Page 1

INSTALLATION INSTRUCTIONS

MV75-2ERV

SUPERSEDES 10-05-11

JUNE 4, 2012

EN ERGY RE COV ERY WHEEL

INSTALLATION INSTRUCTIONS FOR MINI VENTILATOR (MV) WITH FACTORY INSTALLED OPTIONS

(LOW AMBIENT, ROTATION SENSOR AND CLIMATE SMART [PATENT PENDING])

USED AS A STAND ALONE OR WITH SPLIT SYSTEMS UNITS

Energy recovery COMPONENT

certified to the AHRI Air-to-Air

Energy Recovery Ventilation

Equipment Certification Program in

accordance with AHRI Standard

1060-2000. Actual performance in

packaged equipment may vary.

ETL Certified per UL 1995

and CSA 22.2

I - Ship ping And Pack ing List

Package 1 of 1 contains:

1 - Mini Ventilator Assembly (See Figure 1)

II - Ship ping Dam age

Check unit for shipping damage. Receiving party should

contact last carrier immediately if shipping damage is

found.

III - Gen eral

These instructions are intended as a general guide and do

not supersede local codes in any way. Authorities having

jurisdiction should be consulted before installation.

IV - Re quire ments

When installed, the unit must be electrically wired and

grounded in accordance with local codes or, in the

absence of local codes, with the current National Electric

Code, ANSI/NFPA No. 70.

V - Ap pli ca tion

Mini Ventilators (MV) are used as stand alone. These

ventilators conserve energy by mixing warmer air with

cooler air in the following manner:

Re cov ery Wheel Mode

The Recovery Wheel mode is accomplished by two

blowers providing continuous exhaust of stale indoor air

and replacement by equal amount of outdoor air. Energy

recovery is achieved by slowly rotating the energy

recovery wheel within the cassette frame work. In winter,

the MV adsorbs heat and moisture from the exhaust air

stream during one half of a complete rotation and gives

them back to the cold, drier intake air supply during the

other half rotation. In summer, the process is automatically

reversed. Heat and moisture are absorbed from incoming

intake air supply and transferred to the exhaust air stream.

This process allows outdoor air ventilation rates to be

increased by factors of three or more without additional

energy penalty or increase in size of heating or air

conditioning systems.

VI - Rig ging Unit For Lift ing

1. Maximum weight of unit is

Model# C25 / MV250 C45 / MV450 C75 / MV750

Net Weight 195 195 225

Ship Weight 215 215 261

2. Remove carton.

3. All panels must be in place for rigging.

CAUTION

Danger of sharp metallic edges. Can cause injury.

Take care when servicing unit to avoid accidental

contact with sharp edges.

WARNING

Electric shock hazard. Can cause injury

or death. Before attempting to perform

any service or maintenance, turn the

electrical power to unit OFF at

disconnect switch(es). Unit may have

multiple power supplies.

Figure 1

PAGE 1

Page 2

VII - In stal la tion

The unit can be installed using two different intakes

general configurations. The unit is shipped in horizontal

intake configuration. Please refer to the following diagrams

for installation instructions:

Note: All duct work and flex connectors are field

supplied.

