Page 1

Technical Note

Technical Note: PendoTECH Process Control Systems: Pump Calibration

Revision 0

Page 1 of 5

PendoTECH Process Control Systems: Pump

Calibration

1. Introduction

The PendoTECH Filter Screening System (NFF) and TFF Process (TFF) allow users to automatically

control flowrates throughout the duration of an experiment or process. Any pump capable of accepting a

remote-control signal can be interfaced with PendoTECH control systems. PendoTECH systems control

pumps by sending an analog signal which is proportional to the flowrate entered by the user on the

system’s graphical user interface (GUI). The analog output is scaled linearly from the pumps minimum

flowrate to its calculated maximum flowrate. The following note describes the process of configuring a

pump with its nominal flow values and making any necessary adjustments to compensate for the inherent

inefficiencies associated with pump technology.

2. Connecting Pumps

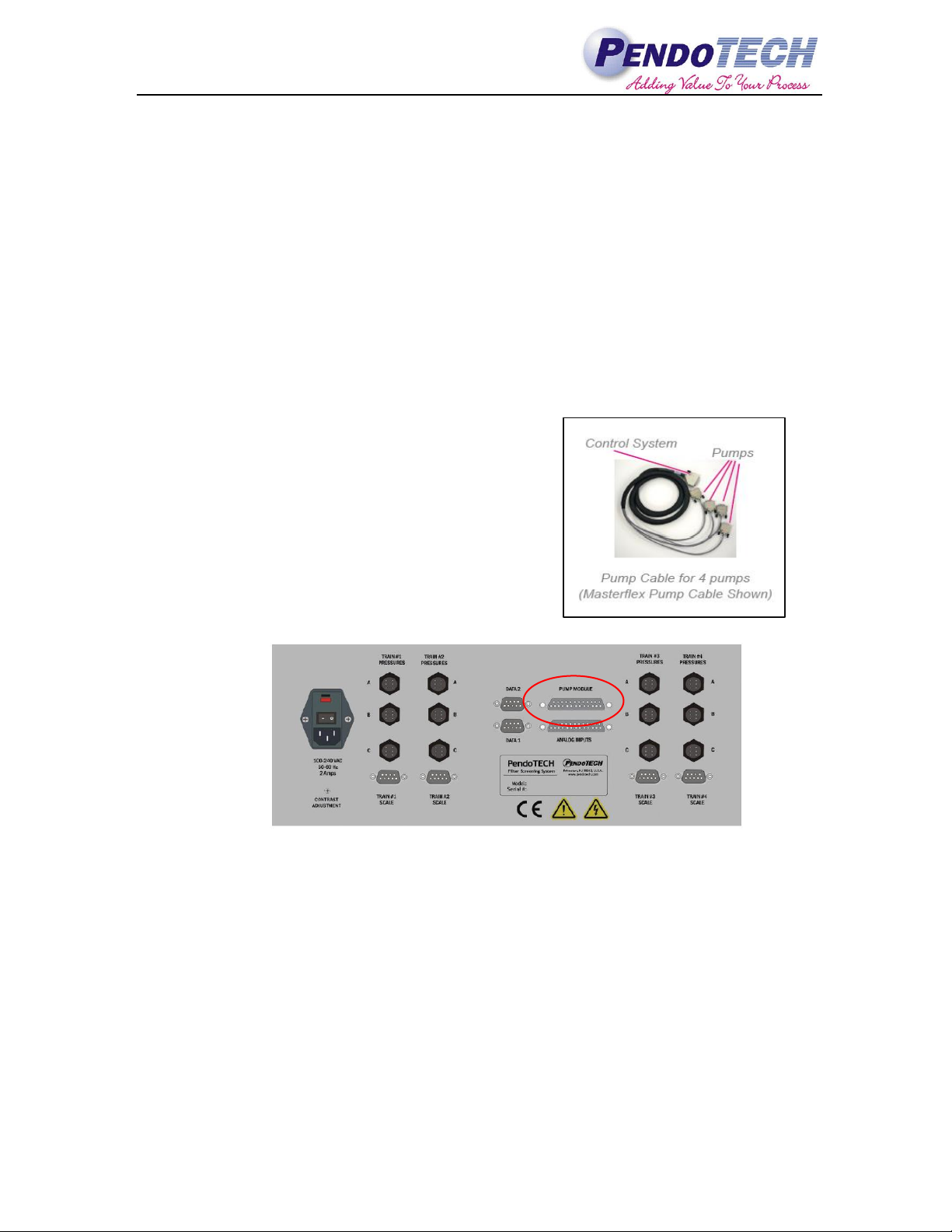

a. PendoTECH NFF System

The PendoTECH NFF system is capable of

independently controlling four pumps simultaneously. A

custom cable is included with purchase of the system that

must be specified to match the manufacturer of the pump

to be used with the system, i.e. Masterflex or WatsonMarlow. The four pumps must also be of identical make

and model in order to be used simultaneously. The use of

an adapter cable is available, upon request, if there is a

need to use a pump of different make and model. An

example of a Masterflex pump cable is shown at right and

the pump cable input is called out in the figure below.

