Pelican WF10 User Manual

Owner’s Manual

Pelican Water Systems

Pelican WF6/WF10 Iron/Manganese

Filter & Salt Free Softener

WF6/WF10 Rev K —

Pelican Water Systems

Pelican WF6/WF10 Iron/Manganese Filter and Salt Free Softener

Page 2

© Copyright 2011 Enviro Water Solutions Inc. All rights reserved.

All information contained herein is the property of Pelican Water Systems. Pelican Water Systems makes

no warranty of any kind with regard to this material, including, but not limited to, the implied warranties of

merchantability and fitness for a particular purpose. Pelican Water Systems shall not be liable for technical

or editorial errors or omissions contained herein or for incidental or consequential damages in connection

with the furnishing, performance, or use of this material. The information is provided “as is” without

warranty of any kind and is subject to change without notice. This document contains proprietary

information which is protected by copyright. No part of this document may be photocopied, reproduced, or

translated into another language without the prior written consent of Pelican Water Systems. Pelican Water

Systems is an Enviro Water Solutions, Inc. company.

© 2011 Enviro Water Solutions, Inc.

3060 Performance Circle, Suite 2, DeLand, FL 32 72 4

www.pelicanwater.com

(877) 842-1635

WF6/WF10 Rev K —

Pelican Water Systems

Pelican WF6/WF10 Iron/Manganese Filter and Salt Free Softener

Page 3

Table of Contents

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Product Operation and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Important Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Water Conditions for Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Complete Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Pre-Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Bypass Valve Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Carbon Tank Soak . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Carbon Tank Wash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Pre-Filter Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Pre-Filter Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Chemical Injector Pump and Solution Tank Installation . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chemical Injector Pump Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Solution Tank Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Iron and Manganese Tank Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Whole House Water Filter Tank Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Whole House Salt Free Water Softener/Conditioner Tank Installation . . . . . . . . . . . . . . . . 16

Media Soak . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Media Flush/Condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Complete the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Programming the Electronic Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Step 1: Setting the Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Step 2: Set Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Iron and Manganese Tank Regen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Testing Chlorine Levels in Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Clean your Hot Water Heater (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

What to Expect with your New Salt Free Water Softener/Conditioner . . . . . . . . . . . . . . . 21

Adding the Pelican Logo Sticker: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Care and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Sediment Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Replacing the Sediment Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Chemical Injector Pump: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Solution Tank Refill — Chlorine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Warranty Registration Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Product Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

© 2011 Enviro Water Solutions, Inc.

3060 Performance Circle, Suite 2, DeLand, FL 32 72 4

www.pelicanwater.com

(877) 842-1635

WF6/WF10 Rev K —

CAUTION:

Pelican Water Systems

Pelican WF6/WF10 Iron/Manganese Filter and Sa lt Free Soften er

Product Operation and Specifications

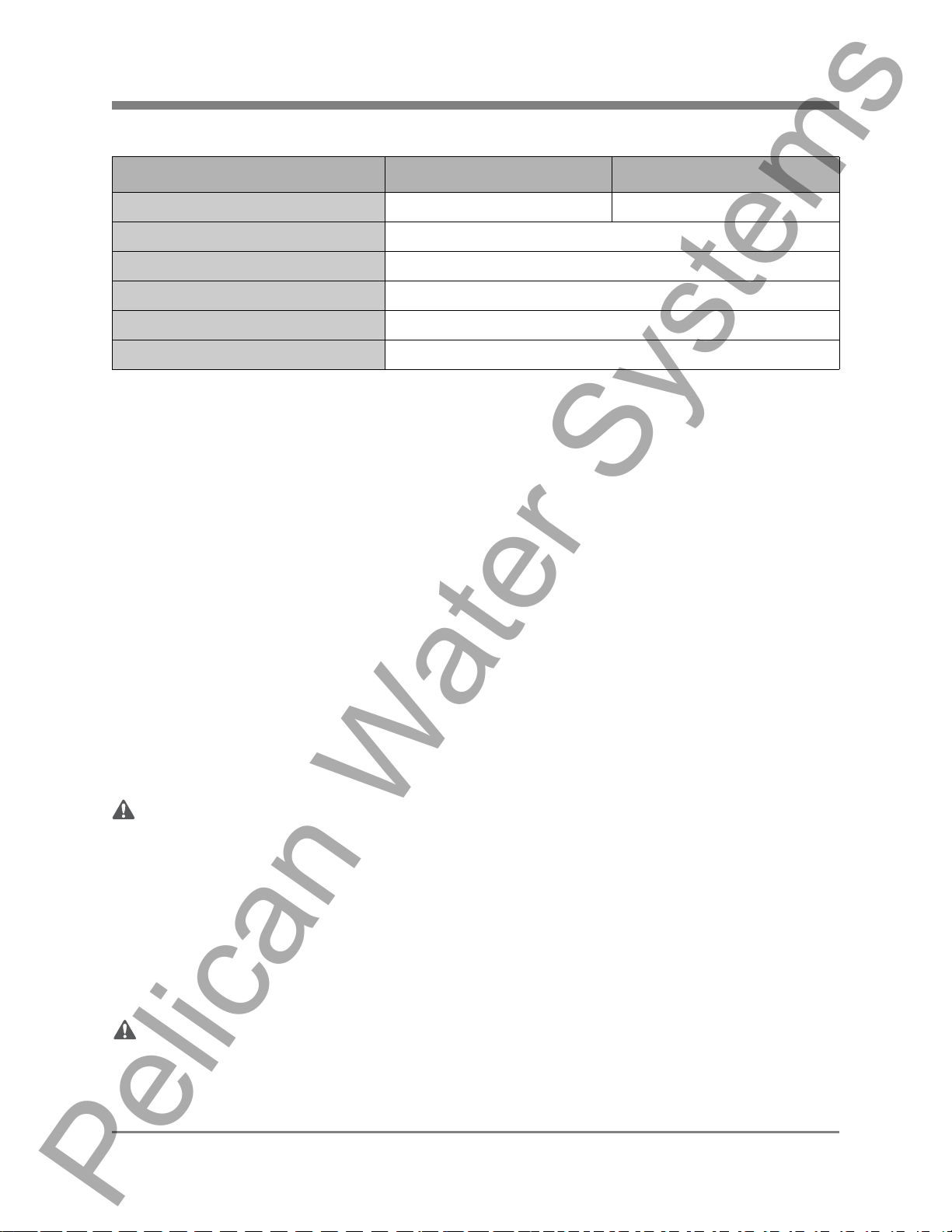

Specification Description WF6 WF10

Max Flow Rate* 10 GPM 15 GPM

Minimum Working Pressure 25 PSI

Maximum Working Pressure 80 PSI

Maximum Vacuum 5 inch/127 mm Hg

Operating Temperatures 36°F – 120°F

pH Range 7 - 11

*Minimum Rated Service Flow must be at least 6 GPM.

Important Information

Read these instructions carefully and determine the location of all system components before

beginning installation.

Check all applicable plumbing, building, and electrical codes for installation compliance.

Install the system on the main water supply.

Systems that contain electronic components cannot be installed outside in uncovered areas.

Page 4

Water Conditions for Operation

The water should be free of hydrogen sulfide, a dissolved gas with a characteristic smell of rotten

eggs. If present, it can coat the catalytic surface of the media and interfere with the process. The gas

should be removed through adequate pre-treatment.

The water should be free of hydrocarbons, oils, and lubricants. If present, they can coat the catalytic

surface of the media and interfere with the process. Remove through adequate pre-treatment.

The water should contain less than 1 mg/l of phosphates. Phosphates sequester dissolved hardness

molecules preventing them from forming crystals and may coat the catalytic media surface and

interfere with the process.

The copper level in the water supply should be below the MCL of 1.3mg/L. If copper is present above

this level, it can attach to the surface of the catalytic media and interfere with the process.

WARNING:

If this or any other system is installed in a metal (co nductive) plumbing system, i.e. copper or

galvanized metal, the plastic components of the system will interrupt the continuity of the

plumbing system. As a result any errant electricity from improperly grounded appliances

downstream or potential galvanic activity in the plumbing system can no longer ground

through contiguous metal plumbing. Older homes may have been built in accordance with

building codes from decades ago, some of which actually encouraged the grounding of

electrical appliances through the plumbing system. Consequently, the installation of a bypass

consisting of the same material as the existing plumbing, or a grounded "jumper wire"

bridging the equipment and re-establishing the contiguous conductive nature of the

plumbing system must be installed prior to your systems use.

