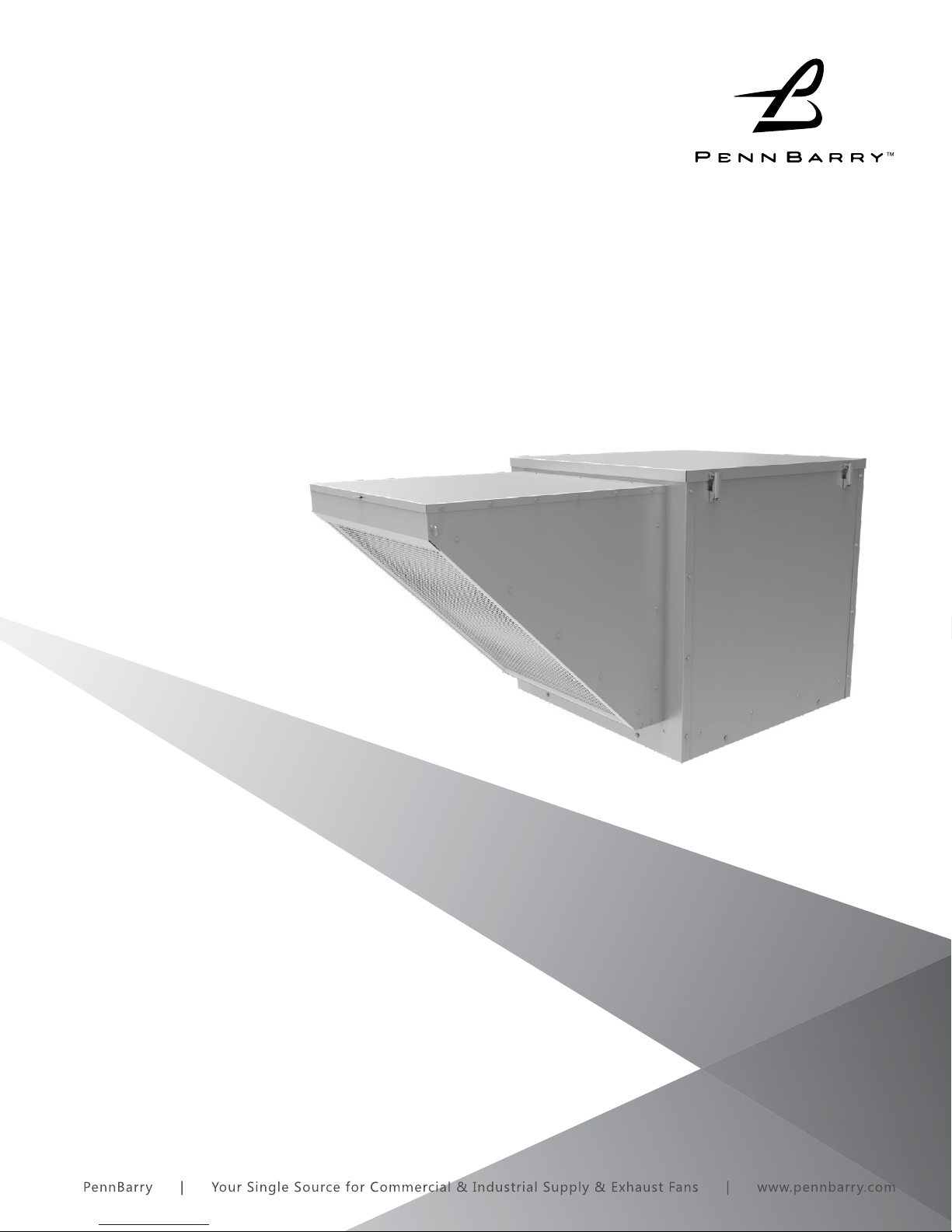

Muffan FS

Filtered Supply Fans

OPERATION & MAINTENANCE MANUAL

IMPORTANT! Read before proceeding!

