Page 1

INSTALLATION/OPERATION

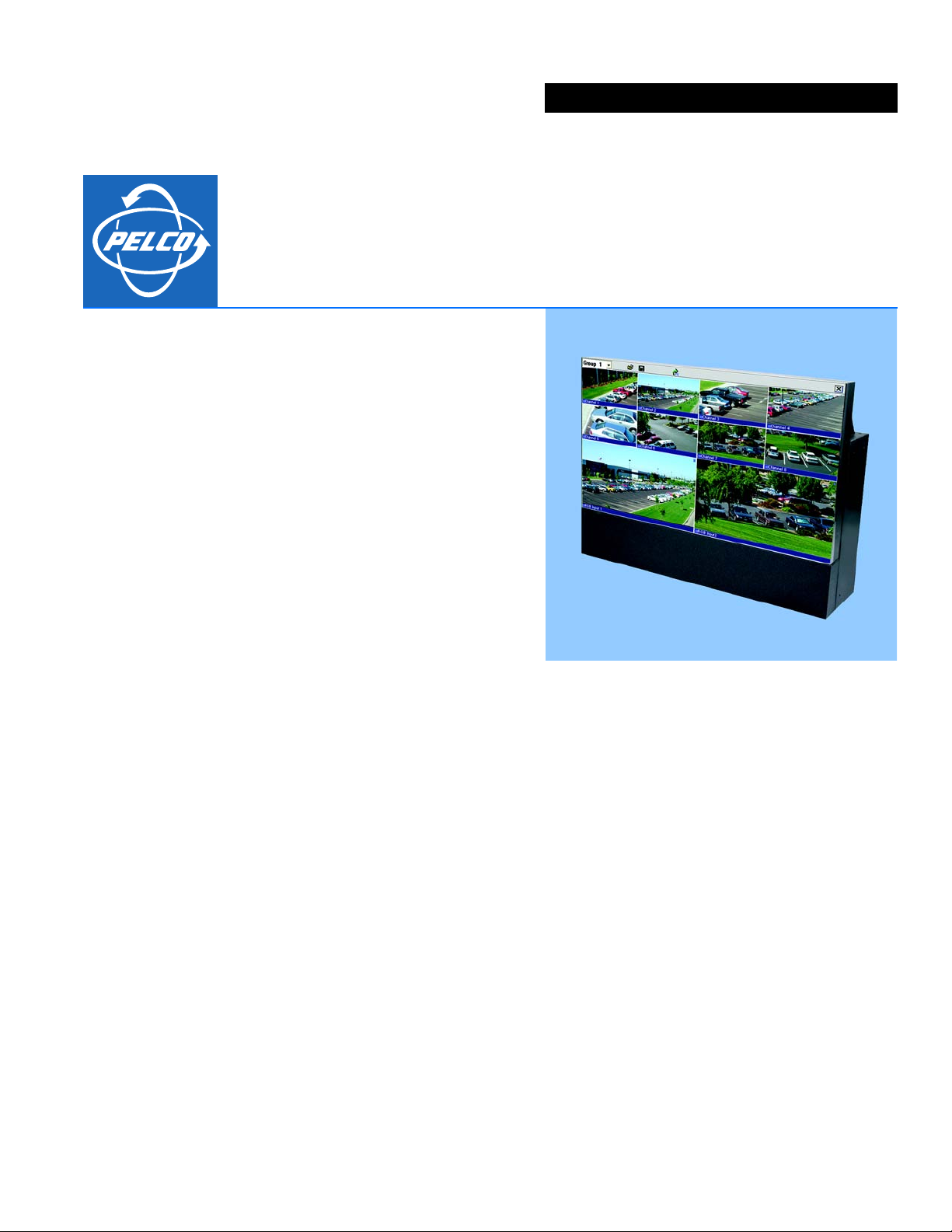

PMCD750 DLP™

®

Display

50-Inch Rear Projection Display

C2928M-A (4/07)

Page 2

Page 3

Contents

Important Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Regulatory Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Assembling the Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Building an Inverted Banner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Connecting Analog and Digital Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Connecting RS-232 and RS-485 Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Installing Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Connecting Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Alignment and Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Aligning the Optical Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Adjusting Analog 1 and Analog 2 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Position and Zoom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Saving and Recalling Adjustments and Deleting a Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Installing a Stand-Alone Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Building a Wall: First Row . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Building a Wall: Second Row and Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Loop-Through Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Changing the Picture and Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Input Level Adjustment, Automatic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Input Level Adjustment, Semiautomatic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Color Balancing a Wall of PMCD750 Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Spreading One Picture Over A Wall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Scaling and Cropping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Image Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Overscan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Preferred Source Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

HD Interlaced Content . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Picture Position Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Zoom Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Saving Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Recalling Slot Preferences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Deleting Stored Slot Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Start-Up Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Lamp Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Shut-Down Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Using the Remote Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Beeper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting a Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Controlling with RS-232/RS-485 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Display IDs and Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Baud Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Asset Tag and Unit Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Removing or Opening a Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Removing a Screen in an Outside Column . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Removing a Center Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

C2928M-A (4/07) 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Page 4

Opening a Screen Temporarily for Work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Changing the Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Removing the Lamp from the Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Removing the Lamp from the Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Replacing the Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Reset Lamp Hours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Changing the Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Removing the Air Filter from the Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Removing the Air Filter from the Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Cleaning the Screen and Mirrors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Removing Dry Dust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Cleaning the Lenses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

On-Screen Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Inside LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4 C2928M-A (4/07)

Page 5

List of Illustrations

1 Mounted Screen Support and Bottom Connection Point. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2 Tie-back Connection Points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3 Alignment Pin Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 6-32 Front Screw Securing Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5 Vertical and Horizontal Connection Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