When adding a filtration/softening system to homes/buildings supplied by well water, the system should be

installed following the pressure tank. DO NOT USE this system for pneumatic or hydro pneumatic

applications. If you are using a booster pump, then install this system following the booster

pump. If you have questions, please call customer service.

© 2011 Enviro Water Solutions, Inc.

3060 Performance Circle, Suite 2, DeLand, FL 32 72 4

www.pelicanwater.com

(877) 842-1635

WF6/WF10 Rev K —

Pelican Water Systems

Pelican WF6/WF10 Iron/Manganese Filter and Sa lt Free Soften er

Page 5

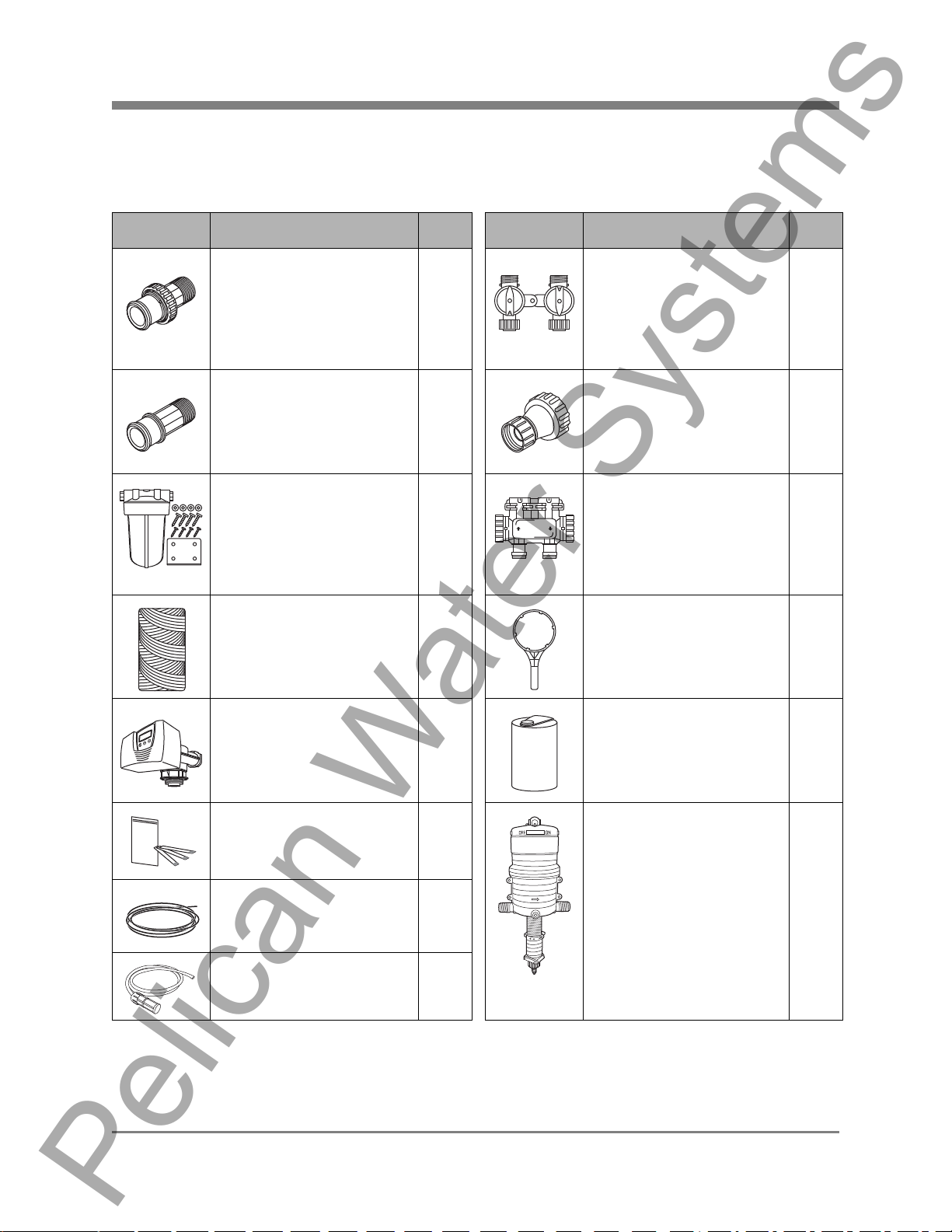

Complete Parts List

Note: Pelican supplies the parts below to accommodate a variety of water supply lines.

