Page 1

INSTALLATION INSTRUCTIONS

STAND ALONE ERV

DXX-2ERV

D-SE RIES

ENERGY RECOVERY VENTILATOR SERIES D11, D20, D28, D36, D46, D62, D80 & D12

INSTALLATION INSTRUCTIONS FOR ENERGY RECOVERY VENTILATOR (FIXED)

FOR STAND ALONE ROOFTOP APPLICATION

Energy recovery COMPONENT certified

to the AHRI Air-to-Air Energy Recovery

Ventilation Equipment Certification

Program in accordance with AHRI

Standard 1060-2000. Actual performance

in packaged equipment may vary.

ETL Certified per UL 1995

and CSA 22.2

OCTOBER 6, 2015

SUPERCEDES 10-29-14

I - Ship ping and Pack ing List

Package contains:

1 — Energy Recovery Ventilator Assembly

1 — Assembled Exhaust Hood

II - Shipping Damage

Check the unit for shipping damage. Receiving party

should contact last carrier immediately if shipping damage

is found.

III - General

These instructions are intended as a general guide and do

not supersede local codes in any way. Authorities having

jurisdiction should be consulted before installation.

IV - Requirements

When installed, the unit must be electrically wired and

grounded in accordance with local codes or, in absence of

local codes, with the current National Electric Code,

ANSI/NFPA No. 70.

V - Application

These Energy Recovery Ventilators (ERVs) are used in a

down discharge manner equipped with a field provided

balancing damper assembly through the roof. A roof

curb must be provided by contractor to manufacturers

specifications. These ventilators conserve energy by

transferring humidity and heat energy across two opposing

air streams using a rotary heat exchanger (the energy

recovery wheel). This process works in the summer by

rejecting heat energy from incoming intake air and in the

winter by conserving heat energy from the exhaust air,

allowing outdoor ventilation rates to be increased by

factors of three or more without additional energy penalty

or increase in size of heating or air conditioning systems.

VI - Rigging for lifting

1. Maximum weight of the unit varies per series

(300-1200 lbs crated)

2. Remove crating

3. All panels must be in place for rigging.

4. Remove box containing screws and accessories from

the Controls section.

5. Duct work should be installed into roof curb before

installing ERV on curb.

6. Roof curb gasket should be applied to all top surfaces

of the curb. (refer to roof curb install instructions).

7. Forklift channels (if used) must be removed from the

base of the ERV before setting unit on curb. See

Figure 1.

8. Attach lifting straps to the provided lifting lugs on the

top 4 corners of the D-11 through D-62 units, on D-80

and D-120 units cutouts are provided on the bottom 4

corners for attachment of lifting straps.

9. Position unit on roof curb being sure to provide service

access to ERV control access door and wheel.

WARNING

Electric shock hazard. Can cause injury

or death. Before attempting to perform

any service or maintenance, turn the

electrical power to unit OFF at

disconnect switch(es). Unit may have

multiple power supplies.

CAUTION

Danger of sharp metallic edges. Can cause injury.

Take care when servicing unit to avoid accidental

contact with sharp edges.

FIGURE 1

FORKLIFT CHANNELS

PAGE 1

Page 2

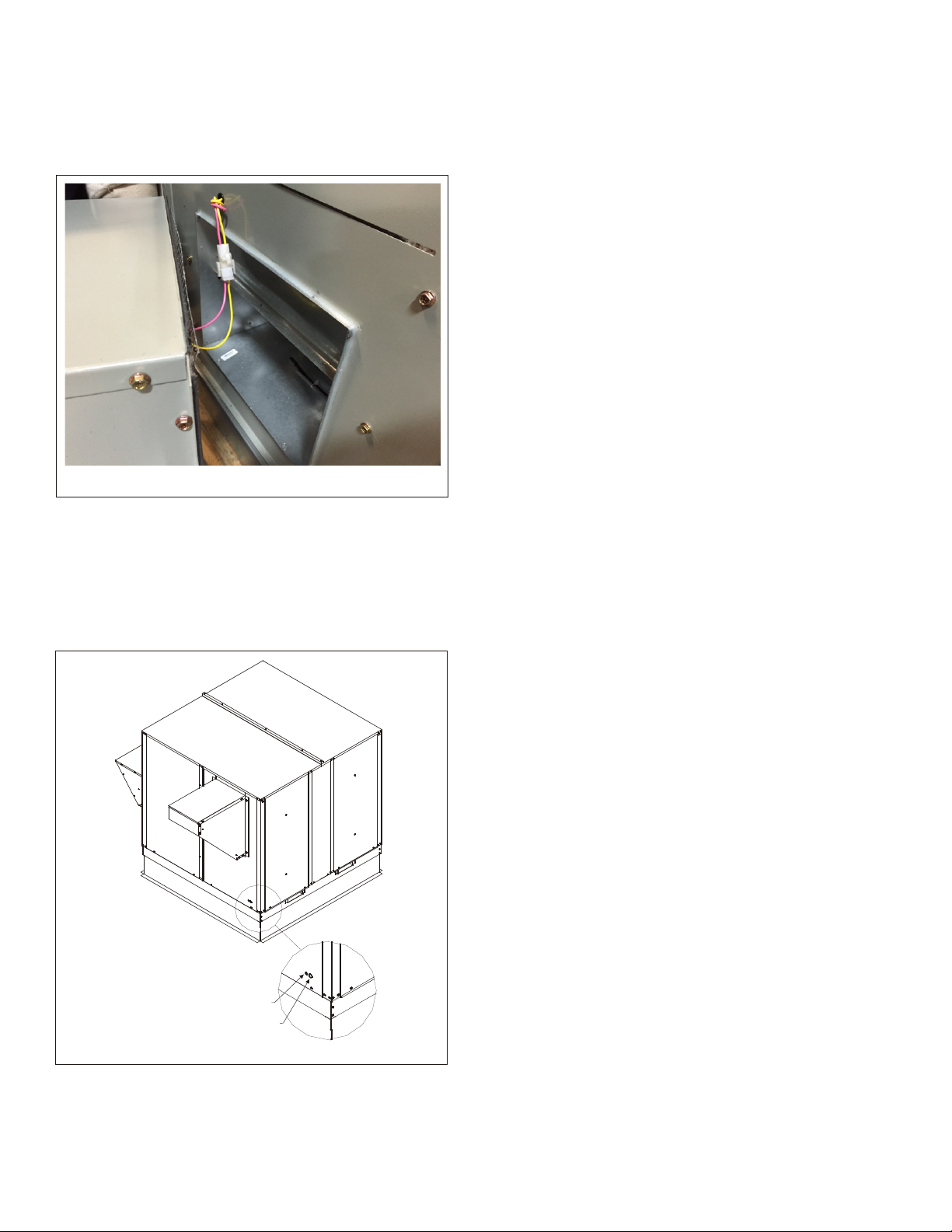

VII - Installation

1. Install exhaust hood assembly shipped with ERV on

pallet using screws provided in accessory box. On

units with motorized exhaust damper connect Plug

(P.161) to jack after removing PK-3 jumper before

attaching hood with screws. See Figure 2.

FIGURE 2

2. Remove ERV control access panels to connect field

wiring.

Low Voltage

3. Route Class II low voltage wire (3 conductor) from

thermostat, relay, or Energy Management through

small bushing provided in the end panel in the ERV.

See Figure 3 for location of penetration.

THERMOSTAT PENETRATION

HIGH VOLTAGE KNOCKOUT

FIGURE 3

5. On units with Variable Frequency Drives a separate

terminal strip is provided to connect low voltage (0-10

VDC) controls [field supplied] for the Drives.