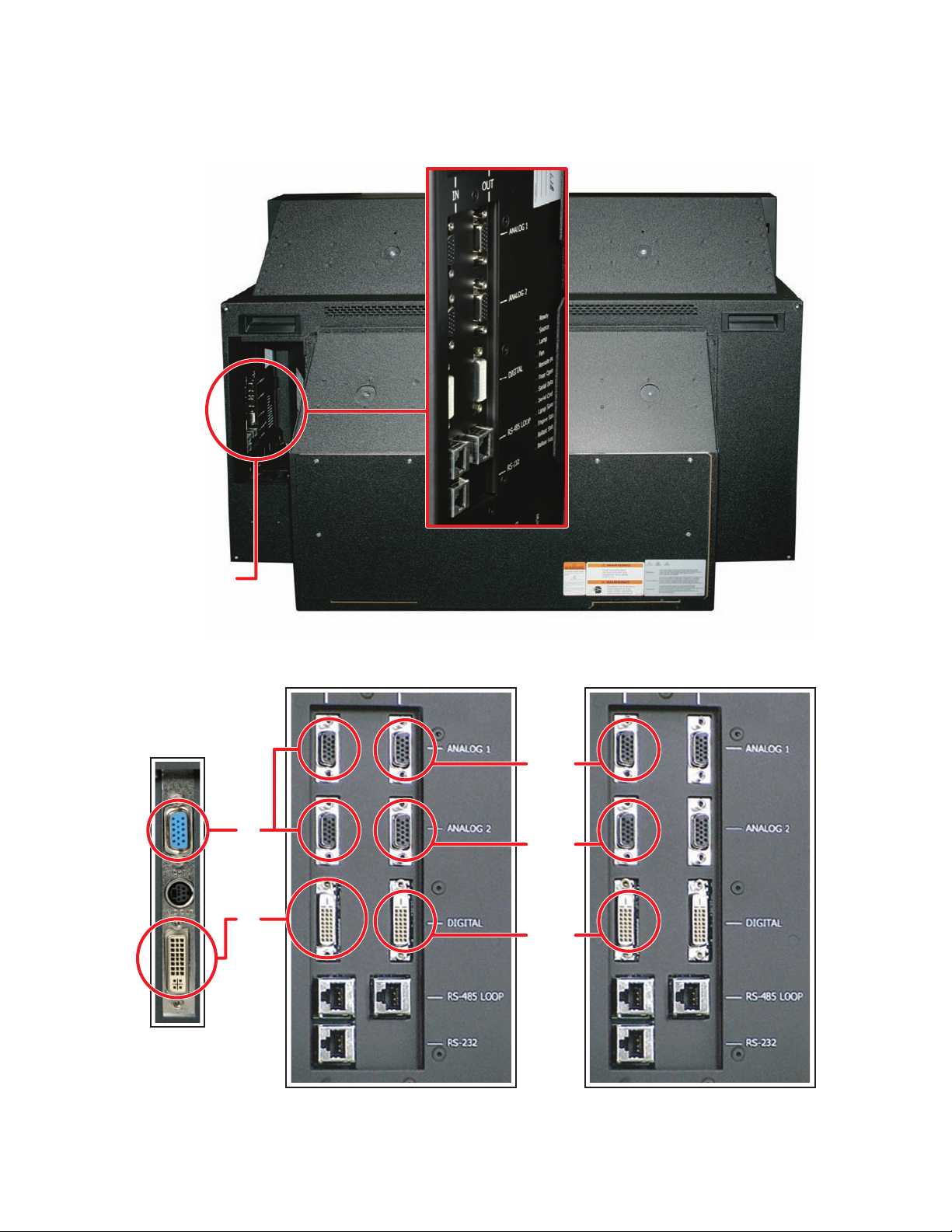

6 Input Panel Connections (Rear View) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

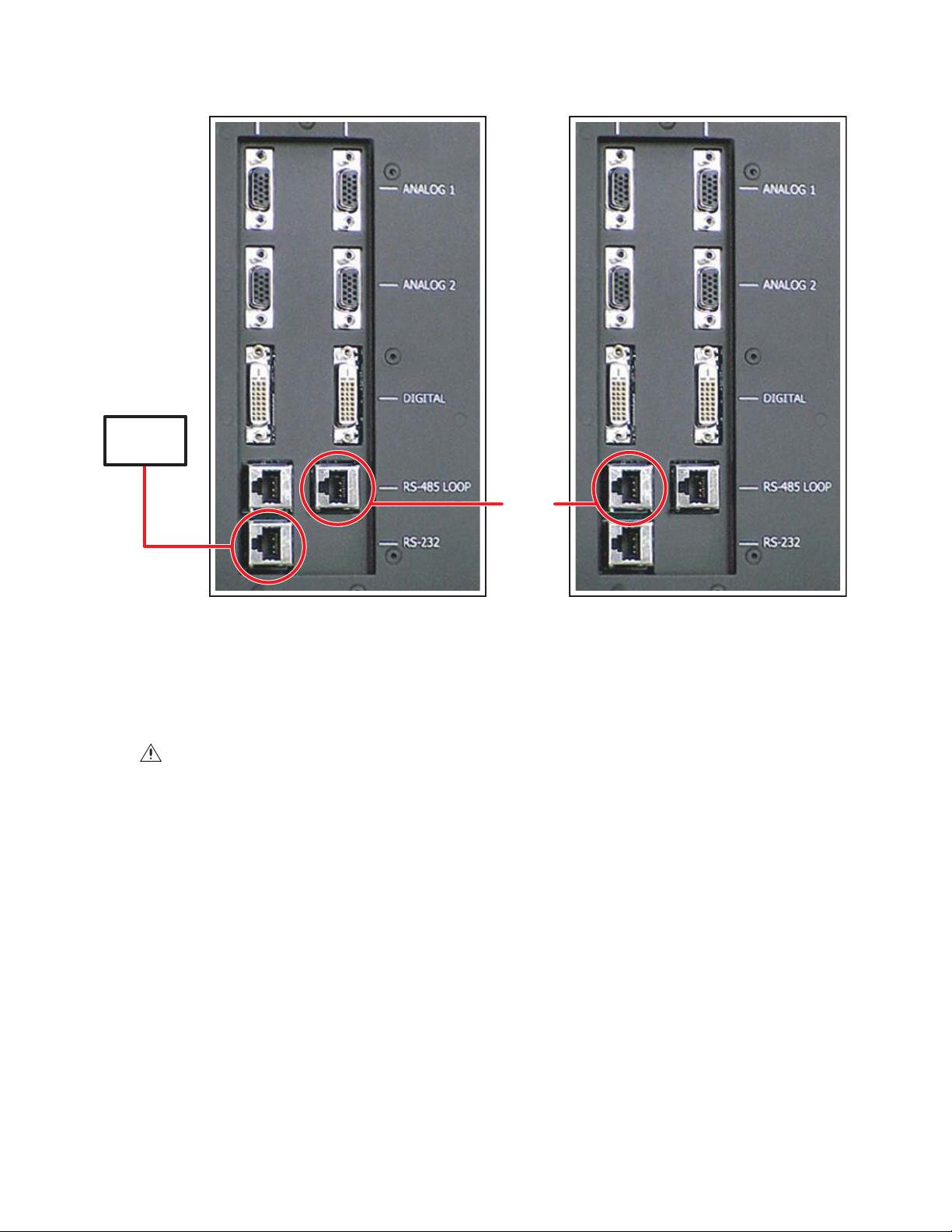

7 RS-232 and RS-485 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

8 Screen Rails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

9 L-Shaped Screen Slot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

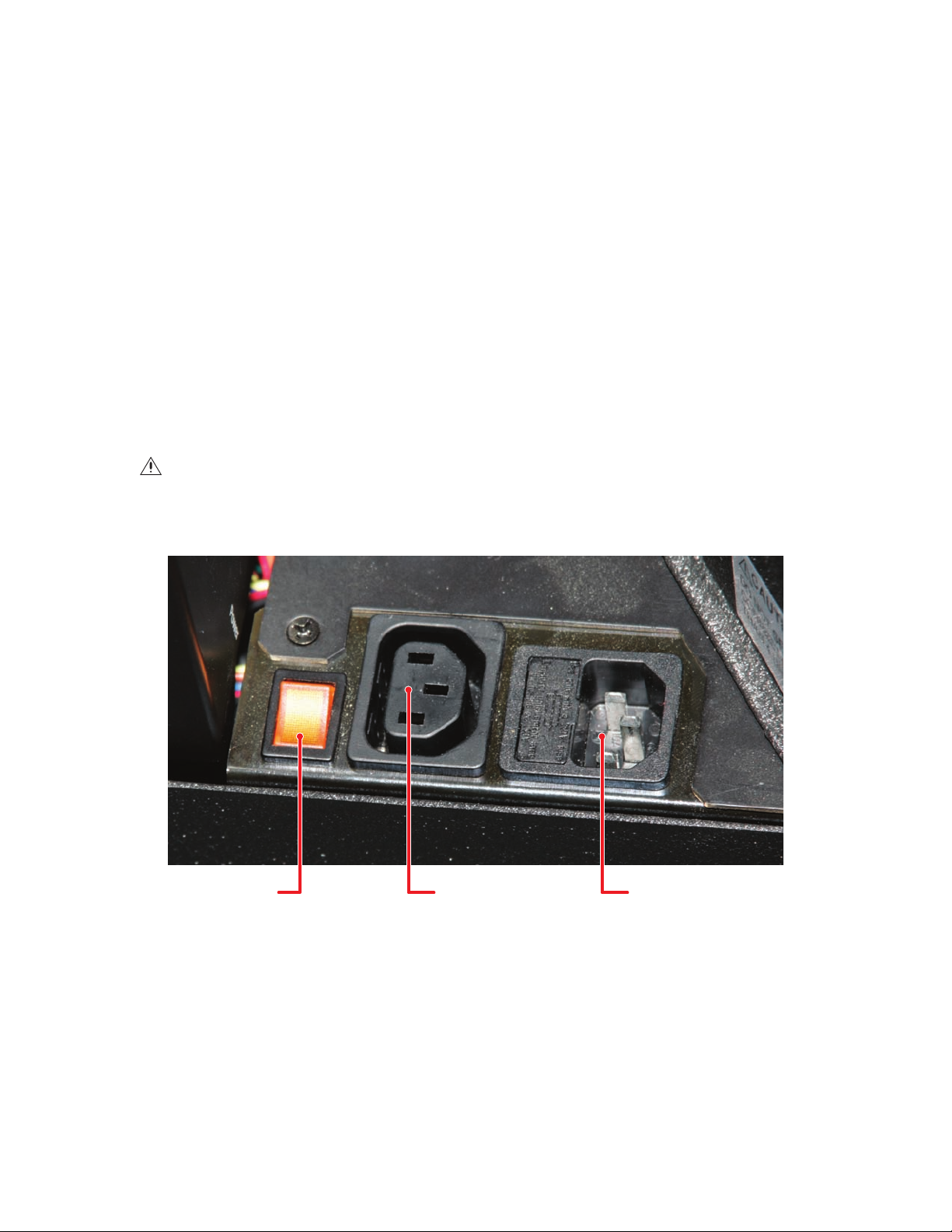

10 Power Switch and Receptacles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

11 Test Pattern. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

12 Grid and Alignment Test Patterns. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

13 Inverted Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

14 Auto Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

15 Input Level Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

16 Color Balancing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

17 Scaling and Cropping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

18 Justifying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

19 Overscanning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

20 Preferred Source Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

21 HD Interlaced Content . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

22 Picture Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

23 Zooming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

24 Saving Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

25 Recalling Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

26 Lamp Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

27 Remote Control Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

28 Beeper Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

29 Selecting a Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

30 Serial Port ID Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

31 Baud Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

32 RS-485 Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

33 Unit Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

34 Suction Cup Placement Order. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

35 Screen Removal Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

36 Screen Rail Hook. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

37 Light Shield Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

38 Light Shield Latch and Securing Screw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

39 Opened Light Shield and Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

40 Lamp Detail. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

41 Rear Panel Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

42 Resetting the Lamp Hours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

43 Open Light Shield and Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

44 Rear View of Input Panel and LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

45 Light Shield and Electronics Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

List of Tables

A On-Screen Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

B LED Code Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

C2928M-A (4/07) 5

Page 6

Important Safety Instructions

1. Read these instructions.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all instructions.

5. Do not use this apparatus near water.

6. Clean only with dry cloth.

7. Do not block any ventilation openings. Install in accordance with the manufacturer’s instructions.

8. Do not install near any heat sources such as radiators, heat registers, stoves, or other apparatus (including amplifiers) that produce heat.