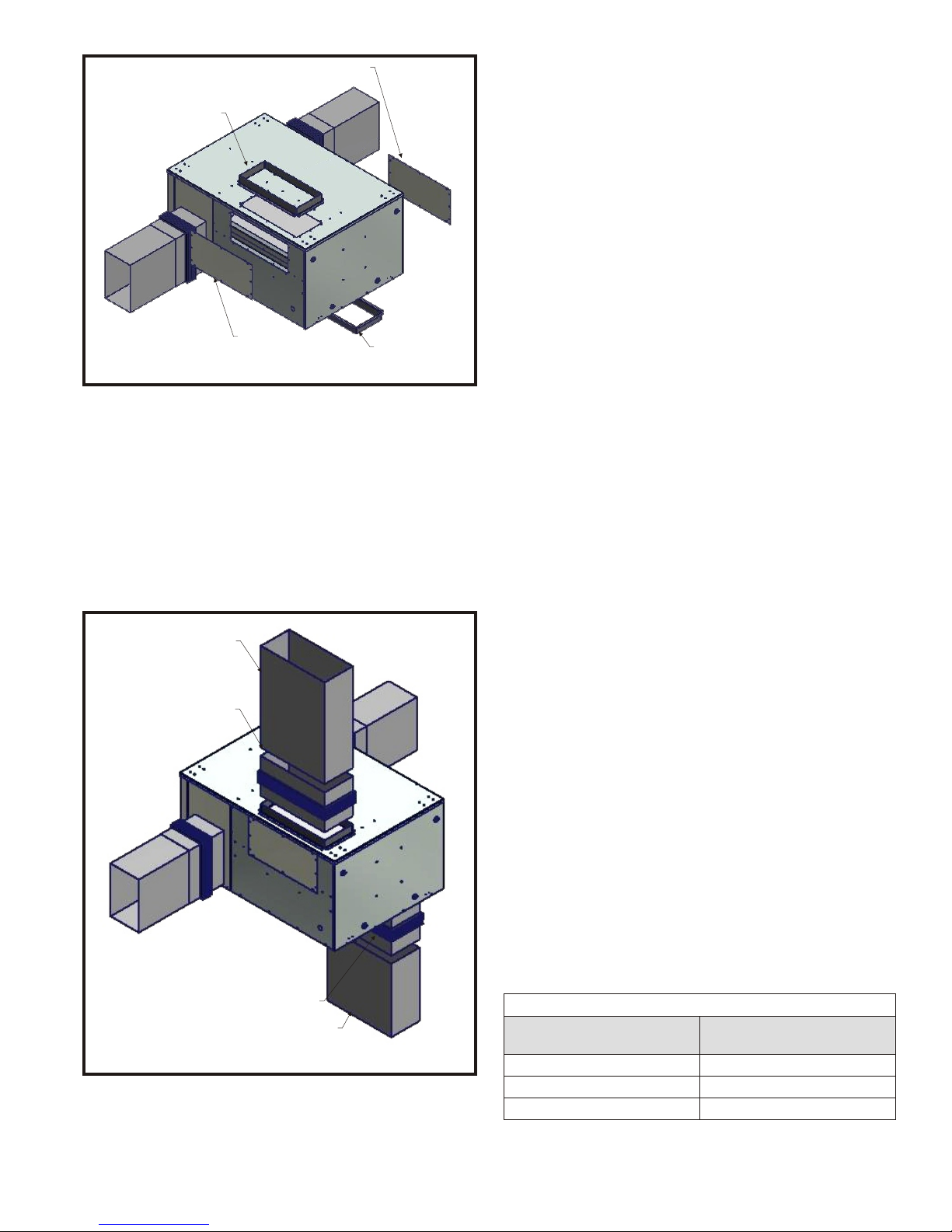

A - Hor i zon tal Configuration Duct Work In stal la tion

1. Attach Flexible Duct Collar to the MV fresh air intake

and secure with screws. See Figure 2.

2. Attach fresh air supply duct work to fresh air supply

Flexible Duct Collar and secure with screws. See

Figure 2.

3. Attach Flexible Duct Collar return air exhaust and

secure with screws. See Figure 2.

4. Attach return air exhaust duct work to return air

exhaust Flexible Duct Collar and secure with screws.

See Figure 2.

RE TURN AIR EX HAUST

RE TURN AIR EX HAUST

FLEX I BLE DUCT COLLAR

DUCT WORK

RE TURN AIR INTAKE

FLEX I BLE DUCT COLLAR

RE TURN AIR INTAKE

DUCT WORK

FRESH AIR INTAKE

FRESH AIR INTAKE

DUCT WORK

FLEX I BLE DUCT COLLAR

Figure 3

4. Attach return air exhaust duct work to return air

exhaust Flexible Duct Collar and secure with screws.

See Figure 2.

5. Remove fresh air intake duct collar from lateral intake.

See Figure 4.

6. Remove return air intake duct collar from lateral

intake. See Figure 4.

FRESH AIR SUPPLY

FRESH AIR SUPPLY

DUCT WORK

FLEX I BLE DUCT COLLAR

Figure 2

5. Attach Flexible Duct Collar to MV fresh air intake and

secure with screws. See Figure 3.

6. Attach fresh air intake duct work to fresh air intake

Flexible Duct Collar and secure with screws. See

Figure 3.

7. Attach Flexible Duct Collar to return air intake and

secure with screws. See Figure 3.

8. Attach return air intake duct work to return air intake

Flexible Duct Collar and secure with screws. See

Figure 3.

B - Top/Bottom Configuration Duct Work Installation

1. Attach Flexible Duct Collar to the MV fresh air intake

and secure with screws. See Figure 2.

2. Attach fresh air supply duct work to fresh air exhaust

Flexible Duct Collar and secure with screws. See

Figure 2.

3. Attach Flexible Duct Collar return air exhaust and

secure with screws. See Figure 2.

