Page 1

PressureMAT™

System User Guide

Revision 8

www.pendotech.com

Page 2

PressureMAT User Guide

WARNING: DANGEROUS VOLTAGE INSIDE THE CONTROL BOX.

REPRESENTATIVE. NO USER SERVICEABLE PARTS INSIDE.

WARNING: POTENTIAL SHOCK HAZARD. UNLESS PROPERLY PANEL

CORD AND WHERE THE POWER CORD WILL NOT BE DAMAGED.

Revision 8

PressureMAT System User Guide

Model PMAT2

Model PMAT2P

Model PMAT3

Model PMAT3P

Model PMAT4A

Model PMAT4R

Model PMAT3A

Model PMAT2A

Model PMAT2F

Model PMAT2HR

Model PMAT-S

Model PMAT-SHR

All rights reserved. No part of this publication may be reproduced, sto red in an electronic retrieval system, or transmitted,

in any for m or by any means , whether electronic, mechanical, by photo copying, or otherwis e, without the written consent

of PendoTECH.

The infor mation in this User Guide is believed to be accurate and reliable for use and operation of the control system,

however, PendoTECH assumes no responsibility for the use of this product except for what is covered in the Limited

Warranty and Terms and Condition of Sale.

PressureMAT is a Trademark of PendoTECH Copyright © 2010 -2014, PendoTECH

Used throughout this guide:

WARNING: “WARNING” is used to indicate the presence of a hazard which can cause severe

personal injury, death, or substantial property damage if the warning is ignored.

Note: “Note” is used to notify the user of installation or operation information which is

important but not hazard related.

CONTROL BOX ONLY TO BE OPENED BY PENDOTECH OR AUTHORIZED

MOUNTED, DO NOT USE THIS PRODUCT NEAR WATER OR IF YOU ARE

WET. DO NOT SUBMERGE THIS PRODUCT. USE ONLY IN A GROUNDED

ELECTRICAL OUTLET. UNLESS PROPERLY PANEL MOUNTED, UNPLUG

THE PRODUCT FROM THE OUTLET BEFORE CLEANING WITH ANY

LIQUIDS. INSTALL SECURELY ON A STABLE SURFACE. INSTALL IN A

LOCATION WHERE NO ONE CAN STEP ON OR TRIP OVER THE POWER

WARNING: GOODS AND SOFTWARE ARE NOT DESIGNED, INTENDED OR AUTHORIZED FOR USE AS

COMPONENTS IN LIFE SUPPOR T OR MEDICAL DEVICES. THEY ARE NOT DESIGNED FOR ANY

APPLICATION IN WHICH THE FAILURE OF THE PRODUCT COULD RESU LT IN PERSONAL INJURY,

DEATH OR PROPERTY DAMAGE.

Page 2/48

Page 3

PressureMAT User Guide

Revision 8

Table of Contents

1. Overview of PendoTECH PressureMAT................................................................................ 4

1.2. Instrument Details .................................................................................................................... 5

1.2.1. Hardware Details ................................................................................................................. 6

1.2.2. Software Details ................................................................................................................. 13

2. Setup and Use of the System ................................................................................................ 23

2.1. System Setup* ........................................................................................................................ 23

2.2. Using the System* ................................................................................................................. 24

3. Flow Meter Function in PressureMAT-PLUS (2P, 3P & 2F) .............................................. 25

3.1. Display ................................................................................................................................... 25

3.2. Back Panel ............................................................................................................................. 25

3.3. Connection to Back Panel ...................................................................................................... 26

3.4. Navigation in the Flow Meter Input Channel ........................................................................ 26

4. Analog Input Function in PressureMAT-PLUS (2P, 3A & 2A only)................................... 30

4.1. Display ................................................................................................................................... 30

4.2. Back Panel ............................................................................................................................. 30

4.3. Connection to Back Panel ...................................................................................................... 31

4.4. Navigation in the Analog Input Channel ............................................................................... 31

5. Cable Information ................................................................................................................. 34

5.1. Cable for Pressure Inputs ....................................................................................................... 34

APPENDIX A: PRODUCT WARRANTY ................................................................................. 35

APPENDIX B: PendoTECH Single Use Pressure Sensors ......................................................... 36

APPENDIX C: PressureMAT Data Acquisition Software .......................................................... 37

APPENDIX D: Panel Mount of System ...................................................................................... 39

APPENDIX E: EC Declaration of Conformity ........................................................................... 41

APPENDIX F: Pinch Valve Box Accessory (PDKT-PVE) ........................................................ 42

APPENDIX G: Using the PressureMAT with WinWedge Software .......................................... 44

APPENDIX H: PressureMAT Smoothing Function (PV Filter) ................................................. 45

Page 3/48

Page 4

PressureMAT User Guide

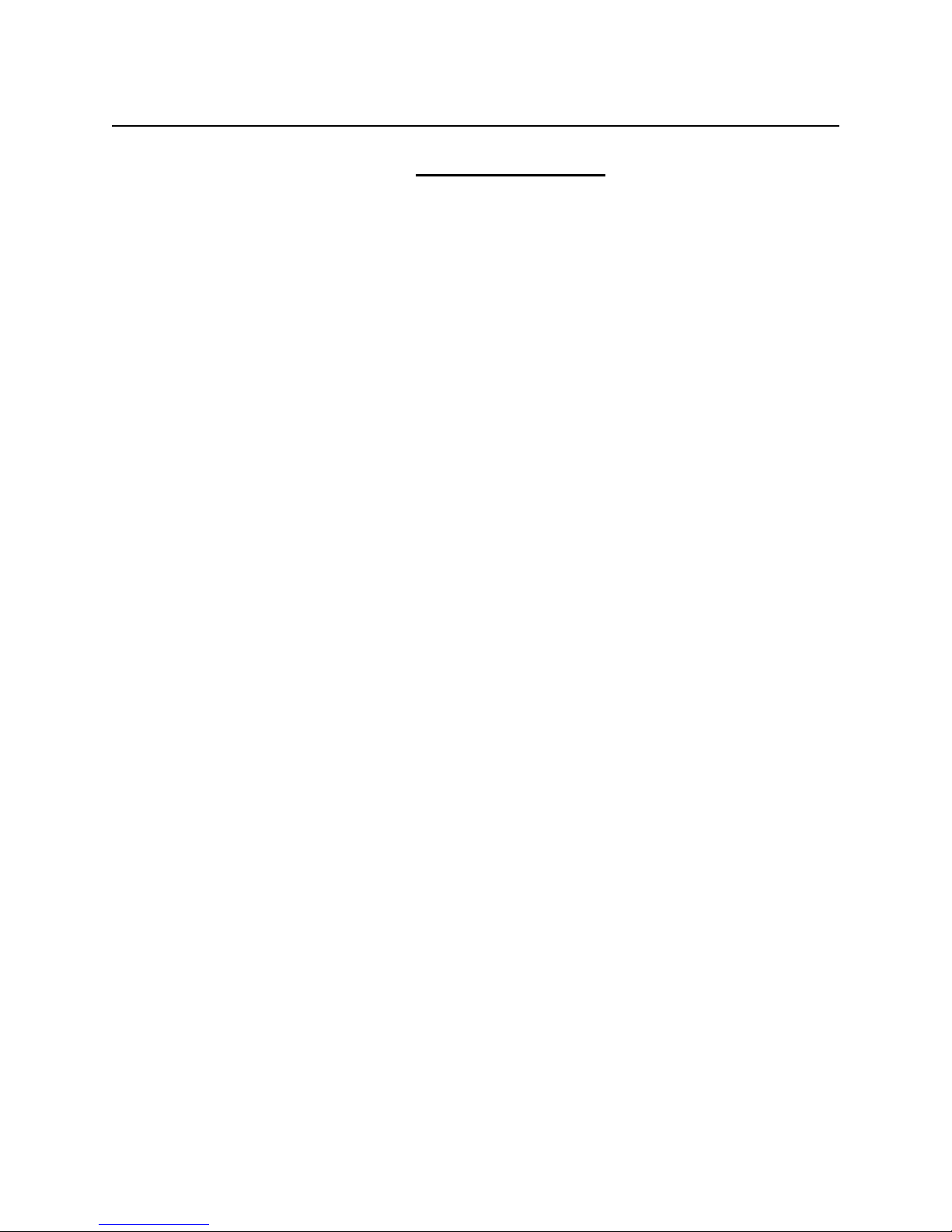

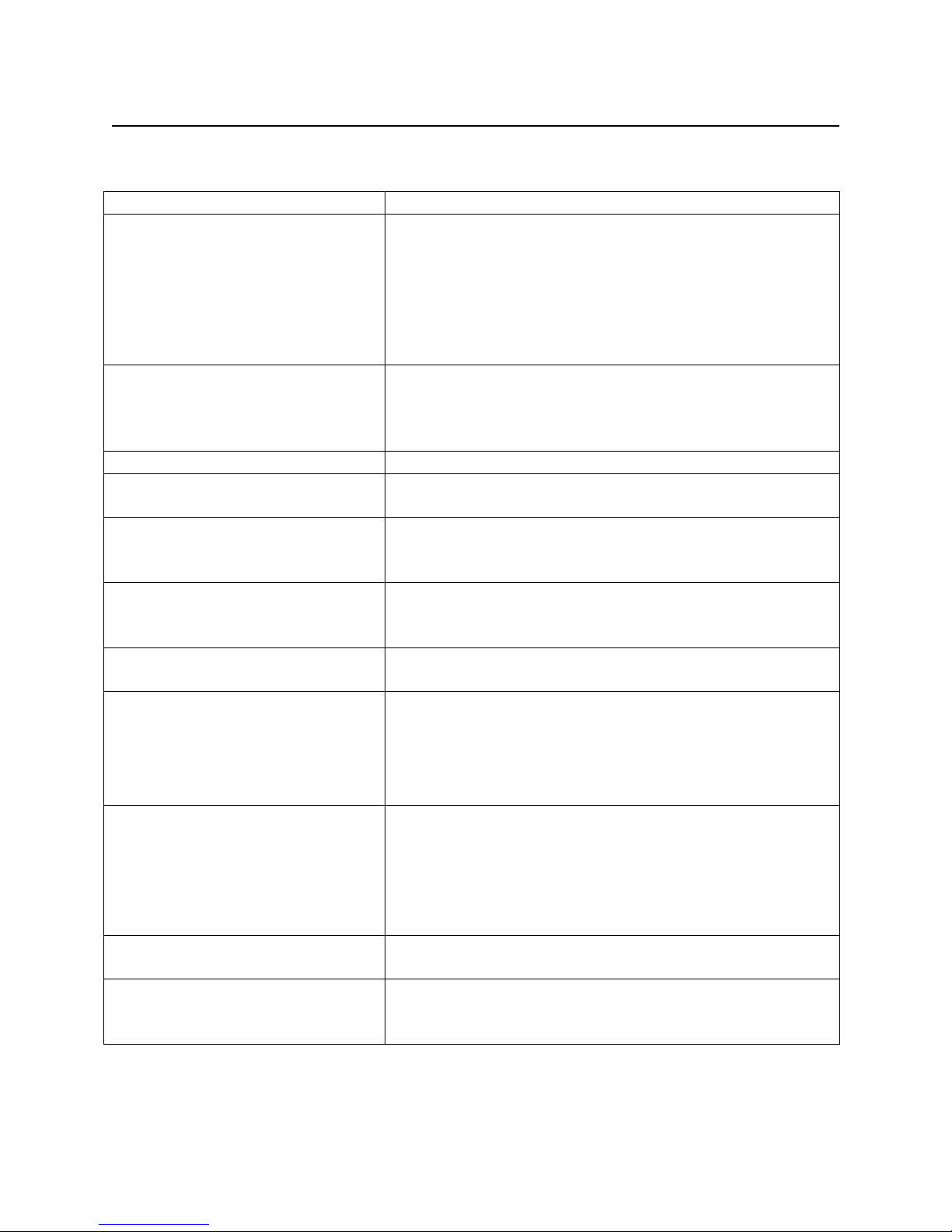

Model Number

Number of

Inputs

Number of

Outputs

Outputs

PMAT2* 2 4

2 Relays / 2 Analogs or 4 Relays

PMAT2P

2 pressure/1

flow/1 analog

4

4 Analogs [may be re-configured]

PMAT3 3 4

3 Analogs / 1 Relay (for all sensors)

PMAT3P

3 pressure/1 flow

4

4 Analogs [may be re-configured]

PMAT4A 4 4

4 Analogs

PMAT4R 4 4

4 Relays

PMAT3A

3 pressure/

1 analog

4

4 Analogs [may be re-configured]

PMAT2A

2 pressure/

2 analog

4

4 Analogs [may be re-configured]

PMAT2F

2 pressure/

2 flow

4

4 Analogs [may be re-configured]

PMAT-S* 1 3

1 Relay /1 Analog / 1 remote tare

Revision 8

1. Overview of PendoTECH PressureMAT

The PressureMAT is a monitor, alarm, and transmitter system designed for use with Single Use

Pressure Sensors from PendoTECH. It is comprised of the control system box with user interface and

the connectors on the back panel where input and output components can be interfaced. If equipped,

the alarm output function includes a dry contact relay output. The transmitter function delivers an

analog 4 – 20 milliamp output signal corresponding to the pressure reading on the display. There are

numerous applications in biopharmaceutical production processes where the system can be used.