High Voltage

6. All Electrical connections must conform to any local

codes and current National Electric Codes (NEC) or

Canadian Electric Codes (CEC). Refer closely to unit

wiring diagram in the unit and/or in these instructions

for proper wiring connections.

7. Refer to unit nameplate for minimum circuit ampacity

(MCA) and maximum overcurrent protection size

(fuse).

8. Electrical data is listed on unit rating plate as well as

the motor name plates.

9. Connect line voltage power from field installed power

disconnect to ERV fuse block in the control box of the

unit. Use provided knockout on outside panel next to

controls section. See Wiring Diagram pg???

10. Ground unit with suitable ground connection

either through unit supply wiring or to an earth ground.

Note: Unit voltage entries must be sealed weather

tight after wiring is complete.

11. Remove motor access panels, check that blowers

have belts in place and that motors spin freely. Blower

RPM can be adjusted to meet CFM and external static

pressure requirements by adjusting the sheave on the

blower motors and by replacing the pulley kits on units

ordered without variable frequency drives. Multiple

pulley arrangements are available from the

manufacturer to meet the entire range of the units CFM

options.

Caution: Blower speed must be adjusted for the given

external static pressure and airflow (CFM)

requirements. If blower speed is not adjusted for

conditions, possible motor overloading can

occur.

12. Unit Startup. Turn on power disconnect, turn on unit

either from controls or by Jumping 24v+ from

transformer (blue low voltage wire) to terminal #1.

Check that motors are spinning the right direction (3

phase units only) that the enthalpy wheel is spinning

and that motorized intake air and exhaust dampers are

opening.

If unit is operating properly proceed to next step, if not

operating properly See Trouble shooting guide on

Page 4.

13. Clean up, caulk any open joints, holes or seams to

make the unit completely air and water tight. Remove

any jumpers, replace all access panels on the unit and

secure.

14. Leave this instruction manual with the owner or in an

envelope near the unit.

See System Check or Trouble shooting guide for

further information on the proper operation of the

ERV.

PAGE 2

Page 3

VIII - Stand Alone ERV Controls Schemes

Dependent options

Thermostat: This is the standard way to wire an ERV,

when the ductwork of the stand alone ERV is attached to

the ductwork of a single AC system the controls of the ERV

should be wired in parallel with the controls with "G" to 1,

"C" to 2 and "W" to 3. The ERV will operate when ever the

RTU's blower is operating.

Energy Management – Building Management Systems:

The ERV needs a 24 Volt AC signal to operate, connect the

24V+ to 1 and the 24V C to 2, the unit can be operated off of

a relay or BMS controller if necessary.

Dedicated options

When using a control method that does not involve an

outside 24V controls signal power can be borrowed from

the unit's transformer for short thermostat wire runs. Any

run over 150' however should be powered by a separate

transformer.

Thermostat: When using an ERV to service a large area

with multiple AC units or when not tying directly into the

ductwork of a single AC system the ERV can be run off of

its own Thermostat. Splice the 24V+ wire "R" onto the

XFORMER + terminal of the ERV control board, then wire

"G" and "C" onto terminals 1 and 2 respectively, program

Thermostat to energize G when space is occupied.

CO2 Sensor/ Transmitter: An ERV can be wired to a wall

mounted CO2 Sensor/ Transmitter with relay like Johnson

Controls CD-WR0-00-0 (or CD-WRD-00-0) in order to

operate the ERV when ventilation is required due to high

CO2 levels. This type of transmitter has an adjustable set

point, and a relay that the 24V+ signal can be wired into

and "G" wire can be wired out of. "G" should be wired to #1

terminal. The ERV will then turn on and provide fresh air to

the space to lower CO2 levels.

Quickstep: Units equipped with the Quick Step controls

option use an onboard microprocessor, factory installed

CO2 sensor and variable frequency drives to modulate

airflow through the ERV to control for Carbon Dioxide. To

operate the unit enter the Supply and Exhaust CFM values

(they do not have to be the same value) into the Quick Step

flexstat control along with maximum CO2 level and the

controls will modulate the blowers to ensure CO2 levels are

not above set point.

ON/OFF switch or Timer: Wire 24V+ from transformer

onto the input of the switch and connect the output of the

switch to terminal 1 on the control board. The ERV can be

turned on manually or be set to turn on at a regular

schedule when the building is occupied.

IX – Operation

How It Works.

The unit contains an energy recovery wheel (ERW) that is

a revolutionary concept in rotary air-to-air heat

exchangers. Designed as a packaged unit for ease of

installation and maintenance, only the connection of

electrical power is required to make the system

operational.

When slowly rotating through counter flowing exhaust and

fresh air streams the ERW absorbs sensible heat and

latent heat from the warmer air stream in the first half of its

rotation and transfers this total energy to the cooler air

stream during the second half of this rotating cycle.

Rotating at 50-60 RPM, the ERW provides a constant flow

of energy from the warmer to the cooler air stream. The

large energy transfer surface and laminar flow through the

ERW causes this constant flow of recovered energy to

represent up to 85% of the difference in total energy

contained within the two air streams.

Sensible and latent heat are the two components of total

heat, sensible heat is energy contained in dry air and latent

heat is the energy contained within the moisture of the air.

The latent heat load from the outdoor fresh air on an air

conditioning system can often be two to three times that of

the sensible heat load and in the winter it is a significant

part of a humidification heat load.

During both the summer and the winter, the ERW transfers

moisture entirely in the vapor phase. This eliminates wet

surfaces that retain dust and promote fungal growth as well

as the need for a condensate pan and drain to carry water.

Because it is constantly rotating when in the air stream, the

ERW is always being cleaned by air, first in one direction

and then the other. Because it is always dry, dust or other

particles impinging on the surface during one half of the

cycle are readily removed during the next half of the cycle.

During the heating season, when outdoor air temperatures

are below 15oF, it is recommended to use the (optional)

low ambient kit.

Optional Kits

Motorized Intake Air Damper

This damper mounts inside the outdoor air intake hood, it

opens when the ERV supply blower is energized and

closes when de-energized.

Motorized Exhaust Air Damper

Damper mounts inside the exhaust air hood, it opens when

the ERV is energize and closes when the ERV is

de-energized.

Pressure Sensors

Measurement devices (Magnahelics) on ERV that

measure pressure across the energy recovery wheel.

Rotation Sensor

A magnetic sensor and logic board that measure pulses

from a magnet on the spinning energy recovery wheel. A

lack of measured pulses after initial start up results in an

alarm. The alarm can be wired into building management

hardware or to a thermostat with alarm switch terminals, it

will warn that the wheel has stopped spinning, but does not

otherwise effect operation.

Stop, Start, Jog [Climate Smart]

This option adds an Economizer or free cooling mode to

the ERV. The wheel stops spinning to allow air to pass

without energy transfer, starting and spinning

intermittently in order to keep the wheel clean.

Low Ambient Kit

Prevents frost buildup on energy recovery wheel by

terminating intake air when the discharge air temperature

falls below a set level. Intake blower operation resumes

after a 16oF rise above the field adjustable set point.

The frost threshold is the outdoor temperature at which

frost will begin to form on the ERV wheel. For energy

recovery ventilators, the frost is typically below 10oF. Frost

threshold is dependent on indoor temperature and

humidity. The table shows how the frost threshold

temperatures vary depending on indoor conditions.

