PressureMAT™

System User Guide

Revision 7

www.pendotech.com

PressureMAT User Guide

WARNING: DANGEROUS VOLTAGE INSIDE THE CONTROL BOX.

CONTROL BOX ONLY TO BE OPENED BY PENDOTECH OR AUTHORIZED

REPRESENTATIVE. NO USER SERVICEABLE PARTS INSIDE.

WARNING: POTENTIAL SHOCK HAZARD. UNLESS PROPERLY PANEL

MOUNTED, DO NOT USE THIS PRODUCT NEAR WATER OR IF YOU ARE

WET. DO NOT SUBMERGE THIS PRODUCT. USE ONLY IN A GROUNDED

ELECTRICAL OUTLET. UNLESS PROPERLY PANEL MOUNTED, UNPLUG

THE PRODUCT FROM THE OUTLET BEFORE CLEANING WITH ANY

LIQUIDS. INSTALL SECURELY ON A STABLE SURFACE. INSTALL IN A

LOCATION WHERE NO ONE CAN STEP ON OR TRIP OVER THE POWER

CORD AND WHERE THE POWER CORD WILL NOT BE DAMAGED.

Revision 7

PressureMAT System User Guide

Model PMAT2

Model PMAT2P

Model PMAT3

Model PMAT3P

Model PMAT4A

Model PMAT4R

Model PMAT3A

Model PMAT2A

Model PMAT2F

Model PMAT2HR

Model PMAT-S

Model PMAT-SHR

All rights reserved. No part of this publication may be reproduced, stored in an electronic retrieval system, or transmitted,

in any form or by any means, whether electronic, mechanical, by photocopying, or otherwise, without the written consent

of PendoTECH.

The information in this User Guide is believed to be accurate and reliable for use and operation of the control system,

however, PendoTECH assumes no responsibility for the use of this product except for what is covered in the Limited

Warranty and Terms and Condition of Sale.

PressureMAT is a Trademark of PendoTECH Copyright © 2010 -2014, PendoTECH

Used throughout this guide:

WARNING: “WARNING” is used to indicate the presence of a hazard which can cause severe

personal injury, death, or substantial property damage if the warning is ignored.

Note: “Note” is used to notify the user of installation or operation information which is

important but not hazard related.

WARNING: GOODS AND SOFTWARE ARE NOT DESIGNED, INTENDED OR AUTHORIZED FOR USE AS

COMPONENTS IN LIFE SUPPORT OR MEDICAL DEVICES. THEY ARE NOT DESIGNED FOR ANY

APPLICATION IN WHICH THE FAILURE OF THE PRODUCT COULD RESULT IN PERSONAL INJURY,

DEATH OR PROPERTY DAMAGE.

Page 2/47

PressureMAT User Guide

Revision 7

Table of Contents

1. Overview of PendoTECH PressureMAT................................................................................ 4

1.2. Instrument Details .................................................................................................................... 6

1.2.1. Hardware Details ................................................................................................................. 6

1.2.2. Software Details ................................................................................................................. 12

2. Setup and Use of the System ................................................................................................ 22

2.1. System Setup* ........................................................................................................................ 22

2.2. Using the System* ................................................................................................................. 23

3. Flow Meter Function in PressureMAT-PLUS (2P, 3P & 2F) .............................................. 24

3.1. Display ................................................................................................................................... 24

3.2. Back Panel ............................................................................................................................. 24

3.3. Connection to Back Panel ...................................................................................................... 25

3.4. Navigation in the Flow Meter Input Channel ........................................................................ 25

4. Analog Input Function in PressureMAT-PLUS (2P, 3A & 2A only)................................... 29

4.1. Display ................................................................................................................................... 29

4.2. Back Panel ............................................................................................................................. 29

4.3. Connection to Back Panel ...................................................................................................... 30

4.4. Navigation in the Analog Input Channel ............................................................................... 30

5. Cable Information ................................................................................................................. 33

5.1. Cable for Pressure Inputs ....................................................................................................... 33

APPENDIX A: PRODUCT WARRANTY ................................................................................. 34

APPENDIX B: PendoTECH Single Use Pressure Sensors ......................................................... 35

APPENDIX C: PressureMAT Data Acquisition Software .......................................................... 36

APPENDIX D: Panel Mount of System ...................................................................................... 38

APPENDIX E: EC Declaration of Conformity ........................................................................... 40

APPENDIX F: Pinch Valve Box Accessory (PDKT-PVE) ........................................................ 41