The models are as follows:

* Available in “High Resolution” model with HR s uffix

System Components Su ppl ied:

• PressureMAT Instrument

• Cable(s) for connection of pressure sensors to the control system

• Connectors for cable for each output

• 4 Screws for mounting

• Power supply

Options:

• PMAT-STND Benchtop St and

• PMAT-GUI PressureMAT Data Acquisition Software (Appendix C)

• PDKTP-RS232U RS-232 cable for data output to a PC via USB

• PMAT-PANEL Panel mount kit (Appendix D)

• PMAT-WALL4 Wall mount stainless steel box

• PDKT-650-298CVR Pressure sensor cable dust cover / zero simulator for PressureMAT

• PressureMAT Carts – contact PendoTECH for details

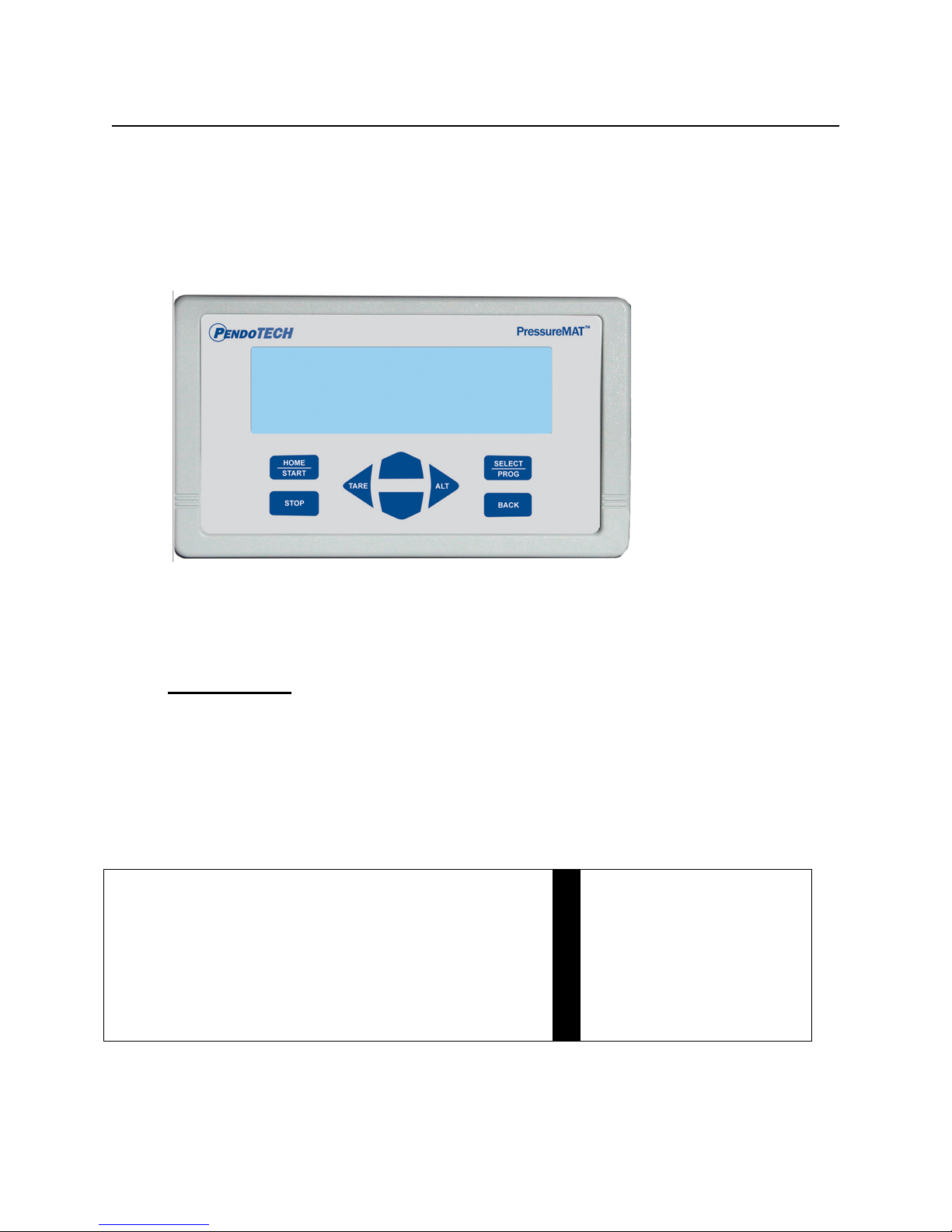

1.1. PressureMAT Instrument

Page 4/48

Page 5

PressureMAT User Guide

Benchtop Stand

Wall Mount Stainless Steel Box

Revision 8

The PressureMAT with its user interface is used to display pressure readings, zero calibrate the

pressure sensor, and to access the program menus to edit the alarm high and low set point values and

other tasks.

The sensor pressure is displayed on the LCD display for each input channel. High and low alarm

pressure set points are entered on the keypad for each channel and if the process pressure goes below

the low setting or above the high setting, the system will go into alarm state. With models with the

relay output, the alarm function includes activation of the dry contact relay output, a flashing

“ALARM>” indication on LCD on the same line as the pressure input channel in the alarm state, and

an audible tone for 30 seconds. When an alarm condition goes away, all indicators automatically go

back to normal (unless the optional alarm latching function is turned on which requires STOP to be

pressed to clear the alarm). The alarm functions are always active for all channels. For the

PressureMAT PLUS models, flow or a scaled analog input value can measure & display other values.

Also available is a single channel model PMAT-S:

The model has a unique remote pressure tare input.

Some available options:

1.2. Instrument Details

Page 5/48

Page 6

PressureMAT User Guide

LCD BACKLIT

DISPLAY

KEYPAD

Revision 8

1.2.1. Hardware Details

There is no power switch so the system cannot be accidentally turned off. When the wall power

supply is connected to the system and plugged into a wall outlet, the system will turn ON. Instructions

to power down the system without unplugging are in Section 1.2.2 (System Power). The Front and

Back Panels details are as shown:

FRONT PANEL:

Note: If a pressure sensor is not connected or is disconnected during operation of the system,

the pressure reading will drift and eventually go to a value greater than 75psi/5.17 bar and an

alarm condition will occur. The time until the high alarm occurs may vary and this feature

should not be used to control a process due to the time variance. Associated relays will switch

and the analog output will send greater than 20mA.

The Sensor Cable Dust Cover / Zero Simulator for PressureMAT (PDKT-650-298CVR) can be used

to:

1) Maintain a zero pressure when a channel is not in use

2) Protect the pins on the re-usable cable

Page 6/48

Page 7

PressureMAT User Guide

Revision 8

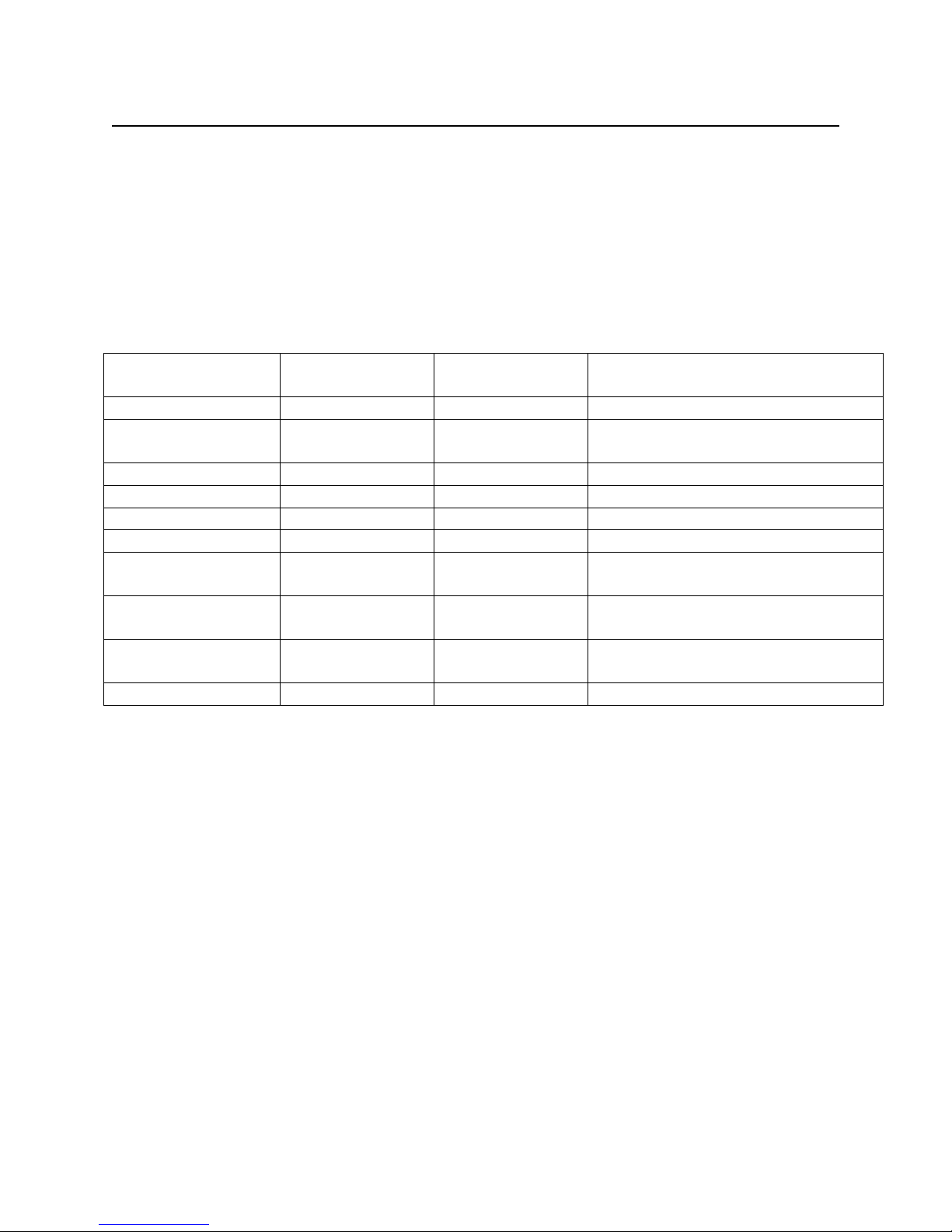

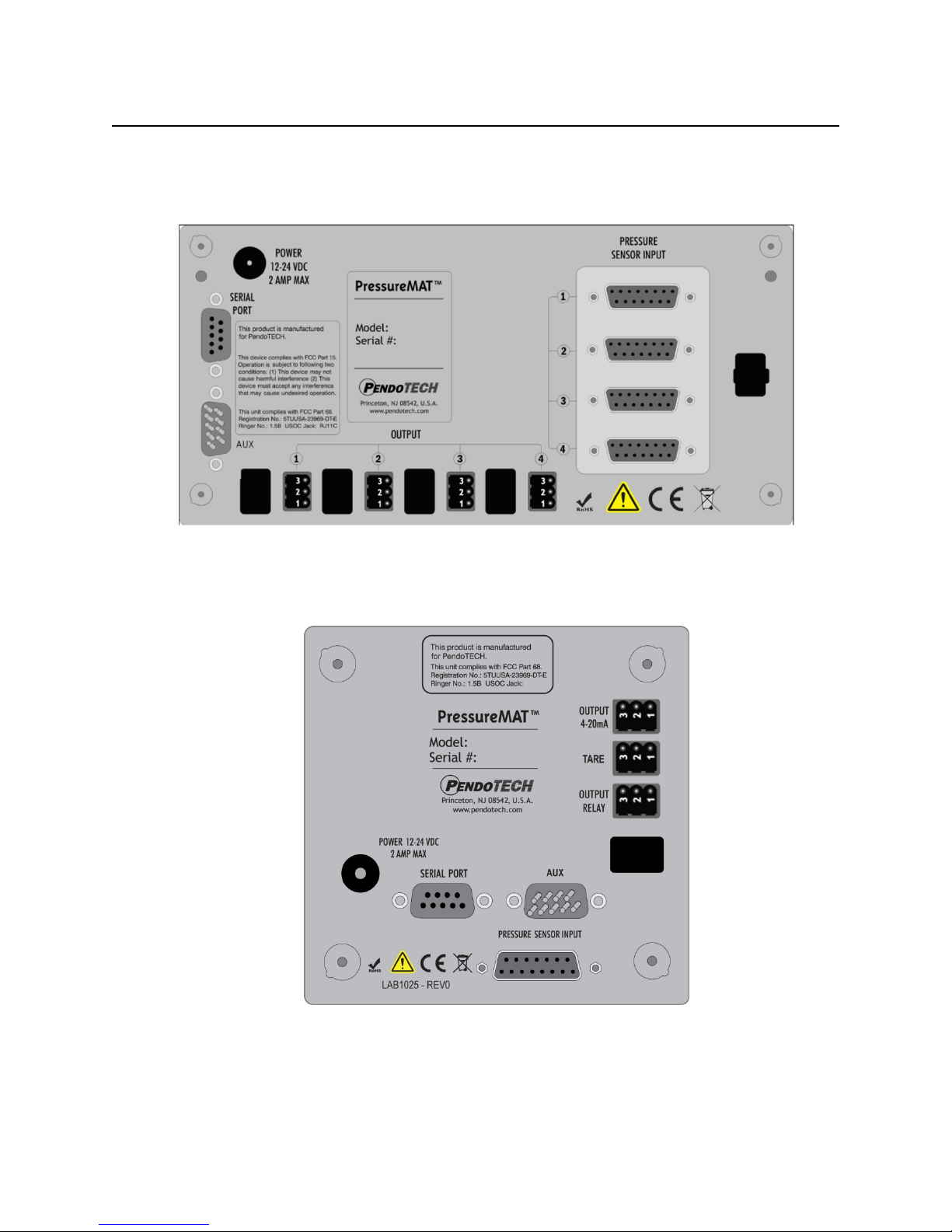

BACK PANEL CONFIGURATIONS:

PMAT2- Two Input Unit (two relays, one for each channel;4-20mA for each channel):

PMAT3- Three Input Unit:

Page 7/48

Page 8

PressureMAT User Guide

Revision 8

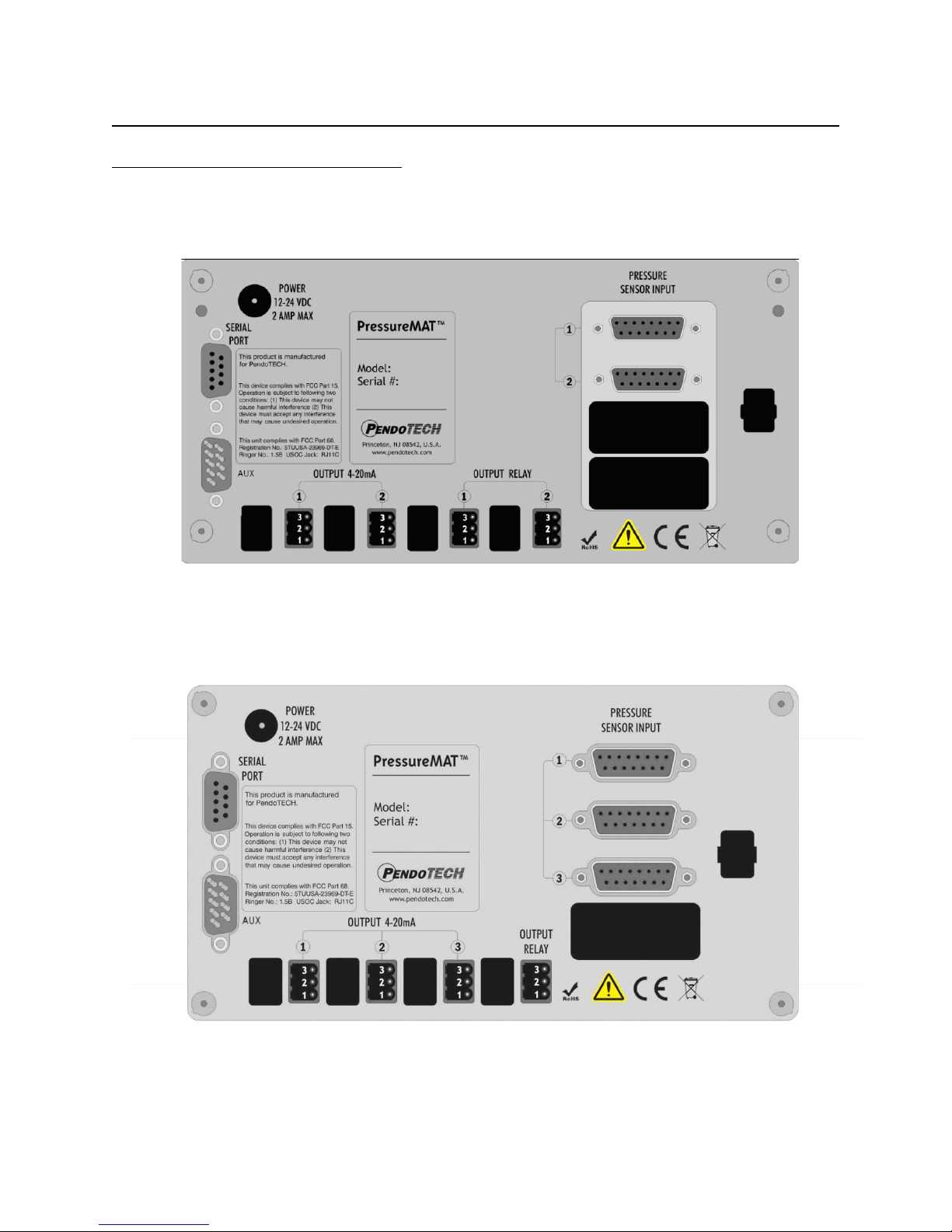

PMAT4x- Four Input Unit (If 4R outputs are relays; if 4A, outputs are 4-20mA):

PMAT-S - One Input Unit:

NOTE: The PMAT2P, PMAT3P, PMAT3A, PMAT2A, and PMAT2F back panel schematics

are shown in Section 3

Page 8/48

Page 9

PressureMAT User Guide

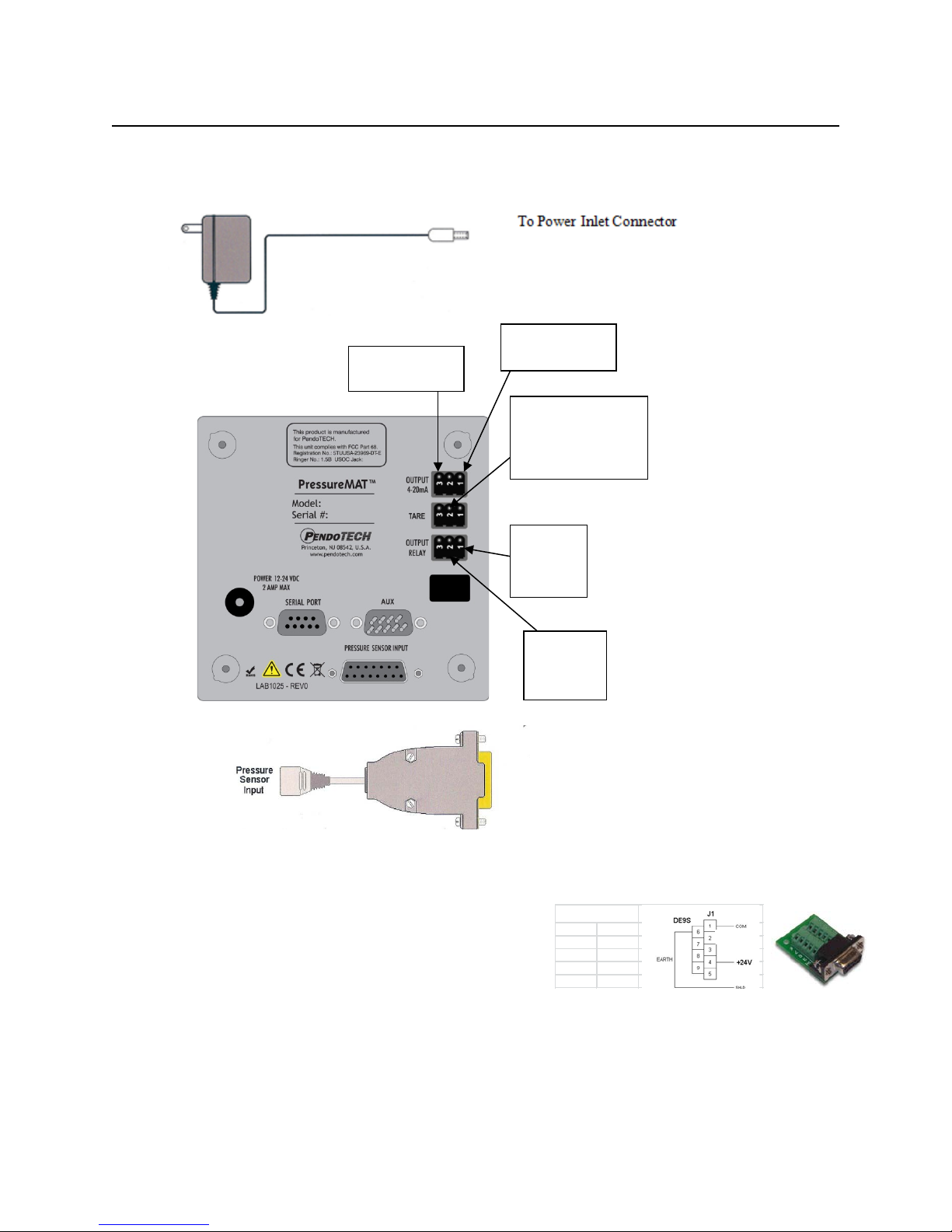

To Power Inlet Connector

Wire here

CLOSED

Wire here

Revision 8

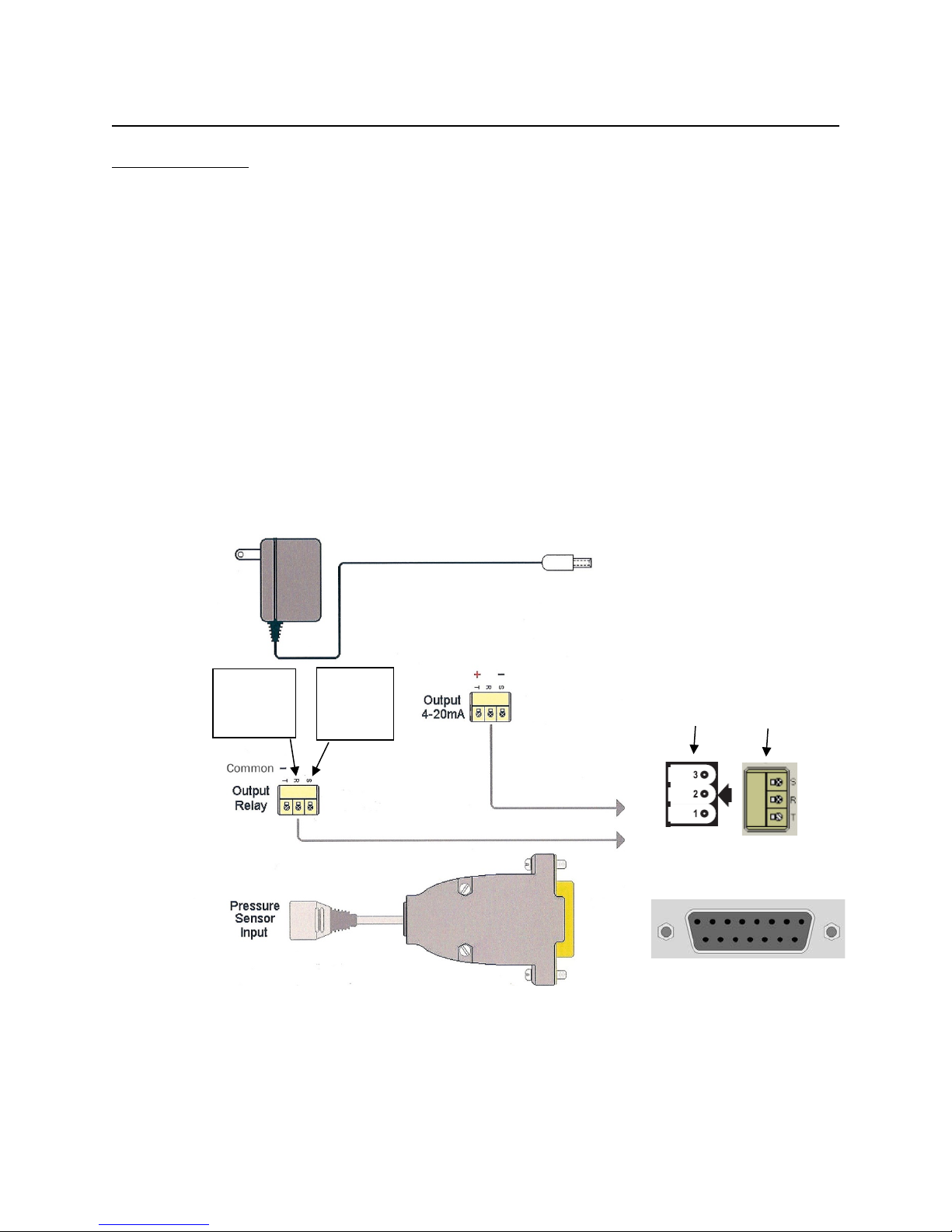

CONNECTIONS:

The external connections to the back panel are as shown below.