7. Remove cover panel from top fresh air intake. See

Figure 4.

8. Remove cover panel from bottom return air intake.

See Figure 4.

RE TURN AIR INTAKE

DUCT COLLAR

FRESH AIR INTAKE

COVER PANEL

FRESH AIR INTAKE

DUCT COLLAR

Figure 4

RETURN AIR INTAKE

COVER PANEL

9. Attach fresh air duct collar to top fresh air intake and

secure with provided screws. See Figure 5.

10. Attach return air duct collar to bottom return air intake

and secure with provided screws. See Figure 5.

11. Attach fresh air cover panel to lateral fresh air intake

and secure with provided screws. See Figure 5.

12. Attach return air cover panel to lateral return air intake

and secure with provided screws. See Figure 5.

PAGE 2

Page 3

RE TURN AIR IN TAKE

COVER PANEL

FRESH AIR IN TAKE

DUCT COL LAR

FRESH AIR INTAKE

COVER PANEL

Figure 5

RE TURN AIR INTAKE

DUCT COLLAR

13. Attach Flexible Duct Collar to the MV fresh air intake

and secure with screws. See Figure 6.

14. Attach fresh air intake duct work to fresh air intake

Flexible Duct Collar and secure with screws. See

Figure 6.

15. Attach Flexible Duct Collar to return air intake and

secure with screws. See Figure 6.

16. Attach return air intake duct work to return air intake

Flexible Duct Collar and secure with screws. See

Figure 6.

FRESH AIR IN TAKE

DUCT WORK

FRESH AIR IN TAKE

FLEX I BLE DUCT COL LAR

VIII - Op er a tion

How It Works

The unit contains an Mini Ventilator that is a new concept in

a rotary air-to-air heat exchanger. Designed as a

packaged unit for ease of installation and maintenance,

only connection of electrical power is required to make the

system operational. The concept consists of a unique

rotary energy recovery wheel that rotates in and out of

fresh air streams within a heavy duty, permanently

installed blower cabinet that provides ready access to all

internal components. The Energy Recovery Wheel

contains spirally wound polymeric material that is coated

and permanently bonded with a silica gel desiccant for

transfer of sensible and latent heat. The wheel is belt

driven by one motor and stretch urethane perimeter drive

belt.

When slowly rotating through counter flowing exhaust and

intake air streams the MV adsorbs sensible heat and latent

heat from the warmer air stream and transfers this total

energy to the cooler air stream during the second half of its

rotating cycle. Rotating the wheel provides constant flow of

energy from warmer to cooler air stream. The large

energy transfer surface and laminar flow through the wheel

causes this constant flow of recovered energy to

represent up to 85% of the difference in total energy

contained within the two air streams.

Sensible and latent heat are the two components of total

heat. Sensible heat is energy contained in dry air and latent

heat is the energy contained within the moisture of the air.

The latent heat load from the outdoor fresh air on an air

conditioning system can often be two to three times that of

the sensible heat load and in the winter it is a significant

part of a humidification heat load.

During both the summer and winter, the MV transfers

moisture entirely in the vapor phase. This eliminates wet

surfaces that retain dust and promote fungal growth as well

as the need for a condensate pan and drain to carry water.

Because it is constantly rotating when in the air stream, the

MV is always being cleared by air, first in one direction

then the other. Because it is always dry, dust or other

particles impinging on the surface during one half cycle,

are readily removed during the next half cycle.

RE TURN AIR INTAKE

FLEX I BLE DUCT COLLAR

RE TURN AIR INTAKE

DUCT WORK

Figure 6

PAGE 3

In the heating season, when outdoor air temperatures are

below 10oF, it is recommended to use the (optional) low

ambient kit (factory installed 02 models only). At these

conditions you will need to determine the frost threshold

parameters.

The frost threshold is the outdoor temperature at which

frost will begin to form on the MV wheel. For energy

recovery ventilators, the frost threshold is typically below

10oF. Frost threshold is dependent on indoor temperature

and humidity. The table shows how the frost threshold

temperatures vary depending on indoor conditions.

FROST THRESH OLD TEM PER A TURE

IN DOOR RH AT 70oF

FROST THRESH OLD

TEM PER A TURE

20% 0oF

30% 5oF

40% 10oF

Page 4

Because Mini Ventilators have a low frost threshold, frost

control options are not necessary in many climates. Where

outdoor temperatures may drop below the frost threshold

during the MV operational hours, exhaust only frost control

option is available.