Table 1: Parts List

Part Description Qty. Part Description Qty.

1" Plastic Male NPT

Assembly:

V3007-04 WS1 Fitting 1"

Plastic Male NPT Assembly

(2): O-Rings (2), Split Rings

(2), and Connectors (2)

1" PVC Tail Adaptor for

Electronic Head Bypass

Pre-Filter System:

PP5 Big Blue Pre-Filter

Housing, Mounting Bracket,

Phillips Head Screws (4), Bolt

Head Screws (4), and Washers

(4)

Sediment Filter:

PC40-1 5 Micron Poly-Spun

Sediment Filter

Electronic Head 1 Solution Tank 1

2 Bypass Valve:

In/Out Bypass Valve with Red

Arrow Handles

2 Hose Bib Assembly 1

1 Bypass Valve for

Electronic Head

1 Pre-Filter Wrench 1

2

1

Chlorine Test Strips 1 Chemical Injector Pump 1

PVC Tubing Drain Line

(50 ft.)

Chemical Injector Pump

Tubing

© 2011 Enviro Water Solutions, Inc.

3060 Performance Circle, Suite 2, DeLand, FL 32 72 4

1

1

www.pelicanwater.com

(877) 842-1635

WF6/WF10 Rev K —

Pelican Water Systems

Pelican WF6/WF10 Iron/Manganese Filter and Sa lt Free Soften er

Part Description Qty. Part Description Qty.

Page 6

Pelican Whole House

Water Filter

Pelican Salt Free Water

Softener/Conditioner

Note: Drawings are not to scale.

Additional fittings will be needed to adapt to your plumbing.

1 Pelican Whole House Iron

1

1

& Manganese Filter

© 2011 Enviro Water Solutions, Inc.