1. POWER SUPPLY connected to the power inlet connector

2. The PRESSURE SENSOR INPUTS connected via a DB15 connector

3. The OUTPUT RELAY:

a. NORMALLY OPEN- wired to terminals S and T via supplied connector (will switch to

CLOSED position with alarm condition)

b. NORMALLY CLOSED- wired to terminals R and T via supplied connector (will

switch to OPEN position with alarm condition)

c. POWER REMOVED- OPEN (S and T position) is the condition for relay(s)

4. The 4-20mA ANALOG OUTPUTS are wired to terminals S and T via supplied connector as

shown

5. Serial Port- send data RS232 to be collected by an external device (such as a PC)

6. Auxiliary input- alternate power input connection for panel mounting

7. Tare (S model only)- external relay (dry contact) closure across pins will tare sensor to zero

External Cable Connections to Back Panel for Multi-channel Units

for

Normally

for

Normally

OPEN

___________________

Panel Connector

_____________________

DB15

Page 9/48

Page 10

PressureMAT User Guide

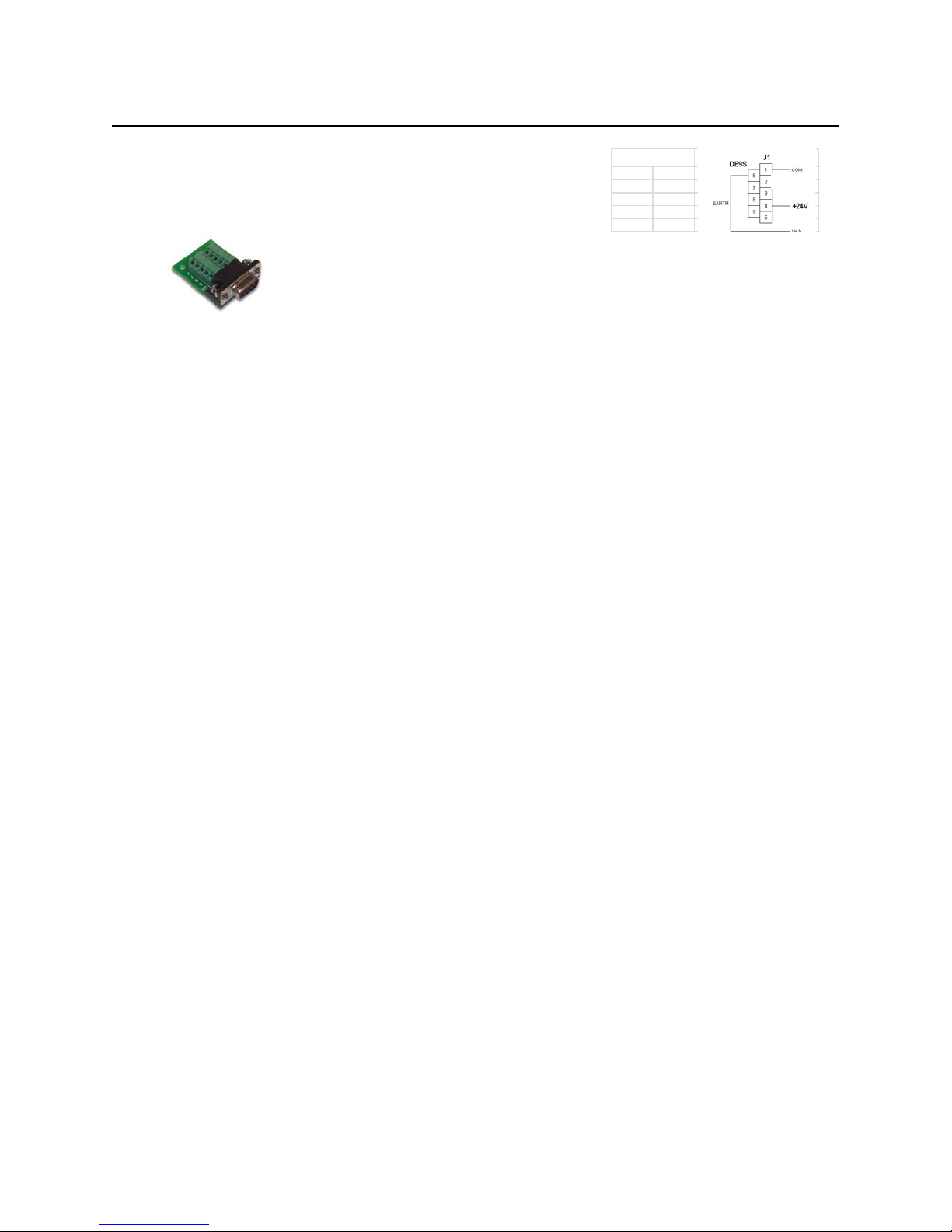

Power Wiring

Signal DB9

+12-24V D

4

Common 1

Revision 8

Power Inlet to Auxiliary (AUX) Connector (for panel mount): r

Page 10/48

Page 11

PressureMAT User Guide

Power Wiring

Signal DB9

+12-24V D

4

Common 1

Pin 2 for

Pin1 for

Pin 3 is common

Pin 2 for Remote tare

command

Pin 1 for 4-20mA

Revision 8

External Cable Connections to Back Panel for PMAT-S Single Channel Unit

output signal (+)

on all connectors

input- a momentary

contact c lo sure is used

to create this input

Normally

OPEN

Normally

CLOSED

To Pressure Sensor Inputs(DB15)

Power Inlet to Auxiliary (AUX) Connector (for panel mount): r

Page 11/48

Page 12

PressureMAT User Guide

Control System Component

Specifications

Enclosure

Multi-channel models PMAT-S:

NEMA 4X front panel

Environmental

Temperature: 0–55° C (32–132° F)

(warm up to rated accuracy = 6 min.)

Keypad

8 button keypad with LEXAN® overlay

Display

8 line LCD backlit blue- psi as XX.X and bar as X.XX

HR Models: X.XXpsi and bar as X.XXX

Power Inlet

2.5 mm Circular Power Jack (center post positive)

4 Watts (powered by supplied appropriate wall supply)

Pressure Sensor Inputs

Configured for PendoTECH Single Use Pressure Sensors*

Excitation voltage: 4.096V +/- 0.22%

Flow Meter Input

(2P, 2F and 3Ponly)

Input to measure 5V square wave frequency/pulse

Relay Output

• Normally OPEN or CLOSED via wiring

Screw terminal connector

Analog Outputs (4-20 mA)

Screw terminal connector

Load Impedance: Zero Ohm minimum resistance

Analog Input (4-20 mA)

(2P, 2A, and 3A only)

Screw terminal connector

4-20mA Range +/- 0.01% of full scale; 100 Ohms

Regulatory Compliances

CE Mark EN61326-1

FCC Part 68 5TUUSA-23969-DT-E

Revision 8

Specifications

H x W x D: 7.86” x 4.47” x 2.25” 4.70” x 4.70” x 2.25”

(19.96 x 11.35 x 5.72 cm) (11.94 x 11.94 x 5.72cm)

Approx: 1.43 lbs. (0.65 kgs) 0.86 lbs (0.39 kg)

Material: ABS Plastic

Panel/wall mount optional

Humidity: 0–95% RH non-condensing, Shipping/Storage:

–20° to +85° C

12-24 Volts DC

Connector on reusable cable: DB15

• 28 Volt AC/DC Maximum

• 1 amp closure, 2 amps maximum current

• 20 mS max turn on/off time

•

4-20mA Range: -10 to 75 psi (-0.69 bar to 5.17 bar)

HR Models: -1 to 3 psi (0.069 bar to 0.207 bar)

Accuracy: 0.1% of full scale

Sourcing w/Maximum Load: 400 Ohms

FCC Part 15 Class B verified

* See Appendix B for important information on this product

LEXAN® is a registered trademark of General Electric Company

Page 12/48

Page 13

PressureMAT User Guide

> 1 Pressure . . . . . . 0.0 psi

0.0

2 Pressure . . . . . . 0.0 psi

Revision 8

1.2.2. Software Details

The software interface consists of the keypad (shown below) and the 8 line LCD backlit

display. The program/firmware is stored in memory in the control system and cannot be edited

by users. Only settings in the software menus can be changed. The system does not store any

data unless equipped with optional data logger.

There is no power switch so the system cannot be accidentally turned off. When the wall

power supply is connected to the system and plugged into a wall outlet, the welcome screen

will appear momentarily followed by 2 beeps, then the HOME screen will appear.

Home Screen

When the system is powered on, the following HOME screen appears after the welcome screen

with pressures 1 through 4 shown depending on the model number

(with X.XX bar or XX.X psi as designated):

HOME Screen:

Multi-channel unit (PMAT4 shown with all 4 channels): PMAT-S

3 Pressure . . . . . . 0.0 psi

4 Pressure . . . . . . 0.0 psi

Pressure psi

NOTE: Number 3 and 4 Pressure readings are replaced by the flow values and analog input

values in the models PMAT2P, PMAT3P, PMAT3A, PMAT2A, and PMAT2F. Back panel

schematics are shown in Section 3. Different models and/or settings may show different number

of digits to the right of the decimal.

Page 13/48

Page 14

PressureMAT User Guide

HOME/START

Dual Purpose:

2- Used to power on the system if turned off

STOP

Used to reset alarms (if optional alarm latching

turned ON)

TARE/LEFT ARROW

Dual Purpose:

when on the HOME screen

RIGHT ARROW/ALT

Used when in the program menu to scroll the cursor

right

UP ARROW

Three Purposes:

selected value

DOWN ARROW

Three Purposes:

selected value

SELECT/PROG

Used to enter the program menu for the selected

and save changes to a setting

BACK

Dual Purpose:

GLOBAL SETTINGS menu

Revision 8

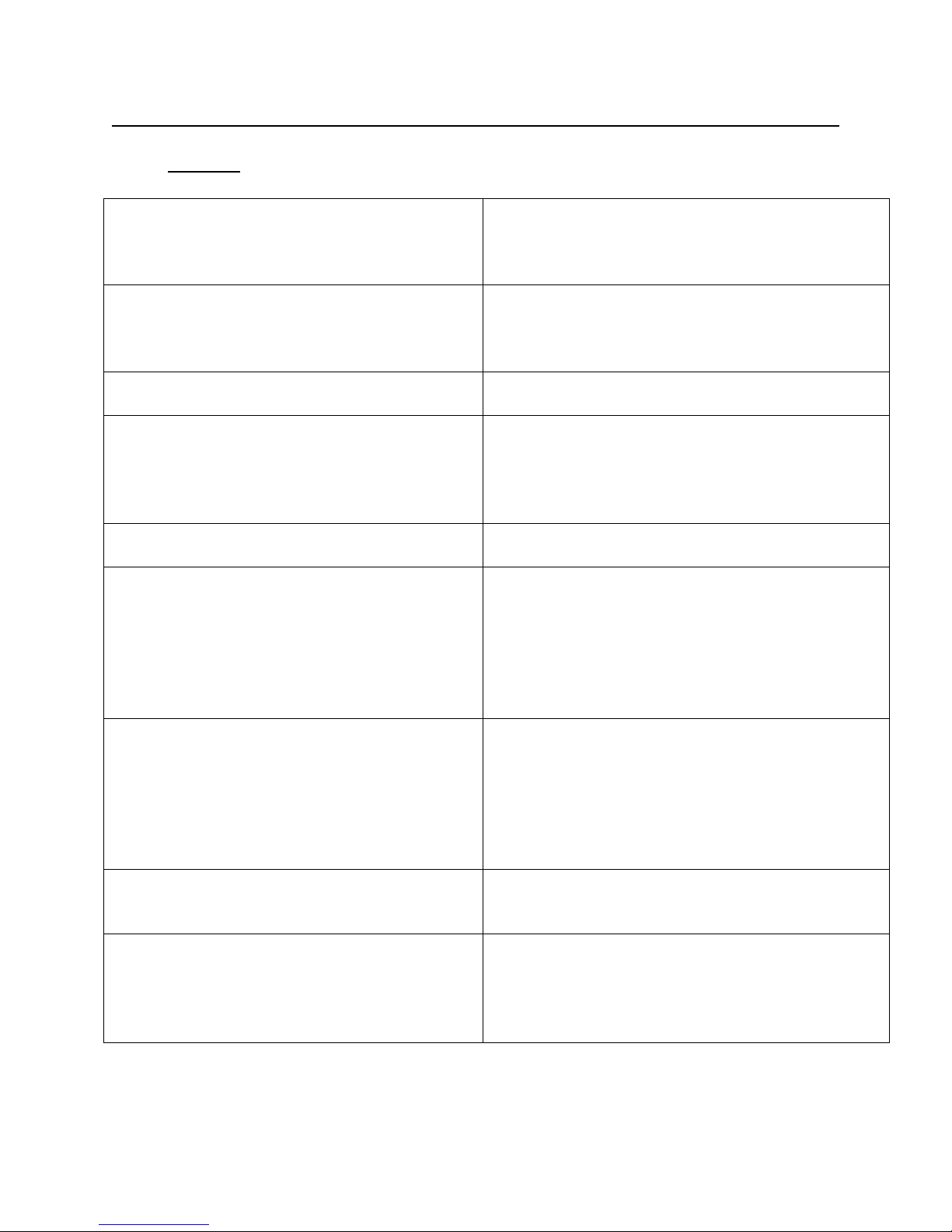

Keypad

KEY

Function

1- Used to return to the HOME screen from the

program menus

1- Used when in the program menu to scroll

the cursor left

2- Zero pressure sensor of selected channel

1- When on the HOME screen used to select

different input channels

2- In the program menus, used to select

different sub-menus

3- Within a program menu, used to change a

1- When on the HOME screen used to select

different input channels

2- In the program menus, used to select

different sub-menus

3- Within a program menu, used to change a

channel or for the selected menu; used to confirm

1- Used to return to the previous screen when

in a program menu

2- Can be pressed three times to access the

Page 14/48

Page 15

PressureMAT User Guide

Channel X

> Input Viewing

Revision 8

Navigation Between Pressure Sensor Input Channels

At the HOME screen, the UP/DOWN arrows are used to change the selected pressure input

channel.

Zero Calibration for Pressure Sensors

1. Select the desired input channel using the UP/DOWN buttons

2. With a pressure sensor connected to the system and EXPOSED ONLY TO

ATMOSPHERIC PRESSURE, press the Tare Button (LEFT ARROW button) on the

keypad

3. The display should read 0.0 psi / 0.00 bar

4. If 0.0 psi / 0.00 bar is not displayed, press the ZERO/TARE button on the keypad again

Note: a minus sign may appear on the display when it reads 0.0 psi / 0.00 bar; this is

normal as the pressure measured by the system may be a value such as -0.001 but

displayed as -0.0 psi / -0.00 bar.