9. Do not defeat the safety purpose of the polarized or grounding-type plug. A polarized plug has two blades with one wider than the other.

A grounding plug has two blades and a third grounding prong. The wide blade or the third prong are provided for your safety. If the provided

plug does not fit into your outlet consult an electrician for replacement of the obsolete outlet.

10. Protect the power cord from being walked on or pinched particularly at plugs, convenience receptacles, and the points where they exit from

the apparatus.

11. Only use attachments/accessories specified by the manufacturer.

12. Use only with the cart, stand, tripod, bracket, or table specified by the manufacturer, or sold with the apparatus. When a cart is used, use

caution when moving the cart/apparatus combination to avoid injury from tip-over.

13. Unplug this apparatus during lightning storms or when unused for long periods of time.

14. Refer all servicing to qualified service personnel. Servicing is required when the apparatus has been damaged in any way, such as powersupply cord or plug is damaged, liquid has been spilled or objects have fallen into the apparatus, the apparatus has been exposed to rain or

moisture, does not operate normally, or has been dropped.

15. Apparatus shall not be exposed to dripping or splashing and that no objects filled with liquids, such as vases shall be placed on the

apparatus.

16. WARNING: To reduce the risk of fire or electric shock, do not expose this apparatus to rain or moisture.

17. Installation should be done only by qualified personnel and conform to all local codes.

18. Unless the unit is specifically marked as a NEMA Type 3, 3R, 3S, 4, 4X, 6, or 6P enclosure, it is designed for indoor use on ly and it must not

be installed where exposed to rain and moisture.

19. Use only installation methods and materials capable of supporting four times the maximum specified load.

20. A readily accessible disconnect device shall be incorporated in the building installation wiring.

21. The socket-outlet shall be installed near the equipment and shall be easily accessible.

22. CAUTION: These servicing instructions are for use by qualified service personnel only. To reduce the risk of electric shock do not perform

any servicing other that contained in the operating instructions unless you are qualified to do so.

23. Only use replacement parts recommended by Pelco.

24. WARNING: The lamp needs 15,000 volts to start.

25. WARNING: There is no electrical interlock on the screen. Opening the screen does not turn off the high voltage to the lamp.

26. CAUTION: The lamp gets very hot. Allow it to cool before removing it.

27. CAUTION: The lamp produces UV (ultraviolet) radiation that can cause retinal damage. Although very bright, the light exiting the optical

engine contains no significant UV radiation.

28. CAUTION: Static electricity can damage sensitive electronic components.

• Always use a grounding strap connnected to an approved ground when handling the optical engine or electronics module.

• When shipping these parts, do not use styrofoam packing material. This can carry static electricity and damage the components. Use an

antistatic bag or ESD (Electrostatic discharge) protective wrap.

The product and/or manual may bear the following marks:

This symbol indicates that dangerous voltage constituting a risk of electric

shock is present within this unit.

This symbol indicates that there are important operating and maintenance

instructions in the literature accompanying this unit.

CAUTION:

RISK OF ELECTRIC SHOCK.

DO NOT OPEN.

6 C2928M-A (4/07)

Page 7

Regulatory Notice

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this device may not cause harmful

interference, and (2) this device must accept any interference received, including interference that may cause undesired operation.

RADIO AND TELEVISION INTERFERENCE

This equipment has been tested and found to comply with the limits of a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may

cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in

which case the user will be required to correct the interference at his own expense.

Changes and Modifications not expressly approved by the manufacturer or registrant of this equipment can void your authority to operate this

equipment under Federal Communications Commission’s rules.

In order to maintain compliance with FCC regulations shielded cables must be used with this equipment. Operation with non-approved

equipment or unshielded cables is likely to result in interference to radio and television reception.

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

C2928M-A (4/07) 7

Page 8

Overview

DESCRIPTION

The PMCD750 DLP™ display is a 50-inch rear projection monitor that combines the best features of direct view and rear projection technology. It

uses Digital Light Processing (DLP) technology to deliver high color performance and brightness in a zero-mullion, high definition format that is

ideal for creating video walls.

The PMCD750 DLP display is designed for use in multidisplay towers and walls requiring seamless images, or it can be used as a stand-alone

display. The PMCD750 DLP display is the perfect alternative to CRT monitors. Setup is made easy with the use of a hand-held remote control.

NOTE: An optional screen support (PMCD750-SB) is recommended for additional stability and cosmetic improvement for single displays, and is

required for every display on the bottom row of a multidisplay/wall configuration. The screen support is not supplied; it must be ordered.

PARTS LIST

Qty Description

2 6-32 x 3/8-inch screw

2 1/4-20 x 3.5-inch bolt

2 1/4-20 x 2-inch bolt

2 1/4-20 x 3/8-inch bolt

8Flat washers

4 Wing nuts

2 Suction cups

1 VGA cable

1 DVI cable

1 AC power cord

1 Remote control (with batteries installed)

6 (or more) Screen shims

8 C2928M-A (4/07)

Page 9

Installation

UNPACKING

Unpack the PMCD750 unit. The screen is not needed yet and should be left in its container at this time.

ASSEMBLING THE CHASSIS

WARNING: The chassis weighs 65 pounds (29.5 kg). Two people are required to handle and position the display safely.

INSTALLING A STAND-ALONE UNIT

NOTE: A screen support (PMCD750-SB) is recommended for single displays to provide additional stability and cosmetic improvement.

Attach the optional screen support (PMCD750-SB) to the front edge of the chassis with supplied screen support bolts. The screen support mounts

only one way. It incorporates a stop (rest) for the screen.

BUILDING A WALL: FIRST ROW

Straightness of the PMCD750 display is critical because the screens have no mullion (outside screen border). The advantage of this design is that

the finished wall will have virtually no black lines between images on the screens.

WARNINGS:

A chassis weighs 65 pounds (29.5 kg). When assembling a wall, two people are required to handle and position the display safely.

•

• Do not put the screens on yet. If the first row is not straight, the misalignment will worsen as the wall goes up and the screens will not align

properly.

• If you are constructing the wall at ground level, choose a site that is as flat as possible to avoid gaps between the screens in the wall.

• A screen support (PMCD750-SB) is required for every display on the bottom row of a multidisplay/wall configuration.