PAGE 3

Page 4

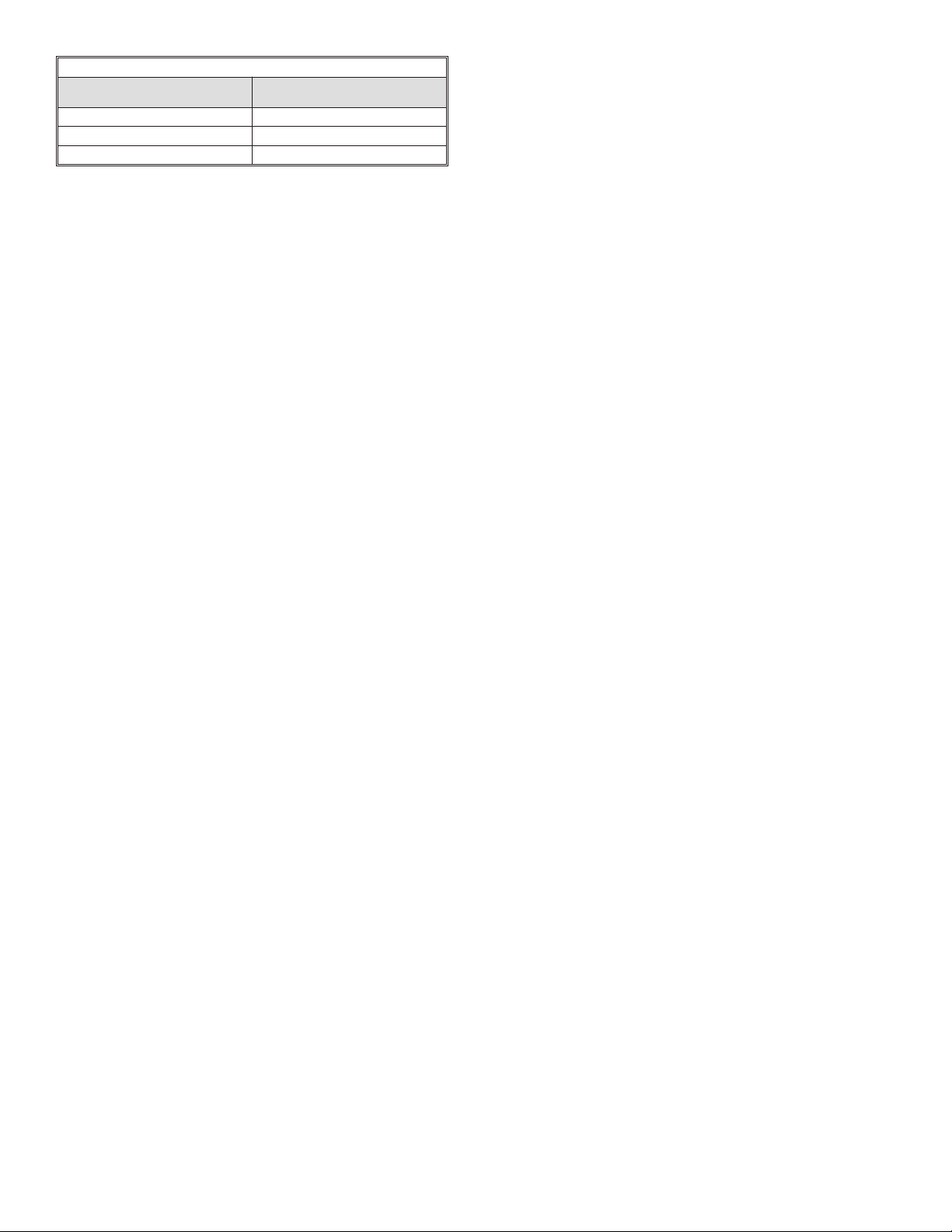

FROST THRESH OLD TEM PER A TURE

IN DOOR RH AT 70oF

20% 0oF

30% 5oF

40% 10oF

FROST THRESH OLD

TEM PER A TURE

Because energy recovery ventilators have a low frost

threshold, frost control options are not necessary in many

climates. The Low Ambient Kit is available for units

installed where outdoor temperatures may drop below the

frost threshold during the ERV operational hours.

Filter Racks/ Filter Options

Stand alone units come with return air filters standard,

MERV 8, 11, or 13 filters can be ordered with the unit.

Supply air filter racks can be added as an option with the

same efficiency filter options.

Dirty Filter Switches

Pressure differential switches that can be hooked up to an

alarm to alert when pressure drops across a filter bank

indicating dirty or clogged filter, they do not otherwise

effect operation.

Wheel Type

While the standard energy recovery wheel absorbs both

sensible and latent heat a sensible only wheel can be

ordered for applications where the sensible portion of the

heat load needs to be removed from a space without

returning the humidity.

Smoke Detector

Smoke detectors can be factory ordered with the ERV, a

qualified technician needs to field wire the smoke detector

into the controls to break common in case of alarm.

CO2 Sensor

See Quickstep in Controls schemes. A factory installed

Co2 sensor can be added to the unit to adjust ventilation on

a CO2 parts per million demand. This sensor is mounted

next to the return air inlet and is not a relay, it only provides

feedback to the quick step controls to adjust motor speed

and is not suitable to turn the unit on and off on CO

demand.

X – System Check

1. Disconnect main power

2. On units controlled by thermostats turn T-stat fan

switch to "On". Otherwise jump 24v+ to terminal #1.

3. Restore power to unit, observe ERV wheel rotation

and both fresh air and exhaust air blowers.

Note: If the low ambient kit is used the jumper between

terminals 5&6 should be removed and replaced

with blue and yellow wires for the sensor. If system

check out is being done at low ambient

temperatures this kit can cause the unit not to

operate. Under these conditions jump terminals

5&6.

4. Verify the ERV three phase blower motors are phased

sequentially ensuring correct rotation and operation. If

both blowers are running backwards:

A. Disconnect Power.

B. Reverse and two high voltage line in wires on the

ERVs fuse block.

C. Reapply Power.

Note: Blower Motor rotation is checked in factory, do

not switch wires at contactors or on motors if

blowers are spinning backwards at startup.

5. Verify that both blower motors are operating under

their full load AMP rating (FLA). The FLA can be found

on each motor and on the unit's name plate.

6. Verify that the fresh air and exhaust air motorized

dampers are opening and closing when unit turns

on/off.

Note: If unit is not operating properly refer to

troubleshooting guide.

7. Return damper settings. When tied into an HVAC

system manually adjust the position of the field

installed dampers to balance Air flow.

8. Static test ports are provided to verify intake and

exhaust CFM, these ports can also be used with a

temperature probe to verify temperature transfer

through the wheel.

Adjustment to the blower speed is accomplished by

changing the sheave setting on both fresh air and exhaust

air blowers.

Flow / Blower Speed Ad just ment

Blower speed selection is accomplished by changing the

sheave setting on both fresh air and exhaust air blowers.

To set ERV for the required air flow (CFM), the external

static pressure applied to the ERV (duct static) must be

known. See the CFM vs External Static Pressure chart for

the appropriate unit to determine the correct blower RPM

for the specified CFM and External Static Pressure.

After blower speed adjustments have been made. Ensure

that when the belt is replaced it is tensioned correctly. The

motor mounting plate can be adjusted to tension the belt. If

using a belt tension checker, adjust the span to the

appropriate setting and check the belt defection force. The

belt deflection force should be between 5-8 lbs or the

lowest tension at which the belt will not slip under peak load

conditions.

2

1. Disconnect main power to unit before making

adjustment to economizer and/or ERV unit.

2. Replace ERV control access cover.

3. Set thermostat to normal operating position.

4. Restore power to unit.

XI - Se quence of Op er a tion

1. The thermostat or Building Management System

(BMS), sends a 24 Volt AC signal to the HVAC system

for cooling, heating, fan only or ventilation operation.

2. The ERV is activated simultaneously with the blower of

the AC system. The intake air blower, the exhaust

blower and the enthalpy wheel motor of the ERV are

activated, these motors will remain energized as long

as the blower in the AC system is energized and the

outdoor conditions are adequate for energy recovery.