Please read and save these instructions. Read carefully before attempting to

assemble, install, operate or maintain the product described. Protect yourself

and others by observing all safety information. Failure to comply with instructions

could result in personal injury and/or property damage! Retain instructions for

future reference.

1

Page 2

TABLE OF CONTENTS

INTRODUCTION 3

INSTALLATION 4-7

START-UP AND OPERATION 8

MAINTENANCE 9-10

TROUBLESHOOTING CHECKLIST 11

2

www.PennBarry.com

Page 3

INTRODUCTION

Receiving and Handling

PennBarry fans are carefully inspected before leaving the factory. When the unit is received, inspect the carton/crate for any signs of

tampering. Inspect the unit for any damage that may have occurred during transit and check for loose, missing or damaged parts.

Mishandled units can void the warranty provisions. If units are damaged in transit, it is the responsibility of the receiver to make all

claims against the carrier. PennBarry is not responsible for damages incurred during shipment.

Avoid severe jarring and/or dropping. Handle units with care to prevent damage to components or nishes. If the unit is scratched

due to mishandling, the protective coating may be damaged. Incorrect lifting may damage the fan and void the warranty.

Storage

Long-term storage requires special attention. Store units on a level, solid surface, preferably indoors. If outside storage is necessary,

protect the units against moisture and dirt by encasing the carton/crates in plastic or in some similar weatherproof material.

Periodically inspect units and rotate wheels to spread bearing lubricant. Failure to rotate wheels results in reduced bearing life and

may void the manufacturer’s warranty. If the unit will be stored for an extended time, remove belts. Belts which remain under tension

in a stationary position for extended periods are likely to have a reduced operating life.

Unpacking

Place the carton/crate in an upright position and remove the staples or use a sharp (knife edge) tool to carefully cut or scribe the

sealing tape on both sides at the top of the carton/crate. Open carton/crate aps. Remove any cardboard and wooden ller pieces,

as well as loose components or accessories shipped with the unit.

Carefully remove the unit from the carton/ crate. Inspect the unit for any damage that may have occurred during transit and check

for loose, missing or damaged parts.

www.PennBarry.com

3

Page 4

INSTALLATION

ROOF MOUNTING

The PennBarry FS is a fresh air supply fan. Accordingly, before installation, make sure that the unit is not located next to an exhaust

fan so that dirty or noxious air is not brought back inside the building. Mounting the unit on a roof necessitates prior installation of

the proper height and size roof curb. Curb must be installed securely and sealed carefully to the roof construction. Dampers, when

required, should be installed prior to mounting on the curb.

Dampers must be secured to the inside of the curb without undue twisting which may distort the damper frame. Damper frame

must be reasonably level on all sides. Check for free operation. If dampers are motor operated type, ascertain that proper voltage

is impressed on motor terminals.

POSITIONING AND RUNNING POWER LINES

Power is normally brought from within the building through proper conduit lines and placed inside one corner of the curb. It is

then fed through the clearance hole provided in the damper and, in turn, fed through the fan to the service switch, if furnished. The

number of wires, type of insulation and protection by metal rigid or exible conduit must be suitable for motor load on line voltage

service.

NOTE: Care should be taken to follow all local electrical safety and building codes. All electrical parts must be grounded, and grounding

conductor should be checked for continuity.

Some local codes prohibit the connection of in-line, aluminum fans in kitchen hood exhaust systems. According to present NFPA96

interpretation, ANY fan used in such duct work must be made of steel, with liquid-tight welds at all seams and connections. If local

codes are in accordance with NFPA96, do not use ANY FAN that is not completely welded closed for such duty. Refer to PennBarry’s

Fumex and Dynamo products for roof and wall mounted exhausters approved for use on kitchen hood exhaust systems.

ANCHORING AND SECURING THE FAN

Units should be seated on a properly sized curb. The gap between the base of the fan and the top of the curb should be sealed with a

neoprene 1” X 1/4” gasket. The gasket should be glued or attached with a pressure-sensitive adhesive. The fan must be rmly secured

to a metal curb with stainless steel or cadmium coated self-tapping screws, 18” on center. Units installed in areas subject to high

winds or unusual eld conditions may require additional fastening with guy wires. If the contractor removes the ventilator parts to

facilitate installation and electrical connections, all parts should be reassembled replacing all spacers, washers, nuts, bolts, fasteners

and components exactly as they were found prior to removal. All fasteners are to be drawn tight and secure.