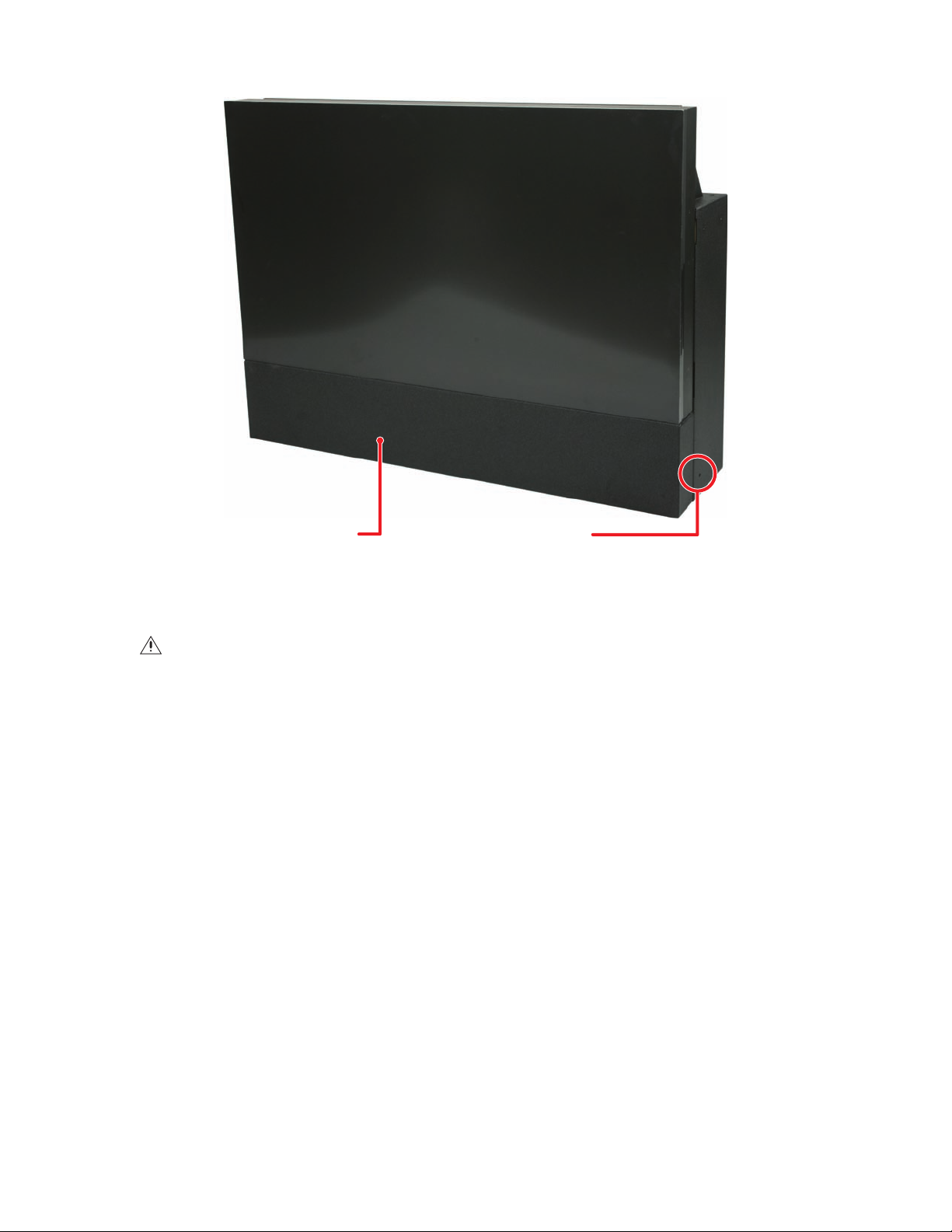

To build the first row, do the following:

1. Set the first row of PMCD750 units side by side without the screens. Bolt them loosely together through the bottom connection points with

the 1/4-20 x 3.5-inch bolts, washers, and wing nuts. Refer to Figure 1.

2. Attach the screen supports to the front edge of the first row with the supplied screen support bolts, which were shipped with the support

when ordered. The screen support mounts only one way and is used on the bottom row only. It incorporates a stop (rest) for the bottom

screens. Refer to Figure 1.

C2928M-A (4/07) 9

Page 10

SCREEN SUPPORT

BOTTOM CONNECTION POINT

Figure 1. Mounted Screen Support and Bottom Connection Point

3. Check the first row for horizontal straightness by making sure the front and top edges of adjacent units are flush. If necessary, use shims

under the units to make sure the top edges of adjacent units are flush.

WARNING: It is important to ensure that each unit in the first row is level on all planes and resting firmly on its own support before

tightening the units together. The 1/4-20 x 3.5-inch bolts are not capable of supporting the weight of a wall and should not be used to level

the first row.

4. When the first row is straight horizontally and vertically, tighten the bolts holding the units together.

5. Verify the straightness of the row again. Make any necessary adjustments to ensure that the first row is straight horizontally and vertically

prior to building subsequent rows.

10 C2928M-A (4/07)

Page 11

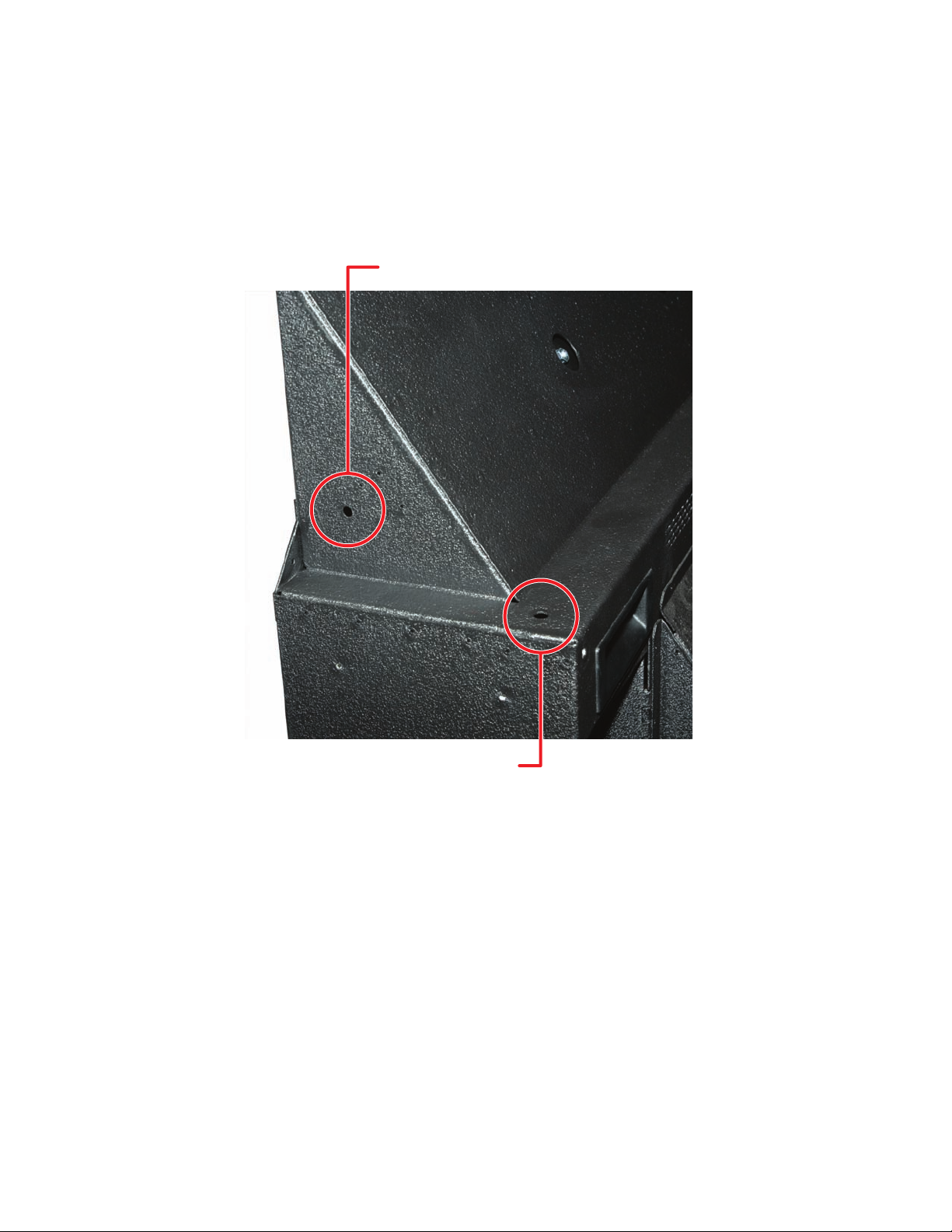

BUILDING A WALL: SECOND ROW AND UP

DANGER: Because the PMCD750 unit has a narrow front-to-back profile, the danger of tipping exists with high walls. For walls over two

units high and all tilted walls, use the four tie-back points (1/4-20 threaded holes) on the rear of the unit to secure the video wall to a

structural part of the building. If the wall is tilted forward, tie the wall all the way up. Do this as the wall is being built up; do not wait until

the wall is finished. Pelco does not provide any special brackets to secure the PMCD750 unit. The method to use is best determined on site

due to the many variables to consider, and must be capable of sustaining five times the weight of each PMCD750 unit; a total of

340 pounds (154 kg) per unit.

TIE BACK POINTS

Figure 2. Tie-back Connection Points

After verifying that the first row is straight and solid, continue building the wall. To continue building the wall, do the following:

WARNING: The maximum stack height for a wall is four units.

1. Stack another row of PMCD750 units on the first row. As you stack, be careful inserting the alignment pins on the second row chassis into

the alignment holes on the lower unit. Refer to Figure 3.

C2928M-A (4/07) 11

Page 12

SECOND

ROW

ALIGNMENT PIN DETAIL

ALIGNMENT PINS

ALIGNMENT HOLES

FIRST

ROW

Figure 3. Alignment Pin Locations

12 C2928M-A (4/07)

Page 13

2. As each unit is placed in the second row, secure it to the front of the lower unit with two 6-32 x 3/8-inch screws. Refer to Figure 4.

FRONT SCREW CONNECTION POINTS

FRONT SCREW CONNECTION POINT DETAIL

Figure 4. 6-32 Front Screw Securing Locations

C2928M-A (4/07) 13

Page 14

3. Bolt the PMCD750 units together vertically through the vertical connection points using the 1/4-20 x 3/8-inch bolts. Refer to Figure 5.