APPENDIX G: Using the PressureMAT with WinWedge Software .......................................... 43

APPENDIX H: PressureMAT Smoothing Function (PV Filter) ................................................. 44

Page 3/47

PressureMAT User Guide

Model Number

Number of

Inputs

Number of

Outputs

Outputs

PMAT2* 2 4

2 Relays / 2 Analogs or 4 Relays

PMAT2P

2 pressure/1

flow/1 analog

4

4 Analogs [may be re-configured]

PMAT3 3 4

3 Analogs / 1 Relay (for all sensors)

PMAT3P

3 pressure/1 flow

4

4 Analogs [may be re-configured]

PMAT4A 4 4

4 Analogs

PMAT4R 4 4

4 Relays

PMAT3A

3 pressure/

1 analog

4

4 Analogs [may be re-configured]

PMAT2A

2 pressure/

2 analog

4

4 Analogs [may be re-configured]

PMAT2F

2 pressure/

2 flow

4

4 Analogs [may be re-configured]

PMAT-S* 1 3

1 Relay /1 Analog / 1 remote tare

Revision 7

1. Overview of PendoTECH PressureMAT

The PressureMAT is a monitor, alarm, and transmitter system designed for use with Single Use

Pressure Sensors from PendoTECH. It is comprised of the control system box with user interface and

the connectors on the back panel where input and output components can be interfaced. If equipped,

the alarm output function includes a dry contact relay output. The transmitter function delivers an

analog 4 – 20 milliamp output signal corresponding to the pressure reading on the display. There are

numerous applications in biopharmaceutical production processes where the system can be used.

The models are as follows:

* Available in “High Resolution” model with HR suffix

System Components Supplied:

PressureMAT Instrument

Cable(s) for connection of pressure sensors to the control system

Connectors for cable for each output

4 Screws for mounting

Power supply

Options:

PMAT-STND Benchtop Stand

PMAT-GUI PressureMAT Data Acquisition Software (Appendix C)

PDKTP-RS232U RS-232 cable for data output to a PC via USB

PMAT-PANEL Panel mount kit (Appendix D)

PMAT-WALL4 Wall mount stainless steel box

PDKT-650-298CVR Pressure sensor cable dust cover / zero simulator for PressureMAT

PressureMAT Carts – contact PendoTECH for details

Page 4/47

PressureMAT User Guide

Benchtop Stand

Wall Mount Stainless Steel Box

Revision 7

1.1. PressureMAT Instrument

The PressureMAT with its user interface is used to display pressure readings, zero calibrate the

pressure sensor, and to access the program menus to edit the alarm high and low set point values and

other tasks.

The sensor pressure is displayed on the LCD display for each input channel. High and low alarm

pressure set points are entered on the keypad for each channel and if the process pressure goes below

the low setting or above the high setting, the system will go into alarm state. With models with the

relay output, the alarm function includes activation of the dry contact relay output, a flashing

“ALARM>” indication on LCD on the same line as the pressure input channel in the alarm state, and

an audible tone for 30 seconds. When an alarm condition goes away, all indicators automatically go

back to normal (unless the optional alarm latching function is turned on which requires STOP to be

pressed to clear the alarm). The alarm functions are always active for all channels. For the

PressureMAT PLUS models, flow or a scaled analog input value can measure & display other values.

Also available is a single channel model PMAT-S:

The model has a unique remote pressure tare input.

Some available options:

Page 5/47

PressureMAT User Guide

LCD BACKLIT

DISPLAY

KEYPAD

Revision 7

1.2. Instrument Details

1.2.1. Hardware Details

There is no power switch so the system cannot be accidentally turned off. When the wall power

supply is connected to the system and plugged into a wall outlet, the system will turn ON. Instructions

to power down the system without unplugging are in Section 1.2.2 (System Power). The Front and

Back Panels details are as shown:

FRONT PANEL:

Note: If a pressure sensor is not connected or is disconnected during operation of the system,

the pressure reading will drift and eventually go to a value greater than 75psi/5.17 bar and an

alarm condition will occur. The time until the high alarm occurs may vary and this feature

should not be used to control a process due to the time variance. Associated relays will switch

and the analog output will send greater than 20mA.