IX - Standard Features

Low Am bi ent Kit

Extremely cold outdoor air temperatures can cause

moisture condensation and frosting on the energy

recovery wheel (ERW). The outside temperature below

which frost will begin to accumulate is referred to as the

Frost Threshold Temperature, and is a function of both the

indoor DB temperature and the indoor relative humidity

See Table #2. Frost formation causes reduction of airflow

through the ERW; therefore, without frost control, energy

recovery and airflow may be significantly reduced.

A thermostat control is provided to shut down the supply

blower when outdoor temperature drops to a field-selected

frost control setting. The thermostat is located within the

outdoor air intake hood. To avoid depressurization of the

conditioned space, automatic or pressure operated fresh

air dampers may be required as part of the ventilation

system. Factory setting is 20oF.

FROST THRESH OLD TEM PER A TURE (OD DB)

IN DOOR

RH (%)

20

30

40

50

60

IN DOOR DB TEMPERATURE

70oF 72oF 75oF 80oF

-14 -13 -11 -8

-3 -2 -1 3

5 7 9 11

13 13 15 18

18 19 21 26

Table #2

Rotation Sensor

The circuit indicates the absence of pulses, within a

specified time range, provided by a magnetic sensor

detecting a magnet mounted on wheel surface. After the

initial time delay of approximately 5 seconds from circuit

power up, if the sensor fails to provide a signal pulse (no

wheel rotation) within approximately 5 additional seconds,

the alarm relay will activate the latch (until circuit powers

down) providing a 5 amp contact closure output. This

would indicate no wheel rotation and/or magnet in the

system has stopped at the magnetic sensor pickup point. If

the pulse (wheel rotation) is detected within the

approximately 5 second time period, the alarm relay will

remain open. No field timing adjustment of any type will be

required.

of the circuit board. The following diagram details the

jumper location for each mode of operation:

Temperature Control (See Figure 7)

The temperature mode of operation incorporates one

sensor located in the fresh air intake of the ERV. The Start

Stop Jog sequence is activated when the outside air

temperature is between 70°F and 40°F. The SSJ module

provides two potentiometers in order to adjust the Low and

High temperature range of the start stop jog sequence. To

adjust the High temperature range, place a Multimeter on

the COM and HIGH test points. Use a screw driver to

adjust the potentiometer to the desired VDC representing

the temperature. The Low temperature range is adjusted

by placing a Multimeter on the COM and LOW test points

with the adjustment of the potentiometer to the desired

VDC representing temperature. The VDC can be

calculated for a desired temperature using the following

formula: VDC = 0.1429 x (Temperature) - 5.7143.

Figure 7

Enthalpy Control (See Figure 8)

The enthalpy mode of operation incorporates one enthalpy

sensor located in the fresh air intake of the ERV. The SSJ

module compares the outdoor enthalpy to a preselected

set point. The value of the set point can be identified on a

psychometric chart with the standard control curves as A,

B, C or D. The set point can be selected as an aggressive

set point A for higher levels of free cooling or a

conservative set point D for lower levels of free cooling.

The Enthalpy sensor provides a 4-20 mA (0-100%) signal

proportional to the selected control curve A, B, C, or D. The

SSJ module begins the start stop jog sequence when the

Enthalpy sensor reports 60%. The Enthalpy 60% setpoint

for each control curve is detailed in the following table:

Climate Smart [Patent Pending]

There are three modes of control strategies available.

Temperature, Single Enthalpy, or Enthalpy and

Temperature control.

Mode of Operation

The mode of operation is selected with the adjustment of a

jumper. The jumper is located at the lower center position

Figure 8

PAGE 4

Page 5

Enthalpy and Temperature (See Figure 9)

The combination mode of operation will activate the Start

Stop Jog sequence when the Enthalpy meets the control

curve setpoint and the outside air temperature is between

the Low and High temperature setpoint.

Figure 6

LED and Test Switch

There is a +5V LED indicating the module is wired and

powered properly. If the LED is not illuminated check the

wiring and power supply. The SSJ LED indicates when the

SSJ module has entered the start stop jog sequence. The

RELAY LED illuminates when the relay is activated cutting

power to the relay contacts.

The pushbutton on the module is used to test the relay.

When the pushbutton is activated the LED under the

button illuminates. The LED indicates test mode of the

relay is operating. The SSJ sequence will not operate while

the module is test mode.

Re cov ery Wheel Mode

On a call for operation the MV media will rotate between

intake air and exhaust air streams. Both the intake air

blower and exhaust air blowers will also be operating to

overcome the air resistance of the MV media.