4

www.PennBarry.com

Page 5

INSTALLATION

1

2B

2

2A

1A

2C

1

2

2B

2A

INTAKE HOUSING ASSEMBLY

(STANDARD) (REFER TO FIGURES 2 - 6)

1. Remove #1A to gain access to #2. Depending upon the HP factory supplied, #2 may be partially unassembled.

2. Cut or remove packaging as required. Carefully lift #2 out of #1. Determine if #2B is attached. If not, remove #2B from #1 and

attach to #2 via hardware as shown in gure 3.

3. Attach fully assembled #2 to #1 via hardware as shown in gure 3.

4. Remove #2A from #2 per gure 4. Install #2C lter(s) per gure 5. Re-attach #2A.

5. Caulk per gure 6. Re-install item #1A.

Figure 2

1

Figure 3

Figure 5 Figure 6

2

2C

2A

2B

1

3/16” silicone bead

all perimeter

2C

Figure 4

2

2A

2B

5

Table 1: Parts Reference

Ref. No. Description Qty.

1 Side Flo Muffan Assembly 1

1A Top 1

2 Intake Housing Assembly 1

2A Intake Housing Door 1

2B Intake Housing Bottom 1

2C Cleanable Filter 1 2*

Table 2: Parts Reference

Ref. No. Description Qty.

*FS10B, FS12B, FS15B, FS18B/FS20B

www.PennBarry.com

4 No. 10 - 5/8” Self Drive Screw 16/20*

5 1/4” - 20 X 3/4” Tumb Screw 3/4*

5

Page 6

INSTALLATION

INTAKE EXTENSION ASSEMBLY

(OPTIONAL) (REFER TO FIGURES 7 & 8)

1. Remove #3 and other loose parts from crating and packaging.

2. Blower housing (#1) must be attached to roof curb in order to x the intake height.

3. Lift and place #3 to opening of #1. Hold horizontal and provide temporary support underneath. Be certain that end of #3 closest

to #1 has solid side panels; holes in side panels (see detail A) are for legs located at the opposite end.

4. Secure #3 to #1 via hardware as shown in gure 7.

5. Assemble #3B to #3A via hardware as shown in gure 6 to complete a set of two legs. Note the legs must be assembled to be

right hand and left hand as shown in gure 7.

6. Locate proper holes on each leg to match pre-punched holes of #3A per detail A. Attach legs via hardware as shown in gure

7.

7. Attach #3C and #3D to #3A per detail B via hardware as shown in gure 7.

8. Attach #2 to #3 via hardware as shown in gure 7. Refer to instructions above for installing the Intake Housing Assembly for

details.

9. Caulk in two places as shown in gure 8.

3/16” silicone bead

all perimeter

3

3/16” silicone bead

1

1A

3A

3

1

3C

3D

3

Detail A Detail B

3C

3D

3A

3B

all perimeter

2

2C

2A

3B

2A

2B

6

3A

3C

3D

3A

3D

3A

www.PennBarry.com

Page 7

INSTALLATION

Table 3: Parts Reference

Ref. No. Description Qty.

1 Side Flo Muffan Assembly 1

1A Top 1

2 Intake Housing Assembly 1

2A Intake Housing Door 1

2B Intake Housing Bottom 1

2C Cleanable Filter 1 2*

Table 4: Parts Reference

Ref. No. Description Qty.

3 Intake Extension Assembly 1

3A Intake Extension Vertical Support 2

3B Intake Extension Horizontal Support 2

3C Intake Extension Horizontal Stiffener 1

3D Intake Extension Gusset 2

Table 5: Parts Reference

Ref. No. Description Qty.