3060 Performance Circle, Suite 2, DeLand, FL 32 72 4

www.pelicanwater.com

(877) 842-1635

WF6/WF10 Rev K —

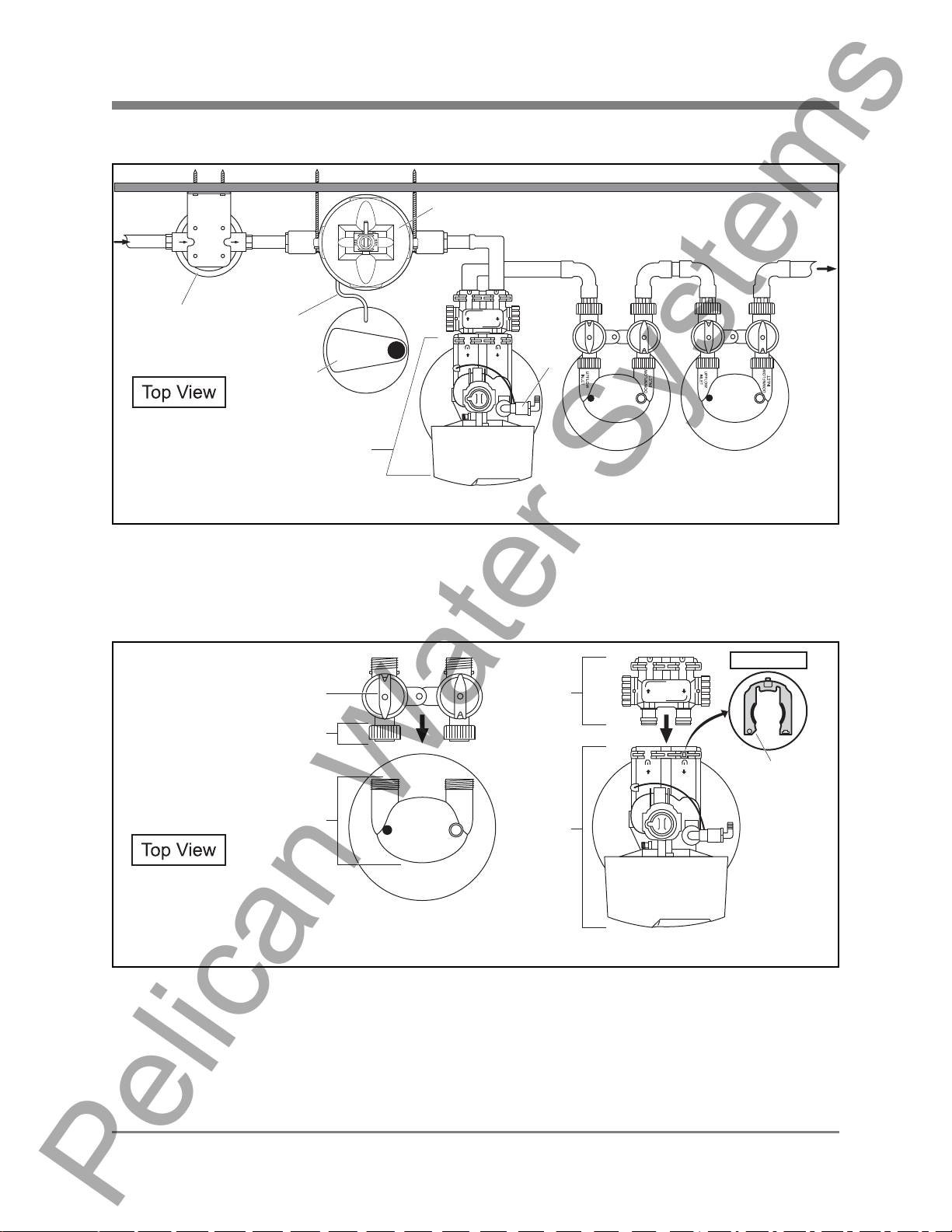

Salt Free Water

Softener/Conditioner

Discharge

Line

Whole House

Water Filter

Outgoing

Water to

House

Whole House

Iron & Manganese Filter

IN

OUT

Pre-Filter

Incoming

Water

Supply

Wall Wall

Solution Tank

Electronic

Head

Chemical

Injector

Pump Tubing

Chemical Injector

Pump

Pelican Water Systems

Pelican WF6/WF10 Iron/Manganese Filter and Sa lt Free Soften er

Installation Overview

Page 7

Figure 1

Pre-Installation

Bypass Valve Installation

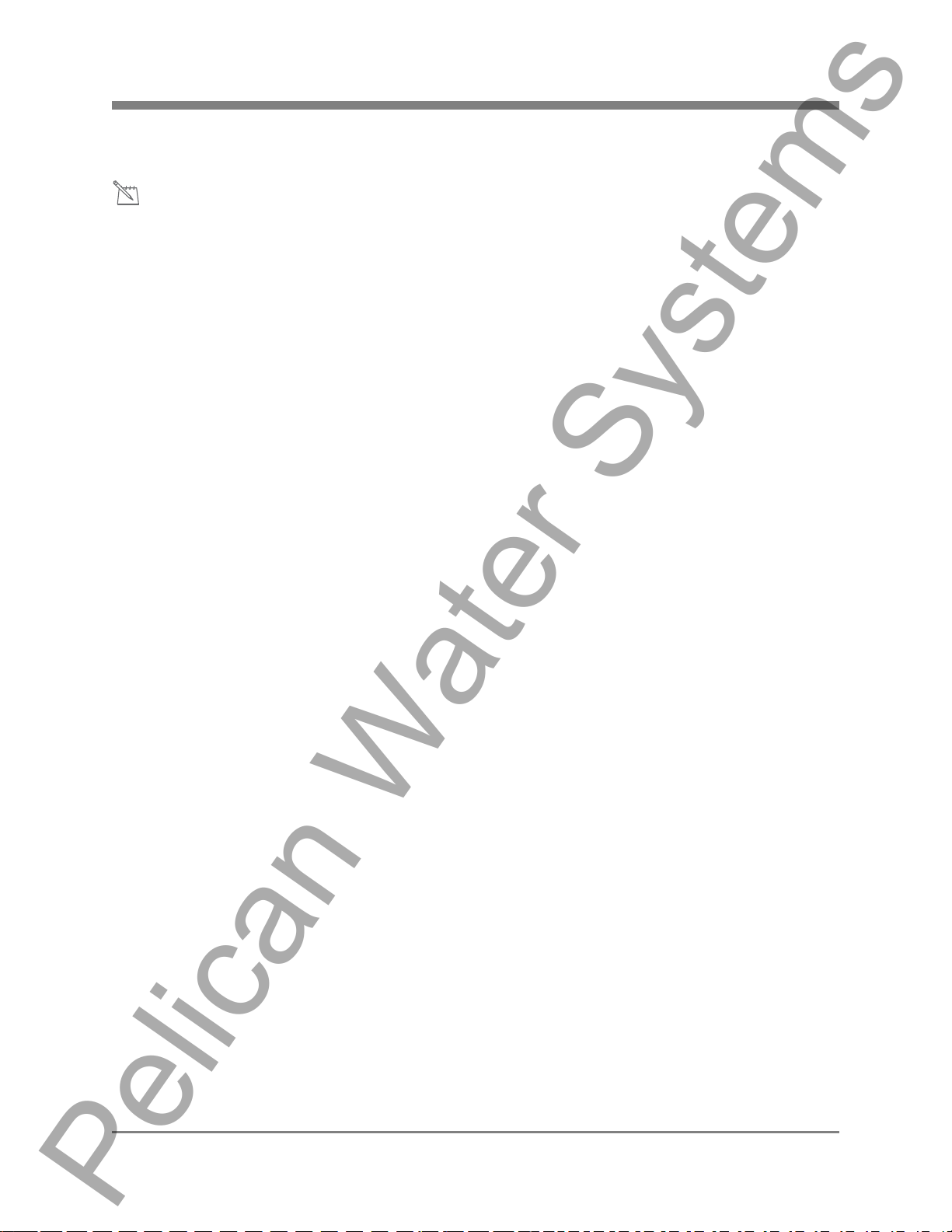

Red Arrow

Quick

Connect Nut

UPFLOW

INLET

Water Filter

Head

Whole House Water Filter &

Salt Free Water Softener/Conditioner

Figure 2

Whole House Water Filter & Salt Free Water Softener/Conditioner - The Bypass Valve comes pre-

assembled and ready to install with the O-Rings, Split Rings, and Quick Connect Nuts. Push the Bypass

Valve into the head of the Pelican Whole House Water Filter or Salt Free Water Softener/Conditioner with

the unthreaded ends orientated towards the tank and hand-tighten the Quick Connect Nuts.

INLET

DOWNFLOW

Bypass

Valve

Electronic

Head

Iron & Manganese Filter

Front View

Red

Clip

Whole House

© 2011 Enviro Water Solutions, Inc.

