Page 1

Please read and save these instructions.

Read carefully before attempting to assemble, install, operate or maintain the product

described. Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal

injury and/or property damage! Retain instructions for future reference.

O

peration and Maintenance Manual

Axial Fan

Handling

which should be used only to stabilize

weight.

where they contact the fan, especially

where special coatings and paints are

waterproof paper. Electrical connections

A spray lubricant such as:

Dow Corning Molykote 557

Dow Corning Molykote G Spray-

Bonded Lubricant

or equivalent should be applied to

will be adequate to

lubricate

waterproof material.

Fax: 972.497.0468

Avoid severe jarring and/or dropping. Handle units with care to prevent damage to components or fi nishes. If the unit is scratched due

Page 2

PENNBARRY

Fax: 972.497.0468

Axial Fan

put hands near or allow

put hands into inlet or outlet

while unit is running. It is sometimes

operate fan with guards

take chances.

AFETY FIRST!!!

wear.

Adjustable motor bases are provided on

Arrangement 9 fans for belt tensioning.

/or motor

All AC induction motors will perform

Repulsion

It is suggested that rotation change

APPROVED REPAIR SHOP,

Allow motor to run for 10 minutes to expel

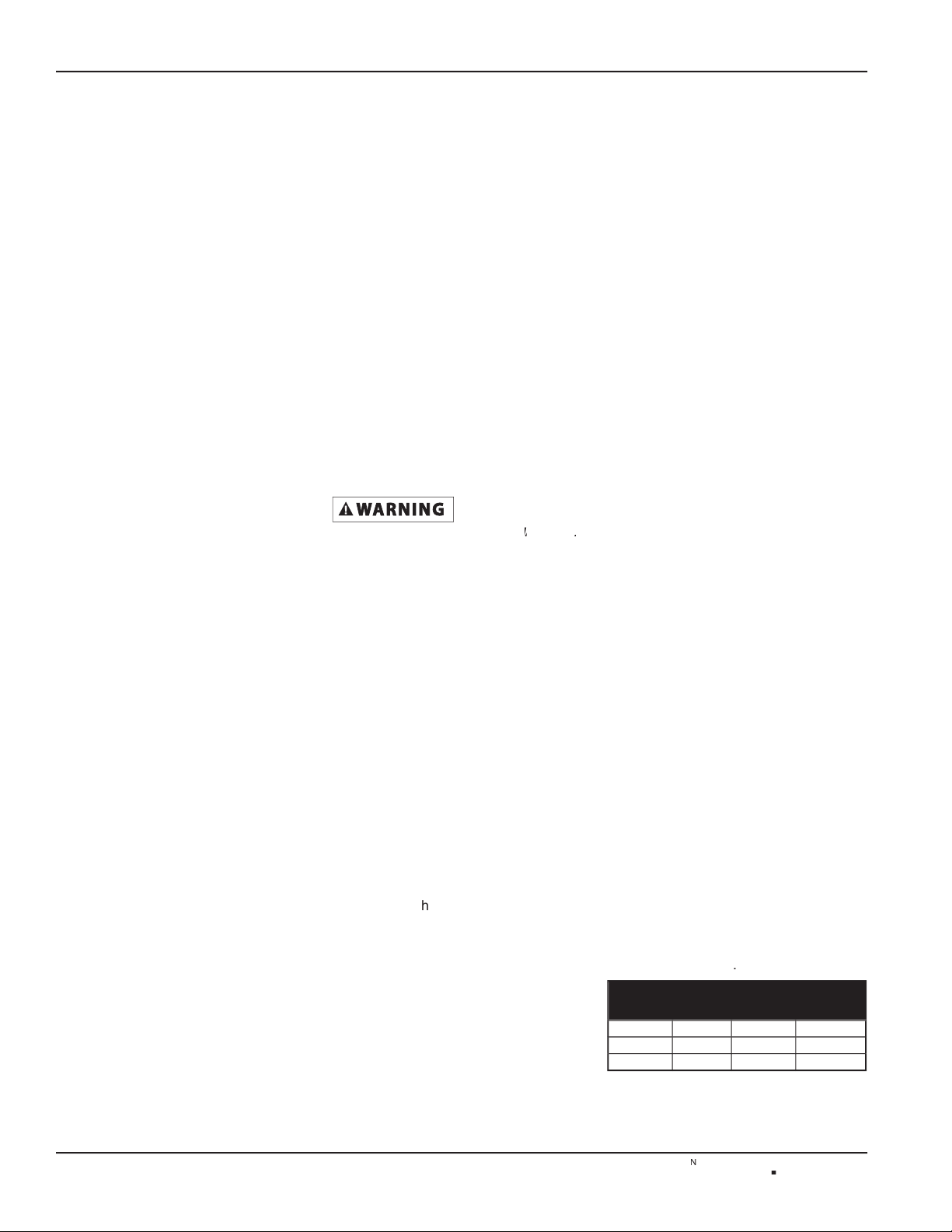

H.P.

Range

Standard

Duty

8 Hr./Day

Severe Duty

24 Hr./Day

Dirty, Dusty

Extreme Duty

Very Dirty

High Ambients

Page 3

Fax: 972.497.0468

Axial Fan

California)

California)

Alvania No. 2 (Shell Oil Company)

- It is recommended that all

Access Doors

- They should be tight and

weld studs are as follows:

- Check bearing alignment and

- Turn over rotating assembly

- Check electrical wiring to the

- Make certain all safety guards

- Must be in alignment; with

- The connections

joints should be sealed to prevent air leaks

At fi rst indication of trouble or vibration,

Always disconnect or shut off fan

A defi nite time schedule for inspecting all

will be necessary. If grease is found to

with steam or water jet is usually suffi cient,

withstand the operating temperatures. For

with an acid resisting paint. Competent

Air pressure above 50 psi should not

OSHA air

wheel to be removed. Be certain to

one side of the split in

the

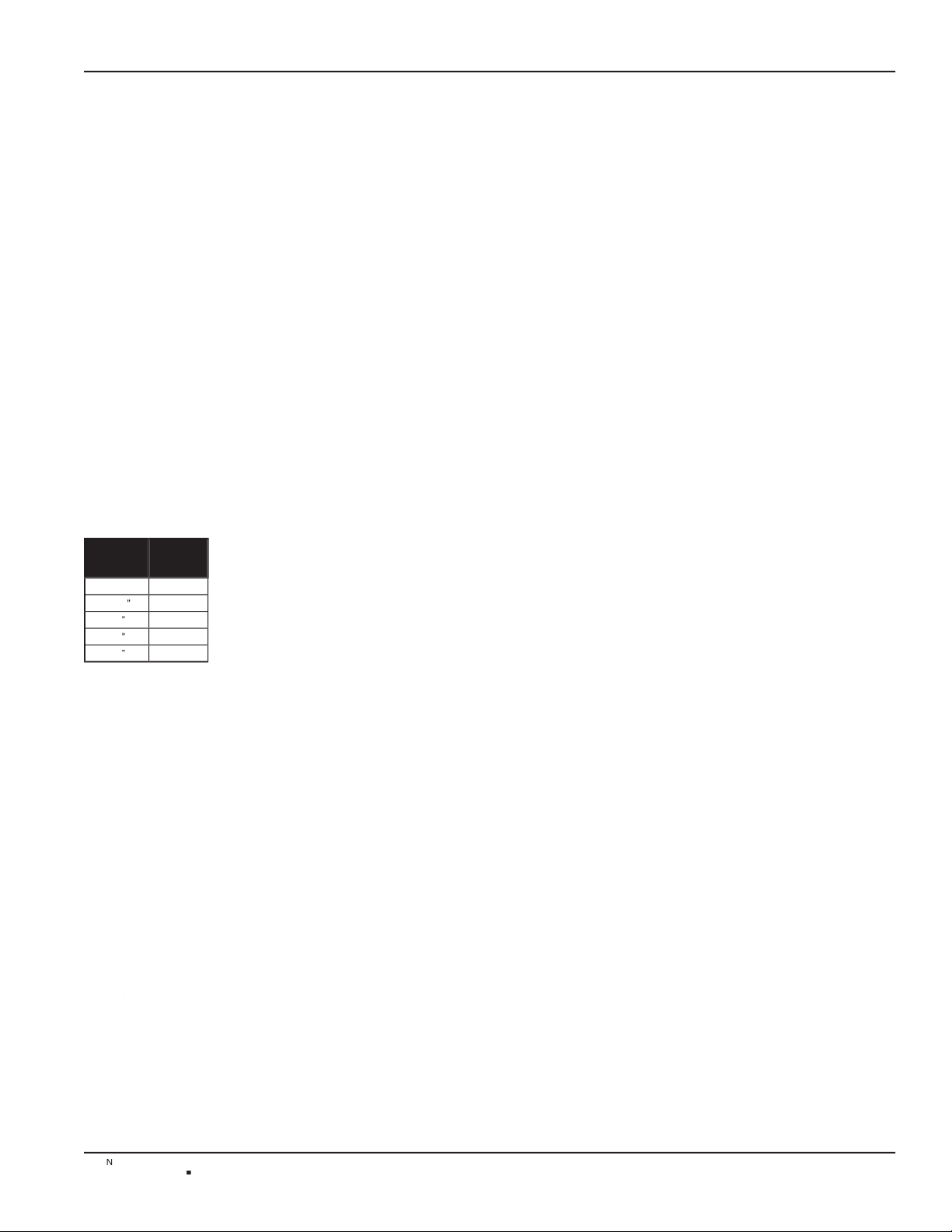

STUD SIZE

TORQUE

(FL. LBS.)

PENNBARRY

Page 4

PENNBARRY

Fax: 972.497.0468

Axial Fan

will affect the dynamic balance of the fan.

without blowing bearing seals or over-

A fan handling clean air should not need

will indicate vibration in mils (1 mil = 0.001

A COMPONENT OF THE ROTATING

ASSEMBLY IS REPLACED OR

ALTERED

California)

California)

Alvania No. 2 (Shell Oil Company)

where the environmental conditions are

Alignment must be checked before

Page 5

Fax: 972.497.0468

Axial Fan

without forcing. Do not roll belts or use

with single groove sheaves. If multiple

Adjust belt tension until only a slight

with improper tension will shorten belt

with fi ne emery cloth or a honing

wheel hub.

wheel. The wheels are mounted

All fans are dynamically balanced at the

PENNBARRY

Page 6

Fax: 972.497.0468

Axial Fan

KAE

POT-KA

E

P - SLIM - TNEM

EC

A

LP

SID

NO

ITAR

BI

V

Vibration Frequency* - CPM

KA

E

P - CES/N

I

Y

TICOLEV NOITARBIV

60

50

40

30

20

15

10

8

7

1.5

6

5

4

3

2

1.0

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0.05 IN/SE

C

0.10 IN/SE

C

0.20 IN/SE

C

0.80 IN/SE

C

0.40 IN/SE

C

00

3