Figure 2.1 Back Panel of NFF Control System

b. PendoTECH TFF System

The PendoTECH TFF system can control up to three pumps simultaneously, specifically a main

circulation pump, a diafiltration pump, and a Filtrate/Permeate pump. Unlike the NFF system, the

pumps being used on the TFF system do not need to be of the same make and model. However, it

is important to note that the connection cable between the control system and pump will vary

between different model pumps The pump inputs for the TFF system are called out below.

Note - Only one of the following inputs will be used: Circulation Pump/Circ Pump Alternate

Page 2

Technical Note

Technical Note: PendoTECH Process Control Systems: Pump Calibration

Revision 0

Page 2 of 5

Figure 2.2 Back Panel of TFF Control System

3. Calibrating Pumps

There are two primary parameters that determine the performance of a particular pump; the maximum

rotations per minute (RPM) of the pumps drive and the amount of liquid that is moved per revolution. The

first parameter is labeled in PendoTECH control systems as Max RPM and the second is labeled as

mL/rotation. These parameters must be input on the “Maintenance View” tab of the control system

software each time a new pump is connected to the system. Once the pump calibration parameters are input

they will be saved to the internal memory of the control system. The parameters are also stored within the

PC program and re-sent to the control system each time the PC software is opened. This is done to confirm

the correct settings are stored in the control system.