The Sensor Cable Dust Cover / Zero Simulator for PressureMAT (PDKT-650-298CVR) can be used

to:

1) Maintain a zero pressure when a channel is not in use

2) Protect the pins on the re-usable cable

Page 6/47

PressureMAT User Guide

Revision 7

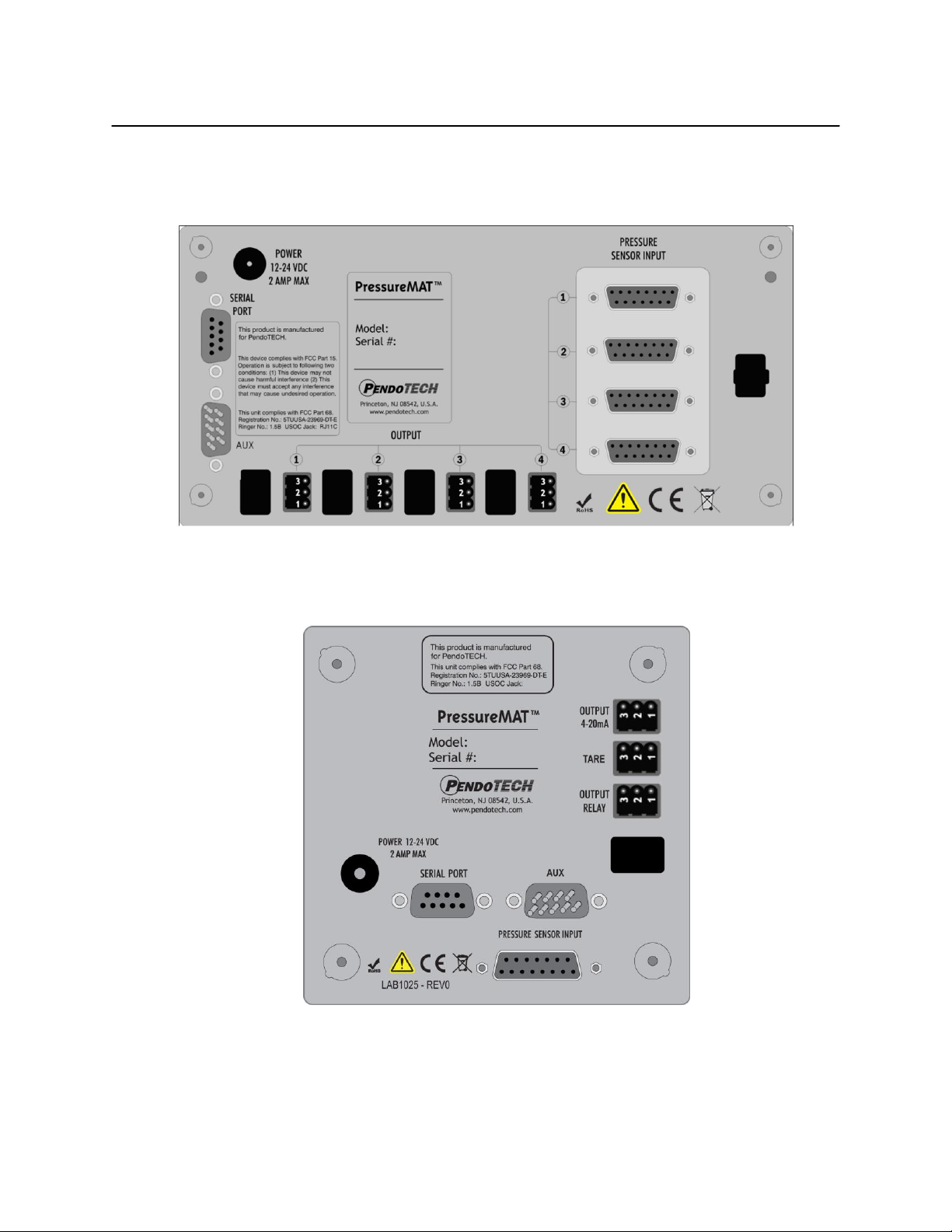

BACK PANEL CONFIGURATIONS:

PMAT2- Two Input Unit (two relays, one for each channel;4-20mA for each channel):

PMAT3- Three Input Unit:

Page 7/47

PressureMAT User Guide

Revision 7

PMAT4x- Four Input Unit (If 4R outputs are relays; if 4A, outputs are 4-20mA):

PMAT-S - One Input Unit:

NOTE: The PMAT2P, PMAT3P, PMAT3A, PMAT2A, and PMAT2F back panel schematics

are shown in Section 3

Page 8/47

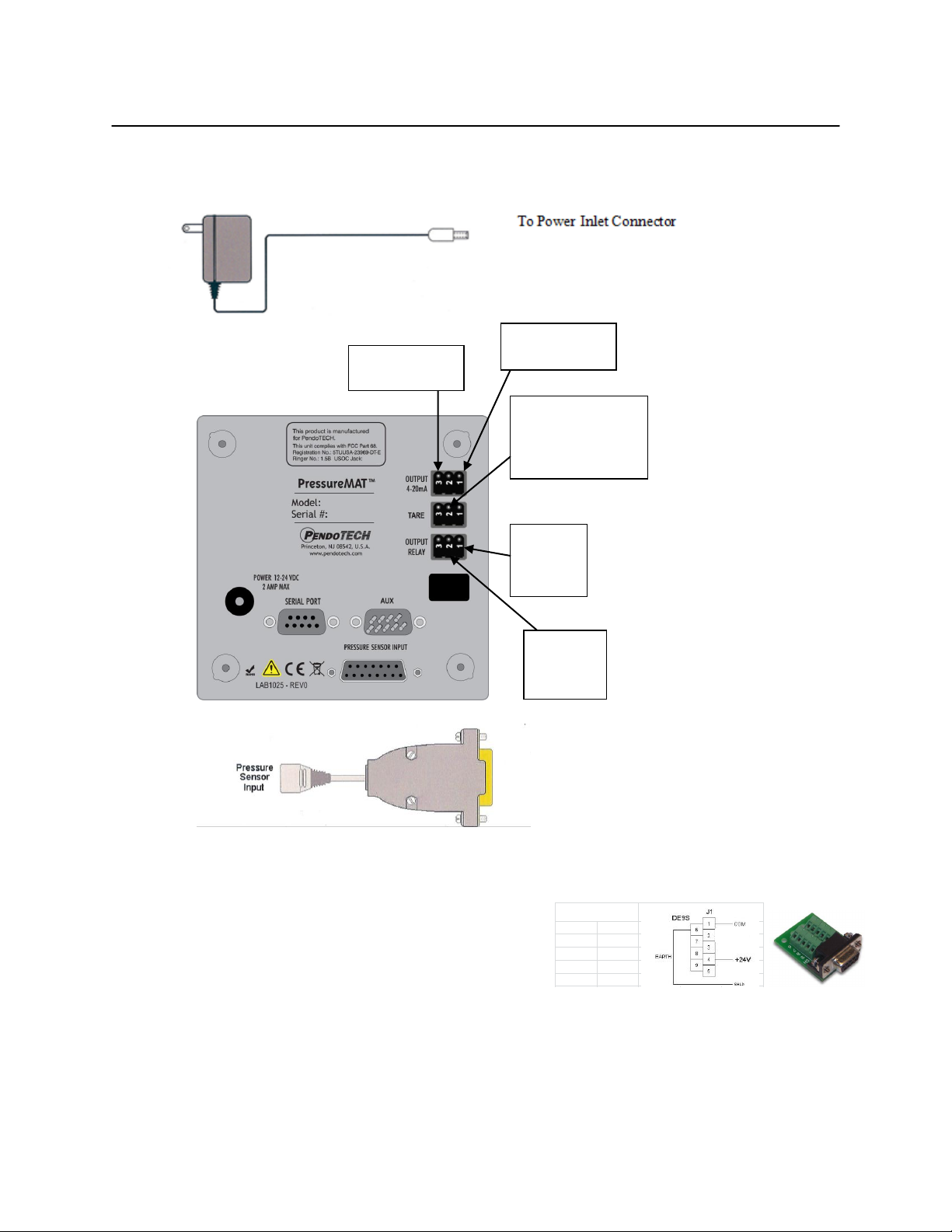

PressureMAT User Guide

To Power Inlet Connector

___________________

Panel Connector

_____________________

To Pressure Sensor Inputs(DB15)

Power Wiring

Signal DB9

+12-24VDC

4

Common 1

Wire here

for

Normally

CLOSED

Wire here

for

Normally

OPEN

Revision 7

CONNECTIONS:

The external connections to the back panel are as shown below.