X - Sys tem Check

1. Disconnect MV main power.

2. Remove control access panel and apply jumper to low

voltage terminal strip at “1” and “3”.

3. Restore power to unit. Observe MV drive motor for

wheel and both blowers are running.

4. Verify that the MV blower motors are set to “high”

speed for correct speed and operation.

A - Blower Speed Ad just ment

Blower speed selection is accomplished by changing the

speed selection switch on terminal strip in control box.

Both fresh air and exhaust air blowers are direct drive

multi-tap motors. Both blowers are factory set at “high”

speed for maximum airflow. To determine air flow setting,

external static pressure readings will need to be read

across the MV.

B - Air Bal anc ing Ad just ment

1. Remove plastic plugs in door panels(4 total).

2. With a manometer measure pressure drop [inches of

water column] across left half of MV(top and bottom

holes in door panel). Unit CFM is determined then by

referring to Table #2.

3. Repeat the same process for the right half of MV.

4. Place plastic plugs back in to door panels.

XI - Main te nance

1. All motors use prelubricated sealed bearings; no

further lubrication is necessary.

2. Make visual inspection of filters, motor assemblies

and MV rotating bearings during routine maintenance.

3. Filters should be checked periodically and cleaned

when necessary. Filter is located in front of MV unit

and before blower cabinet.

4. MV segment is positioned on a shaft extended from

middle support bar. Annual inspection of the self

cleaning wheel is recommended. With power

disconnected, remove MV access panels and unplug

[J150 & P150] (Refer to wiring diagram in this

instruction manual). Then remove wheel cassette

from cabinet by sliding assembly out of support tracks

Ex ter nal Static Pres sure

CFM

Ex ter nal Static Pres sure

CFM

Ex ter nal Static Pres sure 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

CFM

Low 498 479 459 435 411 384 347 307 263 218 175

High 592 565 530 496 463 431 398 356 311 262 218

Low 656 640 625 609 590 570 552 538 511 477 440

Me dium 729 708 690 671 649 627 605 582 560 530 495

High 783 765 740 721 700 678 650 622 598 580 560

Low 823 822 821 819 808 790 778 762 755 738 718

Me dium 997 992 985 975 960 940 928 905 884 872 850

High 1162 1145 1130 1104 1095 1090 1068 1047 1020 998 967

0.0

0.0

C25 / MV250 Cab i net

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

C45 / MV450 Cab i net

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

C75 / MV750 Cab i net

Table #2

PAGE 5

Page 6

in center of unit. Discoloration and staining of wheel

segment does not affect its performance. Only

excessive buildup of foreign material need be

removed. If the segment appears excessively dirty, it

should be cleaned to ensure maximum operating

efficiency. Thoroughly spray plastic surface with

household cleaner such as Fantastic® or equivalent or

middle detergent and gently rinse with warm water

using a soft brush to remove heavier accumulation.

Shake excess water from segment and replace in

reverse of removal instructions.

A - Wheel Removal (See Figure 10)

1. Remove Filter Access panel to expose wheel.

2. Disconnect wheel electrical harness.

3. Carefully slide the wheel outwards.

WHEEL

WHEEL ELEC TRI CAL HARNESS

FIL TER AC CESS PANEL

Figure 10

B - Filter Removal (See Figure 11)

1. Remove the Filter Access panel to expose filters.

2. Remove the filter pushers.

3. Slide filters outwards.

TERMINAL BLOCK

CONTROL BOX

Figure 12

XII - War ranty

RRS Man u fac tured Parts

In the event that defects in workmanship or materials

originate in any part manufactured by RRS, FOB point of

manufactured, we guarantee to repair or replace that part,

within three (3) months of the shipment date.

Other Sup plied Parts

Additionally, RRS guarantees to replace standard

components purchased new from a RRS vendor, (motors,

controls, etc.) that may be found defective, within twelve

(12) months of the installation date. The components

warranty, however, excludes service call charges and

labor cost for replacing or adjusting the defective part.

Lim i ta tion Of War ran ties

Misapplication, destruction, negligence or alteration

constitute the warranty and/or the components warranty of

RRS products and/or parts, null and void. This warranty is

provided in lieu of all other written, stated or implied

warranties.

FILTER

FIL TER PUSHER

FIL TER AC CESS PANEL

Figure 11

C - Control Box Location (See Figure 12)

The control box is located on the bottom left hand corners

of the MV when the Filter Access Panel is removed.