4 No. 10-5/8 Self Drive Screw 3/4

5 1/4-20 X 3/4 Thumb Screw 3/4*

6 No. 10-1 Self Drive Screw 12/16*

7 1/4-20 Riv Nut 4/6**

8 1/4-20 X 3/4 Whiz Bolt 24/28*

9 1/4-20 Whiz Nut 20/24*

www.PennBarry.com

7

Page 8

START-UP AND OPERATION

Careful inspection should be made before starting up. Make sure that all instructions on labels are understood and executed. All

motor bolts should be securely tightened. Blower wheels should be rotated by hand to ensure free movement. Lock out power

supply before rotating wheel. The inlet louvers should be clean and free from obstruction.

Check condition of belts and the amount of tension prior to start-up. DO NOT overtighten, as bearing damage will occur.

Recommended belt tension should permit deection of 1/64” of the belt on each side of the belt measured halfway between the

pulley centerline. Exercise extreme care when adjusting belts as not to misalign the pulleys. Any misalignment will cause a sharp

reduction in belt life and produce squeaky, annoying noises. On units equipped with two or three groove pulleys, adjustments must

be made so that there is equal tension on all belts (see Figure 1).

Figure 1: Pulley Alignment & Tension

Whenever belts are removed or installed, never force belts over pulleys without loosening motor rst to relieve belt tension.

CAUTION

Before putting fan into operation, complete the following check list:

a. Lock out primary and secondary power source.

b. Make sure installation is in accordance with manufacturer’s instructions.

c. Check and tighten all fasteners.

d. Spin centrifugal wheel to see if rotation is free and doesn’t bind or rub.

e. Check all set-screws and keys; tighten if necessary.

f. Check belt for alignment (use recommended belt tension gauges).

g. Check belt for proper sheave selection (Make sure it is not in reverse position).

h. Make sure there is no foreign loose material in ductwork leading to and from fan or in the fan itself.

j. Properly secure all safety guards.

k. Secure all access doors to fan and ductwork.

l. Check line voltage with motor nameplate.

m. Check wiring.

(On single phase motors, the terminal block must be set up in accordance with the nameplate instructions and/or wiring

diagram. This set up must match the line voltage. If the motor is multi-speed or multivoltage, the winding leads must be

CAUTION

8

grouped and connected as shown on the motor wiring diagram. The line voltage must correspond with proper grouping of

motor leads. The wiring diagram must be followed explicitly or serious motor or starter damage will occur.)

www.PennBarry.com

Page 9

MAINTENANCE

Do not attempt maintenance on fan until the electrical supply has been completely disconnected. If a service switch has not been

provided, remove all fuses from the circuit and lock the fuse panel so they cannot be accidentally replaced.

Lubrication is a primary maintenance responsibility. Check all bearings periodically. Inspect belts for tightness. If the fan is installed in

a corrosive or dirty atmosphere, periodically clean the centrifugal wheel, inlet, motor housing and other moving parts.

FAN SHAFT LUBRICATION

Fan shaft bearing pillow blocks are furnished in the greasable type. The greasable type are factory greased eliminating the need

for greasing initially. Follow the lubricating schedule recommended by the factory. This practice should not supersede any safety

considerations.

Use low pressure grease guns only. High pressure guns tend to blow out or unseat bearing seals, leaving the bearing open

CAUTION

LUBRICATION SCHEDULE

Always follow the bearing manufacturer’s recommended lubrication schedule. If none is available, use the following general schedule.

a. Under average conditions where ambient temperatures do not exceed 120°F, lubrication is required 1 to 2 times a year

b. Under dirt laden atmosphere where there is a temperature range of 120°F to 150°F, lubrication is required from 3 to 6 times a

c. Under extreme temperature conditions and extremely dirty atmospheres, lubrication should be scheduled at least once or twice

to collect grime, dust and foreign particles.

year.

a month.

d. Belt drive units maximum temperature should not exceed 160°F. Direct driven models have temperature range stamped on

motor.