1. POWER SUPPLY connected to the power inlet connector

2. The PRESSURE SENSOR INPUTS connected via a DB15 connector

3. The OUTPUT RELAY:

a. NORMALLY OPEN- wired to terminals S and T via supplied connector (will switch to

CLOSED position with alarm condition)

b. NORMALLY CLOSED- wired to terminals R and T via supplied connector (will

switch to OPEN position with alarm condition)

c. POWER REMOVED- OPEN (S and T position) is the condition for relay(s)

4. The 4-20mA ANALOG OUTPUTS are wired to terminals S and T via supplied connector as

shown

5. Serial Port- send data RS232 to be collected by an external device (such as a PC)

6. Auxiliary input- alternate power input connection for panel mounting

7. Tare (S model only)- external relay (dry contact) closure across pins will tare sensor to zero

External Cable Connections to Back Panel for Multi-channel Units

Power Inlet to Auxiliary (AUX) Connector (for panel mount):

r

Page 9/47

PressureMAT User Guide

To Pressure Sensor Inputs(DB15)

Power Wiring

Signal DB9

+12-24VDC

4

Common 1

Pin 2 for

Normally

CLOSED

Pin1 for

Normally

OPEN

Pin 3 is common

on all connectors

Pin 2 for Remote tare

input- a momentary

contact closure is used

to create this input

command

Pin 1 for 4-20mA

output signal (+)

Revision 7

External Cable Connections to Back Panel for PMAT-S Single Channel Unit

Power Inlet to Auxiliary (AUX) Connector (for panel mount):

r

Page 10/47

PressureMAT User Guide

Control System Component

Specifications

Enclosure

Multi-channel models PMAT-S:

H x W x D: 7.86” x 4.47” x 2.25” 4.70” x 4.70” x 2.25”

(19.96 x 11.35 x 5.72 cm) (11.94 x 11.94 x 5.72cm)

Approx: 1.43 lbs. (0.65 kgs) 0.86 lbs (0.39 kg)

Material: ABS Plastic

Panel/wall mount optional

NEMA 4X front panel

Environmental

Temperature: 0–55° C (32–132° F)

Humidity: 0–95% RH non-condensing, Shipping/Storage:

–20° to +85° C

(warm up to rated accuracy = 6 min.)

Keypad

8 button keypad with LEXAN® overlay

Display

8 line LCD backlit blue- psi as XX.X and bar as X.XX

HR Models: X.XXpsi and bar as X.XXX

Power Inlet

2.5 mm Circular Power Jack (center post positive)

12-24 Volts DC

4 Watts (powered by supplied appropriate wall supply)

Pressure Sensor Inputs

Configured for PendoTECH Single Use Pressure Sensors*

Connector on reusable cable: DB15

Excitation voltage: 4.096V +/- 0.22%

Flow Meter Input

(2P, 2F and 3Ponly)

Input to measure 5V square wave frequency/pulse

Relay Output

Normally OPEN or CLOSED via wiring

28 Volt AC/DC Maximum

1 amp closure, 2 amps maximum current

20 mS max turn on/off time

Screw terminal connector

Analog Outputs (4-20 mA)

Screw terminal connector

4-20mA Range: -10 to 75 psi (-0.69 bar to 5.17 bar)

HR Models: -1 to 3 psi (0.069 bar to 0.207 bar)

Accuracy: 0.1% of full scale

Sourcing w/Maximum Load: 400 Ohms

Load Impedance: Zero Ohm minimum resistance

Analog Input (4-20 mA)

(2P, 2A, and 3A only)