Alarm Function

If any channel has an alarm set, the alarm function includes:

a. The display screen will blink “ALARM>” on the channel with the alarm

b. An audible tone for 30 seconds during the present alarm (it is reset for a new alarm

condition)

c. If present, a dry contact relay associated with that channel will switch (i.e., if wired as

normally CLOSED, it will OPEN; if wired as normally OPEN, it will CLOSE)

When an alarm condition goes away, all indicators automatically go back to normal (unless the

optional alarm latching function is turned on). If a sensor is inadvertently not connected or

becomes accidentally disconnected during a process the pressure reading will drift and

eventually go to a value greater than 75psi/5.17 bar and an alarm condition will occur if the

high alarm set-point is surpassed or in psi when the value goes above the hard-coded limit of

75. The time until the high alarm occurs may vary and this feature should not be used to

control a process due to the time variance. Associated relays will switch and the analog output

will send greater than 20mA.

Program M enu

To access the program menu for a pressure sensor, press the PROG key on the keypad with the

desired input channel selected. The program menu is mainly used for setting of the high and

low alarm set points and alarm detect delay. After pressing the PROG key, the following

screen appears with X indicating selected channel:

Output Viewing

Input Programming

Output Programming

Note: the PMAT-S menu selections are truncated due to space limitations on certain scre ens

Page 15/48

Page 16

PressureMAT User Guide

Channel X Input Viewing

> * Pressure 0.0 psi

[SELECT] home display value

Channel X Output Viewing

> * Name

SP Typ Monitor

[SELECT] home display value

Select Home Value

Revision 8

At the program menu, the BACK button may be pressed to return to the HOME screen or

SELECT/PROG button pressed with the desired menu selected. The appearance and functions

of the menus are as follows:

Input Viewing

At this screen the UP/DOWN arrows are used to select what value is displayed on the HOME

screen. Press the SELECT/PROG button to select what value appears on the home screen for

the respective channel. The “*” appears next to the current selection for HOME screen

display. In most case this will remain as the Pressure value. PV Signal is the present value of

raw sensor reading. The Service Time is the number of hours the system has been in service.

Pressing the SELECT/PROG button will confirm a change- UNTIL THIS IS DONE, A

SETTING CHANGE IS NOT CONFIRMED. Pressing the HOME or BACK button before

confirming a setting change with the SELECT/PROG button will escape from that program

menu without saving changes made before confirming the entry.

PV Signal x.xxx V

Service Time XXXX hrs

Output Viewing

At this screen the UP/DOWN arrows are used to select what value is displayed on the HOME

screen. Press the SELECT/PROG button to select what value appears on the home screen on

the line under the respective channel. The “*” appears next to the current selection for HOME

screen display. The SP Signal is the milliamp output corresponding to the pressure reading.

Name which by default is blank can be programmed in the in the output programming menu.

Pressing the SELECT/PROG button will confirm a change- UNTIL THIS IS DONE, A

SETTING CHANGE IS NOT CONFIRMED. Pressing the HOME or BACK button before

confirming a setting change with the SELECT/PROG button will escape from that program

menu without saving changes made before confirming the entry.

Multi-channel unit (PMAT4 shown with all 4 channels): PMAT-S

SP Signal 20.000 mA

*>Port Relay <1

SP Sig Relay

Page 16/48

Page 17

PressureMAT User Guide

Channel X Input Programming

> Lo PV Alarm 0.00 bar

Revision 8

Input Programming

At this screen the UP/DOWN arrows are used to select what function to program. Press the

SELECT/PROG button to program the function. The setting or digit of a setting that can be

changed with the UP/DOWN arrows blinks. If there is more than one digit in a setting, use the

RIGHT/LEFT arrows to scroll within the possible digit locations within a setting. Pressing the

SELECT/PROG button will confirm a change- UNTIL THIS IS DONE, A SETTING

CHANGE IS NOT CONFIRMED. Pressing the HOME or BACK button before confirming a

setting change with the SELECT/PROG button will escape from that program menu without

saving changes made before confirming the entry.

Hi PV Alarm 0.00 bar

Alarm Valid 000 sec

Time Alarm 0000 hrs

Comm Port Off

PV Filter Off

Log Type Off

Channel Name

After 30 seconds of inactivity in the program menu, the selected setting to change stops

blinking and the value before the setting was selected is restored.

Changing the Low Pressure Alarm Point- Press the SELECT/PROG with Low Alarm selected

Use the RIGHT ARROW button on the keypad until you get to the digit that you want to

change. Use the DOWN ARROW/UP ARROW buttons on the keypad to change the values.

Press the RIGHT ARROW then UP ARROW to get the minus sign. To change a digit from a

numerical value to zero, change the value to a zero. When the correct value has been selected,

press the SELECT/PROG button and the value will be confirmed. To escape from this menu

without changing the value, press the BACK button and the main channel men u will appear.

Changing the High Pressure Alarm Point- Press the SELECT/PROG with High Alarm selected

Use the RIGHT ARROW button on the keypad until you get to the digit that you want to

change. Use the DOWN ARROW/UP ARROW buttons on the keypad to change the values.

Use the DOWN ARROW/UP ARROW buttons on the keypad to change the values. Press the

RIGHT ARROW then UP ARROW to get the minus sign. To change a digit from a numerical

value to zero, change the value to a zero. When the correct value has been selected, press the

SELECT/PROG button and the value will be confirmed. To escape from this menu without

changing the value, press the BACK button and the main channel menu will appear.

Note: If the High or Low Pressure Alarm Points are set to 0.00 then there will be no

alarm setting and an alarm will only occur if a sensor is disconnected

Page 17/48

Page 18

PressureMAT User Guide

Revision 8

Alarm Valid- This value is set to a default of 0 seconds. This is the amount of time an alarm

condition must be present for an actual alarm to occur. In certain processes with rapidly

changing pressures, this value can be changed to prevent undesired false alarms. Press the

SELECT/PROG with Alarm Valid selected.

Use the RIGHT ARROW button on the keypad until you get to the digit that you want to

change. Use the DOWN ARROW/UP ARROW buttons on the keypad to change the values.

To change a digit from a numerical value to zero, change the value to a zero. When the correct

value has been selected, press the SELECT/PROG button and the value will be confirmed. To

escape from this menu without changing the value, press the BACK button and the main

channel menu will appear.

Comm Port- Indicates data output function. There are several settings but the only active

settings are Off and Serial Report (Sio Report). If Off is selected, no data for the selected

channel is sent out the Serial Port. If Sio Report is selected, data is sent out the Serial RS232

port at the frequency programmed in the Global Settings Menu (contact PendoTECH for more

details on data collection from the PressureMAT). Press the SELECT/PROG with Comm Port

selected. The port settings are:

9600 baud

No Parity

8 data bits

1 stop bit

No flow control

Use the DOWN ARROW/UP ARROW buttons on the keypad to change the settings. When

the correct setting has been selected, press the SELECT/PROG button and the value will be

confirmed. To escape from this menu without changing the value, press the BACK button and

the main channel menu will appear.

The command AZK<cr> can be also used to generate a report as desired. The unit operates

using half duplex request-and-reply protocol; after sending the request, DO NOT send anything

else until the resulting expected response is received. THEN the requestor is free to proceed.

(ie, send one AZK<cr>, THEN make sure a successful response is received).

Note: See Appendix C on Data Collection to a PC

Time Alarm- This value is set to a default of 000 hours. This can be set to trigger an alarm in

a set period of time and most likely will remain at 000 hours which indicates it is not active.

Press the SELECT/PROG with Alarm Valid selected.

Use the RIGHT ARROW button on the keypad until you get to the digit that you want to

change. Use the DOWN ARROW/UP ARROW buttons on the keypad to change the values.

To change a digit from a numerical value to zero, change the value to a zero. When the correct

value has been selected, press the SELECT/PROG button and the value will be confirmed. To

escape from this menu without changing the value, press the BACK button and the main

channel menu will appear.

Page 18/48

Page 19

PressureMAT User Guide

Channel X Output Programming

Port Type Out 0-20mA

Channel X Output Programming

Port Type Out Relay

Revision 8

PV Filter

This option can be used to smooth pressure readings which may be desirable in certain

applications such as a pump pulsating. It is by default turned Off but can be changed to Low,

Medium or High. The feature gives the following smoothing choices:

Low

Medium

High

WARNING: Smoothing will lead to delayed alarm detection because readings are being

averaged and pressure spikes will not be immediately recognized.

Note: See Appendix H for more information and data on this feature.

Name- Only names the menu for the respective input channel.

Output Programming

At this screen the UP/DOWN arrows are used to select what function to program. The only

function active is the Name. The Port Type can be selected and changed but no changes will

be confirmed and will revert to the default setting.

> Chan Name

or

> Chan Name

Press the SELECT/PROG button to program a name that appears on the line under the line

where the pressure value is displayed for the selected channel (if Name is selected on the

Output Viewing menu). A wide range of alpha-numeric digits can be selected. Use the

RIGHT ARROW button on the keypad until you get to the digit that you want to change. Use

the DOWN ARROW/UP ARROW buttons on the keypad to change the values. The “*”

character indicates a space. Pressing the SELECT/PROG button will confirm a changeUNTIL THIS IS DONE, A SETTING CHANGE IS NOT CONFIRMED. Pressing the HOME

or BACK button before confirming a setting change with the SELECT/PROG button will

escape from that program menu without saving changes made before confirming the entry.

Page 19/48

Page 20

PressureMAT User Guide

GLOBAL SETTINGS

> Information

CONTROL SERVICE

> PV Decimal Off

Revision 8

Global Sett ings Menu

The Global Settings menu can be used to program settings for the system that impacts all

channels; turn ON or OFF features, or view system information. To access the Global

Settings menu press the BACK button three times in rapid succession. The following screen

appears:

System Power

Control Service

Communication

Date and Time

Note: Date and Time not present in S model

At this screen the UP/DOWN arrows are used to select the Global Setting. HOME/START

can be pressed at any time to return to the HOME screen.

Information

If SELECT/PROG button pressed, system information including firmware version is displayed.

Press the BACK button to return to the main menu.

System Power

If SELECT/PROG button pressed, the system power is removed. Press the HOME/START to

restore power.

Control Service

If SELECT/PROG button pressed, the following sub-menu appears with the following default

settings:

Pressure Normal

Alarm Latch Off

Backlight High

Audio Beep On

Keypad Secure Off

Note: On model S, Pressure and Backlight not shown

PV Decimal

At this screen the UP/DOWN arrows are used to select the Control Service setting.

If turned on, the 2nd decimal place is shown. If off only one decimal place is shown. In the HR

models, this will enable the 3rd decimal.

Page 20/48

Page 21

PressureMAT User Guide

DATE and TIME

> Date-Time DDMMMYY HH:MM:SS

Revision 8

Pressure

Gives the option to display calculated values on the 4th line of the HOME screen. Options:

Normal: Display pressure reading (PMAT4A or PMAT4R only)

Blank: Display is blank (all models but PMAT2P, 2A, 3A, 2F & 3P)

TMP: Displays (P1+P2)/2 - P3 (all models but PMAT1, 2P, 2A, 3A, 2F & 3P)

deltaP: Displays (P1- P2) (all models but PMAT1, 2P, 2P, 2A, 3A, 2F, & 3P)

Alarm Latch

If turned on, alarm conditions will remain after an alarm state occurred but is no longer present

until the STOP button is pressed.

Backlight

Can be set to High, Medium or Low.

Audio Beep

Can be turned Off.

Keypad Secure

If turned On, the function to zero the sensor with the left arrow is disabled.

Communications

Displays setting not used in the unit at the present time. DO NOT CHANGE SETTINGS.

Date and Time

If SELECT/PROG button pressed, the following sub-menu appears:

Report Next DDMMMYY HH:MM:SS

Report Start DDMMMYY HH:MM:SS

Report Rate 000 hrs

Daylit Time Off

This menu is used mainly for controlling data output to a PC.

Note: See Appendix C on Data Collection to a PC

At this screen the UP/DOWN arrows are used to select the setting.

Page 21/48

Page 22

PressureMAT User Guide

Revision 8

Date-Time

Used to set the current time. Use the RIGHT/LEFT ARROW button on the keypad

until you get to the digit that you want to change. Use the DOWN ARROW/UP

ARROW buttons on the keypad to change the values. To change a digit from a

numerical value to zero, change the value to a zero. When the correct value has been

selected, press the SELECT/PROG button and the value will be confirmed. To escape

from this menu without changing the value, press the BACK button and the main

channel menu will appear.

Next Report

Indicates the next data report time. A report of the current system data is sent out the

serial port with the RS232 protocol and can be captured into a PC program or other

device. The time will be displayed automatically commencing with the start of the first

report, and this field should not be changed by the user. The PressureMAT Data

Acquisition Software does not require reports to be generated automatically but for

other external devices, this is required.

Report Start

Report start is used to set time of the next data report. Use the RIGHT/LEFT ARROW

button on the keypad until you get to the digit that you want to change. Use the

DOWN ARROW/UP ARROW buttons on the keypad to change the values. To change

a digit from a numerical value to zero, change the value to a zero. When the correct

value has been selected, press the SELECT/PROG button and the value will be

confirmed. To escape from this menu without changing the value, press the BACK

button and the main channel menu will appear. The report start time must be set later

than the current time for data output to commence. The The PressureMAT Data

Acquisition Software does not require reports to be generated automatically but for

other external devices, this is required.

Report Rate

Report rate is used to set the frequency of data report. The frequency (sec, min, hours,

days or months may be selected). Use the RIGHT/LEFT ARROW button on the

keypad until you get to the digit that you want to change. Use the DOWN

ARROW/UP ARROW buttons on the keypad to change the values. To change a digit

from a numerical value to zero, change the value to a zero. When the correct value has

been selected, press the SELECT/PROG button and the value will be confirmed. To

escape from this menu without changing the value, press the BACK button and the

main channel menu will appear. The PressureMAT Data Acquisition Software does not

require reports to be generated automatically but for other external devices, this is

required.