4. Bolt the PMCD750 units together through the bottom connection points the same as the first row.

5. Bolt the PMCD750 units together through the horizontal connection points using the 1/4-20 x 2-inch bolts, washers, and wing nuts. Refer to

Figure 5.

6. Check the straightness of the second row.

7. Continue in this way with the rest of the rows, checking straightness as each row is completed.

HORIZONTAL CONNECTION POINT

VERTICAL CONNECTION POINT

Figure 5. Vertical and Horizontal Connection Points

BUILDING AN INVERTED BANNER

It is possible to hang a single row of PMCD750 units upside down to make a banner.

Pelco does not provide any special brackets to hang a PMCD750 unit upside down. The method to use is best determined on site due to the many

variables to consider. The ceiling and method used must be capable of sustaining five times the weight of each PMCD750 unit – a total of

340 pounds (154 kilograms) per unit.

The screen supports, which normally hold screens up, will now be above the row of screens. You may wish to devise a way to push the screens

up from the bottom to press them against this support to prevent a gap. It is not necessary to use the screen support parts in an inverted

installation. The screen supports can be used to cover part of the unit, but they are unnecessary in the inverted configuration.

For inverted operation, the picture and menus must be inverted. Refer to the Changing the Picture and Menus section.

14 C2928M-A (4/07)

Page 15

CONNECTING ANALOG AND DIGITAL SOURCES

The PMCD750 will accept video input from devices with VGA or DVI output. Video source devices with either or both of these output types can

have their images displayed on the PMCD750.

INPUT CONNECTORS

IN OUT IN OUT

LOOPING

VGA

LOOPING

DVI

LOOPING

VIDEO SOURCE

OUTPUT

FIRST DISPLAY SECOND DISPLAY

Figure 6. Input Panel Connections (Rear View)

C2928M-A (4/07) 15

Page 16

For stand-alone units, connect the video input to the Analog 1, Analog 2, or Digital In input. Multiple inputs can be connected simultaneously.

Refer to Figure 6.

For wall systems, connect the video input to the Analog 1, Analog 2, or Digital In input. Multiple inputs can be connected simultaneously.

Loop the video out from the first display to the input connector of the second display. Continue looping until all displays are connected.

If you used an analog input on the first display, you can loop the video to the other displays using the anlog inputs and outputs. However, the

Digital Out connector carries video from the analog inputs as well as the digital input. For improved image quality it is recommended that analog

video from the first display be looped using the digital connectors.

All of the video inputs have buffered loop-through output connectors.

Analog 1 and Analog 2 are 15-pin VGA-type connectors. The PMCD750 will accept a wide range of computer inputs with resolutions up to

1600 x 1200 and 1920 x 1080. Each of these connectors has a dedicated loop-through output. These connectors are also used for RGB video with

separate horizontal and vertical sync, composite sync, or sync on green; also for YPbPr video at 480p, 720p, or 1080i.

When an analog input has a source with sync on green or composite sync, the DVI Out may not show the picture properly. If the source is present

at power up, it typically works well, but if the source is disconnected and then reconnected, the DVI loop-through stops working for these two

types of sync.

Digital In is a standard DVI cable input. It has a loop-through, but the Digital Out connector is not dedicated exclusively to the Digital In connector.

Instead, the Digital Out connector carries the picture of the currently selected input. For instance, if the Analog 1 connector is selected, the picture on the Digital Out connector is a DVI version of that Analog 1 picture.

LOOP-THROUGH LIMITS

A signal cannot loop-through indefinitely due to degredation of the signal as it progresses through the loop. Depending on the strength of the

signal, the loop-through limit is four units for digital (DVI) signals, and twelve units for analog (VGA) signals. When a loss of signal is experienced

due to loop-through degredation, a distribution amplifier can be used to compensate.

CONNECTING RS-232 AND RS-485 CONTROL

With serial control, you can control a stand-alone unit, a whole wall, several walls, and any single display in a wall.

To connect an external controller, refer to Figure 7 and do the following:

1. Using a straight-through computer serial cable, connect the RS-232 input of the stand-alone unit or the first unit in the wall to the serial out

port of the external control device, such as a video controller.

2. Connect this first display’s RS-485 Out to the next display’s RS-485 In.

NOTES:

For best results, the RS-485 cables should be twisted pair. The pairs are pins 3 and 6 (signal) and pins 1 and 2 (ground). Cat5 cable has the correct

•

twisted pairs.

• For very long runs of RS-485 cable, it may be necessary to terminate the last PMCD750 unit in the loop. To terminate the last unit, refer to the

Controlling with RS-232/RS-485 Interface section.

16 C2928M-A (4/07)

Page 17

VIDEO

CONTROLLER

IN OUT IN OUT

LOOPING

INSTALLING SCREENS

The PMCD750 screens in a wall are quite close together, so the order in which they are installed in a wall is very important.

WARNING: Do not install any screen until reading and understanding this section. If screens are installed improperly, they may be

damaged.

To install a screen on a stand-alone unit, follow the instructions in steps 2a, 2b, and 2c.

1. Verify that the wall of PMCD750 units is straight and that the corners are square by measuring the diagonals of the whole wall. If the

diagonals are equal, the wall is a perfect rectangle.

2. To install the PMCD750 screens, start in the middle of the bottom row and install that screen. The screen supports should be installed on

the bottom row of PMCD750 screens.

a. Pull the screen rails all the way out on both sides of the PMCD750 chassis. The screen rails each have a large pin that mates with the

L-shaped slot located on each side of the screen. Refer to Figure 8.

b. With one person holding each side, hang the screen so that the pins on the screen rails go into the L-shaped slots on the sides of the

screen. Refer to Figure 9.

c. Slide the screen closed, lifting it slightly to avoid scraping on the screen support below.

FIRST DISPLAY SECOND DISPLAY

Figure 7. RS-232 and RS-485 Connections

C2928M-A (4/07) 17

Page 18

SCREEN RAILS

SCREEN RAIL PIN DETAIL

Figure 8. Screen Rails

Figure 9. L-Shaped Screen Slot

18 C2928M-A (4/07)

Page 19

3. Install the screens to the left and right of the center screen to complete the bottom row. After adding a screen, press it toward the center.

4. Check the line of this bottom row of screens. If they are not straight, use shims on the top of the screen support until the screens are

straight.

5. Starting in the second row and working up, install all remaining center screens. Lift each screen and press it in so that it does not scrape on

the screen below. Continue until you reach the top.

6. Working upward and outward, finish all the rows.

7. Perform a final check of screens for alignment with each other. The horizontal and vertical spaces between each screen should form

straight lines where they intersect.

CONNECTING POWER

NOTE: The use of an uninterruptible power supply (UPS) manufactured by Powerware, Model PW9120 700i, or equivalent, is required to comply

with EMC Directive 89/336/EEC.

To apply power to the display:

1. Bring in AC power next to the electronics module. Connect the power to the receptacle located on the rear panel. The voltage can be

115 VAC (90–132 VAC) or 230 VAC (200–254 VAC). Refer to Figure 10.

WARNING: Do not exceed the recommended number of PMCD750 units linked in series for AC power or the current draw will be too great.

2. The AC power can be looped through to the next PMCD750 unit, resulting in fewer main outlet sockets needed for operation. The total

number of units in one power loop cannot exceed four (115 VAC) or eight (230 VAC) units.

POWER SWITCH AC INAC OUT

Figure 10. Power Switch and Receptacles

3. Turn on the power switch for each display. When AC power is applied, there are a few seconds of apparent inactivity in which the

electronics module begins start up and initialization. Next, if the optical engine is warm, the intake and lamp fans start. Because the service

life of the lamp can be significantly shortened if turned on when hot, the lamp cannot be turned on during this time. The lamp fan runs for

approximately one minute to ensure the lamp is cool. If the temperature sensor on the optical engine determines that the lamp is

sufficiently cool at power up, this cool-down period is skipped.

NOTES:

The AC switch on each PMCD750 unit controls that display only. Turning off the switch on any display does not cut the AC power to the other

•

displays. The switch is lit when it is ON and there is AC power to the PMCD750 unit.

• The AC input is fused with a 10 A fuse. If the fuse in any PMCD750 unit blows, all displays downstream from this one will go off.

C2928M-A (4/07) 19

Page 20

Alignment and Adjustment

ALIGNING THE OPTICAL ENGINE

The optical engine must be adjusted to aim the picture accurately at the screen. Although the optical engine was perfectly adjusted when the

PMCD750 unit left the factory, vibration along the way may have moved it. It is important to check this mechanical adjustment of the optical

engine before any electronic adjustments are made to the picture.

The following procedure is required for a stand-alone unit and all units in a wall system.

To align the optical engine, refer to Figure 11 and do the following:

1. Open the Main Menu by pressing the MENU button on the remote control.

2. Using the

! button on the remote, scroll down to Advanced Options, and then press the + button on the remote.