PAGE 6

Page 7

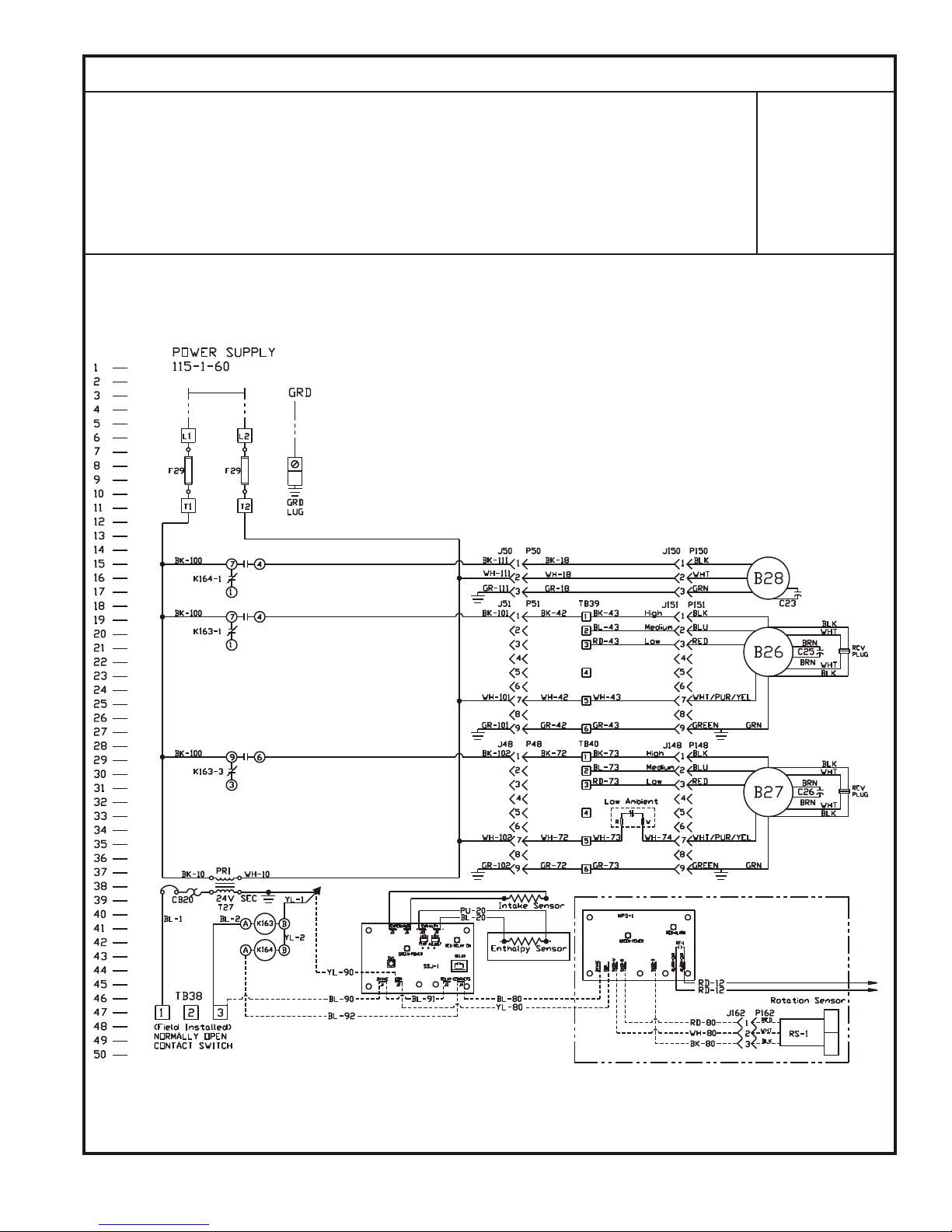

C25/MV250 UNIT SCHE MATIC DIAGRAM

B26 Mo tor, Ex haust Air

B27 Mo tor, Fresh Air

B28 Mo tor, Desiccant Wheel

C23 Ca pac i tor, W heel Mo tor

C25 Ca pac i tor, Mo tor Ex haust Air

C26 Ca pac i tor, Mo tor Fresh Air

CB20 Cir cuit Breaker, Trans former

ES Sen sor, Enthalpy

F29 Fuse

J48 Jack, Con trol Box (Fresh Air)

J50 Jack, Con trol Box (Wheel)

COM PO NENT CODE

J51 Jack, Con trol Box (Ex haust Air)

J148 Jack, Fresh Air Mo tor Har ness

J150 Jack, Wheel Mo tor Har ness

J151 Jack, Ex haust Air Mo tor Har ness

K163 Re lay, Mo tors

K164 Re lay, Wheel

LA Switch, Low Ambient

MPD-

Board, Rotation

1

P48 Plug, Con trol Box (Fresh Air)