Daylight Save

Since the clock is used only to generate data reports that can be time stamped by the

receiving device, it is recommended to keep this in the Off selection.

Page 22/48

Page 23

PressureMAT User Guide

Revision 8

2. Setup and Use of the System

2.1. System Setup*

1. Connect the pressure sensor cables to the back panel. If a pressure sensor is not connected

when power is supplied to the system, the pressure will go to a value greater than 75 psi/

5.17 bar and an high pressure alarm condition will occur on the respective channel(s). If a

sensor is inadvertently disconnected during a process and stops monitoring pressure, there

will be an alarm notification. An associated relay will switch and the analog output will

send >20mA.

2. Connect the analog and relay outputs, if required as shown in Section 1.2.1

3. Connect the pressure sensor(s) to the cable(s) connected to the system.

4. Connect system to appropriate power source.

Note: If a pressure sensor is not connected or is disconnected during operation of the system,

the pressure reading will drift and eventually go to a value greater than 75psi/5.17 bar and

an alarm condition will occur. The time until the high alarm occurs may vary and this

feature should not be used to control a process due to the time variance. Associated relays

will switch and the analog output will send >20mA. Also, a new sensor that has not been

zero-calibrated can bypass an alarm set-point triggering an alarm condition.

5. Using the instructions from the previous section 1.2.2 and while the sensor(s) is at

atmospheric pressure, zero calibrate the sensor(s) being used (if not reading 0.0 psi / 0.00

bar when installed) by pressing the Tare (LEFT ARROW) button with the proper channel

selected.

* See Section 3 for information on the flow meter input function and Section 4 for analog input

function.

Page 23/48

Page 24

PressureMAT User Guide

Revision 8

2.2. Using the System*

1. Using the instructions from the previous section 1.2.3, set the appropriate high and low alarm

pressure settings for each channel. The unit is supplied with the low alarm set at -7 psi (- 0.5

bar) and with the high alarm set at 30 psi (2 bar). These are the set-points that will trigger an

alarm condition. High and low pressure settings are entered on the key pad and if the process

pressure goes below the low setting or above the high setting, the system will go into alarm

state. The alarm function includes:

a. An audible tone for 30 seconds,

If present, a dry contact relay associated with that channel will switch (i.e., if wired as

b.

normally CLOSED, it will OPEN; if wired as normally OPEN, it will CLOSE)

When an alarm condition goes away, all indicators automatically go back to normal (unless the

optional alarm latching function is turned on which requires the STOP button to be pressed to

clear the alarms). If the alarm settings are set to 0.00, then no alarm conditions are monitored,

however, if a sensor is disconnected, an alarm will still occur.

2. If a pressure sensor is not connected or is disconnected during operation of the system, the

pressure reading will drift and eventually go to a value greater than 75psi/5.17 bar and an alarm

condition will occur if the high alarm set-point is surpassed or in psi when the value goes

above the hard-coded limit of 75. . The time until the high alarm occurs may vary and this

feature should not be used to control a process due to the time variance (and a 20mA signal

will be transmitted from the analog output and/or relays will switch, depending on model).

3. The HOME screen will display pressure from the sensors that are connected.

* See Section 3 for information on the flow meter input function and Section 4 for analog input

function.

Page 24/48

Page 25

PressureMAT User Guide

1 Pressure X.XX bar

Revision 8

3. Flow Meter Function in PressureMAT-PLUS (2P, 3P & 2F)

3.1. Display

The home screen displays flow on the 4th line as shown below (PMAT3P shown and bar units shown).

2 Pressure X.XX bar

3 Pressure X.XX bar

4 PV Rate X.XX mL/m

3.2. Back Panel

The back panel of the unit is as shown below:

PMAT3P:

PMAT2P:

Page 25/48

Page 26

PressureMAT User Guide

+5V

( - )Return

Signal: 0-16.38KHz

FLOW

As shown on the back panel label, the SIGNAL

before connecting.

Revision 8

3.3. Connection to Back Panel

External Cable Connections to Back Panel

input is on the middle pin, the return/common is

on the top pin and if required (varies by type of

flow meter) the +5VDC is on the bottom pin.

NOTE: Wire colors may vary- confirm signals

___________________

Common

METER

INPUT

_____________________

3.4. Navigation in the Flow Meter Input Channel

At the HOME screen, the UP/DOWN arrows are used to select the flow input channel. The

flow meter menus are as follows.

Input Viewing

At this screen the UP/DOWN arrows are used to select what value is displayed on the HOME

Panel Connector

screen. Press the SELECT/PROG button to select what value appears on the home screen for

the respective channel. The “*” appears next to the current selection for HOME screen

display. In most case this will remain as the PV Rate value (Present Value Flow Rate).

PV Qty 1 and PV Qty 2 are flow totalizers. They accumulate total flow. They can be reset to

zero by pressing the left arrow button. The PV signal is the frequency of pulses from the flow

meter and this is converted to flow by the pulse constant:

Flow (mL/m) = pulses/sec * 60 sec/min / pulses/mL

The pulse constant is set in the programming menu for the respective channel.

Page 26/48

Page 27

PressureMAT User Guide

Channel 4 Input Viewing

> * PV Qty 1 XXXXX.XX L

[SELECT] home display value

Channel 4 Input Programming

> Port Type In Plse

Channel Name

Revision 8

The Service Time is the number of hours the system has been in service. Pressing the

SELECT/PROG button will confirm a change- UNTIL THIS IS DONE, A SETTING

CHANGE IS NOT CONFIRMED. Pressing the HOME or BACK button before confirming a

setting change with the SELECT/PROG button will escape from that program menu without

saving changes made before confirming the entry.

PV Qty 2 XXXXX.XX L

PV Rate 0.00 L/m

PV Signal 0 Hz

Service Time XXXX hrs

Input Programming

At this screen the UP/DOWN arrows are used to select what function to program. Press the

SELECT/PROG button to program the function. The setting or digit of a setting that can be

changed with the UP/DOWN arrows blinks. If there is more than one digit in a setting, use the

RIGHT/LEFT arrows to scroll within the possible digit locations within a setting. Pressing the

SELECT/PROG button will confirm a change- UNTIL THIS IS DONE, A SETTING

CHANGE IS NOT CONFIRMED. Pressing the HOME or BACK button before confirming a

setting change with the SELECT/PROG button will escape from that program menu without

saving changes made before confirming the entry.

IT IS ONLY RECOMMENDED THAT THE ITEMS IN SHOWN IN BOLD BELOW

ARE CHANGED. SCROLL TO SEE ALL SETTINGS:

Time Base min

Decimal Point xx.x

Measure Units L

Scale Factor 1.000

Pulse Constant 100000 p/L

PV Average 1.0 sec

Lo PV Alarm 0.00 L/min

Hi PV Alarm 0.00 L/min

Alarm Valid 002 sec

Qty1 Alarm 0.00 L

Qty2 Alarm 0.00 L

Time Alarm 0000 hrs

Comm Port Off

Log Type Off

Note: If the Alarm Points are set to 0.00 then there will be no alarm

After 30 seconds of inactivity in the program menu, the selected setting to change stops

blinking and the value before the setting was selected is restored.

Page 27/48

Page 28

PressureMAT User Guide

Revision 8

Changing the Pulse Constant- Press the SELECT/PROG with Pulse Constant selected. The

default value is 100000 pulses/L which is the default value for the PDKT-FM

22WV flow meter with the ¼ inch hosebarb. To determine a pulse constant, set the pulse

constant to 1 and totalize flow through the flow meter rotor. The total flow registered on the

LCD is actually the number of pulses and this can be divided by the volume collected to yield

pulses/mL.

Changing the Alarm Point- Press the SELECT/PROG with the desired Alarm selected. Use

the RIGHT ARROW button on the keypad until you get to the digit that you want to change.

Use the DOWN ARROW/UP ARROW buttons on the keypad to change the values. To

change a digit from a numerical value to zero, change the value to a zero. When the correct

value has been selected, press the SELECT/PROG button and the value will be confirmed. To

escape from this menu without changing the value, press the BACK button and the main

channel menu will appear.

Alarm Valid- This value is set to a default of 0 seconds. This is the amount of time an alarm

condition must be present for an actual alarm to occur. In certain processes with rapidly

changing pressures, this value can be changed to prevent undesired false alarms. Press the

SELECT/PROG with Alarm Valid selected. Use the RIGHT ARROW button on the keypad

until you get to the digit that you want to change. Use the DOWN ARROW/UP ARROW

buttons on the keypad to change the values. To change a digit from a numerical value to zero,

change the value to a zero. When the correct value has been selected, press the

SELECT/PROG button and the value will be confirmed. To escape from this menu without

changing the value, press the BACK button and the main channel menu will appear.

Comm Port- Indicates data output function. There are several settings but the only active

settings are Off and Serial Report (Sio Report). If Off is selected, no data for the selected

channel is sent out the Serial Port. If Sio Report is selected, data is sent out the Serial RS232

port at the frequency programmed in the Global Settings Menu if set for automatic report

generation. Reports are not required to be automatically generated with the PressureMAT Data

Acquisition Software (see Appendix C for details on data collection from the PressureMAT).

Press the SELECT/PROG with Comm Port selected.

Use the DOWN ARROW/UP ARROW buttons on the keypad to change the settings. When

the correct setting has been selected, press the SELECT/PROG button and the value will be

confirmed. To escape from this menu without changing the value, press the BACK button and

the main channel menu will appear.

Note: See User Guide Appendix C on Data Collection to a PC

Page 28/48

Page 29

PressureMAT User Guide

Revision 8

Time Alarm- This value is set to a default of 0000 hours. This can be set to trigger an alarm

in a set period of time and most likely will remain at 0000 hours which indicates it is not

active. Press the SELECT/PROG with Alarm Valid selected.

Use the RIGHT ARROW button on the keypad until you get to the digit that you want to

change. Use the DOWN ARROW/UP ARROW buttons on the keypad to change the values.

To change a digit from a numerical value to zero, change the value to a zero. When the correct

value has been selected, press the SELECT/PROG button and the value will be confirmed. To

escape from this menu without changing the value, press the BACK button and the main

channel menu will appear.

Page 29/48

Page 30

PressureMAT User Guide

1 Pressure X.XX bar

Revision 8

4. Analog Input Function in PressureMAT-PLUS (2P, 3A & 2A only)

4.1. Display

The home screen displays the scaled analog input value as shown below (PMAT2P shown and bar

units shown).

2 Pressure X.XX bar

3 PV X.XX YYY

4 PV Rate X.XX mL/m

4.2. Back Panel

The back panel of the unit is as shown below:

PMAT2P:

Page 30/48

Page 31

PressureMAT User Guide

Channel 3 Input Viewing

> * PV X.XX YYY

[SELECT] home display value

(-) Return

Signal

ANALOG

As shown on the back panel label, the ANALOG

Revision 8

4.3. Connection to Back Panel

External Cable Connections to Back Panel

INPUT signal is on the middle pin and the top pin

is the common / ground. The ANALOG

OUTPUT signal is on the bottom pin and the top

is common ground.

___________________

Panel Connector

Common

INPUT

_____________________

4.4. Navigation in the Analog Input Channel

At the HOME screen, the UP/DOWN arrows are used to select the Analog input channel (3rd

line). The menu is as follows.

Input Viewing

At this screen the UP/DOWN arrows are used to select what value is displayed on the HOME

screen. Press the SELECT/PROG button to select what value appears on the home screen.

The “*” appears next to the current selection for HOME screen display. In most case this will

remain as the PV which is the scaled value based the values entered for the 4-20mA values.

PV Signal is the actual mA input value. The Service Time is the number of hours the system

has been in service. Pressing the SELECT/PROG button will confirm a change- UNTIL THIS

IS DONE, A SETTING CHANGE IS NOT CONFIRMED. Pressing the HOME or BACK

button before confirming a setting change with the SELECT/PROG button will escape from

that program menu without saving changes made before confirming the entry.

PV Signal 0.000 mA

Service Time XXXX hrs

Input Programming

Page 31/48

Page 32

PressureMAT User Guide

Channel 3 Input Programming

> Port Type In 0-20mA

Channel Name

Revision 8

At this screen the UP/DOWN arrows are used to select what function to program. Press the

SELECT/PROG button to program the function. The setting or digit of a setting that can be

changed with the UP/DOWN arrows blinks. If there is more than one digit in a setting, use the

RIGHT/LEFT arrows to scroll within the possible digit locations within a setting. Pressing the

SELECT/PROG button will confirm a change- UNTIL THIS IS DONE, A SETTING

CHANGE IS NOT CONFIRMED. Pressing the HOME or BACK button before confirming a

setting change with the SELECT/PROG button will escape from that program menu without

saving changes made before confirming the entry.

IT IS ONLY RECOMMENDED THAT THE ITEMS IN SHOWN IN BOLD BELOW

ARE CHANGED. SCROLL TO SEE ALL SETTINGS:

Measure Units YYY

Time Base Scalar

Decimal Point xx.x

Low Signal 4.000 mA

Low Units 0.0 YYY

High Signal 20.000 mA

High Units 70.0 YYY

Lo PV Alarm 0.00 YYY

Hi PV Alarm 0.00 YYY

Alarm Valid 000 sec

Time Alarm 0000 hrs

Comm Port Off

Log Type Off

Note: If the Alarm Points are set to 0.00 then there will be no alarms

After 30 seconds of inactivity in the program menu, the selected setting to change stops

blinking and the value before the setting was selected is restored.