MOTOR LUBRICATION

In general, standard motors are furnished with pre-lubricated, sealed-for-life ball bearings which require no lubrication for 7 to 10

years of normal service. Where motors have been ordered with greasable bearings, these bearings are factory lubricated and require

no attention for one year under normal conditions. If grease relief ttings are provided, remove them when performing maintenance

to allow grease to ow out. Whenever possible, apply grease while the motor is running. This practice should not supersede any

safety considerations. DO NOT OVER-GREASE, as most lubricants deteriorate motor windings and thereby reduce motor life.

Table 6: Recommended Lubricants

Manufacturer Product Temp. Range

BP LG-#P-1

Gulf Gulfcrown EP-1

Imperial Oil Unirex EP-1

Shell Alvania R-1

BP Energrease, MPMK11

Gulf Gulfcrown EP-2

Imperial Oil Unirex EP-2

Shell Alvania R-3

Below 32°F (0°C)

32°F to 150°F (0°C to 66°C)

Sun Oil Sun Prestige 42

Texaco Regal AFB2

www.PennBarry.com

9

Page 10

MAINTENANCE

Filters

Filters are an integral part of the FS Muan. The lters are washable aluminum mesh with sizes and quantities per model listed

below. Filter inspection and cleaning intervals will vary depending upon the amount of contaminant present and when this will raise

the pressure drop across the lters to an unacceptable level. To clean the lters, rst remove the intake housing door marked 2A in

Figure 5. The lters can then be pulled up and out of the lter tracks through the top of the intake housing assembly. Use a brush or

vacuum for dry dust and contaminants. Then rinse with water in the opposite direction of airow through the lter. For contaminants

that are not easily removed with water, a light detergent can be used. Filters should be allowed to dry thoroughly and then placed

back within the lter tracks. Replace the intake housing door and all screws as originally found.

Special Purpose Systems

Environments that are explosive, corrosive, subject to high temperatures etc. may require special construction, inspection and

maintenance. It is necessary to observe the fan manufacturer’s recommendations and limitations concerning the type of material to

be handled by the fan and its application to special conditions.

Hidden Danger

In addition to the normal dangers of rotating machinery, fans present an additional hazard in their ability to suck in not only air, but

loose material as well. Solid objects can pass through the fan and be discharged by the impeller as potentially dangerous projectiles.

Therefore, screen intake to ductwork, whenever possible, to prevent the accidental entrance of solid objects. Never open access

doors to a duct system with the fan running.

On the downstream (or pressure) side of the system, releasing the door with the system in operation may result in an explosive

opening. On the upstream (or suction) side, the inow may be sucient to suck tools and clothing, etc., and may even cause a man

to lose his balance.

When a fan is being started for the rst time, a complete inspection of the duct work and interior of the fan should be made (with

the power locked o) to make certain there is no foreign material which can be sucked into or blown through the duct work.

Guards

All fans have moving parts which require guarding in the same way as other moving machinery. In areas which are accessible only

to experienced personnel, a standard industrial type guard may be adequate. This type of guard will prevent the entry of thrown or

dropped objects with a minimum restriction of airow.

Where the fan is accessible to untrained personnel or the general public, use maximum safety guards, even at the cost of some

performance loss. Unprotected fans located less than 7’ above the oor also require guarding as specied in the Occupational Safety

and Health Act (OSHA). Roof mounted equipment will require guards when access is possible.

Centrifugal fans may be connected directly to ductwork which will prevent contact with the internal moving parts, but when the inlet

or outlet is exposed, install a suitable guard. PennBarry Ventilation recommends the use of guards on all exposed non-ducted fans,

ceiling and wall mounted.

Replacement Parts

When replacing parts, do so with properly selected components which duplicate the original parts correctly. Incorrectly sized shafts,

belts, pulleys, centrifugal wheels, etc., can damage the fan.

Don’t decrease size of driven pulleys; overspreading will overload motors and blow wheels. Don’t increase size of driver pulleys. Don’t

change section “A” belts to “B” or single groove design to two groove type. Heavier belts require extra tension which will decrease

life of bearings. Don’t change type of lters especially to those of unknown eciency and loading capacity.