3. If the optional motorized intake air damper is present,

the damper must open causing a proving switch to

close in order to energize the intake air blower (10-20

seconds after the exhaust blower and enthalpy wheel

have started).

4. If the optional low ambient kit is present, and the

temperature leaving the exhaust side of the enthalpy

wheel is lower than the field adjusted set point on the

PAGE 4

Page 5

temperature sensor, the optional motorized fresh air

damper will close and the intake blower will

de-energize. The exhaust blower and enthalpy wheel

motor will continue to operate until the temperature

sensor has a 16F rise, at this point the enthalpy wheel

should be defrosted and the optional motorized

damper will open and the fresh air blower will

reactivate.

5. If the start, stop, jog [Climate Smart] option is present

and outside conditions are adequate for free cooling

the enthalpy wheel motor will stop for 10 minutes to

allow for cool air to enter the building. It will then start or

jog the wheel for 1 minute to keep dirt from building up

on the wheel.

XII - Trou ble Shoot ing guide

ERV will not op er ate:

1. Quick check items.

A. Verify that the door switch is closed, the switch

must be in the closed position in order to power

the control board.

B. Verify 24V power to the control board at terminals

Xformer + & -. If voltage is low check high voltage

into the unit (sec 2-A) and check that the T-1 wire

from the high voltage into the step down

transformer is on the correct terminal

(208v-230v-460V) for the units voltage.

C. Verify 24V to the control board's terminal strip at

T-1 (G) and T-2 (Com) in Fan or Cool or T-2 (Com)

and T-3 (W) in Heat. These terminals must be

powered by an external power source to

operate the ERV.

A jumper from Xformer + to T-1 can be used to test

operation of the ERV if an external 24V controls signal is

not available.

1. Verify high voltage to ERV

A. Verify that the unit has the proper voltage in at

terminals L1, L2 and/or L3 at the fused high

voltage connection terminal block. Voltage

specifications are on the units name plate.

B. Verify that the fuses are good, (check voltage

across fuses with power on, voltage should be 0)

replace any bad fuses.

ERV Has Power, But Motors Are Spinning Backwards

1. Motors are checked for proper rotation at the factory, if

the motors are spinning backwards after install

reverse the phase by switching two wires on the high

voltage IN terminals.

2. If the motor is spinning backwards after replacement

switch the L1 & L2 wires connected inside the motors

access panel. Do no rewire unit.

*Many of motors used in production of the ERVs are multi

voltage (230/460V) motors. When replacing motors or

diagnosing a motor that won't start. Care should be taken

to make sure the wires inside the motors access panel are

connected securely and in the proper configuration.

ERV Has Power, But the Enthalpy Wheel Does Not

Spin (Start Stop Jog #1)

1. If the unit has the Start, Stop, Jog option installed the

enthalpy wheel motor will turn off for 10 minute

intervals when outside conditions are optimal for free

PAGE 5

cooling, the fresh air and exhaust blowers will continue

running. The Start, Stop, Jog control board has a white

test button that when pressed will bypass the boards

logic and turn the enthalpy wheel on. See Start, Stop,

Jog in Options/Accessories troubleshooting for further

information.

2. With the power off, check that the wheel belt is in place

and tight.

3. Check for 24 volts between terminals Exhaust (K163)

A&B, if the unit doesn't have Start, Stop, Jog the relay

is connected directly to the Exhaust A and B terminals

on the control board. If terminals 1&2 or 3&2 are

energized with 24V, there is 24V in to Xformer + & - ,

and there is no voltage to Exhaust A&B the board is

bad.

4. If there is 24 Volts at Exhaust A&B trace wires to the

enthalpy wheel relay, check terminals A&B on the

Relay for 24 Volts, check for high voltage power into

and out of the relay. If the relay is energized/closed

and no power is passing from terminals 7 to 4 or 9 to 6

the relay is bad.

5. You can jump the enthalpy wheel relay to test its

operation by running a jumper from the 24v out on the

transformer (blue wire) to the A terminal on the relay

after removing the pink wire.

6. If the relay is closing and there is proper voltage

between terminals 4&6 on the relay check the wheel's

motor for proper voltage by using a multi-meter at Plug

P-150 next to the enthalpy wheel motor.

A. If voltage is present and this is a single phase

motor (most units) check the motor's capacitor.

B. If the capacitor is bad replace the capacitor,

continue testing the motor

C. If proper voltage is present and the capacitor is

good check the wires into the motor for continuity,

if there is no continuity through the windings a wire

connection is loose or the motor is bad, check wire

connections between harness and windings, if

connections are good the motor is bad, replace

motor.

ERV Has Power But the Exhaust Blower Does Not

Operate

1. With power off. On units with belts, check that the

blower's belt is tight and in place, if it is loose adjust the

motor or sheave to tighten it, if it is broken replace it.

2. Check the contactor (K-163) to see if the issue is with

high voltage or low voltage, if the contactor is closed

check the motor. If it is open, push closed to check that

the motor starts then check controls

3. Check for 24 Volts between Exhaust A&B terminals on

the control board.

A. If the controls are calling for operation but there are

not 24 Volts between Exhaust A&B the board is

bad.

B. If the controls are calling for operation and there

are 24 Volts between Exhaust A&B check the

yellow wire for direct connection to the proper

contactor (K-136), then check the pink wire for

continuity through the field installed exhaust

damper motor (if option was chosen) or the factory

installed plug (PK-3) at the Jack (J-161) located in

the exhaust blower section.

Page 6

3. If contactor is closed check voltage to the motor by

testing wires at Plug P-151, proper voltage is listed on

the unit's information tag. If there is proper voltage to

the motor and the motor is not spinning the motor is

bad. With single phase units check the capacitor, if

capacitor is bad replace it then continue checking the

motor.

ERV Has Power But The Intake Air Blower Does Not

Operate

1. With power off. On units with belts, check that the

blower's belt is tight and in place, if it is loose adjust the

motor or sheave to tighten it, if it is broken replace it.

2. Check the contactor (K-164) to see if the issue is with

high voltage or low voltage. If the contactor is closed

check the motor. If it is open, push closed to check that

the motor starts, then check controls.

3. If the contactor is open check for 24 Volts between

Fresh A&B terminals on the control board.

A. If the controls are calling for operation and there is

no voltage between Fresh A&B check terminals

5&6 to see if low ambient kit is installed (blue and

yellow wires installed instead of a jumper),

jumping terminals 5&6 will bypass the low ambient

sensor and energize terminals Fresh A&B. See

Low Ambient Kit in Options/Accessories

troubleshooting for further information.

B. If the controls are calling for operation and there is

no voltage between Fresh A&B and there is

continuity between terminals 5&6 then the board

is bad.

C. If the controls are calling for operation and

terminals Fresh A&B are energized but the

contactor is not energizing, check the yellow wire

from terminal Fresh B to contactor (K-164), check

the orange wire for continuity from terminal Fresh

A through factory installed fresh air damper plug

(P-160) to contactor. In models without a fresh air

damper option there should be an orange jumper

between pins 3&4 on the P-160 plug, when the

fresh air damper option is chosen these wires

connect to an end switch that is closed by a cam

when the fresh air damper opens. See Sequence

of Operations.

1. If contactor is closed check voltage to the motor by

testing wires at plug P-148, proper voltage is listed on

the unit's information tag. If there is proper voltage to

the motor and the motor is not spinning the motor is

bad. With single phase units check the capacitor, if

capacitor is bad replace it then check the motor.