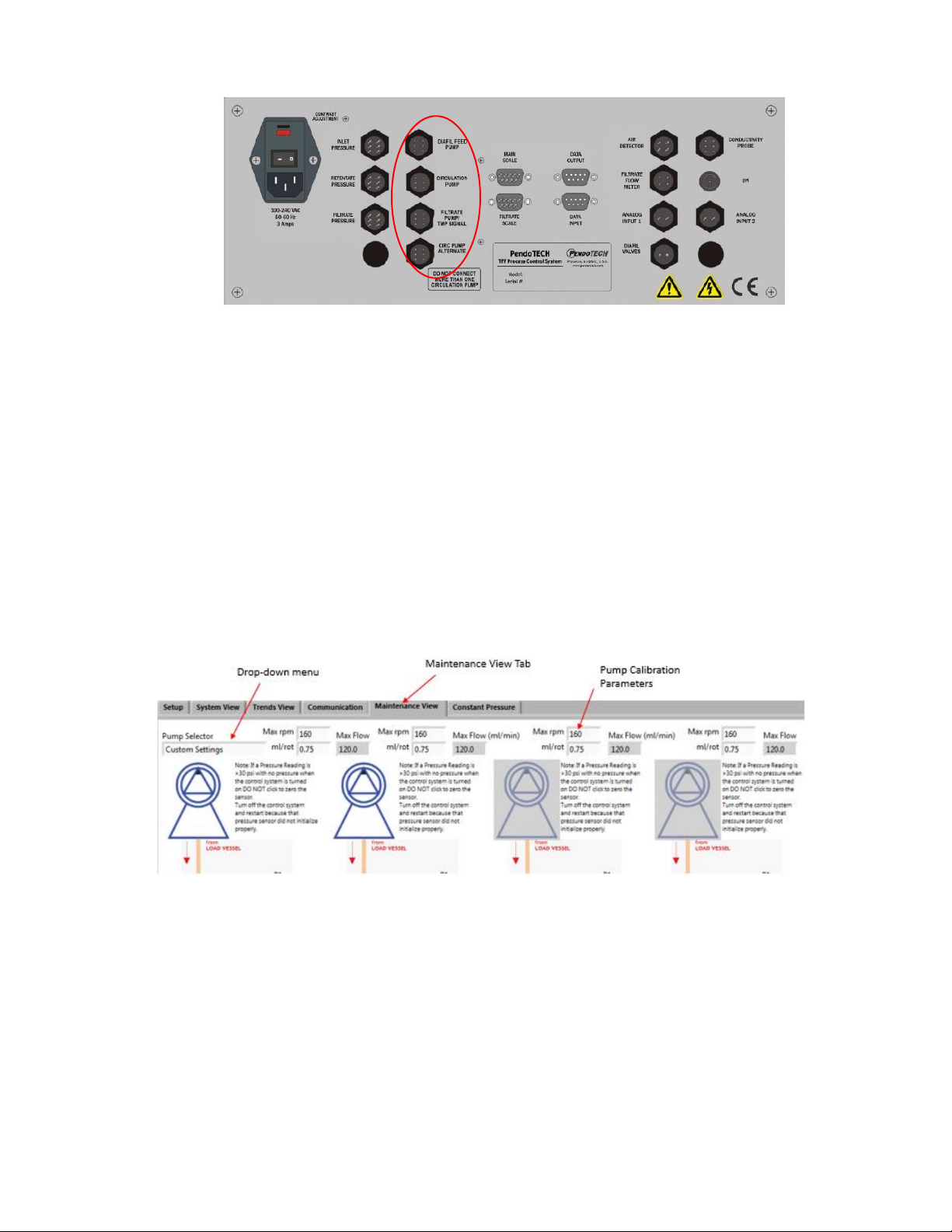

The following screenshot from the NFF control system software shows where the max RPM and mL/rot

values are entered. The control system has a drop-down menu that allows the user to select from a list of

standard pump offerings and will populate the nominal performance values for each pump across all four

trains. The user can also select “Custom Settings” if their pump is not listed or if they want to tweak the

nominal settings for more accurate flow control. Refer to section 4 for the process of verifying the

calibration of each pump.

Figure 3.1 NFF GUI "Maintenance View" Tab

Calibrating pumps on the TFF Process Control System software is done in a similar manner. The

calibration parameters are entered on the “Maintenance View” tab however, there is no drop-down pump

selector. Users normally connect different models of pumps to serve as the circulation pump and

diafiltration feed pump in order to achieve optimal flows. Therefore, each pump calibration must be input

separately into the fields noted below. Selection guides available from PendoTECH for popular peristaltic

pump models that provide this information based on tube size.

Page 3

Technical Note

Technical Note: PendoTECH Process Control Systems: Pump Calibration

Revision 0

Page 3 of 5

Figure 3.2 TFF GUI "Maintenance View" Tab

Note: The input fields for the “Filtrate Pump” will only appear if “Yes” is selected from the dropdown menu located below the text reading “Enable filtrate Pump”.

The following table lists some of the most popular nominal pump calibration paramters for PendoTECH’s

standard offering of pumps used with either the NFF or TFF control system. As shown below, the mL/rot

parameter for peristaltic pumps is dependent on tubing size while it is constant for diaphragm pumps

irregardless of the size of tubing connected to the inlet/outlet. The nominal values listed below are taken

directly from manufacturer documentation.

Manufacturer

Model

Max

RPM

ml/rot

(Size 14)

ml/rot

(Size 16)

ml/rot

(Size 17)

ml/rot

(Size 24)

ml/rot

(Size 36)

Quattroflow

Q150

3000

1

Quattroflow

Q1200

1200

17

Quattroflow

Q4400

583

99

Masterflex

L/S

600

0.22

0.8

2.8

2.8

4.8

Watson-Marlow

120U

200

0.14

0.47

N/A

N/A

N/A

Please refer to vendor documentation provided on PendoTECH.com or contact PendoTECH customer

service if you do not see your pump or tubing size listed above. In most cases, the mL/rot is the maximum

flow in mL/min divided by the maximum RPMs.