3060 Performance Circle, Suite 2, DeLand, FL 32 72 4

www.pelicanwater.com

(877) 842-1635

WF6/WF10 Rev K —

Notice:

Pelican Water Systems

Pelican WF6/WF10 Iron/Manganese Filter and Sa lt Free Soften er

Whole House Iron & Manganese Filter - If the Red Clips are in the slots (female opening of Electronic

Head) remove them. Push the male O-Ring side of the Bypass Valve into the female opening of the

Electronic Head. Push the Red Clips back into the slots to tighten.

The Bypass Valve on the Electronic Head can be set to Bypass or Service by turning the knobs on the side

of the valve. If the holes are up and down then the tank is in the Bypass Mode. If the holes are side to side

then the tank is in the Service Mode. Do not remove the red clips from the Bypass Valve after connecting

to main water supply.

Note: The Whole House Water Filter and the Salt Free Softener/Conditioner flow in a different direction

than the Iron Manganese Filter. The Red Arrows on the Whole House Filter and Softener/Conditioner

Bypass may be pointing in a different direction then shown in Figure 2. If this is the case, remove the Red

Arrows by pulling them straight up. Turn them around and reposition correctly onto the Bypass Valve so

they are positioned as shown in Figure 2.

Page 8

© 2011 Enviro Water Solutions, Inc.