ERV Has Power But The Motorized Fresh Air Damper

Does Not open

1. Verify 24V in between terminals 1&2 or 3&2

2. Check voltage at junction J-56 on the ERV control

board, there should be 24V between J-56 1&2 during

normal operation, If the unit has a low ambient kit

installed and temperatures are low the controls

de-energize J-56 and Fresh K-164 terminals on the

control board, jump Terminals 5&6 on the Terminal

strip to bypass see Low Ambient Kit in

Options/Accessories Troubleshooting for further

information.

3. If there is voltage at the control board check for 24V at

plug P-160 between pins 1&2

4. If there is voltage at P-160 make sure the damper

linkage isn't binding and that the wires are attached to

the actuator firmly. If the actuator still doesn't move

when 24V is applied replace the actuator.

ERV Has Power But The Motorized Exhaust Air

Damper Does Not Open

1. Verify 24V In between terminals 1&2 or 3&2

2. Check voltage at Exhaust A&B on control board

3. If there is voltage at Exhaust A&B on the control board,

trace wires to the exhaust blower compartment and

plug P-161, Check for 24V between Pins 1&3.

4. If there is 24V at plug P-161 make sure the field

connected P-161 plug for the damper is inserted firmly

into J-161, that the damper linkage isn't binding and

that the wires are connected firmly to the actuator. If

the damper actuator still does not move the actuator is

bad.

Options and Accessories Troubleshooting

Start, Stop, Jog [Climate Smart]

The Start, Stop, Jog kit is an optional control board with

temperature and/or enthalpy sensor(s) that stops the

enthalpy wheel from spinning (and transferring heat) when

temperature conditions are conducive for free cooling. The

board will spin the wheel intermittently in 10 min off 1 min

on intervals to keep dust from building up on the surface.

All units shipped with the Start, Stop, Jog option installed

have the temperature and enthalpy sensors installed, and

the jumper (J9) set to T(emp). A qualified tech can adjust

the setting to E(nthalpy) only or Temp and Enthalpy by

adjusting the jumper (J9).

The factory set points to allow for free cooling during

ventilation are 40F-70F, but they can be field adjusted to

narrow the band by adjusting two potentiometers while

measuring VDC between the Com & High or Com & Low

terminals (0 VDC = 40 degrees, low set point, 5 VDC = 70

degrees, high set point).

Low Ambient Kit

The low ambient kit is an optional temperature probe on a

normally closed switch that closes the fresh air damper

and turns off the fresh air blower when temperatures in the

blower compartment suggest a frosted enthalpy wheel.

The adjustable sensor is factory set for 20F. The sensor is

mounted in the blower compartment with its probe near the

blower's inlet, it is wired into the terminal strip 5&6

terminals.

It can be tested in hot weather by turning the dial up to a

higher temperature and checking to see if the normally

closed relay opens. In cold weather if the "R" terminal and

"W" terminal in the sensor show an open circuit the bulb

can be warmed above the set-point at which point the relay

should close.

Dirty Filter Switch

Dirty filter switches are an optional kit that put an

adjustable pressure switch with the Low inlet on the blower

side of the filter and the High inlet connected to the far side

of the filter via tubing. A dirty filter moves less air lowering

the pressure on the fan side Low inlet closing the normally

open sensor switch and allowing an alarm. The sensor(s)

are prewired into their own terminal strip and can be field

wired in series (normally closed), in parallel (normally

open) or individually to an alarm device.

PAGE 6

Page 7

Note: The Dirty Filter switch is not wired into the logic

of the ERV, it will not stop the ERV if filters are

dirty, it will only set off a field installed alarm or

warning that the filters are dirty and need to be

changed.

Pressure Gauge

An optional Magnahelic pressure gauge can be ordered as

an option to check pressure in In W.C., the Magnahelics

are factory installed in the doors of the ERV to give

pressure readings in the different quadrants of the unit.

Occasional re-zeroing of the gauge is required.

Rotation Sensor

The rotation sensor is an optional missing pulse detector

powered off of the exhaust and wheel 24v signal. A sensor

is mounted in the exhaust compartment near the wheel

and senses rotation via a magnet on the outside frame of

the wheel. Its output is wired to a terminal strip and an

alarm can be connected to alert when rotation of the wheel

has stopped.

If an alarm is going off and the wheel is rotating properly

check that the rotation sensor is mounted and adjusted to

properly sense the sensor magnet in the wheel. Check

wire connections to make sure they are secure.

If an alarm is tripped and the wheel is not rotating check the

wheels belt, it's motor, and capacitor for proper operation.

XIII - Main te nance

1. All motors use prelubricated sealed bearings; no

further lubrication is necessary.

2. Make visual inspection of motors, belts and wheel

rotating bearings during routine maintenance.

3. Eight pie-shaped segments, are seated on stops

between the segment retainer which pivots on the

wheel rim and secured to the hub and rim of wheel.

Annual inspection of the self cleaning wheel is

recommended. With power disconnected, remove

ERV access panels (rear) and unplug [J150 & P150]

(Refer to wiring diagram in this instruction

manual). Remove segment and wash with water

and/or mild detergent.

4. To install wheel segments follow steps A through E .

See Figure 4. Reverse procedure for segment

removal.

SEGMENT RETAINER CATCH

WHEEL RIM

E

SEGMENT RETAINER

A

A. Unlock two segment retainers (one on each side of

the selected segment opening.

B. With the embedded stiffener facing the motor side,

insert the nose of the segment between the hub

plates.

C. Holding segment by the two outer corners, press

the segment towards the center of the wheel and

inwards against the spoke flanges. If hand

pressure does not fully seat the segment, insert

the flat tip of a screw driver between the wheel rim

and outer corners of the segment and apply

downward force while guiding the segment into

place.

D. Close and latch each segment retainer under

segment retaining catch.

E. Slowly rotate the wheel 180o. Install the second

segment opposite the first for counterbalance.

Rotate the two installed segments 90o to balance

the wheel while the third segment is installed.

Rotate the wheel 180o again to install the fourth

segment opposite the third. Repeat this sequence

with the remaining four segments.

XIV - Pul ley Kit In stal la tion

The units are shipped from the factory at the low static

setting. Pulley kits are available for the medium and high

static settings. To install a pulley kit.

1. Check content of pulley kit, if pulley kit contains:

A. An adjustable sheave and a fixed pitch pulley then

remove belt and both motor and blower pulley.

B. An adjustable sheave then remove the motor

pulley.

C. A fixed pitch pulley then remove the blower pulley.

2. Replace pulley(s) with the pulley(s) from pulley kit.

Make sure each pulley is installed with a key. Tighten

the set screw on the pulley(s) to 100 in.lb.

3. Install the belt that came with the pulley kit. Tension

belt as explained in the blower speed adjustment

section.

4. Check the speed of the blower. Adjust the motor

sheave to increase or decrease the speed of the

blower. See blower adjustment section.

D

SPOKE

B

HUB

FIGURE 3

C

D

SEGMENT

PAGE 7

Page 8

D-02 Series Stand Alone ERV'S For Down Discharge Duct Arrangements

Features and Notes

1. Stand alone design allows higher levels of outdoor

air to be introduced into the a/c space.

2. Static test ports provided to verify intake and

exhaust CFM.

3. Balancing damper(s) field supplied in duct work when

connected to ERV.