P50 Plug, Con trol Box (Wheel)

P51 Plug, Con trol Box (Ex haust Air)

P148 Plug, Fresh Air Mo tor

P150 Plug, Wheel Mo tor

P151 Plug, Ex haust Air Mo tor

RS-1 Sen sor, Rotation

S26 Switch, Low Am bi ent (Op tional)

SSJ-1 Board, Start-Stop-Jog

T27 Trans former, Step-down

TB38 Ter mi nal Block (Low Volt age)

TB39 Ter mi nal Block (High Volt age, Ex haust)

TB40 Ter mi nal Block (High Volt age, Fresh)

TS Sen sor, Temperature

WIRE COLOR

BK Black

BL Blue

GR Green

OR Orange

PU Violet

RD Red

WH Whit e

YL Yel low

MV75-2ERW

PAGE 7

Page 8

snoi tpO dellat snI yro tcaF /W ro ta li tneV iniM

10-Hx2052 C-10 :#tinU

)HP 1( V511

MARGAID GN IRIW TINU 052VM/52C

PAGE 8

Page 9

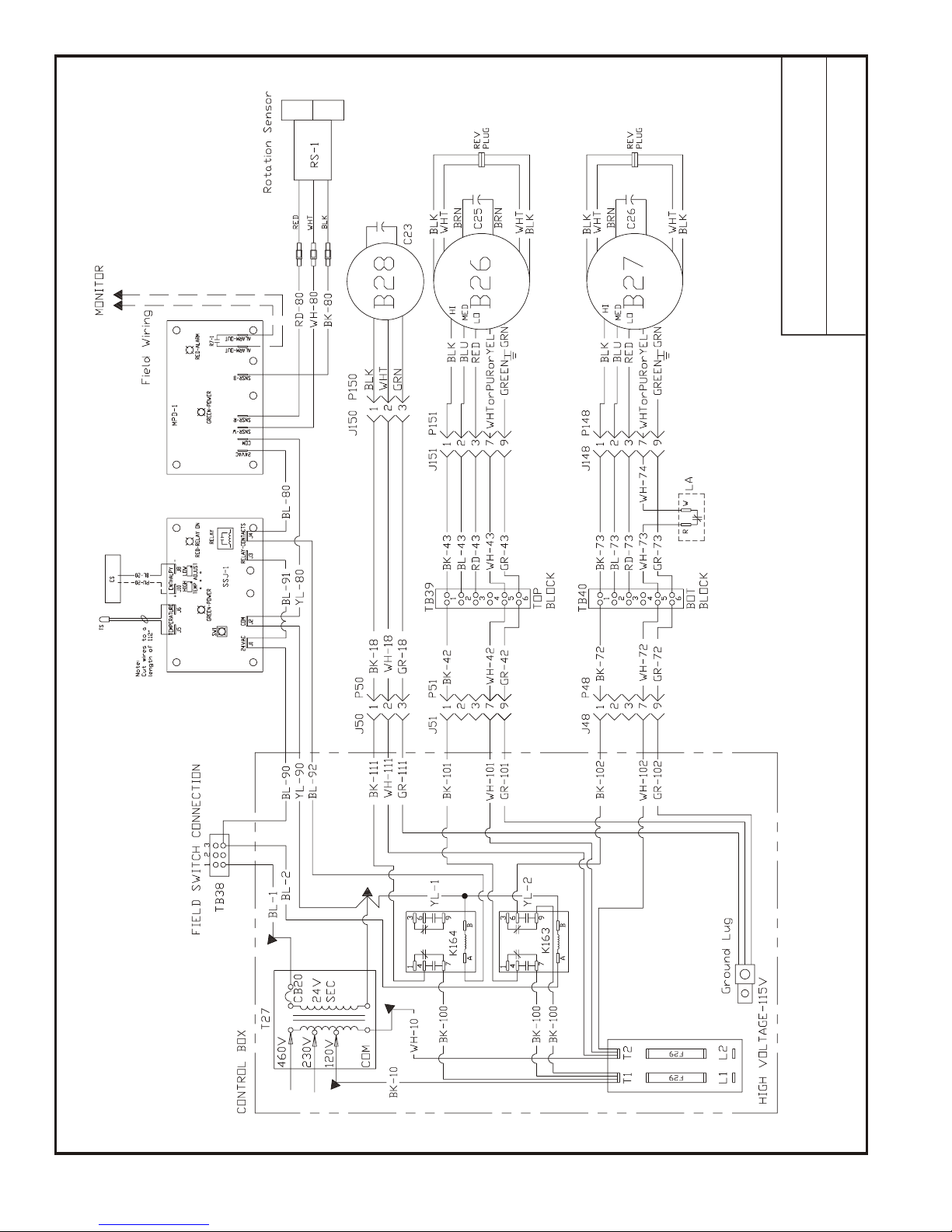

C45/MV450 / C75/MV750 UNIT SCHE MATIC DIAGRAM

B26 Mo tor, Ex haust Air

B27 Mo tor, Fresh Air

B28 Mo tor, Desiccant Wheel

C23 Ca pac i tor, W heel Mo tor

C25 Ca pac i tor, Mo tor Ex haust Air

C26 Ca pac i tor, Mo tor Fresh Air

CB20 Cir cuit Breaker, Trans former

ES Sen sor, Enthalpy

F29 Fuse

J48 Jack, Con trol Box (Fresh Air)

J50 Jack, Con trol Box (Wheel)

COM PO NENT CODE

J51 Jack, Con trol Box (Ex haust Air)

J148 Jack, Fresh Air Mo tor Har ness

J150 Jack, Wheel Mo tor Har ness

J151 Jack, Ex haust Air Mo tor Har ness

K163 Re lay, Mo tors

K164 Re lay, Wheel

LA Switch, Low Ambient

MPD-

Board, Rotation

1

P48 Plug, Con trol Box (Fresh Air)

P50 Plug, Con trol Box (Wheel)

P51 Plug, Con trol Box (Ex haust Air)

P148 Plug, Fresh Air Mo tor

P150 Plug, Wheel Mo tor

P151 Plug, Ex haust Air Mo tor

RS-1 Sen sor, Rotation

S26 Switch, Low Am bi ent (Op tional)

SSJ-1 Board, Start-Stop-Jog

T27 Trans former, Step-down

TB38 Ter mi nal Block (Low Volt age)

TB39 Ter mi nal Block (High Volt age, Ex haust)

TB40 Ter mi nal Block (High Volt age, Fresh)

TS Sen sor, Temperature

WIRE COLOR

BK Black

BL Blue

GR Green

OR Orange

PU Violet

RD Red

WH Whit e

YL Yel low

MV75-2ERW