4. Flow Verification

This section will illustrate how to further calibrate

pumps if the nominal settings described in section 3

are insufficient. The PendoTECH NFF and TFF

systems control pumps, set to remote control, by

sending analog signals, generally 4-20 mA, that are

proportional to the flowrate entered by the user. The

user enters the unique calibration values for the

pump they are using as described in section 3. The

system then scales the ouput linearly from the

minimum flow value (0 LPM) to the calculated

maximum flowrate which is simply equal to MAX

RPM * mL/rotation. The following graph shows the

control logic for a Masterflex L/S pump with size 16

tubing installed.

Page 4

Technical Note

Technical Note: PendoTECH Process Control Systems: Pump Calibration

Revision 0

Page 4 of 5

Using an output that is scaled linearly assumes an ideal relationship between pump revolution and

displacement at all speeds. This is a fairly safe assumption at lower flowrates, due to limited back pressure

acting on the pump, and will generally yield stable results within 3-5% of the user entered flowrate.

However, with larger systems and higher flowrates, backpressure increases and inefficiences in the

pumping mechanisms are exascerbated leading to a non-linear flowcurve. A more realistic flowcurve is

shown in the graph below. At low-moderate drive speeds the Quattroflow Q150 flowcurve is still largely

linear but as the motor speed and backpressure increase the curve begins to flatten out as the pump is no

longer operating as efficiently.

In order to compensate for the inefficiencies desribed above PendoTECH recommends conducting a flow

verification during a conditioning or flushing step. An off-line bucket check can be performed to determine

the exact flowrate being output by the system. If a retentate flow meter is in line, the permeate can be

closed and the flow meter can be used to monitor pump outptut flow. The following data demonstrates an

extreme case of non-linearity. Data provided by Triangle Process Equipment during testing of Quattroflow

Q4400 with PendoTECH TFF Process Control System.

Shaft Speed RPM

HMI set point (LPM)

Actual (LPM)

Variance

215

21.66

20.7

- 4.5%

297

31

28.2

- 9%

400

40.7

37.88

- 7%

If an error of 5-10% is unacceptable by process standards than a one-point calibration can be performed to

dial in the required flowrate. This can be done by tweaking the ml/rot factor on the maintenace view sceen

as described in section 3. For example, if a 31 LPM flowrate was required, the data above shows that the

system was producing a flowrate that was 9% less than the expected value. To address this, the user could

simply decrease the ml/rot value for the circulation pump by 9% which would lead to the system delivering

exactly the required flowrate. A flowchart can be found in the appendix of this document which details how

to properly execute this procedure.

It is important to note that only the ml/rot value should be changed and not the Max RPM. If necessary this

routine can be performed for each pump operating as part of the system. In the case of the NFF, different

ml/rot values can be entered for each pump by selecting custom settings then tweaking the parameter

accordingly.

This calibration procedure is not unique to PendoTECH control system. For example, the flowrate

displayed on a Masterflex L/S during manual use is simply the pump assuming a linear flowcurve and

using the nominal values listed in section 3. The pump can then be further calibrated by the end user in

order to increase the accuracy of the system The deafult pump calibration procedure is essentially

changing the pump’s nominal mL/rotation parameter. For pumps that have an RPM display only, the user

0

0.5

1

1.5

2

2.5

3

3.5

0 500 1000 1500 2000 2500 3000

Flowrate (L/min)

Pump Speed (RPM)

Quattroflow Q150 Flow Curve

0 Bar

2 Bar

4 Bar

6 Bar

Page 5

Technical Note

Technical Note: PendoTECH Process Control Systems: Pump Calibration

Revision 0

Page 5 of 5

must develop a single or multi-point calibration to define the relationship between RPMs and flow which is

defined by mL/rotation factor.

Please visit PendoTECH.com or contact PendoTECH customer service if any further information is

required.

5. Appendix

Flow veritication Flowchart

Loading...

Loading...