Measure Units- This determines the label for the analog input units

Changing the Low and High Units- This determines the scale of the calculated units for the

analog input. The PV is determined by the following formula based on the Low and High

Units entered:

PV = ((PVmA Signal – 4) /16) * (High Units - Low Units) YYY

Changing the Alarm Point- Press the SELECT/PROG with the desired Alarm selected. Use

the RIGHT ARROW button on the keypad until you get to the digit that you want to change.

Use the DOWN ARROW/UP ARROW buttons on the keypad to change the values. To

change a digit from a numerical value to zero, change the value to a zero. When the correct

value has been selected, press the SELECT/PROG button and the value will be confirmed. To

escape from this menu without changing the value, press the BACK button and the main

channel menu will appear.

Page 32/48

Page 33

PressureMAT User Guide

Revision 8

Alarm Valid- This value is set to a default of 0 seconds. This is the amount of time an alarm

condition must be present for an actual alarm to occur. In certain processes with rapidly

changing conditions, this value can be changed to prevent undesired false alarms. Press the

SELECT/PROG with Alarm Valid selected. Use the RIGHT ARROW button on the keypad

until you get to the digit that you want to change. Use the DOWN ARROW/UP ARROW

buttons on the keypad to change the values. To change a digit from a numerical value to zero,

change the value to a zero. When the correct value has been selected, press the

SELECT/PROG button and the value will be confirmed. To escape from this menu without

changing the value, press the BACK button and the main channel menu will appear.

Comm Port- Indicates data output function. There are several settings but the only active

settings are Off and Serial Report (Sio Report). If Off is selected, no data for the selected

channel is sent out the Serial Port. If Sio Report is selected, data is sent out the Serial RS232

port at the frequency programmed in the Global Settings Menu. Reports are not required to be

automatically generated with the PressureMAT Data Acquisition Software (see Appendix C for

details on data collection from the PressureMAT). Press the SELECT/PROG with Comm Port

selected. Use the DOWN ARROW/UP ARROW buttons on the keypad to change the settings.

When the correct setting has been selected, press the SELECT/PROG button and the value will

be confirmed. To escape from this menu without changing the value, press the BACK button

and the main channel menu will appear.

Note: See User Guide Appendix C on Data Collection to a PC

Time Alarm- This value is set to a default of 0000 hours. This can be set to trigger an alarm

in a set period of time and most likely will remain at 0000 hours which indicates it is not

active. Press the SELECT/PROG with Alarm Valid selected.

Use the RIGHT ARROW button on the keypad until you get to the digit that you want to

change. Use the DOWN ARROW/UP ARROW buttons on the keypad to change the values.

To change a digit from a numerical value to zero, change the value to a zero. When the correct

value has been selected, press the SELECT/PROG button and the value will be confirmed. To

escape from this menu without changing the value, press the BACK button and the main

channel menu will appear.

Page 33/48

Page 34

PressureMAT User Guide

Revision 8

5. Cable Information

5.1. Cable for Pressure Inputs

12 feet (3.7 m) in length with a 4 pin connector to connect a pressure sensor on one end

and a male DB 15connector to connect to the PressureMAT on the other end

(DB15 connector connected to PendoTECH Part Number PDKT-650-298)

Wiring:

DB15 Pins: 2: WHITE 7: GREEN 9: RED 12: BLACK and SHEILD (Silver)

Page 34/48

Page 35

PressureMAT User Guide

Revision 8

APPENDIX A: PRODUCT WARRANTY

PENDOTECH LIMITED WARRANTY

LIMITED WARRANTY: Subject to the limitations contained in LIMITATION OF REMEDY AND LIABILITY and except as otherwise expressly

provided herein, PendoTECH LLC (“Seller”) warrants that the Software will execute the programming instructions provided by Seller, and that the

products, systems and goods (“Goods”) manufactured by Seller will be free from defects in materials or workmanship under normal use and

service until the expiration of tw enty -four (24) months from the date of shipment by Seller. Expendable items are warranted to be free from defects

in material and workmanship under normal use and service for a period of ninety (90) days from the date of shipment by Seller. Products

purchased by Seller from a third party for resale to Buyer (“Resale Products”) shall carry only the warranty extended by the original manufacturer.

Buyer agrees that Seller has no liability for Resale Products beyond making a reasonable commercial effort to arrange for procurement and

shipping of the Resale Products. If, within thirty (30) days after Buyer’s discovery of any warranty defects during the applicable warranty period,

Buyer notifies Seller thereof in writing, Seller shall, at its option and as Buyer’s sole and exclusive remedy hereunder, promptly correct any errors

that are found by Seller to exist in the Software, or repair or replace F.O.B. point of manufacture, that portion of the Goods or Software found by

Seller to be defective. All replacements or repairs necessitated by inadequate preventive maintenance, or by normal wear and usage, or by fault

of Buyer, or by unsuitable power sources or by attack or deterioration under unsuitable environmental cond itions, or by abuse, accident , alteration,

misuse, improper installation, modification, repair, storage or handling, or any other cause not the fault of Seller are not covered by this limited

warranty, and shall be at Buyer’s expense. Seller shall not be obligated to pay any costs or charges incurred by Buyer or any other party except

as may be agreed upon in writing in advance by an authorized Seller representative . All costs of dismantlin g, reinstallation and freight and the time

and expenses of Seller’s personnel for site travel and diagnosis under this warranty clause shall be borne by Buyer unless accepted in writing by

Seller. Failure by Buyer to give such written notice of defects within the applicable time period shall be deemed an absolute and unconditional

waiver of Buyer’s claim for such defects. Goods repaired and parts replaced during the warranty period shall be in warranty for the remainder of

the original warranty period or ninety (90) days, whichever is longer. All warranties, either express or implied, extend to BUYER only. All

descriptions, representations and/or other information concerning Goods on the PendoTECH website and/or contained in PendoTECH’s

advertisements, brochures, promotional material, or statements made by employees or sales representatives of PendoTECH are solely for

general informational purposes only and are not binding upon PendoTECH. No employee or sales representative of PendoTECH shall have any

authority to establish, expand or otherwise modify PendoTECH’s warranty associated with the sale of Goods. SELLER shall not be liable to

BUYER in any manner with respect to Goods sold. SELLER MAKES NO REPRESENTATIONS OR WARRANTIES OF ANY TYPE, EXPRESS

OR IMPLIED, AND EXPRESSLY DISCLAIMS AND EXCLUDES ANY REPRESENTATION OR WARRANTY OF MERCHANTABILITY,

FITNESS FOR A PARTICULAR PURPOSE OR USE, NON-INFRINGEMENT OR WARRANTY ARISING FROM USAGE OF TRADE, COURSE

OF DEALING OR PERFORMANCE. PendoTECH, LLC makes no warranty or representation regarding whether or not a customer’s end use of

any PendoTECH product, sys tem or good infringes the valid in tellec tual property rights of others.

LIMITATION OF REMEDY AND LIABILITY: SELLER SHALL N OT B E LI ABL E FOR DAMAGES CAUSED BY DEL AY IN P ERF OR M ANC E.

THE SOLE AND EXCLUSIVE REMEDY FOR BREACH OF WARRANTY HEREUNDER SHALL BE L IMIT ED T O R E PAIR, CO RRE CTION O R

REPLACEMENT UNDER THE LIMITED WARRANTY. IN NO EVENT, REGARDLESS OF THE FORM OF THE CLAIM OR CAUSE OF

ACTION (WHETHER BASED IN CONTRACT, INFRINGEMENT, NEGLIGENCE, STRICT LIABILITY, OTHER TORT OR OTHERWISE), SHALL

SELLER’S LIABILITY TO BUYER AND/OR ITS CUSTOMERS EXCEED THE PRICE TO BUYER OF THE SPECIFIC GOODS

MANUFACTURED BY SELLER GIVING RISE TO THE CLAIM OR CAUSE OF ACTION. BUYER AGREES THAT IN NO EVENT SHALL

SELLER’S LIA BIL IT Y TO BU Y ER A ND /OR IT S CU ST OM ER S EX TEN D TO INC L UD E IN C ID ENT AL , CON SEQ U EN TI AL OR PU N IT IV E

DAMAGES. THE TERM “CONSEQUENTIAL DAMAGES” SHALL INCLUDE, BUT NOT BE LIMITED TO, LOSS OF ANTICIPATED PROFITS,

LOSS OF USE, LOSS OF REVENUE AND COST OF CAPITAL. Rev. 0

Page 35/48

Page 36

PressureMAT User Guide

Revision 8

APPENDIX B: PendoTECH Single Use Pressure Sensors

PendoTECH’s Single Use Pressure Sensors are a low-cost solution for use with tubing and bioprocess

containers and are compatible with both gamma, ETO and autoclave sterilization. They can be

integrated for pressure measurement and control. The sensors are designed for use with products

offered by PendoTECH. Other sensor monitors must be tested for compatibility and PendoTECH

assumes no responsibility of compatibility of performance with other instruments.

Warranty:

They are covered by a separate product warranty from the PressureMAT system.

General Information:

They must be qualified by the user for suitability for an application.

WARNING: EACH PROSPECTIVE USER MUST TEST THE SENSOR FOR ITS

PROPOSED APPLICATION TO DETERMINE ITS SUITABILITY FOR THE PURPOSE

INTENDED PRIOR TO INCORPORATING THE SENSOR TO ANY PROCESS OR

APPLICATION. THE SENSORS ARE NOT INTENDED FOR USE AS COMPONENTS IN

LIFE SUPPORT. THE SENSORS ARE NOT DESIGNED FOR ANY APPLICATION IN

WHICH THE FAILURE OF THE PRODUCT COULD RESULT IN PERSONAL INJURY OR

DEATH.

THEY ARE NOT DESIGNED FOR USE ABOVE 75 PSI (5.2 BAR)

For More Information:

http://www.pendotech.com/pressure

Application Notes are available on Autoclave of the Sensors and Compatibility with NaOH used in

sanitization.

Page 36/48

Page 37

PressureMAT User Guide

Select Model

Pressure Units

Flow Units

Weight Units

View Present Values for current PMAT model and scale if connected

Set Units of Measure from pick-listIndicate if scale connected

Select

PMAT

Model

Display

Calculated

Values

Enter informat ion

that is written to

data file header

Select file

update rate

Start writing

data to file

Tab navigation

Indicates file

location

Scale must be set to:

Continuous data output.

Revision 8

APPENDIX C: PressureMAT Data Acquisition Software

The PendoTECH PressureMAT (PMAT) monitor/transmitter that is used to read the PendoTECH Pressure

Sensors comes with an RS232 data port as a standard feature. PendoTECH has a customized software package

(Part # PMAT-GUI ) to trend data real-time and also collect the data to a file that can be opened by programs

such as Excel. The software has settings to choose the PressureMAT model from a list and it can optionally

perform calculated values such as DeltaP and also trans-membrane pressure that are used for certain filtration

applications. PMAT-PLUS models will collect the flow data into a trend separate from the pressure data. The

PMAT-2PLUS model has an analog input port to which different sensors such as the PendoTECH Temperature

Sensor, UV Sensor, Turbidity Sensor or other sensor can be connected via their 4-20mA transmitter and this

data can be logged with the pressure and flow data. Additionally, a scale with an RS232 output maybe plugged

into the PC directly and the software can acquire weight data along with the PressureMAT data.

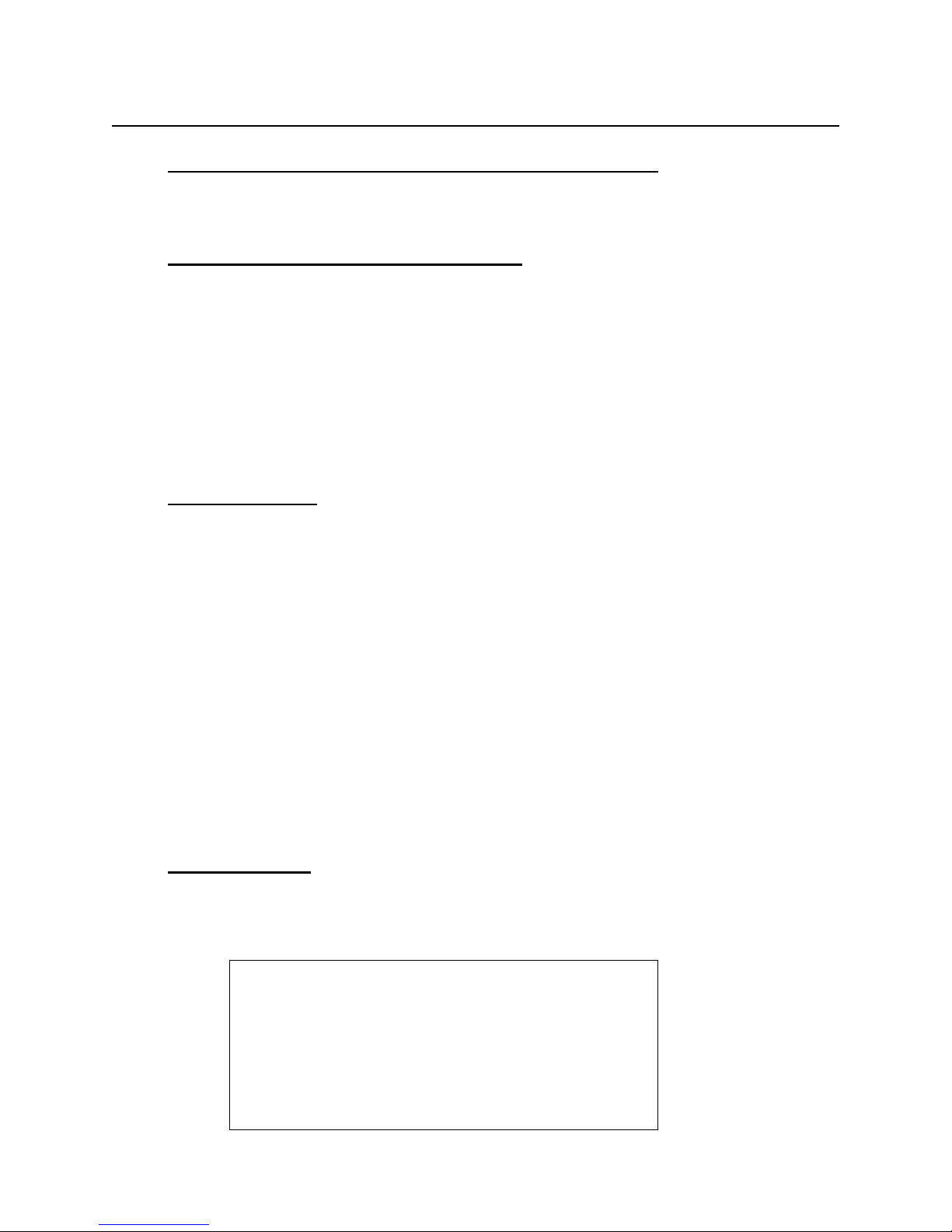

Setup View

The setup view is used to enter information specific to the PMAT model and to select calculated values for specific

applications. Data collection from a scale can be activated here also. The units of measure are selected to match the units

on the PressureMAT and scale. At the top, information can be entered that is specific to an experiment and this data is

written to the header of the data file when the data file is created. The data file location is also displayed. The data file

may be updated at a rate of every 2 seconds or slower. All of the inputs to this view are locked out when the “Start Process

Data Collection” button is clicked .