3. Scroll down to Engine Alignment, and then press +.

4. Scroll down to Test Pattern.

Main Menu

Picture

Size & Position

Aspect Ratio & Wall

Memory

Diagnostics

Advanced Options

Program Information

Engine Alignment

Left Side

Right Side

Horizontal

Image Size

Test Pattern Grid

Advanced Options

Color Balance

Miscellaneous Options

Lamp Settings

Serial Port Settings

Auto Setup Options

Engine Alignment

Menu Options

Figure 11. Test Pattern

5. Press the ENTER button on the remote control until Grid appears. A grid pattern will fill the screen. Refer to Figure 12.

20 C2928M-A (4/07)

Page 21

GRID PATTERN

Figure 12. Grid and Alignment Test Patterns

6. To position the grid pattern to the center of the screen:

a. Use the " button to scroll up to Left Side.

b. Press the + button to adjust the left side of the image up.

c. Press the – button to adjust the left side of the image down.

d. Scroll down to Right Side. Perform steps b and c to adjust the image position up and down.

e. Scroll down to Horizontal. Perform step b (entire image moves right) and c (entire image moves left) as necessary. When the maximum

level of adjustment is reached, the image will tilt up or down slightly.

7. Scroll down to Test Pattern.

8. Press ENTER twice. The screen will be filled with the Alignment pattern that shows the last six pixels at each edge. Refer to Figure 12.

9. To size the Alignment pattern on the screen:

a. Scroll up to Image Size.

b. Press the + button (to enlarge) and – button (to reduce) the image size so that the pattern has equal amounts of pixels visible at each

edge. It is normal for a small amount of curvature (barrel or pincushion distortion) to be present at the edges. There will be no more

than one pixel of curvature along any edge.

NOTES:

Hiding one pixel on all sides is optimal. Try to hide at least one pixel per side, but no more than three.

•

• The Image Size control may affect the rotation or position of the image. Going back and forth between the Grid and Alignment procedures will

ensure the best adjustment.

10. Press the MENU button on the remote to close the menu.

ALIGNMENT PATTERN

CHANGING THE PICTURE AND MENUS

Each PMCD750 unit in an inverted wall must have the image and the menus inverted. Refer to Figure 13 and do the following:

1. Press the MENU button on the remote control.

2. Scroll down to Advanced Options.

3. Press + on the remote.

4. Scroll down to Miscellaneous Options, and then press +.

5. Scroll down to Inverted Installation.

C2928M-A (4/07) 21

Page 22

6. Press ENTER on the remote. A checkmark appears next to the selection and the picture and menus are inverted. The left-right of the optical

engine alignment motors are also reversed to make the left-right orientation correct for viewing.

Main Menu

Picture

Size & Position

Aspect Ratio & Wall

Memory

Diagnostics

Advanced Options

Program Information

Advanced Options

Color Balance

Miscellaneous Options

Lamp Settings

Serial Port Settings

Auto Setup Options

Engine Alignment

Menu Options

Miscellaneous

Beeper

Curtain Pattern

Auto Codes

Plug and Play (EDID Enable)

Inverted Installation

Preferred Source Detection 16 x 9

HD Interlaced Content

White

Normal

Figure 13. Inverted Installation

ADJUSTING ANALOG 1 AND ANALOG 2 INPUT

Displays differ from one another because of very small differences in the color of the light produced by the lamp and by differences in the dyes

used to make the color in a DLP optical engine. Adjusting all the displays in a wall ensures that the image produced will be uniform in

appearance.

INPUT LEVEL ADJUSTMENT, AUTOMATIC

NOTE: For superior results, semiautomatic adjustment of the black and white levels is recommended. Refer to the Input level Adjustment,

Semiautomatic section.

To set the Auto Setup functions, refer to Figure 14 and do the following:

1. Press MENU on the remote.

2. Scroll down to Advanced Options, and then press +.

3. Scroll down to Auto Setup Options, and then press +.

4. Scroll down to Do Black/White Levels, and then press ENTER to select it.

The following functions have been preselected:

Retry on lost signal: If video is lost on the current input, the display will search for and display video from another input.

Do Frequency: This feature automatically adjusts the frequency of the electronics module to match the frequency of the video signal.

Do Phase: This feature automatically adjusts the phase of the electronics module to match the phase of the video signal.

Do Position: This feature puts the upper left pixel of the picture in the upper left corner of the screen.

22 C2928M-A (4/07)

Page 23

Main Menu

Advanced Options

Picture

Size & Position

Aspect Ratio & Wall

Memory

Diagnostics

Advanced Options

Program Information

Color Balance

Miscellaneous Options

Lamp Settings

Serial Port Settings

Auto Setup Options

Engine Alignment

Menu Options

Auto Setup Options

Retry on lost signal

Do Black/White Levels

Do Frequency

Do Phase

Do Position

Figure 14. Auto Setup

5. Press MENU to close the menu.

6. Press SETUP on the remote control. The display will now perform an automatic adjustment of the black and white levels, as well as all of

the other functions selected in the Auto Setup Options menu.

INPUT LEVEL ADJUSTMENT, SEMIAUTOMATIC

NOTE: When the source image controller used for adjustments is changed, the associated input will require readjustment to the new source.

To adjust each PMCD750 input level, refer to Figure 15 and do the following:

1. Display a black image. A black screen image can be created in many graphics software. The source used for these adjustments must be the

same source that is going to be used regularly to display images.

2. Press the MENU button on the remote control.

3. Scroll down to Picture and then press +.

4. Scroll to Source and then press +.

5. Scroll to either Analog 1 or Analog 2, relative to the input being used, and then press ENTER. This will display the input source on the

screen and all adjustments made will affect this input.

6. Scroll down to Input Levels, and then press +.

7. Scroll to Auto Black Level, and then press ENTER.

8. Display a white image from the controller.

9. Scroll to Auto White Level, and then press ENTER.

10. Press MENU to close the menu.

C2928M-A (4/07) 23

Page 24

Main Menu

Picture

Size & Position

Picture

Aspect Ratio & Wall

Memory

Diagnostics

Source Analog 1

Advanced Options

Colorspace RGB

Program Information

Sync Type Separate H&V

Vertical Frequency 60 Hz

Horizontal Frequency 43.38 kHz

Pixel Frequency 65.02 MHz

Picture

Horizontal Resolution 1280

Vertical Resolution 768

Source Analog 1

Frequency - + 1344

Colorspace RGB

Phase - +

Sync Type Separate H&V

Sharpness Sharpest

Vertical Frequency 60 Hz

Input Levels

Horizontal Frequency 43.38 kHz

Pixel Frequency 65.02 MHz

Horizontal Resolution 1280

Vertical Resolution 768

Frequency - + 1344

Phase - +

Sharpness Sharpest

Input Levels

Analog 1

Analog 2

Digital

Input Levels

Auto Black Level (offset)

Auto White Level (gain)

Center Point 2 1 4

Black Level (offset) - All - + 55

Red - + 68

Green - + 57

Blue - + 69

White Level (gain) - All - + 130

Red - + 128

Green - + 131

Blue - + 130

Figure 15. Input Level Adjustment

24 C2928M-A (4/07)

Page 25

COLOR BALANCING A WALL OF PMCD750 DISPLAYS

Color balancing will make the individual units within a wall show uniform colors. This can be performed before or after adjustment of the input

levels.

The following procedure is required for all units in a wall system.

To adjust the color balance for a wall, refer to Figure 16 and do the following:

1. Make sure the lamps in each unit have warmed up for at least five minutes. The lamps must be thoroughly warm before color balancing.

2. For each display, press MISC once on the remote.

NOTE: If the wall has never been color balanced, make sure you start with the same color temperature setting on each display. If you are not

interested in achieving a specific color temperature, use the default of 8500°K, which is the brightest. If the display has been color balanced

before, it will display Custom in the Color Temperature setting, because the balance values do not match any of the preset color temperatures.

3. Scroll down to Color Temperature. Press ENTER on the remote to choose one of the color temperatures. The choices are 3200°K, 5500°K,

6500°K, and 8500°K.

4. Scroll down to Gamma. Press ENTER to change this setting to Video (optimal brightness) or Film (deeper reds). Use the same setting for all

displays in the wall.

5. Scroll down to White Boost. Press ENTER to change this setting to Off.

6. Scroll up to Test Pattern. Press ENTER to change the setting to White.

NOTE: Always use the internal test patterns for color balancing, not an external pattern.

Color Balance

Color Temperature

White Balance - All

Red

Green

Blue

Gray Balance - All

Red

Green

Blue

Test Pattern White

Hide Menu

Copy to Clipboard

Recall From Clipboard

Reset to Defaults

Gamma

White Boost

-+

-+

-+

-+

-+

-+

Video

Off

(Clipboard)

100

70

53

(99)

(88)

(90)

7

(11)

7

( 9)

7

(12)

Figure 16. Color Balancing

7. Check the color balance values for all displays. All white balance values should be 100, and all Gray balance values should be 7. If any of

these values vary from these levels, scroll down to Reset to Defaults and then press ENTER on the remote. This is the correct starting point

for color balancing.