Screw terminal connector

4-20mA Range +/- 0.01% of full scale; 100 Ohms

Regulatory Compliances

CE Mark EN61326-1

FCC Part 15 Class B verified

FCC Part 68 5TUUSA-23969-DT-E

Revision 7

Specifications

* See Appendix B for important information on this product

LEXAN® is a registered trademark of General Electric Company

Page 11/47

PressureMAT User Guide

> 1 Pressure . . . . . . 0.0 psi

0.0

2 Pressure . . . . . . 0.0 psi

3 Pressure . . . . . . 0.0 psi

4 Pressure . . . . . . 0.0 psi

Pressure psi

Revision 7

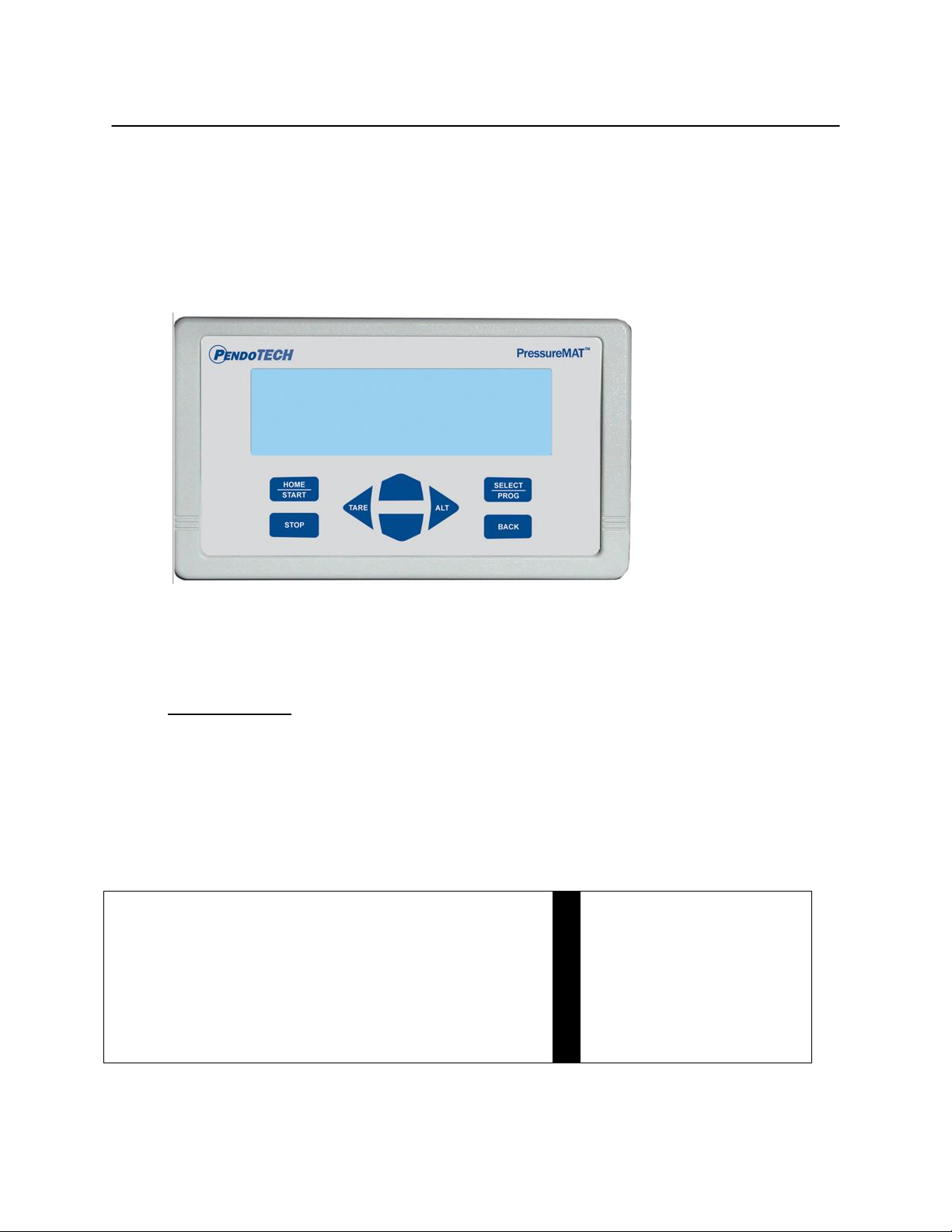

1.2.2. Software Details

The software interface consists of the keypad (shown below) and the 8 line LCD backlit

display. The program/firmware is stored in memory in the control system and cannot be edited

by users. Only settings in the software menus can be changed. The system does not store any

data unless equipped with optional data logger.

There is no power switch so the system cannot be accidentally turned off. When the wall

power supply is connected to the system and plugged into a wall outlet, the welcome screen

will appear momentarily followed by 2 beeps, then the HOME screen will appear.

Home Screen

When the system is powered on, the following HOME screen appears after the welcome screen

with pressures 1 through 4 shown depending on the model number

(with X.XX bar or XX.X psi as designated):

HOME Screen:

Multi-channel unit (PMAT4 shown with all 4 channels): PMAT-S

NOTE: Number 3 and 4 Pressure readings are replaced by the flow values and analog input

values in the models PMAT2P, PMAT3P, PMAT3A, PMAT2A, and PMAT2F. Back panel

schematics are shown in Section 3. Different models and/or settings may show different number

of digits to the right of the decimal.