10

www.PennBarry.com

Page 11

TROUBLESHOOTING CHECKLIST

Symptom Possible Cause Corrective Action

1. Defective or Loose Motor Bearings 1. Replace Motor with Same Frame Size

2. Ventilator Base Not Securely Anchored 2. Reset Properly

Excessive Noise

3. Loose or Unbalanced Wheel/Propeller

4. Misaligned Pulleys or Shaft 4. Correct Alignment

5. Loose or Damaged Wheel/Propeller 5. Replace Wheel/Propeller

6. Wheel Running In Wrong Direction 6. Reverse Direction

1. Blown Fuse or Open Circuit Breaker 1. Replace Fuses or Circuit Breaker

3. Tighten Screws, Remove Build-Up, Balance Wheel/

Propeller

Fan Inoperative

Insufcient Airow

Water Leaking Into

Ductwork or Collection of

Grease Under Fan

Motor Overheating

2. Loose or Disconnected Wiring For Proper Connections 2. Shut Off Power and Check Wiring

3. Defective Motor 3. Repair or Replace Motor

4. Broken Belts 4. Replace Belts

1. Open Access Doors or Loose Sections of Ducts 1. Check for Leakage

2. Clogged Filters 2. Clean Filters

3. Operation in Wrong Direction 3. Correct Rotation of Wheel/Propeller

4. Insufcient Make-Up Air Direction 4. Add Make-Up Fan or Louver Opening

1. Fan Installed With Slope in the Wrong Direction 1. Slope Should Be Fitted in the Direction of the

2. Clogged Drain Spout 2. Clean Drain Spout

3. Cooling Tube or Motor Dome Top Removed 3. Install New Cooling Tube With Gasket and Dome Top

4. Grease Container Full 4. Empty Grease Box

1. Belt Slippage 1. Adjust Tension or Replace Bad Belts

2. Over Voltage Or Under Voltage 2. Contact Power Supply Company

3. Operation In Wrong Direction 3. Reverse Direction of Motor

4. Fan Speed Too High 4. Slow Down Fan By Opening Variable Pitch

5. Incorrect Motor (Service Factor 1.0, Low Ambient

Temperature)

5. Replace Motor With Correct Open, Nema Service

Factors (1.15 or Higher) with 40 Degrees Ambient

6. Blocked Cooling Tube Or Leaky Gasket 6. Remove Blockage And Seal Cooling Tube in Place

7. Insufcient Airow to Kitchen Hood Fan Operating

8. Undersized Motor

Note: Care should be taken to follow all local electrical, safety and building codes. Provisions of the National Electric Code (NEC), as wells as the

Occupational Safety and Health Act (OSHA) should be followed.

All motors are checked prior to shipment. If motor defects should develop, prompt service can be obtained from the nearest

authorized service station of the motor manufacturer while under warranty. Exchange, repair or replacement will be provided on a

no charge basis if the motor is defective within the warranty period. The PennBarry representative in your area will provide a name

and address of an authorized service station if requested. WARNING: Motor guarantee is void unless overload protection is provided

in motor wiring circuit.

www.PennBarry.com

7. Check Airow Under Hood and Adjust on Low Speed

with Kitchen In Full Operation

8. Check Motor Ratings with Catalog Speed and Air

Capacity Chart

11

Page 12

PennBarry is proud to be your preferred manufacturer of commercial and industrial fans and blowers. Learn how PennBarry can assist

you in your next application by contacting your PennBarry Representative or visiting us on the web at www.pennbarry.com.

PennBarry | www.pennbarry.com | pennbarrysales@pennbarry.com | tel: 972.212.4700 | fax: 972.212.4702

PennBarry reserves the right to make changes at any time, without notice, to models, construction, specications, options and

availability. This manual illustrates the appearance of PennBarry products at the time of publication.

View the latest updates on the PennBarry website.

© 2018 PennBarry. All Rights Reserved. Revised AUGUST 2018

Loading...

Loading...