8. On each display, scroll down to Hide Menu and then press ENTER. This will remove all menus so that the entire wall can be seen as a

whole. To reopen the Color Balance menu, aim the remote at the desired display and then press ENTER.

C2928M-A (4/07) 25

Page 26

9. Look at all the displays together. Stand far enough away from the wall so that you are looking almost squarely at all of them. Pay attention

to the large central area, not the edges.

10. Find the darkest display. This will serve as the baseline display for adjusting all of the displays in the wall. Do not change any settings on

this display.

11. Choose a display next to, above, or below the baseline display. This will serve as the variable display.

NOTE: To avoid activating another display within the wall, stand within 18 inches (46 cm) of the target display when using the remote.

12. Point the remote directly at the screen, press ENTER to open the Color Balance menu, and then do the following:

a. Scroll to White Balance-All. Press the – button on the remote to reduce the brightness until it matches the baseline display.

b. Scroll down to Red. Press the + and – buttons on the remote to adjust the amount of red in the image to match that of the baseline

display.

c. Scroll down to Green and repeat adjustments from step b.

d. Scroll down to Blue and repeat adjustments from step b.

e. To save all of the current settings to a temporary memory, scroll down to Copy to Clipboard and then press ENTER. Further

adjustments can be made to try to improve the image, but if they do not improve the image, scroll down to Recall From Clipboard to

restore the previously saved settings.

NOTE: The clipboard is only for testing. These values are not saved when AC power is off.

f. Once the image matches that of the baseline display, scroll down to Hide Menu, and then press ENTER. This adjusted unit is now a

baseline display.

13. Repeat steps 11 and 12 for the remaining displays. Use adjacent baseline units for adjusting variable units.

14. For each display, open the Color Balance menu by pressing ENTER on the remote.

15. Scroll down to Test Pattern and press ENTER to change the setting to Gray.

16. Find the display with the least amount of gray. This will serve as the baseline display for adjusting all of the displays in the wall. Do not

change any settings on this display.

17. Choose a display next to, above, or below the baseline display. This will serve as the variable display.

18. Repeat steps 12 and 13 applying them to Gray Balance-All, and associated Red, Green, and Blue settings.

19. After adjusting all units in the wall, turn off the test pattern for each display by doing the following:

a. Press ENTER on the remote.

b. Scroll down to Test Pattern.

c. Press ENTER to change the setting to Off.

20. Press MENU on the remote to exit the menu.

SPREADING ONE PICTURE OVER A WALL

To spread one picture over a wall, an external controller must be used. Contact Pelco for information on compatible products.

SCALING AND CROPPING

The following procedure is required for a stand-alone unit and all units in a wall system.

In some cases, the aspect ratio of an image does not match that of a wall. The aspect ratio of an image is its width divided by its height.

Example: 1024 ÷ 768 = an aspect ratio of 1.33.

The native aspect ratio of the PMCD750 is 1.77 (16 x 9), the same as HDTV. When the aspect ratio of the source image and the PMCD750 wall

differ, it may be necessary to make an adjustment. The following options are available:

Fill All: This will stretch the picture until it touches all edges of the display. This setting can produce some image distortion.

26 C2928M-A (4/07)

Page 27

Crop: This will expand the picture until the second edges (refer to Letterbox/Pillarbox) touch the border and let the other edges of the picture fall

outside the wall and get cropped. Justification adjustments can be employed to better center the image.

Letterbox/Pillarbox: This will expand the picture until the first edges (top-bottom or left-right) touch the border of the wall, then fill in the other

sides with a solid color.

Widescreen (16 x 9): This will force the image into an aspect ratio of 16 x 9 (1.77), the same as that of the PMCD750 display. This is

recommended for sources that have a native 16 x 9 aspect ratio. Similar to Fill All, this can cause image distortion, depending on the source

image’s native aspect ratio.

Normal (4 x 3): This will force a 4 x 3 (1.33) aspect ratio, the ratio of standard television. This is recommended for sources that have a native

4 x 3 aspect ratio. Similar to Fill All, this can cause image distortion, depending on the source image’s native aspect ratio.

One to One: This will display the image with no change to its original aspect ratio.

To set the aspect ratio, refer to Figure 17 and do the following:

1. Press the MENU button on the remote.

2. Scroll down to Aspect Ratio & Wall, and then press + on the remote control.

3. Scroll to Scale Mode, and then press + on the remote control.

4. Scroll down to the desired aspect ratio setting.

a. Press + on the remote to see the preview effect with the menu still open.

b. Press ENTER.

5. If Letterbox, Widescreen, or One to One was selected, do the following:

a. Scroll down to Border Color.

b. Repeatedly press ENTER to choose the desired color. This color will be displayed in the blank areas around the image.

6. Press the MENU button on the remote to close the menu.

Main Menu

Picture

Size & Position

Aspect Ratio & Wall

Memory

Aspect Ratio & Wall

Diagnostics

Advanced Options

Program Information

Scale Mode

Justify

Overscan

Border Color

Fill All

Center

0 %

Black

Fill All

Crop

Letterbox/Pillarbox

Widescreen (16x9)

Normal Video (4x3)

One to One

Figure 17. Scaling and Cropping

C2928M-A (4/07) 27

Page 28

IMAGE POSITIONING

After the aspect ratio has been set, the image position on the screen can be adjusted.

The following procedure is required for a stand-alone unit and all units in a wall system.

To adjust the position of the image, refer to Figure 18 and do the following:

1. Press the MENU button on the remote.

2. Scroll down to Aspect Ratio & Wall, and then press +.

3. Scroll to Justify, and then press + on the remote control.

4. Select the appropriate setting. Press + to toggle through the following choices:

• Select Center, which places the image in the exact center of the wall.

• Select Bottom Right if the image is too wide for the wall and is cropped on the sides.

• Select Top Left if the image is too tall for the wall and is cropped on the top and bottom.

5. Press the MENU button on the remote to close the menu.

Main Menu

Picture

Size & Position

Aspect Ratio & Wall

Memory

Diagnostics

Advanced Options

Program Information

Aspect Ratio & Wall

Scale Mode

Justify

Overscan

Border Color

Fill All

Center

0 %

Black

Figure 18. Justifying

28 C2928M-A (4/07)

Page 29

OVERSCAN

The overscan feature allows the image to be expanded up to a maximum of 20%.

The following procedure is required for a stand-alone unit and all units in a wall system.

To change the overscan setting, refer to Figure 19 and do the following:

1. Press the MENU button on the remote.

2. Scroll down to Aspect Ratio & Wall, and then press +.

3. Scroll to Overscan and then do the following:

a. Press the + button on the remote to increase the image size in 1% increments.

b. Press the – button on the remote to decrease the image in 1% increments. This function will only work if the value is greater than 0%.

4. Press MENU on the remote to close the menu.

Main Menu

Picture

Size & Position

Aspect Ratio & Wall

Memory

Diagnostics

Advanced Options

Program Information

Aspect Ratio & Wall

Scale Mode

Justify

Overscan

Border Color

Fill All

Center

0 %

Black

Figure 19. Overscanning

C2928M-A (4/07) 29

Page 30

PREFERRED SOURCE DETECTION

When the PMCD750 attempts to detect an analog mode, it uses the horizontal frequency, the vertical frequency, and the number of horizontal

lines per vertical interval. Unfortunately, some signals can have the same measurement on these three parameters, most notably resolutions of

1024 x 768, 1280 x 768 and 1366 x 768. When the display detects an ambiguous input, the Preferred Source Detection menu tells the display

which aspect ratio to use; the default is 16 x 9. If this is not the desired aspect ratio, the setting can be changed. For example, if the display is

used with a laptop computer that outputs 1024 x 768, the setting would be changed to 4 x 3. In most cases this setting will not need to be

adjusted. Preferred Source Detection menu choices are 16 x 9, 5 x 4, 4 x 3, or 15 x 9.

The following procedure is required for a stand-alone unit and all units in a wall system.