4. Roof curbs are available for the ERV's.

5. See blower performance charts for airflow at various E.S.P..

6. Filter rack with 2" pleated filters included.

ERV Roof Curbs

Se ries Model No

D11 01- 2D1- 2514

D20 01- 2D1- 3014

D28 01- 2D1- 3614

D36 01- 2D1- 4114

D46 01- 2D1- 4614

D62 01- 2D1- 5214

D80 01-2D1-5814

D12 01-2D1-7414

A

D

B

EXHAUST HOOD

C

FRESH AIR HOOD

EXHAUST RETURN DUCT

(FIELD SUPPLIED)

E

F

4

FRESH AIR SUPPLY DUCT

G

EXHAUST

(FIELD SUPPLIED)

RETURN

J

FRESH AIR

SUPPLY

H

I

K

J

ERV Data Di men sional Data

ERV

Se ries

D11-02 300-1100 17.00 x 11.38 44.75 32.13 33.50 14.38 43.00 39.00 17.50 30.25 26.25 11.88 2.50

D20-02 1200-2000 21.88 x 14.00 54.38 37.25 37.50 17.50 52.75 48.75 22.38 35.50 31.50 14.50 2.50

D28-02 1200-2800 20.25 x 17.00 52.25 42.63 43.56 25.50 49.50 45.50 20.75 41.00 37.00 17.50 2.00

D36-02 2000- 3600 23.38 x 17.38 60.00 46.69 57.37 25.50 55.75 51.75 23.88 41.81 37.81 17.91 2.00

D46-02 3000- 4600 23.38 x 20.38 60.00 52.69 57.37 28.06 55.75 51.75 23.88 47.81 43.81 20.91 2.00

D62-02 4600- 6200 29.38 x 30.00 72.00 70.88 63.63 37.75 67.75 63.75 29.88 66.00 62.00 30.00 2.00

D80-02 6000-8000 38.75 x 35.38 101.38 78.38 71.34 21.75 99.75 95.75 38.75 76.75 72.75 35.38 2.00

D12-02 8000-13000 40.00 x 44.50 120.38 88.38 86.63 28.50 118.50 114.50 44.88 86.50 82.50 40.25 2.00

CFM Range

Duct Size

(G x J)

A B C D E F G H I J K

ERV Roof Curb

PAGE 8

Page 9

A131 Fixed Re lay Board

B26 Mo tor, Ex haust Air

B27 Mo tor, In take Air

B28 Mo tor, Desiccant Wheel

B30 Mo tor, Damper In take (Op tional)

B31 Mo tor, Damper Ex haust (Op tional)

C23 Ca pac i tor, Wheel Mo tor

C25 Ca pac i tor, Ex haust Air

C26 Ca pac i tor, In take Air

F29 Fuse

J48 Jack, Con trol Box (In take Air)

J50 Jack, Con trol Box (Wheel)

J51 Jack, Con trol Box (Ex haust Air)

J56 Jack, Con trol Box (Damper)

J148 Jack, In take Air Mo tor Har ness

J150 Jack, Wheel Mo tor Har ness

COMPONENT CODE

J151 Jack, Ex haust Air Mo tor Har ness

J160 Jack, Damper In take Mo tor Har ness

J161 Jack, Damper Ex haust Mo tor Har ness

K163 Contactor, Ex haust Air Mo tor

K164 Contactor, In take Air Mo tor

MPD-1 Miss ing Pulse De tec tor Board (Op tional)

P48 Plug, In take Air Mo tor Har ness

P50 Plug, Wheel Mo tor Har ness

P51 Plug, Ex haust Air Mo tor Har ness

P56 Plug, Damper Mo tor Har ness

P148 Plug, In take Air Mo tor

P150 Plug, Wheel Mo tor

P151 Plug, Ex haust Air Mo tor

P160 Plug, Damper In take Mo tor Har ness

P161 Plug, Damper Ex haust Mo tor Har ness

RS-1 Ro ta tion Sen sor (Op tional)

S26 Switch, Low Am bi ent (Op tional)

S51 Switch, Door

S52 Switch, Damper In take

S53 Switch, Damper Ex haust

SD Smoke De tec tor (Op tional)

SSJ Cli mate Smart Board (Op tional)

T27 Trans former, Con trol

T28 Trans former, Step-down (Op tional)

TB37 Ter mi nal Block (Low Volt age)

TB39 Ter mi nal Block (Mon i tor ing)

WHL Re lay, Wheel Mo tor

WIRE COLOR

CODE

BK Black

BL Blue

GR Green

GY Gray

OR Orange

PK Pink

RD Red

WT White

YL Yellow

D11-21-2ERV

PAGE 9

Notes:

1. Re move jumper to in stall field op tional low am bi ent switch.

2. Se lec tive volt age ter mi nal for proper unit volt age

3. Op tional low am bi ent switch.

4. Op tional mo tor ized in take damper.

5. Op tional Stop, Start and Jog Con trol (Cli mate Smart).

6. For en ergy man age ment sys tems con nect +24v to "G"

and com mon 24v to "C".

7. Op tional mo tor ized ex haust damper.

8. Op tional wheel ro ta tion sen sor.

9. Op tional smoke de tec tor.

Page 10

ERV UNIT WIR ING DIAGRAM

. "C" o t v42 nommoc dna

:setoN

.1 .hctiws tneibma wol lanoitpo dleif llatsni ot repmuj evomeR

.2 egatlov tinu reporp rof lanimret egatlov evitceleS

.3 .hctiws tneibma wol lanoitpO

.4 .repmad ekatni dezirotom lanoitpO

.5 .)tramS etami lC( lortnoC goJ dna tratS ,potS lanoi tpO

.6 "G" ot v42+ tcennoc smetsys tnemeganam ygrene roF

. 7 .r epmad t suahxe dezir o tom lanoit pO

. 8 .r o snes noitato r le ehw la noitpO

.9 .rotc ete d e k oms la n oitpO

PAGE 10

Desiccant Wheel for Rooftop Unit

208-230V (1 PH)

Unit#: 01-D11-02XX-21

Page 11

A131 Fixed Relay Board

B26 Motor, Exhaust Air

B27 Motor, Intake Air

B28 Motor, Desiccant Wheel

B30 Motor, Damper Intake (Optional)

B31 Motor, Damper Exhaust (Optional)

C23 Capacitor, Wheel Motor

F29 Fuse

J48 Jack, Control Box (Intake Air)

J50 Jack, Control Box (Wheel)

J51 Jack, Control Box (Exhaust Air)

J56 Jack, Control Box (Damper)

J148 Jack, Intake Air Motor Harness

J150 Jack, W heel Motor Harness

J151 Jack, Exhaust Air Motor Harness

J152 Jack, Transformer (High Voltage)

COMPONENT CODE

J160 Jack, Damper Intake Motor Harness

J161 Jack, Damper Exhaust Motor Harness

K163 Contactor, Exhaust Air Motor

K164 Contactor, Intake Air Motor

MPD-1 Missing Pulse Detector Board (Optional)

P48 Plug, Intake Air Motor Harness

P50 Plug, Wheel Motor Harness

P51 Plug, Exhaust Air Motor Harness

P56 Plug, Damper Motor Harness

P148 Plug, Intake Air Motor

P150 Plug, Wheel Motor

P151 Plug, Exhaust Air Motor

P152 Plug, Transformer (High Voltage)

P160 Plug, Damper Intake Motor Harness

P161 Plug, Damper Exhaust Motor Harness

RS-1 Rotation Sensor (Optional)

S26 Switch, Low Ambient (Optional)

S51 Switch, Door

S52 Switch, Damper Intake

S53 Switch, Damper Exhaust

SD Smoke Detector (Optional)

SSJ Climate Smart Board (Optional)

T27 Transformer, Control

T28 Transformer, Step-down (Optional)

TB37 Terminal Block (Low Voltage)

TB39 Terminal Block (Monitoring)

WHL Relay, Wheel Motor

WIRE COLOR

CODE

BK Black

BL Blue

GR Green

GY Gray

OR Orange

PK Pink

RD Red

WT White

YL Yellow

D11-D62-2ERV

Notes:

1. Remove jumper to install field optional low ambient switch.

2. Step-down transformer assembly for 460/575 volt units.

3. Selective voltage terminal for proper unit voltage

4. Optional low ambient switch.

5. Optional motorized intake damper.

6. Optional Stop, Start and Jog Control (Climate Smart).

7. For energy management systems connect +24v to "G" and common 24v to "C".

8. Optional motorized exhaust damper.

9. Optional wheel rotation sensor.

PAGE 11

Page 12

ERV UNIT WIR ING DIAGRAM

:setoN

.1 .hctiws tneibma wol lanoitpo dleif llatsni ot repmuj evomeR

.2 .stinu tlov 575/064 rof ylbmessa remrofsnart nwod-petS

.3 egatlov tinu reporp rof lanimret egatlov evitceleS

.4 .hctiws tneibma wol lanoi tpO

.5 .repmad ekatni dezi rotom lanoitpO

.6 . )t ramS etamilC( lor tnoC goJ dna t ratS ,potS l ano itpO

.01 .rotceted ekom s lanoitp O

.7 ."C" o t v42 nommoc dna "G" o t v42+ tcennoc sme ts ys tnemeganam y g r ene r oF

.8 .re pma d ts ua h xe d e zirotom la n oitpO

.9 .ro sn es n oitator lee h w lanoitpO

PAGE 12

Desiccant Wheel for Rooftop Unit

208-230/460/575V (3 PH)

Unit#: 01-D11-D62-02XX-23 thru -43

Page 13

ERV UNIT SCHE MATIC DIAGRAM

Notes:

1. Selective voltage terminals for proper unit voltage.

2. Remove jumper to install field optional low ambient switch.

3. Optional low ambient switch.

4. Optional motorized intake damper.

5. Optional Stop, Start and Jog Control.

6. Optional Motorized Exhaust Damper

7. For energy management systems connect +24v to "G" and common 24v to "C".

8. Optional Wheel Rotation Detection.

9. Optional Dirty Filter Sensors.

PAGE 13

D80-D12-2ERV

Page 14

ERV UNIT WIR ING DIAGRAM

Desiccant Wheel for Rooftop Unit

208-230/460/575V (3 PH)

Unit#: 01-D80-D12-02XX-23 thru -43

Notes:

1. Selective voltage terminals for proper unit voltage.

2. Remove jumper to install field optional low ambient switch.

3. Optional low ambient switch.

4. Optional motorized intake damper.

5. Optional Stop, Start and Jog Control.

6. Optional Motorized Exhaust Damper

7. For energy management systems connect +24v to "G" and common 24v to "C".

8. Optional Wheel Rotation Detection.

9. Optional Dirty Filter Sensors.

PAGE 14

Page 15

SUP PLY

CFM

EXHAUST

CFM

300

500

700

900

1100

300

500

700

900

1100

Blower RPM for D11

Mist Elimi na tor Fil ter in In take Hood (1.5HP)

Ex ter nal Static Pres sure (in wa ter)

0 0.25 0.5 0.75 1 1.25 1.5

N/A N/A 1175 1350 1450 1605 1730

N/A 1170 1340 1540 1655 1725 1840

1295 1425 1600 1625 1795 1960 2035

1540 1660 1720 1790 2030 2110 2195

1785 1915 2025 2185

Ba ro met ric Hood, 2" Pleated Fil ters (1.5HP)

Ex ter nal Static Pres sure (in wa ter)

0 0.25 0.5 0.75 1 1.25 1.5

N/A N/A 1030 1225

N/A 1025 1180 1265 1425 1535

1120 1190 1340 1445 1540 1645 1720

1285 1525 1500 1575 1670 1785 1865

1570 1665 1670 1775 1860 1920

N/A N/A N/A

n/a n/a n/a

n/a

N/A

Notes:

1. Drive losses included in the above tables.

2. Performance can vary depending on ambient conditions.

3. Blower RPMs are for reference only.

Blower RPM for D20

SUP PLY

Mist Elimi na tor Fil ter in In take Hood (2HP)

0 0.25 0.5 0.75 1 1.25 1.5

1055 1135 1295 1420 1540 1650 1725

1140 1240 1340 1490 1600 1690 1795

1200 1330 1460 1565 1645 1740 1830

1320 1405 1525 1615 1705 1785 1885

1415 1515 1605 1690 1775 1875 1960

Ba ro met ric Hood, 2" Pleated Fil ters (2HP)

0 0.25 0.5 0.75 1 1.25 1.5

1010 1195 1350 1445 1580 1685 1735

1125 1315 1435 1545 1620 1730 1800

1185 1370 1500 1610 1695 1790 1965

1305 1485 1600 1685 1781 1955 2030

1410 1550 1670 1765 1855

CFM

EXHAUST

CFM

1200

1400

1600

1800

2000

1200

1400

1600

1800

2000

RPM Range

Low 1000- 1300 Stan dard Unit

Me dium 1300- 1700 Op tional Kit

High 1750-2200 Op tional Kit

Ex ter nal Static Pres sure (in wa ter)

Ex ter nal Static Pres sure (in wa ter)

N/A N/A

Notes:

1. Drive losses included in the above tables.

2. Performance can vary depending on ambient conditions.

3. Blower RPMs are for reference only.

RPM Range

Low 1000- 1300 Stan dard Unit

Me dium 1300- 1700 Op tional Kit

High 1700- 2080 Op tional Kit

PAGE 15

Page 16

SUP PLY

CFM

EXHAUST

CFM

1200

1600

2000

2400

2800

1200

1600

2000

2400

2800

Blower RPM for D28

Mist Elimi na tor Fil ter in In take Hood (3HP)

Ex ter nal Static Pres sure (in wa ter)

0 0.25 0.5 0.75 1 1.25 1.5

N/A 790 960 1110 1210 1315 1380

750 900 1005 1145 1230 1365 1410

900 1005 1105 1210 1275 1400 1450

1005 1125 1210 1275 1365 1450 1500

1125 1230 1315 1380 1450 1535 1600

Ba ro met ric Hood, 2" Pleated Fil ters (3HP)

Ex ter nal Static Pres sure (in wa ter)

0 0.25 0.5 0.75 1 1.25 1.5

750 885 1015 1145 1260 1350 1485

870 1015 1125 1215 1325 1410 1500

1015 1145 1240 1345 1410 1485 1560

1125 1250 1345 1430 1500 1575 1630

1250 1410 1485 1520 1630 1650 1675

Notes:

1. Drive losses included in the above tables.

2. Performance can vary depending on ambient conditions.

3. Blower RPMs are for reference only.

Blower RPM for D36

SUP PLY

Mist Elimi na tor Fil ter in In take Hood (3HP)

0 0.25 0.5 0.75 1 1.25 1.5

725 825 900 1000 1070 1180 1250

800 900 1000 1070 1160 1250 1275

900 1000 1070 1160 1250 1275 1340

1000 1070 1160 1250 1275 1340 1400

1055 1180 1250 1300 1360

Ba ro met ric Hood, 2" Pleated Fil ters (3HP)

0 0.25 0.5 0.75 1 1.25 1.5

750 865 950 1030 1100 1200 1265

820 950 1035 1100 1200 1265 1300

925 1035 1150 1200 1265 1315 1350

1035 1160 1215 1265 1325 1350 1390

1100 1215 1300 1350 1390

CFM

EXHAUST

CFM

2000

2400

2800

3200

3600

2000

2400

2800

3200

3600

RPM Range

Low 750-975 Stan dard Unit

Me dium 1008-1314 Op tional Kit

High 1311-1708 Op tional Kit

Ex ter nal Static Pres sure (in wa ter)