00

4

005

0

06

00700

8

0

0

0

1

009

0021

0051

0081

0002

00

0

3

0063

0

0

52

Values are for filtered

readings taken on th

e

bearing caps.

Shut Down

Rough

Slightly Rough

Fair

Good

Smoot

h

Alignment, balance and the integrity of the support

Requires reasonable care on installation, proper

Fan equipment can operate in this region, but

Requires service. Dangerous operating conditions

Do not operate fan equipment. Potential for

PENNBARRY

Page 7

Fax: 972.497.0468

Axial Fan

Symptom Possible Cause(s) Corrective Action

Adjust drive

Adjust

Air leaks in system

Vibration and Noise

Adjust and tighten

Vibration transmitted to fan from some other source

Allow run time to purge (24 hours)

Abnormal end thrust

Adjust

Adjust s

Verify and correct

d

windings

Vibration and noise

WARNING:

guarantee is void unless overload protection is provided in motor wiring circuit.

PENNBARRY

Page 8

PENNBARRY

Fax: 972.497.0468

Axial Fan

What Products Are Covered

workmanship for a period of one (1) year from the date of shipment.

What You Must Do

Product.

Product must have been installed and maintained in accordance with good industry practice and any specifi c

recommendations.

Product is incorporated.

reserves the right to fully satisfy its obligations under the Limited Warranties by refunding the

Product (or, if the

Product has been discontinued, of the most nearly

reserves the right to furnish a substitute or replacement component or product in the event a PennBarry Product

shall be to pass through the

warranty made by the manufacturer of the defective component.

w (including any warranty of merchant

without limitation lost profi ts or revenues, loss of use of equipment, cost of capital, cost of substitute products,

1401 North Plano Road, Richardson, TX 75081.

Loading...

Loading...