Page 12/47

PressureMAT User Guide

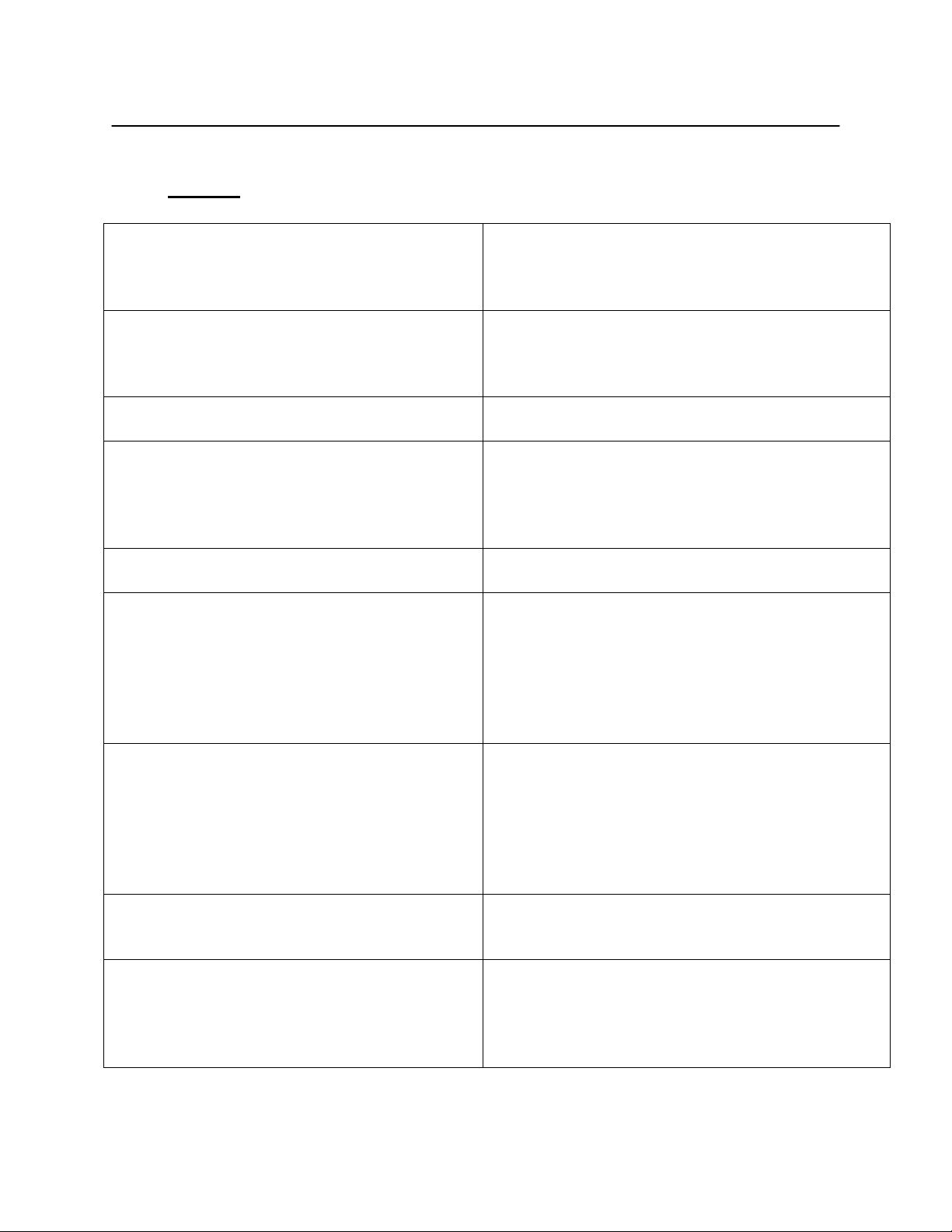

KEY

Function

HOME/START

Dual Purpose:

1- Used to return to the HOME screen from the

program menus

2- Used to power on the system if turned off

STOP

Used to reset alarms (if optional alarm latching

turned ON)

TARE/LEFT ARROW

Dual Purpose:

1- Used when in the program menu to scroll

the cursor left

2- Zero pressure sensor of selected channel

when on the HOME screen

RIGHT ARROW/ALT

Used when in the program menu to scroll the cursor

right

UP ARROW

Three Purposes:

1- When on the HOME screen used to select

different input channels

2- In the program menus, used to select

different sub-menus

3- Within a program menu, used to change a

selected value

DOWN ARROW

Three Purposes:

1- When on the HOME screen used to select

different input channels

2- In the program menus, used to select

different sub-menus

3- Within a program menu, used to change a

selected value

SELECT/PROG

Used to enter the program menu for the selected

channel or for the selected menu; used to confirm

and save changes to a setting

BACK

Dual Purpose:

1- Used to return to the previous screen when

in a program menu

2- Can be pressed three times to access the

GLOBAL SETTINGS menu

Revision 7

Keypad

Page 13/47

PressureMAT User Guide

Channel X

> Input Viewing

Output Viewing

Input Programming

Output Programming

Revision 7

Navigation Between Pressure Sensor Input Channels

At the HOME screen, the UP/DOWN arrows are used to change the selected pressure input

channel.