PAGE 9

Page 10

snoi tpO dellat snI yro tcaF /W ro ta li tneV iniM

10-Hx2057C/54 C-10 :#tinU

)HP 1( V511

MARGAID GN IRIW TINU 057VM/57C / 054VM/54C

PAGE 10

Page 11

START UP INFORMATION SHEET

VOLTAGE - MV UNIT

In com ing Volt age L1-L2

Run ning Volt age L1-L2

Sec ond ary Volt age

AM PER AGE - MV MO TORS

In take Mo tor: Nom i nal HP Rated Amps Run ning Amps

Ex haust Mo tor: Nom i nal HP Rated Amps Run ning Amps

Wheel Mo tor: Nom i nal HP Rated Amps Run ning Amps

AIR FLOW

In take De sign CFM Pres sure Drop Cal cu lated CFM

Ex haust De sign CFM Pres sure Drop Cal cu lated CFM

Amb. db Temp Re turn Air db Temp* Tem pered Air db Temp*

Amb. wb Temp Re turn Air wb Temp* Tem pered Air wbTemp*

* Mea sure af ter 15 min utes of run time

IN STAL LA TION CHECK LIST

MV Model # Se rial #

Owner Owner Phone #

Owner Ad dress

In stall ing Con trac tor Start Up Me chanic

q Inspect the unit for transit damage and report any damage on the carrier’s freight bill.

q Check model number to insure it matches the job requirements.

q Install field accessories and unit adapter panels as required. Follow accessory and unit installation manuals.

q Verify field wiring, including the wiring to any accessories.

q Check all multi-tap transformers, to insure they are set to the proper incoming voltage.

q Verify blower wheels are centered. Realign if needed.

q Prior to energizing the unit, inspect all the electrical connections.

q Power the unit. Bump the motor relay to check rotation. If blower motor fans are running backwards,

de-energize power to the unit, then swap reversing plug on motors to change direction. Re-check.

q Perform all start up procedures outlined in the installation manual shipped with the unit.

q Fill in the Start Up Information as outlined on the opposite side of this sheet.

q Provide owner with information packet. Explain the thermostat and unit operation.

PAGE 11

Loading...

Loading...