To adjust preferred source detection, refer to Figure 20 and do the following:

1. Press MENU on the remote control.

2. Scroll down to Advanced Options, and then press + on the remote control.

3. Scroll down to Miscellaneous Options, and then press + on the remote.

4. Scroll down to Preferred Source Detection.

5. Press ENTER on the remote. Each press will change the setting.

6. Press MENU to exit the menu.

Main Menu

Picture

Size & Position

Aspect Ratio & Wall

Memory

Diagnostics

Advanced Options

Program Information

Advanced Options

Color Balance

Miscellaneous Options

Lamp Settings

Serial Port Settings

Auto Setup Options

Engine Alignment

Menu Options

Miscellaneous

Beeper

Curtain Pattern

Auto Codes

Plug and Play (EDID Enable)

Inverted Installation

Preferred Source Detection 16 x 9

HD Interlaced Content

White

Normal

Figure 20. Preferred Source Detection

30 C2928M-A (4/07)

Page 31

HD INTERLACED CONTENT

When displaying 1080i video sources, deinterlacing artifacts can sometimes be visible. HD interlaced content can minimize or eliminate these

artifacts to produce a sharper image. There are two levels of this function.

Normal: For static (still) and normal motion images.

Rapid: For images with rapid movement, such as an auto race.

The following procedure is required for a stand-alone unit and all units in a wall system.

To adjust HD interlaced content, refer to Figure 21 and do the following:

1. Press MENU on the remote control.

2. Scroll down to Advanced Options, and then press + on the remote control.

3. Scroll down to Miscellaneous Options, and then press + on the remote.

4. Scroll down to HD Interlaced Content.

5. Press ENTER on the remote. Each press will change the setting.

6. Press MENU to exit the menu.

Main Menu

Picture

Size & Position

Aspect Ratio & Wall

Memory

Diagnostics

Advanced Options

Program Information

Advanced Options

Color Balance

Miscellaneous Options

Lamp Settings

Serial Port Settings

Auto Setup Options

Engine Alignment

Menu Options

Miscellaneous

Beeper

Curtain Pattern

Auto Codes

Plug and Play (EDID Enable)

Inverted Installation

Preferred Source Detection 16 x 9

HD Interlaced Content

White

Normal

Figure 21. HD Interlaced Content

C2928M-A (4/07) 31

Page 32

POSITION AND ZOOM

Position moves the picture on the screen. This is not the same as optical engine alignment. Zoom adjusts the edges of the image to make them

fit with the other images in a wall.

NOTE: If the screen has a black edge on one or both sides and the image cannot be repositioned to cover it, the optical engine must be adjusted.

Refer to the Aligning the Optical Engine section.

PICTURE POSITION ADJUSTMENT

The following procedure is required for a stand-alone unit and all units in a wall system.

If necessary, adjust the position of the image. Refer to Figure 22 and do the following:

1. Press the MENU on the remote control.

2. Scroll down to Size & Position, and then push +.

3. Select Picture Position, and then press +. The numeric values for the current horizontal and vertical position of the image are displayed.

4. Make necessary adjustments.

a. To adjust horizontally, use the + and – buttons.

b. To adjust vertically, use the

" and ! buttons.

5. Press the MENU button on the remote to close the menu.

Main Menu

Picture

Size & Position

Aspect Ratio & Wall

Memory

Diagnostics

Advanced Options

Program Information

Picture Position

Use arrow keys to move image

Size & Position

Picture Position

Zoom Window Top & Left

Zoom Window Botom & Right

Viewport Window Top & Left

Viewport Window Bottom & Right

Reset All Windows to Default

Horizontal Position 256

Vertical Position 28

Figure 22. Picture Positioning

32 C2928M-A (4/07)

Page 33

ZOOM ADJUSTMENT

The following procedure is required for a stand-alone unit and all units in a wall system.

Zoom is primarily used to adjust the edges of a single image spread over several displays.

NOTE: If the screen has a black edge on one or both sides and the image cannot be zoomed to cover it, the optical engine must be adjusted.

Refer to the Aligning the Optical Engine section.

Adjust the level of zoom for the image. Refer to Figure 23 and do the following:

1. If you are in the Size and Position submenu, go to step 2. From the Main Menu, scroll to Size and Position and then press the ENTER button

on the remote.

2. Scroll to Zoom Window Top & Left.

3. Use the

", !, +, and – buttons on the remote to zoom the image up and left relative to the top and left edges.

4. Press the PREV button on the remote.

5. Scroll to Zoom Window Bottom & Right.

6. Use the

", !, +, and – buttons on the remote to zoom the image down and right relative to the bottom and right edges.

7. Press the MENU button on the remote to close menu.

Main Menu

Picture

Size & Position

Aspect Ratio & Wall

Memory

Diagnostics

Advanced Options

Program Information

Zoom Top & Left

Size & Position

Picture Position

Zoom Window Top & Left

Zoom Window Botom & Right

Viewport Window Top & Left

Viewport Window Bottom & Right

Reset All Windows to Default

Arrows move top and left

+ 1

+ 1+ 0

- 2

Image resolution 1024x768

This Cube 511x385 2x2 1.2

Figure 23. Zooming

C2928M-A (4/07) 33

Page 34

SAVING AND RECALLING ADJUSTMENTS AND DELETING A MEMORY

The PMCD750 has 40 numbered memory slots that can be used to save and recall image adjustments and apply them to a specific source and

input. Once assigned, the input will have these image adjustments applied each time the associated source is detected. Each input can have multiple sources and associated preferences.

An example of this application would be having a computer connected to the Analog 1 input. The Analog 1 input can have one of the 40 settings

applied to it each time that specific source computer is detected at the Analog 1 input. If the input source changes, the same settings will still be

applied, but if you wish to assign different settings for the new source, selecting a different memory slot will apply the new settings each time

that source is detected at the Analog 1 input. If the previous source is detected, the previous settings will be applied. This flexibility can be

applied to each of the video inputs.

SAVING ADJUSTMENTS

The following procedure is required for a stand-alone unit and all units in a wall system.

To save image adjustments, refer to Figure 24 and do the following:

1. Make all image adjustments. Refer to the Alignment and Adjustment section.

2. Press the MENU button on the remote.

3. Scroll down to Memory.

4. Press + on the remote.

Main Menu

Picture

Size & Position

Aspect Ratio & Wall

Memory

Diagnostics

Advanced Options

Program Information

Memory

Recall

Save

Delete

Save

1 9 17 25 33

2 10 18 26 34

3 11 19 27 35

4 12 20 28 36

5 13 21 29 37

6 14 22 30 38

7 15 23 31 39

8 16 24 32 40

Figure 24. Saving Adjustments

34 C2928M-A (4/07)

Page 35

5. Scroll down to Save, press + on the remote, and then do the following:

a. Use the

b. Press ENTER. The Save menu displays all data that will be stored in this slot.

6. If desired, the Name designation for the slot can be edited. There are 24 character spaces available. To save the data without editing the

designation, go to step 7.

NOTE: The default name for a slot is an abbreviation of the type of connection used, resolution, wall configuration, and wall position (when

applicable).

To edit the Name line:

a. Scroll to Name.

b. Press ENTER.

c. Use the + and – buttons to navigate along the line. Use the

d. Press PREV on the remote to enter each changed character.

7. Scroll to Save Now.

8. Press ENTER to save the settings.

", !, #, and $buttons on the remote to navigate to an unchecked box. Selecting a checked box will overwrite

(replace) the preferences stored there.

"and !buttons to change each character.

C2928M-A (4/07) 35

Page 36

RECALLING SLOT PREFERENCES

The following procedure is required for a stand-alone unit and all units in a wall system.

To recall stored preferences, refer to Figure 25 and do the following:

1. Press the MENU button on the remote.

2. Scroll down to Memory.

3. Press ENTER on the remote.

4. Scroll down to Recall.

5. Press ENTER.

6. Use the

", !, #, and $buttons on the remote to navigate to the desired checked box. Unchecked (empty) boxes cannot be

selected.

7. Press ENTER. The settings for the selected slot are displayed. If the settings in the slot are identical to those currently in use, “Current” will

appear on the top line. To exit this menu without applying these settings, press PREV on the remote control. Otherwise, go to step 8.

8. Scroll to Recall Now.

9. Press ENTER to apply the selected slot settings.

Main Menu

Picture

Size & Position

Aspect Ratio & Wall

Memory

Diagnostics

Advanced Options

Program Information

Memory

Recall

Save

Delete

Recall

1 9 17 25 33

2 10 18 26 34

3 11 19 27 35

4 12 20 28 36

5 13 21 29 37

6 14 22 30 38

7 15 23 31 39

8 16 24 32 40

Figure 25. Recalling Adjustments

36 C2928M-A (4/07)

Page 37

DELETING STORED SLOT SETTINGS

NOTE: It is not necessary to delete a memory slot before saving something new.

The following procedure is required for a stand-alone unit and all units in a wall system.

To delete stored slot settings do the following:

1. Press the MENU button on the remote.

2. Scroll down to Memory.

3. Press ENTER on the remote.

4. Scroll down to Delete.

5. Press ENTER.

6. Use the

7. Press ENTER. The Delete Now line is now selected. To exit this menu without deleting these settings, press PREV on the remote control.

8. Press ENTER to delete the selected slot settings.