Zero Calibration for Pressure Sensors

1. Select the desired input channel using the UP/DOWN buttons

2. With a pressure sensor connected to the system and EXPOSED ONLY TO

ATMOSPHERIC PRESSURE, press the Tare Button (LEFT ARROW button) on the

keypad

3. The display should read 0.0 psi / 0.00 bar

4. If 0.0 psi / 0.00 bar is not displayed, press the ZERO/TARE button on the keypad again

Note: a minus sign may appear on the display when it reads 0.0 psi / 0.00 bar; this is

normal as the pressure measured by the system may be a value such as -0.001 but

displayed as -0.0 psi / -0.00 bar.

Alarm Function

If any channel has an alarm set, the alarm function includes:

a. The display screen will blink “ALARM>” on the channel with the alarm

b. An audible tone for 30 seconds during the present alarm (it is reset for a new alarm

condition)

c. If present, a dry contact relay associated with that channel will switch (i.e., if wired as

normally CLOSED, it will OPEN; if wired as normally OPEN, it will CLOSE)

When an alarm condition goes away, all indicators automatically go back to normal (unless the

optional alarm latching function is turned on). If a sensor is inadvertently not connected or

becomes accidentally disconnected during a process the pressure reading will drift and

eventually go to a value greater than 75psi/5.17 bar and an alarm condition will occur if the

high alarm set-point is surpassed or in psi when the value goes above the hard-coded limit of

75. The time until the high alarm occurs may vary and this feature should not be used to

control a process due to the time variance. Associated relays will switch and the analog output

will send greater than 20mA.

Program Menu

To access the program menu for a pressure sensor, press the PROG key on the keypad with the

desired input channel selected. The program menu is mainly used for setting of the high and

low alarm set points and alarm detect delay. After pressing the PROG key, the following

screen appears with X indicating selected channel:

Note: the PMAT-S menu selections are truncated due to space limitations on certain screens

Page 14/47

PressureMAT User Guide

Channel X Input Viewing

> * Pressure 0.0 psi

PV Signal x.xxx V

Service Time XXXX hrs

[SELECT] home display value

Channel X Output Viewing

SP Signal 20.000 mA

> * Name

*>Port Relay <1

SP Sig Relay

SP Typ Monitor

[SELECT] home display value

Select Home Value

Revision 7

At the program menu, the BACK button may be pressed to return to the HOME screen or

SELECT/PROG button pressed with the desired menu selected. The appearance and functions

of the menus are as follows:

Input Viewing

At this screen the UP/DOWN arrows are used to select what value is displayed on the HOME

screen. Press the SELECT/PROG button to select what value appears on the home screen for

the respective channel. The “*” appears next to the current selection for HOME screen

display. In most case this will remain as the Pressure value. PV Signal is the present value of

raw sensor reading. The Service Time is the number of hours the system has been in service.

Pressing the SELECT/PROG button will confirm a change- UNTIL THIS IS DONE, A

SETTING CHANGE IS NOT CONFIRMED. Pressing the HOME or BACK button before

confirming a setting change with the SELECT/PROG button will escape from that program

menu without saving changes made before confirming the entry.

Output Viewing

At this screen the UP/DOWN arrows are used to select what value is displayed on the HOME

screen. Press the SELECT/PROG button to select what value appears on the home screen on

the line under the respective channel. The “*” appears next to the current selection for HOME

screen display. The SP Signal is the milliamp output corresponding to the pressure reading.

Name which by default is blank can be programmed in the in the output programming menu.

Pressing the SELECT/PROG button will confirm a change- UNTIL THIS IS DONE, A

SETTING CHANGE IS NOT CONFIRMED. Pressing the HOME or BACK button before

confirming a setting change with the SELECT/PROG button will escape from that program

menu without saving changes made before confirming the entry.

Multi-channel unit (PMAT4 shown with all 4 channels): PMAT-S

Page 15/47

Loading...

Loading...