3060 Performance Circle, Suite 2, DeLand, FL 32 72 4

www.pelicanwater.com

(877) 842-1635

WF6/WF10 Rev K —

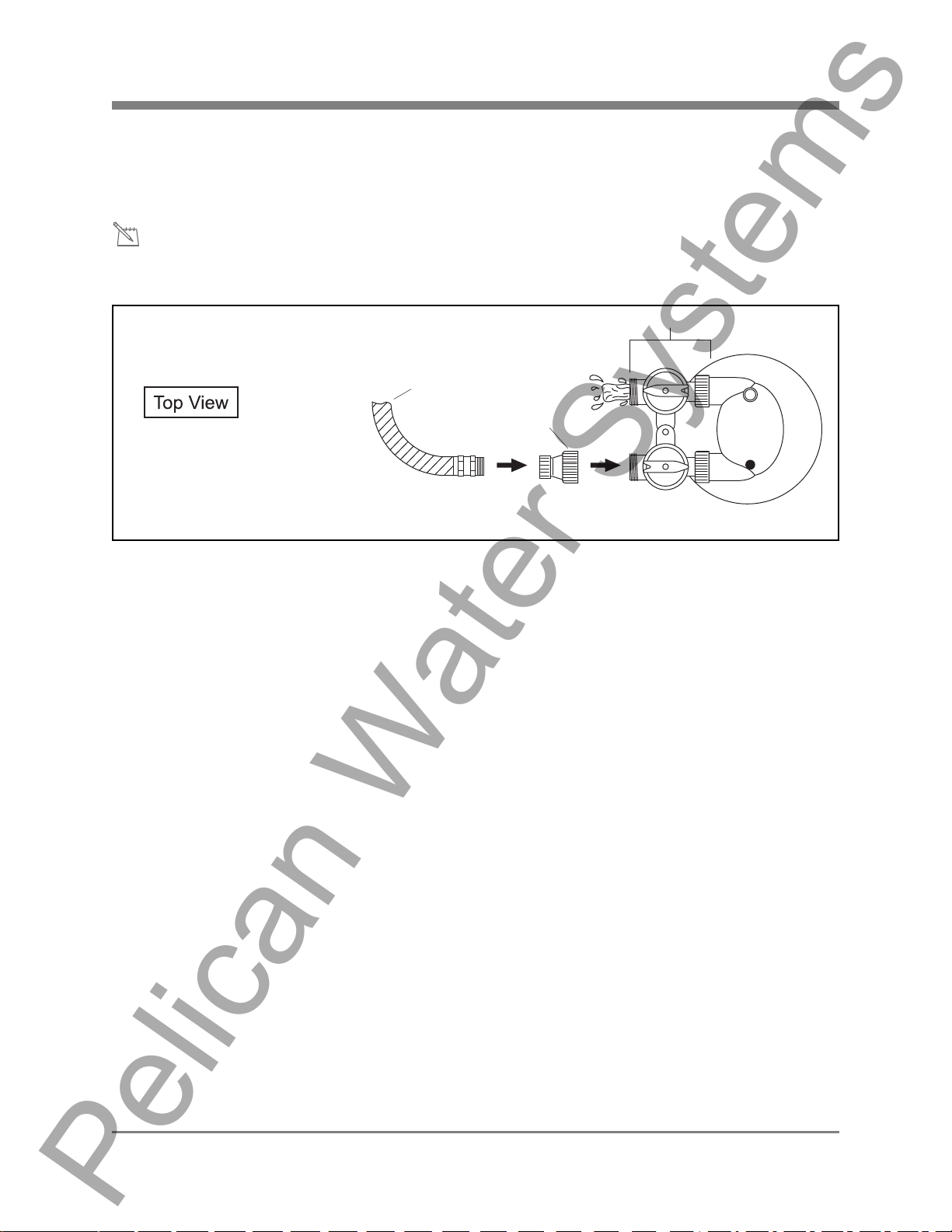

!IMPORTANT!

Notice:

Garden

Hose

Hose Bib

Assembly

UPFLOW

INLET

DOWNFLOW

INLET

Water

Bypass Valve

Whole House Water Filter

Pelican Water Systems

Pelican WF6/WF10 Iron/Manganese Filter and Sa lt Free Soften er

Page 9

Carbon Tank Soak

Your system will not be ready for use for a minimum of 48 hours while the Carbon Soak process takes

place. Please plan your installation accordingly.

Water will flow out of the downflow inlet side of the Bypass Valve during this process. Be sure you perform

this series of steps in a location suitable for water flow.

Figure 3

1. Attach a garden hose to the Hose Bib Assembly.

2. Connect the Hose Bib Assembly to the upflow inlet side of the Bypass Valve and hand tighten.

3. Fill the Pelican Whole House Water Filter Tank full until water comes out of downflow inlet side of

the Bypass Valve.

4. Turn the water off.

5. Remove the garden hose from the Hose Bib Assembly. Do not remove the fitting.

6. Allow the carbon tank to soak for at least 48 hours prior to tank installation.

© 2011 Enviro Water Solutions, Inc.

3060 Performance Circle, Suite 2, DeLand, FL 32 72 4

www.pelicanwater.com

(877) 842-1635

Loading...

Loading...