N/A N/A

Ex ter nal Static Pres sure (in wa ter)

N/A N/A

Notes:

1. Drive losses included in the above tables.

2. Performance can vary depending on ambient conditions.

3. Blower RPMs are for reference only.

RPM Range

Low 725-975 Stan dard Unit

Me dium 1000-1315 Op tional Kit

High 1215-1425 Op tional Kit

PAGE 16

Page 17

SUP PLY

CFM

EXHAUST

CFM

3000

3400

3800

4200

4600

3000

3400

3800

4200

4600

Blower RPM for D46

Mist Elimi na tor Fil ter in In take Hood (5HP)

Ex ter nal Static Pres sure (in wa ter)

0 0.25 0.5 0.75 1 1.25 1.5

900 1030 1100 1165 1240 1285 1350

975 1085 1175 1240 1290 1350 1400

1070 1175 1240 1290 1350 1400 1465

1165 1240 1320 1350 1430 1465 1515

1240 1320 1375 1430 1500 1515 1580

Ba ro met ric Hood, 2" Pleated Fil ters (5HP)

Ex ter nal Static Pres sure (in wa ter)

0 0.25 0.5 0.75 1 1.25 1.5

955 1100 1160 1245 1280 1360 1425

1055 1185 1245 1300 1375 1425 1480

1160 1300 1360 1400 1425 1530 1585

1245 1375 1450 1480 1500 1585 1650

1360 1450 1500 1585 1600 1650 1700

Notes:

1. Drive losses included in the above tables.

2. Performance can vary depending on ambient conditions.

3. Blower RPMs are for reference only.

Blower RPM for D62

SUP PLY

Mist Elimi na tor Fil ter in In take Hood (5HP)

0 0.25 0.5 0.75 1 1.25 1.5

815 900 975 1045 1085 1125 1175

880 940 1015 1060 1135 1175

915 975 1045 1125 1150

975 1045 1085 1175

1000 1075 1165

Ba ro met ric Hood, 2" Pleated Fil ters (5HP)

Ex ter nal Static Pres sure (in wa ter)

0 0.25 0.5 0.75 1 1.25 1.5

825 915 1000 1025 1100 1140 1170

890 975 1025 1100 1140 1170 1240

925 1000 1085 1140 1170 1240 1280

975 1025 1140 1170 1240

1025 1120 1170

CFM

EXHAUST

CFM

4600

5000

5400

5800

6200

4600

5000

5400

5800

6200

RPM Range

Low 780- 1020 Stan dard Unit

Me dium 1000- 1315 Op tional Kit

High 1315- 1700 Op tional Kit

Ex ter nal Static Pres sure (in wa ter)

1215

1195 1250

1250 1260 N/A

1200 N/A N/A N/A

N/A N/A

N/A N/A N/A N/A

Notes:

1. Drive losses included in the above tables.

2. Performance can vary depending on ambient conditions.

3. Blower RPMs are for reference only.

RPM Range

Low 820- 1000 Stan dard Unit

Me dium 1000- 1200 Op tional Kit

High 1175- 1375 Op tional Kit

PAGE 17

Page 18

SUP PLY

CFM

EXHAUST

CFM

6000

6400

6800

7200

7600

8000

6000

6400

6800

7200

7600

8000

Blower RPM for D80

Mist Elimi na tor Fil ter in In take Hood (10HP)

Ex ter nal Static Pres sure (in wa ter)

0 0.25 0.5 0.75 1 1.25 1.5

737 794 851 908 961 1012 1061

786 839 893 947 998 1047 1094

836 886 937 987 1036 1083 1129

885 931 979 1027 1074 1119 1163

934 978 1024 1069 1114 1159 1200

983 1025 1068 1111 1154 1196 1237

Ba ro met ric Hood, 2" Pleated Fil ters (7.5HP)

Ex ter nal Static Pres sure (in wa ter)

0 0.25 0.5 0.75 1 1.25 1.5

599 660 716 769 818 866 911

639 695 748 798 846 892 935

679 733 783 831 877 921 963

719 769 817 863 907 949 990

759 808 854 897 940 980 1020

799 845 889 931 972 1011 1049

Notes:

1. Drive losses included in the above tables.

2. Performance can vary depending on ambient conditions.

3. Blower RPMs are for reference only.

Blower RPM for D12

SUP PLY

Mist Elimi na tor Fil ter in In take Hood (15HP)

0 0.25 0.5 0.75 1 1.25 1.5

427 470 512 552 591 630 667

469 509 547 584 621 656 691

512 548 583 618 651 684 717

555 589 621 653 684 715 746

597 629 659 689 718 747 776

640 670 698 726 754 781 808

Ba ro met ric Hood, 2" Pleated Fil ters (15HP)

0 0.25 0.5 0.75 1 1.25 1.5

437 480 521 551 600 639 676

481 520 558 595 631 665 701

525 561 596 630 663 696 728

569 602 634 665 657 727 758

612 643 674 703 732 761 789

656 685 713 741 768 795 822

CFM

EXHAUST

CFM

8000

8800

9600

10400

11200

12000

8000

8800

8600

10400

11200

12000

RPM Range

Low Stan dard Unit

Me dium Op tional Kit

High Op tional Kit

Ex ter nal Static Pres sure (in wa ter)

Ex ter nal Static Pres sure (in wa ter)

Notes:

1. Drive losses included in the above tables.

2. Performance can vary depending on ambient conditions.

3. Blower RPMs are for reference only.

RPM Range

Low Stan dard Unit

Me dium Op tional Kit

High Op tional Kit

PAGE 18

Page 19

PAGE 19

Page 20

START UP INFORMATION SHEET

VOLTAGE - ERV UNIT

In com ing Volt age L1-L2 L1-L3 L2-L3

Run ning Volt age L1-L2 L 1-L3 L2-L3

Sec ond ary Volt age C (black) to G (green) Volts*

C (black) to W (white) Volts*

* With thermostat calling.

AM PER AGE - ERV MO TORS

In take Mo tor: Nom i nal HP Rated Amps Run ning Amps

Ex haust Mo tor: Nom i nal HP Rated Amps Run ning Amps

Wheel Mo tor: Nom i nal HP Rated Amps Run ning Amps

AIRFLOW

In take De sign CFM Pres sure Drop Cal cu lated CFM

Ex haust De sign CFM Pres sure Drop Cal cu lated CFM

Amb. db Temp Re turn Air db Temp* Tem pered Air db Temp*

Amb. wb Temp Re turn Air wb Temp* Tem pered Air wb Temp*

* Measure after 15 minutes of run time

INSTALLATION CHECK LIST

Model # Se rial #

Owner Owner Phone #

Owner Ad dress

In stall ing Con trac tor Start Up Me chanic

q Inspect the unit for transit damage and report any damage on the carrier's freight bill.

q Check model number to insure it matches the job requirements.

q Install field accessories and unit adapter panels as required. Follow accessory and unit installation manuals.

q Verify field wiring, including the wiring to any accessories.

q Check all multi-tap transformers, to insure they are set to the proper incoming voltage.

q Verify correct belt tension, as well as the belt/pulley alignment. Tighten if needed.

q Prior to energizing the unit, inspect all the electrical connections.

q Power the unit. Bump the motor contactor to check rotation. Three phase motors are synchronized at the

factory. If blower motor fans are running backwards, de-energize power to the unit, then swap two of the three

incoming electrical lines to obtain proper phasing. Re-check.

q Perform all start up procedures outlined in the installation manual shipped with the unit.

q Fill in the Start Up Information as outlined on the opposite side of this sheet.

q Provide owner with information packet. Explain the thermostat and unit operation.

PAGE 20

Loading...

Loading...