RS232 communication

protocol, with settings:

1200 baud, 7 data bits,

ODD parity, 1 stop bit,

NO HANDSHAKE.

The PMAT model and units are selected by pick-lists. These units are then used for the trends view and used in the column headers

of the data files to indicate the units of the values in each column.

Page 37/48

Page 38

PressureMAT User Guide

Units of

measure

are shown

Axis for

each unit

appears and

can be set to

auto or manual

scaling with

one click

Customize

format of

trend line

Set trend

“FIFO” rate

Ability to

Export data

on the trend

only to a file

Trend view

toolszoom, etc.

Set trend

update rate

Available values

can be selected

for trending

Present

values are

shown

Cursor

Values are

shown

Ability to

enter electronic

notes to the

data file

Cursor value selector

Revision 8

Trends View

The Trends View has the fle xibility to allow customization of the view to meet your requirements. The pick lists allow you

to display the data of interest and at any time items can be added or removed from the plot area. It features auto-scaling

options for all axes or manual scaling by simply typing mix/max values at an axis scale. The cursor tool is useful to

compare older data versus present. Electronic Notes may be entered and the notes will be written to the data file with the

following data record. The trends view features are highlighted below which is shown with a PMAT-2PLUS with

temperature as the analog input and TFF calculations enabled. The plot with legend may also be copied as a picture for

immediate placement into a report or presentation.

Data File

The file may be located in any

directory and is created when the

“Start Process Data Collection”

button is clicked. The data is

written to this file that is locked by

the software until the “End Process

Data Collection” button is clicked .

The file format is CSV that is set to

automatically open with Excel.

A file sample is shown. The notes

column is empty except for where

notes were entered so they are easily

located at the time identified.

Page 38/48

Page 39

PressureMAT User Guide

Revision 8

APPENDIX D: Panel Mount of System

PressureMAT

PMAT (except -S) PMAT-S

All dimensions in inches, +/- 0.015

Page 39/48

Page 40

PressureMAT User Guide

Revision 8

PressureMAT Panel Mount Upgrade Kit- Part # PMAT-PANEL

Comprised of :

- 2 gaskets (one and a spare)

- 4 mounting bracket

- Sensor cables and connector (one for each input)

- Power input connector.

Page 40/48

Page 41

PressureMAT User Guide

Herewith declare that the

Information technology equipment devices for

Product Identification (brand

PressureMAT Monitor, Alarm and Transmitter

PendoTECH Single Use Pres sur e Sensors

Revision 8

APPENDIX E: EC Declaration of Conformity

EC Declaration of Conformity

The undersigned, representing the following supplier:

PendoTECH

174 Nassau Street Suite 256

Princeton, NJ 08542 USA

measurement, monitoring, controlling and

communicating for commercial and light industrial application

models)

are in conformity with the provisions of the following EC Directive(s) when installed in accordance with the

instructions contained in supplied product documentation:

2014/30/EU EMC Directive, Class B, Report A50728I1

2014/35/EU Low Voltage Directive, Report A50728I1

2006/42/EC Machinery Directive, Report R-0709-001

2006/95/EC Low Voltage Directive, Report R-0716-001

and the standards and/or technical specifications for EN 61326-1: 2013 comprised on the following

specifications:

IEC 61000-4-2: 2008, IEC 61000-4-3: 2006+A1 : 2007+A2: 2010, I EC 61000-4/4: 2004+A1: 2010, EN 61000-45:2006, IEC 61000-4-6: 2008, IEC 61000-4-8: 2009, IEC 61000-4-11: 2004, EN 61000-3-2:

2006+A1:2009+A2:2009, EN 61000-3-3: 2008, IEC 61000-3-11: 2000, IEC 61000-3-12: 2011, CISPR 11:

2009+A1: 2010, all inclusive.

Safety requirements for electrical equipment for measurement, control and laboratory use, Part 1: General

Requirements; EN 61010-1:2010.

Safety of Machiner y – Safety-related Parts of Contr ol Systems, Par t 1: General Requir ements; EN/ISO 138 491:2009.

Safety of Machinery – Electrical equipment of machines – Part 12: General Requirements: EN 60204-1:2009.

Year of CE Marking: 2008 through Present

(PMAT1, PMAT1HR, PMAT2, PMAT3, PMAT3P, PMAT4A, PMAT4R,

PMAT2P, PMAT2A, P MAT 2F , PMAT2HR, PMAT3A, PMAT DAQ) with

Supplier:

Signature On file

Name: James Furey

Position: General Manager

Date: April 19, 2016

Page 41/48

Page 42

PressureMAT User Guide

PressureMAT

Position

(AMBER)

Normally

Pinch Valve

No Alarm Signal

OFF

CLOSED

Alarm Signal

ON

OPEN

Device

Component

Specifications

Enclosure

Material: ABS Plastic, top and bottom pieces of box sealed with gasket seal rated

to IP66. Note: Hole w her e the valve is mounted is not water tight.

Pinch

Valves

- BioChem Valve Series 100P (http://www.bio-chemvalve.com/Pinch_Valves.pdf )

- Pinch valve catalog number set for specific size tubing and noted on dev i c e

Relay

Connexal PN 6282-2SG-3XX supplied with mating connector and 12 foot cable

connected to PressureMAT pin “T”.

Power Input

- 24 Volts DC

- 0.5 amp max per valve

WARNING- THE PINCH VALVE WILL CLOSE WHEN THE ALARM SIGNAL IS REMOVED FROM

CAN BYPASS AN ALARM SET-POINT TRIGGERING AN ALARM SIGNAL.

Revision 8

APPENDIX F: Pinch Valve Box Accessory (PDKT-PVE)

Overview

One to four pinch valves can be in each device. The cable to the associated PressureMAT relays must

be wired the normally OPEN configuration (wired to S and T as shown in Section 1.2.1). The valves

are normally closed and when there is NO POWER to the valve box or to the PressureMAT, the valves

will be closed. When power is supplied to the valve box the green LED will illuminate. When there is

an alarm condition on the PressureMAT, the PressureMAT relay will close and the valve will open.

Each valve is in the following configuration relative to the alarm signal on the PressureMAT System.

Condition

LED

Closed

Note: When the power supply is removed from the power inlet connector or the power

supply is unplugged from the wall, the valve will be in the “No Alarm Signal” position

independent of PressureMAT condition.

Signal

Input

with two wire leads for connection to PressureMAT. Connexal pin 1 power (plus,

pin with raised dot) for connection to Pr ess ur e M AT pin “S” ; Connexal pin 2 (minus)

THE VALVE. MAKE SURE NO FINGERS OR OBJECTS EXCEPT TUBING ARE INSERTED

INTO THE PINCH VALVE WHEN THE VALVE CLOSES.

WARNING: IF A PRESSURE SENSOR IS NOT CONNECTED WHEN POWER IS SUPPLIED TO

THE SYSTEM, THE PRESSURE WILL GO TO A VALUE GREATER THAN 77 PSI / 5.3 BAR AND

A HIGH PRESSURE ALARM CONDITION WILL OCCUR ON THE RESPECTIVE CHANNEL(S)

AND THE RELAY WILL SWITCH TO THE ALARM SIGNAL. IF A SENSOR IS INADVERTENTLY

DISCONNECTED DURING A PROCESS AND STOPS MONITORING PRESSURE, THERE WILL

BE AN ALARM SIGNAL. ALSO, A NEW SENSOR THAT HAS NOT BEEN ZERO-CALIBRATED

Page 42/48

Page 43

PressureMAT User Guide

Revision 8

Page 43/48

Page 44

PressureMAT User Guide

Revision 8

APPENDIX G: Using the PressureMAT with WinWedge Software

The PressureMAT has RS232 serial data output to a PC and if the PressureMAT Data Acquistion

Software is not used, WinWedge software may be used to collect data directly to Excel.

Winwedge Standard Edition available at: http://www.taltech.com/products/winwedge.html

Instructions

1. Connect the data output cable to the serial port on the back panel of the PressureMAT

2. Connect to your PC via serial port or to a USB port via adapter cable.

3. In the Global Settings menu, set the clock in the PressureMAT and set next report time after the

current time and set report frequency

4. Open the WinWedge software from the Programs menu

5. Open WinWedge file called PressureMAT4.sw3 (this file is available from PendoTECH)

6. Select port / settings and select the COM port (if not sure of COM port number, Open PC Control

Panel and select System/Hardware/Device Manager/Ports and the COM port number should be

evident)

7. Select File/Save in Winwedge

8. In WinWedge, select Activate/Test mode and pressure data should appear in the table

9. Close the WinWedge window

10. Select Activate Normal Mode but in the future open the PressureMAT4.sw3 file by doubleclicking (this file is available from PendoTECH)

11. Using the Input Programming menu in the PressureMAT, select the Comm Port setting in all

channels of data to be collect to Sio Reports

12. Open the PressureMAT4.xls Excel spreadsheet (this file is available from PendoTECH)

and Enable Macros if asked

13. In cell D1, select the same COM port as selected in WinWedge and data should appear at the freq

set in the PressureMAT. Cell D2 can be used to change the frequency of readings recorded in Excel

coming from the PressureMAT.

14. The Excel spreadsheet can be saved as a different file name so it is suggested that a master copy is

kept and use "Save As" for new projects.

For collection to software besides Excel- The data from each channel is output and the pressure

reading is the 6th field in each row. At the beginning of each report, there is a triangle turned on its

side then a heart. At the end there is a triangle turned on its side then a smiling face:

►♥AZ,00000.01,1, 0.00, 0.00,- 0.1 ,- 0.1 ,00026,X,X,X,X,X,F0

AZ,00000.03,1, 0.00, 0.00, 0.0 , 0.0 ,00010,X,X,X,X,X,11

AZ,00000.05,1, 0.00, 0.00,- 0.0 ,- 0.0 ,00010,X,X,X,X,X,F5

AZ,00000.07,1, 0.00, 0.00,- 0.0 ,- 0.0 ,00010,X,X,X,X,X,F3 ►☻

The command AZK<cr> can be also used to generate a report as desired. The unit operates using half

duplex request-and-reply protocol; after sending the request, DO NOT send anything else until the

resulting expected response is received. THEN the requestor is free to proceed.

(ie, send one AZK<cr>, THEN make sure a successful response is received).

Page 44/48

Page 45

PressureMAT User Guide

Revision 8

APPENDIX H: PressureMAT Smoothing Function (PV Filter)

Filtering of the Present Pressure Value with the PV Filter Function (also referred to as smoothing)

attempts to capture important data trends while leaving out noise and other outliers. In certain

applications, having a filter and an option for filter strength proves advantageous when measuring and

recording pressure with a PendoTECH PressureMAT™. The negative that comes with using a filter is

the increased amount of time it takes to stabilize and reach the actual value (if constant).

WARNING: Smoothing will lead to delayed alarm detection because readings are being

averaged and pressure spikes will not be immediately recognized.

The following set of four graphs gives an example of the how smoothing can present pump pulsation

differently by showing no filtering versus averaging a larger set of data values. The following

statistical analysis is used to demonstrate low, medium and high filtering.

%RSD (relative standard deviation) is a statistical measurement that describes the spread of data with

respect to the mean and the result is expressed as a percentage.

Page 45/48

Page 46

PressureMAT User Guide

Revision 8

Page 46/48

Page 47

PressureMAT User Guide

Revision 8

Page 47/48

Page 48

PressureMAT User Guide

Revision 8

As demonstrated with these four graphs, as more data is averaged as the PV Filter Setting is changed

from Low to Medium to High, the data from the same pumping process appears more stable. The

following graph demonstrates the negative that comes with using a filter- which is the increased